ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 991 of 1503

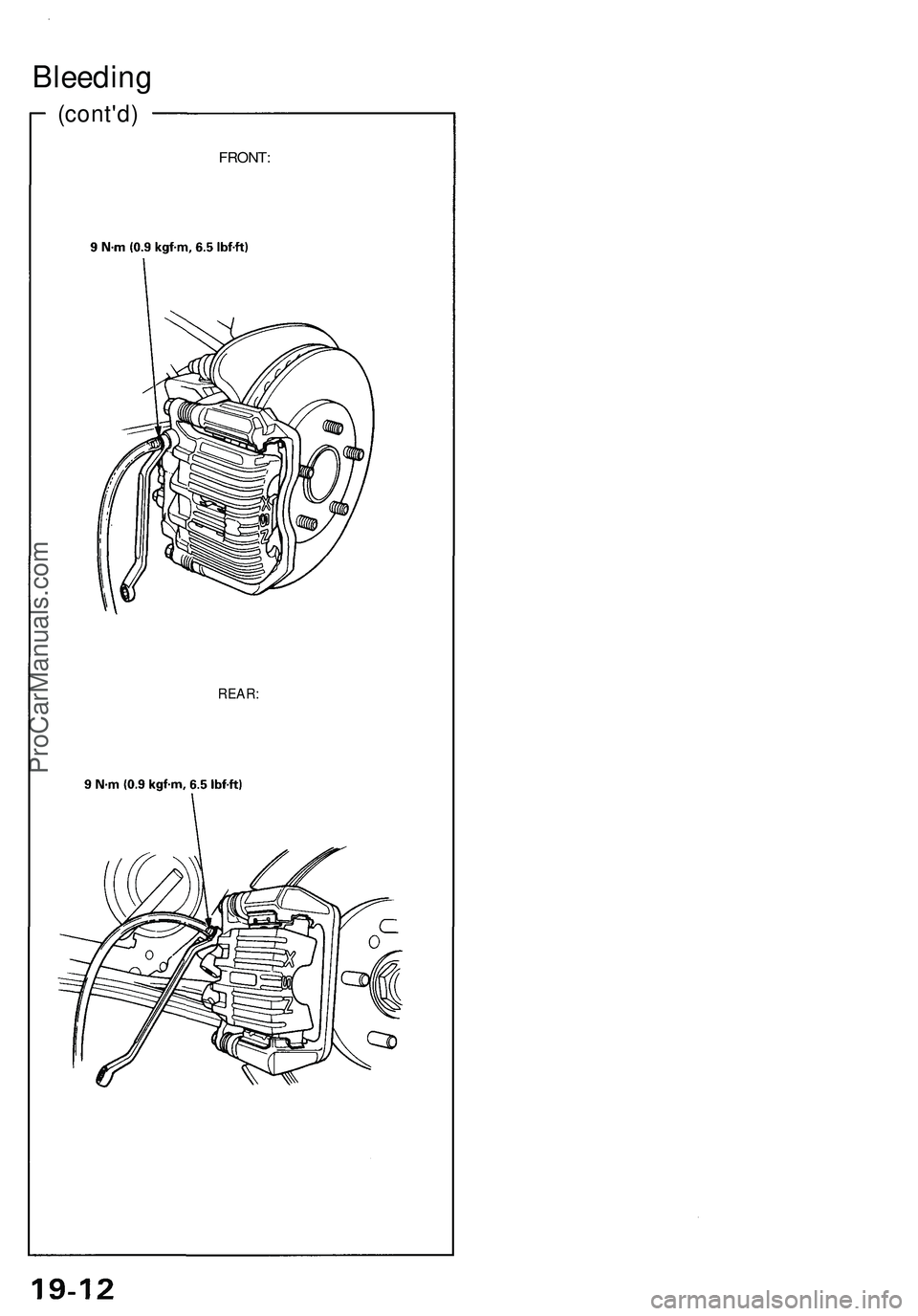

(cont'd)

FRONT:

Bleeding

REAR:ProCarManuals.com

Page 992 of 1503

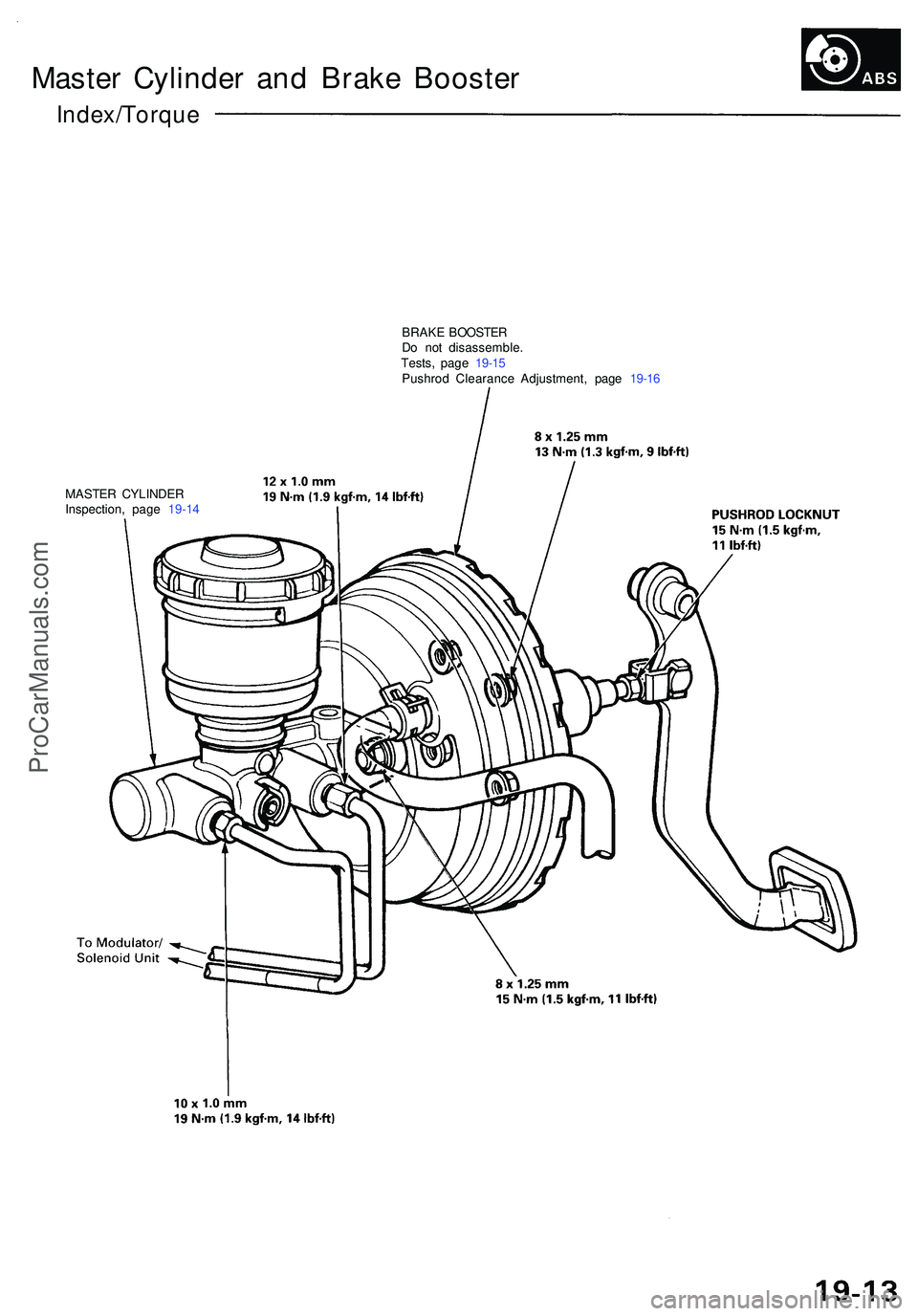

Master Cylinde r an d Brak e Booste r

Index/Torqu e

BRAKE BOOSTE R

D o no t disassemble .

Tests , pag e 19-1 5

Pushro d Clearanc e Adjustment , pag e 19-1 6

MASTE R CYLINDE R

Inspection , pag e 19-1 4

ProCarManuals.com

Page 993 of 1503

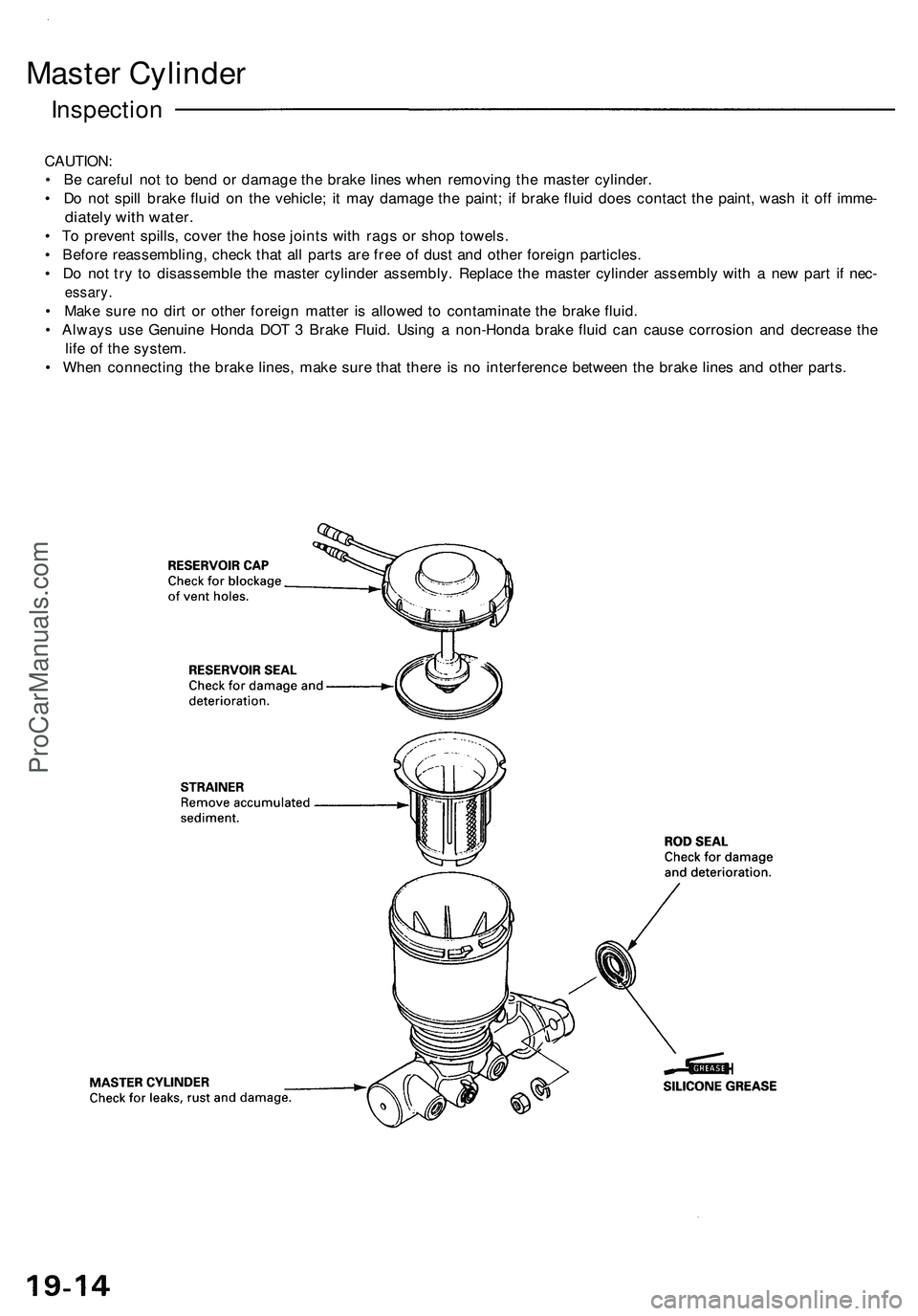

Master Cylinder

Inspection

CAUTION:

• Be careful not to bend or damage the brake lines when removing the master cylinder.

• Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off imme-

diately with water.

• To prevent spills, cover the hose joints with rags or shop towels.

• Before reassembling, check that all parts are free of dust and other foreign particles.

• Do not try to disassemble the master cylinder assembly. Replace the master cylinder assembly with a new part if nec-

essary.

• Make sure no dirt or other foreign matter is allowed to contaminate the brake fluid.

• Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

• When connecting the brake lines, make sure that there is no interference between the brake lines and other parts.ProCarManuals.com

Page 994 of 1503

Tests

Brake Booster

Functional Test

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. If

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve, or

calipers) is leaking.

2. Start the engine with the pedal depressed. If the

pedal sinks slightly, the vacuum booster is operat-

ing normally, if the pedal height does not vary, the

booster or check valve is faulty.

3. With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. If the brake pedal

sinks more than 10 mm (3/8 in.) in three minutes,

the master cylinder is faulty. A slight change in

pedal height when the A/C compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. If the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. If the pedal rises, the booster is

faulty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When the

pedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. If the pedal position does not vary, check

the booster check valve.

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster or at the booster side of the valve.

2. Start the engine and let it idle. There should be vac-

uum. If no vacuum is available, the check valve is

not working properly. Replace the check valve and

retest.ProCarManuals.com

Page 995 of 1503

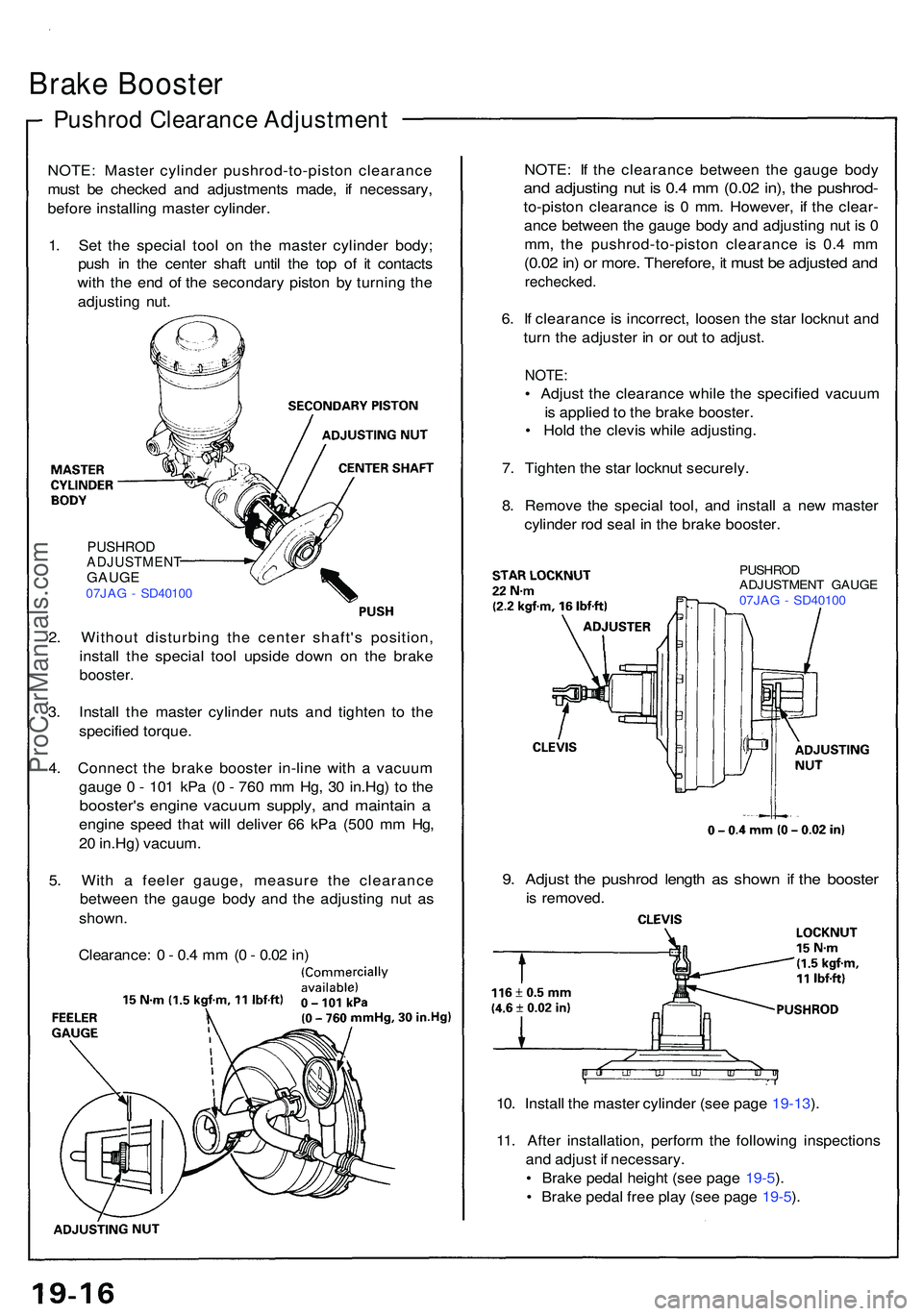

Pushrod Clearanc e Adjustmen t

Brake Booste r

NOTE: Maste r cylinde r pushrod-to-pisto n clearanc e

mus t b e checke d an d adjustment s made , i f necessary ,

befor e installin g maste r cylinder .

1 . Se t th e specia l too l o n th e maste r cylinde r body ;

pus h i n th e cente r shaf t unti l th e to p o f i t contact s

wit h th e en d o f th e secondar y pisto n b y turnin g th e

adjustin g nut . NOTE

: I f th e clearanc e betwee n th e gaug e bod y

and adjustin g nu t i s 0. 4 m m (0.0 2 in) , th e pushrod -

to-piston clearanc e i s 0 mm . However , i f th e clear -

anc e betwee n th e gaug e bod y an d adjustin g nu t i s 0

mm , th e pushrod-to-pisto n clearanc e i s 0. 4 m m

(0.0 2 in ) o r more . Therefore , i t mus t b e adjuste d an d

rechecked .

6. I f clearanc e i s incorrect , loose n th e sta r locknu t an d

tur n th e adjuste r i n o r ou t t o adjust .

NOTE:

• Adjus t th e clearanc e whil e th e specifie d vacuu m

i s applie d to th e brak e booster .

• Hol d th e clevi s whil e adjusting .

7 . Tighte n th e sta r locknu t securely .

8 . Remov e th e specia l tool , an d instal l a ne w maste r

cylinde r ro d sea l i n th e brak e booster.

PUSHRO D

ADJUSTMEN T GAUG E

07JA G - SD4010 0

PUSHRODADJUSTMEN TGAUGE07JAG - SD4010 0

2. Withou t disturbin g th e cente r shaft' s position ,

instal l th e specia l too l upsid e dow n o n th e brak e

booster .

3. Instal l th e maste r cylinde r nut s an d tighte n t o th e

specifie d torque .

4 . Connec t th e brak e booste r in-lin e wit h a vacuu m

gaug e 0 - 10 1 kP a ( 0 - 76 0 m m Hg , 3 0 in.Hg ) t o th e

booster' s engin e vacuu m supply , an d maintai n a

engin e spee d tha t wil l delive r 6 6 kP a (50 0 m m Hg ,

2 0 in.Hg ) vacuum .

5 . Wit h a feele r gauge , measur e th e clearanc e

betwee n th e gaug e bod y an d th e adjustin g nu t a s

shown .

Clearance : 0 - 0. 4 m m (0 - 0.0 2 in )

9. Adjus t th e pushro d lengt h a s show n i f th e booste r

is removed .

10 . Instal l th e maste r cylinde r (se e pag e 19-13 ).

11 . Afte r installation , perfor m th e followin g inspection s

an d adjus t i f necessary .

• Brak e peda l heigh t (se e pag e 19-5 ).

• Brak e peda l fre e pla y (se e pag e 19-5 ).

ProCarManuals.com

Page 996 of 1503

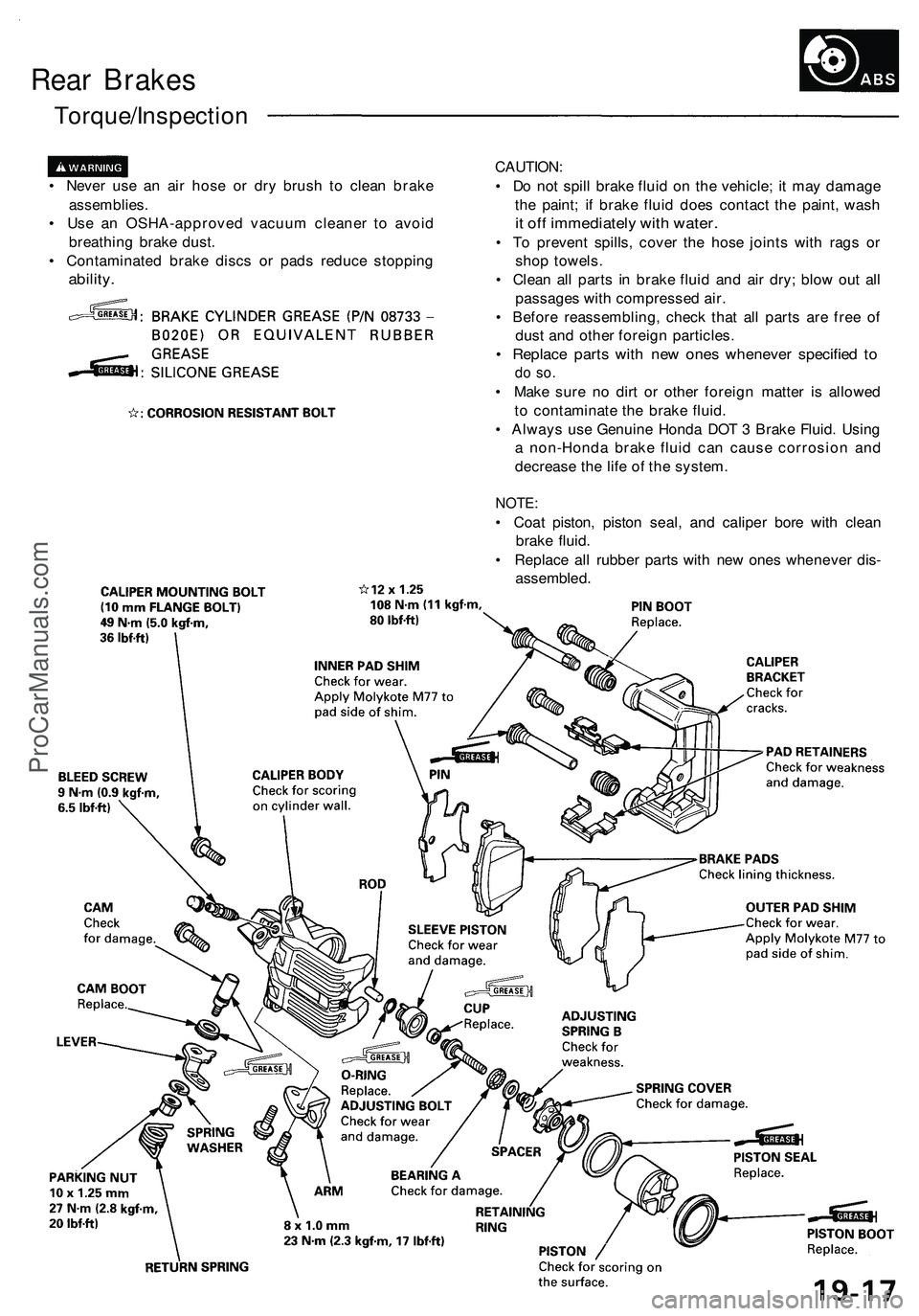

Rear Brakes

Torque/Inspection

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

• Contaminated brake discs or pads reduce stopping

ability.

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

• Before reassembling, check that all parts are free of

dust and other foreign particles.

• Replace parts with new ones whenever specified to

do so.

• Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid.

• Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the system.

NOTE:

• Coat piston, piston seal, and caliper bore with clean

brake fluid.

• Replace all rubber parts with new ones whenever dis-

assembled.ProCarManuals.com

Page 997 of 1503

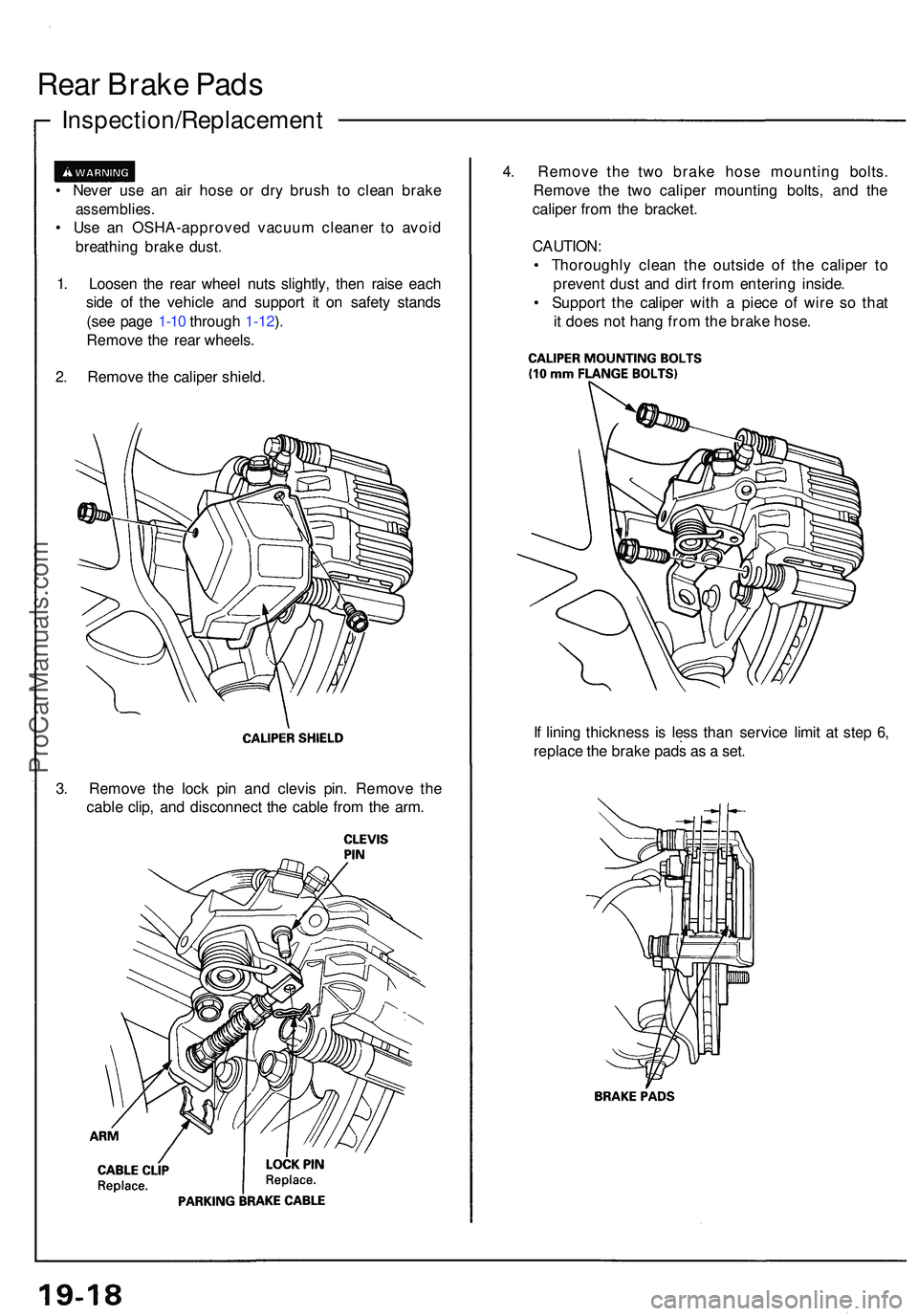

Rear Brak e Pad s

Inspection/Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e rea r whee l nut s slightly , the n rais e eac h

sid e o f th e vehicl e an d suppor t i t o n safet y stand s

(se e pag e 1-10 throug h 1-12 ).

Remov e th e rea r wheels .

2 . Remov e th e calipe r shield . 4

. Remov e th e tw o brak e hos e mountin g bolts .

Remov e th e tw o calipe r mountin g bolts , an d th e

calipe r fro m th e bracket .

CAUTION :

• Thoroughl y clea n th e outsid e o f th e calipe r t o

preven t dus t an d dir t fro m enterin g inside .

• Suppor t th e calipe r wit h a piec e o f wir e s o tha t

i t doe s no t han g fro m th e brak e hose .

I f linin g thicknes s i s les s tha n servic e limi t a t ste p 6 ,

replac e th e brak e pad s a s a set .

3 . Remov e th e loc k pi n an d clevi s pin . Remov e th e

cabl e clip , an d disconnec t th e cabl e fro m th e arm .

ProCarManuals.com

Page 998 of 1503

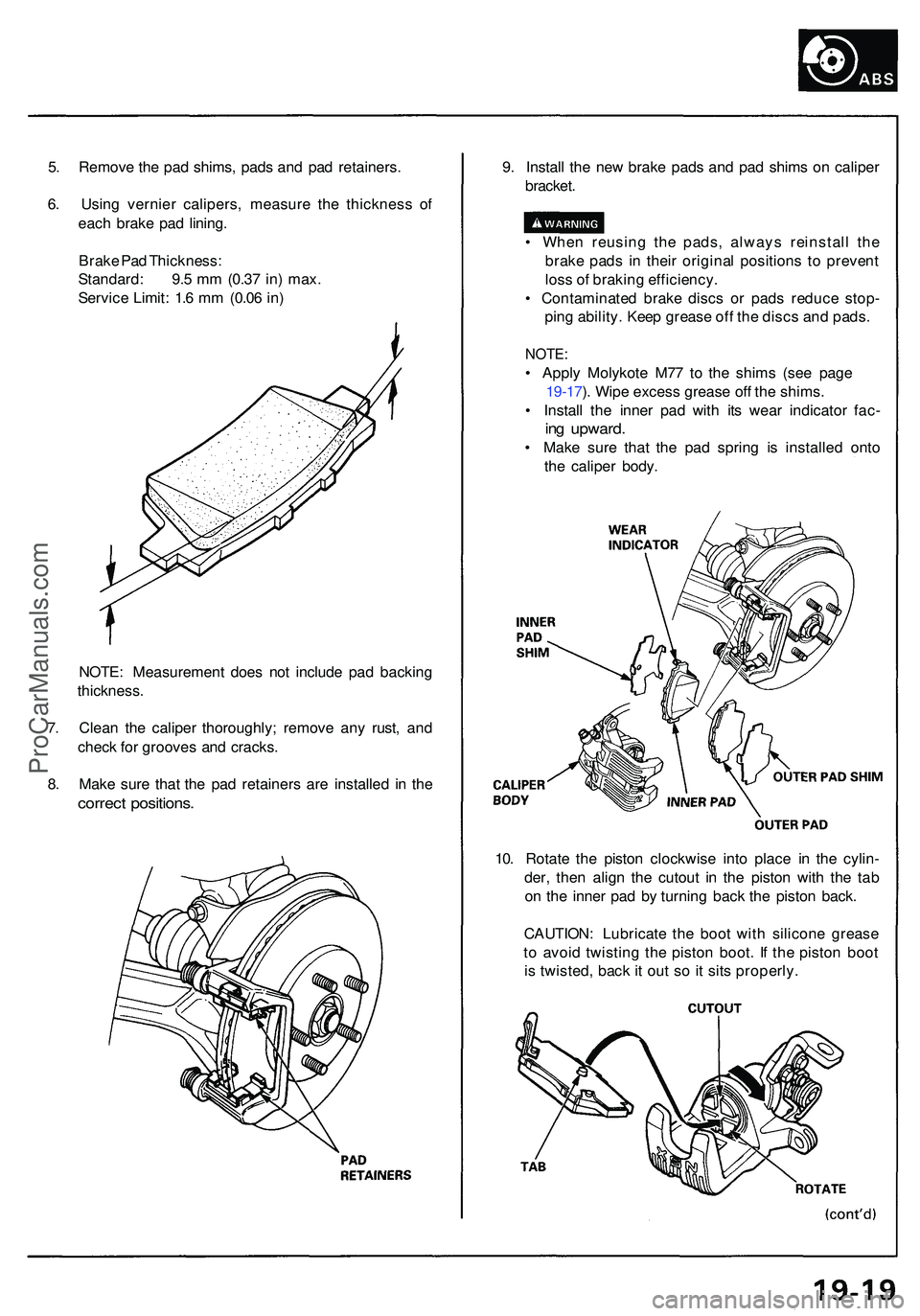

5. Remov e th e pa d shims , pad s an d pa d retainers .

6 . Usin g vernie r calipers , measur e th e thicknes s o f

eac h brak e pa d lining .

Brak e Pa d Thickness :

Standard : 9. 5 m m (0.3 7 in ) max .

Servic e Limit : 1. 6 m m (0.0 6 in ) 9

. Instal l th e ne w brak e pad s an d pa d shim s o n calipe r

bracket .

• Whe n reusin g th e pads , alway s reinstal l th e

brak e pad s i n thei r origina l position s t o preven t

los s o f brakin g efficiency .

• Contaminate d brak e disc s o r pad s reduc e stop -

pin g ability . Kee p greas e of f th e disc s an d pads .

NOTE :

• Appl y Molykote M77 t o th e shim s (se e pag e

19-17 ). Wip e exces s greas e of f th e shims .

• Instal l th e inne r pa d wit h it s wea r indicato r fac -

ing upward .

• Mak e sur e tha t th e pa d sprin g i s installe d ont o

th e calipe r body .

NOTE : Measuremen t doe s no t includ e pa d backin g

thickness .

7 . Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

8 . Mak e sur e tha t th e pa d retainer s ar e installe d i n th e

correc t positions .

10. Rotat e th e pisto n clockwis e int o plac e i n th e cylin -

der , the n alig n th e cutou t i n th e pisto n wit h th e ta b

o n th e inne r pa d b y turnin g bac k th e pisto n back .

CAUTION : Lubricat e th e boo t wit h silicon e greas e

t o avoi d twistin g th e pisto n boot . I f th e pisto n boo t

i s twisted , bac k it ou t s o it sit s properly .

ProCarManuals.com

Page 999 of 1503

Inspection/Replacement (cont'd)

Rear Brake Pads

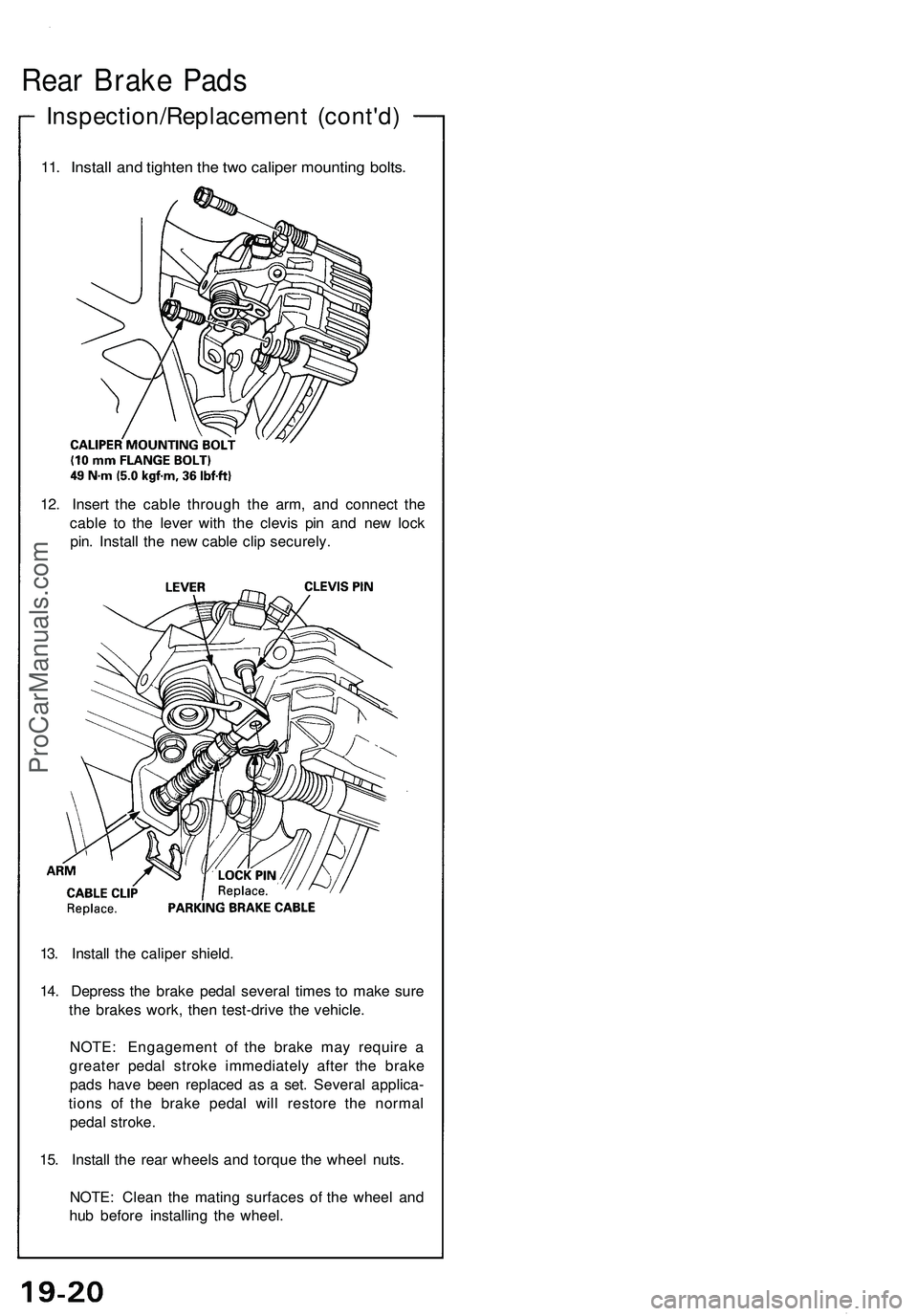

11. Install and tighten the two caliper mounting bolts.

12. Insert the cable through the arm, and connect the

cable to the lever with the clevis pin and new lock

pin. Install the new cable clip securely.

13. Install the caliper shield.

14. Depress the brake pedal several times to make sure

the brakes work, then test-drive the vehicle.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

15. Install the rear wheels and torque the wheel nuts.

NOTE: Clean the mating surfaces of the wheel and

hub before installing the wheel.ProCarManuals.com

Page 1000 of 1503

Rear Brak e Dis c

Run-Ou t Inspectio n

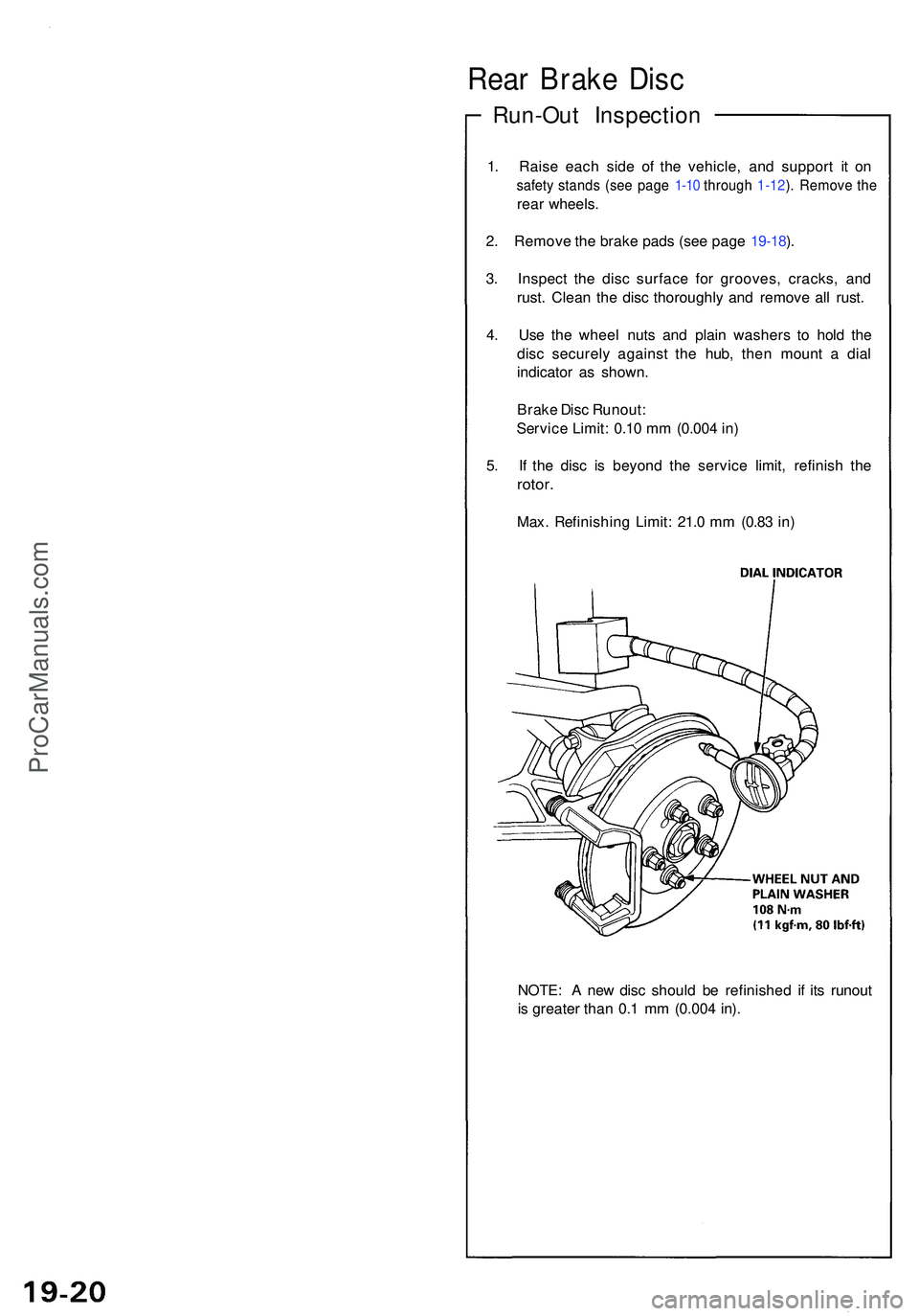

1. Rais e eac h sid e o f th e vehicle , an d suppor t i t o n

safet y stand s (se e pag e 1-10 throug h 1-12 ). Remov e th e

rea r wheels .

2 . Remov e th e brak e pad s (se e pag e 19-18 ).

3 . Inspec t th e dis c surfac e fo r grooves , cracks , an d

rust . Clea n th e dis c thoroughl y an d remov e al l rust .

4 . Us e th e whee l nuts and plai n washer s t o hol d th e

dis c securel y agains t th e hub , the n moun t a dia l

indicato r a s shown .

Brak e Dis c Runout :

Servic e Limit : 0.1 0 m m (0.00 4 in )

5 . I f th e dis c i s beyon d th e servic e limit , refinis h th e

rotor .

Max. Refinishin g Limit : 21. 0 m m (0.8 3 in )

NOTE : A ne w dis c shoul d b e refinishe d i f it s runou t

i s greate r tha n 0. 1 m m (0.00 4 in) .

ProCarManuals.com