ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1001 of 1503

Thickness an d Parallelis m

Inspectio n

1. Rais e bot h side s o f th e vehicle , an d suppor t i t o n

safet y stand s (se e pag e 1- 10 throug h 1-12 ).

Remov e th e rea r wheels .

2 . Mov e th e calipe r an d pad s ou t o f th e wa y a s

describe d o n th e precedin g page .

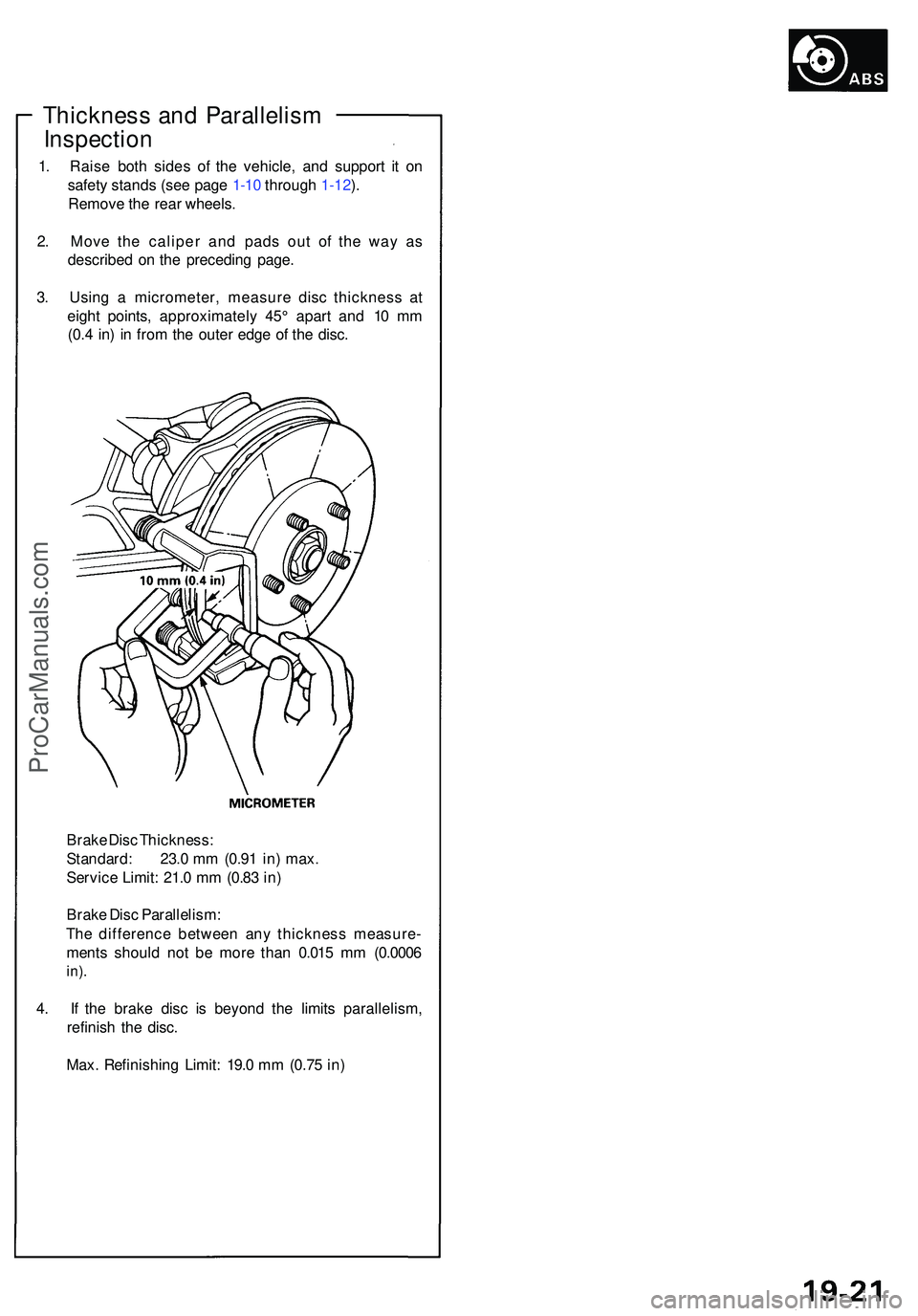

3 . Usin g a micrometer , measur e dis c thicknes s a t

eigh t points , approximatel y 45 ° apar t an d 1 0 m m

(0. 4 in ) i n fro m th e oute r edg e o f th e disc .

Brak e Dis c Thickness :

Standard : 23. 0 m m (0.9 1 in ) max .

Servic e Limit : 21. 0 m m (0.8 3 in )

Brak e Dis c Parallelism :

Th e differenc e betwee n an y thicknes s measure -

ment s shoul d no t b e mor e tha n 0.01 5 m m (0.000 6

in).

4. I f th e brak e dis c i s beyon d th e limit s parallelism ,

refinis h th e disc .

Max . Refinishin g Limit : 19. 0 m m (0.7 5 in )

ProCarManuals.com

Page 1002 of 1503

Rear Calipe r

Disassembl y

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

CAUTION :

• D o no t spil l brak e flui d o n th e vehicle ; i t ma y damag e

th e paint ; i f brak e flui d doe s contac t th e paint , was h

it of f immediatel y wit h water .

• T o preven t spills , cove r th e hos e joint s wit h rag s o r

sho p towels .

• Clea n al l part s i n brak e flui d an d ai r dry ; blo w ou t al l

passage s wit h compresse d air .

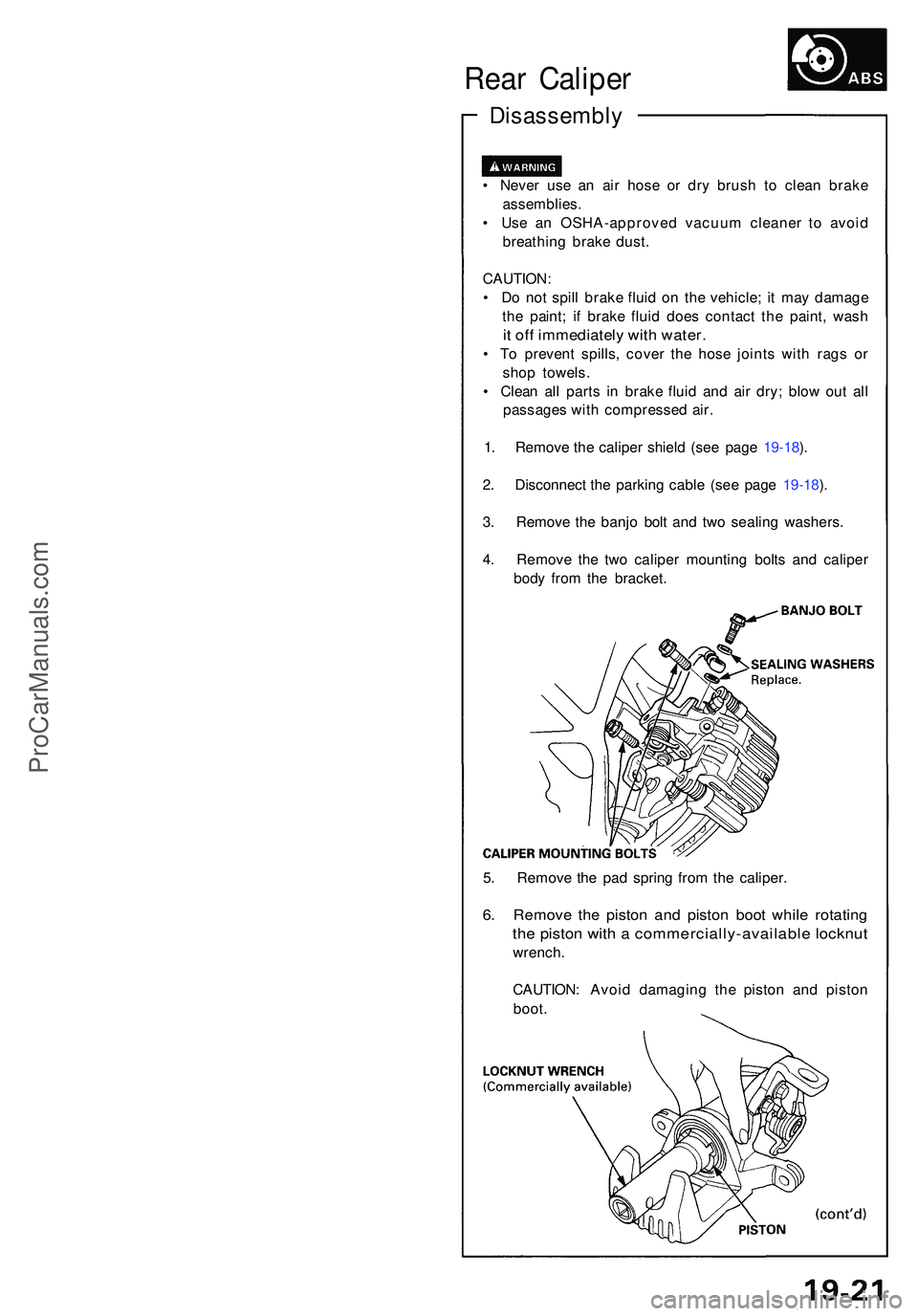

1 . Remov e th e calipe r shiel d (se e pag e 19-18 ).

2 . Disconnec t th e parkin g cabl e (se e pag e 19-18 ).

3 . Remov e th e banj o bol t an d tw o sealin g washers .

4 . Remov e th e tw o calipe r mountin g bolt s an d calipe r

bod y fro m th e bracket .

5 . Remov e th e pa d sprin g fro m th e caliper .

6. Remov e th e pisto n an d pisto n boo t whil e rotatin g

the pisto n wit h a commercially-availabl e locknu t

wrench.

CAUTION : Avoi d damagin g th e pisto n an d pisto n

boot .

ProCarManuals.com

Page 1003 of 1503

Disassembly (cont'd )

Rear Calipe r

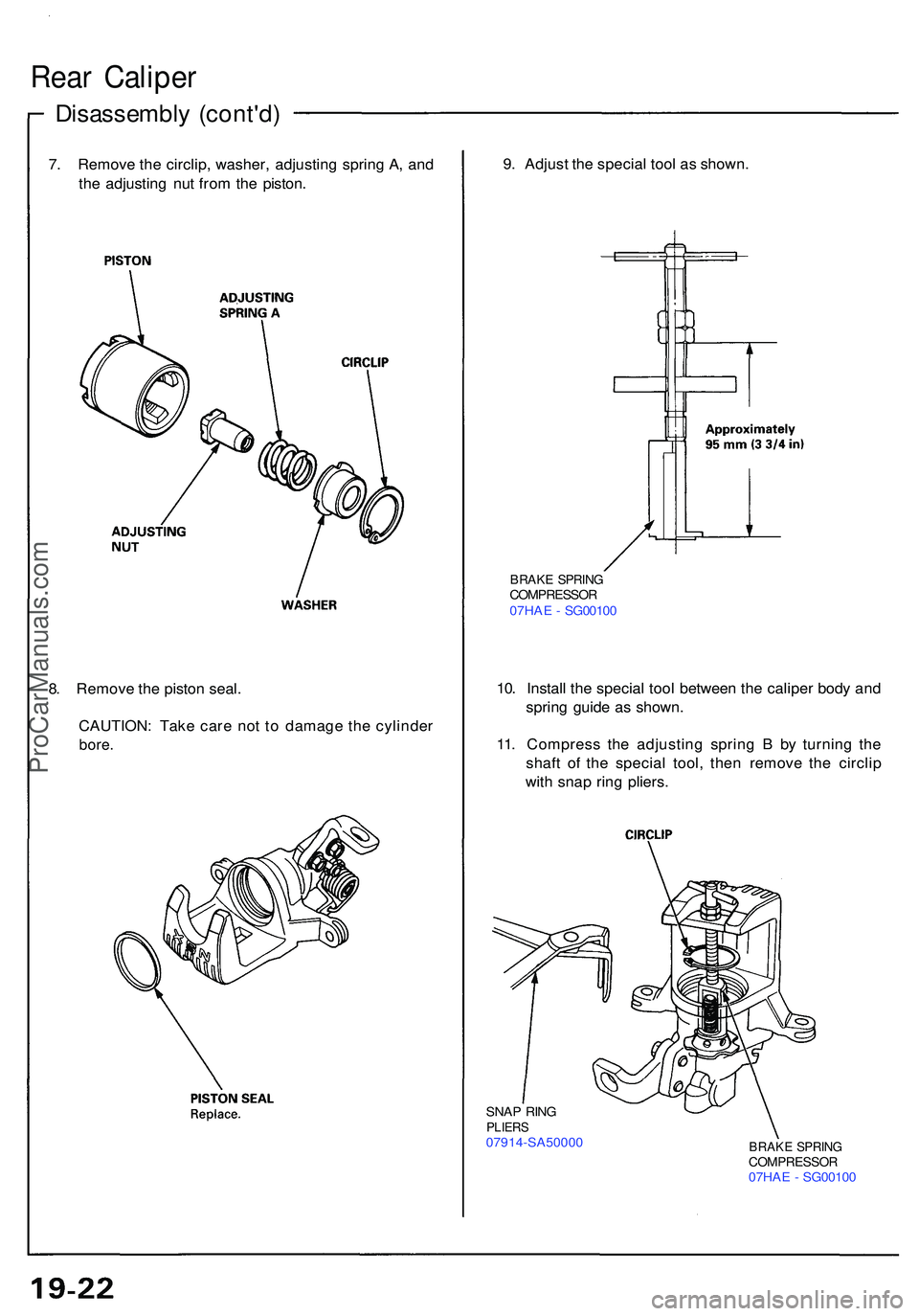

7. Remov e th e circlip , washer , adjustin g sprin g A , an d

th e adjustin g nu t fro m th e piston . 9

. Adjus t th e specia l too l a s shown .

BRAKE SPRIN GCOMPRESSO R

07HA E - SG0010 0

10. Instal l th e specia l too l betwee n th e calipe r bod y an d

sprin g guid e a s shown .

11 . Compres s th e adjustin g sprin g B by turnin g th e

shaf t o f th e specia l tool , the n remov e th e circli p

wit h sna p rin g pliers .

8

. Remov e th e pisto n seal .

CAUTION : Tak e car e no t t o damag e th e cylinde r

bore.

SNAP RIN GPLIER S07914-SA5000 0BRAKE SPRIN GCOMPRESSO R07HAE - SG0010 0

ProCarManuals.com

Page 1004 of 1503

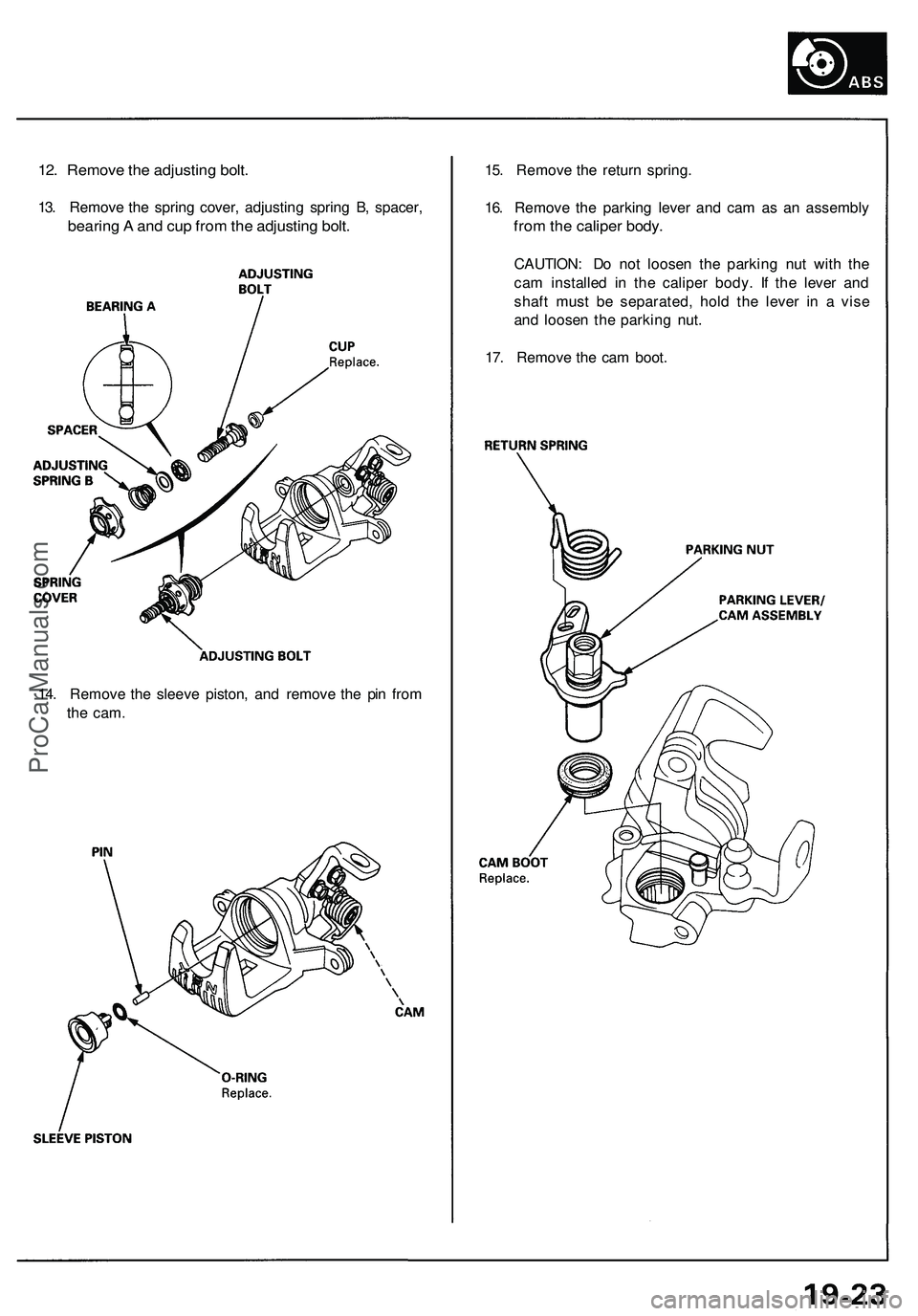

12. Remove the adjusting bolt.

13. Remove the spring cover, adjusting spring B, spacer,

bearing A and cup from the adjusting bolt.

15. Remove the return spring.

16. Remove the parking lever and cam as an assembly

from the caliper body.

CAUTION: Do not loosen the parking nut with the

cam installed in the caliper body. If the lever and

shaft must be separated, hold the lever in a vise

and loosen the parking nut.

17. Remove the cam boot.

14. Remove the sleeve piston, and remove the pin from

the

cam.ProCarManuals.com

Page 1005 of 1503

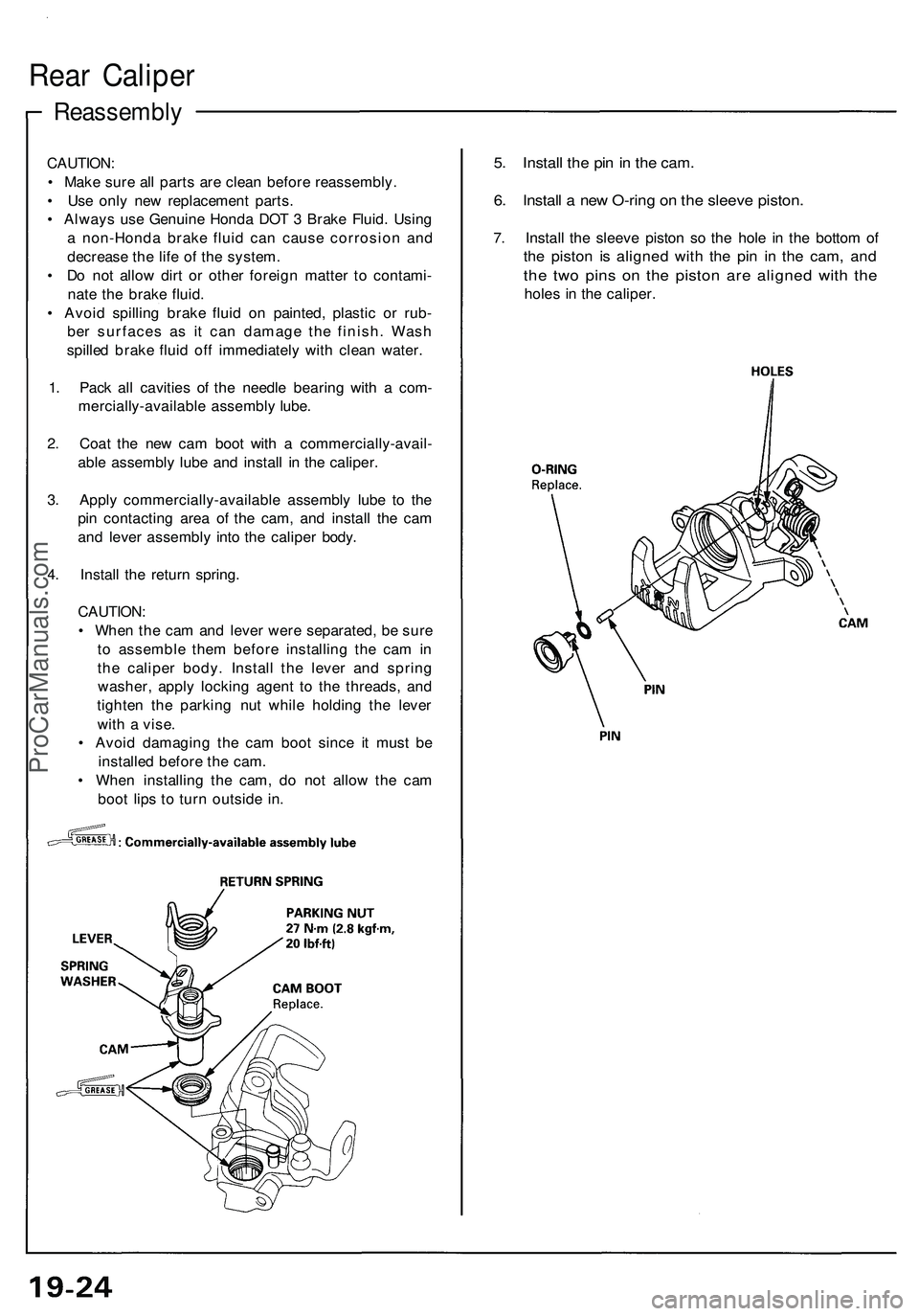

Reassembly

Rear Calipe r

CAUTION :

• Mak e sur e al l part s ar e clea n befor e reassembly .

• Us e onl y ne w replacemen t parts .

• Alway s us e Genuin e Hond a DO T 3 Brak e Fluid . Usin g

a non-Hond a brak e flui d ca n caus e corrosio n an d

decreas e th e lif e o f th e system .

• D o no t allo w dir t o r othe r foreig n matte r t o contami -

nat e th e brak e fluid .

• Avoi d spillin g brak e flui d o n painted , plasti c o r rub -

be r surface s a s i t ca n damag e th e finish . Was h

spille d brak e flui d of f immediatel y wit h clea n water .

1 . Pac k al l cavitie s o f th e needl e bearin g wit h a com -

mercially-availabl e assembl y lube .

2 . Coa t th e ne w ca m boo t wit h a commercially-avail -

abl e assembl y lub e an d instal l i n th e caliper .

3 . Appl y commercially-availabl e assembl y lub e t o th e

pi n contactin g are a o f th e cam , an d instal l th e ca m

an d leve r assembl y int o th e calipe r body .

4 . Instal l th e retur n spring .

CAUTION :

• Whe n th e ca m an d leve r wer e separated , b e sur e

t o assembl e the m befor e installin g th e ca m in

th e calipe r body . Instal l th e leve r an d sprin g

washer , appl y lockin g agen t t o th e threads , an d

tighte n th e parkin g nu t whil e holdin g th e leve r

wit h a vise .

• Avoi d damagin g th e ca m boo t sinc e i t mus t b e

installe d befor e th e cam .

• Whe n installin g th e cam , d o no t allo w th e ca m

boo t lip s t o tur n outsid e in .5. Instal l th e pi n in th e cam .

6. Instal l a ne w O-rin g o n th e sleev e piston .

7. Instal l th e sleev e pisto n s o th e hol e i n th e botto m o f

the pisto n i s aligne d wit h th e pi n i n th e cam , an d

the tw o pin s o n th e pisto n ar e aligne d wit h th e

hole s i n th e caliper .

ProCarManuals.com

Page 1006 of 1503

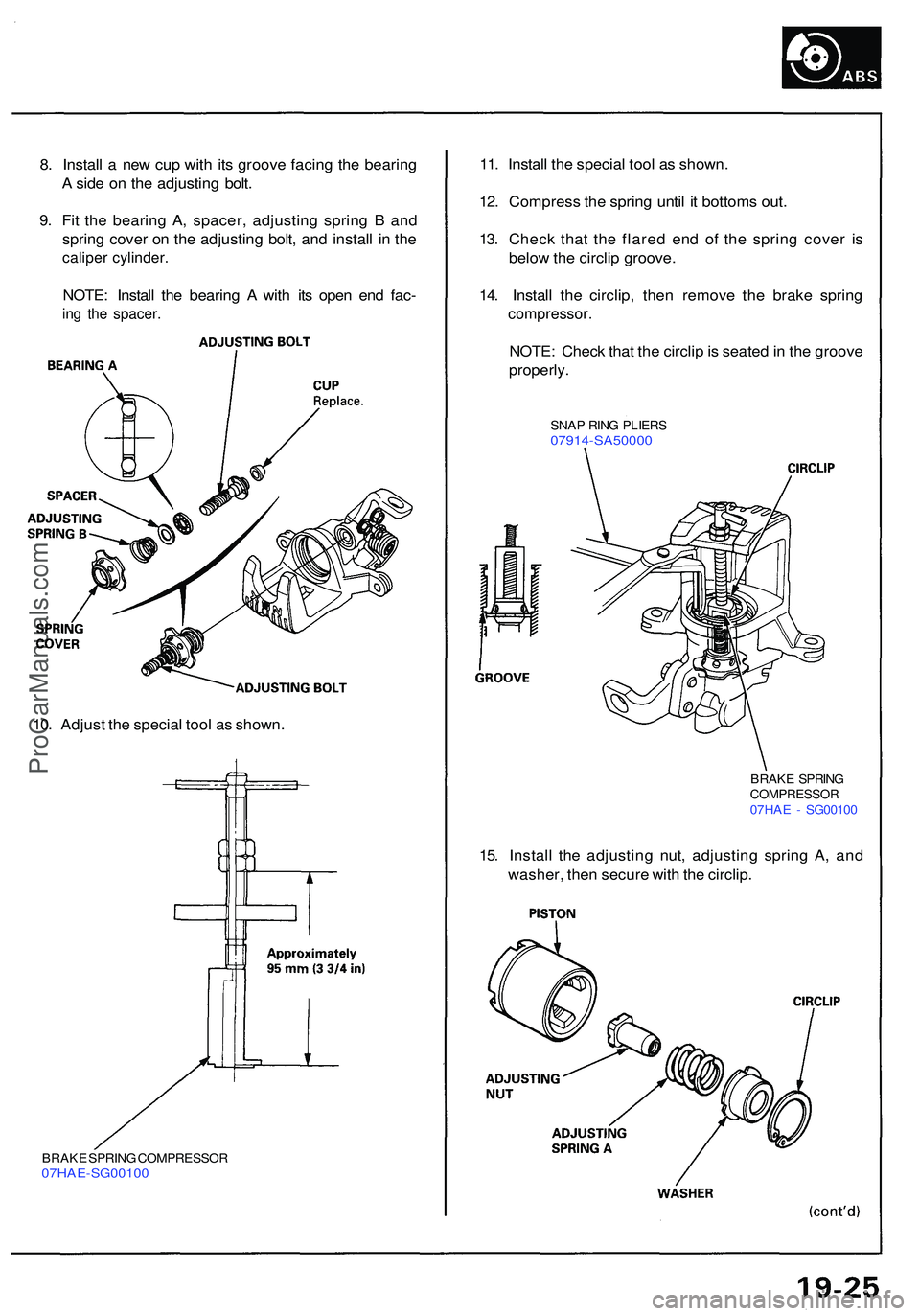

8. Instal l a ne w cu p wit h it s groov e facin g th e bearin g

A sid e o n th e adjustin g bolt .

9 . Fi t th e bearin g A , spacer , adjustin g sprin g B an d

sprin g cove r o n th e adjustin g bolt , an d instal l i n th e

calipe r cylinder .

NOTE: Instal l th e bearin g A wit h it s ope n en d fac -

ing th e spacer .

11. Instal l th e specia l too l a s shown .

12 . Compres s th e sprin g unti l i t bottom s out .

13 . Chec k tha t th e flare d en d o f th e sprin g cove r i s

belo w th e circli p groove .

14 . Instal l th e circlip , the n remov e th e brak e sprin g

compressor .

NOTE: Chec k tha t th e circli p is seate d in th e groov e

properly .

SNAP RIN G PLIER S07914-SA5000 0

BRAKE SPRIN GCOMPRESSO R07HAE - SG0010 0

15. Instal l th e adjustin g nut , adjustin g sprin g A , an d

washer , the n secur e wit h th e circlip .

10

. Adjus t th e specia l too l a s shown .

BRAKE SPRIN G COMPRESSO R07HAE-SG0010 0

ProCarManuals.com

Page 1007 of 1503

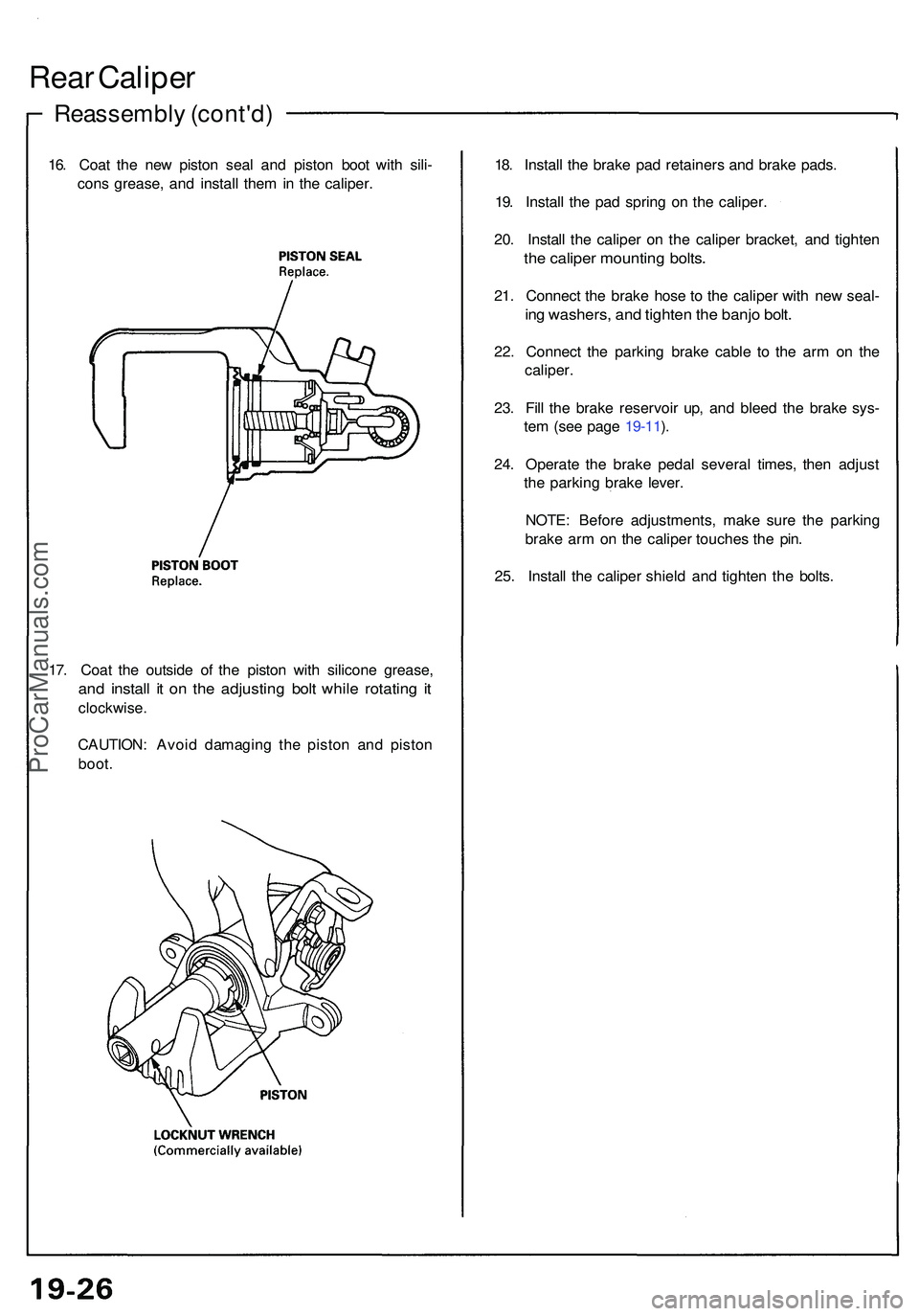

Reassembly (cont'd )

Rear Calipe r

16. Coa t th e ne w pisto n sea l an d pisto n boo t wit h sili -

con s grease , an d instal l the m in th e caliper . 18

. Instal l th e brak e pa d retainer s an d brak e pads .

19 . Instal l th e pa d sprin g o n th e caliper .

20 . Instal l th e calipe r o n th e calipe r bracket , an d tighte n

the calipe r mountin g bolts .

21. Connec t th e brak e hos e t o th e calipe r wit h ne w seal -

ing washers , an d tighte n th e banj o bolt .

22. Connec t th e parkin g brak e cabl e t o th e ar m o n th e

caliper .

23 . Fil l th e brak e reservoi r up , an d blee d th e brak e sys -

te m (se e pag e 19-11 ).

24 . Operat e th e brak e peda l severa l times , the n adjus t

th e parkin g brak e lever .

NOTE : Befor e adjustments , mak e sur e th e parkin g

brak e ar m o n th e calipe r touche s th e pin .

25 . Instal l th e calipe r shiel d an d tighte n th e bolts .

17 . Coa t th e outsid e o f th e pisto n wit h silicon e grease ,

and instal l i t o n th e adjustin g bol t whil e rotatin g i t

clockwise .

CAUTION : Avoi d damagin g th e pisto n an d pisto n

boot .

ProCarManuals.com

Page 1008 of 1503

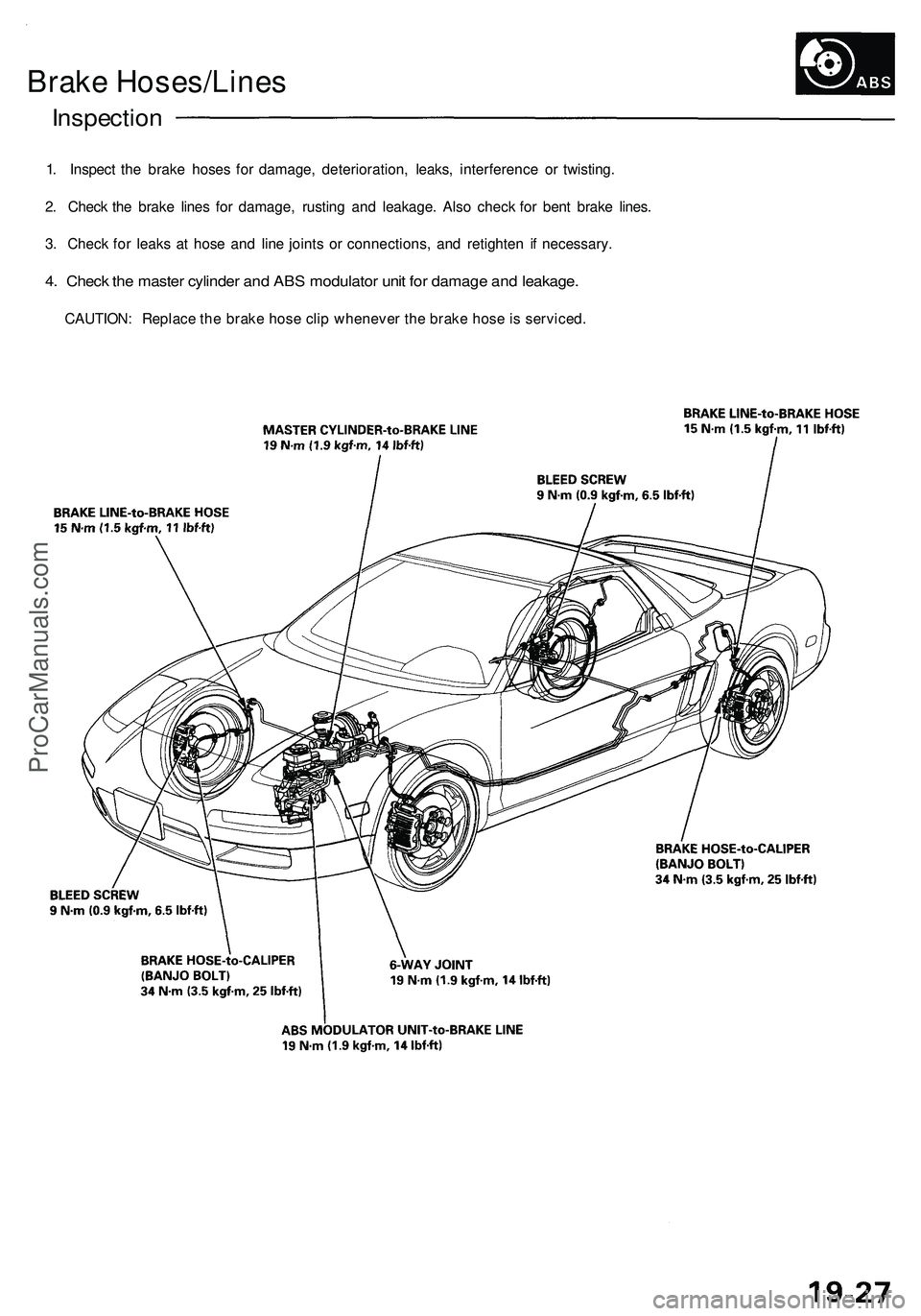

Brake Hoses/Lines

Inspection

1. Inspect the brake hoses for damage, deterioration, leaks, interference or twisting.

2. Check the brake lines for damage, rusting and leakage. Also check for bent brake lines.

3. Check for leaks at hose and line joints or connections, and retighten if necessary.

4. Check the master cylinder and ABS modulator unit for damage and leakage.

CAUTION: Replace the brake hose clip whenever the brake hose is serviced.ProCarManuals.com

Page 1009 of 1503

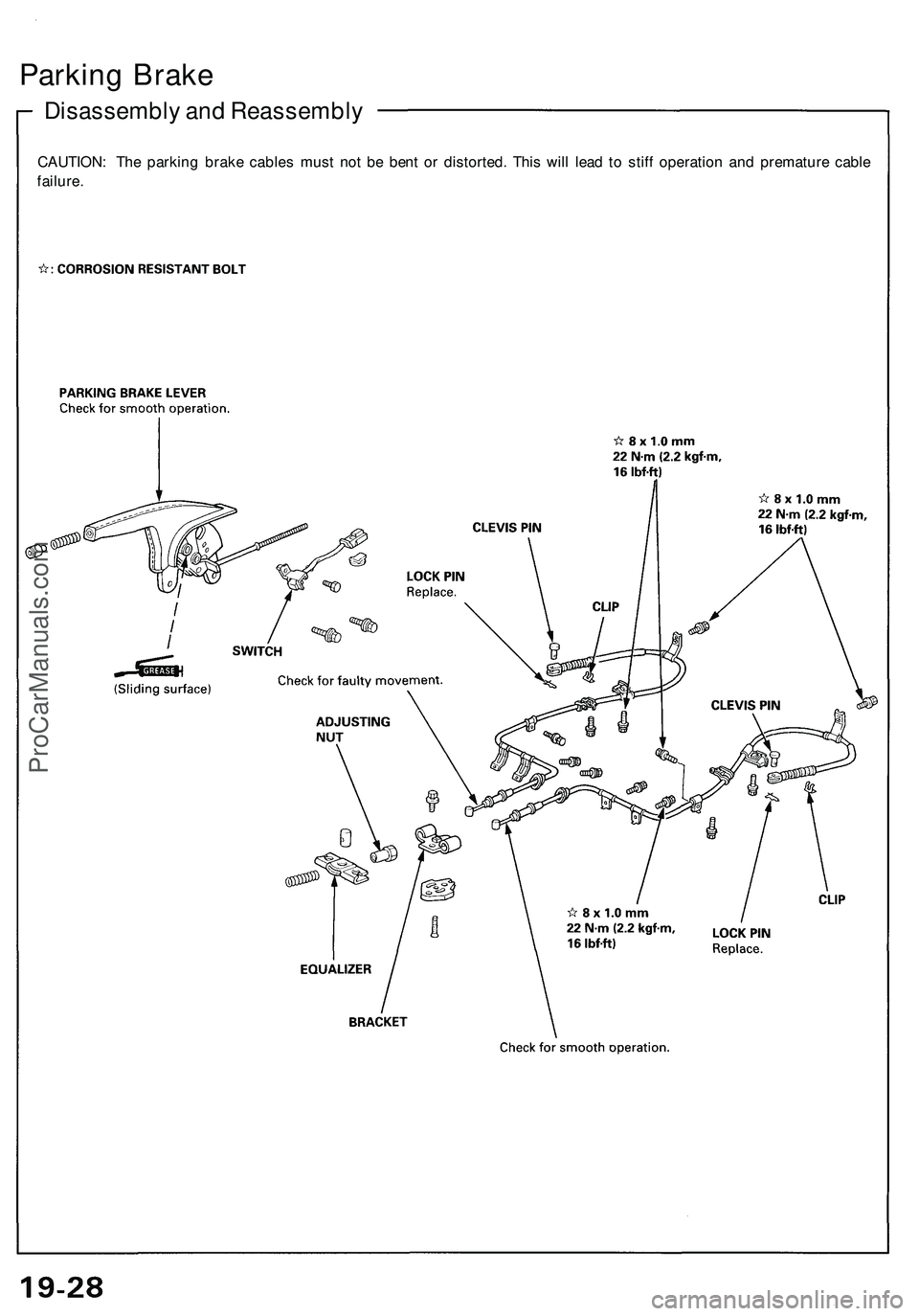

Disassembly and Reassembly

Parking Brake

CAUTION: The parking brake cables must not be bent or distorted. This will lead to stiff operation and premature cable

failure.ProCarManuals.com

Page 1010 of 1503

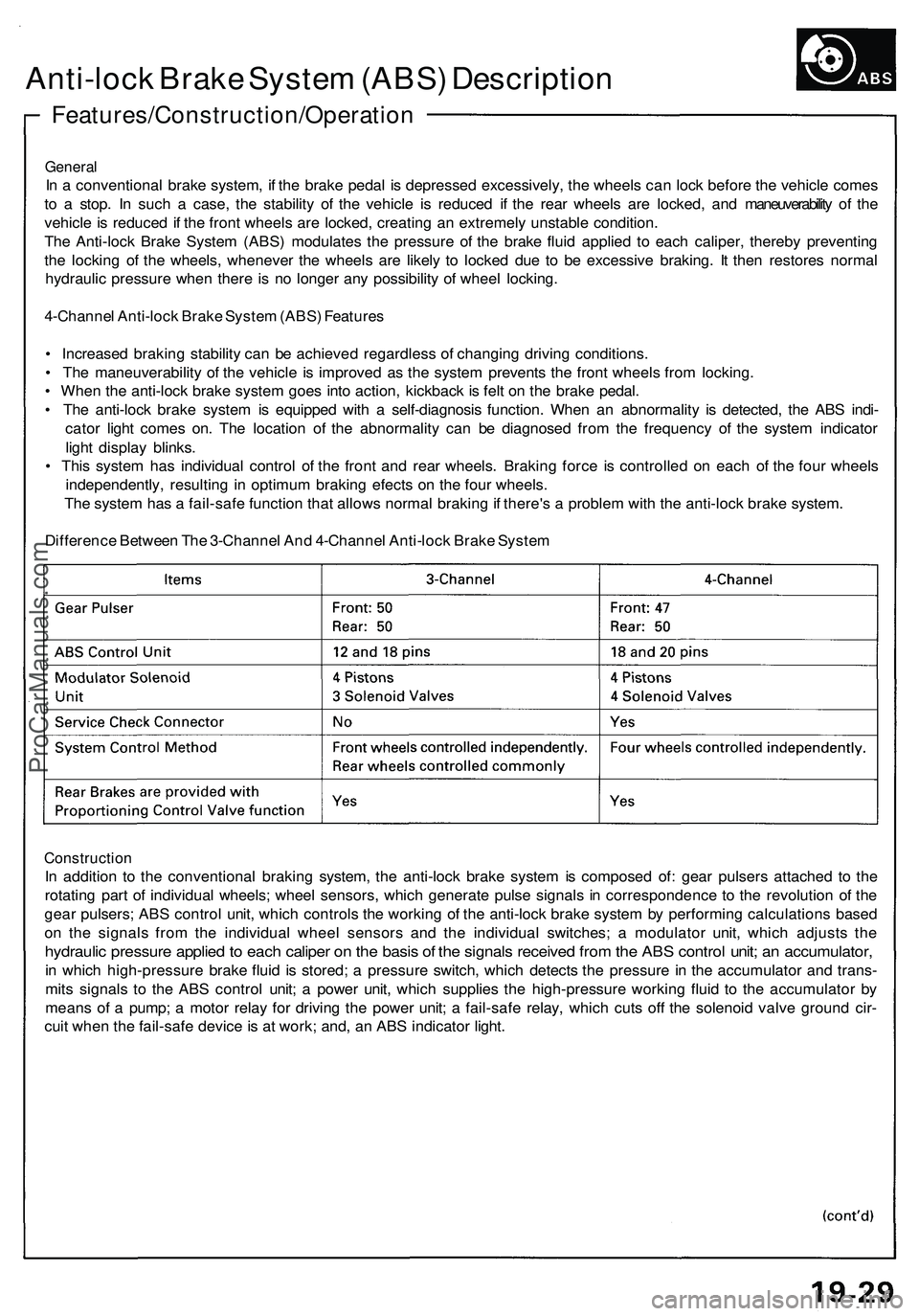

Features/Construction/Operation

Anti-lock Brake System (ABS) Description

General

In a conventional brake system, if the brake pedal is depressed excessively, the wheels can lock before the vehicle comes

to a stop. In such a case, the stability of the vehicle is reduced if the rear wheels are locked, and maneuverability of the

vehicle is reduced if the front wheels are locked, creating an extremely unstable condition.

The Anti-lock Brake System (ABS) modulates the pressure of the brake fluid applied to each caliper, thereby preventing

the locking of the wheels, whenever the wheels are likely to locked due to be excessive braking. It then restores normal

hydraulic pressure when there is no longer any possibility of wheel locking.

4-Channel Anti-lock Brake System (ABS) Features

• Increased braking stability can be achieved regardless of changing driving conditions.

• The maneuverability of the vehicle is improved as the system prevents the front wheels from locking.

• When the anti-lock brake system goes into action, kickback is felt on the brake pedal.

• The anti-lock brake system is equipped with a self-diagnosis function. When an abnormality is detected, the ABS indi-

cator light comes on. The location of the abnormality can be diagnosed from the frequency of the system indicator

light display blinks.

• This system has individual control of the front and rear wheels. Braking force is controlled on each of the four wheels

independently, resulting in optimum braking efects on the four wheels.

The system has a fail-safe function that allows normal braking if there's a problem with the anti-lock brake system.

Difference Between The 3-Channel And 4-Channel Anti-lock Brake System

Construction

In addition to the conventional braking system, the anti-lock brake system is composed of: gear pulsers attached to the

rotating part of individual wheels; wheel sensors, which generate pulse signals in correspondence to the revolution of the

gear pulsers; ABS control unit, which controls the working of the anti-lock brake system by performing calculations based

on the signals from the individual wheel sensors and the individual switches; a modulator unit, which adjusts the

hydraulic pressure applied to each caliper on the basis of the signals received from the ABS control unit; an accumulator,

in which high-pressure brake fluid is stored; a pressure switch, which detects the pressure in the accumulator and trans-

mits signals to the ABS control unit; a power unit, which supplies the high-pressure working fluid to the accumulator by

means of a pump; a motor relay for driving the power unit; a fail-safe relay, which cuts off the solenoid valve ground cir-

cuit when the fail-safe device is at work; and, an ABS indicator light.ProCarManuals.com