ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 341 of 1640

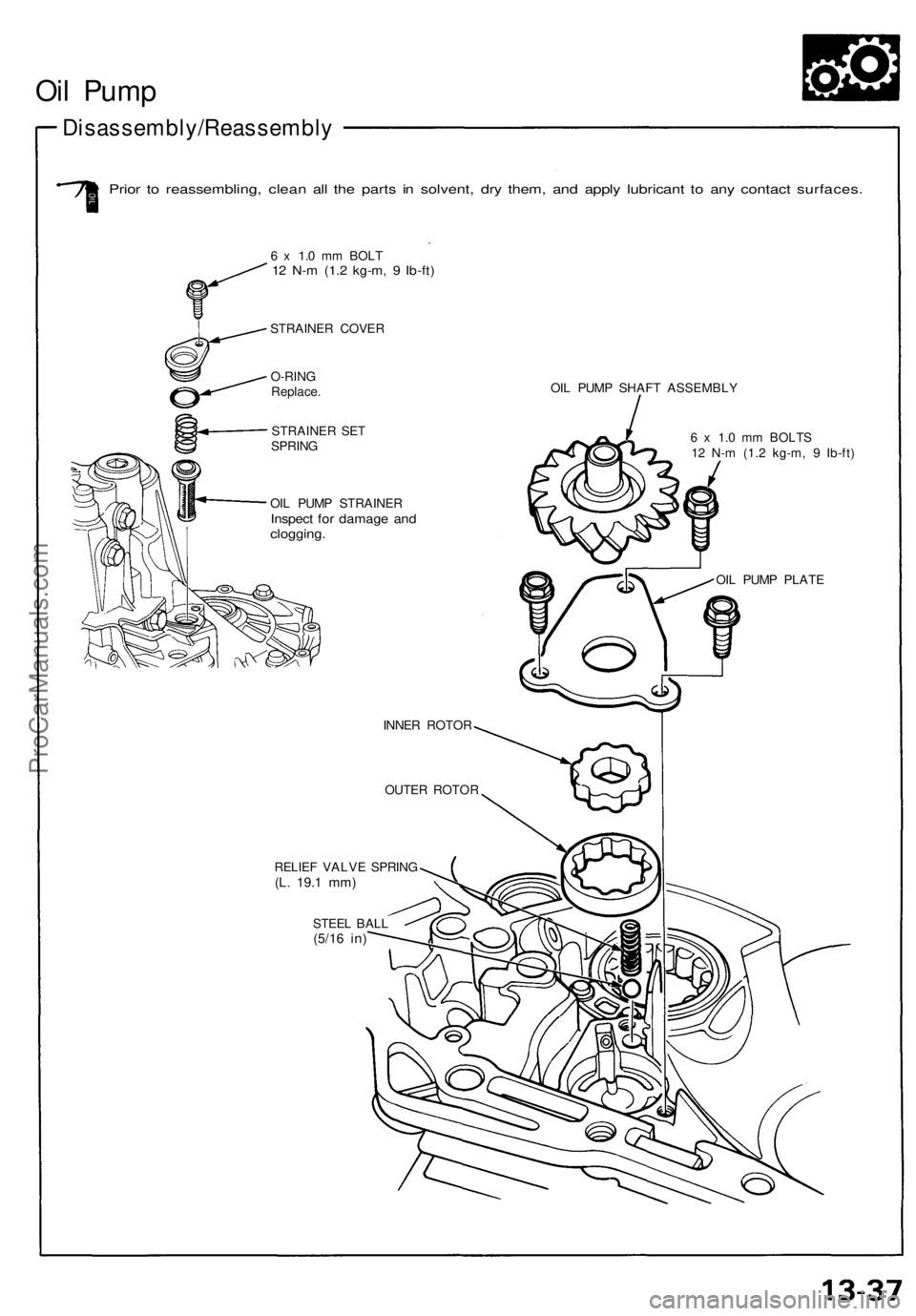

Oil Pump

Disassembly/Reassembly

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact surfaces.

6 x 1.0 mm BOLT

12 N-m (1.2 kg-m, 9 Ib-ft)

STRAINER COVER

O-RING

Replace.

STRAINER SET

SPRING

OIL PUMP STRAINER

Inspect for damage and

clogging.

OIL PUMP SHAFT ASSEMBLY

6 x 1.0 mm BOLTS

12 N-m (1.2 kg-m, 9 Ib-ft)

INNER ROTOR

OUTER ROTOR

RELIEF VALVE SPRING

(L.

19.1

mm)

STEEL BALL

(5/16

in)

OIL PUMP PLATEProCarManuals.com

Page 342 of 1640

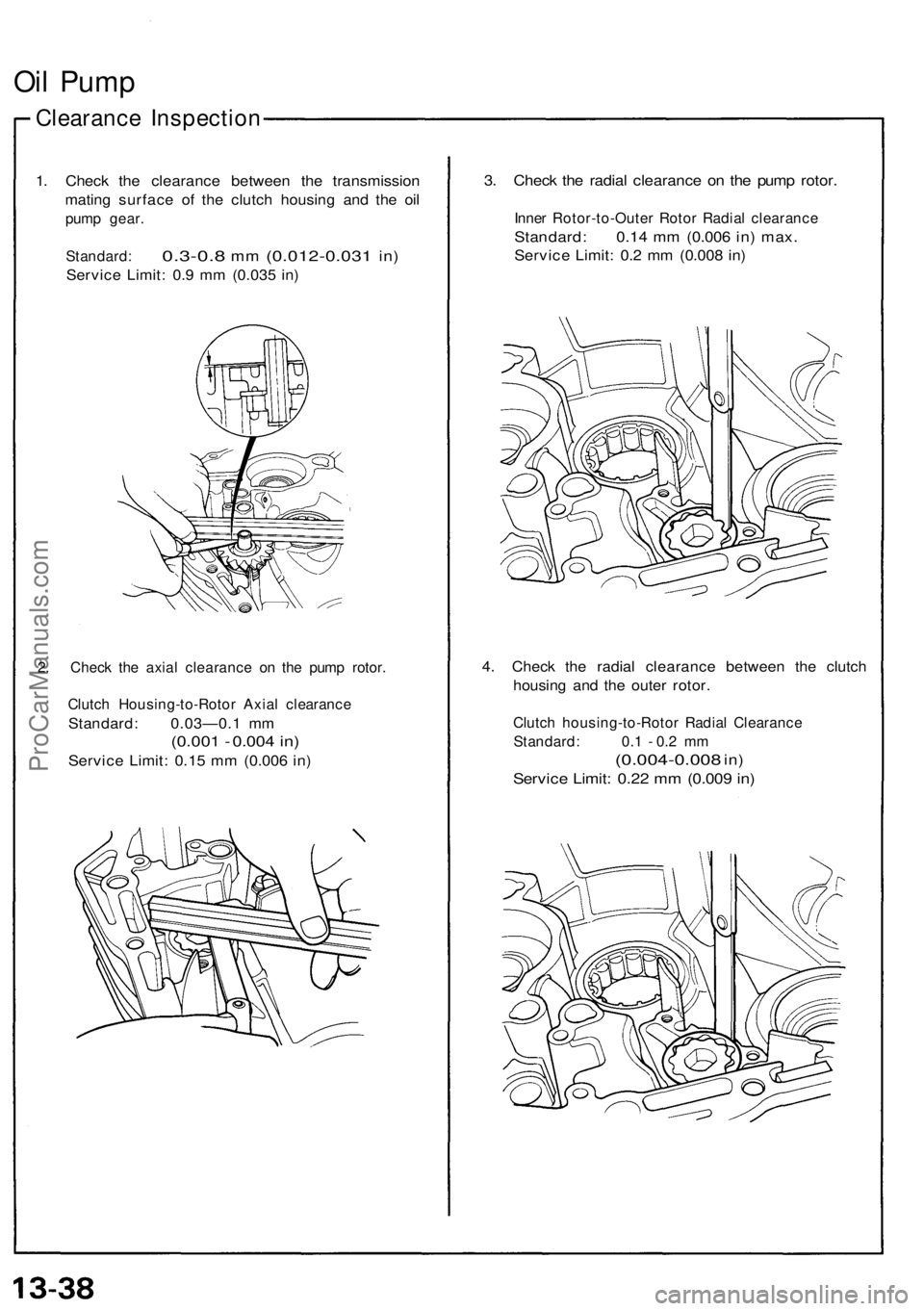

Oil Pump

Clearance Inspection

1. Check the clearance between the transmission

mating surface of the clutch housing and the oil

pump gear.

Standard:

0.3-0.8

mm

(0.012-0.031

in)

Service Limit: 0.9 mm (0.035 in)

2. Check the axial clearance on the pump rotor.

Clutch Housing-to-Rotor Axial clearance

Standard: 0.03—0.1 mm

(0.001 - 0.004 in)

Service Limit: 0.15 mm (0.006 in)

3. Check the radial clearance on the pump rotor.

Inner Rotor-to-Outer Rotor Radial clearance

Standard: 0.14 mm (0.006 in) max.

Service Limit: 0.2 mm (0.008 in)

4. Check the radial clearance between the clutch

housing and the outer rotor.

Clutch housing-to-Rotor Radial Clearance

Standard: 0.1 - 0.2 mm

(0.004-0.008

in)

Service Limit: 0.22 mm (0.009 in)ProCarManuals.com

Page 343 of 1640

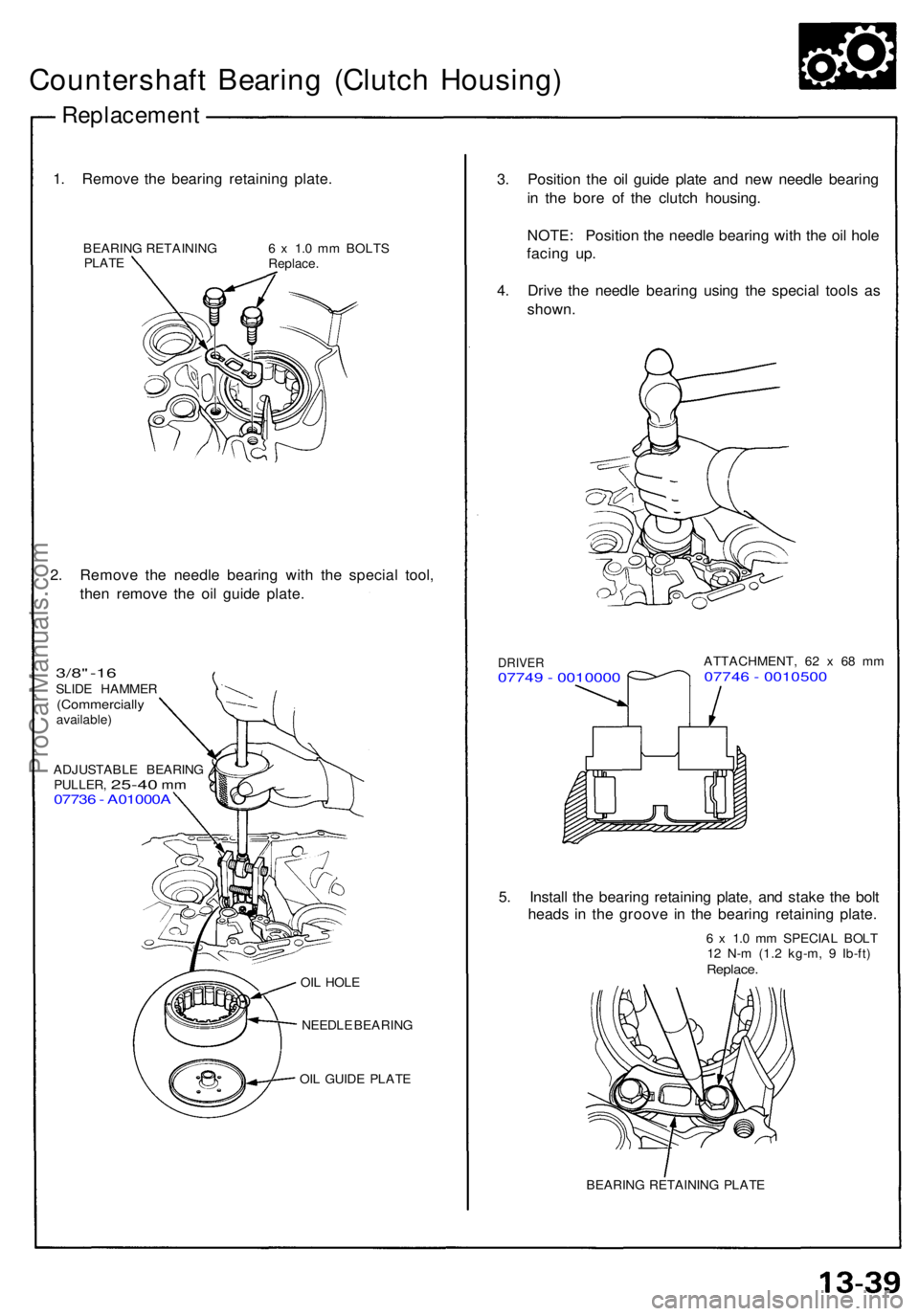

Countershaft Bearin g (Clutc h Housing )

Replacemen t

1. Remov e th e bearin g retainin g plate .

BEARIN G RETAININ G

PLAT E 6

x 1. 0 m m BOLT S

Replace .

2. Remov e th e needl e bearin g wit h th e specia l tool ,

the n remov e th e oi l guid e plate .

3/8"-1 6SLIDE HAMME R(Commerciall yavailable)

ADJUSTABL E BEARIN G

PULLER ,

25-40 mm0773 6 - A01000 A

OIL HOL E

NEEDL E BEARIN G

OI L GUID E PLAT E

3. Positio n th e oi l guid e plat e an d ne w needl e bearin g

i n th e bor e o f th e clutc h housing .

NOTE : Positio n th e needl e bearin g wit h th e oi l hol e

facin g up .

4 . Driv e th e needl e bearin g usin g th e specia l tool s a s

shown .

DRIVE R07749 - 001000 0ATTACHMENT, 6 2 x 68 m m07746 - 001050 0

5. Instal l th e bearin g retainin g plate , an d stak e th e bol t

head s i n th e groov e i n th e bearin g retainin g plate .

6 x 1. 0 m m SPECIA L BOL T

1 2 N- m (1. 2 kg-m , 9 Ib-ft )

Replace .

BEARIN G RETAININ G PLAT E

ProCarManuals.com

Page 344 of 1640

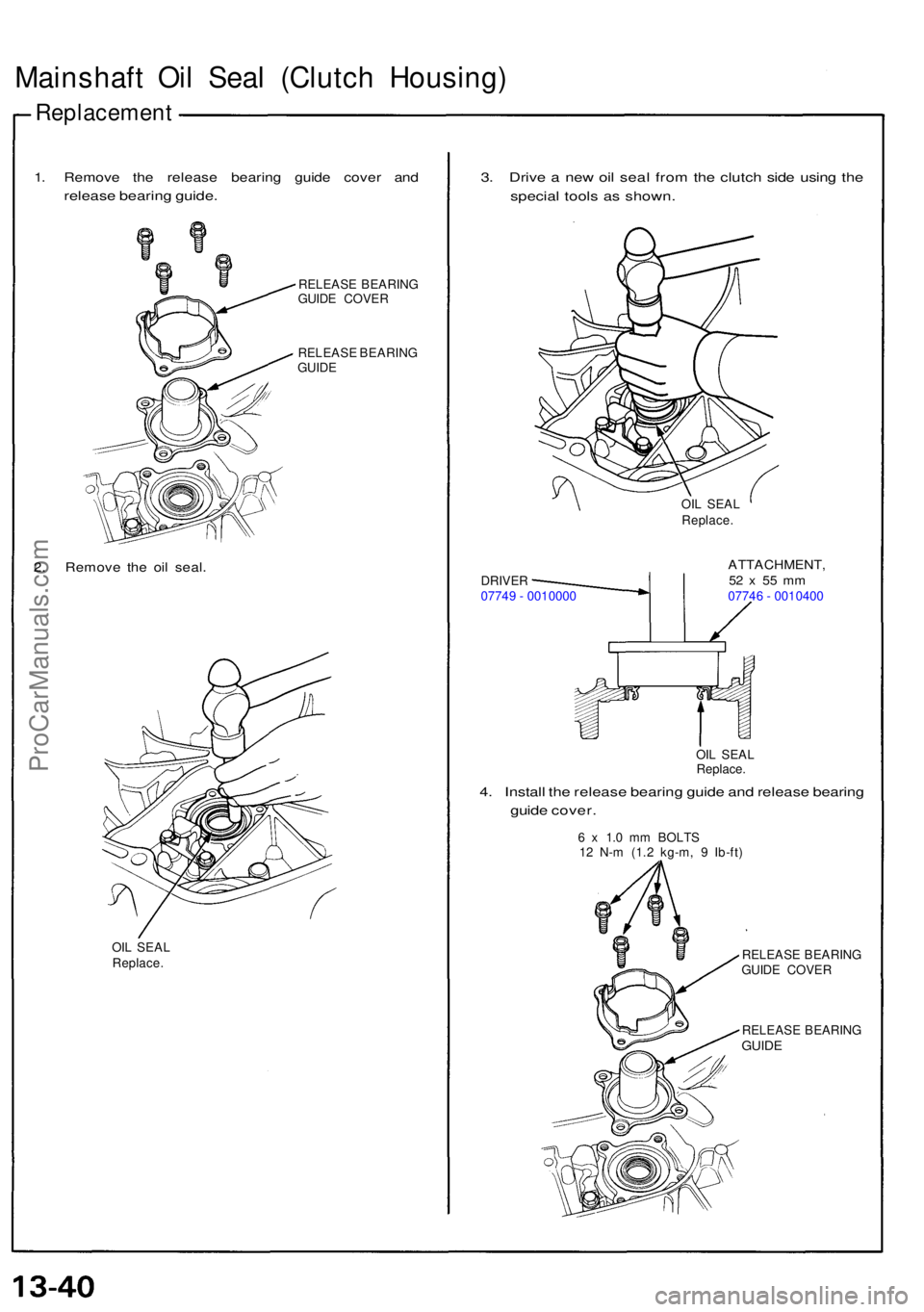

Mainshaft Oi l Sea l (Clutc h Housing )

Replacemen t

1. Remov e th e releas e bearin g guid e cove r an d

releas e bearin g guide .

RELEAS E BEARIN G

GUID E COVE R

RELEAS E BEARIN G

GUID E

2. Remov e th e oi l seal .

OIL SEA L

Replace .

3. Driv e a ne w oi l sea l fro m th e clutc h sid e usin g th e

specia l tool s a s shown .

OIL SEA L

Replace .

DRIVE R

07749 - 0010000

ATTACHMENT ,52 x 5 5 m m07746 - 0010400

OI L SEA L

Replace .

4. Instal l th e releas e bearin g guid e an d releas e bearin g

guid e cover .

6 x 1. 0 m m BOLT S

1 2 N- m (1. 2 kg-m , 9 Ib-ft )

RELEAS E BEARIN G

GUID E COVE R

RELEAS E BEARIN G

GUIDE

ProCarManuals.com

Page 345 of 1640

Mainshaft Thrust Shim

Adjustment

1. Remove the thrust shim and oil guide plate from the

transmission housing.

2. Install the mainshaft in the transmission housing.

NOTE: Do not install the clutch housing side ball

bearing.

3. Measure distance between the end of the

transmission housing and mainshaft.

NOTE:

• Use a straight edge and feeler gauge.

• Measure at three locations and average the

readings.

4. Set the mainshaft ball bearing in the clutch hous-

ing, and measure distance between the

surfaces of the clutch housing and the bearing in-

ner race.

NOTE:

• Use a straight edge and feeler gauge.

• Measure at three locations and average the

readings.

• Do not install the spring washer.

5. Select the proper thrust shim on the basis of the

following calculations.

NOTE: Do not use more than two thrust shims.

(Basic Formula)

A + B — 0.99 mm = shim thickness (max.)

A + B - 1.06 mm = shim thickness (min.)

A - C - 0.99 mm = shim thickness (max.)

A - C - 1.06 mm = shim thickness (min.)

82 mm THRUST SHIM

NOTE: Clean all the parts thoroughly before installation

6. Install the oil guide plate and thrust shim into the

transmission housing.

TRANSMISSION

HOUSING

THRUST SHIM

OIL GUIDE PLATE

13-41ProCarManuals.com

Page 346 of 1640

Mainshaft Thrus t Shi m

Adjustmen t

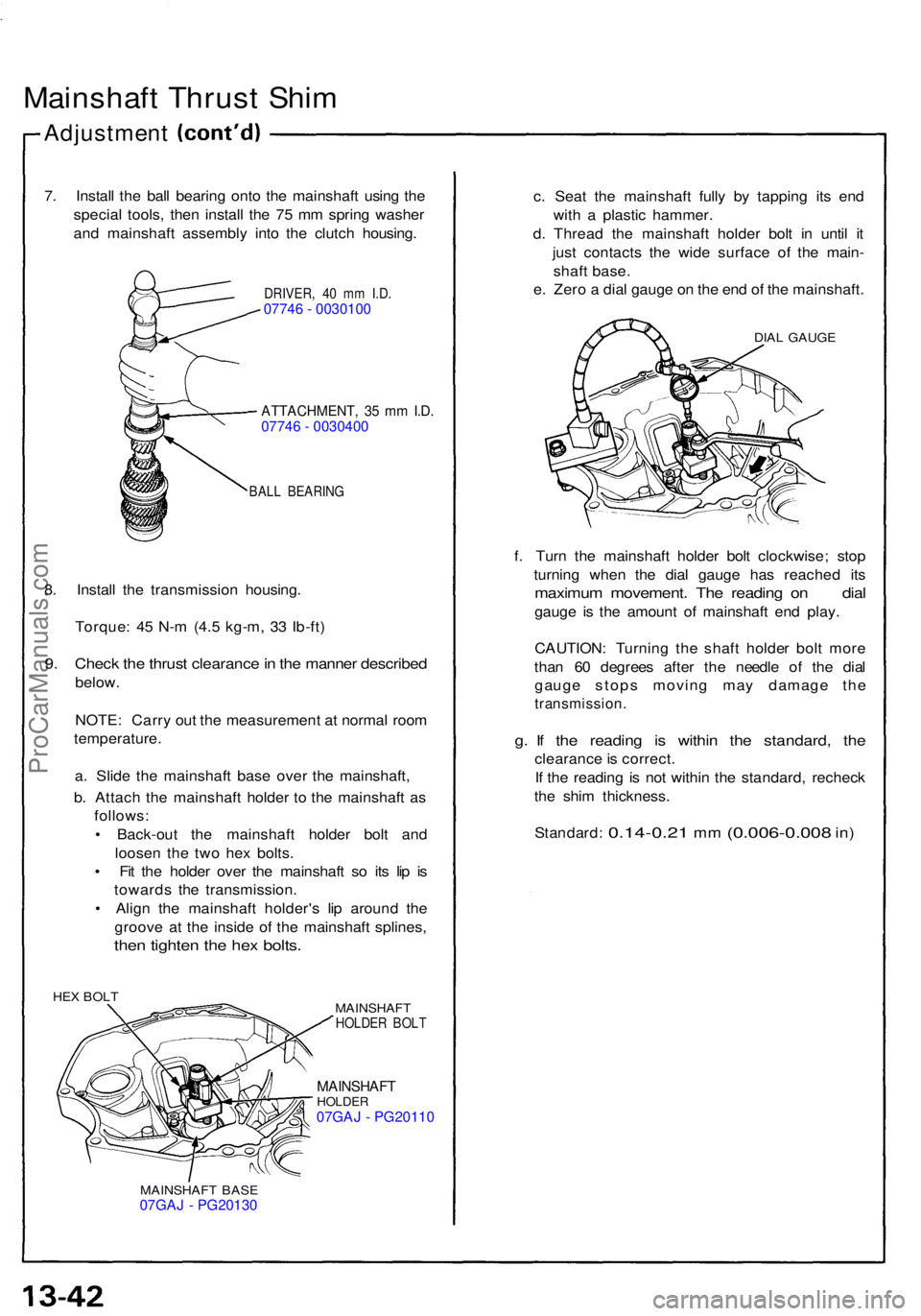

7. Instal l th e bal l bearin g ont o th e mainshaf t usin g th e

specia l tools , the n instal l th e 7 5 m m sprin g washe r

an d mainshaf t assembl y int o th e clutc h housing .

DRIVER, 4 0 m m I.D .07746 - 0030100

ATTACHMENT , 3 5 m m I.D .07746 - 0030400

BAL L BEARIN G

8. Instal l th e transmissio n housing .

Torque : 4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

9. Chec k th e thrus t clearanc e in th e manne r describe d

below.

NOTE : Carr y ou t th e measuremen t a t norma l roo m

temperature .

a . Slid e th e mainshaf t bas e ove r th e mainshaft ,

b . Attac h th e mainshaf t holde r t o th e mainshaf t a s

follows :

• Back-ou t th e mainshaf t holde r bol t an d

loose n th e tw o he x bolts .

• Fi t th e holde r ove r th e mainshaf t s o it s li p i s

toward s th e transmission .

• Alig n th e mainshaf t holder' s li p aroun d th e

groov e a t th e insid e of the mainshaf t splines ,

then tighte n th e he x bolts .

HEX BOL T

MAINSHAFT

HOLDER BOL T

MAINSHAF THOLDER07GAJ - PG20110

MAINSHAF T BAS E07GAJ - PG20130

c. Sea t th e mainshaf t full y b y tappin g it s en d

wit h a plasti c hammer .

d . Threa d th e mainshaf t holde r bol t i n unti l i t

jus t contact s th e wid e surfac e o f th e main -

shaf t base .

e . Zer o a dia l gaug e o n th e en d o f th e mainshaft .

DIAL GAUG E

f. Tur n th e mainshaf t holde r bol t clockwise ; sto p

turnin g whe n th e dia l gaug e ha s reache d it s

maximu m movement . Th e readin g o n dia l

gauge i s th e amoun t o f mainshaf t en d play .

CAUTION : Turnin g th e shaf t holde r bol t mor e

tha n 6 0 degree s afte r th e needl e o f th e dia l

gaug e stop s movin g ma y damag e th e

transmission .

g. I f th e readin g i s withi n th e standard , th e

clearanc e is correct .

I f th e readin g i s no t withi n th e standard , rechec k

th e shi m thickness .

Standard :

0.14-0.21 mm (0.006-0.00 8 in)

ProCarManuals.com

Page 347 of 1640

Transmission

Reassembly

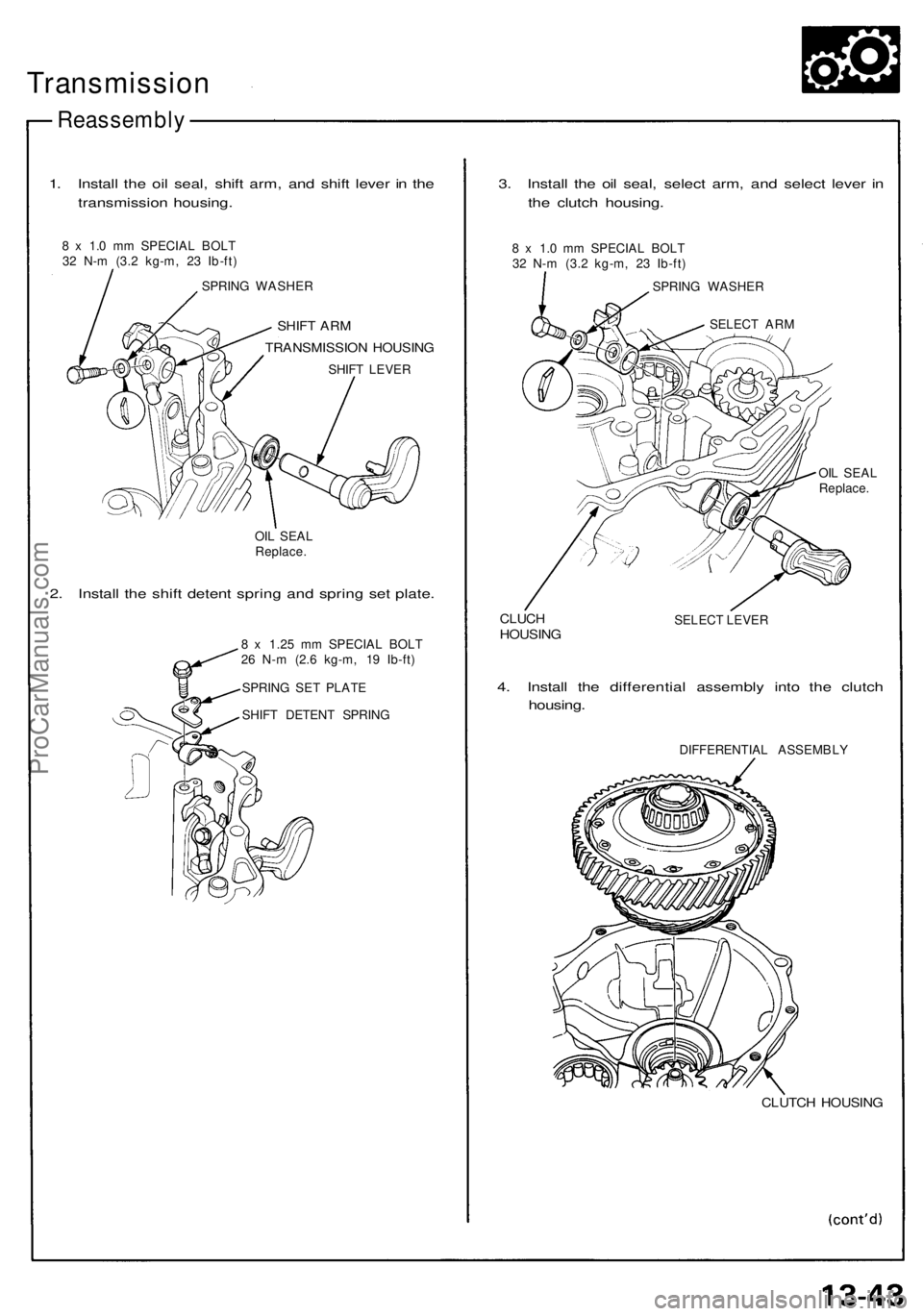

1. Install the oil seal, shift arm, and shift lever in the

transmission housing.

8 x 1.0 mm SPECIAL BOLT

32 N-m (3.2 kg-m, 23 Ib-ft)

SPRING WASHER

SHIFT ARM

TRANSMISSION HOUSING

SHIFT LEVER

OIL SEAL

Replace.

2. Install the shift detent spring and spring set plate.

8 x 1.25 mm SPECIAL BOLT

26 N-m (2.6 kg-m, 19 Ib-ft)

SPRING SET PLATE

SHIFT DETENT SPRING

3. Install the oil seal, select arm, and select lever in

the clutch housing.

8 x 1.0 mm SPECIAL BOLT

32 N-m (3.2 kg-m, 23 Ib-ft)

SPRING WASHER

SELECT ARM

OIL SEAL

Replace.

CLUCH

HOUSING

SELECT LEVER

4. Install the differential assembly into the clutch

housing.

DIFFERENTIAL ASSEMBLY

CLUTCH HOUSINGProCarManuals.com

Page 348 of 1640

Transmission

Reassembly

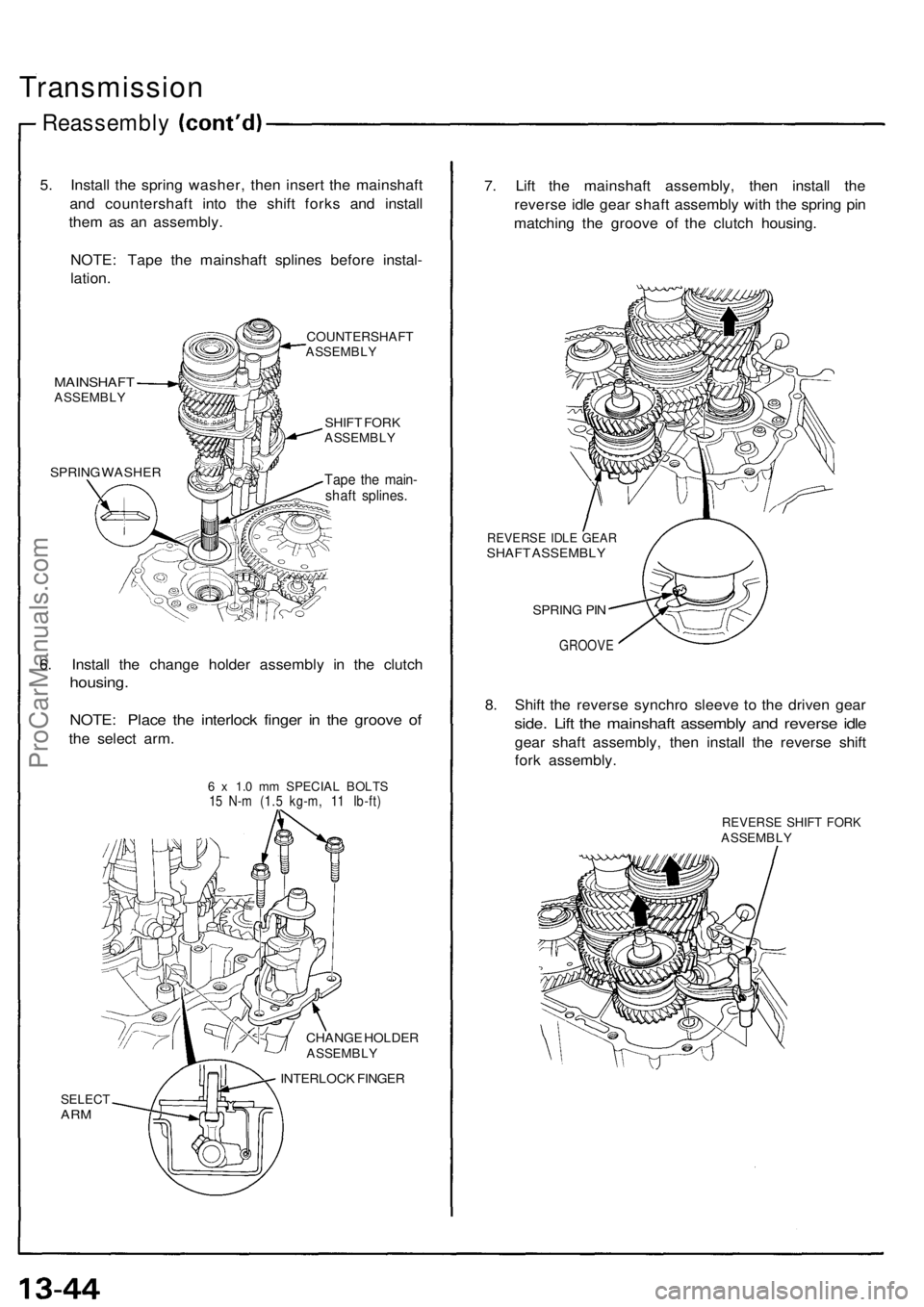

5. Install the spring washer, then insert the mainshaft

and countershaft into the shift forks and install

them as an assembly.

NOTE: Tape the mainshaft splines before instal-

lation.

COUNTERSHAFT

ASSEMBLY

MAINSHAFT

ASSEMBLY

SPRING WASHER

SHIFT FORK

ASSEMBLY

Tape the main-

shaft splines.

6. Install the change holder assembly in the clutch

housing.

NOTE: Place the interlock finger in the groove of

the select arm.

6 x 1.0 mm SPECIAL BOLTS

15 N-m (1.5 kg-m, 11 Ib-ft)

SELECT

ARM

CHANGE HOLDER

ASSEMBLY

INTERLOCK FINGER

7. Lift the mainshaft assembly, then install the

reverse idle gear shaft assembly with the spring pin

matching the groove of the clutch housing.

REVERSE IDLE GEAR

SHAFT ASSEMBLY

SPRING PIN

GROOVE

8. Shift the reverse synchro sleeve to the driven gear

side. Lift the mainshaft assembly and reverse idle

gear shaft assembly, then install the reverse shift

fork assembly.

REVERSE SHIFT FORK

ASSEMBLYProCarManuals.com

Page 349 of 1640

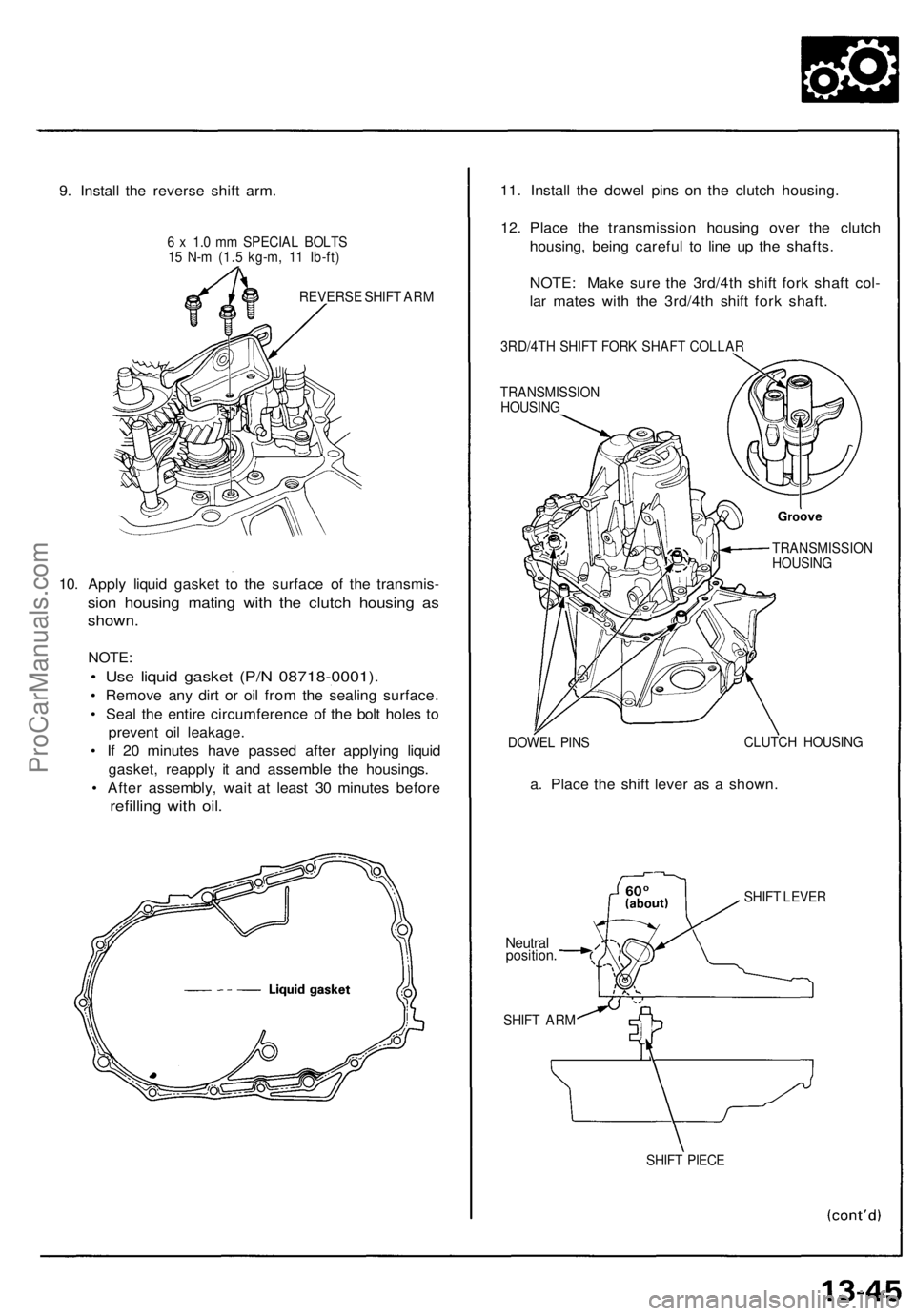

9. Install the reverse shift arm.

6 x 1.0 mm SPECIAL BOLTS

15 N-m (1.5 kg-m, 11 Ib-ft)

REVERSE SHIFT ARM

10. Apply liquid gasket to the surface of the transmis-

sion housing mating with the clutch housing as

shown.

NOTE:

• Use liquid gasket (P/N 08718-0001).

• Remove any dirt or oil from the sealing surface.

• Seal the entire circumference of the bolt holes to

prevent oil leakage.

• If 20 minutes have passed after applying liquid

gasket, reapply it and assemble the housings.

• After assembly, wait at least 30 minutes before

refilling with oil.

11. Install the dowel pins on the clutch housing.

12. Place the transmission housing over the clutch

housing, being careful to line up the shafts.

NOTE: Make sure the 3rd/4th shift fork shaft col-

lar mates with the 3rd/4th shift fork shaft.

3RD/4TH SHIFT FORK SHAFT COLLAR

TRANSMISSION

HOUSING

TRANSMISSION

HOUSING

DOWEL PINS

CLUTCH HOUSING

a. Place the shift lever as a shown.

SHIFT LEVER

Neutral

position.

SHIFT ARM

SHIFT PIECEProCarManuals.com

Page 350 of 1640

Transmission

Reassembly

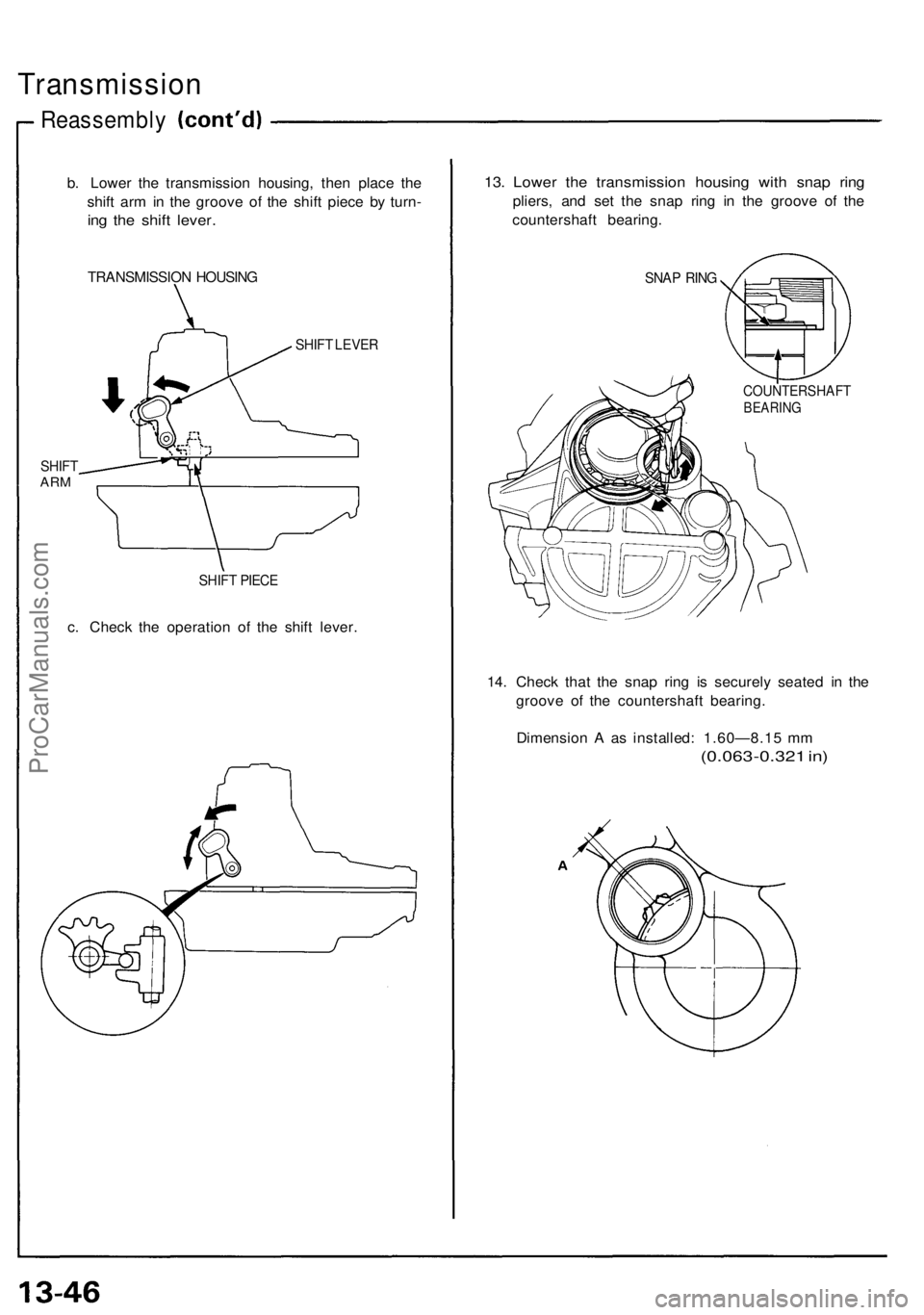

b. Lower the transmission housing, then place the

shift arm in the groove of the shift piece by turn-

ing the shift lever.

TRANSMISSION HOUSING

SHIFT LEVER

SHIFT

ARM

SHIFT PIECE

c. Check the operation of the shift lever.

13. Lower the transmission housing with snap ring

pliers, and set the snap ring in the groove of the

countershaft bearing.

SNAP RING

14. Check that the snap ring is securely seated in the

groove of the countershaft bearing.

Dimension A as installed: 1.60—8.15 mm

(0.063-0.321 in)

COUNTERSHAFT

BEARINGProCarManuals.com