ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 981 of 1640

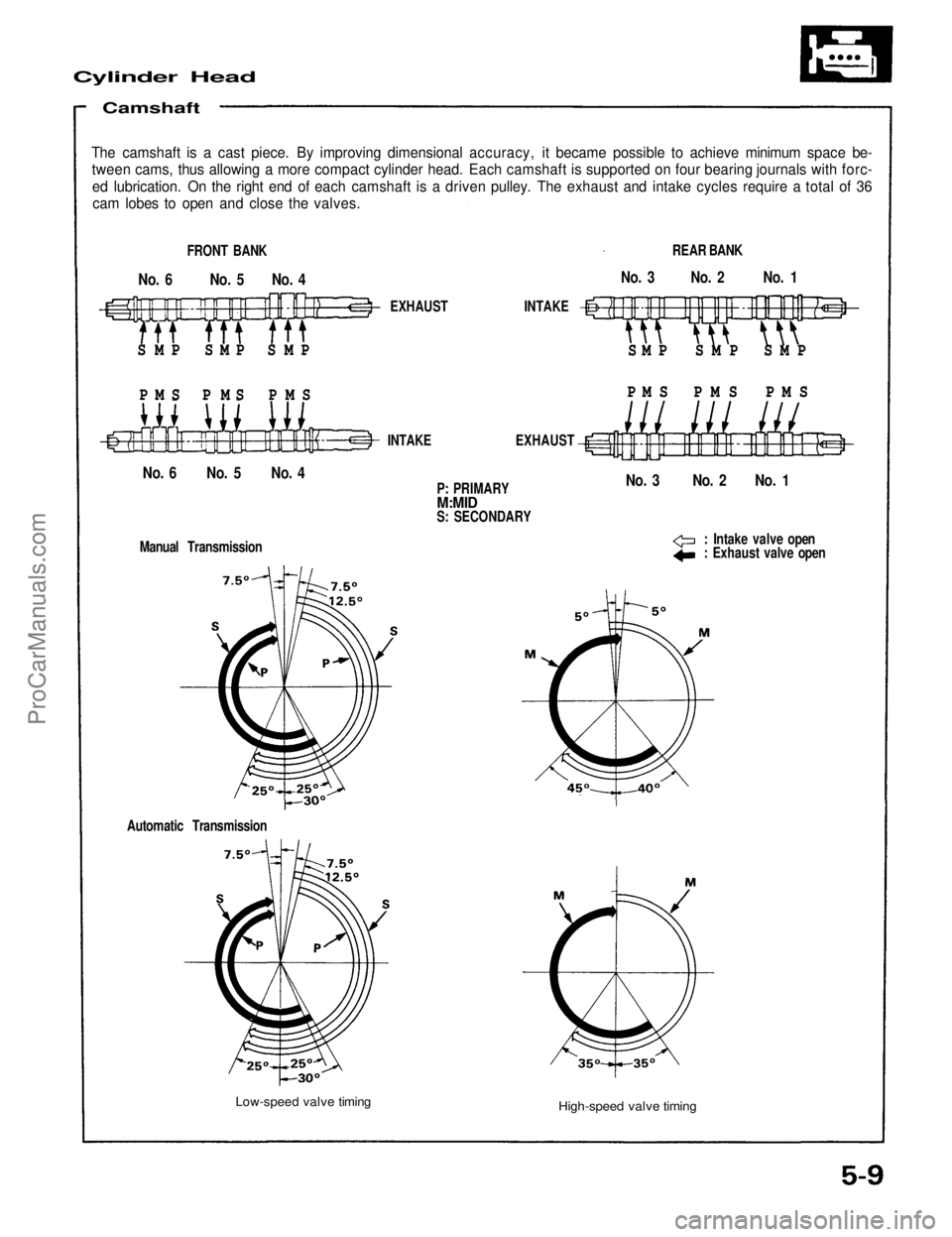

Cylinder Head

Camshaft

The camshaft is a cast piece. By improving dimensional accuracy, it became possible to achieve minimum space be-

tween cams, thus allowing a more compact cylinder head. Each camshaft is supported on four bearing journals with forc-

ed lubrication. On the right end of each camshaft is a driven pulley. The exhaust and intake cycles require a total of 36

cam lobes to open and close the valves.

FRONT BANK

No. 6 No. 5 No. 4

S M P S M P S M P

P M S P M S P M S

EXHAUST INTAKE

S M P S M P S M P

P M S P M S P M S

REAR BANK

No. 3 No. 2 No. 1

No. 3 No. 2 No. 1

No. 6 No. 5 No. 4

INTAKE EXHAUST

P: PRIMARY

M:MID

S: SECONDARY

: Intake valve open

: Exhaust valve open

Manual Transmission

Automatic Transmission

Low-speed valve timing

High-speed valve timingProCarManuals.com

Page 982 of 1640

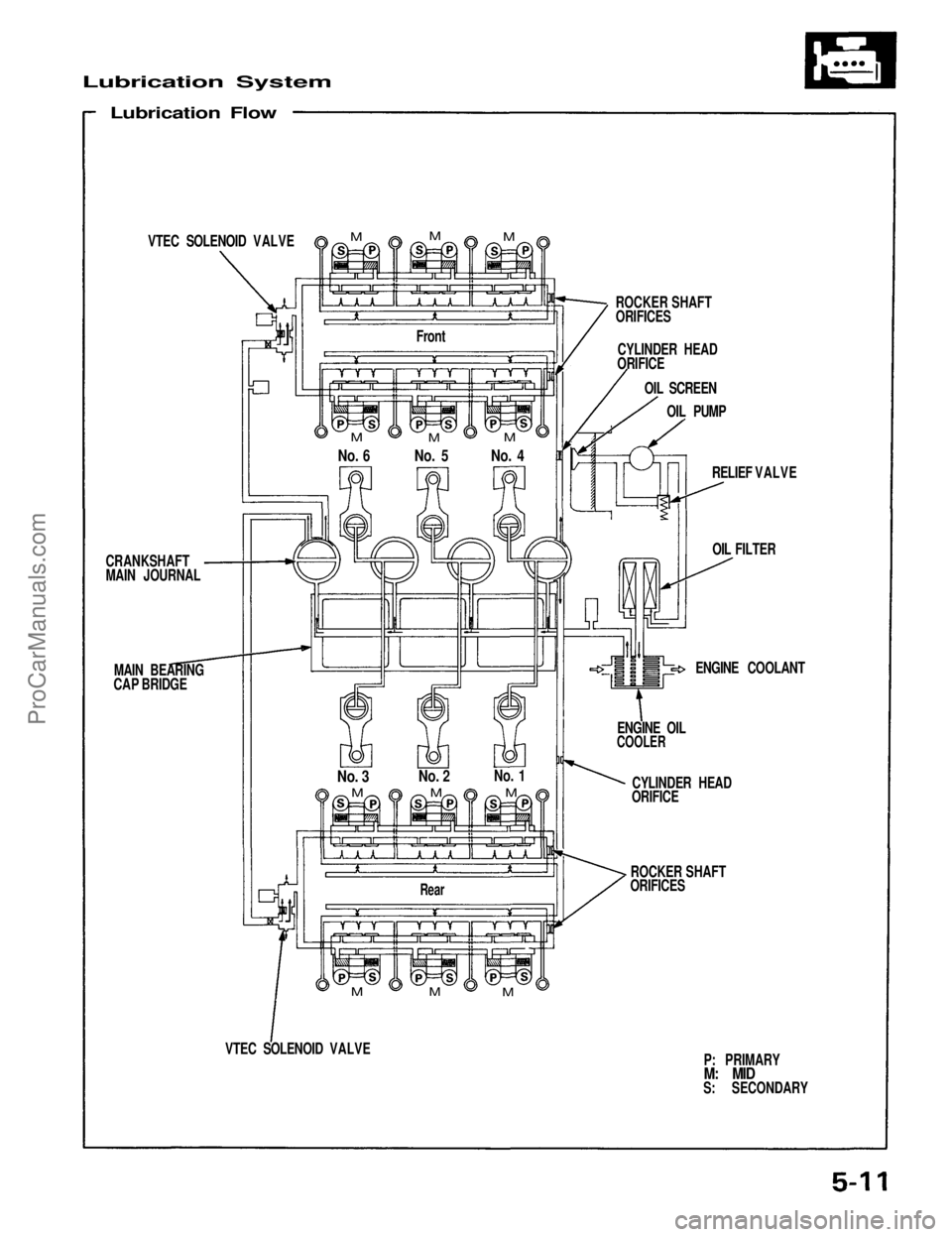

Lubrication System

Lubrication Flow

VTEC SOLENOID VALVE

ROCKER SHAFT

ORIFICES

M

M

M

CYLINDER HEAD

ORIFICE

OIL SCREEN

OIL PUMP

RELIEF VALVE

OIL FILTER

ENGINE COOLANT

ENGINE OIL

COOLER

CYLINDER HEAD

ORIFICE

ROCKER SHAFT

ORIFICES

P: PRIMARY

M: MID

S: SECONDARY

M

M

M

VTEC SOLENOID VALVE

No. 3

M

M

M

No. 1

No. 2

M

M

M

No. 6 No. 5 No. 4

Front

Rear

CRANKSHAFT

MAIN JOURNAL

MAIN BEARING

CAP BRIDGEProCarManuals.com

Page 983 of 1640

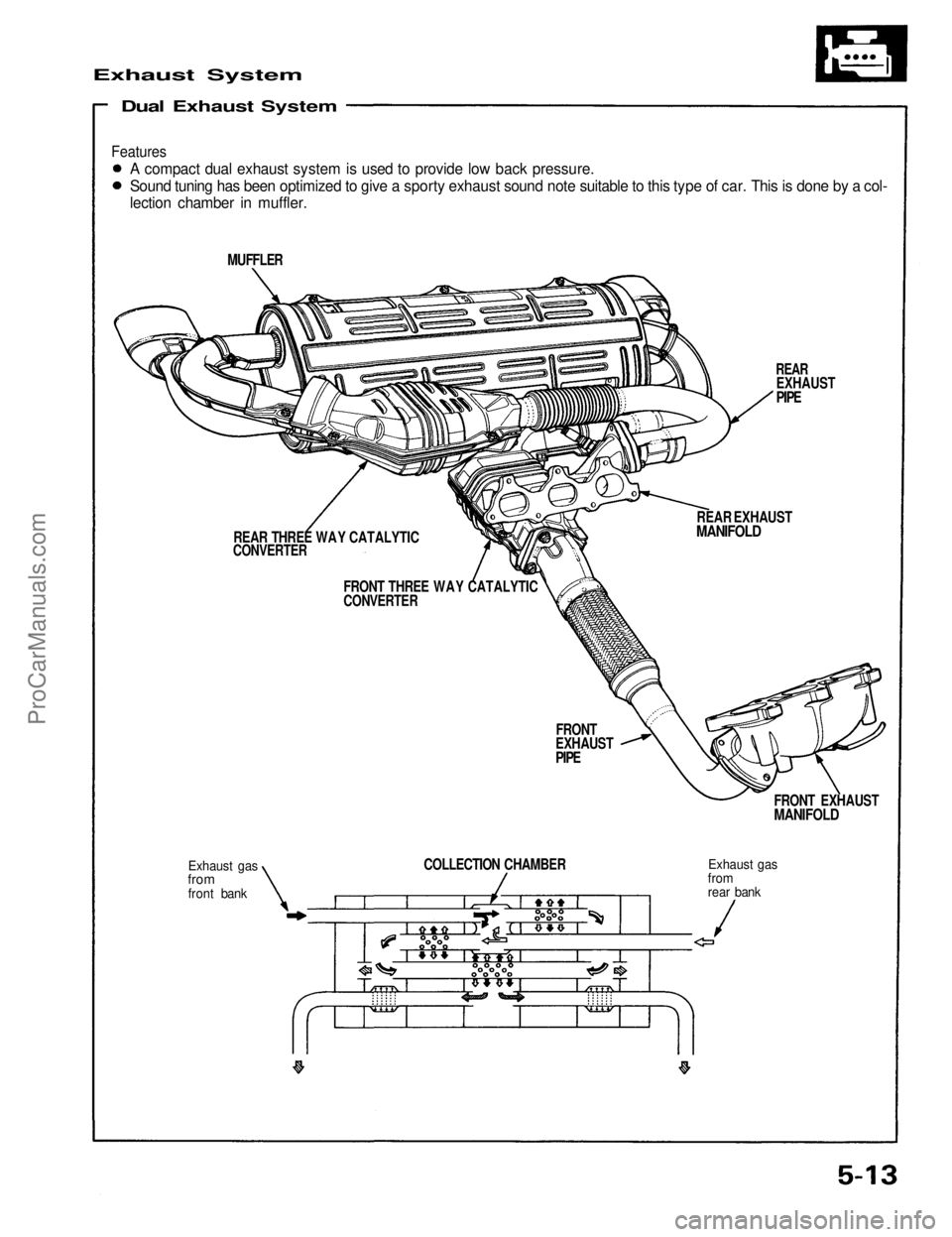

Exhaust System

Dual Exhaust System

A compact dual exhaust system is used to provide low back pressure.

Sound tuning has been optimized to give a sporty exhaust sound note suitable to this type of car. This is done by a col-

lection chamber in muffler.

MUFFLER

REAR

EXHAUST

PIPE

REAR EXHAUST

MANIFOLD

FRONT THREE WAY CATALYTIC

CONVERTER

REAR THREE WAY CATALYTIC

CONVERTER

FRONT

EXHAUST

PIPE

FRONT EXHAUST

MANIFOLD

Exhaust gas

from

rear bank

COLLECTION CHAMBER

Exhaust gas

from

front bank

FeaturesProCarManuals.com

Page 984 of 1640

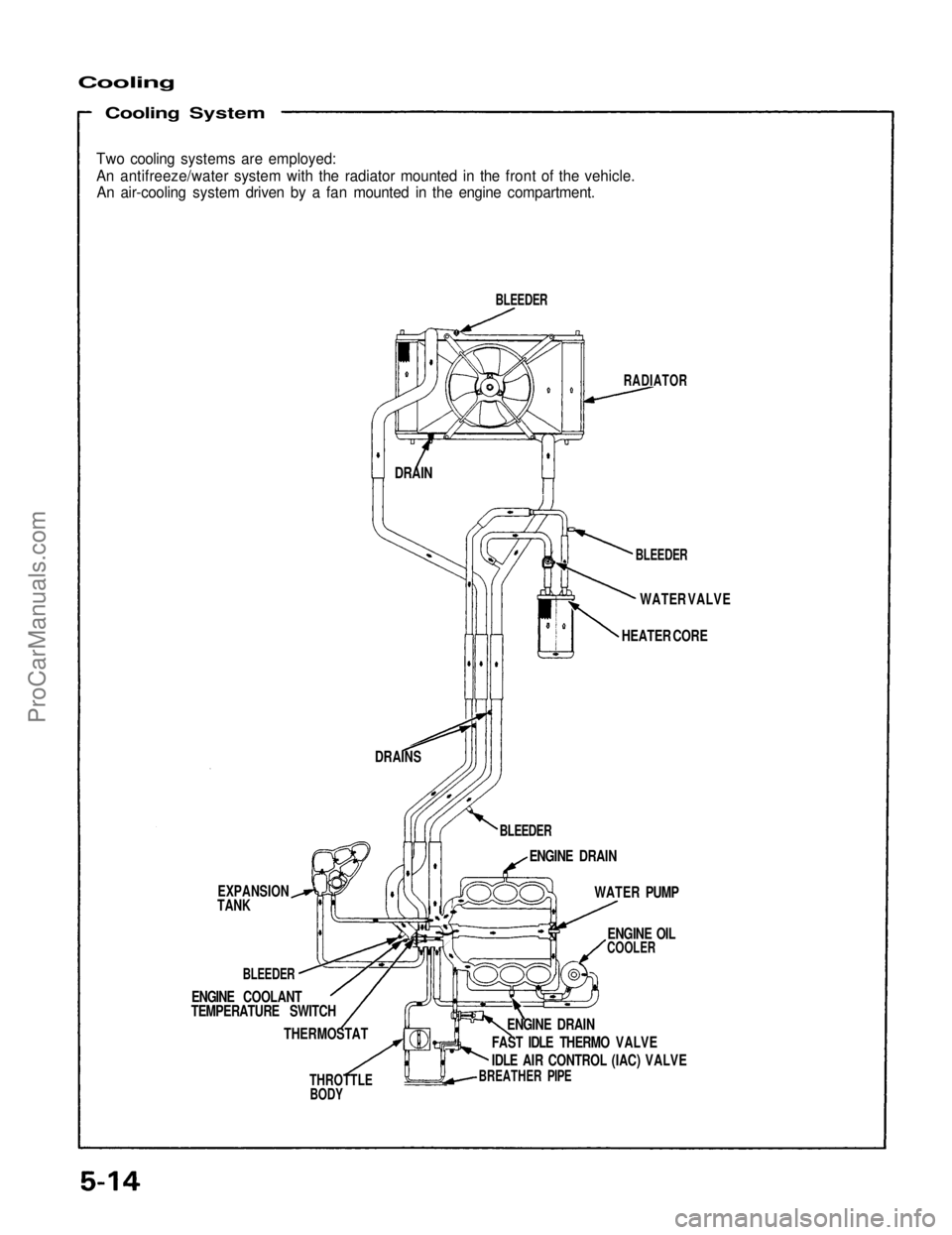

Cooling

Cooling System

Two cooling systems are employed:

An antifreeze/water system with the radiator mounted in the front of the vehicle.

An air-cooling system driven by a fan mounted in the engine compartment.

BLEEDER

RADIATOR

BLEEDER

WATER VALVE

HEATER CORE

DRAIN

DRAINS

BLEEDER

ENGINE DRAIN

WATER PUMP

ENGINE OIL

COOLER

ENGINE DRAIN

FAST IDLE THERMO VALVE

IDLE AIR CONTROL (IAC) VALVE

BREATHER PIPE

THROTTLE

BODY

THERMOSTAT

TEMPERATURE SWITCH

ENGINE COOLANT

BLEEDER

EXPANSION

TANKProCarManuals.com

Page 985 of 1640

Special Tools

Ref.

No.

Tool Number

07MAK-PR7020A

Description

Engine Removal/Installation Fixture

Qty

1

Page Reference

5-27ProCarManuals.com

Page 986 of 1640

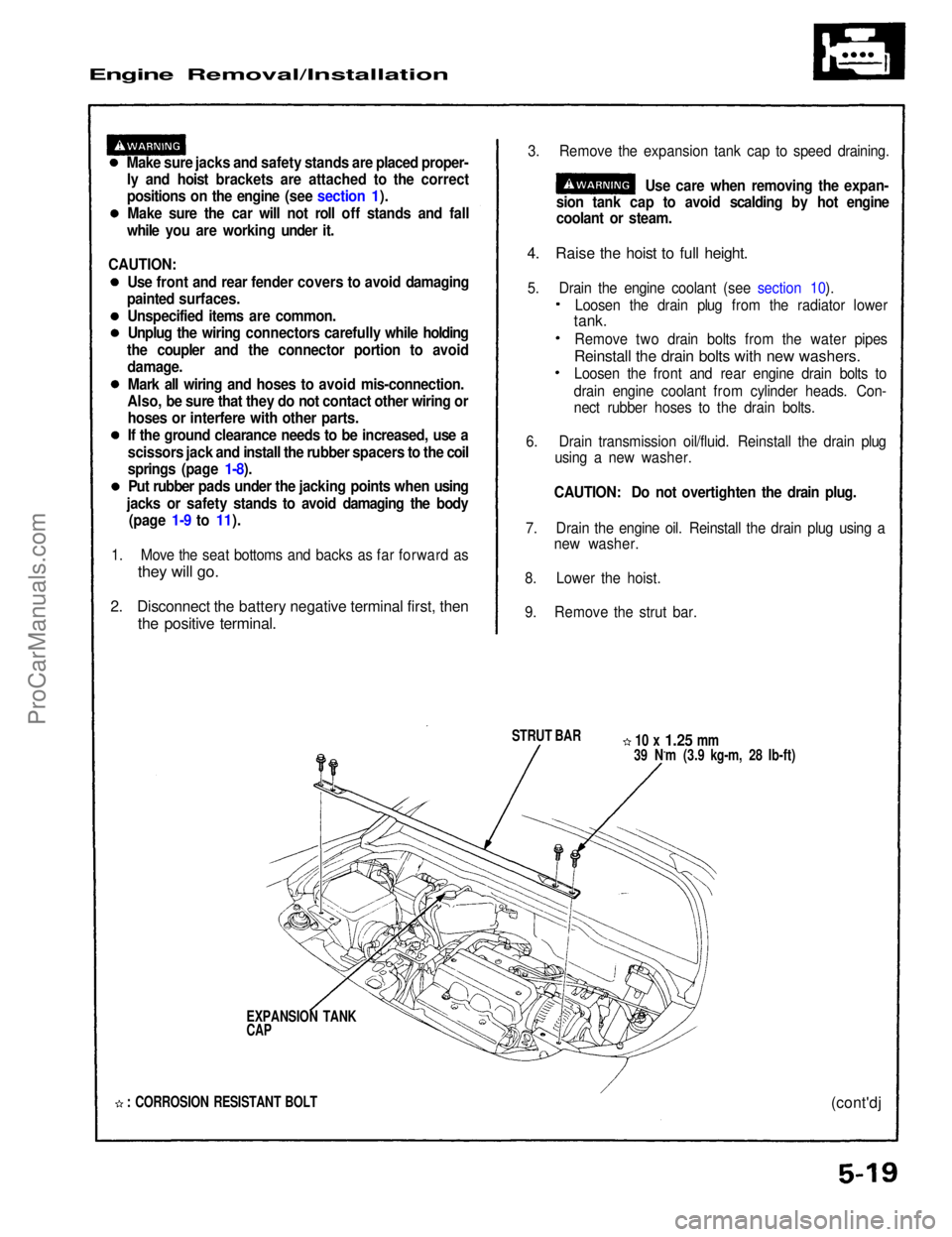

Engine Removal/Installation

Make sure jacks and safety stands are placed proper-ly and hoist brackets are attached to the correct

positions on the engine (see section 1).

Make sure the car will not roll off stands and fall

while you are working under it. 3. Remove the expansion tank cap to speed draining.

Use care when removing the expan-

sion tank cap to avoid scalding by hot engine

coolant or steam.

4. Raise the hoist to full height.

5. Drain the engine coolant (see section 10).

STRUT BAR

10 x

1.25

mm

39 N.m (3.9 kg-m, 28 Ib-ft)

EXPANSION TANK

CAP

: CORROSION RESISTANT BOLT

(cont'dj

1. Move the seat bottoms and backs as far forward as

they will go.

2. Disconnect the battery negative terminal first, then

the positive terminal.

Loosen the drain plug from the radiator lower

tank.

Remove two drain bolts from the water pipes

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from cylinder heads. Con-

nect rubber hoses to the drain bolts.

6. Drain transmission oil/fluid. Reinstall the drain plug using a new washer.

CAUTION: Do not overtighten the drain plug.

7. Drain the engine oil. Reinstall the drain plug using a new washer.

8. Lower the hoist.

9. Remove the strut bar.

CAUTION:

Use front and rear fender covers to avoid damaging

painted surfaces.

Unspecified items are common.Unplug the wiring connectors carefully while holding

the coupler and the connector portion to avoid damage.

Mark all wiring and hoses to avoid mis-connection.

Also, be sure that they do not contact other wiring or hoses or interfere with other parts.

If the ground clearance needs to be increased, use a

scissors jack and install the rubber spacers to the coil

springs (page 1-8).

Put rubber pads under the jacking points when using

jacks or safety stands to avoid damaging the body (page 1-9 to 11).ProCarManuals.com

Page 987 of 1640

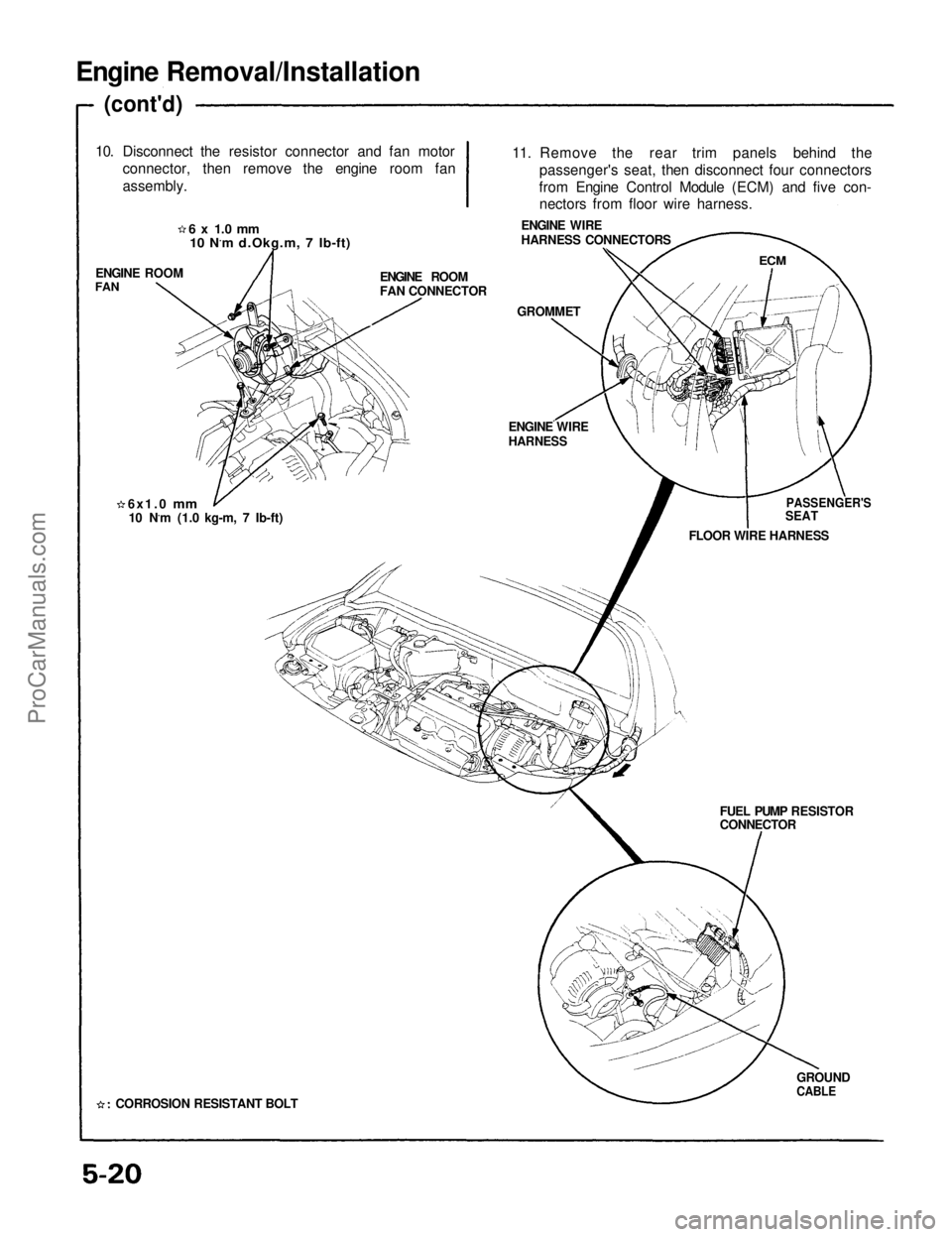

Engine Removal/Installation

(cont'd)

10. Disconnect the resistor connector and fan motor connector, then remove the engine room fan

assembly.

ENGINE ROOM

FAN

ENGINE ROOM

FAN CONNECTOR

GROMMET

11. Remove the rear trim panels behind the

passenger's seat, then disconnect four connectors

from Engine Control Module (ECM) and five con- nectors from floor wire harness.

ENGINE WIRE

HARNESS CONNECTORS

ECM

PASSENGER'S

SEAT

FLOOR WIRE HARNESS

ENGINE WIRE

HARNESS

FUEL PUMP RESISTOR

CONNECTORGROUND

CABLE

6x1.0

mm

10 N.m (1.0 kg-m, 7 Ib-ft)

CORROSION RESISTANT BOLT

6 x 1.0 mm

10 N.m d.Okg.m, 7 Ib-ft)ProCarManuals.com

Page 988 of 1640

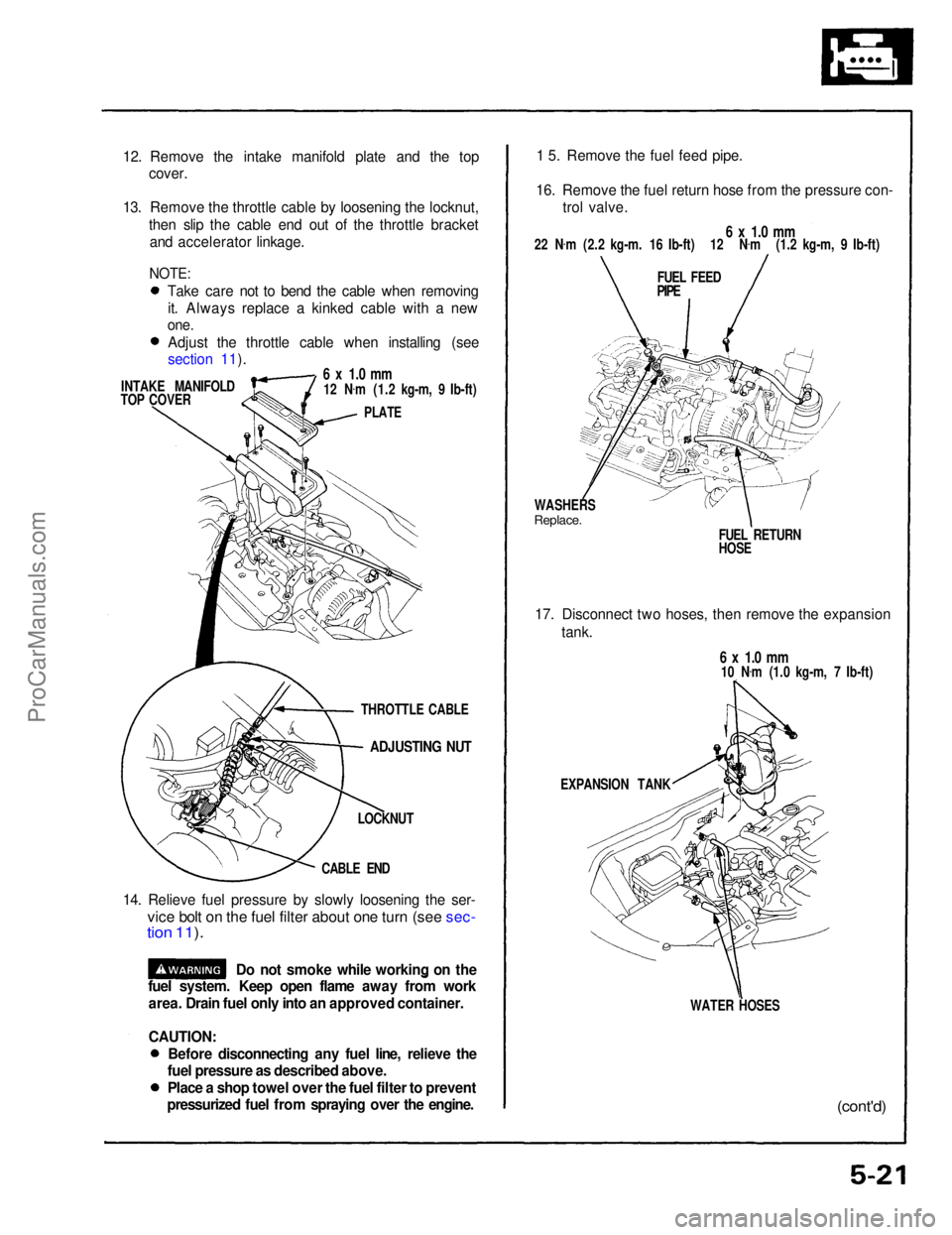

12. Remove the intake manifold plate and the top

cover.

13. Remove the throttle cable by loosening the locknut, then slip the cable end out of the throttle bracketand accelerator linkage.

INTAKE MANIFOLD

TOP COVER

6 x 1.0 mm

12 N .

m (1.2 kg-m, 9 Ib-ft)

PLATE

ADJUSTING NUT

LOCKNUT

CABLE END

14. Relieve fuel pressure by slowly loosening the ser-

vice bolt on the fuel filter about one turn (see sec-

tion 11 ).

1 5. Remove the fuel feed pipe.

16. Remove the fuel return hose from the pressure con- trol valve.

6 x 1.0 mm

22 N .

m (2.2 kg-m. 16 Ib-ft) 12 N .

m (1.2 kg-m, 9 Ib-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

17. Disconnect two hoses, then remove the expansion tank.

6 x 1.0 mm

10 N .

m (1.0 kg-m, 7 Ib-ft)

EXPANSION TANK

WATER HOSES

(cont'd)

Do not smoke while working on the

fuel system. Keep open flame away from work

area. Drain fuel only into an approved container.

CAUTION:

THROTTLE CABLE

NOTE:

Take care not to bend the cable when removingit. Always replace a kinked cable with a new

one.

Adjust the throttle cable when installing (see

section 11).

Before disconnecting any fuel line, relieve the

fuel pressure as described above.

Place a shop towel over the fuel filter to prevent

pressurized fuel from spraying over the engine.ProCarManuals.com

Page 989 of 1640

Engine Removal/Installation

(cont'd)

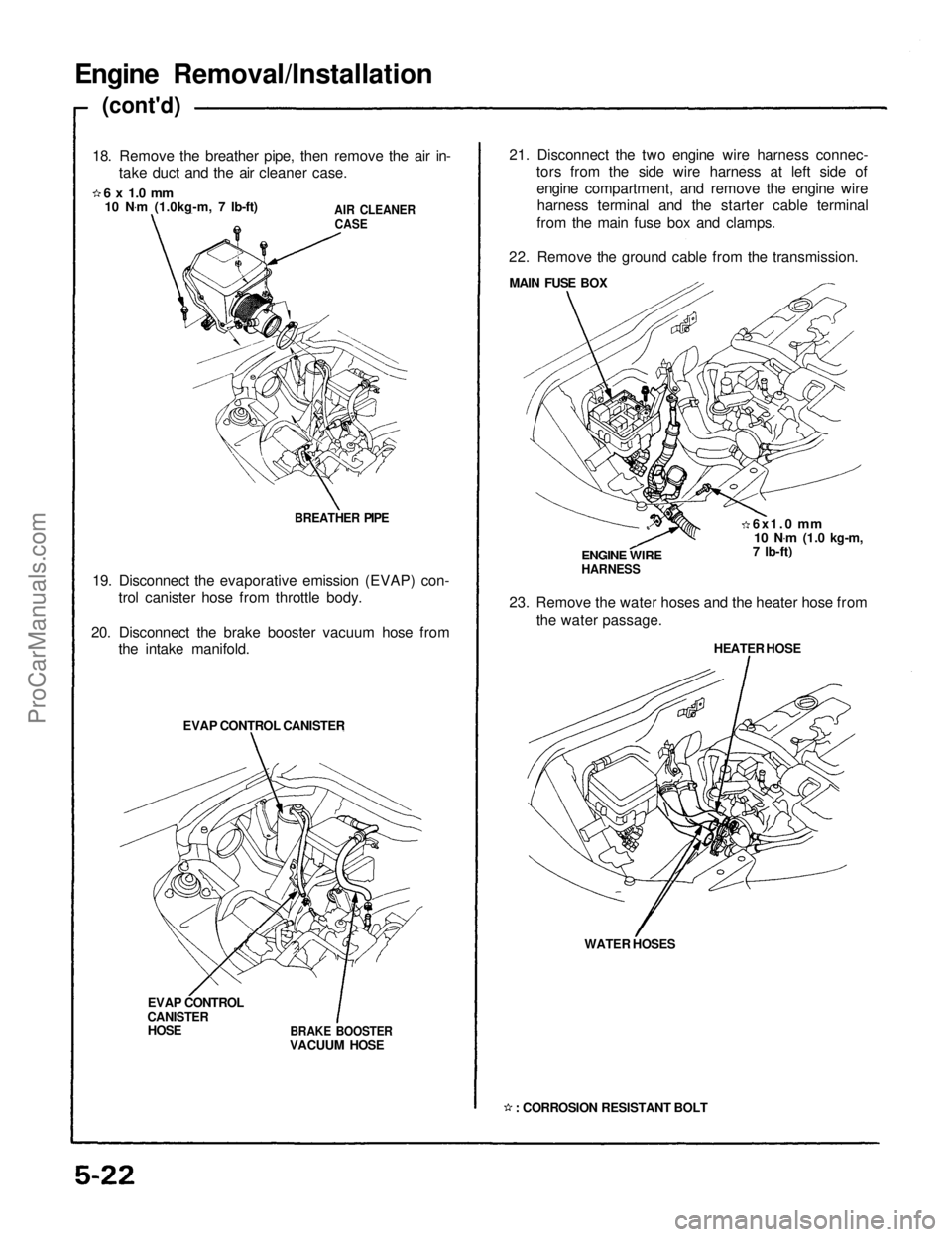

18. Remove the breather pipe, then remove the air in- take duct and the air cleaner case.

6 x 1.0 mm

10 N .

m (1.0kg-m, 7 Ib-ft)

AIR CLEANER

CASE

BREATHER PIPE

19. Disconnect the evaporative emission (EVAP) con- trol canister hose from throttle body.

20. Disconnect the brake booster vacuum hose from the intake manifold.

EVAP CONTROL CANISTER

EVAP CONTROL

CANISTER

HOSE

BRAKE BOOSTER

VACUUM HOSE 21. Disconnect the two engine wire harness connec-

tors from the side wire harness at left side of

engine compartment, and remove the engine wireharness terminal and the starter cable terminal

from the main fuse box and clamps.

22. Remove the ground cable from the transmission. MAIN FUSE BOX

6x1.0

mm

10 N .

m

(1.0 kg-m,

7 Ib-ft)

ENGINE WIRE

HARNESS

23. Remove the water hoses and the heater hose from the water passage.

HEATER HOSE

WATER HOSES

: CORROSION RESISTANT BOLTProCarManuals.com

Page 990 of 1640

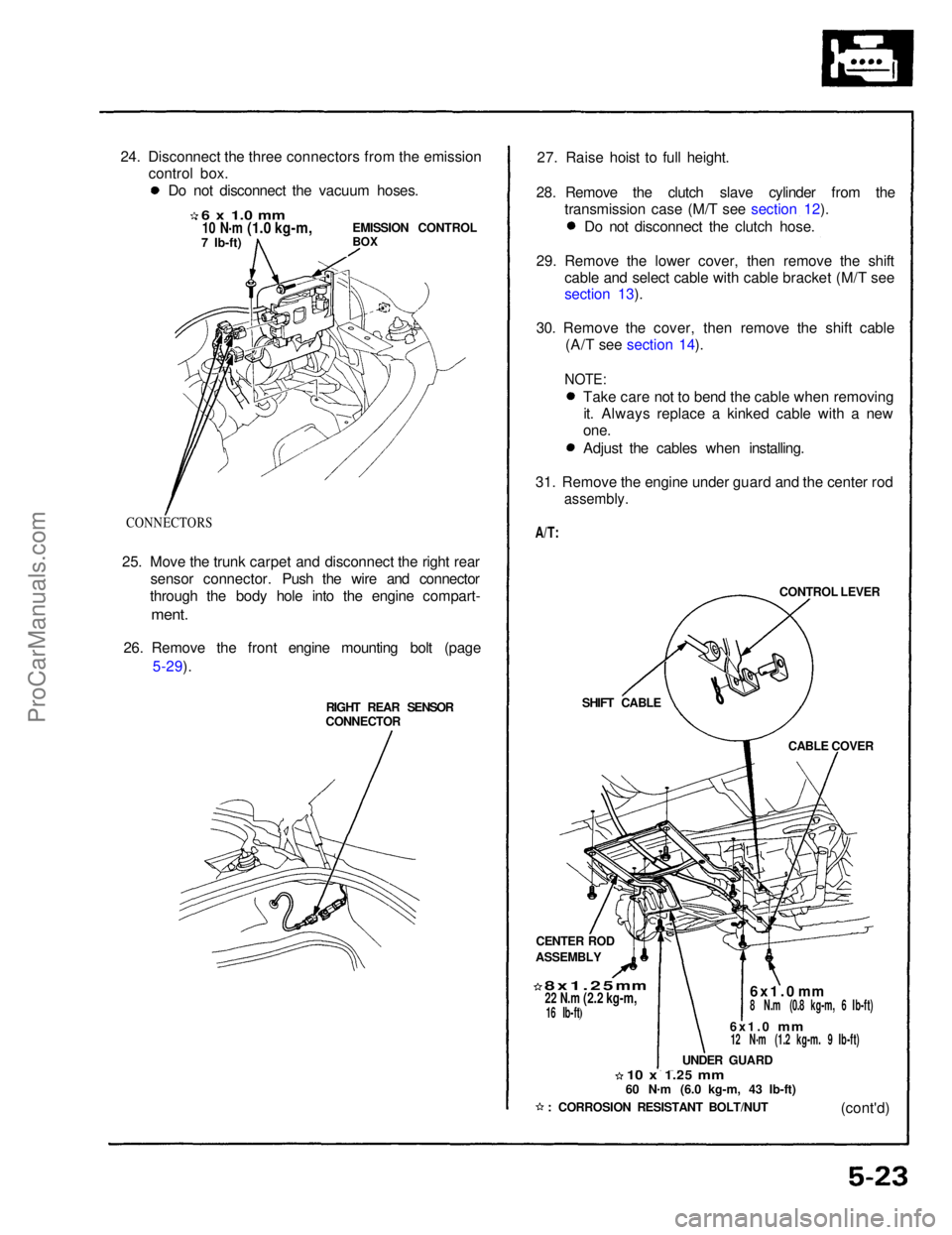

24. Disconnect the three connectors from the emission

control box.

6 x 1.0 mm

10 N .

m

(1.0 kg-m,

7 Ib-ft)

EMISSION CONTROL

BOX

CONNECTORS

25. Move the trunk carpet and disconnect the right rear sensor connector. Push the wire and connector

through the body hole into the engine compart-

ment.

26. Remove the front engine mounting bolt (page 5-29).

RIGHT REAR SENSOR

CONNECTOR 27. Raise hoist to full height.

28. Remove the clutch slave cylinder from the transmission case (M/T see section 12).

CONTROL LEVER

SHIFT CABLE CABLE COVER

CENTER ROD

ASSEMBLY

8x1.25

mm

22 N.m

(2.2 kg-m,

16 Ib-ft)

6x1.0

mm

8 N.m (0.8 kg-m, 6 Ib-ft)

6x1.0

mm

12 N

.

m (1.2 kg-m. 9 Ib-ft)

UNDER GUARD

10 x

1.25

mm

60 N

.

m (6.0 kg-m, 43 Ib-ft)

(cont'd)

: CORROSION RESISTANT BOLT/NUT

Do not disconnect the vacuum hoses.

Do not disconnect the clutch hose.

29. Remove the lower cover, then remove the shift cable and select cable with cable bracket (M/T see

section 13).

30. Remove the cover, then remove the shift cable (A/T see section 14).

NOTE:

Take care not to bend the cable when removingit. Always replace a kinked cable with a new

one.

Adjust the cables when installing.

31. Remove the engine under guard and the center rod

assembly.

A/T:ProCarManuals.com