engine ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 523 of 1503

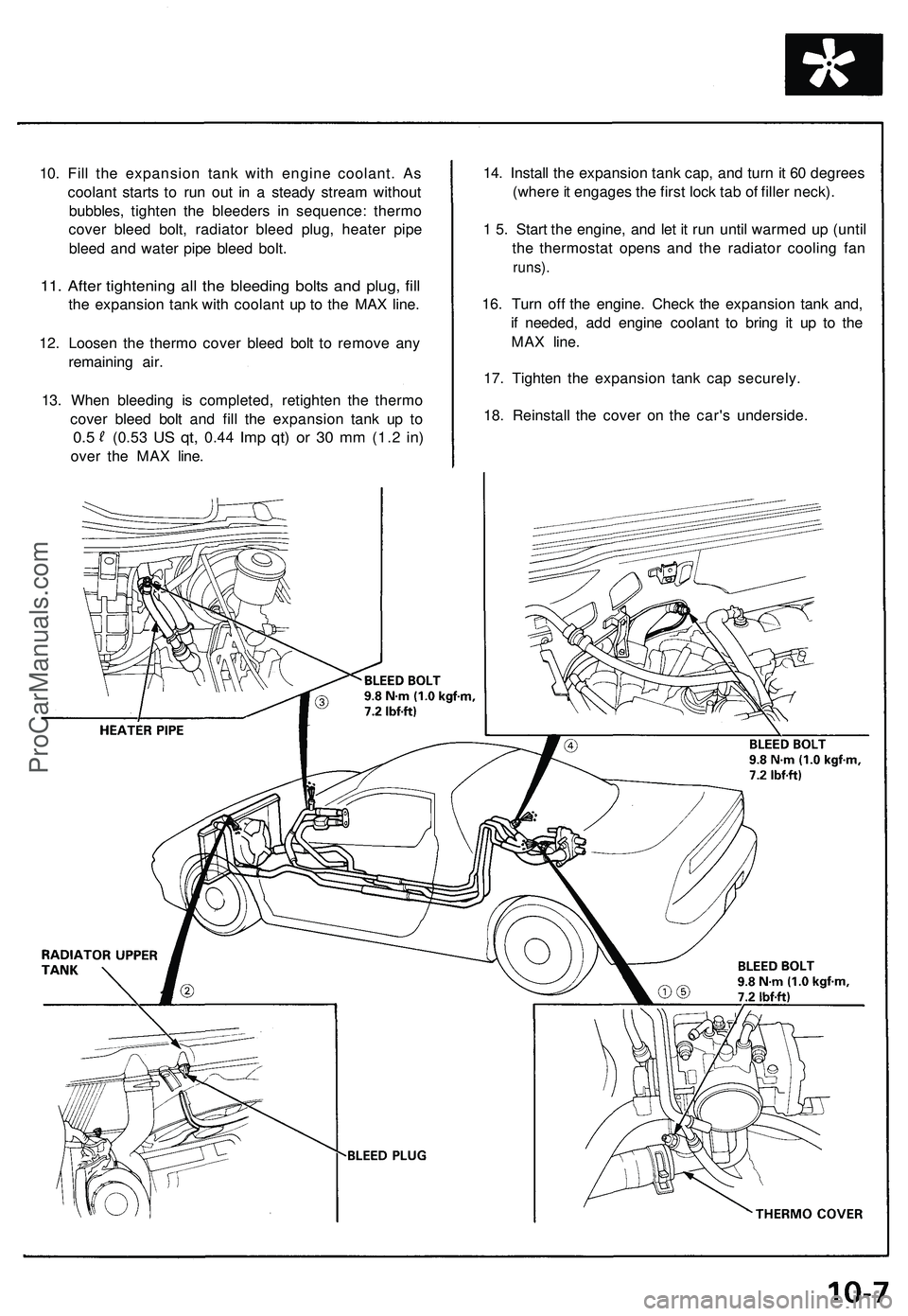

10. Fill the expansion tank with engine coolant. As

coolant starts to run out in a steady stream without

bubbles, tighten the bleeders in sequence: thermo

cover bleed bolt, radiator bleed plug, heater pipe

bleed and water pipe bleed bolt.

11. After tightening all the bleeding bolts and plug, fill

the expansion tank with coolant up to the MAX line.

12. Loosen the thermo cover bleed bolt to remove any

remaining air.

13. When bleeding is completed, retighten the thermo

cover bleed bolt and fill the expansion tank up to

0.5

(0.53

US qt,

0.44

Imp qt) or 30 mm

(1.2

in)

over the MAX line.

14. Install the expansion tank cap, and turn it 60 degrees

(where it engages the first lock tab of filler neck).

1 5. Start the engine, and let it run until warmed up (until

the thermostat opens and the radiator cooling fan

runs).

16. Turn off the engine. Check the expansion tank and,

if needed, add engine coolant to bring it up to the

MAX line.

17. Tighten the expansion tank cap securely.

18. Reinstall the cover on the car's underside.ProCarManuals.com

Page 526 of 1503

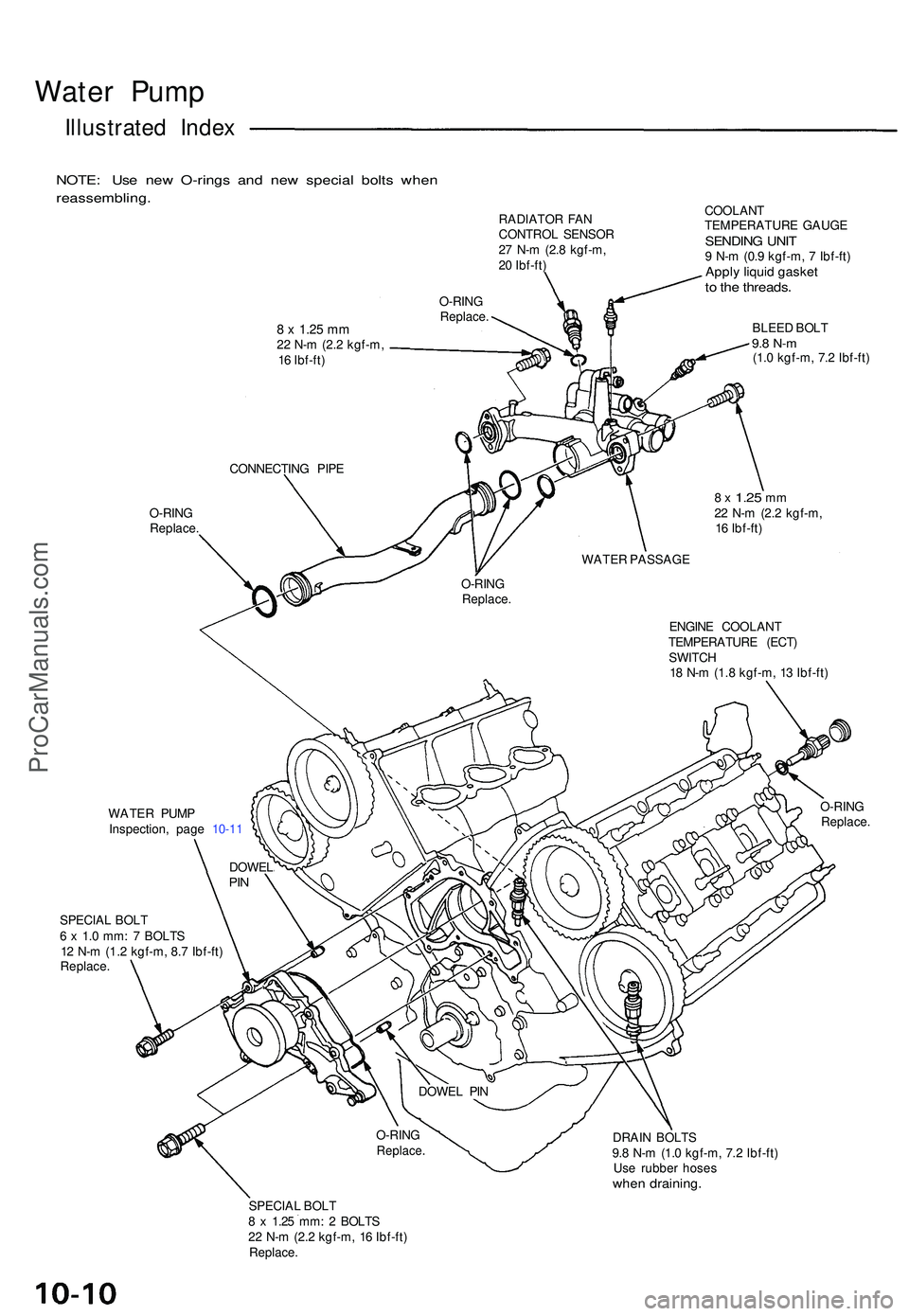

Water Pum p

Illustrate d Inde x

NOTE : Us e ne w O-ring s an d ne w specia l bolt s whe n

reassembling .

RADIATOR FA N

CONTRO L SENSO R

2 7 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft ) O-RIN

G

Replace .

O-RING

Replace . COOLAN

T

TEMPERATUR E GAUG E

SENDIN G UNI T9 N- m (0. 9 kgf-m , 7 Ibf-ft )Apply liqui d gaske tto th e threads .

BLEED BOL T9.8 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

CONNECTIN G PIP E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

WATE R PASSAG E

O-RIN G

Replace .

ENGINE COOLAN T

TEMPERATUR E (ECT )

SWITC H

1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

WATE R PUM P

Inspection , pag e 10-1 1 O-RIN

G

Replace .

SPECIAL BOL T

6 x 1. 0 mm : 7 BOLT S

1 2 N- m (1.2 kgf-m , 8. 7 Ibf-ft )

Replace .

DRAIN BOLT S

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Us e rubbe r hose s

when draining .

SPECIAL BOL T

8 x 1.2 5 mm : 2 BOLT S

2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Replace .

DOWELPIN

DOWE L PI N

O-RIN G

Replace .

ProCarManuals.com

Page 552 of 1503

![ACURA NSX 1997 Service Repair Manual

System Description

System Connectors [Engine Compartment (Left Side)] (cont'd)ProCarManuals.com ACURA NSX 1997 Service Repair Manual

System Description

System Connectors [Engine Compartment (Left Side)] (cont'd)ProCarManuals.com](/img/32/56989/w960_56989-551.png)

System Description

System Connectors [Engine Compartment (Left Side)] (cont'd)ProCarManuals.com

Page 565 of 1503

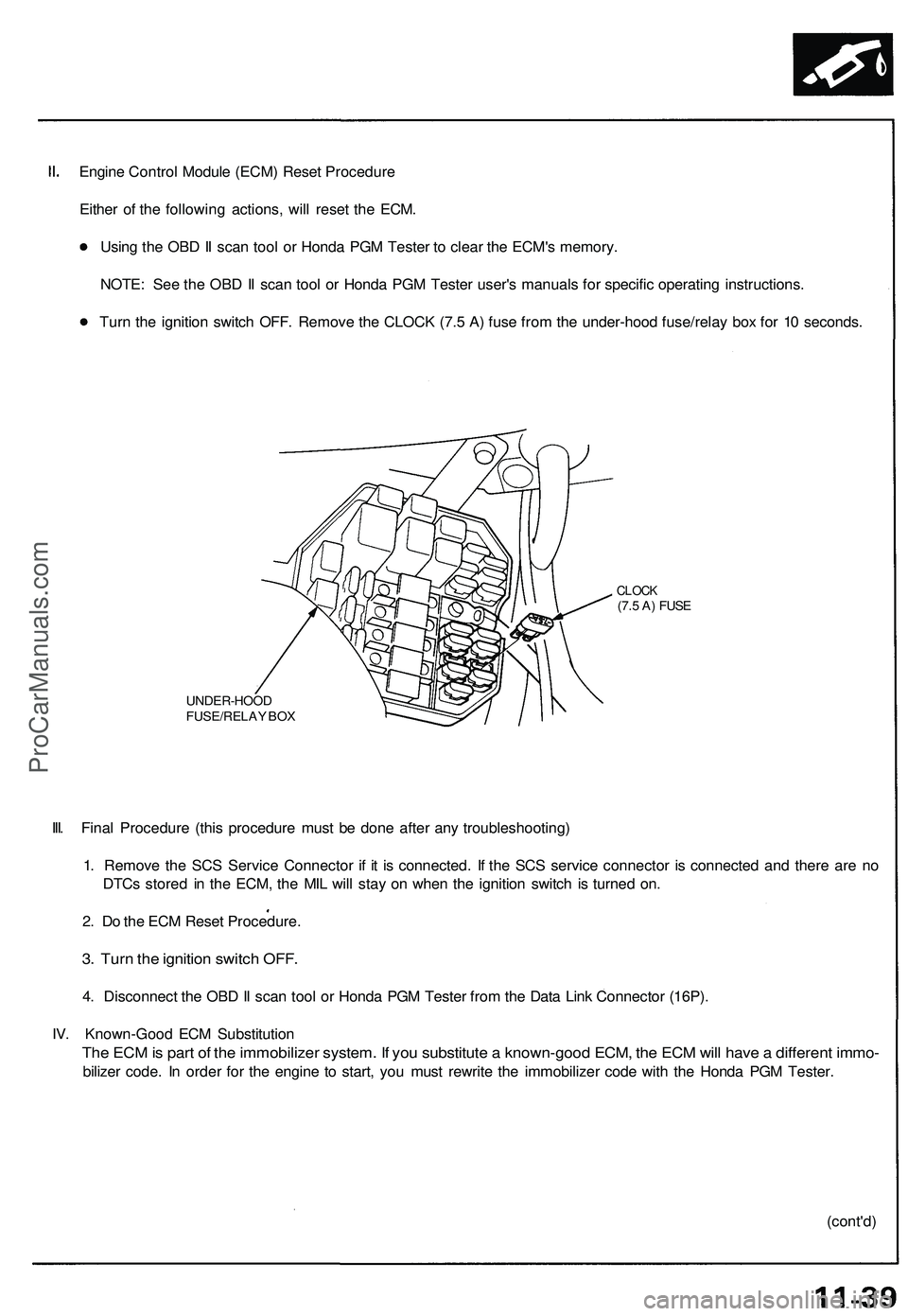

Engine Control Module (ECM) Reset Procedure

Either of the following actions, will reset the ECM.

Using the OBD II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

Turn the ignition switch OFF. Remove the CLOCK (7.5 A) fuse from the under-hood fuse/relay box for 10 seconds.

UNDER-HOOD

FUSE/RELAY BOX

CLOCK

(7.5 A) FUSE

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected. If the SCS service connector is connected and there are no

DTCs stored in the ECM, the MIL will stay on when the ignition switch is turned on.

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD II scan tool or Honda PGM Tester from the Data Link Connector (16P).

IV. Known-Good ECM Substitution

The ECM is part of the immobilizer system. If you substitute a known-good ECM, the ECM will have a different immo-

bilizer code. In order for the engine to start, you must rewrite the immobilizer code with the Honda PGM Tester.

(cont'd)ProCarManuals.com

Page 567 of 1503

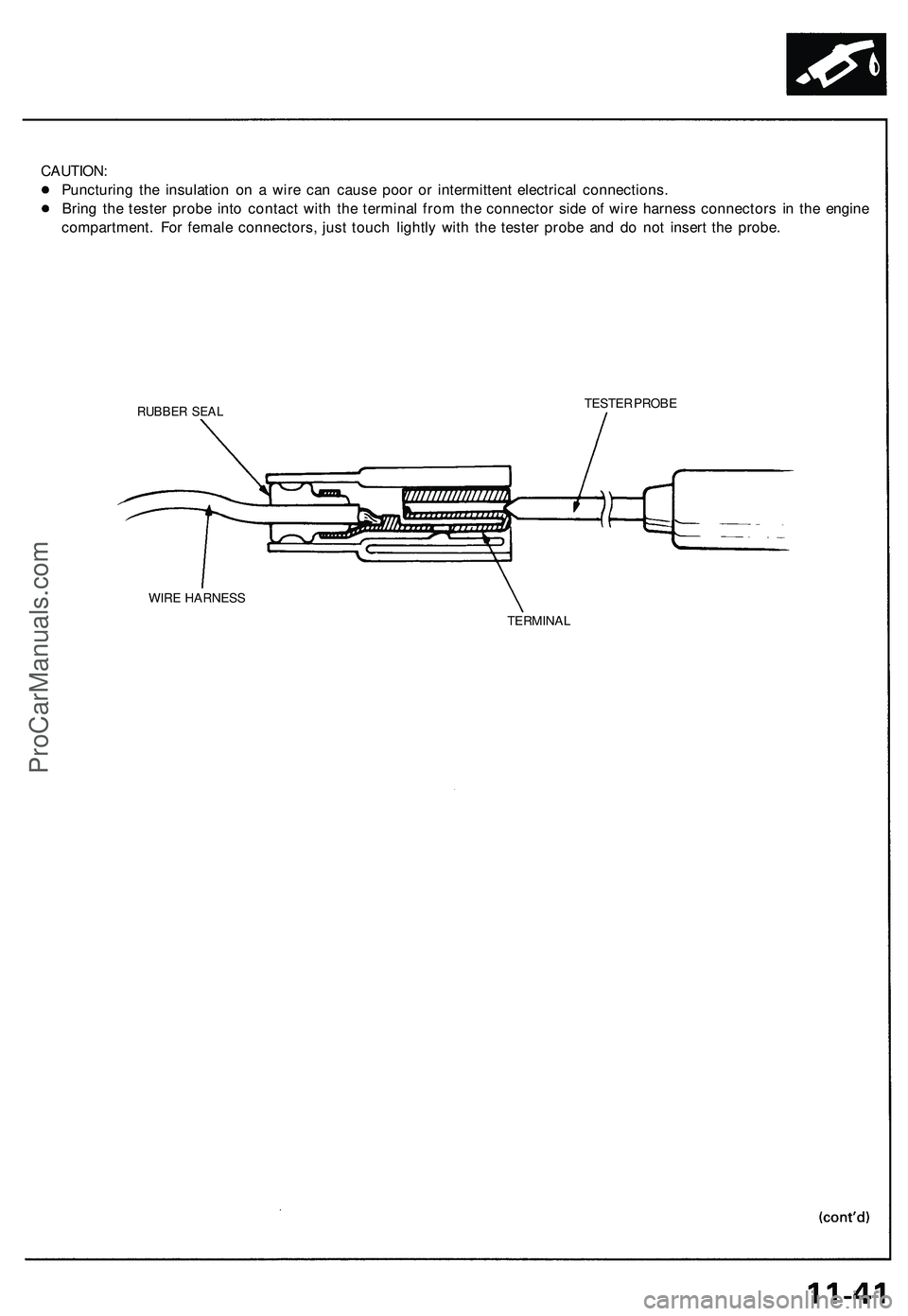

CAUTION:

Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

Bring the tester probe into contact with the terminal from the connector side of wire harness connectors in the engine

compartment. For female connectors, just touch lightly with the tester probe and do not insert the probe.

RUBBER SEAL

WIRE HARNESS

TERMINAL

TESTER PROBEProCarManuals.com

Page 568 of 1503

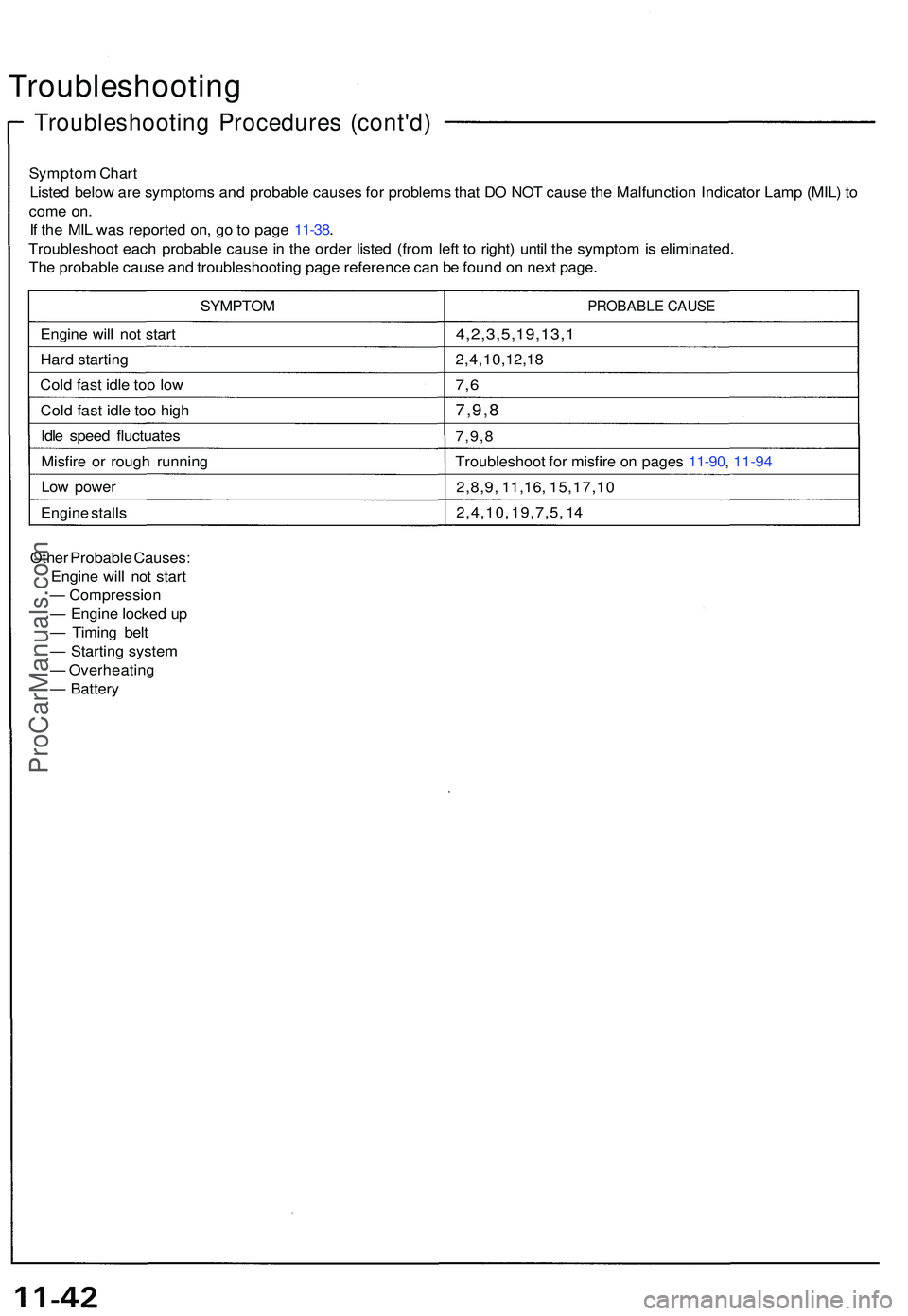

Troubleshooting

Troubleshooting Procedure s (cont'd )

Sympto m Char t

Liste d belo w ar e symptom s an d probabl e cause s fo r problem s tha t D O NO T caus e th e Malfunctio n Indicato r Lam p (MIL ) t o

com e on .

I f th e MI L wa s reporte d on , g o to pag e 11-38 .

Troubleshoo t eac h probabl e caus e in th e orde r liste d (fro m lef t t o right ) unti l th e sympto m is eliminated .

Th e probabl e caus e an d troubleshootin g pag e referenc e ca n b e foun d o n nex t page .

Othe r Probabl e Causes :

Engin e wil l no t start

— Compressio n

— Engin e locke d u p

— Timin g bel t

— Startin g syste m

— Overheatin g

— Batter y Troubleshoo

t fo r misfir e o n page s 11-90 , 11-9 4

PROBABL E CAUS ESYMPTO M

Engine wil l no t start

Har d startin g

Col d fas t idl e to o lo w

Col d fas t idl e to o hig h

Idl e spee d fluctuate s

Misfir e o r roug h runnin g

Lo w powe r

Engin e stall s4,2,3,5,19,13, 1

2,4,10,12,1 8

7,6

7,9, 8

7,9,8

2,8,9 , 11,16 , 15,17,1 0

2,4,10 , 19,7,5 , 1 4

ProCarManuals.com

Page 570 of 1503

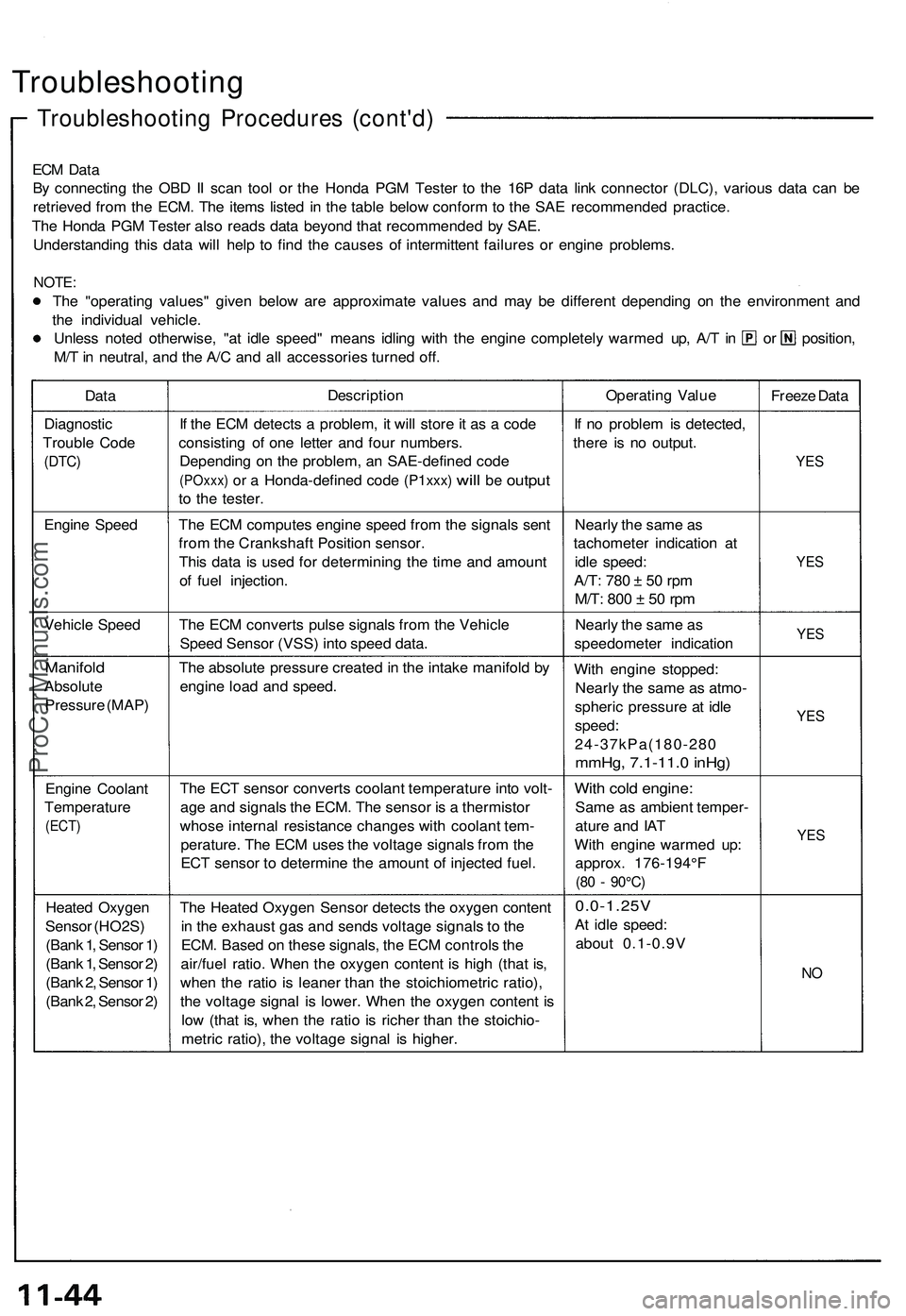

Troubleshooting

Troubleshooting Procedures (cont'd)

ECM Data

By connecting the OBD II scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can be

retrieved from the ECM. The items listed in the table below conform to the SAE recommended practice.

The Honda PGM Tester also reads data beyond that recommended by SAE.

Understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The "operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up, A/T in or position,

M/T in neutral, and the A/C and all accessories turned off.

Data

Description

Operating Value

Freeze Data

Diagnostic

Trouble Code

(DTC)

If the ECM detects a problem, it will store it as a code

consisting of one letter and four numbers.

Depending on the problem, an SAE-defined code

(POxxx)

or a

Honda-defined code

(P1xxx)

will

be

output

to the tester.

If no problem is detected,

there is no output.

YES

Engine Speed

The ECM computes engine speed from the signals sent

from the Crankshaft Position sensor.

This data is used for determining the time and amount

of fuel injection.

Nearly the same as

tachometer indication at

idle speed:

A/T:

780 ± 50 rpm

M/T:

800 ± 50 rpm

YES

Vehicle Speed

The ECM converts pulse signals from the Vehicle

Speed Sensor (VSS) into speed data.

Nearly the same as

speedometer indication

YES

Manifold

Absolute

Pressure (MAP)

The absolute pressure created in the intake manifold by

engine load and speed.

With engine stopped:

Nearly the same as atmo-

spheric pressure at idle

speed:

24-37kPa(180-280

mmHg, 7.1-11.0 inHg)

YES

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM. The sensor is a thermistor

whose internal resistance changes with coolant tem-

perature. The ECM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel.

With cold engine:

Same as ambient temper-

ature and IAT

With engine warmed up:

approx. 176-194°F

(80 - 90°C)

YES

Heated Oxygen

Sensor (HO2S)

(Bank 1, Sensor 1)

(Bank 1, Sensor 2)

(Bank 2, Sensor 1)

(Bank 2, Sensor 2)

The Heated Oxygen Sensor detects the oxygen content

in the exhaust gas and sends voltage signals to the

ECM. Based on these signals, the ECM controls the

air/fuel ratio. When the oxygen content is high (that is,

when the ratio is leaner than the stoichiometric ratio),

the voltage signal is lower. When the oxygen content is

low (that is, when the ratio is richer than the stoichio-

metric ratio), the voltage signal is higher.

0.0-1.25V

At idle speed:

about 0.1-0.9V

NOProCarManuals.com

Page 571 of 1503

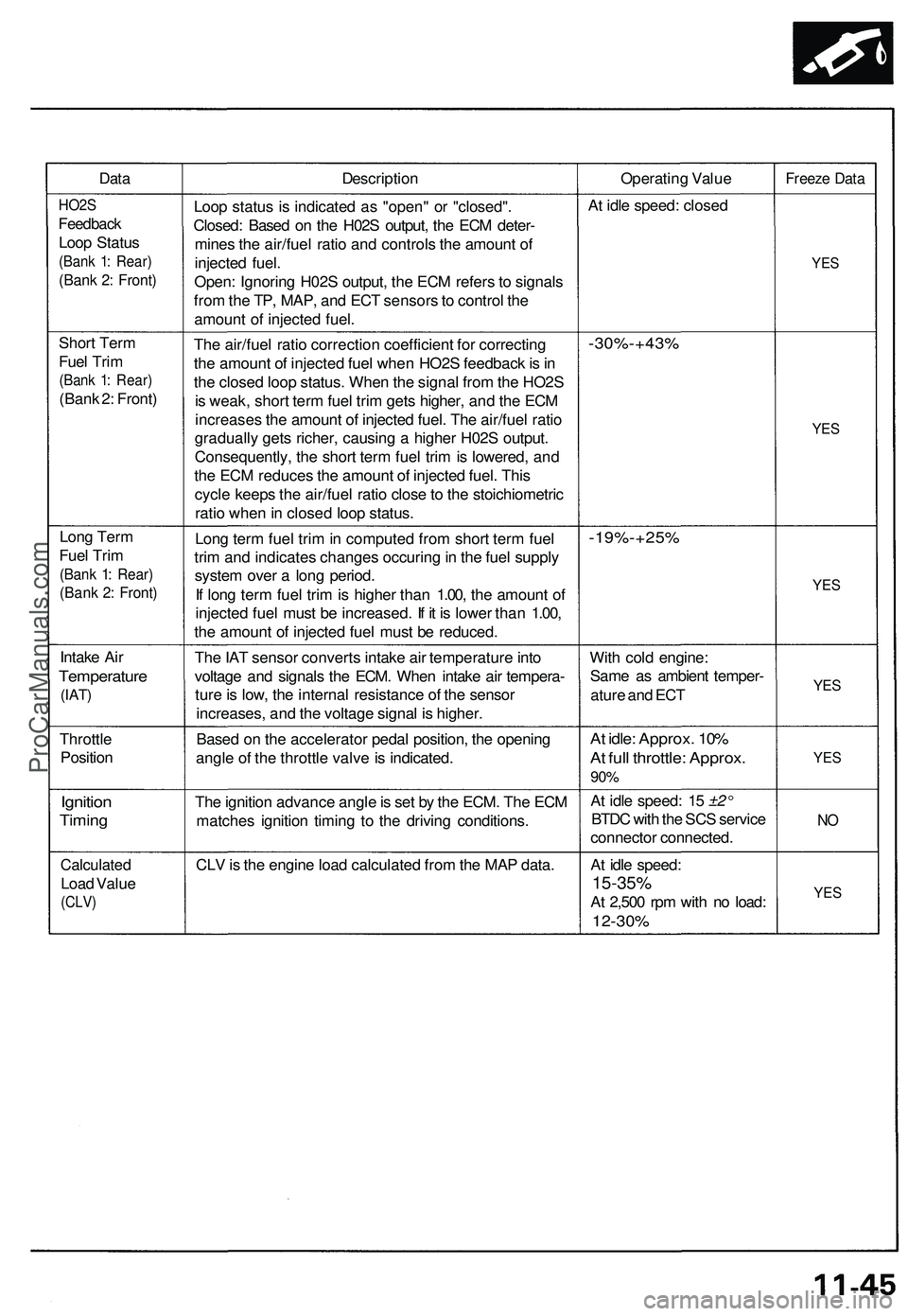

DataDescriptio nOperating Valu eFreez e Dat a

HO2 S

Feedbac k

Loop Statu s

(Bank 1 : Rear )

(Bank 2 : Front )

Loop statu s i s indicate d a s "open " o r "closed" .

Closed : Base d o n th e H02 S output , th e EC M deter -

mine s th e air/fue l rati o an d control s th e amoun t o f

injecte d fuel .

Open : Ignorin g H02 S output , th e EC M refer s t o signal s

fro m th e TP , MAP , an d EC T sensor s to contro l th e

amoun t o f injecte d fuel . A

t idl e speed : close d

YES

Shor t Ter m

Fue l Tri m

(Ban k 1 : Rear )

(Bank 2 : Front ) Th

e air/fue l rati o correctio n coefficien t fo r correctin g

th e amoun t o f injecte d fue l whe n HO2 S feedbac k is in

th e close d loo p status . Whe n th e signa l fro m th e HO2 S

i s weak , shor t ter m fue l tri m get s higher , an d th e EC M

increase s th e amoun t o f injecte d fuel . Th e air/fue l rati o

graduall y get s richer , causin g a highe r H02 S output .

Consequently , th e shor t ter m fue l tri m is lowered , an d

th e EC M reduce s th e amoun t o f injecte d fuel . Thi s

cycl e keep s th e air/fue l rati o clos e to th e stoichiometri c

rati o whe n in close d loo p status .

-30%-+43 %

YES

Lon g Ter m

Fue l Tri m

(Ban k 1 : Rear )

(Bank 2 : Front )

Long ter m fue l tri m in compute d fro m shor t ter m fue l

tri m an d indicate s change s occurin g in th e fue l suppl y

syste m ove r a lon g period .

I f lon g ter m fue l tri m is highe r tha n 1.00 , th e amoun t o f

injecte d fue l mus t b e increased . I f i t i s lowe r tha n 1.00 ,

th e amoun t o f injecte d fue l mus t b e reduced .-19%-+25 %

YES

Intak e Ai r

Temperatur e

(IAT)

The IA T senso r convert s intak e ai r temperatur e int o

voltag e an d signal s th e ECM . Whe n intak e ai r tempera -

tur e is low , th e interna l resistanc e o f th e senso r

increases , an d th e voltag e signa l i s higher . Wit

h col d engine :

Sam e a s ambien t temper -

atur e an d EC T

YES

Throttl e

Positio n Base

d o n th e accelerato r peda l position , th e openin g

angl e o f th e throttl e valv e is indicated .At idle : Approx . 10 %

At ful l throttle : Approx .

90%

YE S

Ignitio n

Timing

The ignitio n advanc e angl e is se t b y th e ECM . Th e EC M

matche s ignitio n timin g t o th e drivin g conditions .A

t idl e speed : 1 5 ±2°

BTD C wit h th e SC S servic e

connecto r connected .

NO

Calculate d

Load Valu e

(CLV )

CLV is th e engin e loa d calculate d fro m th e MA P data . At idl e speed :

15-35%

At 2,50 0 rp m wit h n o load :

12-30 %

YES

ProCarManuals.com

Page 572 of 1503

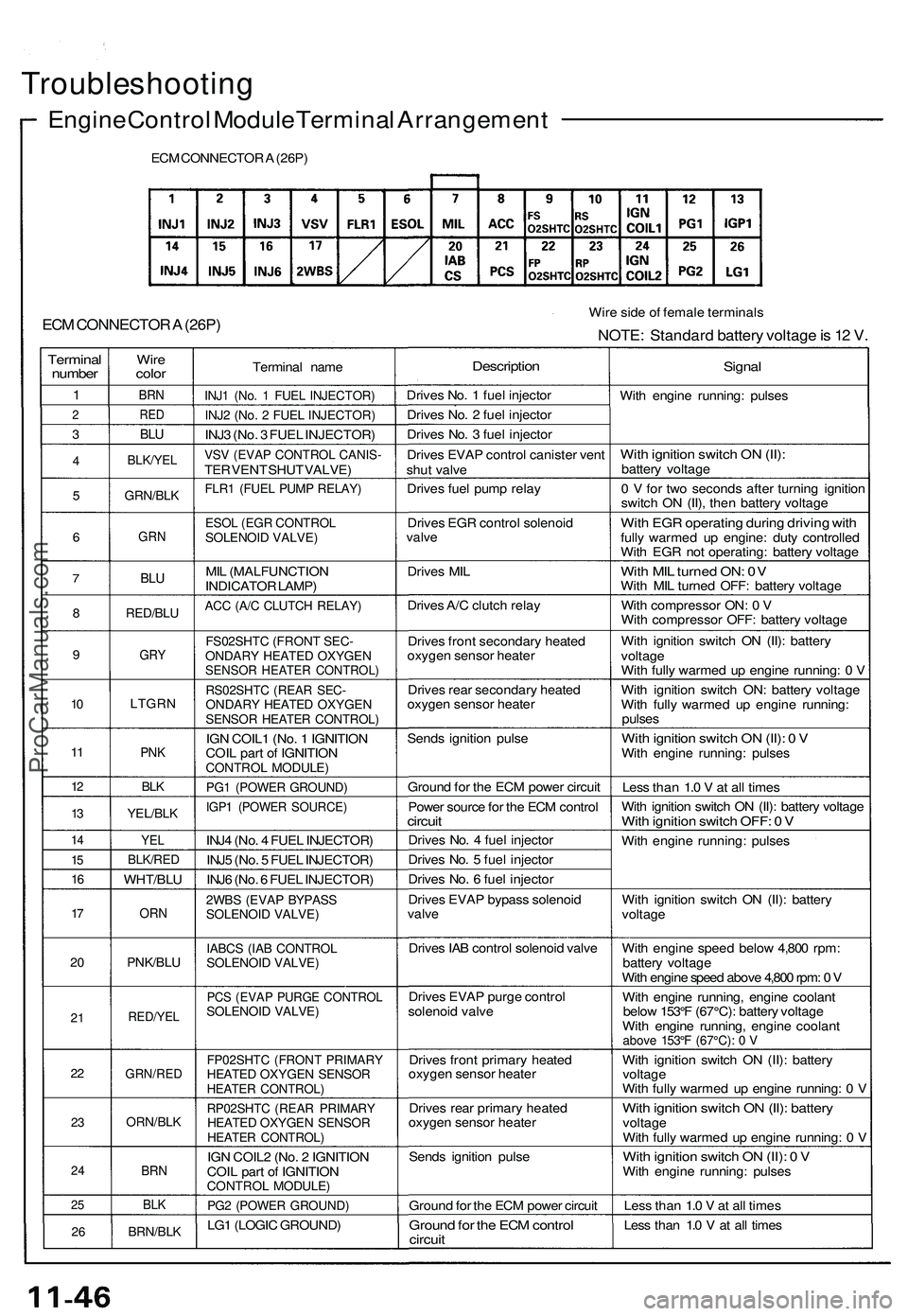

Troubleshooting

Engine Control Module Terminal Arrangement

ECM CONNECTOR A (26P)

ECM CONNECTOR A (26P)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

Terminal

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

Wire

color

BRN

RED

BLU

BLK/YEL

GRN/BLK

GRN

BLU

RED/BLU

GRY

LTGRN

PNK

BLK

YEL/BLK

YEL

BLK/RED

WHT/BLU

ORN

PNK/BLU

RED/YEL

GRN/RED

ORN/BLK

BRN

BLK

BRN/BLK

Terminal name

INJ1 (No. 1 FUEL INJECTOR)

INJ2 (No. 2 FUEL INJECTOR)

INJ3 (No. 3 FUEL INJECTOR)

VSV (EVAP CONTROL CANIS-

TER VENT SHUT VALVE)

FLR1 (FUEL PUMP RELAY)

ESOL (EGR CONTROL

SOLENOID VALVE)

MIL (MALFUNCTION

INDICATOR LAMP)

ACC (A/C CLUTCH RELAY)

FS02SHTC (FRONT SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

RS02SHTC (REAR SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

IGN COIL1 (No. 1 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG1 (POWER GROUND)

IGP1 (POWER SOURCE)

INJ4 (No. 4 FUEL INJECTOR)

INJ5 (No. 5 FUEL INJECTOR)

INJ6 (No. 6 FUEL INJECTOR)

2WBS (EVAP BYPASS

SOLENOID VALVE)

IABCS (IAB CONTROL

SOLENOID VALVE)

PCS (EVAP PURGE CONTROL

SOLENOID VALVE)

FP02SHTC (FRONT PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

RP02SHTC (REAR PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

IGN COIL2 (No. 2 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG2 (POWER GROUND)

LG1 (LOGIC GROUND)

Description

Drives No. 1 fuel injector

Drives No. 2 fuel injector

Drives No. 3 fuel injector

Drives EVAP control canister vent

shut valve

Drives fuel pump relay

Drives EGR control solenoid

valve

Drives MIL

Drives A/C clutch relay

Drives front secondary heated

oxygen sensor heater

Drives rear secondary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Power source for the ECM control

circuit

Drives No. 4 fuel injector

Drives No. 5 fuel injector

Drives No. 6 fuel injector

Drives EVAP bypass solenoid

valve

Drives IAB control solenoid valve

Drives EVAP purge control

solenoid valve

Drives front primary heated

oxygen sensor heater

Drives rear primary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Ground for the ECM control

circuit

Signal

With engine running: pulses

With ignition switch ON (II):

battery voltage

0 V for two seconds after turning ignition

switch ON (II), then battery voltage

With EGR operating during driving with

fully warmed up engine: duty controlled

With EGR not operating: battery voltage

With MIL turned ON: 0V

With MIL turned OFF: battery voltage

With compressor ON: 0 V

With compressor OFF: battery voltage

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON: battery voltage

With fully warmed up engine running:

pulses

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

With ignition switch ON (II): battery voltage

With ignition switch OFF: 0 V

With engine running: pulses

With ignition switch ON (II): battery

voltage

With engine speed below 4,800 rpm:

battery voltage

With engine speed above 4,800 rpm: 0 V

With engine running, engine coolant

below 153°F (67°C): battery voltage

With engine running, engine coolant

above 153°F (67°C): 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

Less than 1.0 V at all timesProCarManuals.com

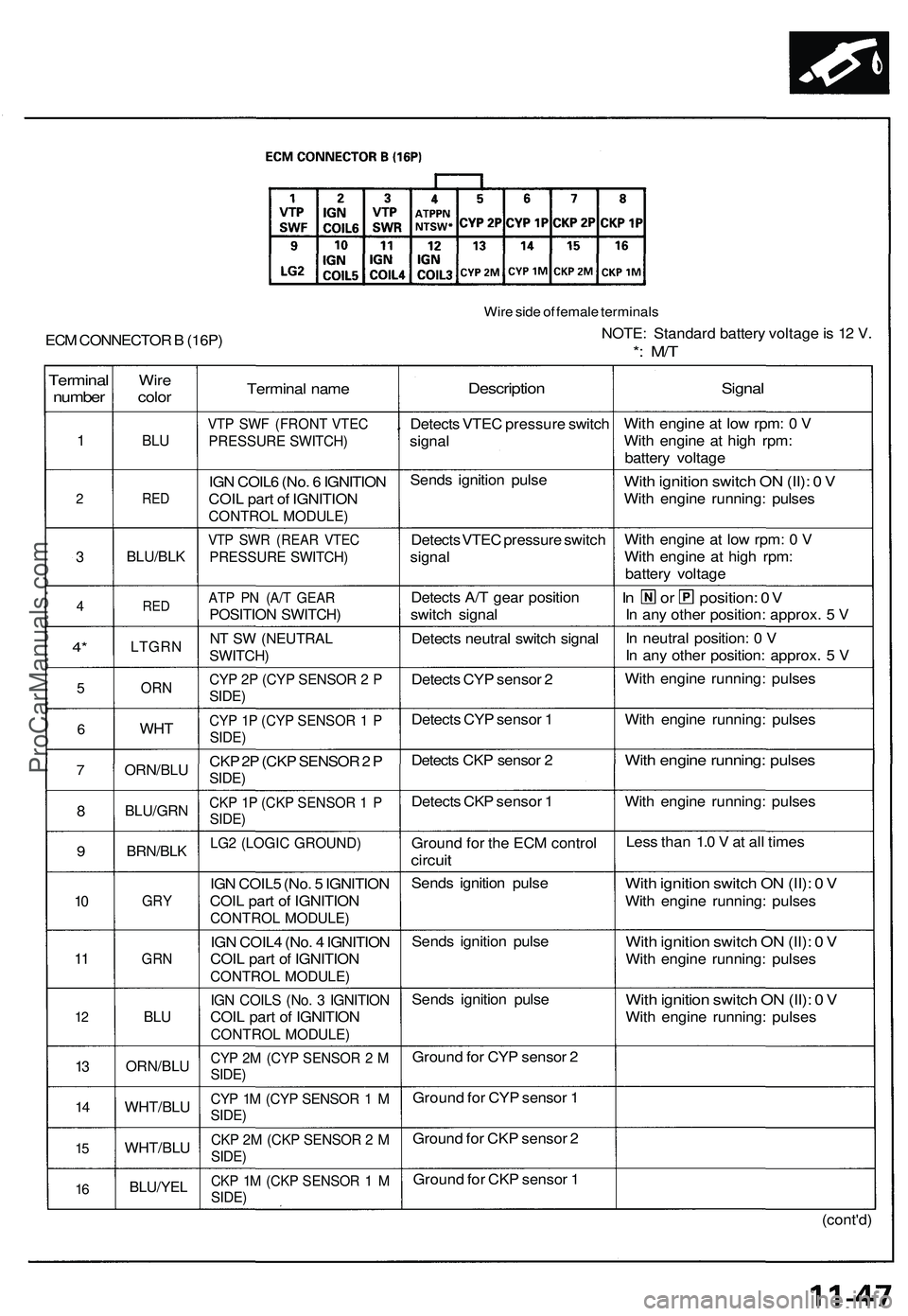

Page 573 of 1503

Terminal

number

1

2

3

4

4*

5

6

7

8

9

10

11

12

13

14

15

16

Wire

color

BLU

RED

BLU/BLK

RED

LTGRN

ORN

WHT

ORN/BLU

BLU/GRN

BRN/BLK

GRY

GRN

BLU

ORN/BLU

WHT/BLU

WHT/BLU

BLU/YEL

Terminal name

VTP SWF (FRONT VTEC

PRESSURE SWITCH)

IGN COIL6 (No. 6 IGNITION

COIL part of IGNITION

CONTROL MODULE)

VTP SWR (REAR VTEC

PRESSURE SWITCH)

ATP PN (A/T GEAR

POSITION SWITCH)

NT SW (NEUTRAL

SWITCH)

CYP 2P (CYP SENSOR 2 P

SIDE)

CYP 1P (CYP SENSOR 1 P

SIDE)

CKP 2P (CKP SENSOR 2 P

SIDE)

CKP 1P (CKP SENSOR 1 P

SIDE)

LG2 (LOGIC GROUND)

IGN COIL5 (No. 5 IGNITION

COIL part of IGNITION

CONTROL MODULE)

IGN COIL4 (No. 4 IGNITION

COIL part of IGNITION

CONTROL MODULE)

IGN COILS (No. 3 IGNITION

COIL part of IGNITION

CONTROL MODULE)

CYP 2M (CYP SENSOR 2 M

SIDE)

CYP 1M (CYP SENSOR 1 M

SIDE)

CKP 2M (CKP SENSOR 2 M

SIDE)

CKP 1M (CKP SENSOR 1 M

SIDE)

Description

Detects VTEC pressure switch

signal

Sends ignition pulse

Detects VTEC pressure switch

signal

Detects A/T gear position

switch signal

Detects neutral switch signal

Detects CYP sensor 2

Detects CYP sensor 1

Detects CKP sensor 2

Detects CKP sensor 1

Ground for the ECM control

circuit

Sends ignition pulse

Sends ignition pulse

Sends ignition pulse

Ground for CYP sensor 2

Ground for CYP sensor 1

Ground for CKP sensor 2

Ground for CKP sensor 1

Signal

With engine at low rpm: 0 V

With engine at high rpm:

battery voltage

With ignition switch ON (II): 0 V

With engine running: pulses

With engine at low rpm: 0 V

With engine at high rpm:

battery voltage

In or position: 0V

In any other position: approx. 5 V

In neutral position: 0 V

In any other position: approx. 5 V

With engine running: pulses

With engine running: pulses

With engine running: pulses

With engine running: pulses

Less than 1.0 V at all times

With ignition switch ON (II): 0 V

With engine running: pulses

With ignition switch ON (II): 0 V

With engine running: pulses

With ignition switch ON (II): 0 V

With engine running: pulses

(cont'd)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

*: M/T

ECM CONNECTOR B (16P)ProCarManuals.com