engine ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 595 of 1503

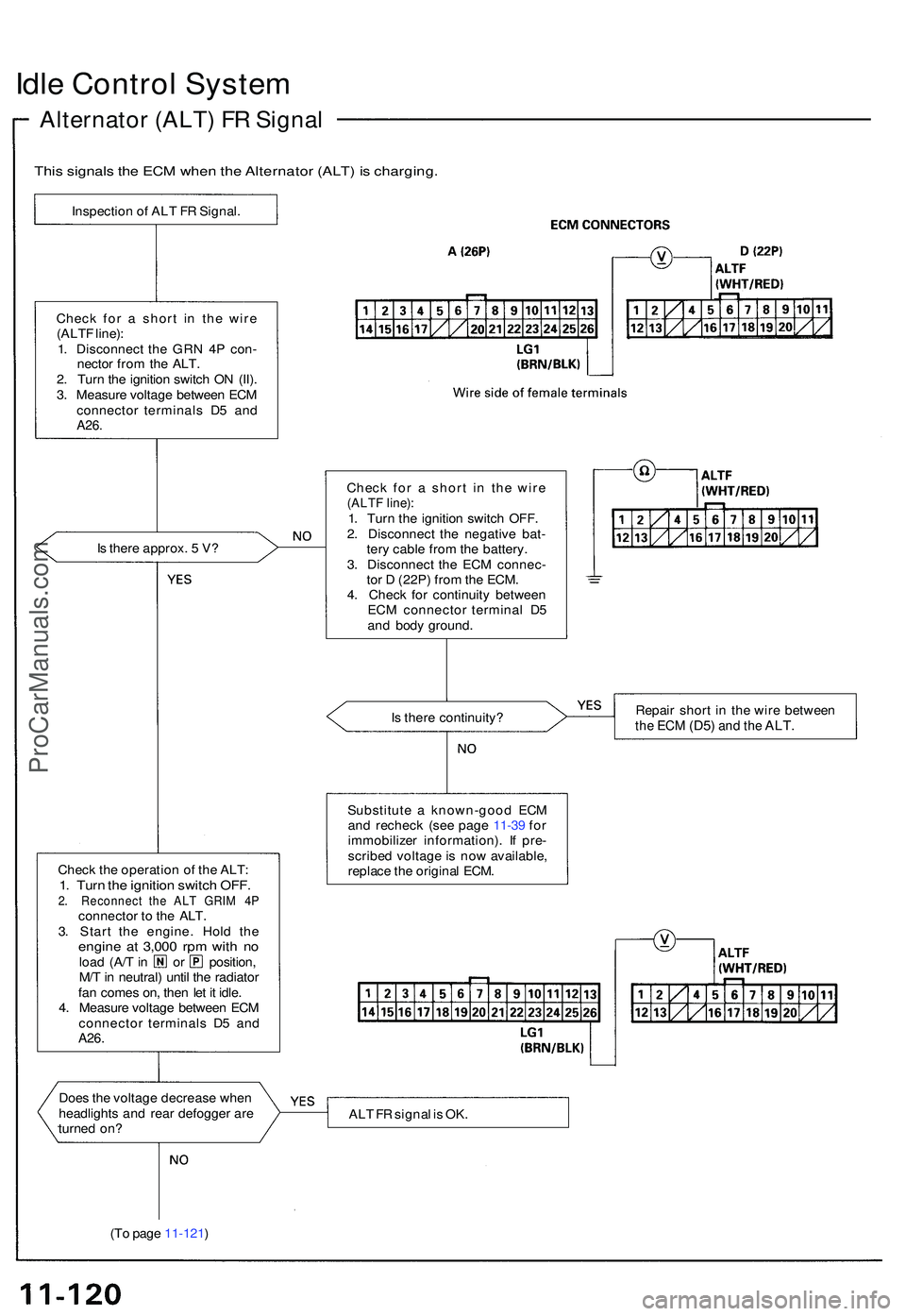

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Inspection o f AL T F R Signal .

Chec k fo r a shor t i n th e wir e

(ALT F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26.

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e AL T GRI M 4 Pconnecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n oloa d (A/ T in o r position ,

M/ T in neutral ) unti l th e radiato r

fa n come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26 .

I

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

(T o pag e 11-121 ) Chec

k fo r a shor t i n th e wir e

(ALT F line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

to r D (22P ) fro m th e ECM .

4 . Chec k fo r continuit y betwee n

EC M connecto r termina l D 5

an d bod y ground .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

the EC M (D5 ) and th e ALT .

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f pre -

scribe d voltag e is no w available ,

replac e th e origina l ECM .

AL T F R signa l i s OK .

ProCarManuals.com

Page 598 of 1503

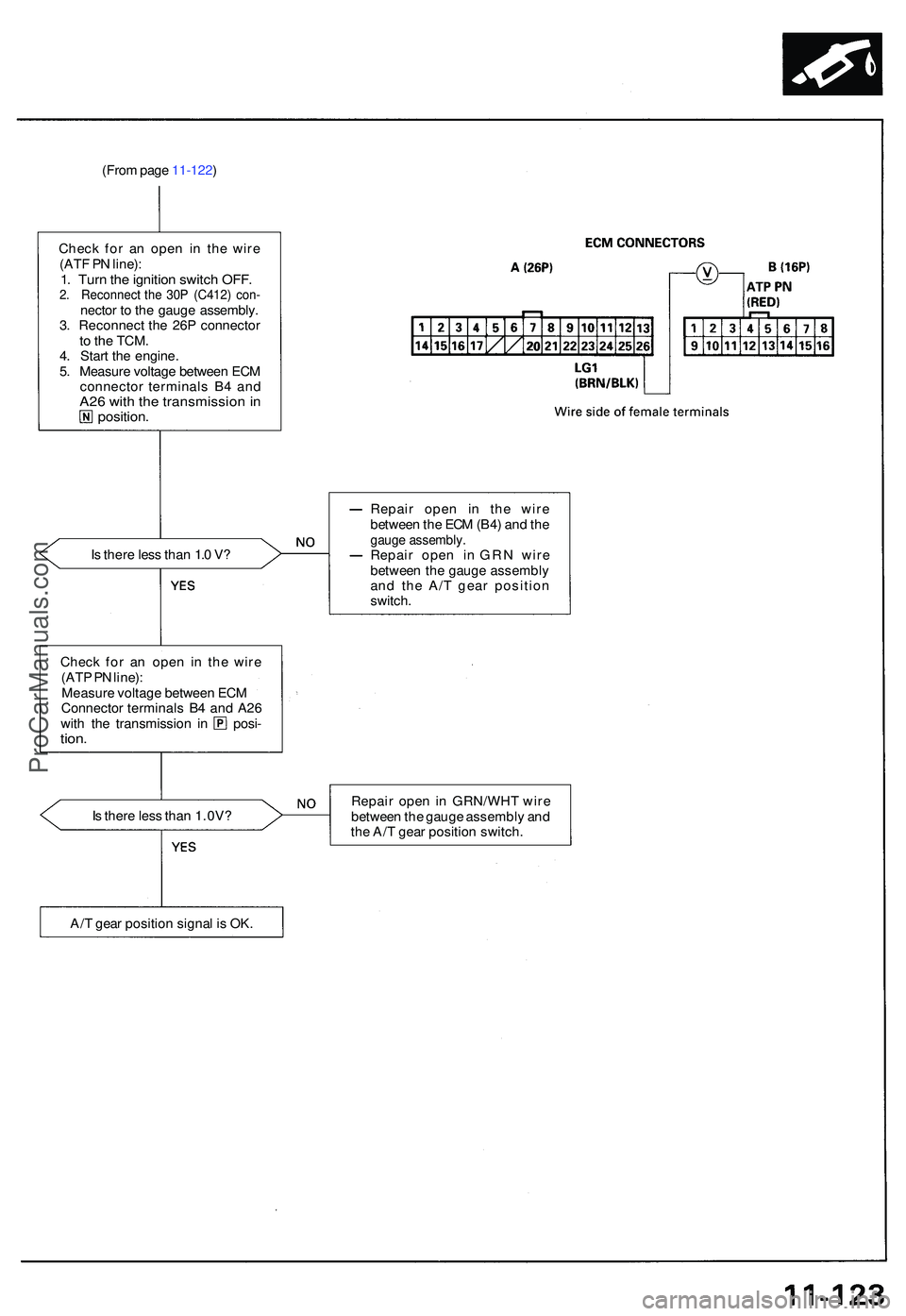

(From pag e 11-122 )

Chec k fo r a n ope n i n th e wir e

(AT F P N line) :

1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e 30 P (C412 ) con -necto r t o th e gaug e assembly .

3 . Reconnec t th e 26 P connecto r

to th e TCM .4. Star t th e engine .

5 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 wit h th e transmissio n inposition .

Is ther e les s tha n 1. 0 V ? Repai

r ope n i n th e wir e

betwee n th e EC M (B4 ) an d th egaug e assembly .Repair ope n i n GR N wir e

betwee n th e gaug e assembl y

an d th e A/ T gea r positio n

switch .

Chec k fo r a n ope n i n th e wir e

(AT P P N line) :

Measur e voltag e betwee n EC M

Connecto r terminal s B 4 an d A2 6

with th e transmissio n i n posi -tion.

Is ther e les s tha n 1.0V ? Repai

r ope n i n GRN/WH T wir e

betwee n th e gaug e assembl y an d

th e A/ T gea r positio n switch .

A/ T gea r positio n signa l i s OK .

ProCarManuals.com

Page 599 of 1503

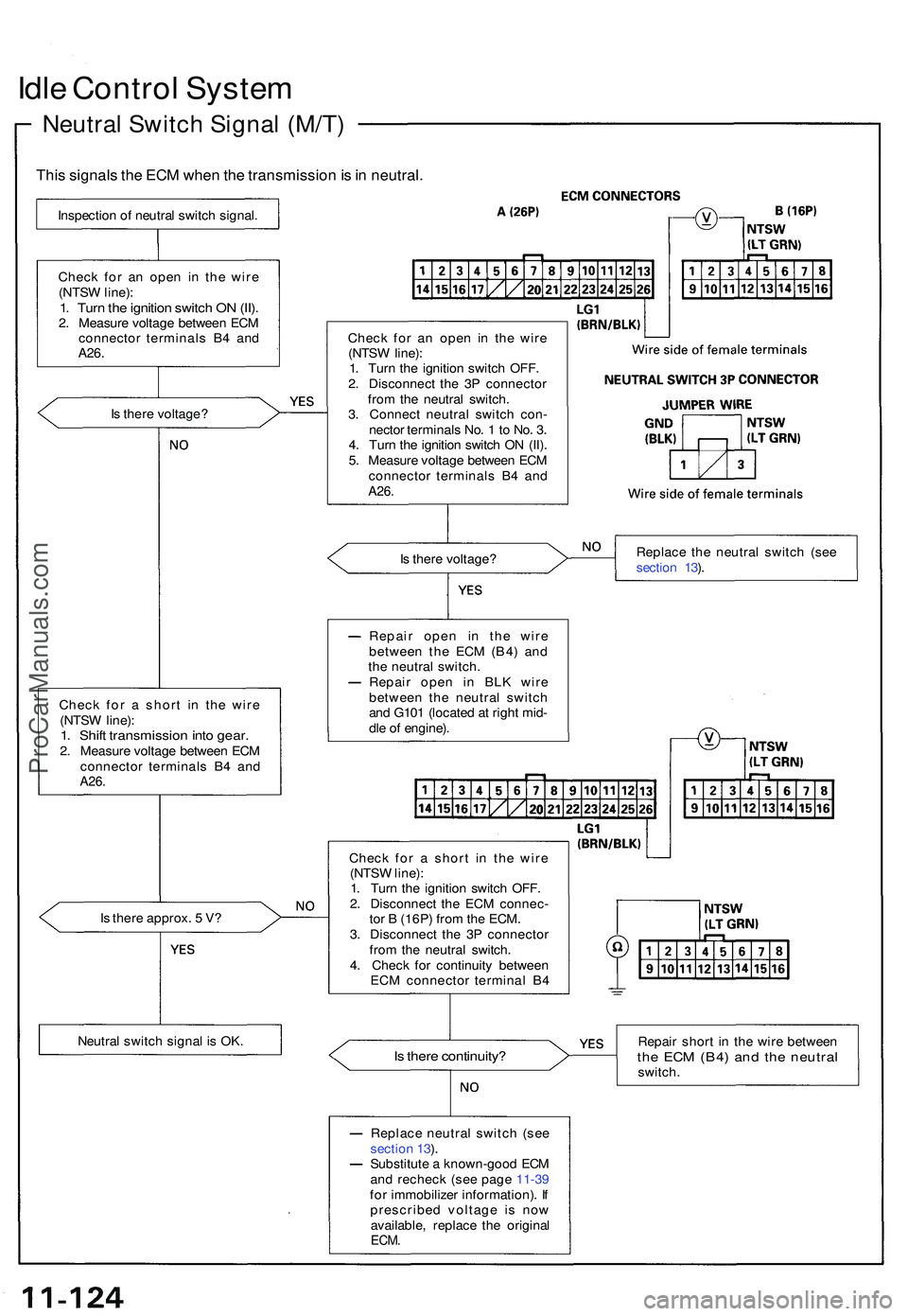

Idle Contro l Syste m

Neutra l Switc h Signa l (M/T )

This signal s th e EC M whe n th e transmissio n is in neutral .

Inspectio n o f neutra l switc h signal .

Chec k fo r a n ope n i n th e wir e

(NTS W line) :

1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

Is ther e voltage ?

Chec k fo r a shor t i n th e wir e

(NTS W line) :

1. Shif t transmissio n int o gear .2. Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

Is ther e approx . 5 V ?

Neutra l switc h signa l i s OK . I

s ther e voltage ? Replac

e th e neutra l switc h (se e

sectio n 13 ).

Repai r ope n i n th e wir e

betwee n th e EC M (B4 ) an d

th e neutra l switch .

Repai r ope n i n BL K wir e

betwee n th e neutra l switc h

an d G10 1 (locate d a t righ t mid -

dl e o f engine) .

Chec k fo r a shor t i n th e wir e

(NTS W line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e EC M connec -

to r B (16P ) fro m th e ECM .

3 . Disconnec t th e 3 P connecto r

fro m th e neutra l switch .

4 . Chec k fo r continuit y betwee n

EC M connecto r termina l B 4

Is ther e continuity ?Repair shor t i n th e wir e betwee nthe EC M (B4 ) an d th e neutralswitch .

Replac e neutra l switc h (se e

sectio n 13 ).

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9

fo r immobilize r information) . I f

prescribe d voltag e i s no w

available , replac e th e origina l

ECM.

Chec k fo r a n ope n i n th e wir e

(NTS W line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e 3 P connecto r

fro m th e neutra l switch .

3 . Connec t neutra l switc h con -

necto r terminal s No . 1 to No . 3 .

4 . Tur n th e ignitio n switc h O N (II) .

5 . Measur e voltag e betwee n EC M

connecto r terminal s B 4 an d

A26 .

ProCarManuals.com

Page 603 of 1503

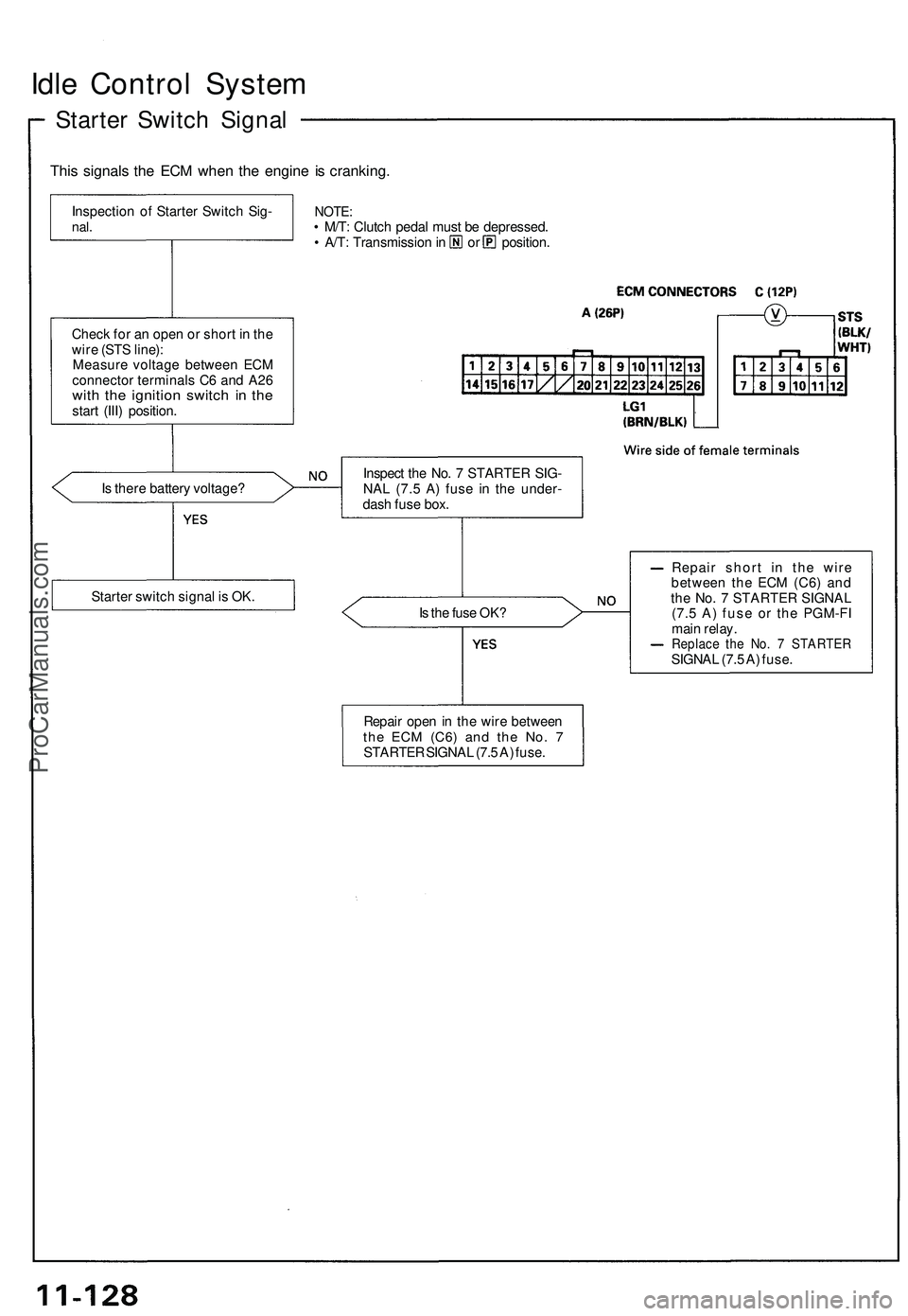

Idle Control System

Starter Switch Signal

This signals the ECM when the engine is cranking.

NOTE:

• M/T: Clutch pedal must be depressed.

• A/T: Transmission in or position.

Is there battery voltage?

Is the fuse OK?

Repair short in the wire

between the ECM (C6) and

the No. 7 STARTER SIGNAL

(7.5 A) fuse or the PGM-FI

main relay.

Replace the No. 7 STARTER

SIGNAL (7.5 A) fuse.

Inspection of Starter Switch Sig-

nal.

Check for an open or short in the

wire (STS line):

Measure voltage between ECM

connector terminals C6 and A26

with the ignition switch in the

start (III) position.

Starter switch signal is OK.

Repair open in the wire between

the ECM

(C6)

and the No. 7

STARTER SIGNAL (7.5 A) fuse.

Inspect the No. 7 STARTER SIG-

NAL (7.5 A) fuse in the under-

dash fuse box.ProCarManuals.com

Page 604 of 1503

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE : Befor e settin g th e idl e speed , chec k th e thes e

items :

Th e MI L ha s no t bee n reporte d on .

Ignitio n timin g

Spark plug s

Air cleane r

PCV syste m

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n tur n th e ignitio n

switch OFF .

2. Connec t th e SC S servic e connecto r t o servic e chec k

connector .

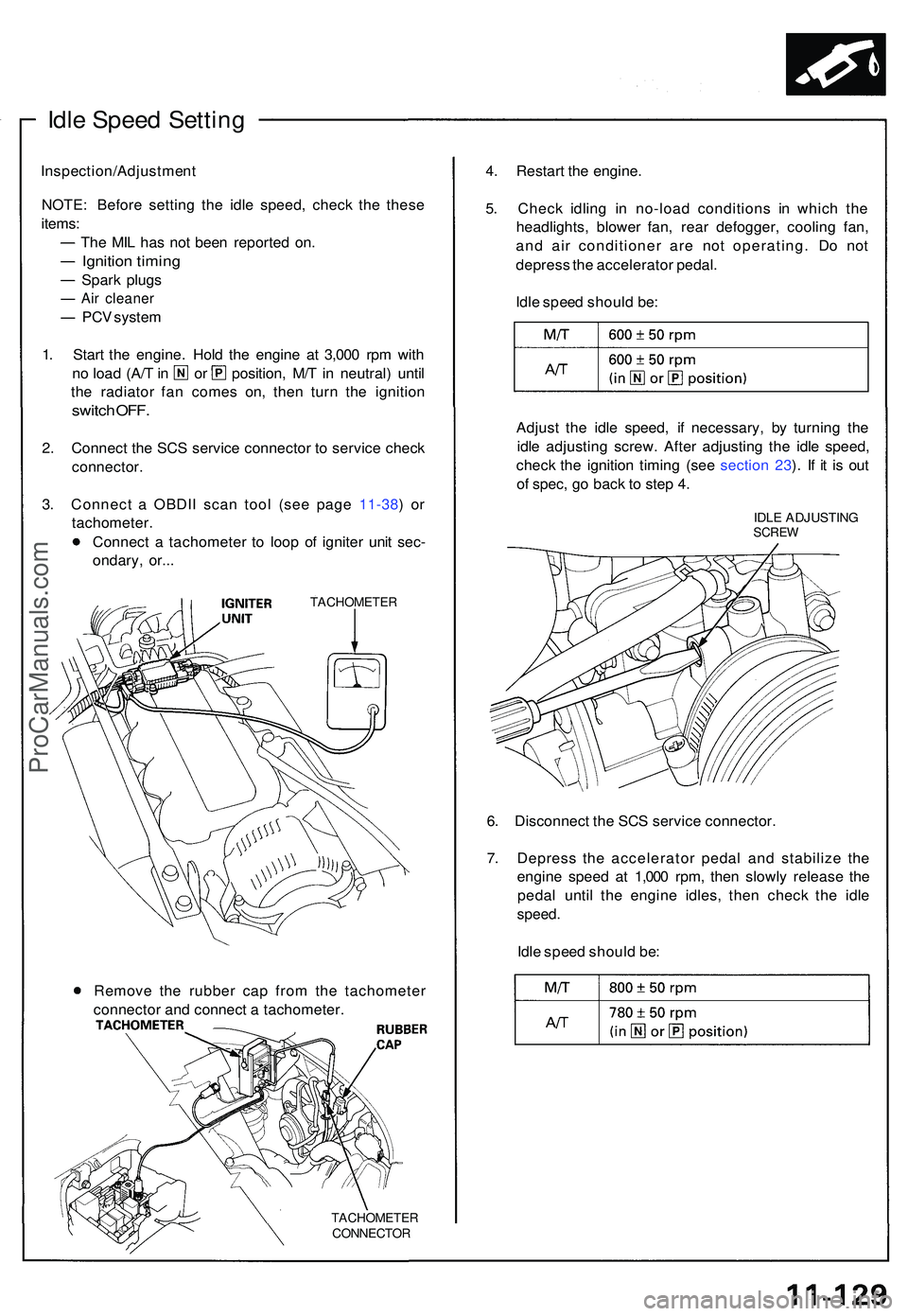

3. Connec t a OBDI I sca n too l (se e pag e 11-38 ) o r

tachometer .

Connec t a tachomete r t o loo p o f ignite r uni t sec -

ondary , or.. .

TACHOMETE R

TACHOMETE R

CONNECTOR

4. Restar t th e engine .

5 . Chec k idlin g i n no-loa d condition s i n whic h th e

headlights , blowe r fan , rea r defogger , coolin g fan ,

an d ai r conditione r ar e no t operating . D o no t

depres s th e accelerato r pedal .

Idl e spee d shoul d be :

Adjus t th e idl e speed , i f necessary , b y turnin g th e

idl e adjustin g screw . Afte r adjustin g th e idl e speed ,

chec k th e ignitio n timin g (se e sectio n 23 ). I f i t i s ou t

o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN GSCREW

6. Disconnec t th e SC S servic e connector .

7 . Depres s th e accelerato r peda l an d stabiliz e th e

engin e spee d a t 1,00 0 rpm , the n slowl y releas e th e

peda l unti l th e engin e idles , the n chec k th e idl e

speed .

Idle spee d shoul d be :

Remov e th e rubbe r ca p fro m th e tachomete r

connecto r an d connec t a tachometer .

ProCarManuals.com

Page 607 of 1503

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump, fuel pump relay, fuel pump

resistor PGM-FI main relay, fuel filter, fuel pressure regu-

lator, fuel injectors, injector resistor (A/T), and fuel deliv-

ery and return lines. This system delivers pressure-regu-

lated fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.ProCarManuals.com

Page 609 of 1503

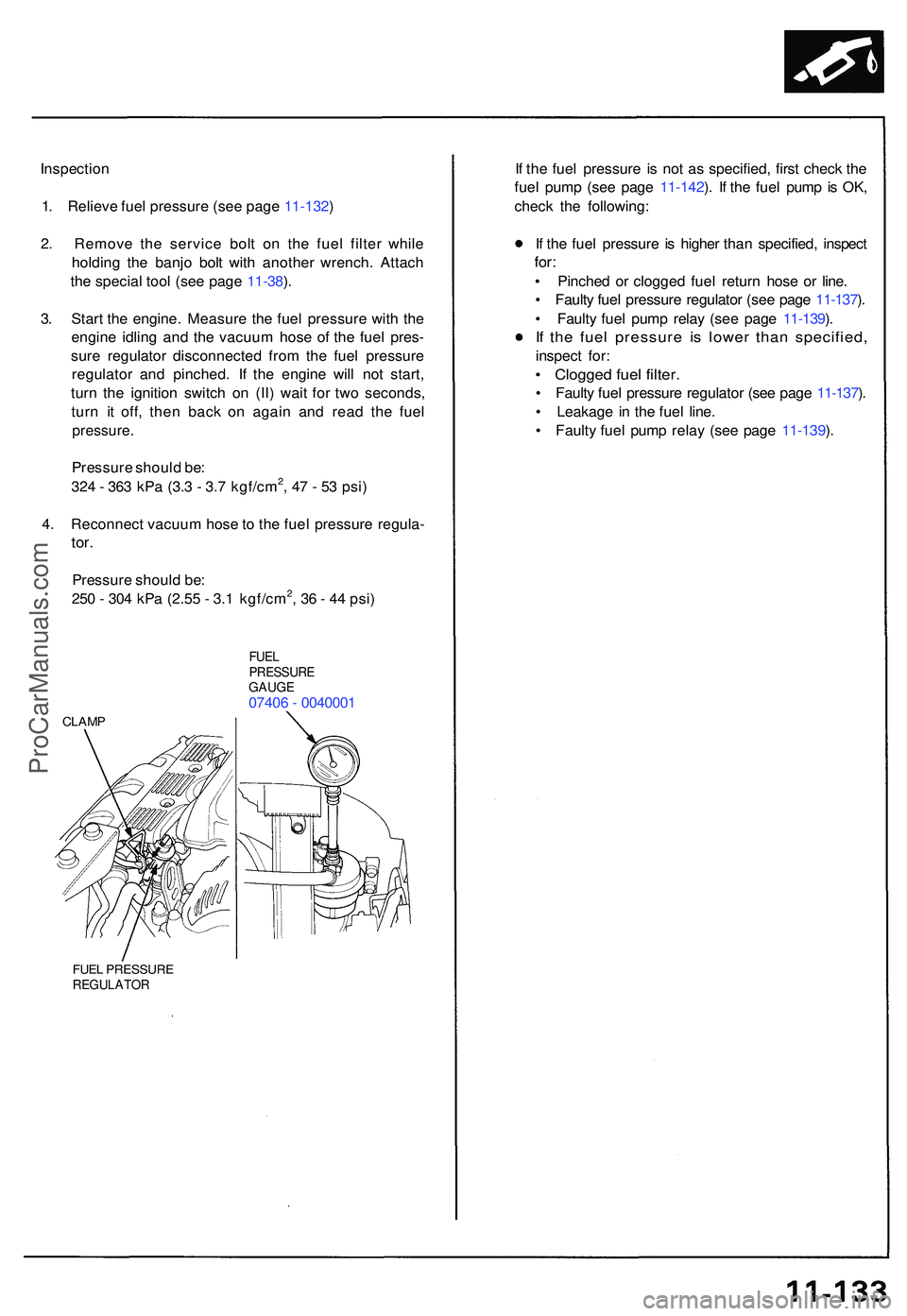

Inspection

1 . Reliev e fue l pressur e (se e pag e 11-132 )

2 . Remov e th e servic e bol t o n th e fue l filte r whil e

holdin g th e banj o bol t wit h anothe r wrench . Attac h

th e specia l too l (se e pag e 11-38 ).

3 . Star t th e engine . Measur e th e fue l pressur e wit h th e

engin e idlin g an d th e vacuu m hos e o f th e fue l pres -

sur e regulato r disconnecte d fro m th e fue l pressur e

regulato r an d pinched . I f th e engin e wil l no t start ,

tur n th e ignitio n switc h o n (II ) wai t fo r tw o seconds ,

tur n i t off , the n bac k o n agai n an d rea d th e fue l

pressure .

Pressure shoul d be :

32 4 - 36 3 kP a (3. 3 - 3. 7 kgf/cm2, 4 7 - 5 3 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

25 0 - 30 4 kP a (2.5 5 - 3. 1 kgf/cm2, 3 6 - 4 4 psi )

FUE LPRESSUR EGAUGE07406 - 004000 1

CLAMP

FUEL PRESSUR EREGULATO R

If th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p is OK ,

chec k th e following :

I f th e fue l pressur e i s highe r tha n specified , inspec t

for:

• Pinche d o r clogge d fue l retur n hos e o r line .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Fault y fue l pum p rela y (se e pag e 11-139 ).

If th e fue l pressur e i s lowe r tha n specified ,

inspect for :

• Clogge d fue l filter .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Leakag e i n th e fue l line .

• Fault y fue l pum p rela y (se e pag e 11-139 ).

ProCarManuals.com

Page 617 of 1503

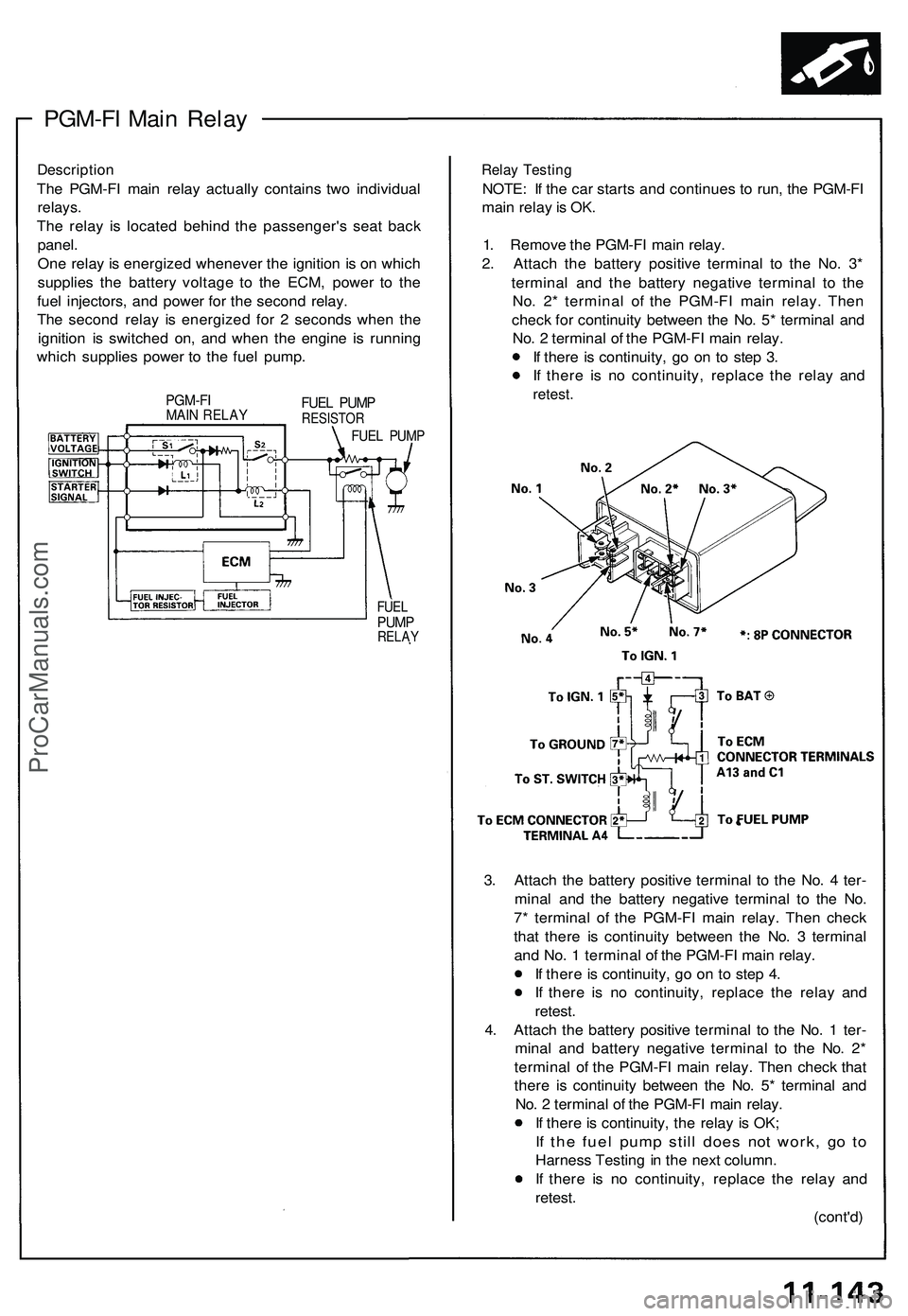

PGM-FI Main Relay

Description

The PGM-FI main relay actually contains two individual

relays.

The relay is located behind the passenger's seat back

panel.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay.

The second relay is energized for 2 seconds when the

ignition is switched on, and when the engine is running

which supplies power to the fuel pump.

PGM-FI

MAIN RELAY

FUEL PUMP

RESISTOR

FUEL PUMP

FUEL

PUMP

RELAY

Relay Testing

NOTE: If the car starts and continues to run, the PGM-FI

main relay is OK.

1. Remove the PGM-FI main relay.

2. Attach the battery positive terminal to the No. 3*

terminal and the battery negative terminal to the

No. 2* terminal of the PGM-FI main relay. Then

check for continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, go on to step 3.

If there is no continuity, replace the relay and

retest.

3. Attach the battery positive terminal to the No. 4 ter-

minal and the battery negative terminal to the No.

7* terminal of the PGM-FI main relay. Then check

that there is continuity between the No. 3 terminal

and No. 1 terminal of the PGM-FI main relay.

If there is continuity, go on to step 4.

If there is no continuity, replace the relay and

retest.

4. Attach the battery positive terminal to the No. 1 ter-

minal and battery negative terminal to the No. 2*

terminal of the PGM-FI main relay. Then check that

there is continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, the relay is OK;

If the fuel pump still does not work, go to

Harness Testing in the next column.

If there is no continuity, replace the relay and

retest.

(cont'd)ProCarManuals.com

Page 618 of 1503

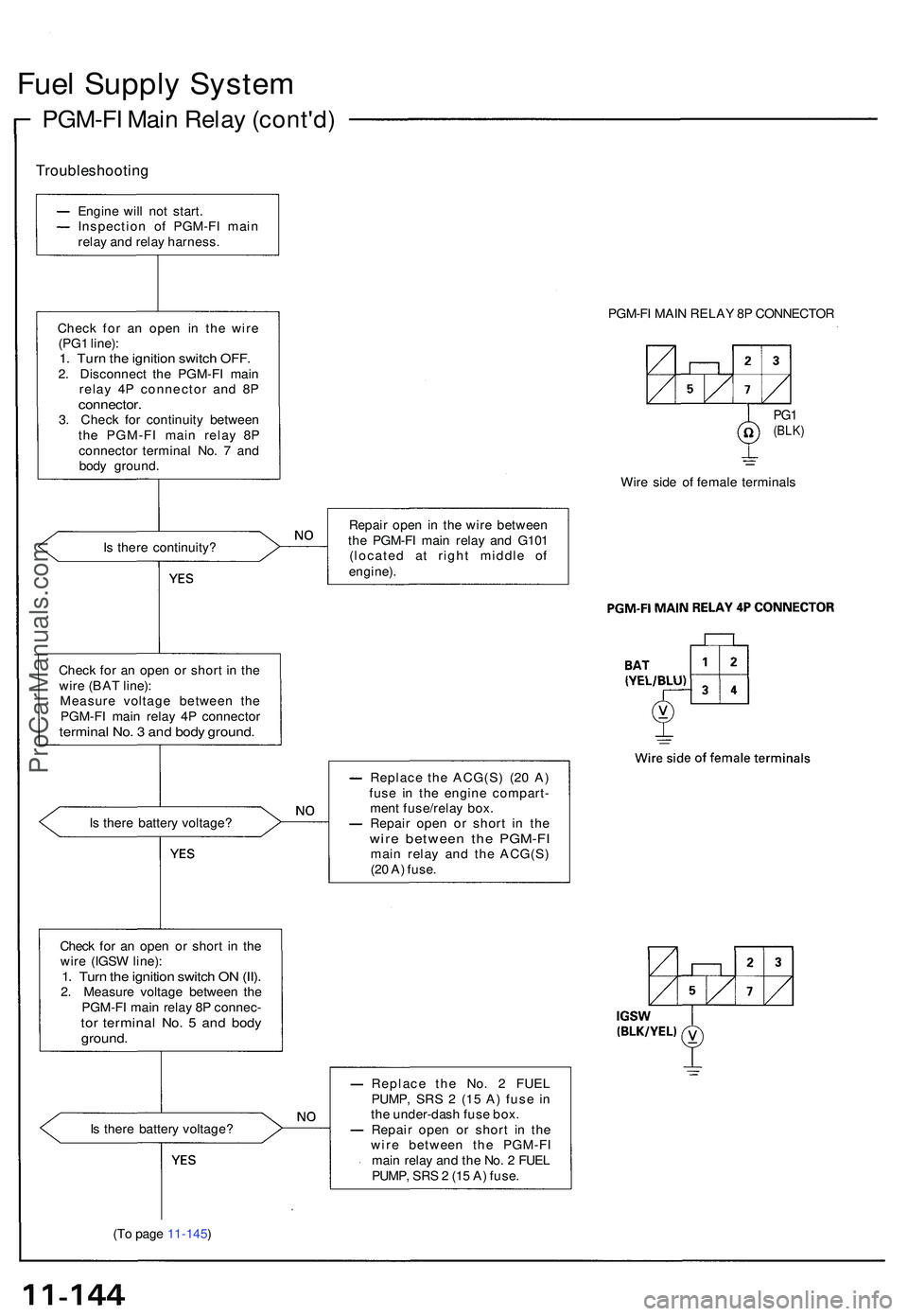

Fuel Suppl y Syste m

PGM-F I Mai n Rela y (cont'd )

Troubleshootin g

Engine wil l no t start .

Inspectio n o f PGM-F I mai n

rela y an d rela y harness .

Chec k fo r a n ope n i n th e wir e

(PG 1 line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e PGM-F I mai n

rela y 4 P connecto r an d 8 P

connector .3. Chec k fo r continuit y betwee n

th e PGM-F I mai n rela y 8 P

connecto r termina l No . 7 an d

bod y ground .

I s ther e continuity ?

Chec k fo r a n ope n o r shor t i n th e

wir e (BA T line) :

Measur e voltag e betwee n th e

PGM-F I mai n rela y 4 P connecto r

terminal No . 3 an d bod y ground .

Is ther e batter y voltage ?

Chec k fo r a n ope n o r shor t i n th e

wir e (IGS W line) :

1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n th e

PGM-F I mai n rela y 8 P connec -

tor termina l No . 5 an d bod yground .

PGM-FI MAI N RELA Y 8 P CONNECTO R

PG1(BLK )

Wire sid e o f femal e terminal s

Repai r ope n i n th e wir e betwee n

th e PGM-F I mai n rela y an d G10 1

(locate d a t righ t middl e o f

engine) .

Replac e th e ACG(S ) (2 0 A )

fus e i n th e engin e compart -

men t fuse/rela y box .

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F Imain rela y an d th e ACG(S )

(2 0 A ) fuse .

I s ther e batter y voltage ?

(T o pag e 11-145 ) Replac

e th e No . 2 FUE L

PUMP , SR S 2 (1 5 A ) fus e i n

th e under-das h fus e box .

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 2 FUE L

PUMP , SR S 2 (1 5 A ) fuse .

ProCarManuals.com

Page 622 of 1503

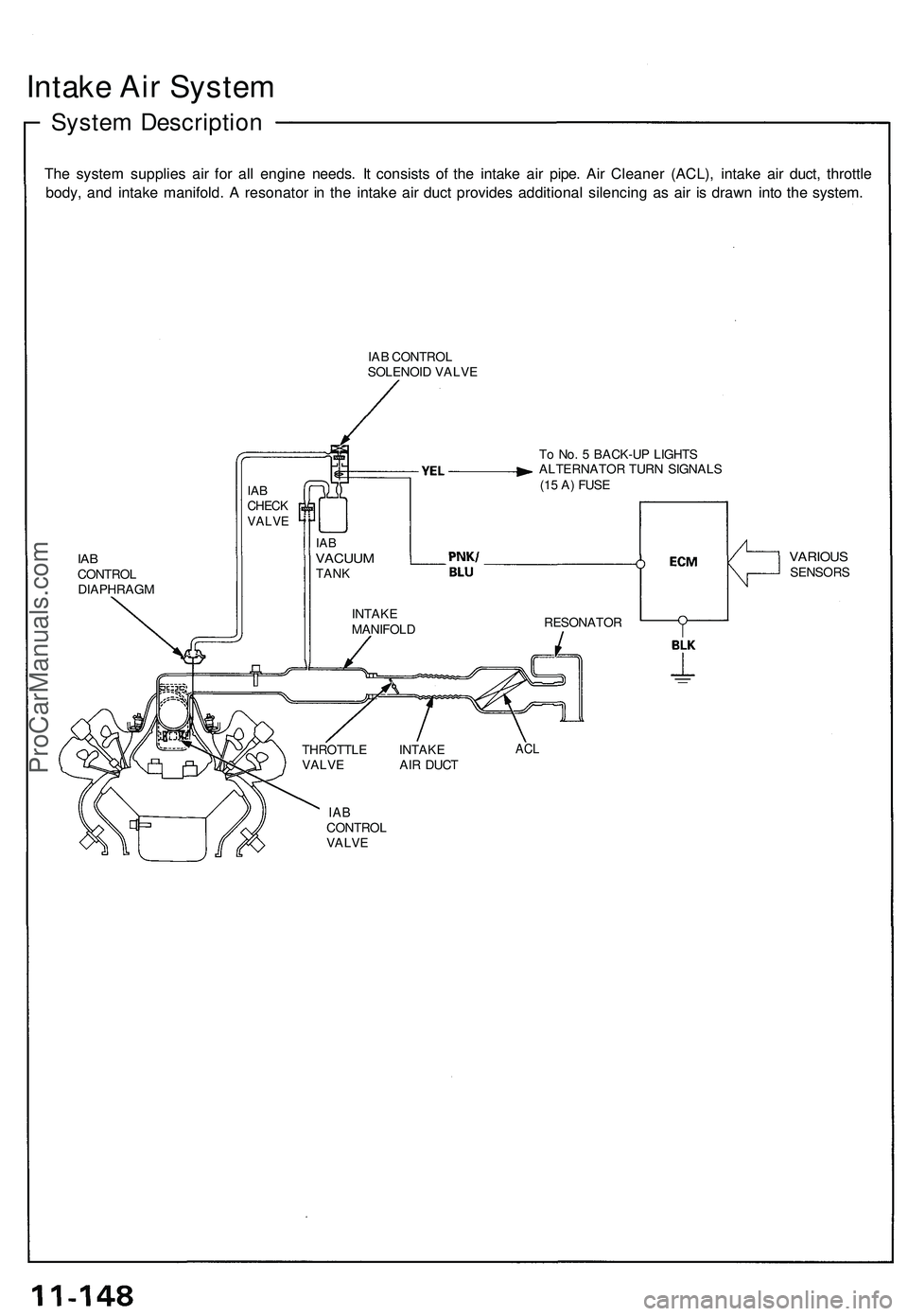

Intake Ai r Syste m

System Descriptio n

The syste m supplie s ai r fo r al l engine needs. I t consist s o f th e intak e ai r pipe . Ai r Cleane r (ACL) , intak e ai r duct , throttl e

body , an d intak e manifold . A resonato r i n th e intak e ai r duc t provide s additiona l silencin g a s ai r i s draw n int o th e system .

IAB CONTRO L

SOLENOI D VALV E

To No . 5 BACK-U P LIGHT S

ALTERNATO R TUR N SIGNAL S

(1 5 A ) FUS E

IABCONTRO L

DIAPHRAG M

THROTTLE INTAK E

VALV E AI R DUC T

VARIOU SSENSOR S

ACL

IABCONTRO LVALVE

INTAK E

MANIFOL DRESONATO R

IABCHEC KVALV E

IABVACUU MTANK

ProCarManuals.com