ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 371 of 1640

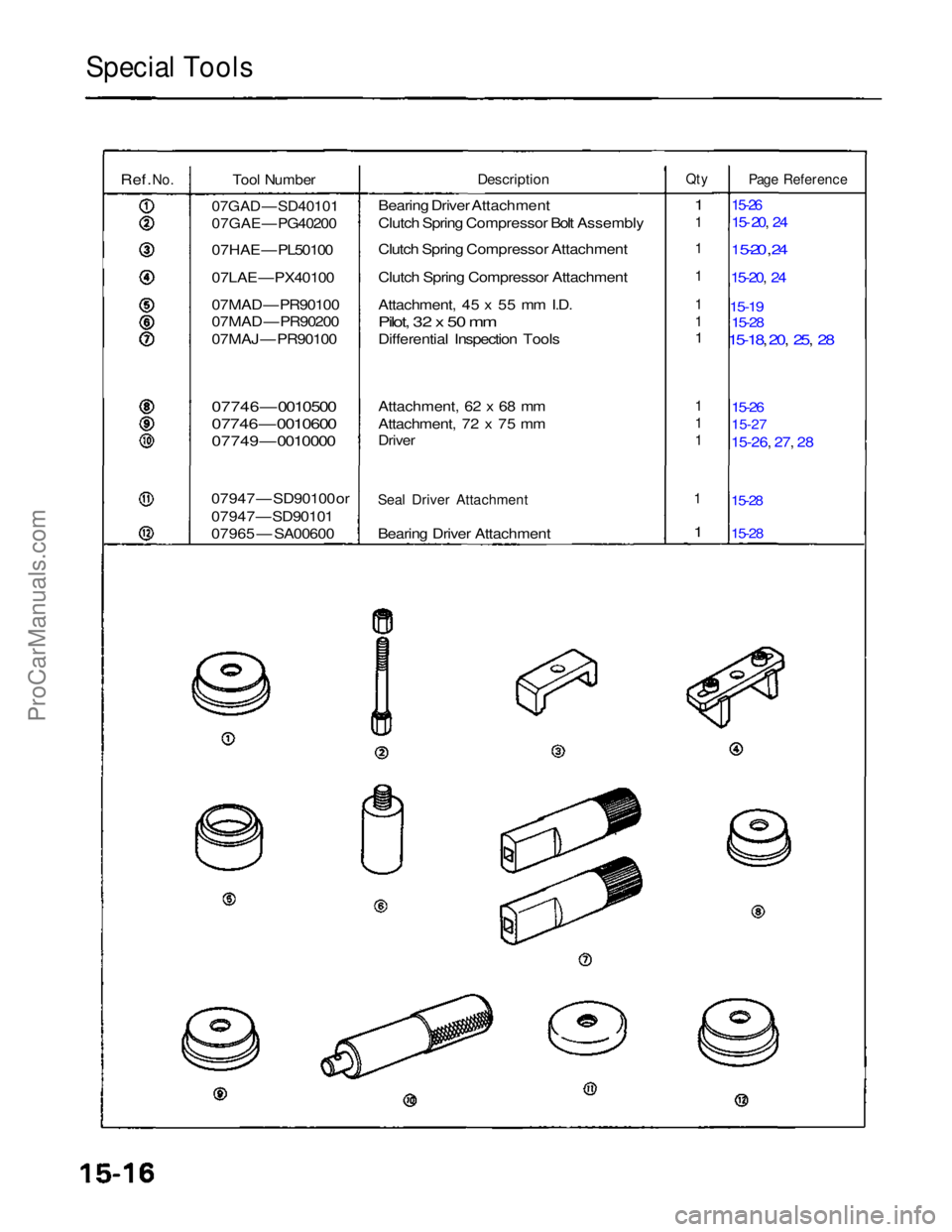

Special Tools

Ref.

No.

Tool Number

07GAD — SD40101

07GAE — PG40200

07HAE — PL50100

07LAE — PX40100

07MAD — PR90100

07MAD — PR90200

07MAJ — PR90100

07746 — 0010500

07746 — 0010600

07749 — 0010000

07947 — SD90100 or

07947 — SD90101

07965 — SA00600

Description

Bearing Driver Attachment

Clutch Spring Compressor Bolt Assembly

Clutch Spring Compressor Attachment

Clutch Spring Compressor Attachment

Attachment, 45 x 55 mm I.D.

Pilot, 32 x 50 mm

Differential Inspection Tools

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver

Seal Driver Attachment

Bearing Driver Attachment

Qty

1

1

1

1

1

1

1

1

1

1

1

1

Page Reference

15-26

15- 20, 24

1 5-20 , 24

15-20, 24

15-19

15-28

15-18, 20, 25, 28

15-26

15-27

15-26, 27, 28

15-28

15-28

ProCarManuals.com

Page 372 of 1640

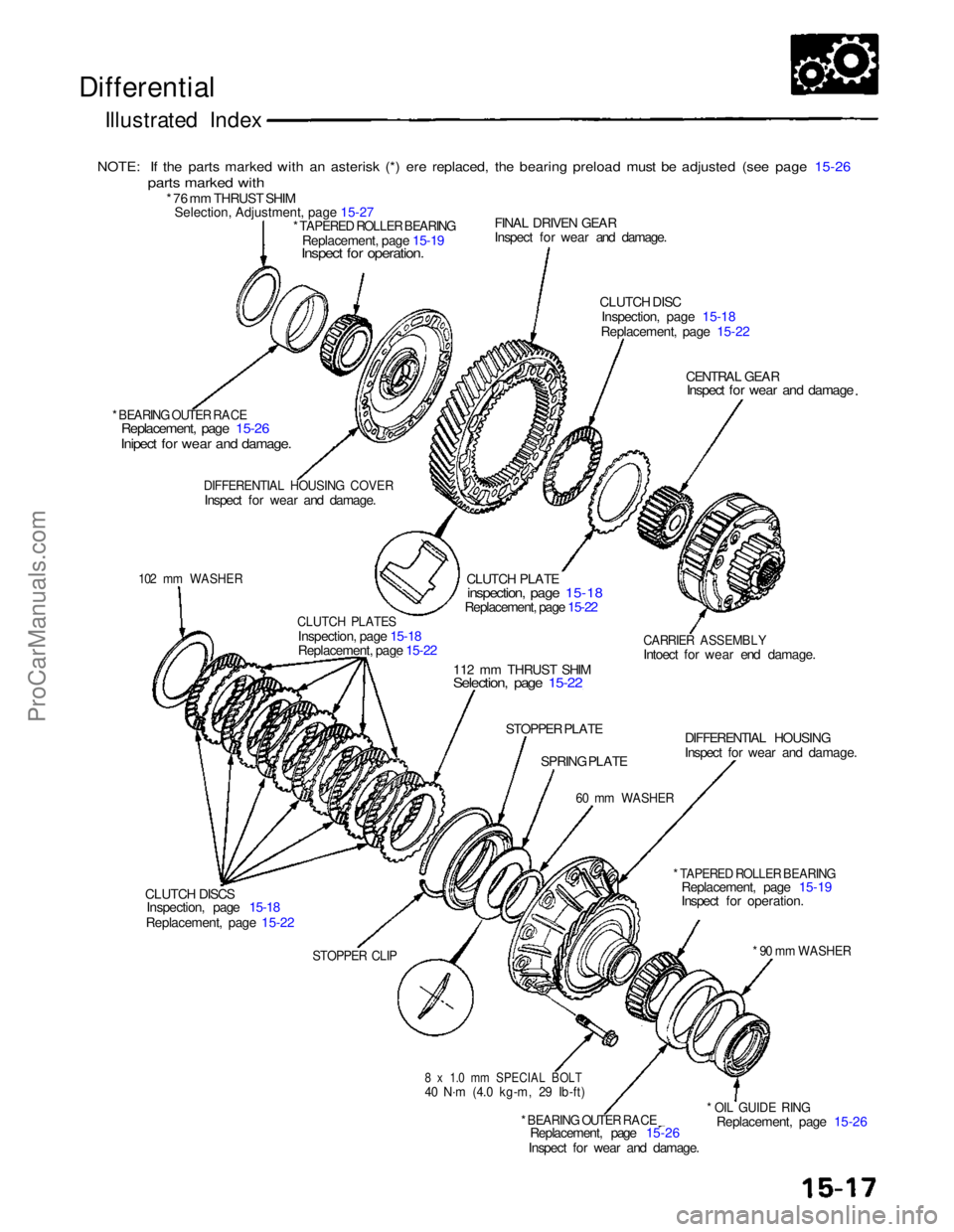

Differential

Illustrated Index

NOTE: If the parts marked with an asterisk (*) ere replaced, the bearing preload must be adjusted (see page 15-26

parts marked with

* 76 mm THRUST SHIM

Selection, Adjustment, page 15-27

* TAPERED ROLLER BEARING

Replacement, page 15-19

Inspect for operation.

FINAL DRIVEN GEAR

Inspect for wear and damage.

CLUTCH DISCInspection, page 15-18

Replacement, page 15-22

CENTRAL GEAR

Inspect for wear and damage

* BEARING OUTER RACE

Replacement, page 15-26

Inipect for wear and damage.

DIFFERENTIAL HOUSING COVER

Inspect for wear and damage.

CLUTCH PLATE

inspection, page 15-18

Replacement, page 15-22

CARRIER ASSEMBLY

Intoect for wear end damage.

102 mm WASHER

CLUTCH PLATES

Inspection, page 15-18

Replacement, page 15-22

112 mm THRUST SHIM

Selection, page 15-22

STOPPER PLATE DIFFERENTIAL HOUSING

Inspect for wear and damage.

SPRING PLATE

60 mm WASHER

* TAPERED ROLLER BEARING

Replacement, page 15-19

Inspect for operation.

* 90 mm WASHER

* OIL GUIDE RING

Replacement, page 15-26

STOPPER CLIP

8 x 1.0 mm SPECIAL BOLT

40 N·m (4.0 kg-m, 29 Ib-ft)

* BEARING OUTER RACE

Replacement, page 15-26

Inspect for wear and damage.

CLUTCH DISCS

Inspection, page 15-18

Replacement, page 15-22ProCarManuals.com

Page 373 of 1640

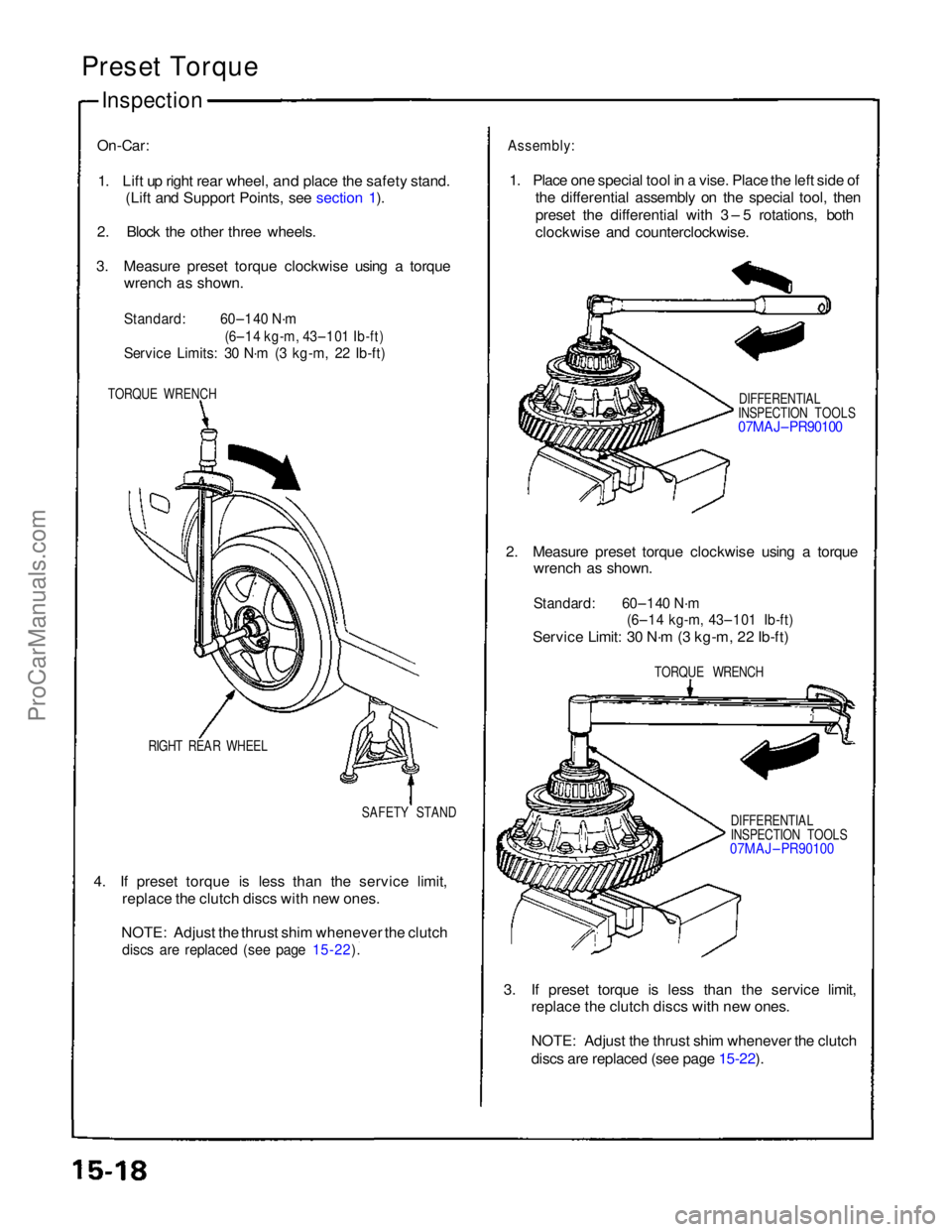

Preset Torque

Inspection

On-Car:

1. Lift up right rear wheel,

and place the safety stand.

(Lift and Support Points, see section 1).

2. Block the other three wheels.

3. Measure preset torque clockwise using a torque wrench as shown.

Standard:

60–140 N·m

(6–14 kg-m, 43–101 Ib-ft)

Service Limits: 30 N·m (3 kg-m, 22 Ib-ft)

TORQUE WRENCH

RIGHT REAR WHEEL SAFETY STAND

4. If preset torque is less than the service limit, replace the clutch discs with new ones.

NOTE: Adjust the thrust shim whenever the clutch

discs are replaced (see page 15-22).

Assembly:

1. Place one special tool in a vise. Place the left side of the differential assembly on the special tool, then

preset the differential with 3 – 5 rotations, both

clockwise and counterclockwise.

DIFFERENTIAL

INSPECTION TOOLS

07MAJ– PR90100

2. Measure preset torque clockwise using a torque wrench as shown.

Standard: 60–140 N·m

(6–14 kg-m, 43–101 Ib-ft)

Service Limit: 30 N·m (3 kg-m, 22 Ib-ft)

TORQUE WRENCH

DIFFERENTIAL

INSPECTION TOOLS

07MAJ – PR90100

3. If preset torque is less than the service limit, replace the clutch discs with new ones.

NOTE: Adjust the thrust shim whenever the clutch

discs are replaced (see page 15-22).

ProCarManuals.com

Page 374 of 1640

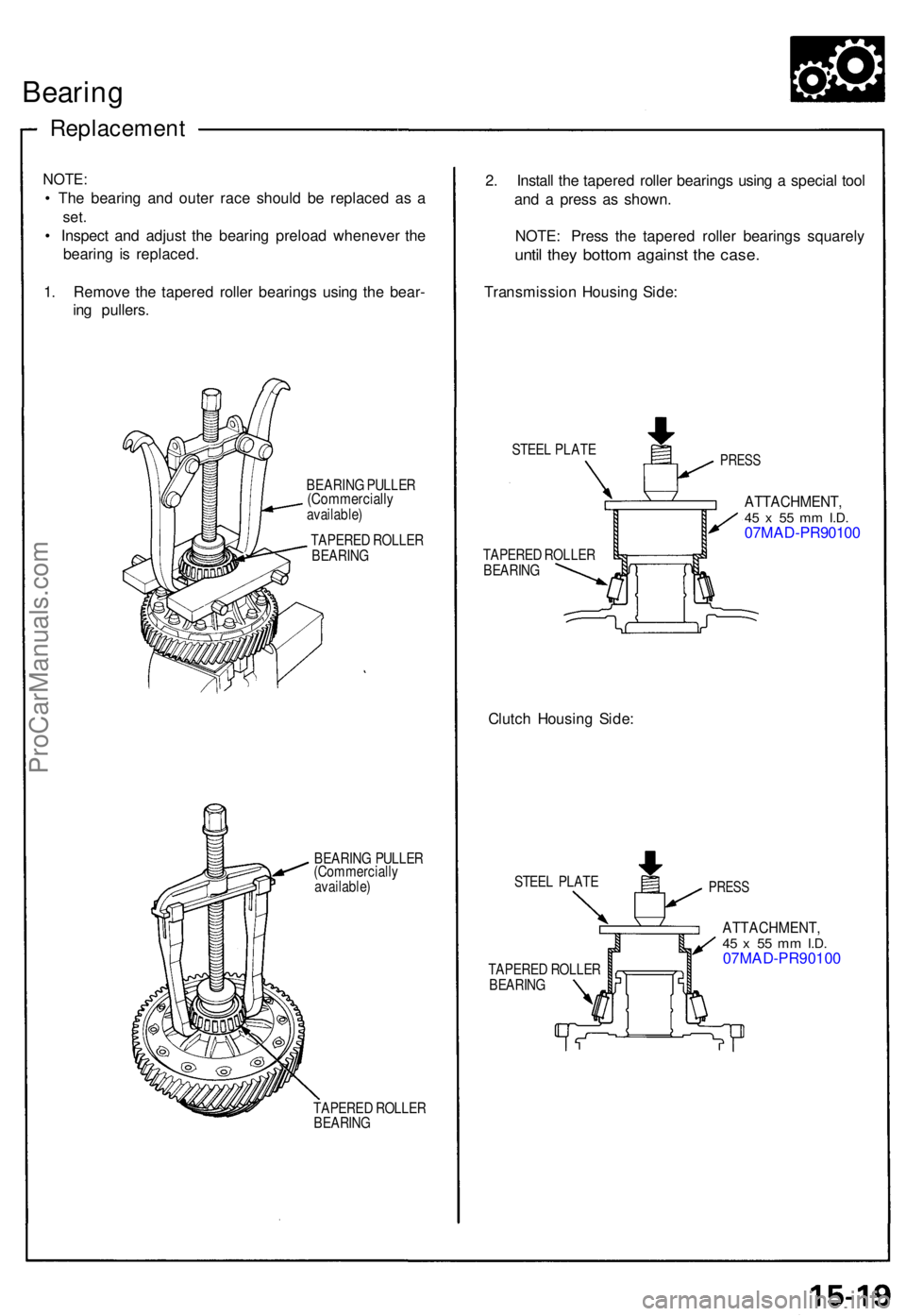

Bearing

Replacemen t

NOTE:

• Th e bearin g an d oute r rac e shoul d b e replace d a s a

set .

• Inspec t an d adjus t th e bearin g preloa d wheneve r th e

bearin g i s replaced .

1 . Remov e th e tapere d rolle r bearing s usin g th e bear -

in g pullers .

BEARIN G PULLE R(Commerciall yavailable)

TAPERE D ROLLE R

BEARIN G

BEARIN G PULLE R

(Commerciall y

available )

TAPERE D ROLLE R

BEARIN G

2. Instal l th e tapere d rolle r bearing s usin g a specia l too l

an d a pres s a s shown .

NOTE : Pres s th e tapere d rolle r bearing s squarel y

until the y botto m agains t th e case .

Transmissio n Housin g Side :

STEE L PLAT EPRESS

TAPERE D ROLLE R

BEARIN G

Clutch Housin g Side :

STEE L PLAT E

TAPERE D ROLLE R

BEARIN G

ATTACHMENT ,45 x 5 5 m m I.D .07MA D-PR9010 0

PRESS

ATTACHMENT ,45 x 5 5 m m I.D .07MAD-PR90100

ProCarManuals.com

Page 375 of 1640

Differential

Disassembl y

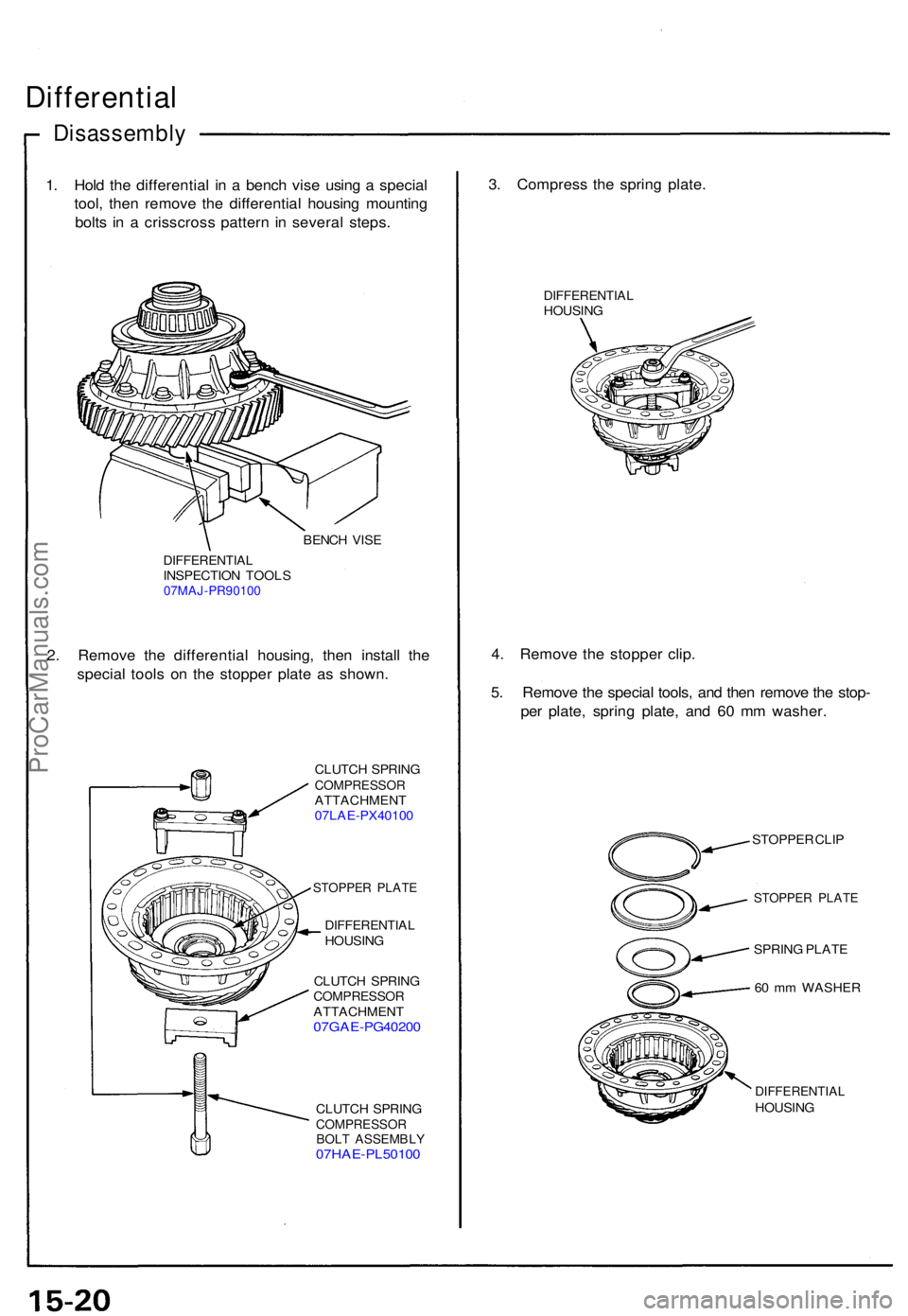

1. Hol d th e differentia l i n a benc h vis e usin g a specia l

tool , the n remov e th e differentia l housin g mountin g

bolt s i n a crisscros s patter n i n severa l steps .

BENCH VIS E

DIFFERENTIA LINSPECTION TOOL S07MAJ-PR90100

2. Remov e th e differentia l housing , the n instal l th e

specia l tool s o n th e stoppe r plat e a s shown .

CLUTCH SPRIN GCOMPRESSO RATTACHMENT

07LA E-PX4010 0

STOPPE R PLAT E

DIFFERENTIA LHOUSING

CLUTC H SPRIN G

COMPRESSO RATTACHMENT07GAE-PG4020 0

CLUTCH SPRIN GCOMPRESSO RBOLT ASSEMBL Y07HAE-PL5010 0

3. Compres s th e sprin g plate .

DIFFERENTIA LHOUSING

4. Remov e th e stoppe r clip .

5 . Remov e th e specia l tools , an d the n remov e th e stop -

pe r plate , sprin g plate , an d 6 0 m m washer .

STOPPE R CLI P

STOPPE R PLAT E

SPRING PLAT E

6 0 m m WASHE R

DIFFERENTIA LHOUSING

ProCarManuals.com

Page 376 of 1640

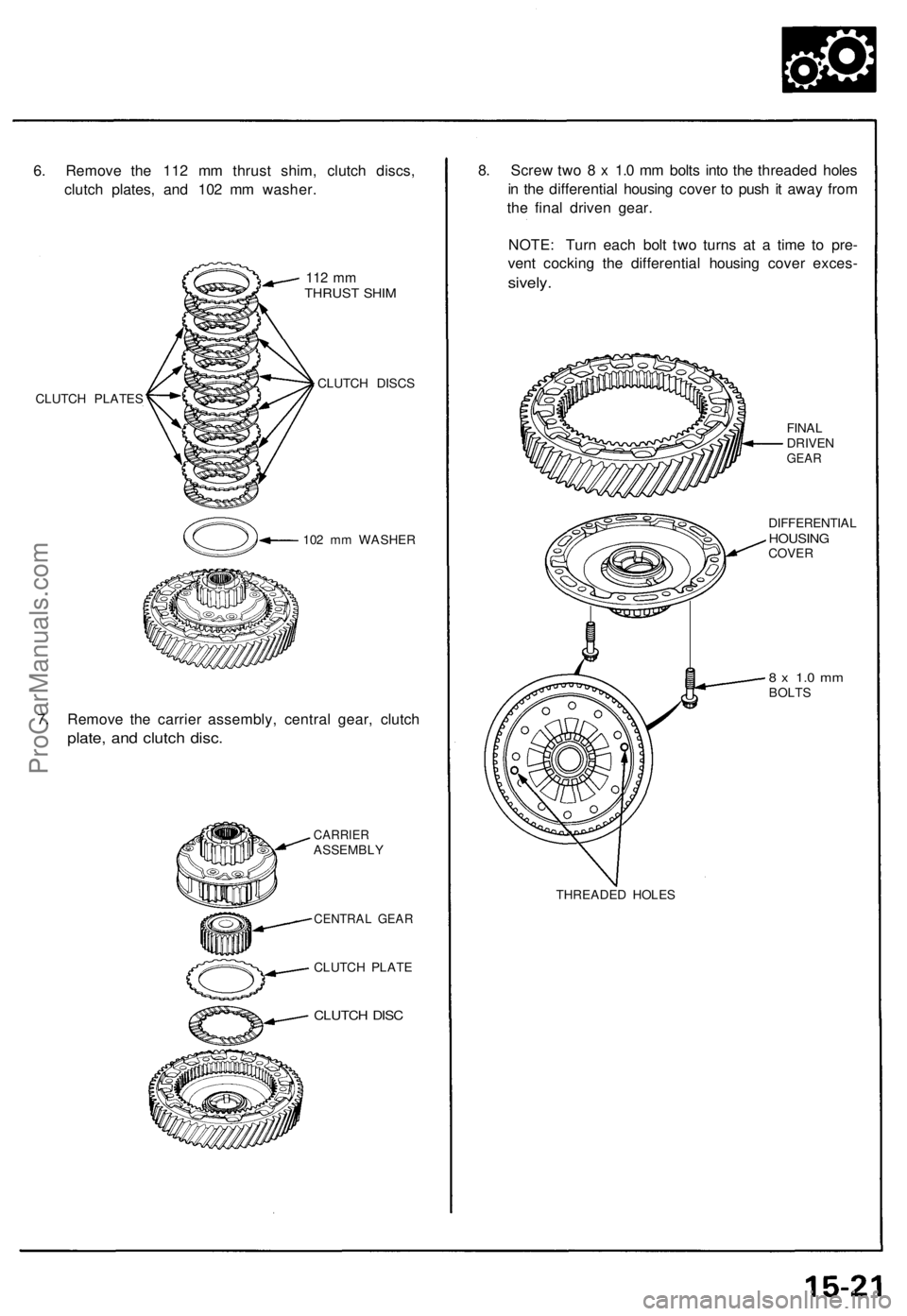

6. Remove the 112 mm thrust shim, clutch discs,

clutch plates, and 102 mm washer.

112 mm

THRUST SHIM

CLUTCH PLATES

CLUTCH DISCS

102 mm WASHER

7. Remove the carrier assembly, central gear, clutch

plate, and clutch disc.

CARRIER

ASSEMBLY

CENTRAL GEAR

CLUTCH PLATE

CLUTCH DISC

8. Screw two 8 x 1.0 mm bolts into the threaded holes

in the differential housing cover to push it away from

the final driven gear.

NOTE: Turn each bolt two turns at a time to pre-

vent cocking the differential housing cover exces-

sively.

THREADED HOLES

FINAL

DRIVEN

GEAR

DIFFERENTIAL

HOUSING

COVER

8 x 1.0 mm

BOLTSProCarManuals.com

Page 377 of 1640

\

I

Clutch Disc, Clutch Plate

Replacement

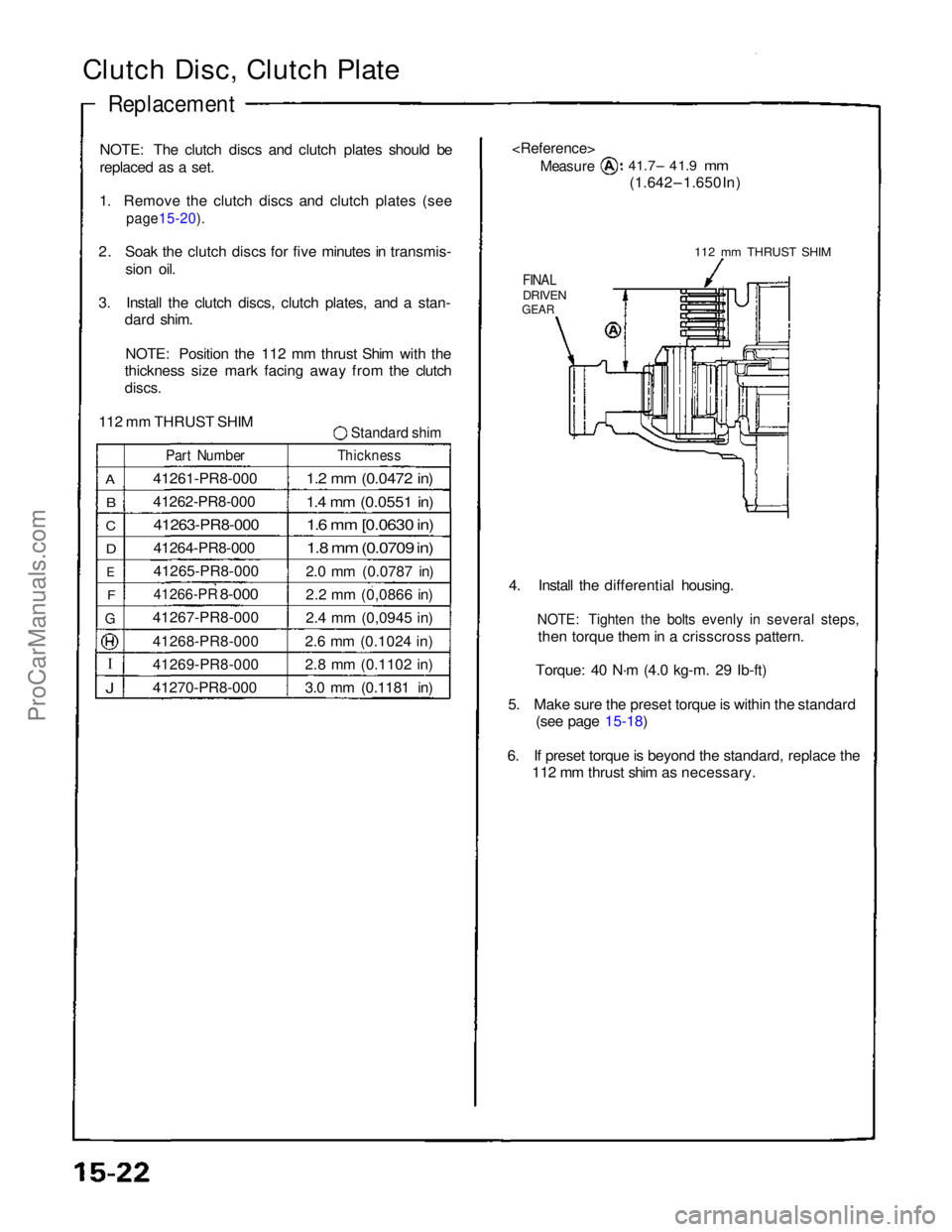

NOTE: The clutch discs and clutch plates should be

replaced as a set.

1. Remove the clutch discs and clutch plates (see

page15-20).

2. Soak the clutch discs for five minutes in transmis-

sion oil.

3. Install the clutch discs, clutch plates, and a stan- dard shim.

NOTE: Position the 112 mm thrust Shim with the

thickness size mark facing away from the clutch

discs.

112 mm THRUST SHIM

Standard shim

A

B

C

D

E

F

G

J

Part Number

41261-PR8-000

41262-PR8-000

41263-PR8-000

41264-PR8-000

41265-PR8-000

41266-PR

8-000

41267-PR8-000

41268-PR8-000

41269-PR8-000

41270-PR8-000

Thickness

1.2 mm (0.0472 in)

1.4 mm (0.0551 in)

1.6 mm [0.0630 in)

1.8 mm (0.0709 in)

2.0 mm (0.0787 in)

2.2 mm (0,0866 in)

2.4 mm (0,0945 in)

2.6 mm (0.1024 in)

2.8 mm (0.1102 in)

3.0 mm (0.1181 in)

Measure

41.7– 41.9

mm

(1.642 – 1.650 In)

112 mm THRUST SHIM

FINAL

DRIVEN

GEAR

4. Install the differential housing.

NOTE: Tighten the bolts evenly in several steps,

then torque them in a crisscross pattern.

Torque: 40 N·m (4.0 kg-m. 29 Ib-ft)

5. Make sure the preset torque is within the standard (see page 15-18)

6. If preset torque is beyond the standard, replace the 112 mm thrust shim as necessary.ProCarManuals.com

Page 378 of 1640

Differential

Reassembl y

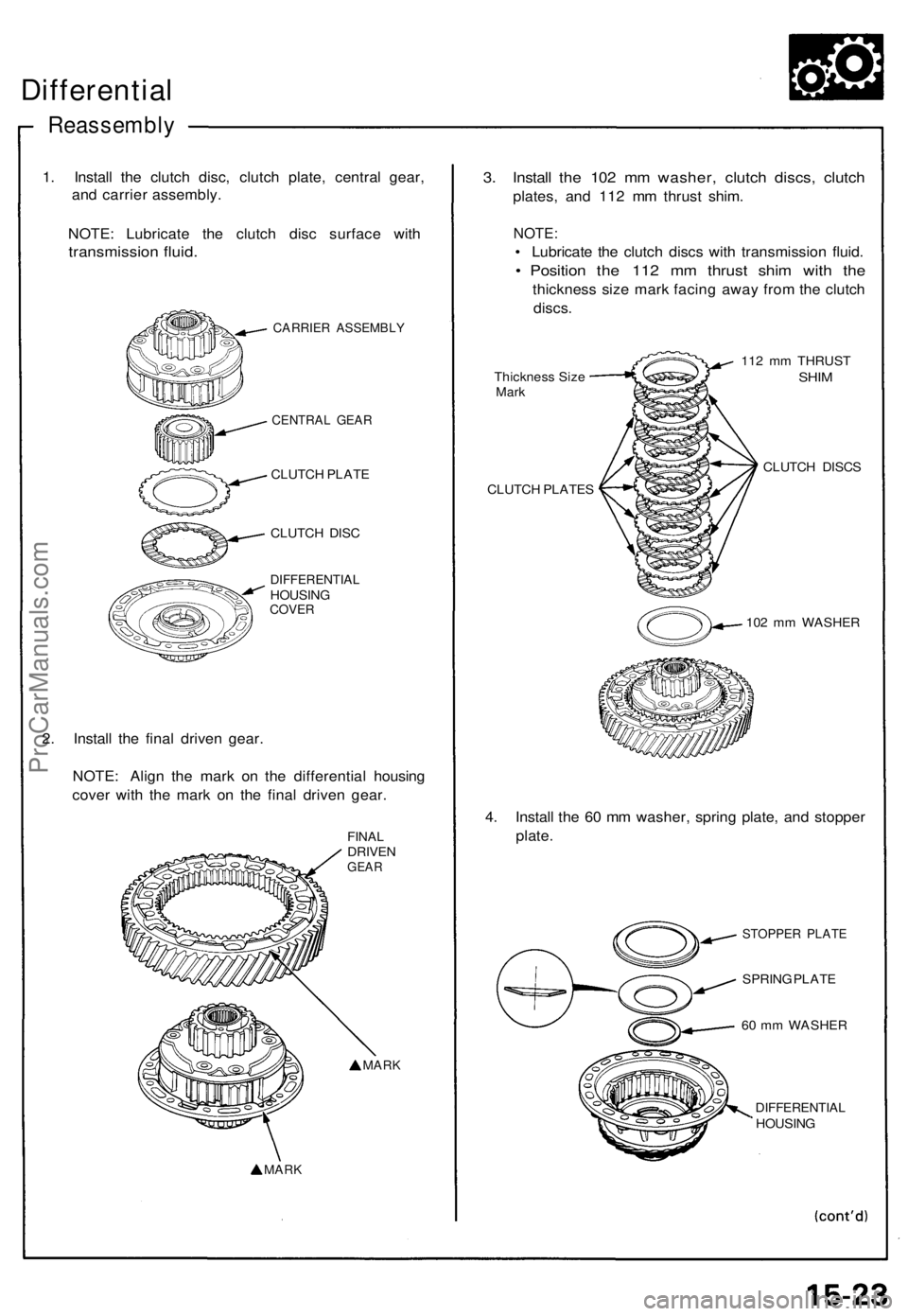

1. Instal l th e clutc h disc , clutc h plate , centra l gear ,

an d carrie r assembly .

NOTE : Lubricat e th e clutc h dis c surfac e wit h

transmissio n fluid .

CARRIE R ASSEMBL Y

CENTRAL GEA R

CLUTC H PLAT E

CLUTC H DIS C

DIFFERENTIA LHOUSINGCOVER

2. Instal l th e fina l drive n gear .

NOTE : Alig n th e mar k o n th e differentia l housin g

cove r wit h th e mar k o n th e fina l drive n gear .

FINALDRIVE NGEAR

MAR K

MAR K

3. Instal l th e 10 2 m m washer , clutc h discs , clutc h

plates , an d 11 2 m m thrus t shim .

NOTE :

• Lubricat e th e clutc h disc s wit h transmissio n fluid .

• Positio n th e 11 2 m m thrus t shi m wit h th e

thicknes s siz e mar k facin g awa y fro m th e clutc h

discs .

Thicknes s Siz eMar k

CLUTC H PLATE S 11

2 m m THRUS T

SHIM

CLUTC H DISC S

10 2 m m WASHE R

4. Instal l th e 6 0 m m washer , sprin g plate , an d stoppe r

plate .

STOPPE R PLAT E

SPRING PLAT E

6 0 m m WASHE R

DIFFERENTIA LHOUSING

ProCarManuals.com

Page 379 of 1640

Differential

Reassembl y

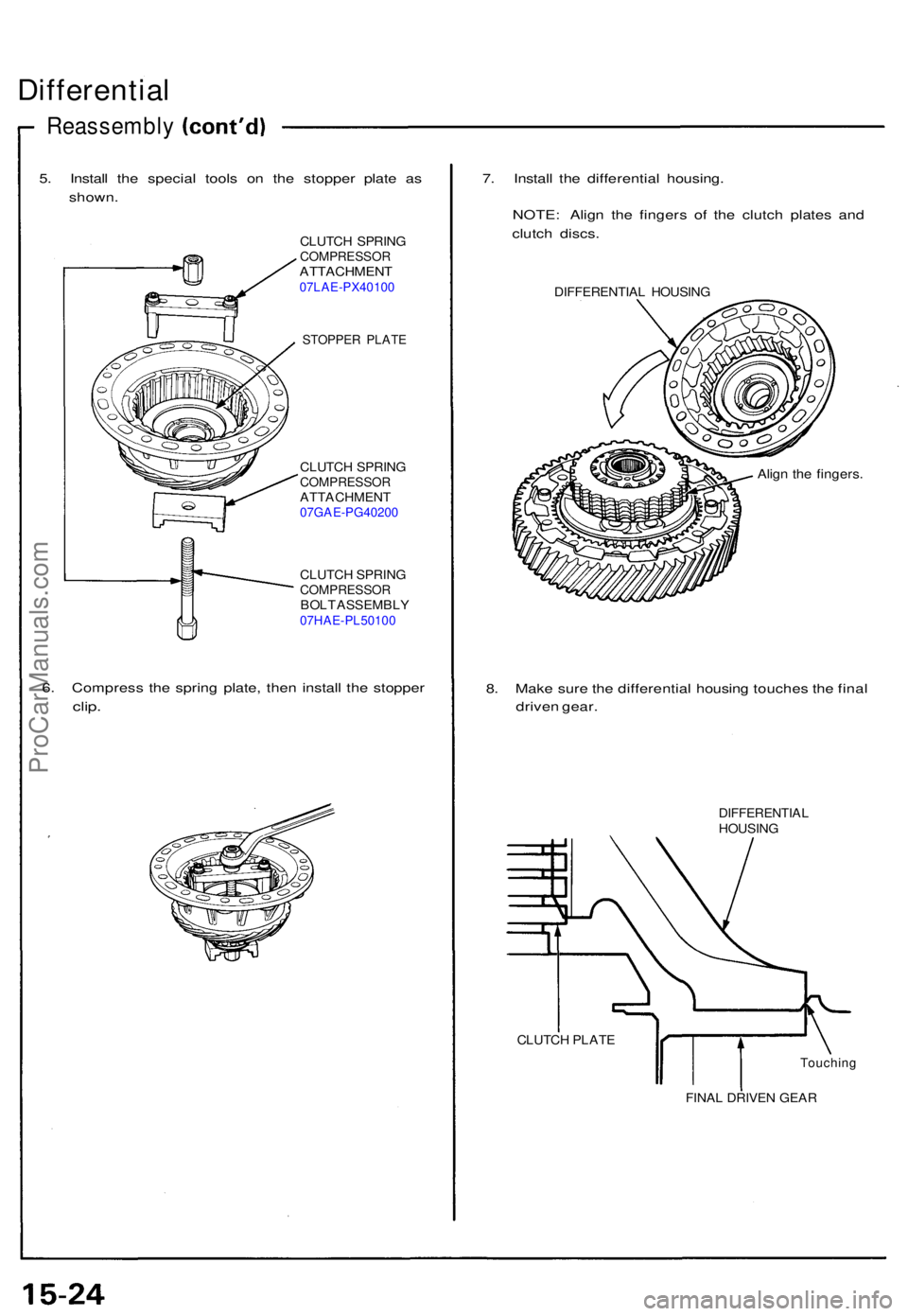

5. Instal l th e specia l tool s o n th e stoppe r plat e a s

shown .

CLUTC H SPRIN GCOMPRESSO RATTACHMENT07LAE-PX40100

STOPPER PLAT E

CLUTC H SPRIN GCOMPRESSO RATTACHMENT07GAE-PG40200

CLUTCH SPRIN GCOMPRESSO RBOLT ASSEMBL Y07HAE-PL50100

6. Compres s th e sprin g plate , the n instal l th e stoppe r

clip.

7. Instal l th e differentia l housing .

NOTE : Alig n th e finger s o f th e clutc h plate s an d

clutc h discs .

DIFFERENTIA L HOUSIN G

Align th e fingers .

8. Mak e sur e th e differentia l housin g touche s th e fina l

drive n gear .

DIFFERENTIA LHOUSING

CLUTC H PLAT E

Touchin g

FINAL DRIVE N GEA R

ProCarManuals.com

Page 380 of 1640

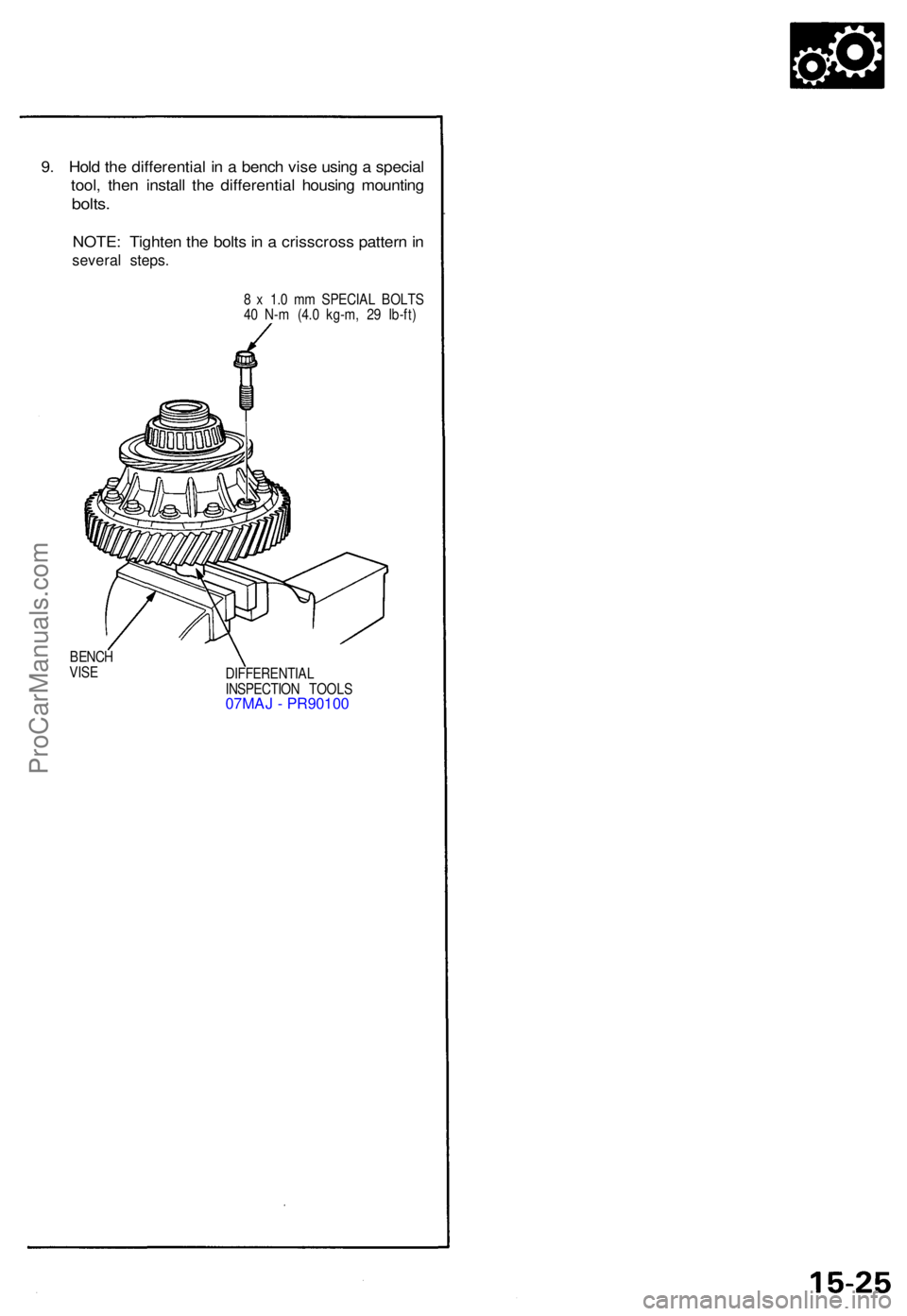

9. Hol d th e differentia l i n a benc h vis e usin g a specia l

tool , the n instal l th e differentia l housin g mountin g

bolts.

NOTE : Tighte n th e bolt s in a crisscros s patter n in

severa l steps .

8 x 1. 0 m m SPECIA L BOLT S

4 0 N- m (4. 0 kg-m , 2 9 Ib-ft )

BENC H

VIS E

DIFFERENTIAL

INSPECTIO N TOOL S

07MAJ - PR90100

ProCarManuals.com