ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 351 of 1640

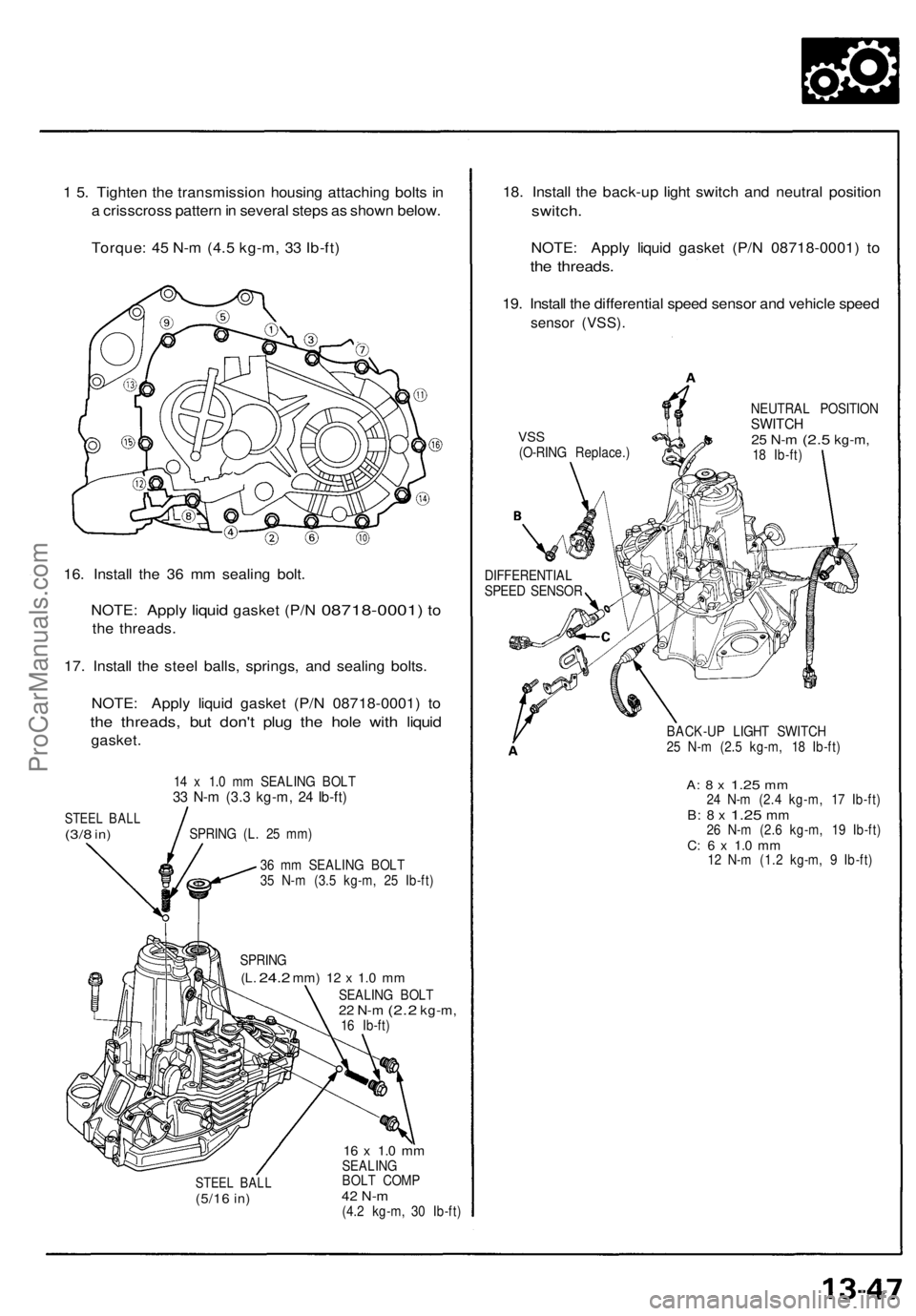

1 5 . Tighte n th e transmissio n housin g attachin g bolt s i n

a crisscros s patter n in severa l step s a s show n below .

Torque : 4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

16 . Instal l th e 3 6 m m sealin g bolt .

NOTE :

Apply liquid gaske t (P/ N 08718-0001 ) to

th e threads .

17 . Instal l th e stee l balls , springs , an d sealin g bolts .

NOTE : Appl y liqui d gaske t (P/ N 08718-0001 ) t o

th e threads , bu t don' t plu g th e hol e with liquid

gasket .

STEEL BAL L(3/8 in)

14 x 1. 0 m m SEALIN G BOL T33 N- m (3. 3 kg-m , 2 4 Ib-ft )

SPRIN G (L . 2 5 mm )

3 6 m m SEALIN G BOL T

3 5 N- m (3. 5 kg-m , 2 5 Ib-ft )

SPRIN G

(L. 24. 2 mm ) 12 x 1. 0 m m

SEALIN G BOL T22 N- m (2. 2 kg-m ,16 Ib-ft )

STEE L BAL L(5/16 in)

16 x 1. 0 m mSEALIN G

BOL T COM P

42 N- m(4.2 kg-m , 3 0 Ib-ft )

18. Instal l th e back-u p ligh t switc h an d neutra l positio n

switch.

NOTE: Appl y liqui d gaske t (P/ N 08718-0001 ) t o

the threads .

19. Instal l th e differentia l spee d senso r an d vehicl e spee d

senso r (VSS) .

VSS(O-RIN G Replace. ) NEUTRA

L POSITIO N

SWITCH25 N- m (2. 5 kg-m ,18 Ib-ft )

DIFFERENTIA L

SPEE D SENSO R

BACK-UP LIGH T SWITC H

2 5 N- m (2. 5 kg-m , 1 8 Ib-ft )

A: 8 x 1.2 5 mm24 N- m (2. 4 kg-m , 1 7 Ib-ft )B: 8 x 1.2 5 mm26 N- m (2. 6 kg-m , 1 9 Ib-ft )C: 6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

ProCarManuals.com

Page 352 of 1640

Transmission Assembl y

Installatio n

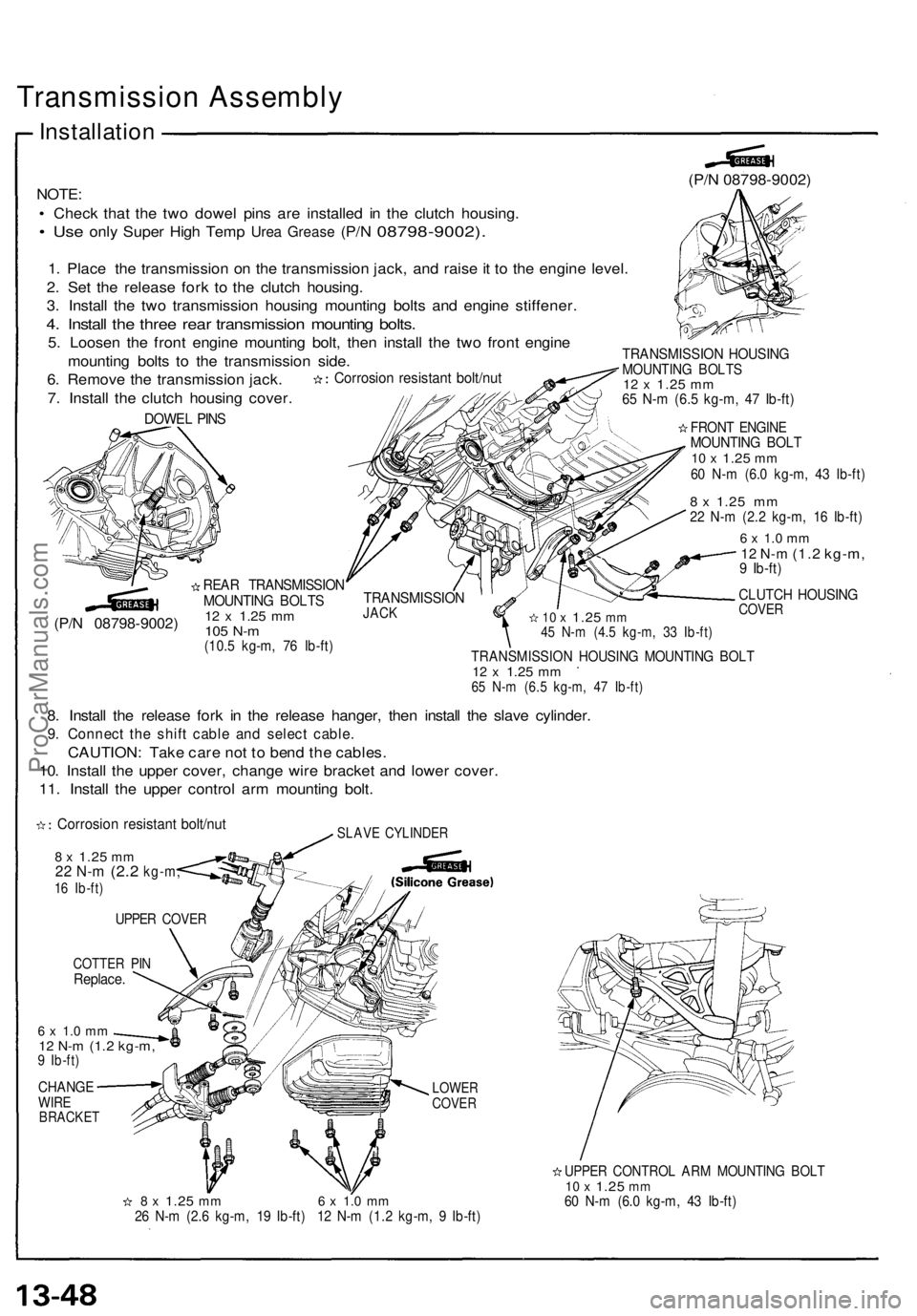

NOTE:

• Chec k tha t th e tw o dowe l pin s ar e installe d i n th e clutc h housing .

• Us e onl y Supe r Hig h Tem p Urea Greas e (P/N 08798-9002) .

1. Plac e th e transmissio n o n th e transmissio n jack , an d rais e it t o th e engin e level .

2 . Se t th e releas e for k t o th e clutc h housing .

3 . Instal l th e tw o transmissio n housin g mountin g bolt s an d engin e stiffener .

4. Instal l th e thre e rea r transmissio n mountin g bolts .

5. Loose n th e fron t engin e mountin g bolt , the n instal l th e tw o fron t engin e

mountin g bolt s t o th e transmissio n side .

6 . Remov e th e transmissio n jack .

7 . Instal l th e clutc h housin g cover .

DOWE L PIN S

(P/N 08798-9002 )

REAR TRANSMISSIO NMOUNTING BOLT S12 x 1.2 5 mm105 N- m(10. 5 kg-m , 7 6 Ib-ft )

TRANSMISSIO NJACK

TRANSMISSIO N HOUSIN GMOUNTIN G BOLT S12 x 1.2 5 mm65 N- m (6. 5 kg-m , 4 7 Ib-ft )

FRON T ENGIN EMOUNTIN G BOL T10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

CLUTC H HOUSIN GCOVER10 x 1.2 5 mm45 N- m (4. 5 kg-m , 3 3 Ib-ft )

TRANSMISSIO N HOUSIN G MOUNTIN G BOL T12 x 1.2 5 mm65 N- m (6. 5 kg-m , 4 7 Ib-ft )

8. Instal l th e releas e for k i n th e releas e hanger , the n instal l th e slav e cylinder .

9. Connec t th e shif t cabl e an d selec t cable .

CAUTION : Tak e car e no t t o ben d th e cables .

10 . Instal l th e uppe r cover , chang e wir e bracke t an d lowe r cover .

11 . Instal l th e uppe r contro l ar m mountin g bolt .

Corrosio n resistan t bolt/nu t

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

COTTE R PI NReplace .

SLAVE CYLINDE R

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

CHANG EWIREBRACKE T

LOWERCOVER

8 x 1.2 5 mm 6 x 1. 0 m m26 N- m (2. 6 kg-m , 1 9 Ib-ft ) 1 2 N- m (1. 2 kg-m , 9 Ib-ft )

UPPE R CONTRO L AR M MOUNTIN G BOL T10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

(P/N 08798-9002 )

Corrosion resistan t bolt/nu t

UPPER COVE R

ProCarManuals.com

Page 353 of 1640

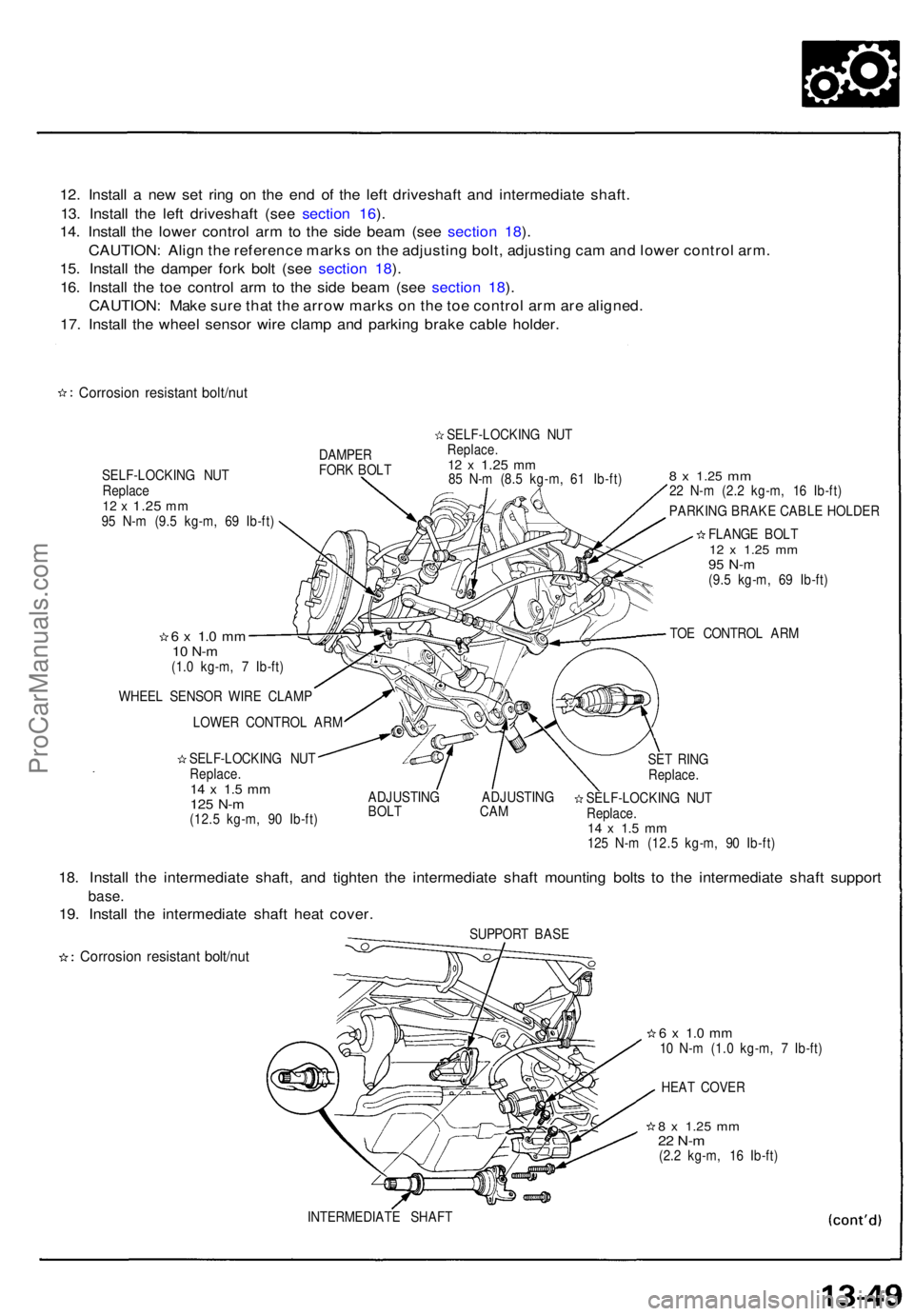

12. Instal l a ne w se t rin g o n th e en d o f th e lef t driveshaf t an d intermediat e shaft .

13 . Instal l th e lef t driveshaf t (se e sectio n 16 ).

14 . Instal l th e lowe r contro l ar m to th e sid e bea m (se e sectio n 18 ).

CAUTION : Alig n th e referenc e mark s o n th e adjustin g bolt , adjustin g ca m an d lowe r contro l arm .

15 . Instal l th e dampe r for k bol t (se e sectio n 18 ).

16 . Instal l th e to e contro l ar m to th e sid e bea m (se e sectio n 18 ).

CAUTION : Mak e sur e tha t th e arro w mark s o n th e to e contro l ar m ar e aligned .

17 . Instal l th e whee l senso r wir e clam p an d parkin g brak e cabl e holder .

Corrosio n resistan t bolt/nu t

SELF-LOCKIN G NU T

Replac e

12 x 1.2 5 mm95 N- m (9. 5 kg-m , 6 9 Ib-ft ) DAMPE

R

FOR K BOL T SELF-LOCKIN

G NU T

Replace .12 x 1.2 5 mm85 N- m (8. 5 kg-m , 6 1 Ib-ft )

6 x 1. 0 m m10 N- m(1.0 kg-m , 7 Ib-ft )

WHEE L SENSO R WIR E CLAM P

LOWE R CONTRO L AR M

SELF-LOCKIN G NU T

Replace .14 x 1. 5 m m125 N- m(12. 5 kg-m , 9 0 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

PARKIN G BRAK E CABL E HOLDE R

FLANG E BOL T

12 x 1.2 5 mm95 N- m(9.5 kg-m , 6 9 Ib-ft )

TO E CONTRO L AR M

SE T RIN G

Replace .

SELF-LOCKIN G NU T

Replace .

14 x 1. 5 m m125 N- m (12. 5 kg-m , 9 0 Ib-ft )

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

HEA T COVE R

8 x 1.2 5 mm22 N- m(2.2 kg-m , 1 6 Ib-ft )

INTERMEDIAT E SHAF T

18. Instal l th e intermediat e shaft , an d tighte n th e intermediat e shaf t mountin g bolt s t o th e intermediat e shaf t suppor t

base.

19. Instal l th e intermediat e shaf t hea t cover .

SUPPOR T BAS E

Corrosio n resistan t bolt/nu t

ADJUSTIN G ADJUSTIN G

BOL T CA M

ProCarManuals.com

Page 354 of 1640

Transmission Assembl y

Installation

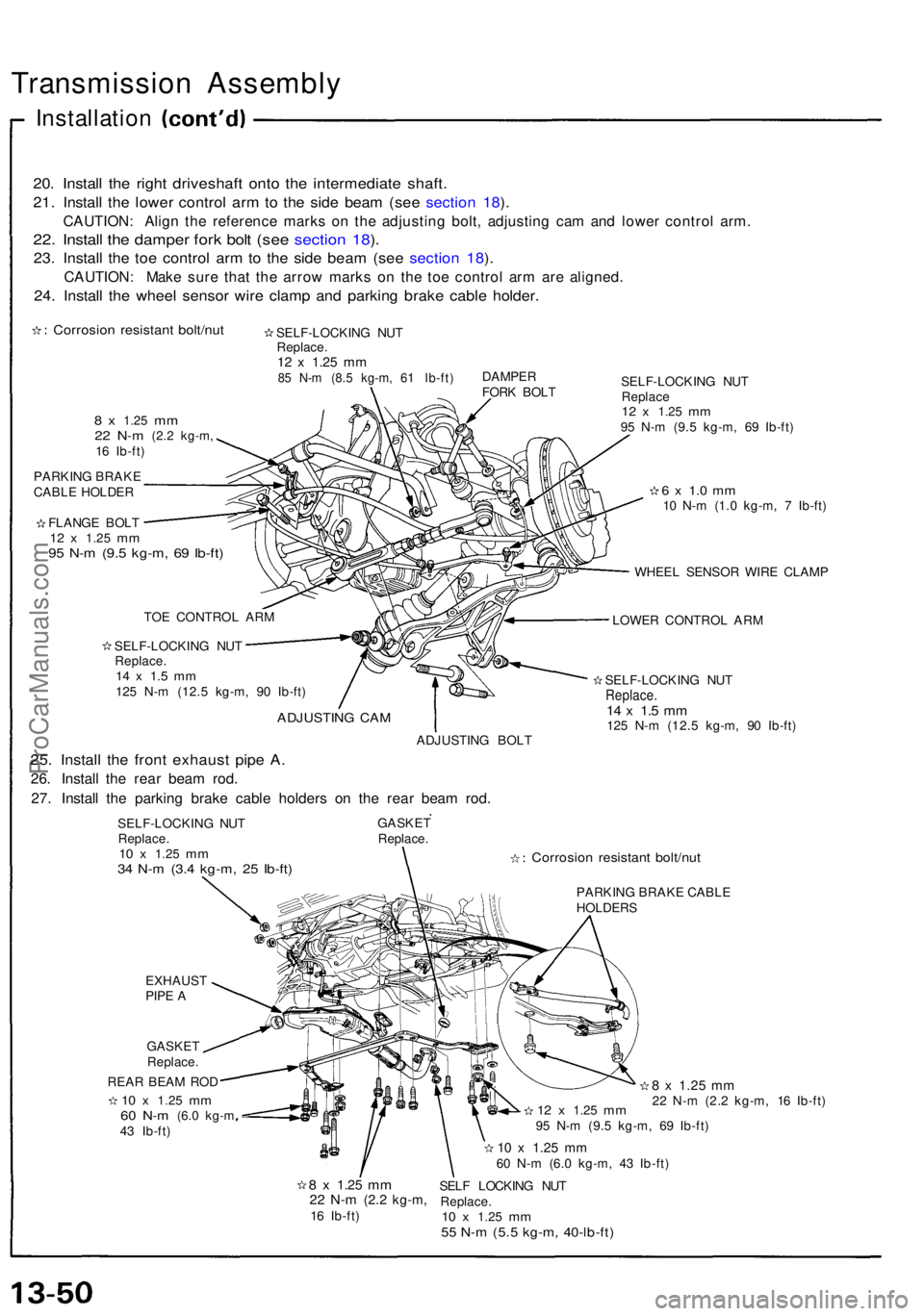

20. Instal l th e righ t driveshaf t ont o th e intermediat e shaft .

21. Instal l th e lowe r contro l ar m to th e sid e bea m (se e sectio n 18 ).

CAUTION : Alig n th e referenc e mark s o n th e adjustin g bolt , adjustin g ca m an d lowe r contro l arm .

22. Instal l th e damper fork bol t (se e sectio n 18 ).

23 . Instal l th e to e contro l ar m to th e sid e bea m (se e sectio n 18 ).

CAUTION : Mak e sur e tha t th e arro w mark s o n th e to e contro l ar m ar e aligned .

24. Instal l th e whee l senso r wir e clam p an d parkin g brak e cabl e holder .

Corrosio n resistan t bolt/nu t

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

PARKIN G BRAK E

CABL E HOLDE R

FLANG E BOL T

12 x 1.2 5 mm95 N- m (9. 5 kg-m , 6 9 Ib-ft )

SELF-LOCKIN G NU T

Replace .

12 x 1.2 5 mm85 N- m (8. 5 kg-m , 6 1 Ib-ft )DAMPE R

FOR K BOL T

TO E CONTRO L AR M

SELF-LOCKIN G NU T

Replace .14 x 1. 5 m m125 N- m (12. 5 kg-m , 9 0 Ib-ft )

ADJUSTIN G CA M

ADJUSTIN G BOL T

25. Instal l th e fron t exhaus t pip e A .

26 . Instal l th e rea r bea m rod .

27 . Instal l th e parkin g brak e cabl e holder s o n th e rea r bea m rod .

SELF-LOCKIN G NU T

Replac e

12 x 1.2 5 mm95 N- m (9. 5 kg-m , 6 9 Ib-ft )

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

WHEE L SENSO R WIR E CLAM P

LOWE R CONTRO L AR M

SELF-LOCKIN G NU T

Replace .14 x 1. 5 m m125 N- m (12. 5 kg-m , 9 0 Ib-ft )

SELF-LOCKIN G NU T

Replace .

10 x 1.2 5 mm34 N- m (3. 4 kg-m , 2 5 Ib-ft )

GASKE TReplace .

Corrosio n resistan t bolt/nu t

PARKIN G BRAK E CABL E

HOLDER S

EXHAUS T

PIP E A

GASKE T

Replace .

REAR BEA M RO D

10 x 1.2 5 mm60 N- m (6. 0 kg- m43 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

12 x 1.2 5 mm95 N- m (9. 5 kg-m , 6 9 Ib-ft )

10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

SEL F LOCKIN G NU T

Replace .

10 x 1.2 5 mm55 N- m (5. 5 kg-m , 40-lb-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

ProCarManuals.com

Page 355 of 1640

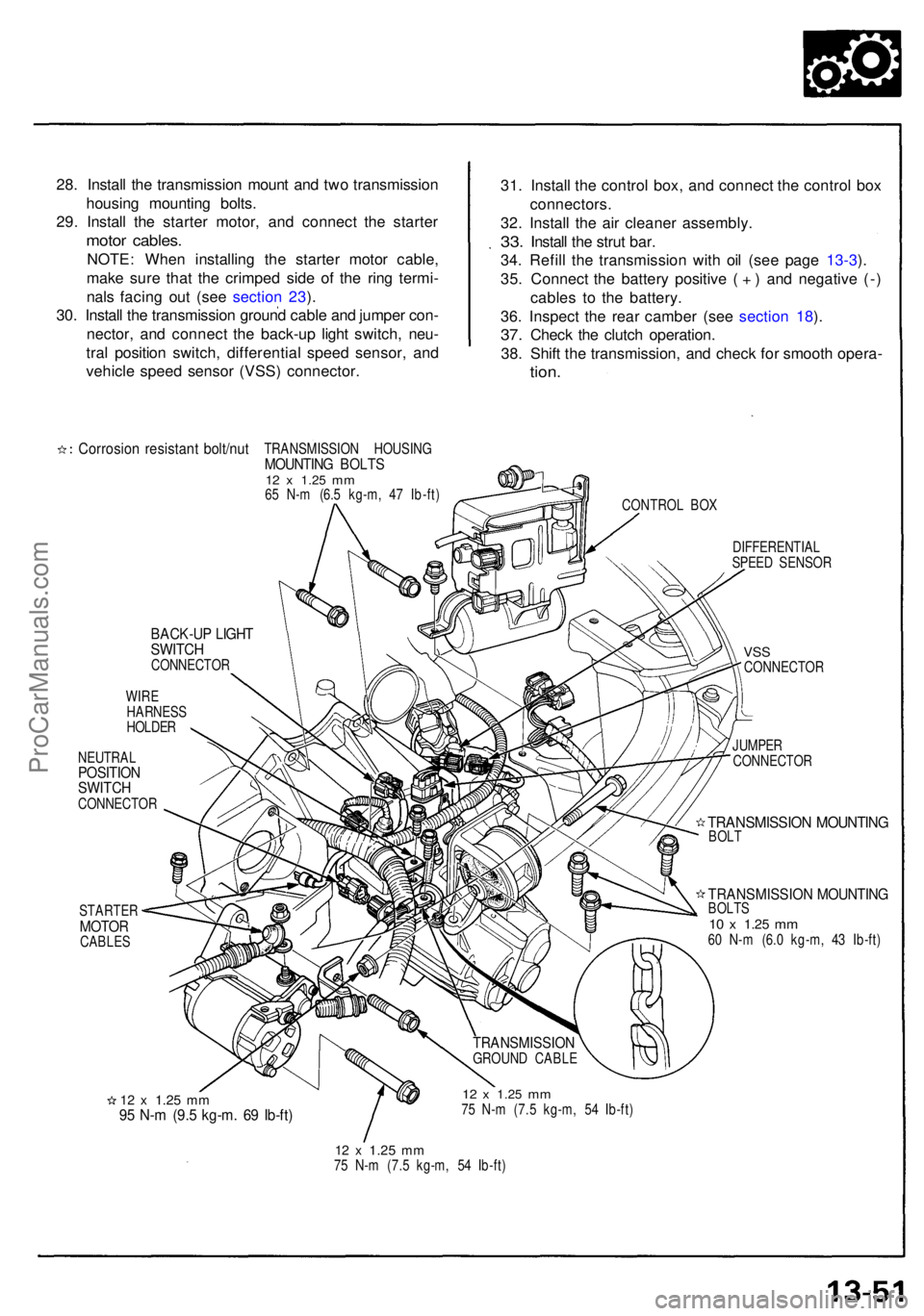

28. Instal l th e transmissio n moun t an d tw o transmissio n

housin g mountin g bolts .

29 . Instal l th e starte r motor , an d connec t th e starte r

motor cables .

NOTE: Whe n installin g th e starte r moto r cable ,

mak e sur e tha t th e crimpe d sid e o f th e rin g termi -

nal s facin g ou t (se e sectio n 23 ).

30 . Instal l th e transmissio n groun d cabl e an d jumpe r con -

nector , an d connec t th e back-u p ligh t switch , neu -

tra l positio n switch , differentia l spee d sensor , an d

vehicl e spee d senso r (VSS ) connector . 31

. Instal l th e contro l box , an d connec t th e contro l bo x

connectors .

32. Instal l th e ai r cleane r assembly .

33. Instal l th e stru t bar .

34 . Refil l th e transmissio n wit h oi l (se e pag e 13-3 ).

35 . Connec t th e batter y positiv e ( + ) an d negativ e (- )

cable s t o th e battery .

36 . Inspec t th e rea r cambe r (se e sectio n 18 ).

37 . Chec k th e clutc h operation .

38 . Shif t th e transmission , an d chec k fo r smoot h opera -

tion.

Corrosio n resistan t bolt/nu tTRANSMISSIO N HOUSIN GMOUNTING BOLT S12 x 1.2 5 mm65 N- m (6. 5 kg-m , 4 7 Ib-ft )

CONTROL BO X

BACK-U P LIGH TSWITC HCONNECTO R

WIR E

HARNES S

HOLDE R

NEUTRA L

POSITIONSWITCHCONNECTO R

STARTE R

MOTORCABLE S DIFFERENTIA

L

SPEE D SENSO R

VSSCONNECTO R

JUMPE R

CONNECTO R

TRANSMISSIO N MOUNTIN GBOLT

TRANSMISSIO N MOUNTIN GBOLTS10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

12 x 1.2 5 mm95 N- m (9. 5 kg-m . 6 9 Ib-ft )

12 x 1.2 5 mm75 N- m (7. 5 kg-m , 5 4 Ib-ft )

12 x 1.2 5 mm75 N- m (7. 5 kg-m , 5 4 Ib-ft )

TRANSMISSIO NGROUND CABL E

ProCarManuals.com

Page 356 of 1640

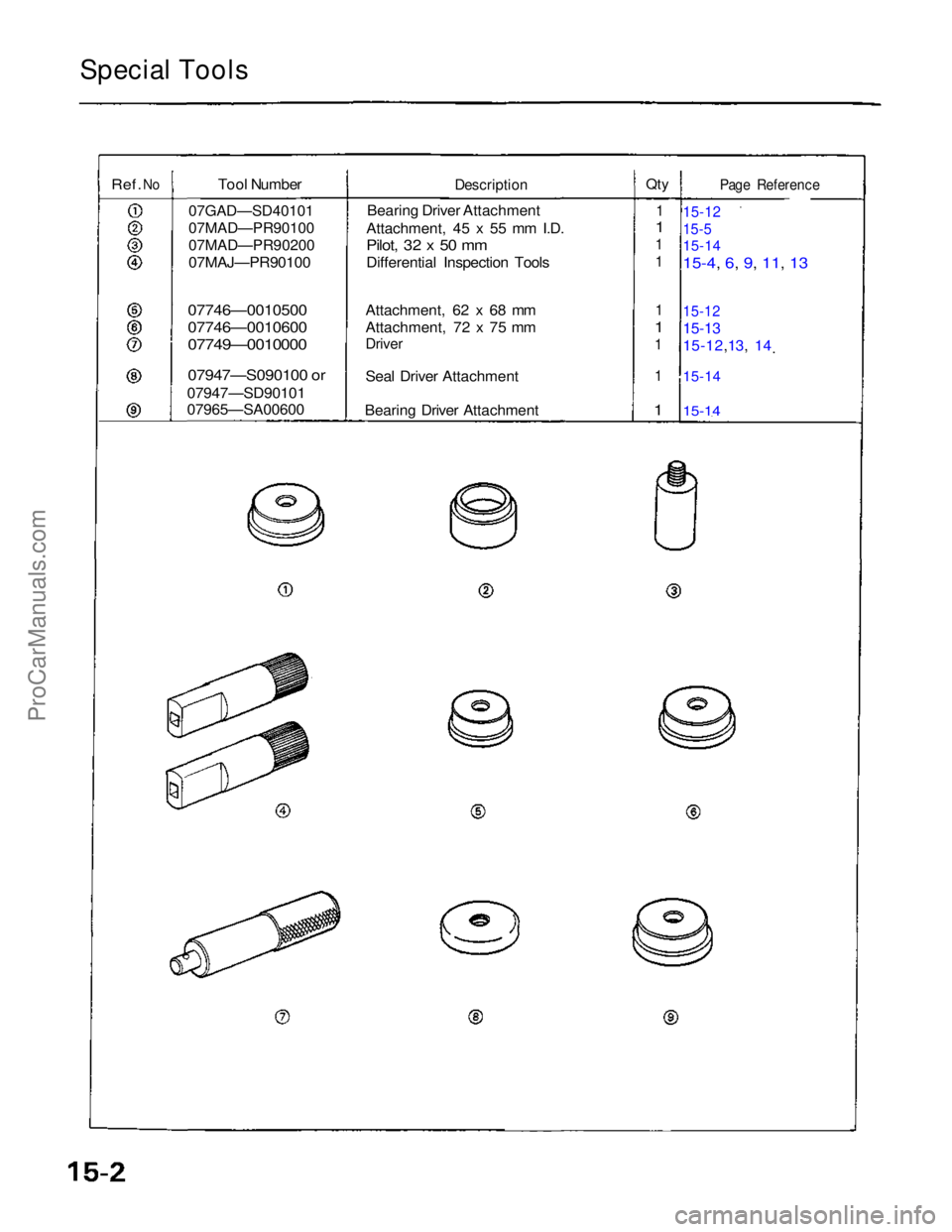

Special Tools

Ref.

No

Tool Number

Description

Qty

Page Reference

07GAD—SD40101

07MAD—PR90100

07MAD—PR90200

07MAJ—PR90100

07746—0010500

07746—0010600

07749—0010000

07947—S090100 or

07947—SD90101

07965—SA00600 Bearing Driver Attachment

Attachment, 45 x 55 mm I.D.

Pilot, 32 x 50 mm

Differential Inspection Tools

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver

Seal Driver Attachment

Bearing Driver Attachment

1

1

1

1

1

1

1

1

1

15-12

15-5

15-14

15-4 , 6, 9, 11, 13

15-12

15-13

15-12,13,

14

15-14

15-14

ProCarManuals.com

Page 357 of 1640

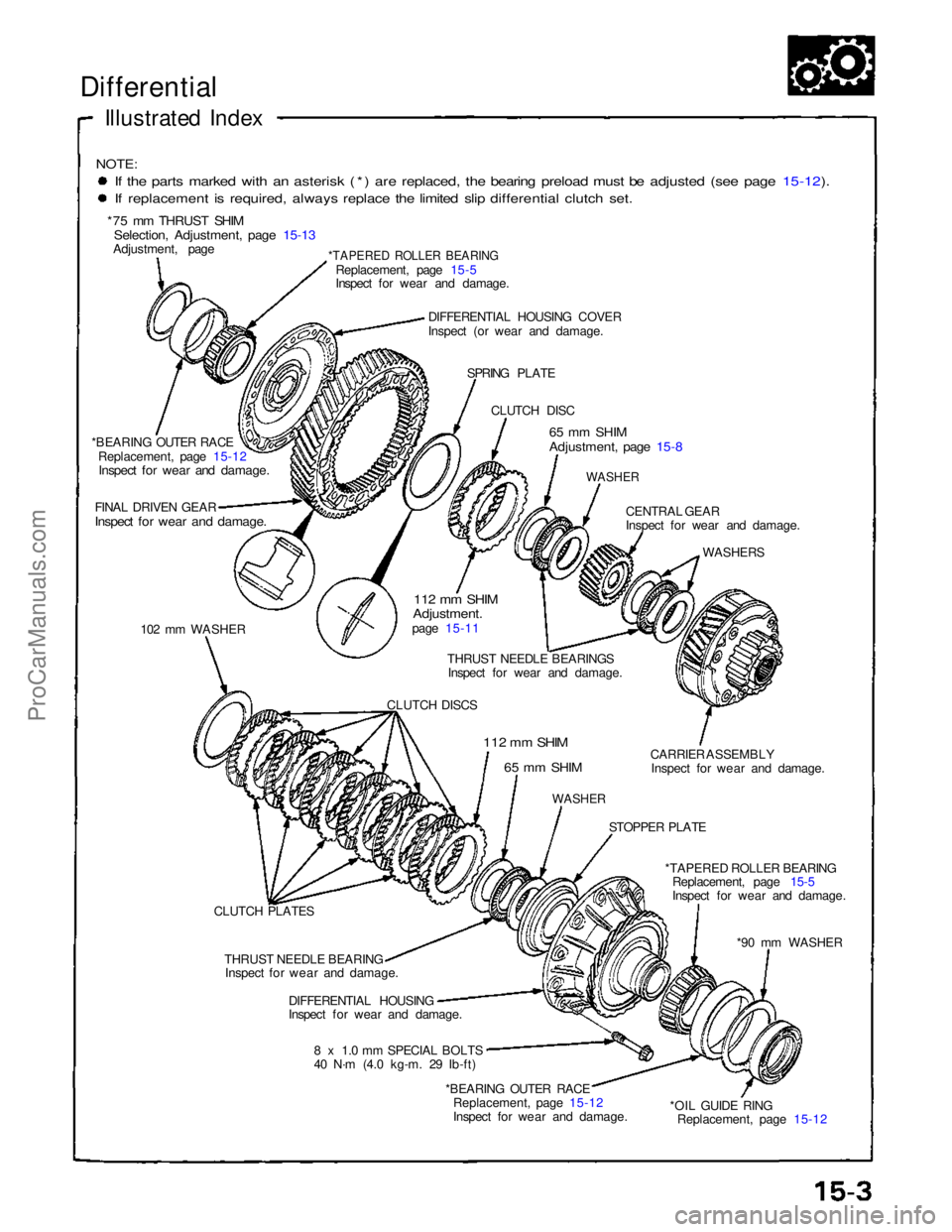

Differential

Illustrated Index

NOTE:

If the parts marked with an asterisk (*) are replaced, the bearing preload must be adjusted (see page 15-12).

If replacement is required, always replace the limited slip differential clutch set.

*75 mm THRUST SHIM

Selection, Adjustment, page 15-13

Adjustment, page

*TAPERED ROLLER BEARING

Replacement, page 15-5

Inspect for wear and damage.

DIFFERENTIAL HOUSING COVER

Inspect (or wear and damage.

SPRING PLATECLUTCH DISC

65 mm SHIM

Adjustment, page 15-8

*BEARING OUTER RACE

Replacement, page 15-12

Inspect for wear and damage.

FINAL DRIVEN GEAR

Inspect for wear and damage.

WASHER

112 mm SHIM

Adjustment.

page 15-11 CENTRAL GEAR

Inspect for wear and damage.

WASHERS

102 mm WASHER THRUST NEEDLE BEARINGSInspect for wear and damage.

CLUTCH DISCS

112 mm SHIM

65 mm SHIM

WASHER

CARRIER ASSEMBLY

Inspect for wear and damage.

STOPPER PLATE *TAPERED ROLLER BEARINGReplacement, page 15-5

Inspect for wear and damage.

*90 mm WASHER

CLUTCH PLATES

THRUST NEEDLE BEARINGInspect for wear and damage.

DIFFERENTIAL HOUSING

Inspect for wear and damage.

8 x 1.0 mm SPECIAL BOLTS

40 N·m (4.0 kg-m. 29 Ib-ft) *BEARING OUTER RACEReplacement, page 15-12

Inspect for wear and damage. *OIL GUIDE RING

Replacement, page 15-12ProCarManuals.com

Page 358 of 1640

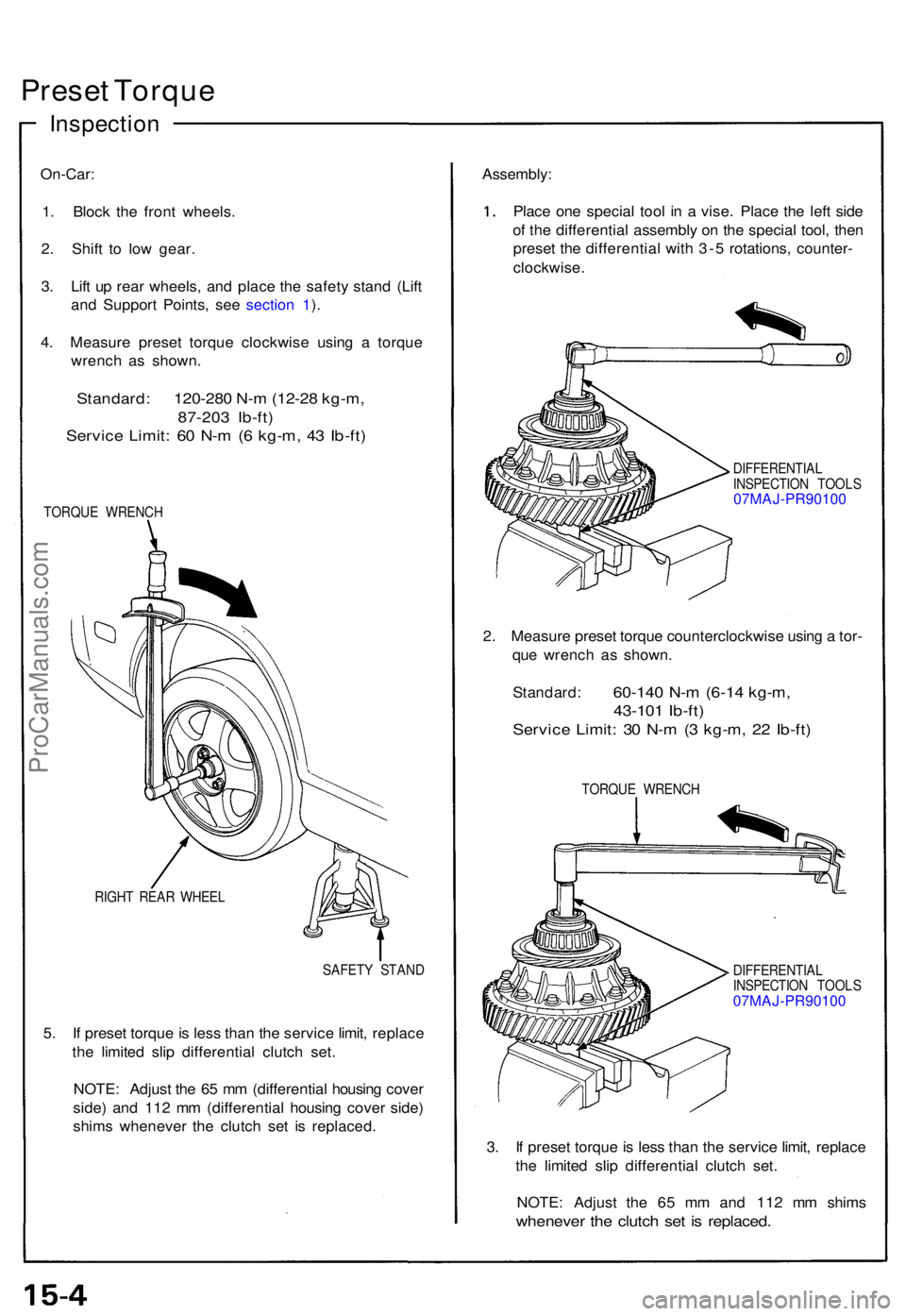

Preset Torqu e

Inspectio n

On-Car:

1 . Bloc k th e fron t wheels .

2 . Shif t t o low gear .

3 . Lif t u p rea r wheels , an d plac e th e safet y stan d (Lif t

an d Suppor t Points , se e sectio n 1 ).

4 . Measur e prese t torqu e clockwis e usin g a torqu e

wrenc h a s shown .

Standard: 120-280 N-m (12-28 kg-m,

87-20 3 Ib-ft )

Servic e Limit : 6 0 N- m (6 kg-m , 4 3 Ib-ft )

TORQU E WRENC H

RIGH T REA R WHEE L

SAFETY STAN D

5. I f prese t torqu e is les s tha n th e servic e limit , replac e

th e limite d sli p differentia l clutc h set .

NOTE : Adjus t th e 6 5 m m (differentia l housin g cove r

side ) an d 11 2 m m (differentia l housin g cove r side )

shim s wheneve r th e clutc h se t i s replaced . Assembly

:

Plac e on e specia l too l i n a vise . Plac e th e lef t sid e

o f th e differentia l assembl y o n th e specia l tool , the n

prese t th e differentia l wit h 3- 5 rotations , counter -

clockwise .

DIFFERENTIA L

INSPECTIO N TOOL S

07MAJ-PR90100

2. Measur e prese t torqu e counterclockwis e usin g a tor -

qu e wrenc h a s shown.

Standard :

60-140 N- m (6-1 4 kg-m ,

43-10 1 Ib-ft )

Servic e Limit : 3 0 N- m (3 kg-m , 2 2 Ib-ft )

TORQU E WRENC H

DIFFERENTIA L

INSPECTIO N TOOL S

07MAJ-PR90100

3 . I f prese t torqu e is les s tha n th e servic e limit , replac e

th e limite d sli p differentia l clutc h set .

NOTE : Adjus t th e 6 5 m m an d 11 2 m m shim s

wheneve r th e clutc h se t i s replaced .

ProCarManuals.com

Page 359 of 1640

Bearing

Replacemen t

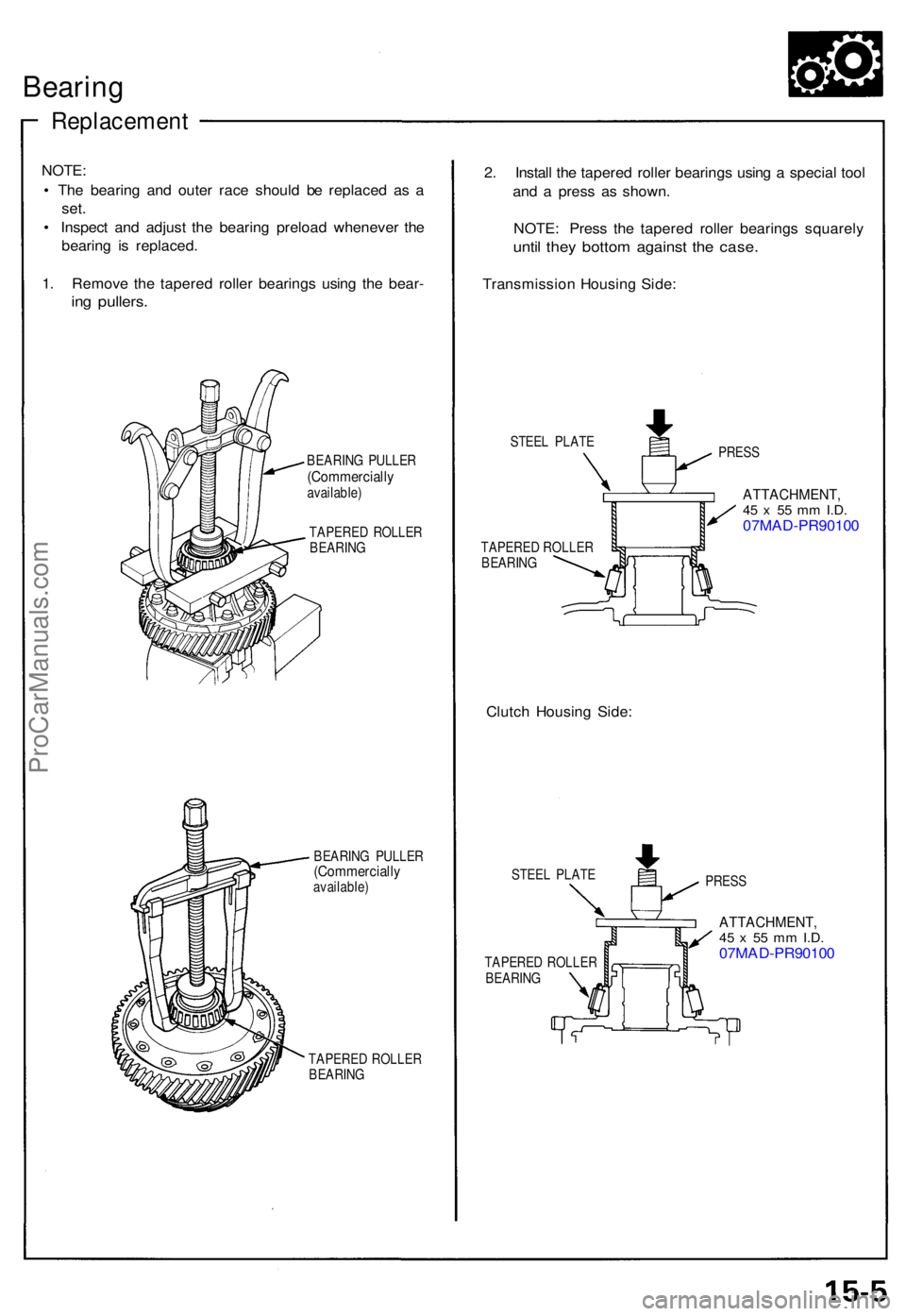

NOTE:

• Th e bearin g an d oute r rac e shoul d b e replace d a s a

set .

• Inspec t an d adjus t th e bearin g preloa d wheneve r th e

bearin g i s replaced .

1 . Remov e th e tapere d rolle r bearing s usin g th e bear -

ing pullers .

BEARIN G PULLE R(Commerciall yavailable)

TAPERE D ROLLE R

BEARIN G

BEARIN G PULLE R

(Commerciall yavailable)

TAPERE D ROLLE R

BEARIN G

2. Instal l th e tapere d rolle r bearing s usin g a specia l too l

an d a pres s a s shown .

NOTE : Pres s th e tapere d rolle r bearing s squarel y

until the y botto m agains t th e case .

Transmissio n Housin g Side :

STEE L PLAT E

PRESS

TAPERE D ROLLE R

BEARIN G

Clutch Housin g Side :

STEE L PLAT E

TAPERE D ROLLE R

BEARIN G

ATTACHMENT ,45 x 5 5 m m I.D .07MA D-PR9010 0

PRESS

ATTACHMENT ,45 x 5 5 m m I.D .07MA D-PR9010 0

ProCarManuals.com

Page 360 of 1640

Differential

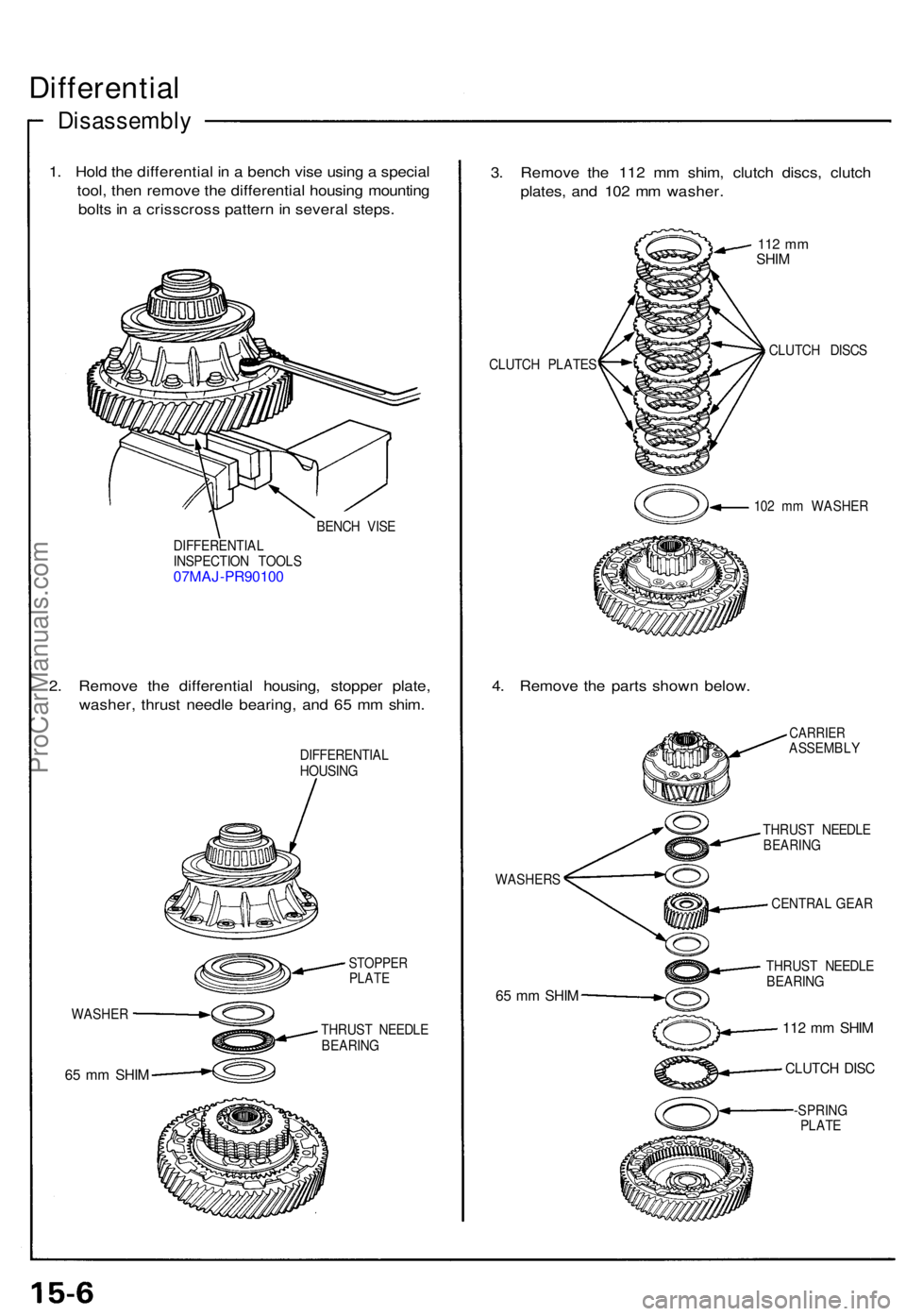

Disassembl y

1. Hol d th e differentia l i n a benc h vis e usin g a specia l

tool , the n remov e th e differentia l housin g mountin g

bolt s in a crisscros s patter n in severa l steps .

BENCH VIS E

DIFFERENTIA L

INSPECTIO N TOOL S

07MAJ-PR9010 0

2. Remov e th e differentia l housing , stoppe r plate ,

washer , thrus t needl e bearing , an d 6 5 m m shim .

DIFFERENTIA L

HOUSIN G

WASHE R

65 m m SHI M

STOPPE RPLATE

THRUS T NEEDL E

BEARIN G

3. Remov e th e 11 2 m m shim , clutc h discs , clutc h

plates , an d 10 2 m m washer .

112 m mSHI M

CLUTC H PLATE S CLUTC

H DISC S

10 2 m m WASHE R

4. Remov e th e part s show n below .

WASHER S

65 m m SHI M

CARRIE RASSEMBL Y

THRUS T NEEDL E

BEARIN G

CENTRA L GEA R

THRUS T NEEDL E

BEARIN G

112 m m SHI M

CLUTC H DIS C

-SPRIN GPLATE

ProCarManuals.com