ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 141 of 1503

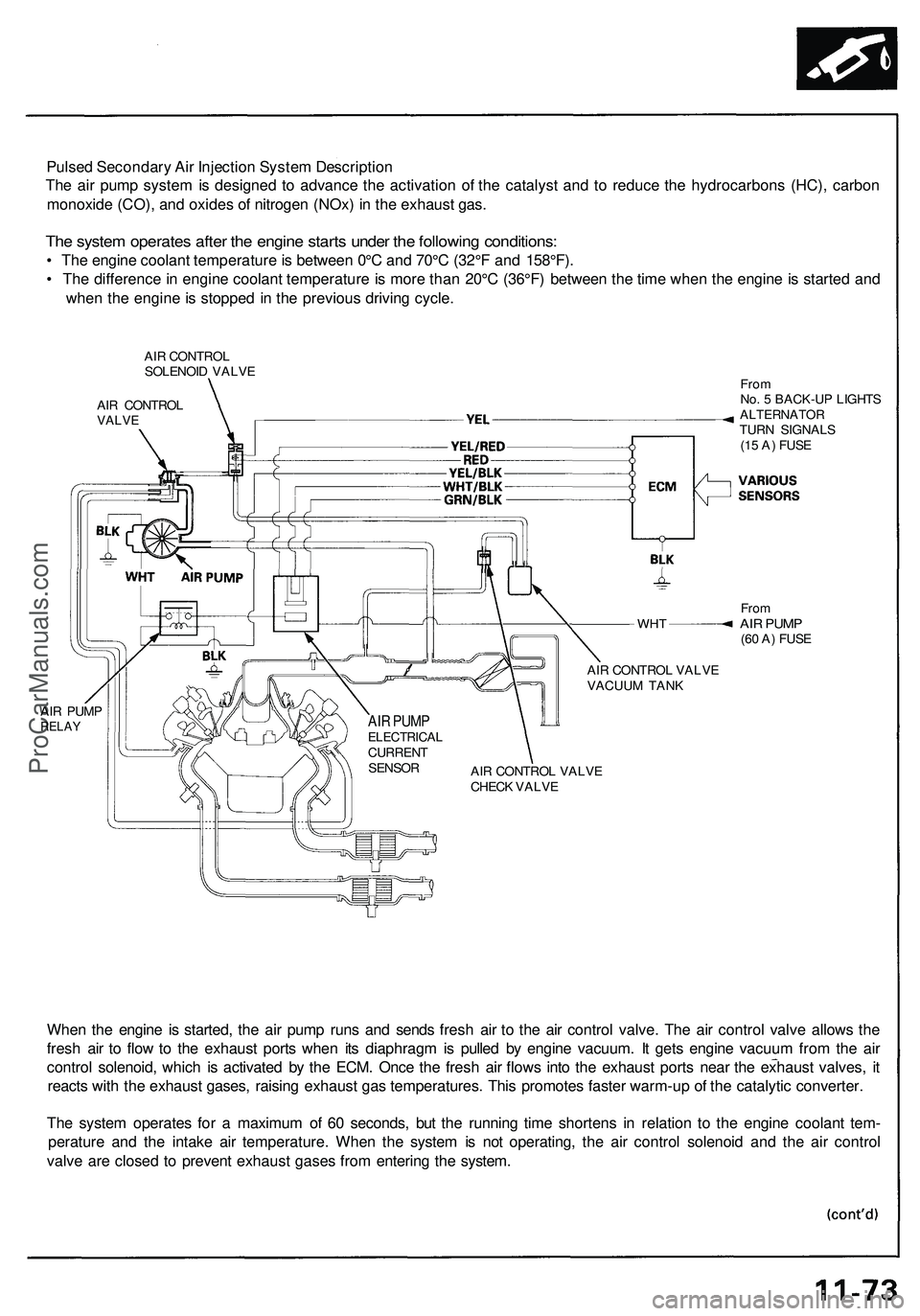

Pulsed Secondary Air Injection System Description

The air pump system is designed to advance the activation of the catalyst and to reduce the hydrocarbons (HC), carbon

monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas.

The system operates after the engine starts under the following conditions:

• The engine coolant temperature is between 0°C and 70°C (32°F and 158°F).

• The difference in engine coolant temperature is more than 20°C (36°F) between the time when the engine is started and

when the engine is stopped in the previous driving cycle.

AIR CONTROL

SOLENOID VALVE

AIR CONTROL

VALVE

WHT

AIR PUMP

RELAY

From

No. 5 BACK-UP LIGHTS

ALTERNATOR

TURN SIGNALS

(15 A) FUSE

From

AIR PUMP

(60 A) FUSE

AIR CONTROL VALVE

VACUUM TANK

AIR CONTROL VALVE

CHECK VALVE

When the engine is started, the air pump runs and sends fresh air to the air control valve. The air control valve allows the

fresh air to flow to the exhaust ports when its diaphragm is pulled by engine vacuum. It gets engine vacuum from the air

control solenoid, which is activated by the ECM. Once the fresh air flows into the exhaust ports near the exhaust valves, it

reacts with the exhaust gases, raising exhaust gas temperatures. This promotes faster warm-up of the catalytic converter.

The system operates for a maximum of 60 seconds, but the running time shortens in relation to the engine coolant tem-

perature and the intake air temperature. When the system is not operating, the air control solenoid and the air control

valve are closed to prevent exhaust gases from entering the system.

AIR PUMP

ELECTRICAL

CURRENT

SENSORProCarManuals.com

Page 142 of 1503

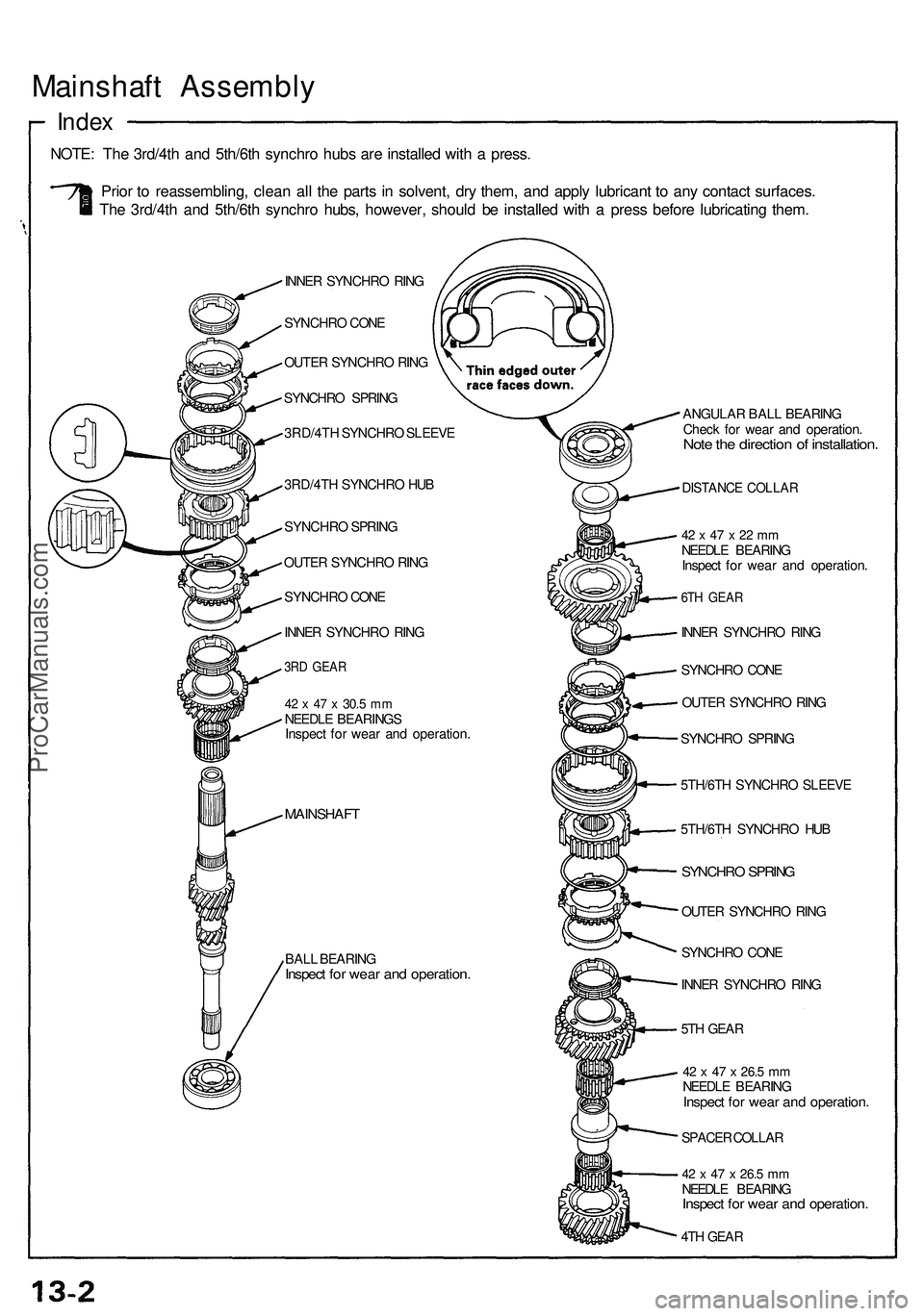

Mainshaft Assembl y

Index

NOTE : Th e 3rd/4t h an d 5th/6t h synchr o hub s ar e installe d wit h a press .

Prio r t o reassembling , clea n al l th e part s i n solvent , dr y them , an d appl y lubrican t t o an y contac t surfaces .

Th e 3rd/4t h an d 5th/6t h synchr o hubs , however , shoul d b e installe d wit h a pres s befor e lubricatin g them .

INNER SYNCHR O RIN G

SYNCHR O CON E

OUTE R SYNCHR O RIN G

SYNCHR O SPRIN G

3RD/4T H SYNCHR O SLEEV E

3RD/4T H SYNCHR O HU B

SYNCHR O SPRIN G

OUTE R SYNCHR O RIN G

SYNCHR O CON E

INNE R SYNCHR O RIN G

3RD GEA R

42 x 47 x 30. 5 mmNEEDL E BEARING S

Inspec t fo r wea r an d operation .

MAINSHAF T

BALL BEARIN GInspect fo r wea r an d operation .

ANGULAR BAL L BEARIN G

Chec k fo r wea r an d operation .

Note th e directio n o f installation .

DISTANCE COLLA R

42 x 47 x 22 m mNEEDL E BEARIN G

Inspec t fo r wea r an d operation .

6TH GEA R

INNER SYNCHR O RIN G

SYNCHR O CON E

OUTE R SYNCHR O RIN G

SYNCHR O SPRIN G

5TH/6T H SYNCHR O SLEEV E

5TH/6T H SYNCHR O HU B

SYNCHR O SPRIN G

OUTER SYNCHR O RIN G

SYNCHR O CON E

INNE R SYNCHR O RIN G

5T H GEA R

42 x 47 x 26. 5 mmNEEDL E BEARIN GInspect fo r wea r an d operation .

SPACER COLLA R

42 x 47 x 26. 5 mmNEEDL E BEARIN GInspect fo r wea r an d operation .

4TH GEA R

ProCarManuals.com

Page 143 of 1503

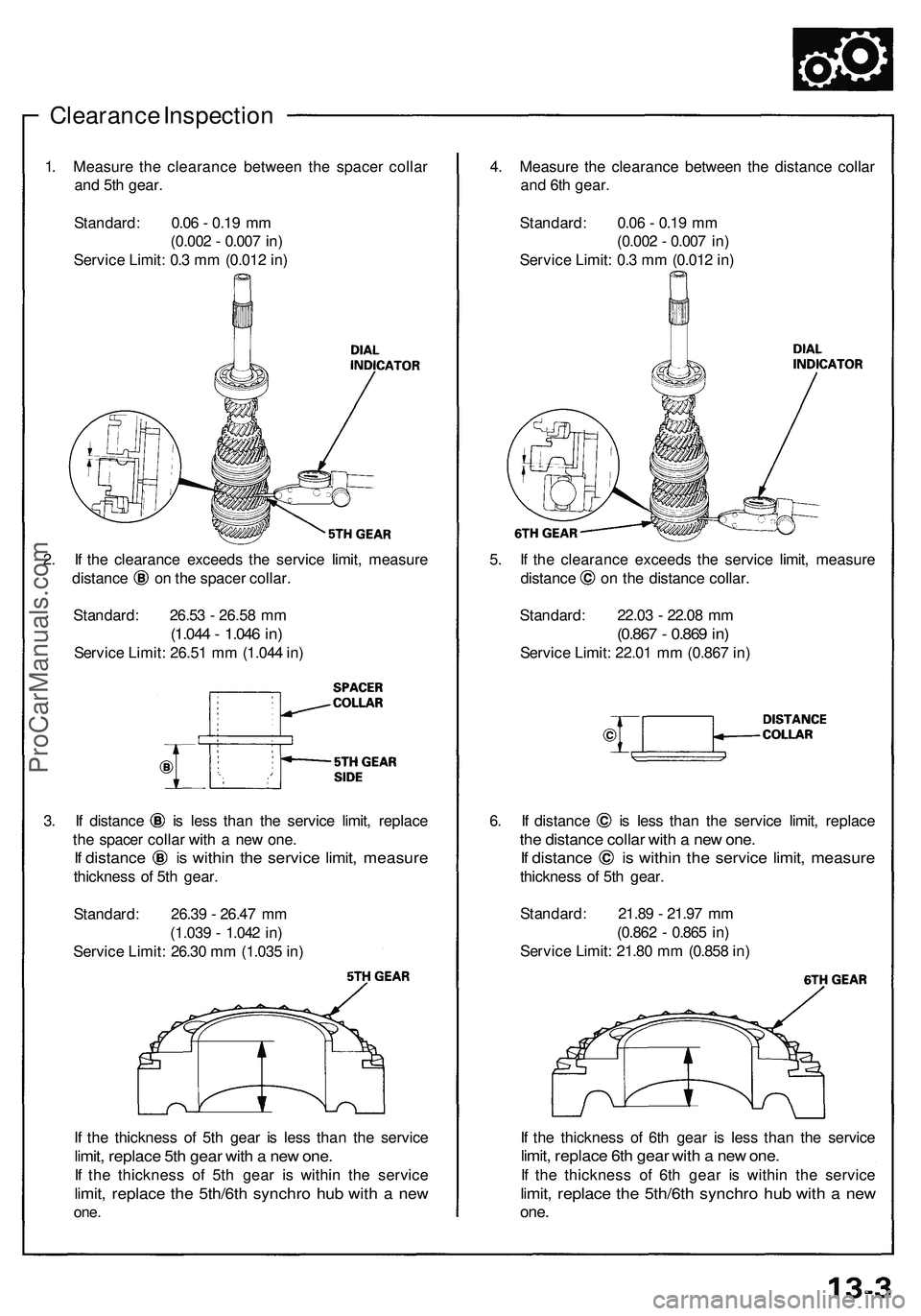

Clearance Inspectio n

1. Measur e th e clearanc e betwee n th e space r colla r

an d 5t h gear .

Standard : 0.0 6 - 0.1 9 m m

(0.00 2 - 0.00 7 in )

Servic e Limit : 0. 3 m m (0.01 2 in )

2 . I f th e clearanc e exceed s th e servic e limit , measur e

distance o n th e space r collar .

Standard : 26.5 3 - 26.5 8 m m

(1.04 4 - 1.04 6 in )

Servic e Limit : 26.5 1 m m (1.04 4 in )

3. I f distanc e i s les s tha n th e servic e limit , replac e

th e space r colla r wit h a ne w one .

If distanc e i s withi n th e servic e limit , measur e

thickness o f 5t h gear .

Standard : 26.3 9 - 26.4 7 m m

(1.03 9 - 1.04 2 in )

Servic e Limit : 26.3 0 m m (1.03 5 in )

I f th e thicknes s o f 5t h gea r i s les s tha n th e servic e

limit, replac e 5t h gea r wit h a ne w one .

If th e thicknes s o f 5t h gea r i s withi n th e servic e

limit, replac e th e 5th/6t h synchr o hu b wit h a ne w

one .

4. Measur e th e clearanc e betwee n th e distanc e colla r

an d 6t h gear .

Standard : 0.0 6 - 0.1 9 m m

(0.00 2 - 0.00 7 in )

Servic e Limit : 0. 3 m m (0.01 2 in )

5 . I f th e clearanc e exceed s th e servic e limit , measur e

distance o n th e distanc e collar .

Standard : 22.0 3 - 22.0 8 m m

(0.86 7 - 0.86 9 in )

Servic e Limit : 22.0 1 m m (0.86 7 in )

6. I f distanc e i s les s tha n th e servic e limit , replac e

the distanc e colla r wit h a ne w one .

If distanc e i s withi n th e servic e limit , measur e

thickness o f 5t h gear .

Standard : 21.8 9 - 21.9 7 m m

(0.86 2 - 0.86 5 in )

Servic e Limit : 21.8 0 m m (0.85 8 in )

I f th e thicknes s o f 6t h gea r i s les s tha n th e servic e

limit, replac e 6t h gea r wit h a ne w one .

If th e thicknes s o f 6t h gea r i s withi n th e servic e

limit, replac e th e 5th/6t h synchr o hu b wit h a ne w

one .

ProCarManuals.com

Page 144 of 1503

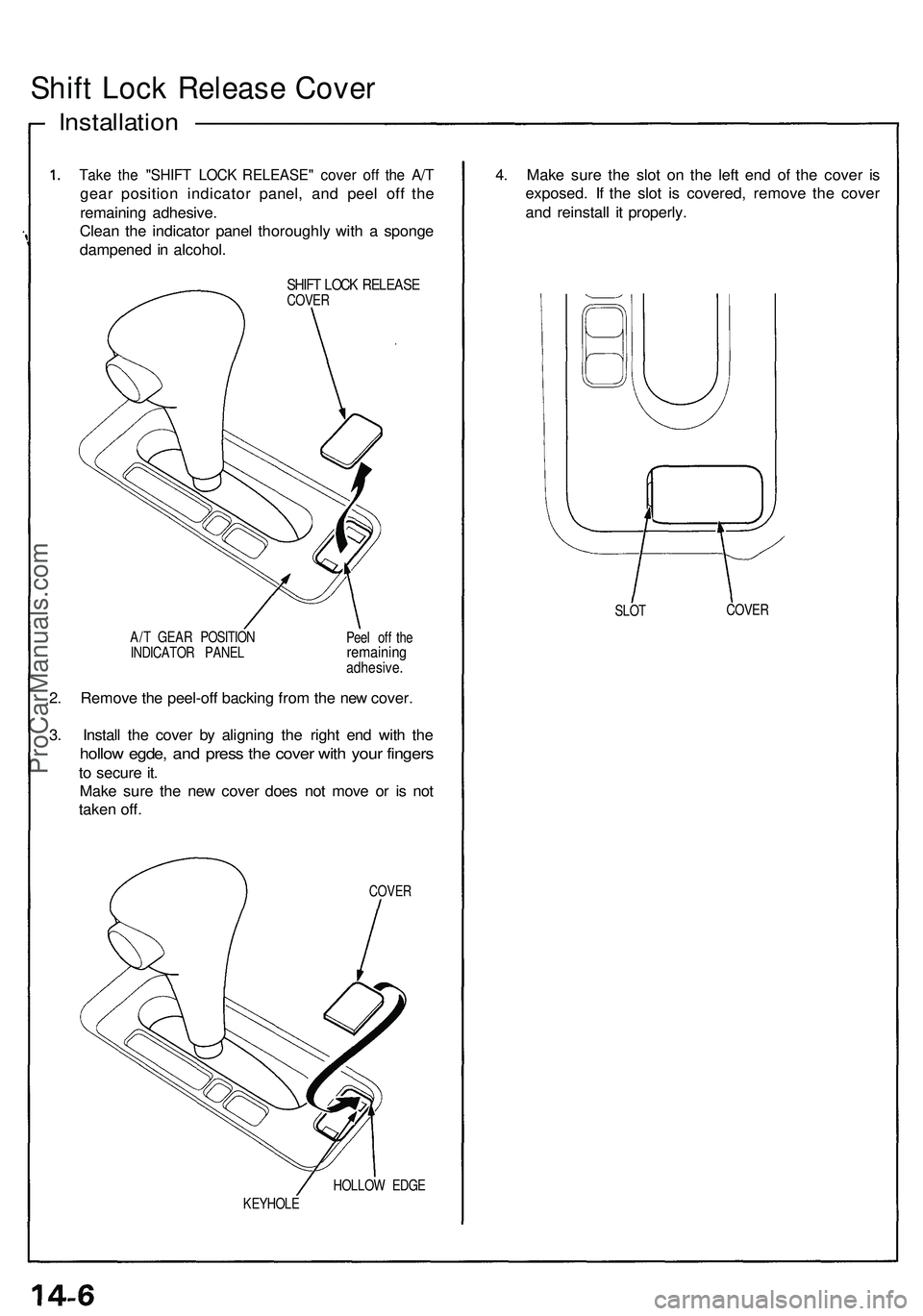

Shift Loc k Releas e Cove r

Installatio n ——————————

Take th e "SHIF T LOC K RELEASE " cove r of f th e A/ T

gea r positio n indicato r panel , an d pee l of f th e

remainin g adhesive .

Clea n th e indicato r pane l thoroughl y wit h a spong e

dampene d in alcohol .

SHIFT LOC K RELEAS ECOVER

A/ T GEA R POSITIO N

INDICATO R PANE L Pee

l of f th e

remainin gadhesive .

2. Remov e th e peel-of f backin g fro m th e ne w cover .

3 . Instal l th e cove r b y alignin g th e righ t en d wit h th e

hollo w egde , an d pres s th e cove r wit h you r finger s

to secur e it .

Mak e sur e th e ne w cove r doe s no t mov e o r i s no t

take n off .

COVE R

HOLLO W EDG E

KEYHOL E

4. Mak e sur e th e slo t o n th e lef t en d o f th e cove r i s

exposed . I f th e slo t i s covered , remov e th e cove r

an d reinstal l i t properly .

SLOT COVE

R

ProCarManuals.com

Page 145 of 1503

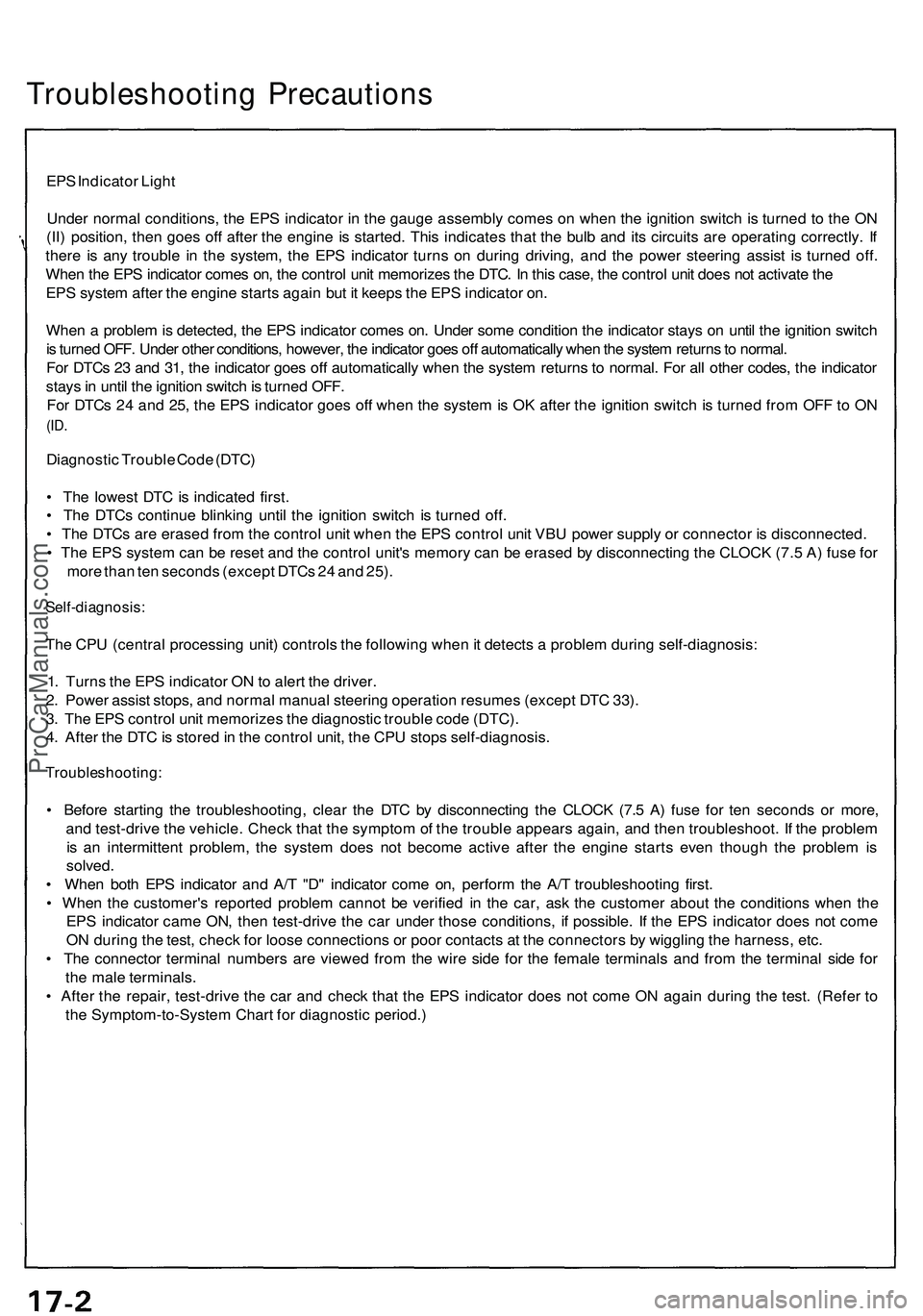

Troubleshooting Precaution s

EPS Indicato r Ligh t

Unde r norma l conditions , th e EP S indicato r i n th e gaug e assembl y come s o n whe n th e ignitio n switc h is turne d t o th e O N

(II ) position , the n goe s of f afte r th e engin e i s started . Thi s indicate s tha t th e bul b an d it s circuit s ar e operatin g correctly . I f

ther e i s an y troubl e i n th e system , th e EP S indicato r turn s o n durin g driving , an d th e powe r steerin g assis t i s turne d off .

Whe n th e EP S indicato r come s on , th e contro l uni t memorize s th e DTC . I n thi s case , th e contro l uni t doe s no t activat e th e

EP S syste m afte r th e engin e start s agai n bu t i t keep s th e EP S indicato r on .

Whe n a proble m is detected , th e EP S indicato r come s on . Unde r som e conditio n th e indicato r stay s o n unti l th e ignitio n switc h

i s turne d OFF . Unde r othe r conditions , however , th e indicato r goe s of f automaticall y whe n th e syste m return s to normal .

Fo r DTC s 2 3 an d 31 , th e indicato r goe s of f automaticall y whe n th e syste m return s t o normal . Fo r al l othe r codes , th e indicato r

stay s in unti l th e ignitio n switc h is turne d OFF .

Fo r DTC s 2 4 an d 25 , th e EP S indicato r goe s of f whe n th e syste m is O K afte r th e ignitio n switc h is turne d fro m OF F to O N

(ID .

Diagnosti c Troubl e Cod e (DTC )

• Th e lowes t DT C is indicate d first .

• Th e DTC s continu e blinkin g unti l th e ignitio n switc h i s turne d off .

• Th e DTC s ar e erase d fro m th e contro l uni t whe n th e EP S contro l uni t VB U powe r suppl y o r connecto r i s disconnected .

• Th e EP S syste m ca n b e rese t an d th e contro l unit' s memor y ca n b e erase d b y disconnectin g th e CLOC K (7. 5 A ) fus e fo r

mor e tha n te n second s (excep t DTC s 2 4 an d 25) .

Self-diagnosis :

The CP U (centra l processin g unit ) control s th e followin g whe n it detect s a proble m durin g self-diagnosis :

1 . Turn s th e EP S indicato r O N to aler t th e driver .

2 . Powe r assis t stops , an d norma l manua l steerin g operatio n resume s (excep t DT C 33) .

3 . Th e EP S contro l uni t memorize s th e diagnosti c troubl e cod e (DTC) .

4 . Afte r th e DT C is store d in th e contro l unit , th e CP U stop s self-diagnosis .

Troubleshooting :

• Befor e startin g th e troubleshooting , clea r th e DT C b y disconnectin g th e CLOC K (7. 5 A ) fus e fo r te n second s o r more ,

an d test-driv e th e vehicle . Chec k tha t th e sympto m o f th e troubl e appear s again , an d the n troubleshoot . I f th e proble m

i s a n intermitten t problem , th e syste m doe s no t becom e activ e afte r th e engin e start s eve n thoug h th e proble m is

solved .

• Whe n bot h EP S indicato r an d A/ T "D " indicato r com e on , perfor m th e A/ T troubleshootin g first .

• Whe n th e customer' s reporte d proble m canno t b e verifie d i n th e car , as k th e custome r abou t th e condition s whe n th e

EP S indicato r cam e ON , the n test-driv e th e ca r unde r thos e conditions , i f possible . I f th e EP S indicato r doe s no t com e

O N durin g th e test , chec k fo r loos e connection s o r poo r contact s a t th e connector s b y wigglin g th e harness , etc .

• Th e connecto r termina l number s ar e viewe d fro m th e wir e sid e fo r th e femal e terminal s an d fro m th e termina l sid e fo r

th e mal e terminals .

• Afte r th e repair , test-driv e th e ca r an d chec k tha t th e EP S indicato r doe s no t com e O N agai n durin g th e test . (Refe r t o

th e Symptom-to-Syste m Char t fo r diagnosti c period. )

ProCarManuals.com

Page 146 of 1503

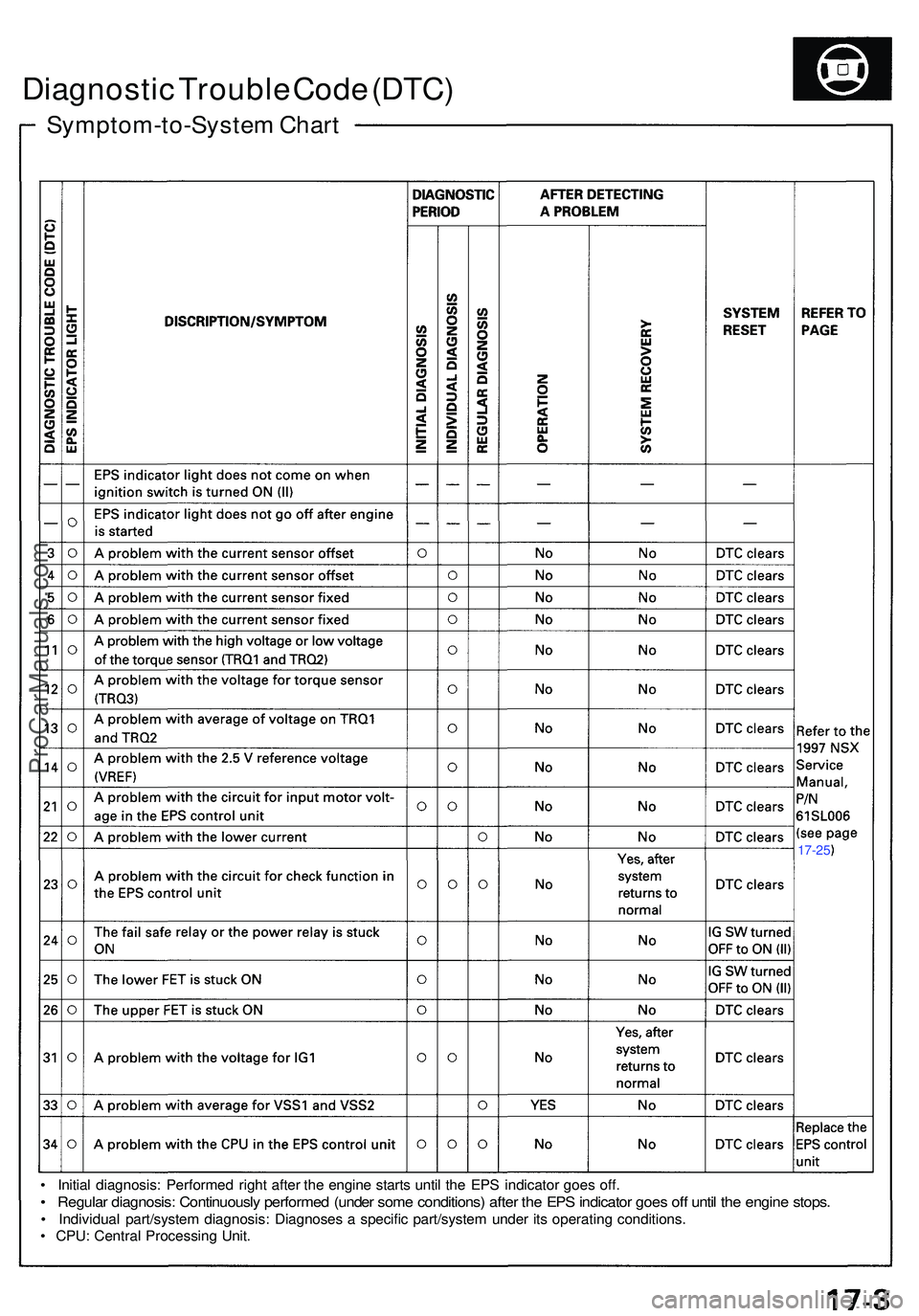

Symptom-to-System Char t

Diagnosti c Troubl e Cod e (DTC )

• Initia l diagnosis : Performe d righ t afte r th e engin e start s unti l th e EP S indicato r goe s off .

• Regula r diagnosis : Continuousl y performe d (unde r som e conditions ) afte r th e EP S indicato r goe s of f unti l th e engin e stops .

• Individua l part/syste m diagnosis: Diagnoses a specifi c part/syste m unde r it s operatin g conditions .

• CPU : Centra l Processin g Unit .

17-25

ProCarManuals.com

Page 147 of 1503

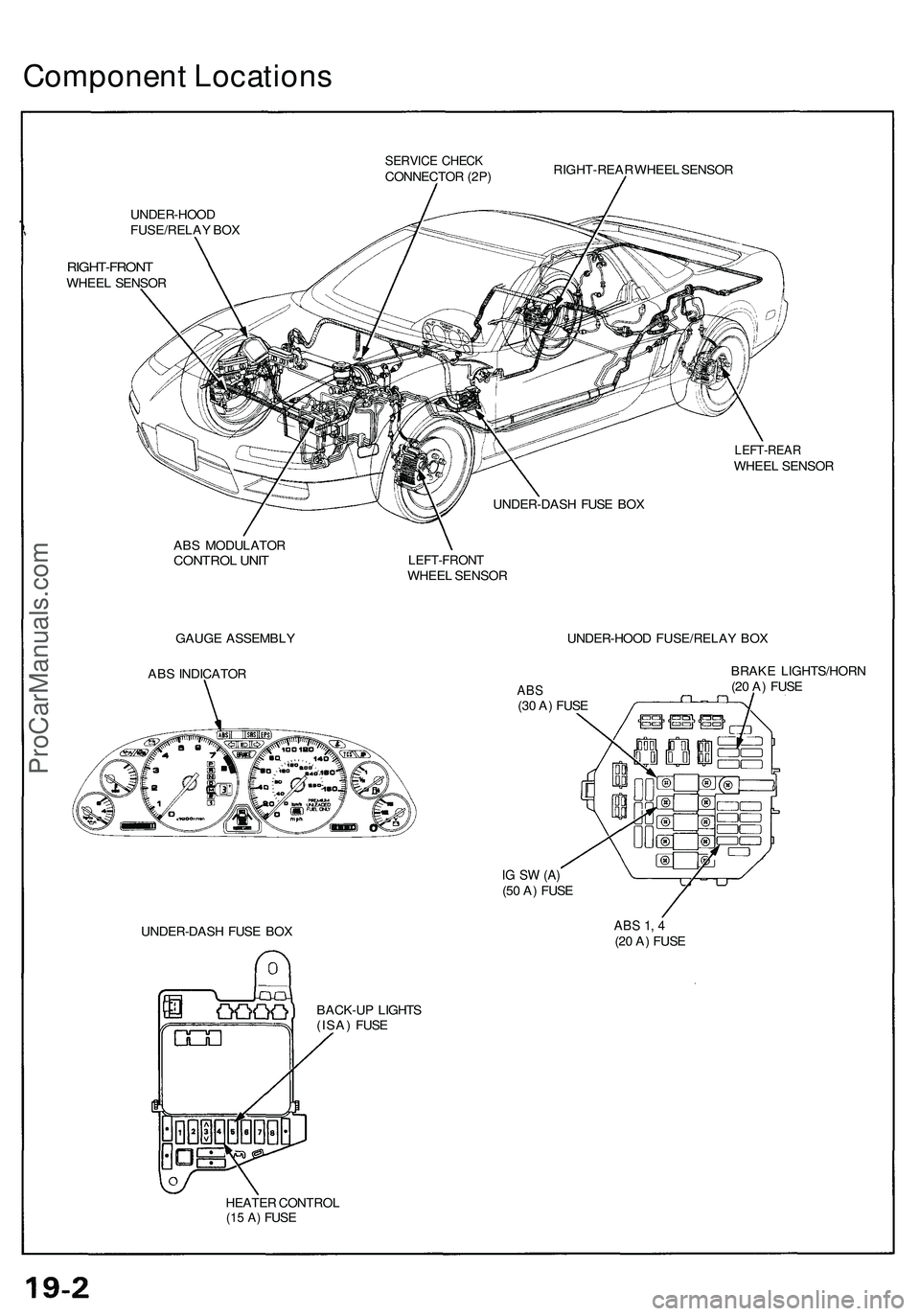

Component Location s

SERVICE CHEC KCONNECTO R (2P ) RIGHT-REA

R WHEE L SENSO R

UNDER-HOO D

FUSE/RELA Y BO X

RIGHT-FRON TWHEEL SENSO R

LEFT-REA RWHEEL SENSO R

UNDER-DAS H FUS E BO X

AB S MODULATO R

CONTROL UNI T

GAUG E ASSEMBL Y

AB S INDICATO R

LEFT-FRON TWHEEL SENSO R

UNDER-HOO D FUSE/RELA Y BO X

ABS(30 A ) FUS E

IG S W (A )(50 A ) FUS E BRAK

E LIGHTS/HOR N

(2 0 A ) FUS E

UNDER-DAS H FUS E BO X

ABS 1 , 4(2 0 A ) FUS E

BACK-U P LIGHT S

(ISA ) FUS E

HEATE R CONTRO L

(15 A) FUSE

ProCarManuals.com

Page 148 of 1503

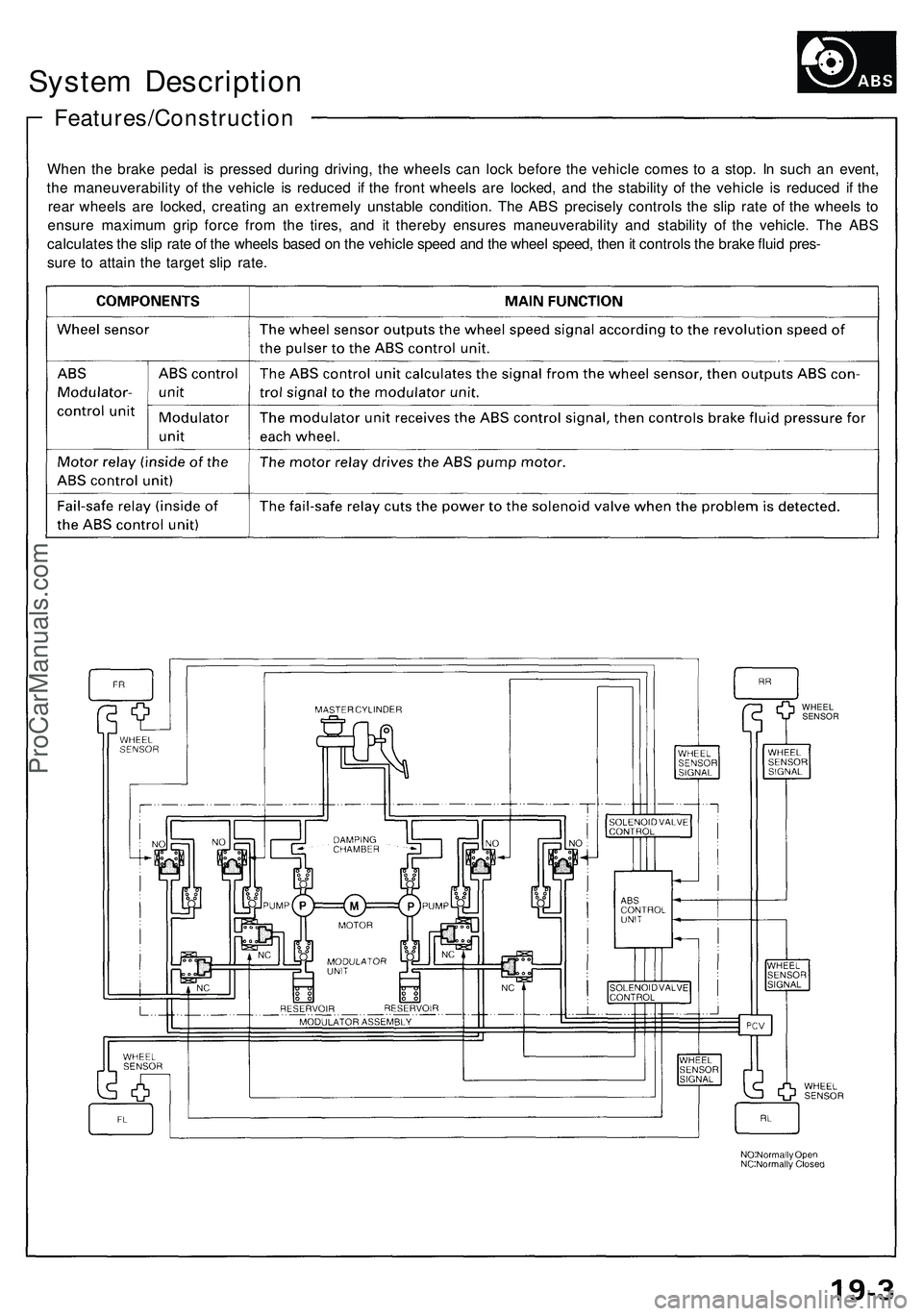

System Descriptio n

Features/Constructio n

When th e brak e peda l i s presse d durin g driving , th e wheel s ca n loc k befor e th e vehicl e come s t o a stop . I n suc h a n event ,

th e maneuverabilit y o f th e vehicl e i s reduce d i f th e fron t wheel s ar e locked , an d th e stabilit y o f th e vehicl e i s reduce d i f th e

rea r wheel s ar e locked , creatin g a n extremel y unstabl e condition . Th e AB S precisel y control s th e sli p rat e o f th e wheel s t o

ensur e maximu m gri p forc e fro m th e tires , an d i t thereb y ensure s maneuverabilit y an d stabilit y o f th e vehicle . Th e AB S

calculate s th e sli p rat e o f th e wheel s base d o n th e vehicl e spee d an d th e whee l speed , the n it control s th e brak e flui d pres -

sur e t o attai n th e targe t sli p rate .

WHEE L

SENSO R

ProCarManuals.com

Page 149 of 1503

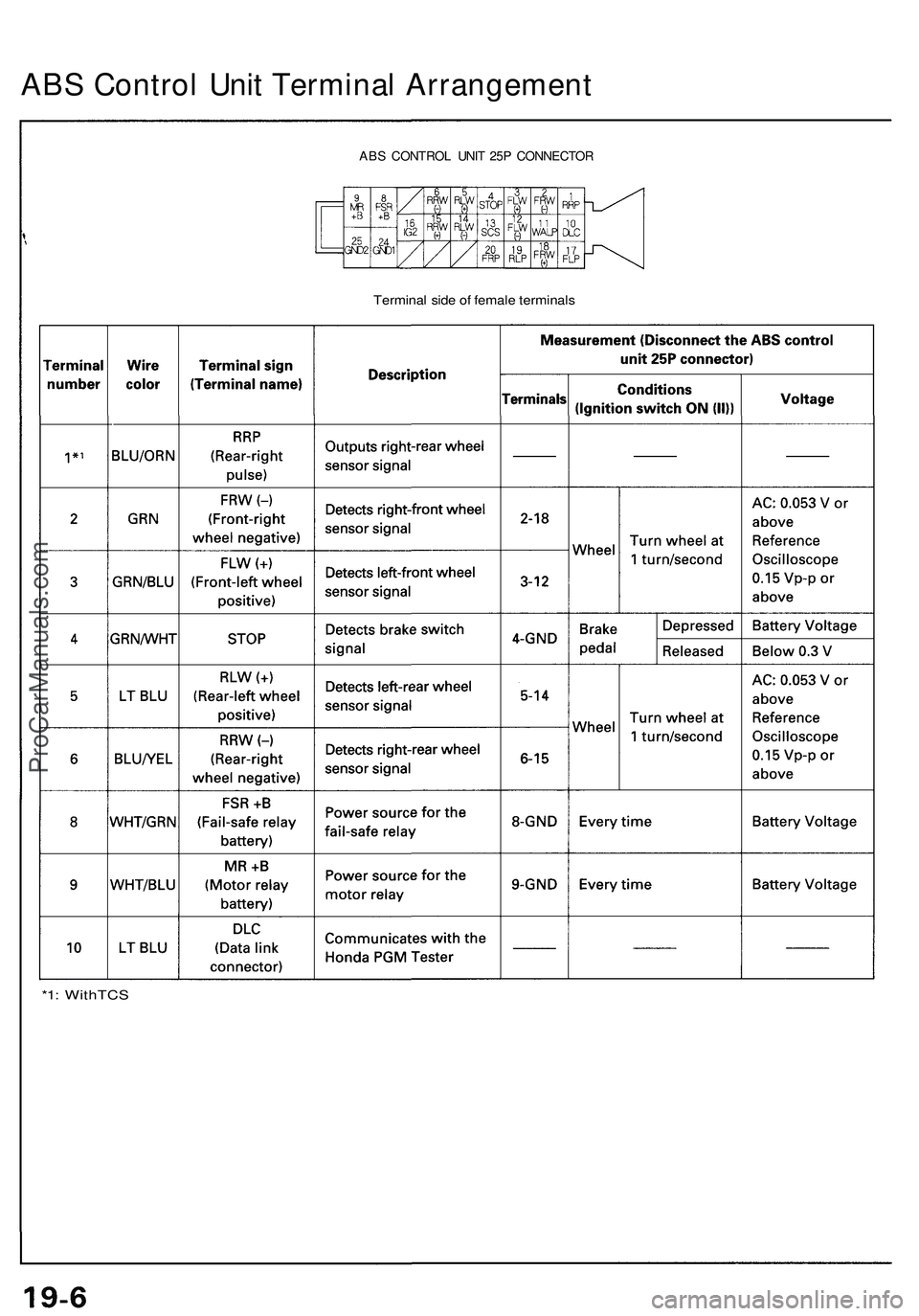

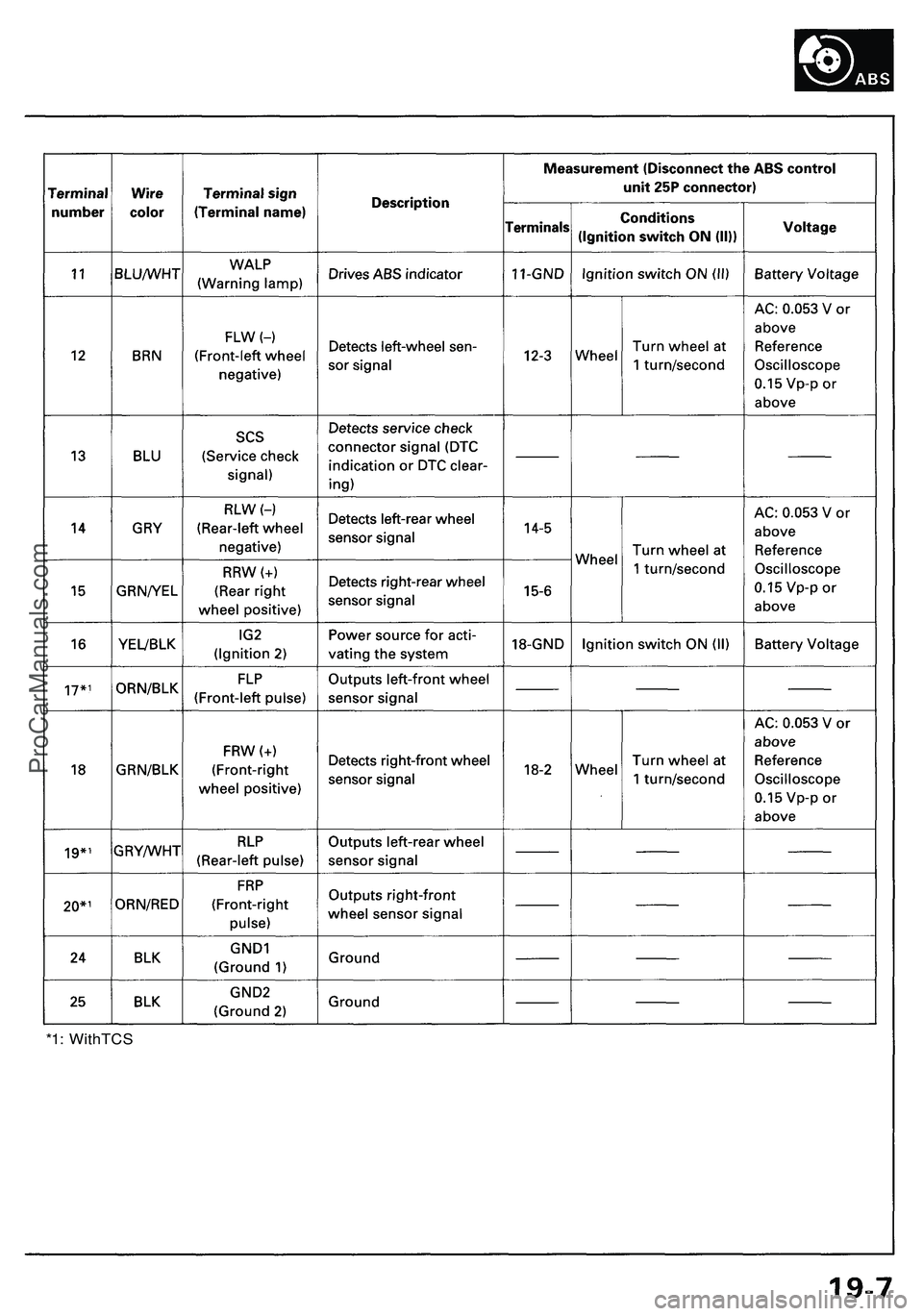

*1: WithTC S

Terminal sid e o f femal e terminal s

ABS CONTRO L UNI T 25 P CONNECTO R

ABS Contro l Uni t Termina l Arrangemen t

ProCarManuals.com

Page 150 of 1503

*1: WithTCSProCarManuals.com