ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 981 of 1503

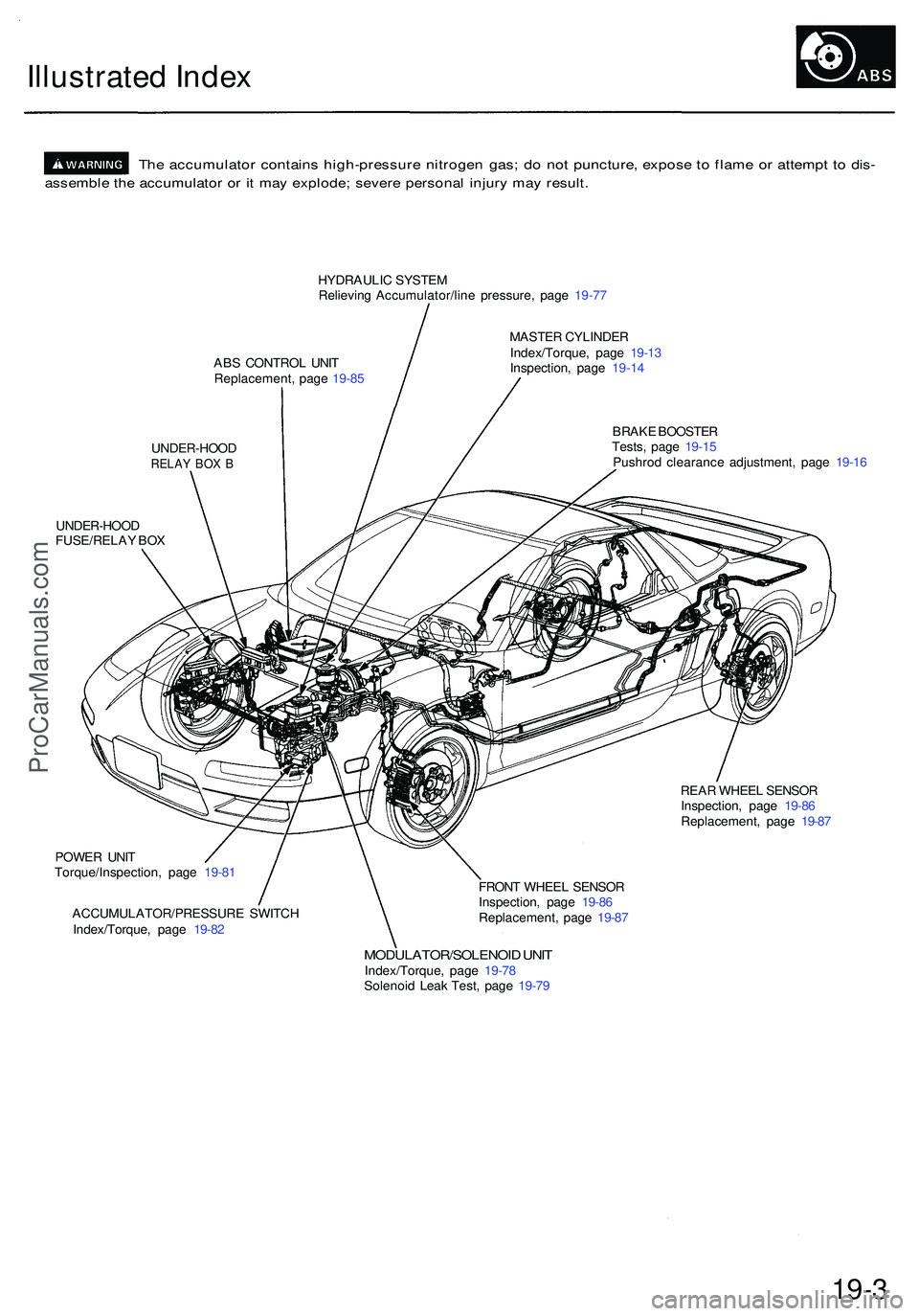

Illustrated Inde x

The accumulato r contain s high-pressur e nitroge n gas ; d o no t puncture , expos e t o flam e o r attemp t t o dis -

assembl e th e accumulato r o r i t ma y explode ; sever e persona l injur y ma y result .

HYDRAULI C SYSTE M

Relievin g Accumulator/lin e pressure , pag e 19-7 7

AB S CONTRO L UNI T

Replacement , pag e 19-8 5 MASTE

R CYLINDE R

Index/Torque , pag e 19-1 3

Inspection , pag e 19-1 4

UNDER-HOO D

RELAY BO X B

BRAK E BOOSTE R

Tests , pag e 19-1 5

Pushro d clearanc e adjustment , pag e 19-1 6

UNDER-HOO D

FUSE/RELA Y BO X

REAR WHEE L SENSO R

Inspection , pag e 19-8 6

Replacement , pag e 19-8 7

POWE R UNI T

Torque/Inspection , pag e 19-81

ACCUMULATOR/PRESSUR E SWITC H

Index/Torque , pag e 19-8 2 FRON

T WHEE L SENSO R

Inspection , pag e 19-8 6

Replacement , pag e 19-8 7

MODULATOR/SOLENOI D UNI TIndex/Torque , pag e 19-7 8

Solenoi d Lea k Test , pag e 19-7 9

19-3

ProCarManuals.com

Page 982 of 1503

Inspection and Adjustment

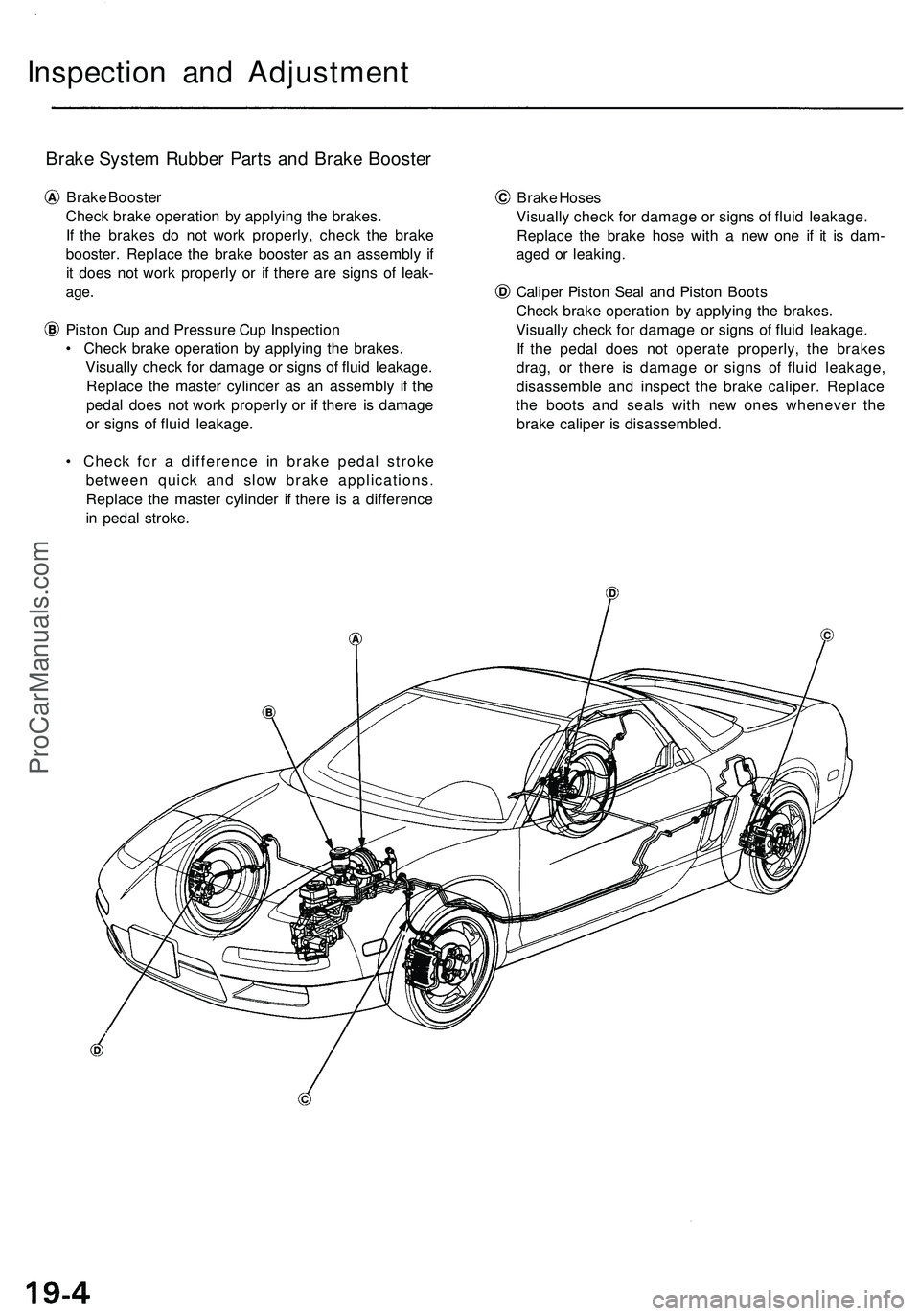

Brake System Rubber Parts and Brake Booster

Brake Booster

Check brake operation by applying the brakes.

If the brakes do not work properly, check the brake

booster. Replace the brake booster as an assembly if

it does not work properly or if there are signs of leak-

age.

Piston Cup and Pressure Cup Inspection

• Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

Replace the master cylinder as an assembly if the

pedal does not work properly or if there is damage

or signs of fluid leakage.

• Check for a difference in brake pedal stroke

between quick and slow brake applications.

Replace the master cylinder if there is a difference

in pedal stroke.

Brake Hoses

Visually check for damage or signs of fluid leakage.

Replace the brake hose with a new one if it is dam-

aged or leaking.

Caliper Piston Seal and Piston Boots

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

If the pedal does not operate properly, the brakes

drag, or there is damage or signs of fluid leakage,

disassemble and inspect the brake caliper. Replace

the boots and seals with new ones whenever the

brake caliper is disassembled.ProCarManuals.com

Page 983 of 1503

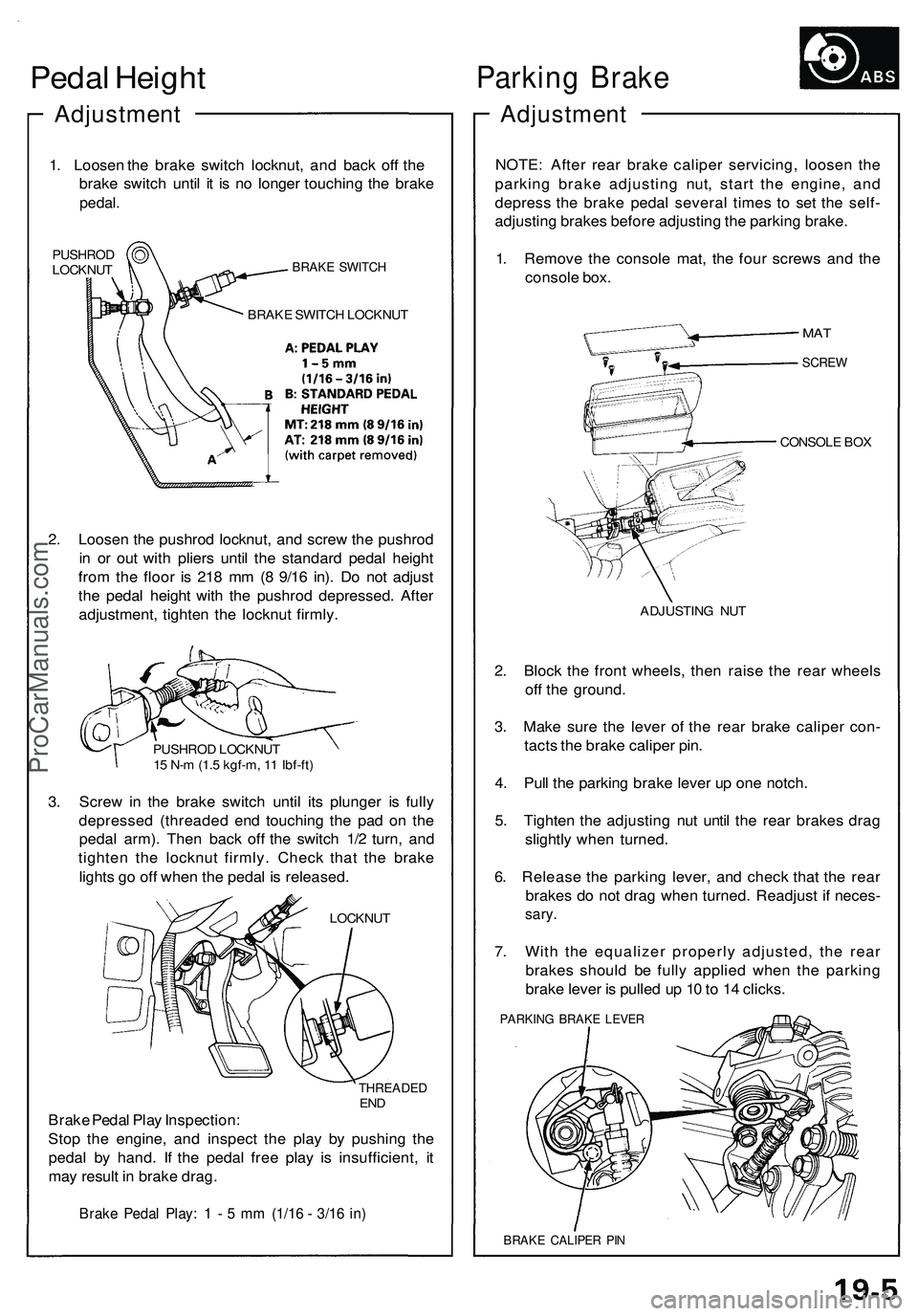

Pedal Heigh t

Adjustmen t

1. Lo osen th e brak e switc h locknut , an d bac k of f th e

brak e switc h unti l i t i s n o longe r touchin g th e brak e

pedal .

PUSHRO D

LOCKNU TBRAKE SWITC H

BRAKE SWITC H LOCKNU T

2. Loose n th e pushro d locknut , an d scre w th e pushro d

i n o r ou t wit h plier s unti l th e standar d peda l heigh t

fro m th e floo r i s 21 8 m m (8 9/1 6 in) . D o no t adjus t

th e peda l heigh t wit h th e pushro d depressed . Afte r

adjustment , tighte n th e locknu t firmly .

PUSHRO D LOCKNU T

1 5 N- m (1. 5 kgf-m , 1 1 Ibf-ft )

3. Scre w in th e brak e switc h unti l it s plunge r i s full y

depresse d (threade d en d touchin g th e pa d o n th e

peda l arm) . The n bac k of f th e switc h 1/ 2 turn , an d

tighte n th e locknu t firmly . Chec k tha t th e brak e

light s g o of f whe n th e peda l i s released .

LOCKNUT

THREADE DEND

Brak e Peda l Pla y Inspection :

Sto p th e engine , an d inspec t th e pla y b y pushin g th e

peda l b y hand . I f th e peda l fre e pla y i s insufficient , i t

ma y resul t i n brak e drag .

Brake Peda l Play : 1 - 5 m m (1/1 6 - 3/1 6 in )

Parkin g Brak e

Adjustmen t

NOTE: Afte r rea r brak e calipe r servicing , loose n th e

parkin g brak e adjustin g nut , star t th e engine , an d

depres s th e brak e peda l severa l time s t o se t th e self -

adjustin g brake s befor e adjustin g th e parkin g brake .

1 . Remov e th e consol e mat , th e fou r screw s an d th e

consol e box .

CONSOL E BO X

ADJUSTIN G NU T

2. Bloc k th e fron t wheels , the n rais e th e rea r wheel s

of f th e ground .

3 . Mak e sur e th e leve r o f th e rea r brak e calipe r con -

tact s th e brak e calipe r pin .

4 . Pul l th e parkin g brak e leve r u p on e notch .

5 . Tighte n th e adjustin g nu t unti l th e rea r brake s dra g

slightl y whe n turned .

6 . Releas e th e parkin g lever , an d chec k tha t th e rea r

brake s d o no t dra g whe n turned . Readjus t i f neces -

sary.

7. Wit h th e equalize r properl y adjusted , th e rea r

brake s shoul d b e full y applie d whe n th e parkin g

brak e leve r i s pulle d u p 1 0 to 1 4 clicks .

PARKIN G BRAK E LEVE R

BRAKE CALIPE R PI N

MA T

SCRE W

ProCarManuals.com

Page 984 of 1503

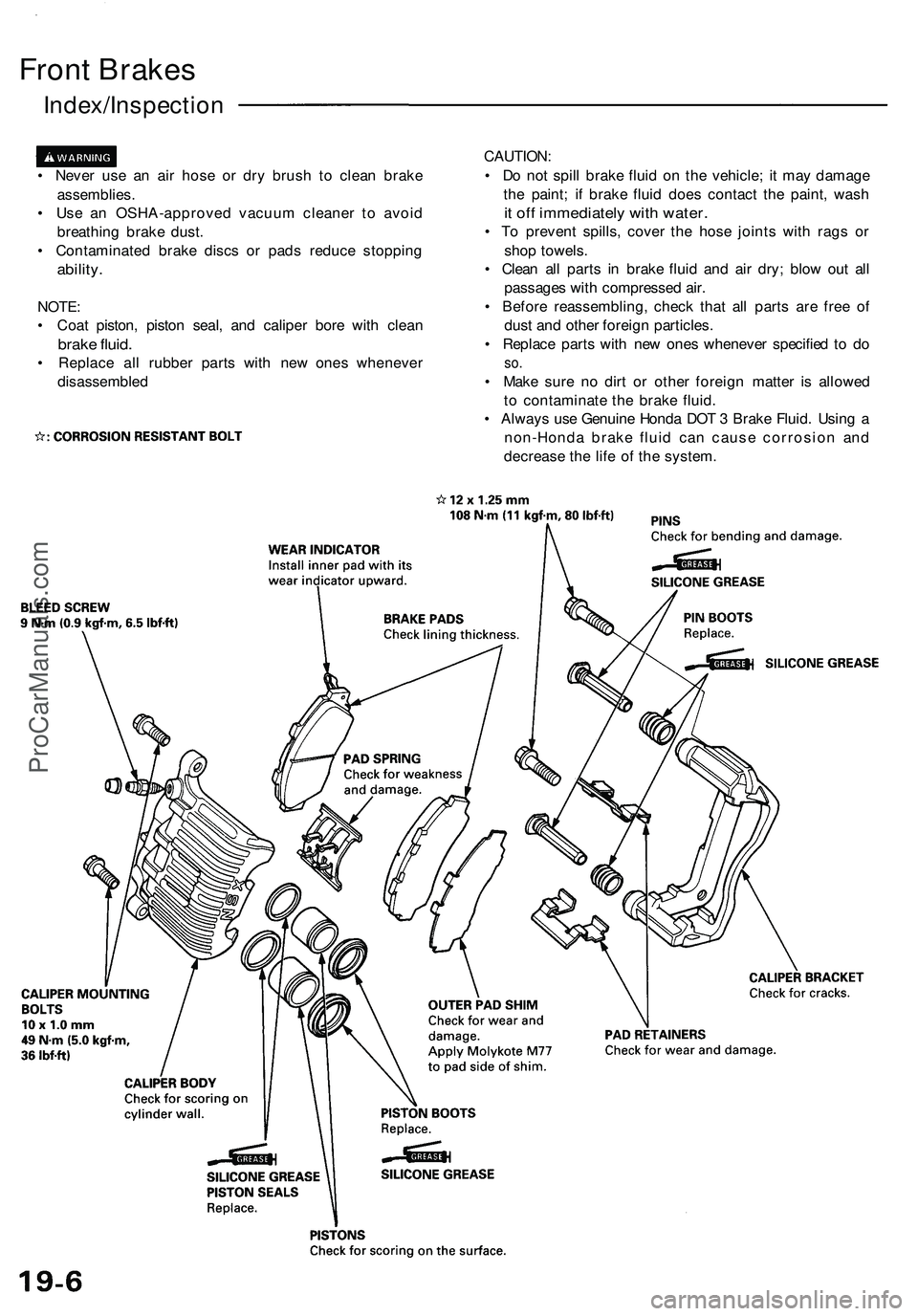

Front Brakes

Index/Inspection

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

• Contaminated brake discs or pads reduce stopping

ability.

NOTE:

• Coat piston, piston seal, and caliper bore with clean

brake fluid.

• Replace all rubber parts with new ones whenever

disassembled

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

• Before reassembling, check that all parts are free of

dust and other foreign particles.

• Replace parts with new ones whenever specified to do

so.

• Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid.

• Always use Genuine Honda DOT 3 Brake Fluid. Using a

non-Honda brake fluid can cause corrosion and

decrease the life of the system.ProCarManuals.com

Page 985 of 1503

Front Brak e Pad s

Inspection/Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

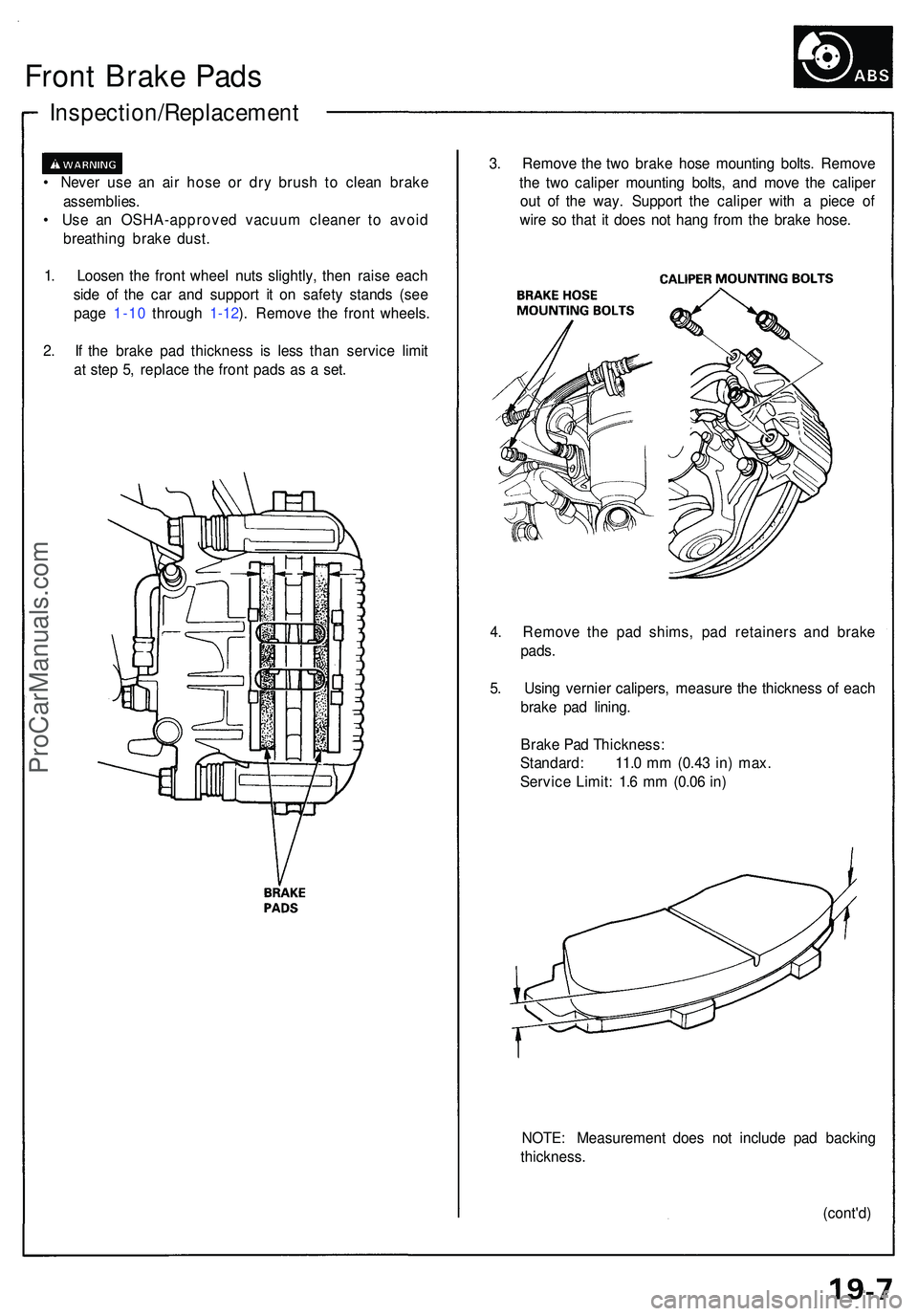

1 . Loose n th e fron t whee l nut s slightly , the n rais e eac h

sid e o f th e ca r an d suppor t i t o n safet y stand s (se e

pag e 1-10 throug h 1-12 ). Remov e th e fron t wheels .

2 . I f th e brak e pa d thicknes s i s les s tha n servic e limi t

a t ste p 5 , replac e th e fron t pad s a s a set . 3

. Remov e th e tw o brak e hos e mountin g bolts . Remov e

th e tw o calipe r mountin g bolts , an d mov e th e calipe r

ou t o f th e way . Suppor t th e calipe r wit h a piec e o f

wir e s o tha t i t doe s no t han g fro m th e brak e hose .

4 . Remov e th e pa d shims , pa d retainer s an d brak e

pads .

5 . Usin g vernie r calipers , measur e th e thicknes s o f eac h

brak e pa d lining .

Brak e Pa d Thickness :

Standard : 11. 0 m m (0.4 3 in ) max .

Servic e Limit : 1. 6 m m (0.0 6 in )

NOTE : Measuremen t doe s no t includ e pa d backin g

thickness .

(cont'd)

ProCarManuals.com

Page 986 of 1503

Inspection/Replacement (cont'd )

Front Brak e Pad s

6. Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

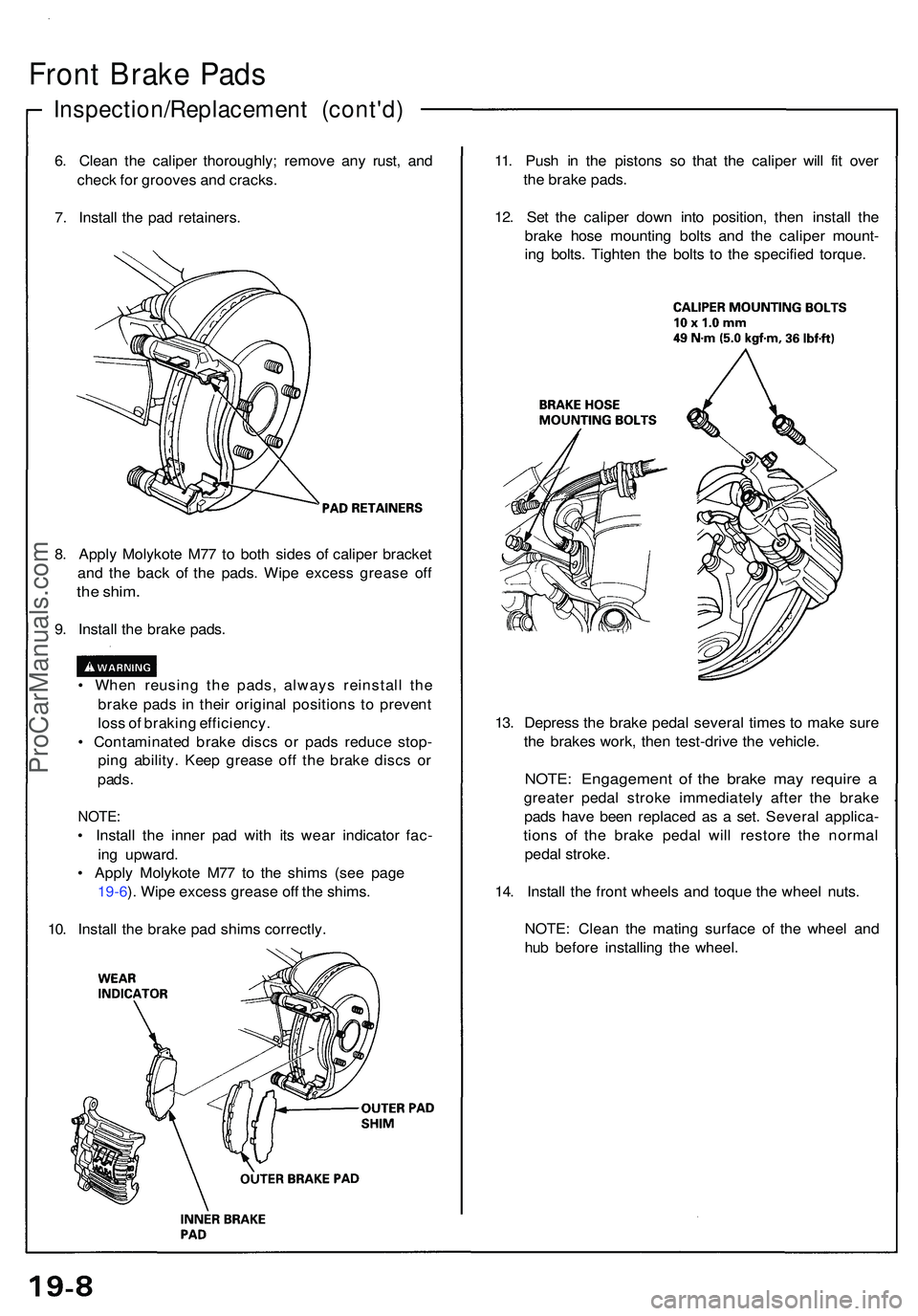

7 . Instal l th e pa d retainers . 11

. Pus h i n th e piston s s o tha t th e calipe r wil l fi t ove r

th e brak e pads .

12 . Se t th e calipe r dow n int o position , the n instal l th e

brak e hos e mountin g bolt s an d th e calipe r mount -

in g bolts . Tighte n th e bolt s t o th e specifie d torque .

8 . Appl y Molykot e M7 7 t o bot h side s o f calipe r bracke t

an d th e bac k o f th e pads . Wip e exces s greas e of f

the shim .

9. Instal l th e brak e pads .

• Whe n reusin g th e pads , alway s reinstal l th e

brak e pad s i n thei r origina l position s t o preven t

los s o f brakin g efficiency .

• Contaminate d brak e disc s o r pad s reduc e stop -

pin g ability . Kee p greas e of f th e brak e disc s o r

pads .

NOTE :

• Instal l th e inne r pa d wit h it s wea r indicator fac-

in g upward .

• Appl y Molykot e M7 7 t o th e shim s (se e pag e

19-6 ). Wip e exces s greas e of f th e shims .

10 . Instal l th e brak e pa d shim s correctly . 13

. Depres s th e brak e peda l severa l time s t o mak e sur e

th e brake s work , the n test-driv e th e vehicle .

NOTE: Engagemen t o f th e brak e ma y requir e a

greate r peda l strok e immediatel y afte r th e brak e

pad s hav e bee n replace d a s a set . Severa l applica -

tion s of the brak e peda l wil l restor e th e norma l

peda l stroke .

14 . Instal l th e fron t wheel s an d toqu e th e whee l nuts .

NOTE : Clea n th e matin g surfac e o f th e whee l an d

hu b befor e installin g th e wheel .

ProCarManuals.com

Page 987 of 1503

Disassembly

Front Caliper

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

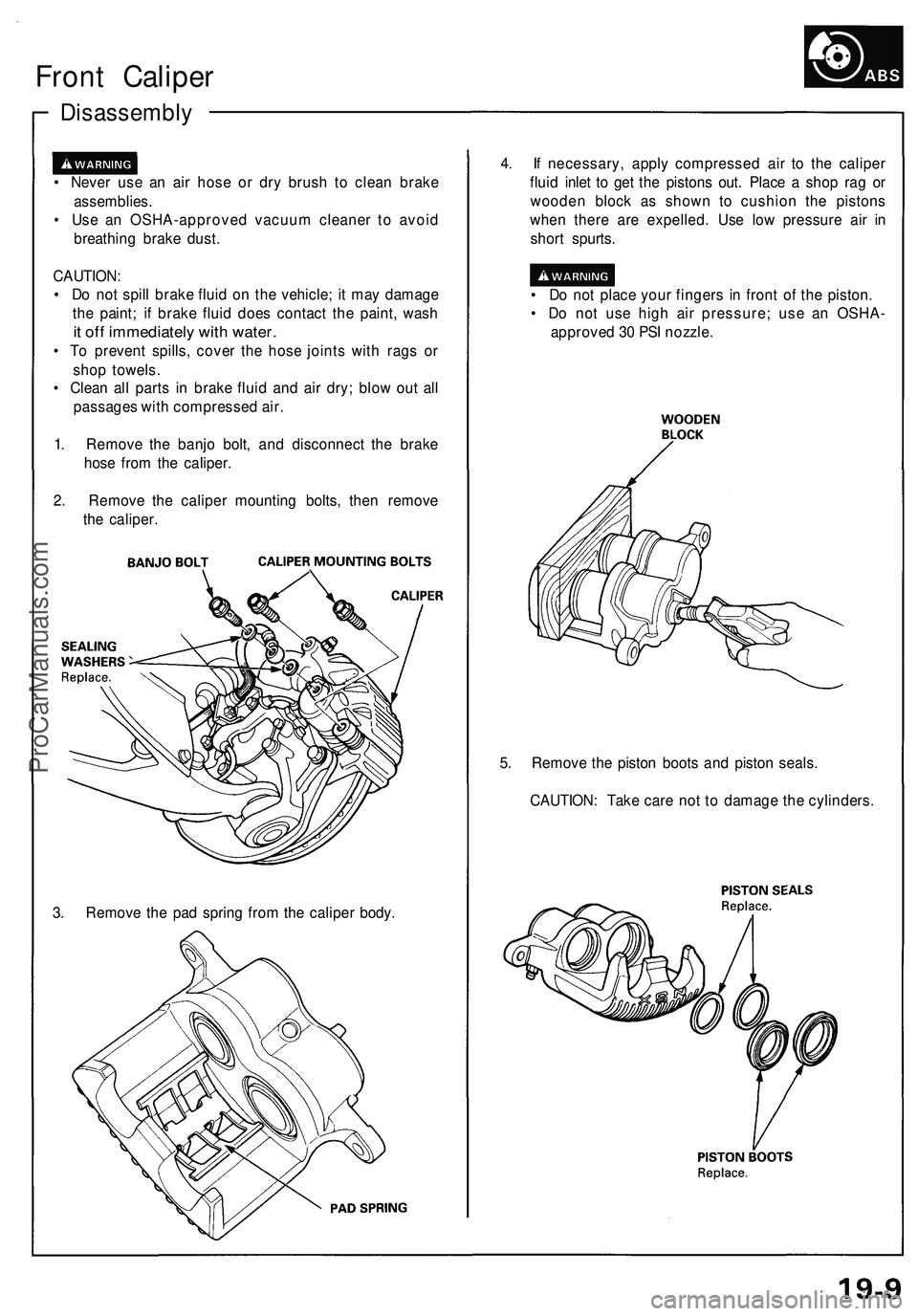

1. Remove the banjo bolt, and disconnect the brake

hose from the caliper.

2. Remove the caliper mounting bolts, then remove

the caliper.

4. If necessary, apply compressed air to the caliper

fluid inlet to get the pistons out. Place a shop rag or

wooden block as shown to cushion the pistons

when there are expelled. Use low pressure air in

short spurts.

• Do not place your fingers in front of the piston.

• Do not use high air pressure; use an OSHA-

approved 30 PSI nozzle.

3. Remove the pad spring from the caliper body.

5. Remove the piston boots and piston seals.

CAUTION: Take care not to damage the cylinders.ProCarManuals.com

Page 988 of 1503

Reassembly

Front Calipe r

CAUTION :

• Befor e reassembling , chec k tha t al l part s ar e fre e o f

dus t an d othe r foreig n particles .

• Replac e part s wit h ne w one s wheneve r specifie d t o

do so .

• Alway s us e Genuin e Hond a DO T 3 Brak e Fluid . Usin g

a non-Hond a brak e flui d ca n caus e corrosio n an d

decreas e th e lif e o f th e system .

• Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

• D o no t spil l brak e flui d o n th e vehicle ; i t ma y damag e

th e paint ; i f brak e flui d doe s contac t th e paint , was h

i t of f immediatel y wit h water .

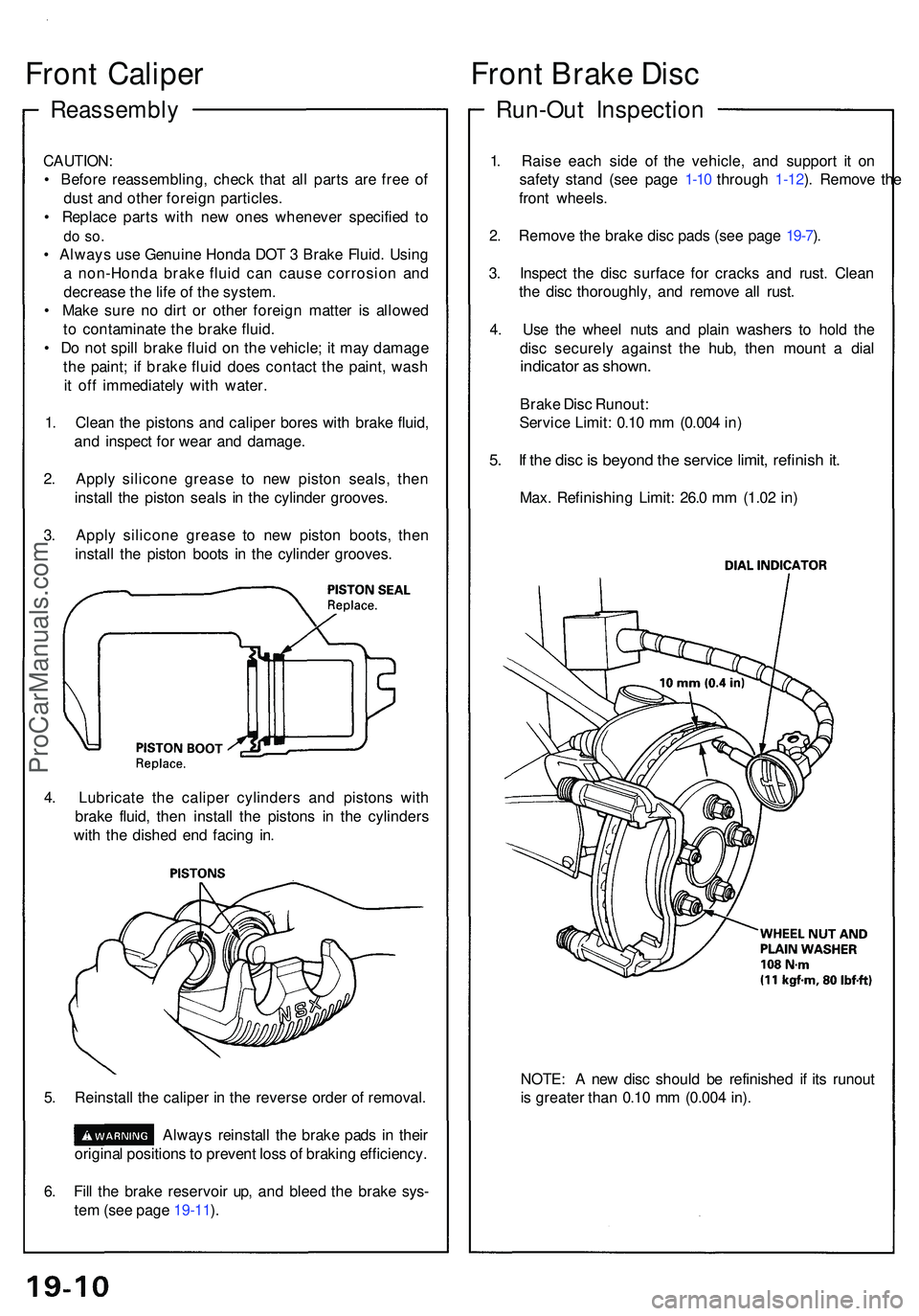

1 . Clea n th e piston s an d calipe r bore s wit h brak e fluid ,

an d inspec t fo r wea r an d damage .

2 . Appl y silicon e greas e t o ne w pisto n seals , the n

instal l th e pisto n seal s i n th e cylinde r grooves .

3 . Appl y silicon e greas e t o ne w pisto n boots , the n

instal l th e pisto n boot s i n th e cylinde r grooves .

Run-Out Inspectio n

Front Brak e Dis c

1. Rais e eac h sid e of the vehicle , an d suppor t i t o n

safet y stan d (se e pag e 1-10 throug h 1-12 ). Remov e th e

fron t wheels .

2 . Remov e th e brak e dis c pad s (se e pag e 19-7 ).

3 . Inspec t th e dis c surfac e fo r crack s an d rust . Clean

th e dis c thoroughly , an d remov e al l rust .

4 . Us e th e whee l nut s an d plai n washer s t o hol d th e

dis c securel y agains t th e hub , the n moun t a dia l

indicato r a s shown .

Brake Dis c Runout :

Servic e Limit : 0.1 0 m m (0.00 4 in )

5. I f th e dis c is beyon d th e servic e limit , refinis h it .

Max . Refinishin g Limit : 26. 0 m m (1.0 2 in )

4 . Lubricat e th e calipe r cylinder s an d piston s wit h

brak e fluid , the n instal l th e piston s i n th e cylinder s

wit h th e dishe d en d facin g in .

5 . Reinstal l th e calipe r i n th e revers e orde r o f removal .

Always reinstal l th e brak e pad s in thei r

origina l position s to preven t los s o f brakin g efficiency .

6 . Fil l th e brak e reservoi r up , an d blee d th e brak e sys -

te m (se e pag e 19-11 ). NOTE

: A ne w dis c shoul d b e refinishe d i f it s runou t

i s greate r tha n 0.1 0 m m (0.00 4 in) .

ProCarManuals.com

Page 989 of 1503

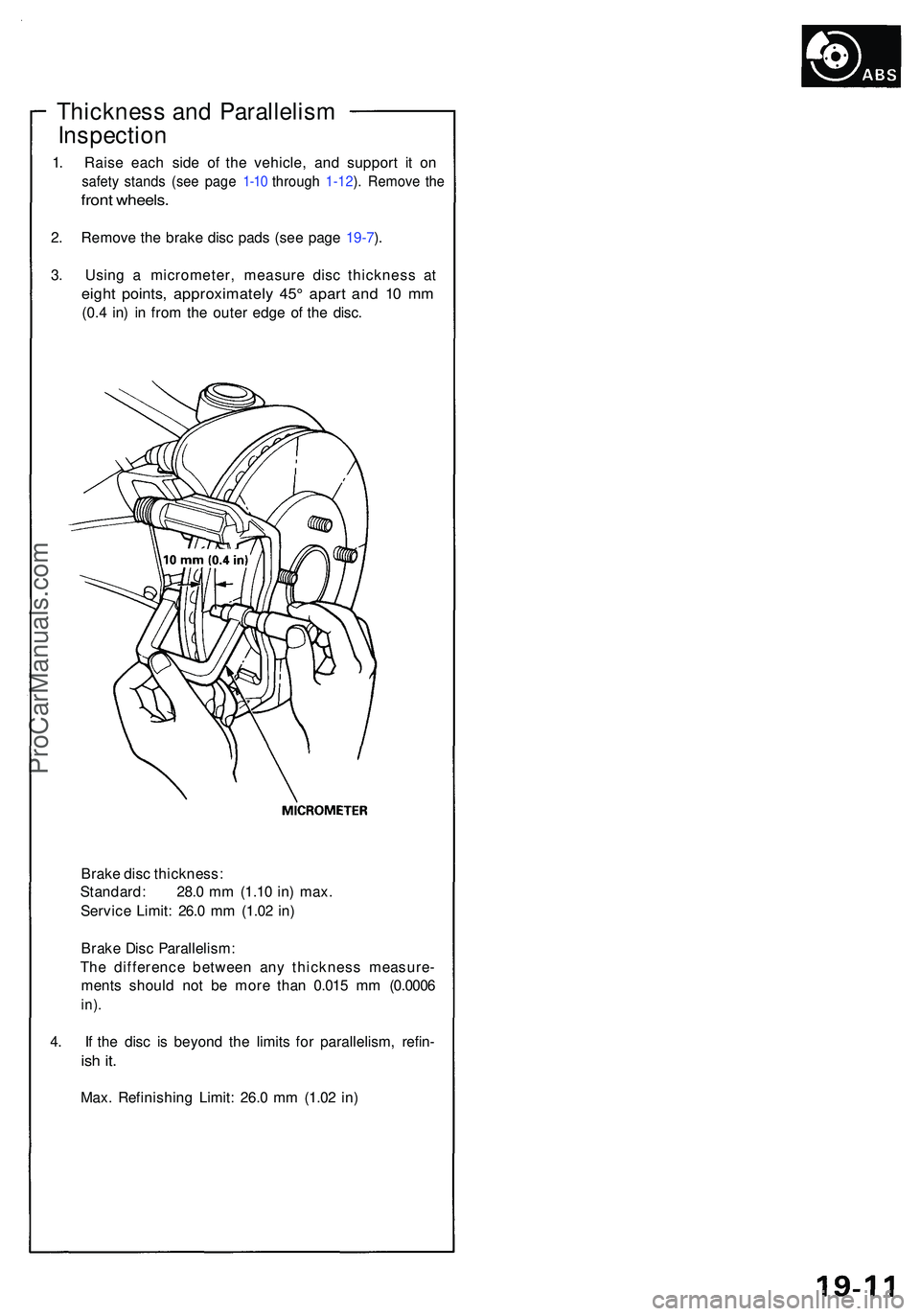

Thickness an d Parallelis m

Inspectio n

1. Rais e eac h sid e o f th e vehicle , an d suppor t i t o n

safet y stand s (se e pag e 1-10 throug h 1-12 ). Remov e th e

fron t wheels .

2. Remov e th e brak e dis c pad s (se e pag e 19-7 ).

3 . Usin g a micrometer , measur e dis c thicknes s a t

eigh t points , approximatel y 45 ° apar t an d 1 0 m m

(0.4 in ) i n fro m th e oute r edg e o f th e disc .

Brak e dis c thickness :

Standard : 28. 0 m m (1.1 0 in ) max .

Servic e Limit : 26. 0 m m (1.0 2 in )

Brak e Dis c Parallelism :

Th e differenc e betwee n an y thicknes s measure -

ment s shoul d no t b e mor e tha n 0.01 5 m m (0.000 6

in).

4. I f th e dis c i s beyon d th e limit s fo r parallelism , refin -

ish it .

Max . Refinishin g Limit : 26. 0 m m (1.0 2 in )

ProCarManuals.com

Page 990 of 1503

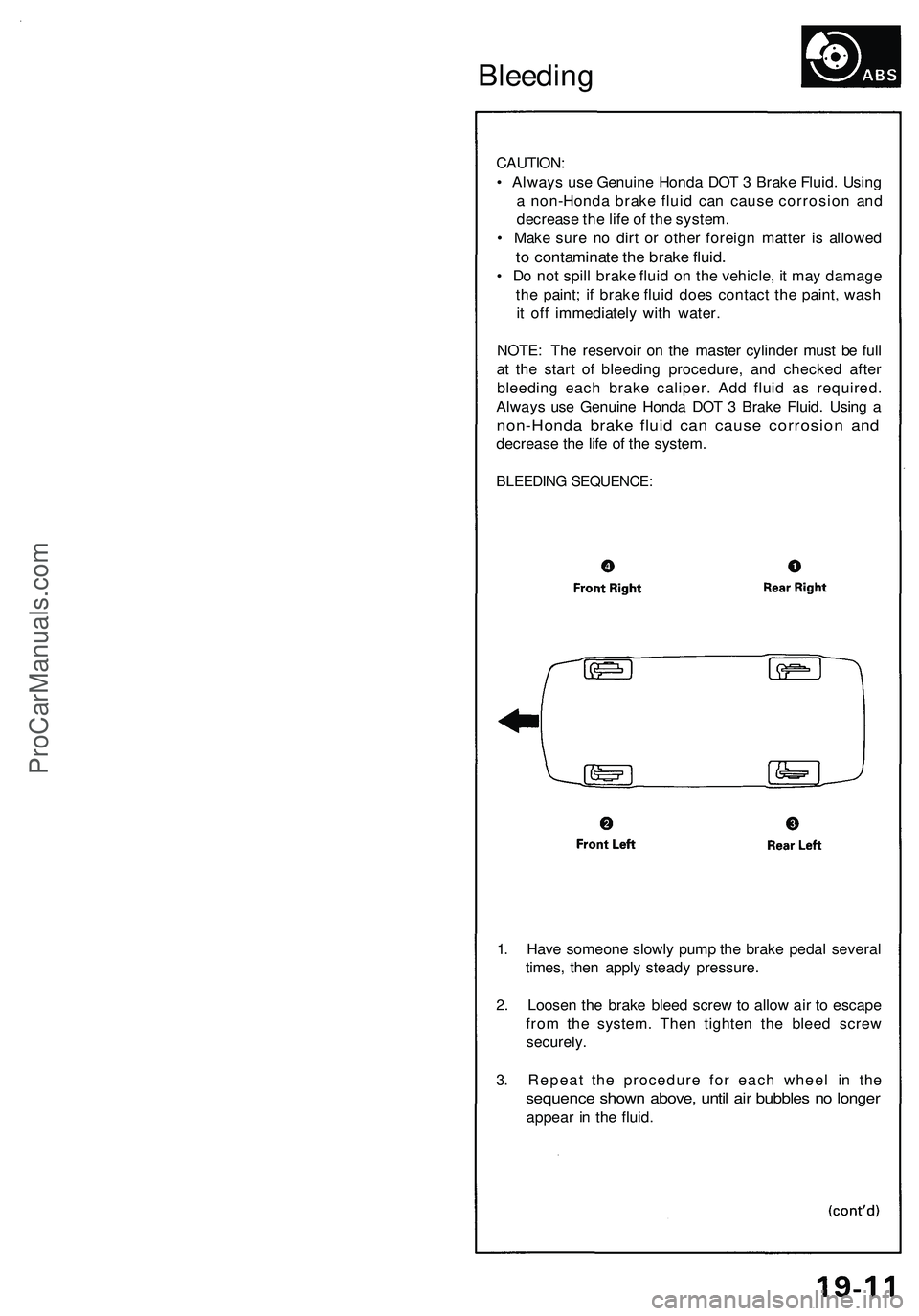

Bleeding

CAUTION:

• Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the system.

• Make sure no dirt or other foreign matter is allowed

to contaminate the brake fluid.

• Do not spill brake fluid on the vehicle, it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

NOTE: The reservoir on the master cylinder must be full

at the start of bleeding procedure, and checked after

bleeding each brake caliper. Add fluid as required.

Always use Genuine Honda DOT 3 Brake Fluid. Using a

non-Honda brake fluid can cause corrosion and

decrease the life of the system.

BLEEDING SEQUENCE:

1. Have someone slowly pump the brake pedal several

times, then apply steady pressure.

2. Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

3. Repeat the procedure for each wheel in the

sequence shown above, until air bubbles no longer

appear in the fluid.ProCarManuals.com