jump start ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 587 of 1503

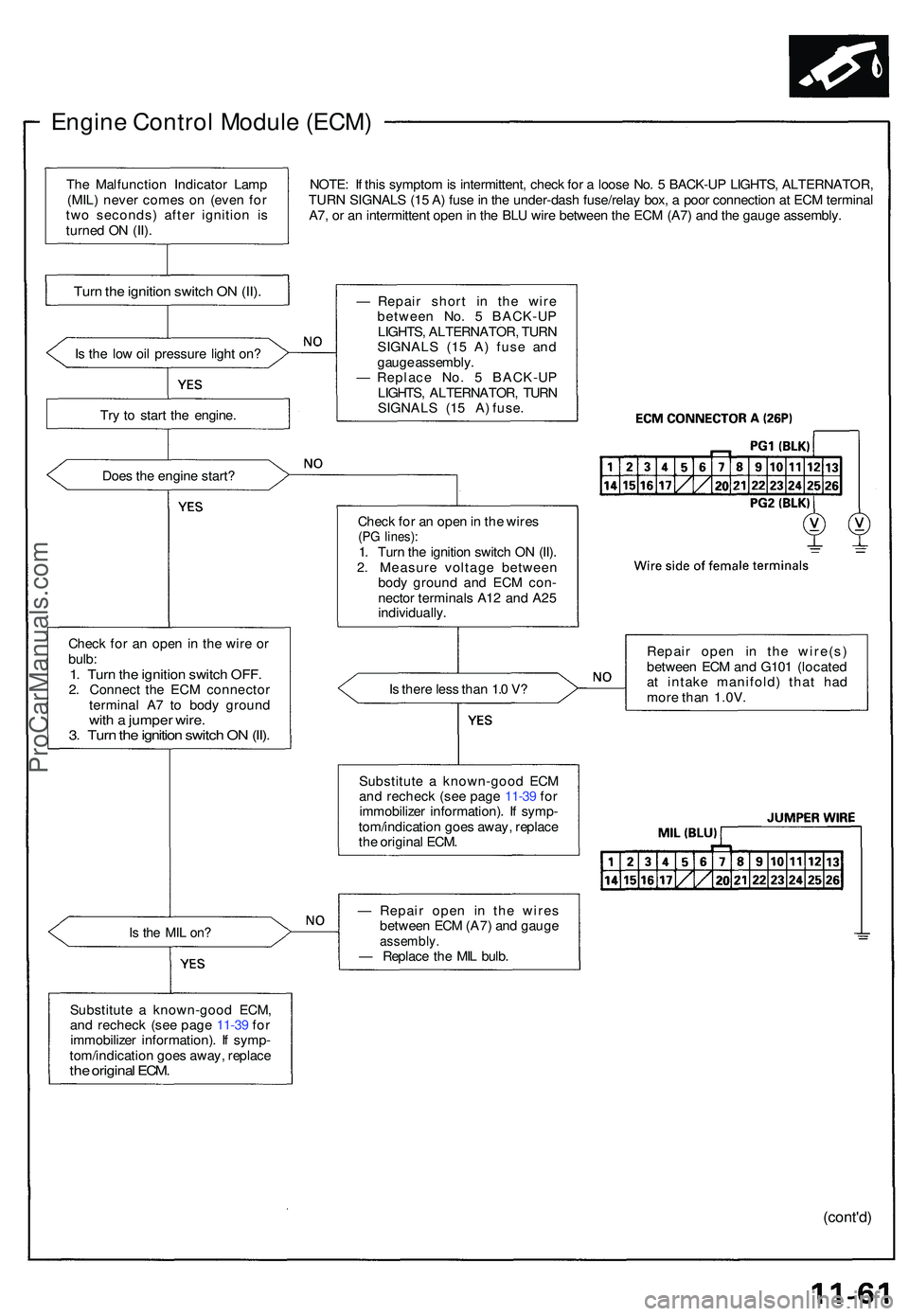

Engine Contro l Modul e (ECM )

NOTE: I f thi s sympto m is intermittent , chec k fo r a loos e No . 5 BACK-U P LIGHTS , ALTERNATOR ,

TUR N SIGNAL S (1 5 A ) fus e in th e under-das h fuse/rela y box , a poo r connectio n a t EC M termina l

A7 , o r a n intermitten t ope n in th e BL U wir e betwee n th e EC M (A7 ) an d th e gaug e assembly .

I s th e lo w oi l pressur e ligh t on ?

Tr y t o star t th e engine .

Doe s th e engin e start ?

Chec k fo r a n ope n in th e wir e o r

bulb :

1. Tur n th e ignitio n switc h OFF .2. Connec t th e EC M connecto r

termina l A 7 t o bod y groun d

with a jumpe r wire .3. Tur n th e ignitio n switc h O N (II) .

Is th e MI L on ?

Substitut e a known-goo d ECM ,

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

the origina l ECM .

— Repai r shor t i n the wir e

betwee n No . 5 BACK-U P

LIGHTS , ALTERNATOR , TUR N

SIGNAL S (1 5 A ) fus e an d

gaug e assembly .

— Replac e No . 5 BACK-U P

LIGHTS , ALTERNATOR , TUR N

SIGNALS (15 A) fuse.

Chec k fo r a n ope n in th e wire s

(PG lines) :1. Tur n th e ignitio n switc h O N (II) .

2 . Measur e voltag e betwee n

bod y groun d an d EC M con -

necto r terminal s A1 2 an d A2 5

individually .

I s ther e les s tha n 1. 0 V ?

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

th e origina l ECM . Repai

r ope n i n th e wire(s )

betwee n EC M an d G10 1 (locate d

a t intak e manifold ) tha t ha d

mor e tha n 1.0V .

— Repai r ope n i n th e wire s

betwee n EC M (A7 ) an d gaug e

assembly .— Replac e th e MI L bulb .

(cont'd )

Turn th e ignitio n switc h O N (II) .

The Malfunctio n Indicato r Lam p

(MIL ) neve r come s o n (eve n fo r

tw o seconds ) afte r ignitio n i s

turne d O N (II) .

ProCarManuals.com

Page 660 of 1503

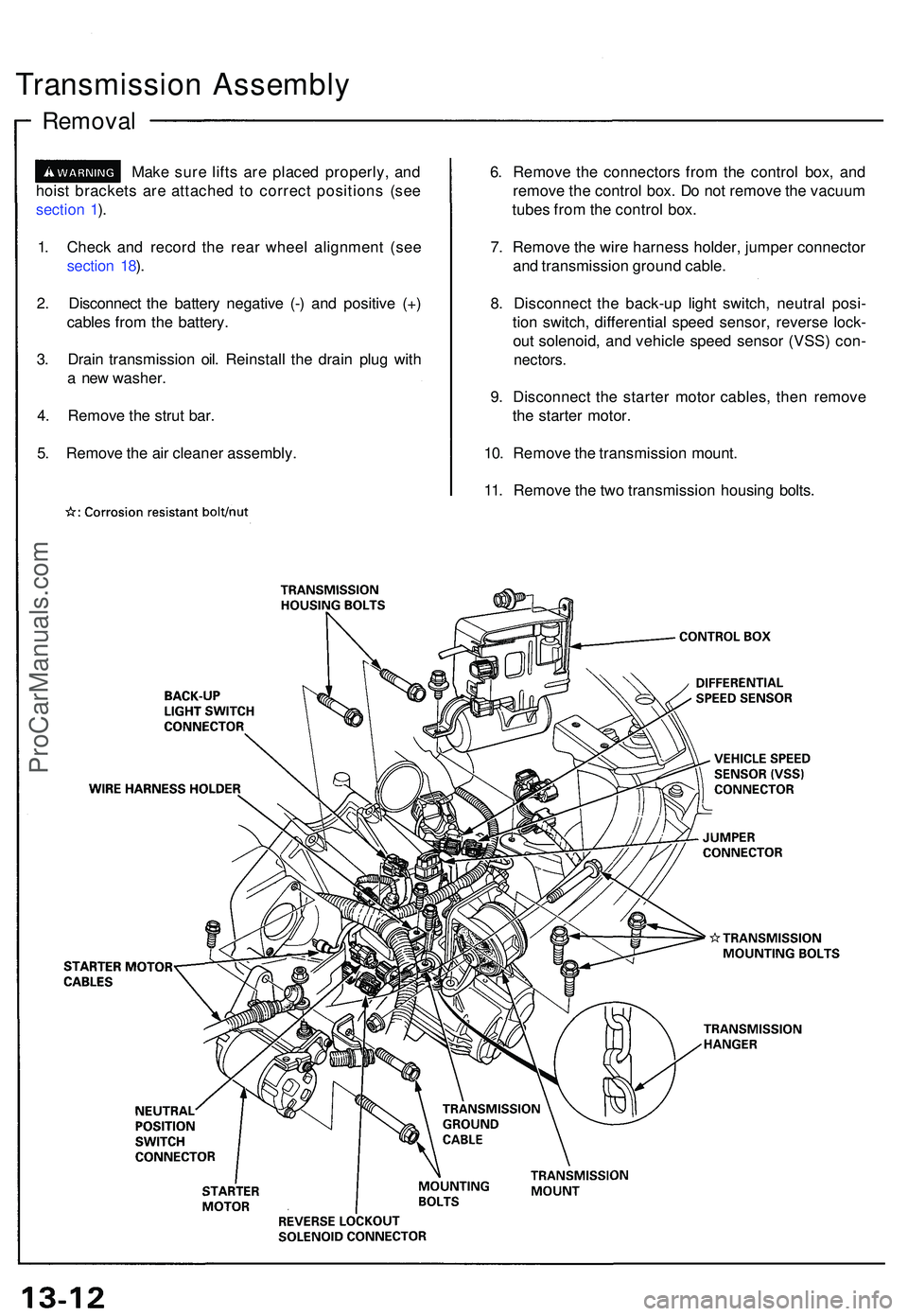

Transmission Assembl y

Removal

Make sur e lift s ar e place d properly , an d

hois t bracket s ar e attache d t o correc t position s (se e

sectio n 1 ).

1 . Chec k an d recor d th e rea r whee l alignmen t (se e

sectio n 18 ).

2 . Disconnec t th e batter y negativ e (- ) an d positiv e (+ )

cable s fro m th e battery .

3 . Drai n transmissio n oil . Reinstal l th e drai n plu g wit h

a ne w washer .

4 . Remov e th e stru t bar .

5 . Remov e th e ai r cleane r assembly . 6

. Remov e th e connector s fro m th e contro l box , an d

remov e th e contro l box . D o no t remov e th e vacuu m

tube s fro m th e contro l box .

7 . Remov e th e wir e harnes s holder , jumpe r connecto r

an d transmissio n groun d cable .

8 . Disconnec t th e back-u p ligh t switch , neutra l posi -

tio n switch , differentia l spee d sensor , revers e lock -

ou t solenoid , an d vehicl e spee d senso r (VSS ) con -

nectors .

9. Disconnec t th e starte r moto r cables , the n remov e

th e starte r motor .

10 . Remov e th e transmissio n mount .

11 . Remov e th e tw o transmissio n housin g bolts .

ProCarManuals.com

Page 710 of 1503

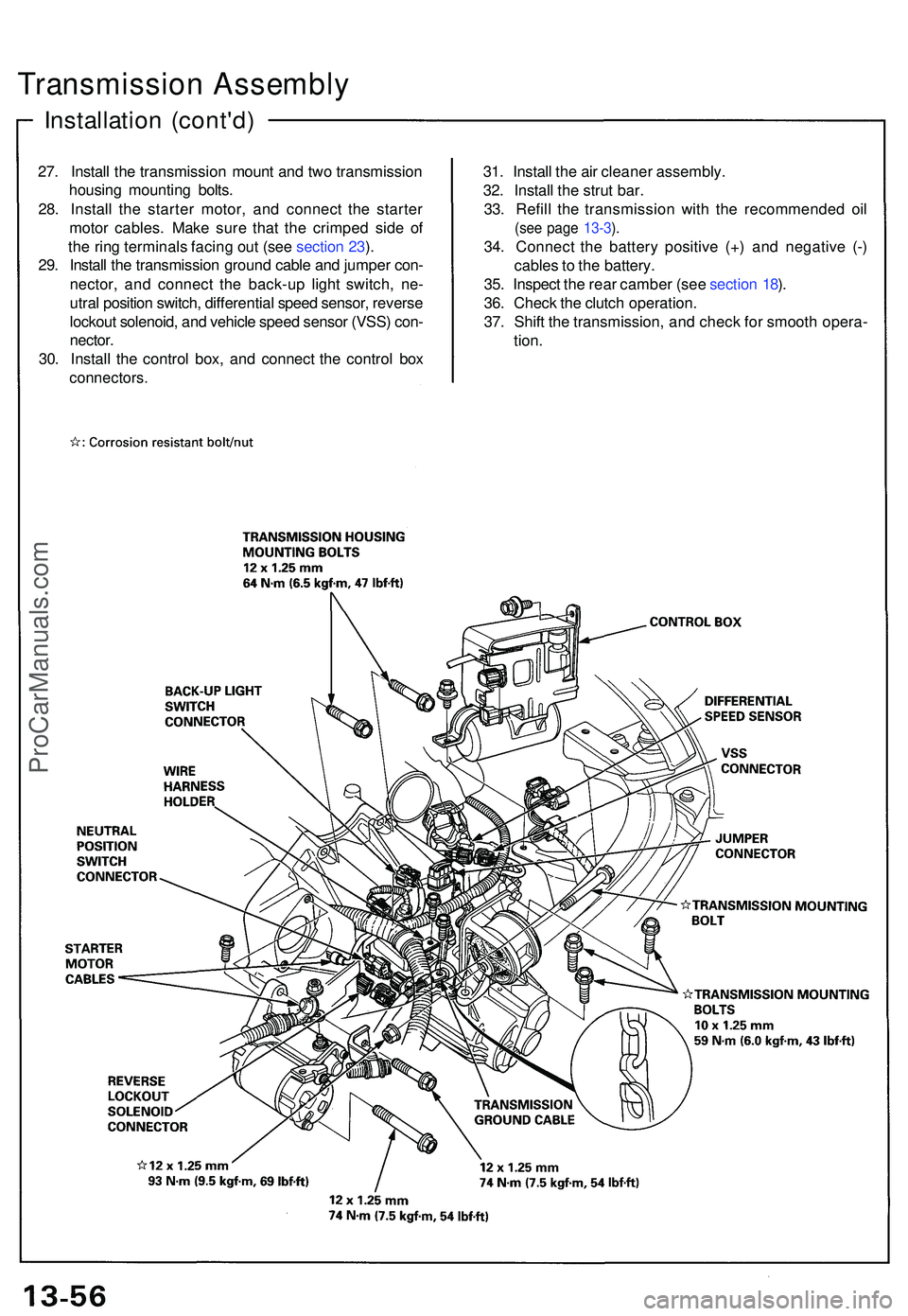

Transmission Assembl y

Installatio n (cont'd )

27. Instal l th e transmissio n moun t an d tw o transmissio n

housin g mountin g bolts .

28 . Instal l th e starte r motor , an d connec t th e starte r

moto r cables . Mak e sur e tha t th e crimpe d sid e o f

th e rin g terminal s facin g ou t (se e sectio n 23 ).

29 . Instal l th e transmissio n groun d cabl e an d jumpe r con -

nector , an d connec t th e back-u p ligh t switch , ne -

utra l positio n switch , differentia l spee d sensor , revers e

lockou t solenoid , an d vehicl e spee d senso r (VSS ) con -

nector .

30 . Instal l th e contro l box , an d connec t th e contro l bo x

connectors .

31. Instal l th e ai r cleane r assembly .

32 . Instal l th e stru t bar .

33 . Refil l th e transmissio n wit h th e recommende d oi l

(se e pag e 13-3 ).

34 . Connec t th e batter y positiv e (+ ) an d negativ e (- )

cable s to th e battery .

35 . Inspec t th e rea r cambe r (se e sectio n 18 ).

36 . Chec k th e clutc h operation .

37 . Shif t th e transmission, and chec k fo r smoot h opera -

tion .

ProCarManuals.com

Page 1035 of 1503

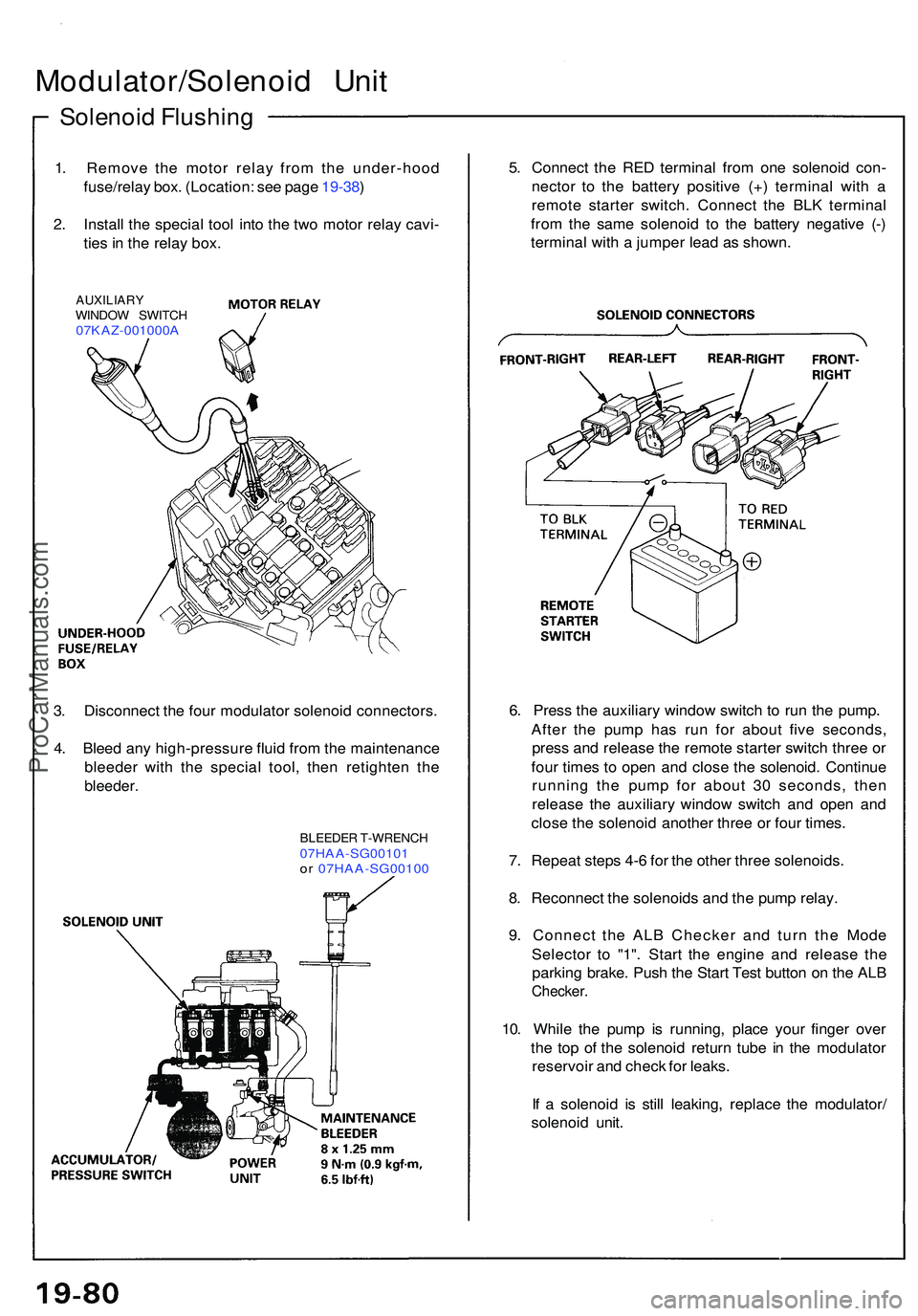

Solenoid Flushin g

Modulator/Solenoi d Uni t

1. Remov e th e moto r rela y fro m th e under-hoo d

fuse/rela y box . (Location : se e pag e 19-38 )

2 . Instal l th e specia l too l int o th e tw o moto r rela y cavi -

tie s in th e rela y box .

AUXILIAR YWINDOW SWITC H07KAZ-001000 A

5. Connec t th e RE D termina l fro m on e solenoi d con -

necto r t o th e batter y positiv e (+ ) termina l wit h a

remot e starte r switch . Connec t th e BL K termina l

fro m th e sam e solenoi d t o th e batter y negativ e (- )

termina l wit h a jumpe r lea d a s shown .

3 . Disconnec t th e fou r modulato r solenoi d connectors .

4 . Blee d an y high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool , the n retighte n th e

bleeder .

BLEEDE R T-WRENC H07HAA-SG0010 1or 07HAA-SG0010 0

6. Pres s th e auxiliar y windo w switc h t o ru n th e pump .

Afte r th e pum p ha s ru n fo r abou t fiv e seconds ,

pres s an d releas e th e remot e starte r switc h thre e o r

fou r time s t o ope n an d clos e th e solenoid . Continu e

runnin g th e pum p fo r abou t 3 0 seconds , the n

releas e th e auxiliar y windo w switc h an d ope n an d

clos e th e solenoi d anothe r thre e o r fou r times .

7 . Repea t step s 4- 6 fo r th e othe r thre e solenoids .

8 . Reconnec t th e solenoid s an d th e pum p relay .

9 . Connec t th e AL B Checke r an d tur n th e Mod e

Selecto r t o "1" . Star t th e engin e an d releas e th e

parkin g brake . Pus h th e Star t Tes t butto n o n th e AL B

Checker .

10. Whil e th e pum p i s running , plac e you r finge r ove r

th e to p o f th e solenoi d retur n tub e i n th e modulato r

reservoi r an d chec k fo r leaks .

I f a solenoi d i s stil l leaking , replac e th e modulator /

solenoi d unit .

ProCarManuals.com

Page 1250 of 1503

Starting Syste m

Starte r Tes t

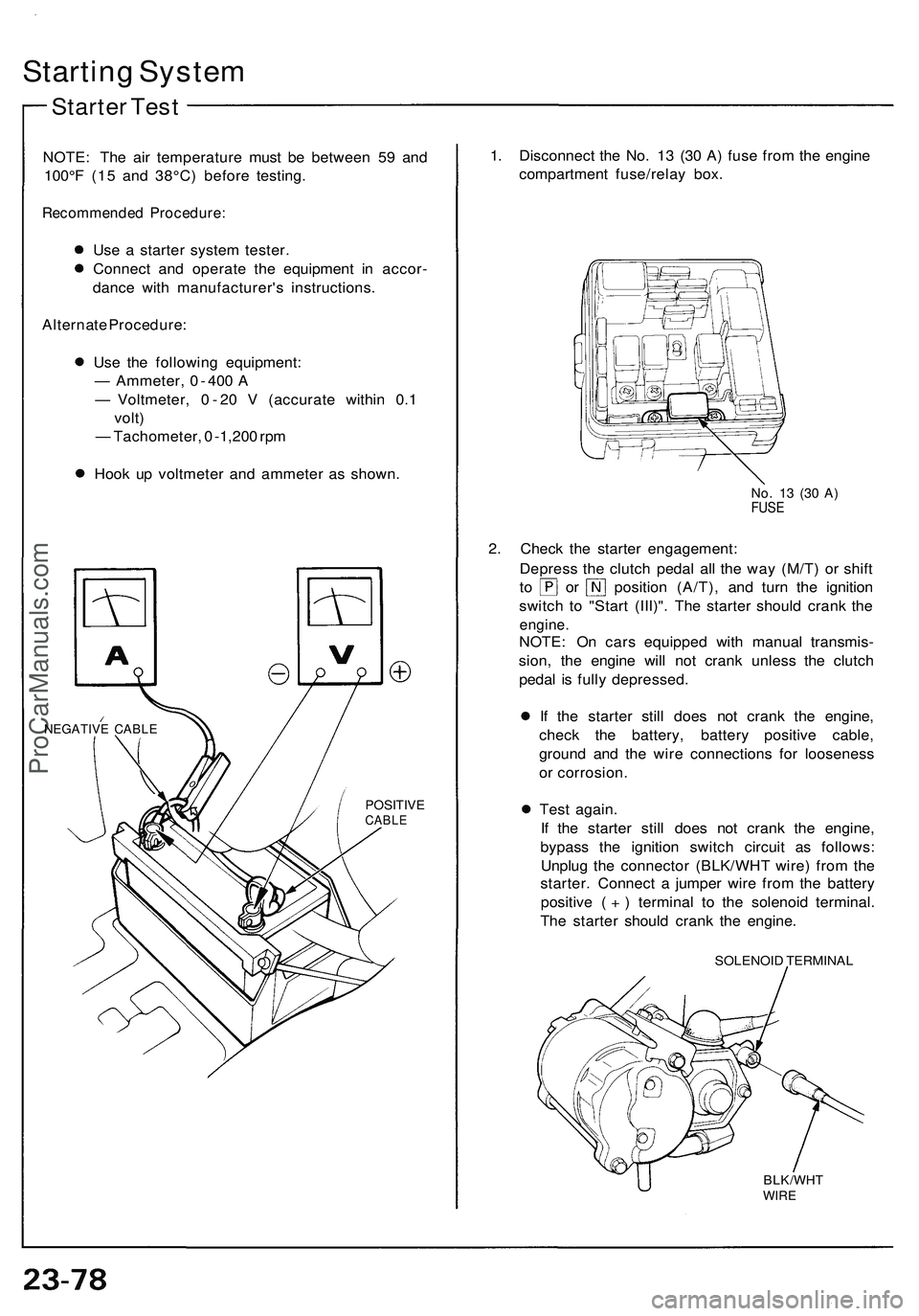

NOTE : Th e ai r temperatur e mus t b e betwee n 5 9 an d

100° F (1 5 an d 38°C ) befor e testing .

Recommende d Procedure :

Use a starte r syste m tester .

Connec t an d operat e th e equipmen t i n accor -

danc e wit h manufacturer' s instructions .

Alternat e Procedure :

Us e th e followin g equipment :

— Ammeter , 0 - 40 0 A

— Voltmeter , 0 - 2 0 V (accurat e withi n 0. 1

volt )

— Tachometer , 0 -1,20 0 rp m

Hoo k u p voltmete r an d ammete r a s shown .

NEGATIV E CABL E

POSITIV ECABLE

1. Disconnec t th e No . 1 3 (3 0 A ) fus e fro m th e engin e

compartmen t fuse/rela y box .

No. 1 3 (3 0 A )FUS E

2. Chec k th e starte r engagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to o r positio n (A/T) , an d tur n th e ignitio n

switc h t o "Star t (III)" . Th e starte r shoul d cran k th e

engine .

NOTE: O n car s equippe d wit h manua l transmis -

sion , th e engin e wil l no t cran k unles s th e clutc h

peda l i s full y depressed .

I f th e starte r stil l doe s no t cran k th e engine ,

chec k th e battery , batter y positiv e cable ,

ground and th e wir e connection s fo r loosenes s

o r corrosion .

Tes t again .

If th e starte r stil l doe s no t cran k th e engine ,

bypas s th e ignitio n switc h circui t a s follows :

Unplu g th e connecto r (BLK/WH T wire ) fro m th e

starter . Connec t a jumpe r wir e fro m th e batter y

positiv e ( + ) termina l t o th e solenoi d terminal .

Th e starte r shoul d cran k th e engine .

SOLENOI D TERMINA L

BLK/WHTWIRE

ProCarManuals.com

Page 1272 of 1503

Charging System

Troubleshooting (cont'd)

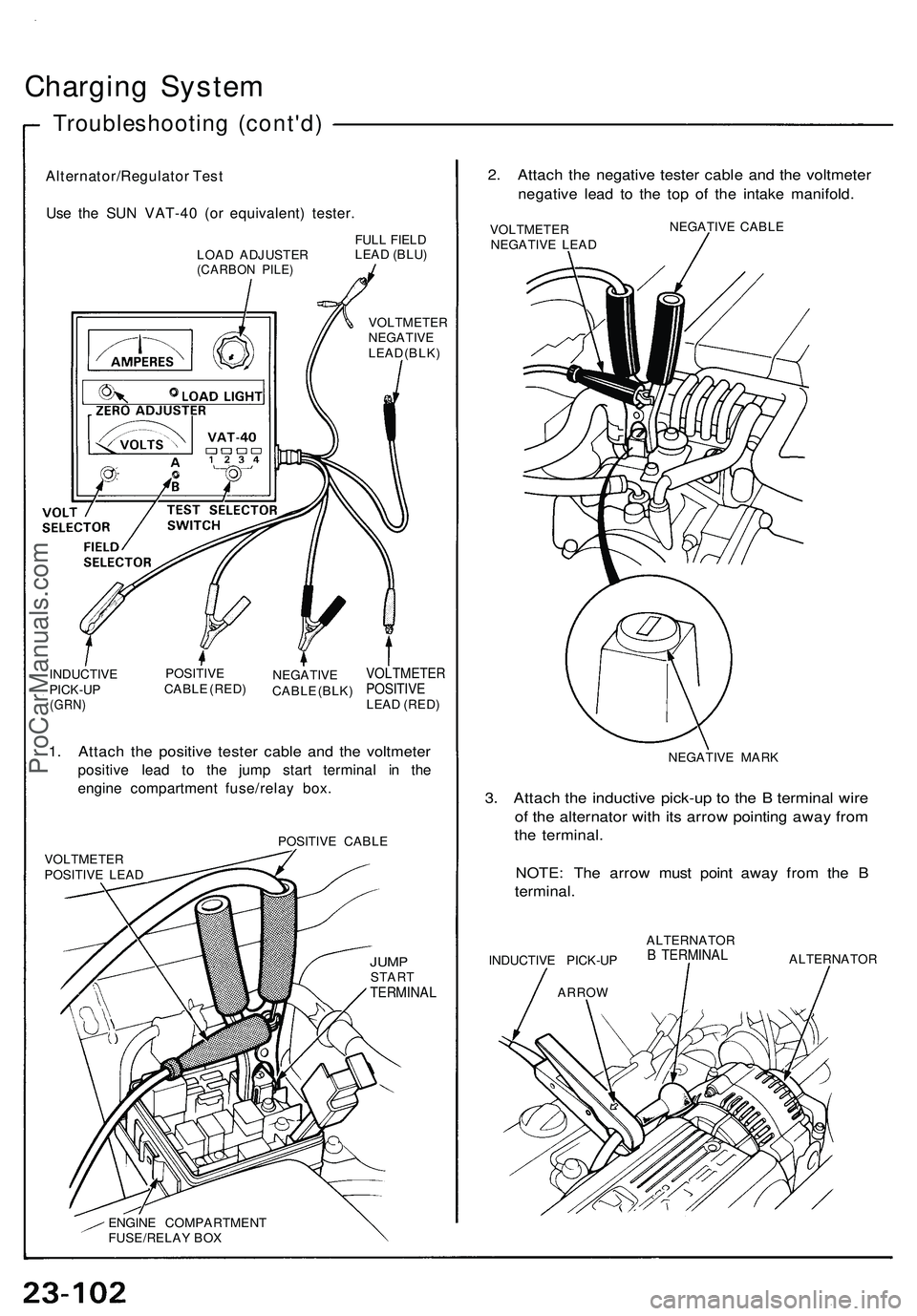

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

ENGINE COMPARTMENT

FUSE/RELAY BOX

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATORProCarManuals.com

Page 1296 of 1503

Fuel Gaug e

Gauge Tes t

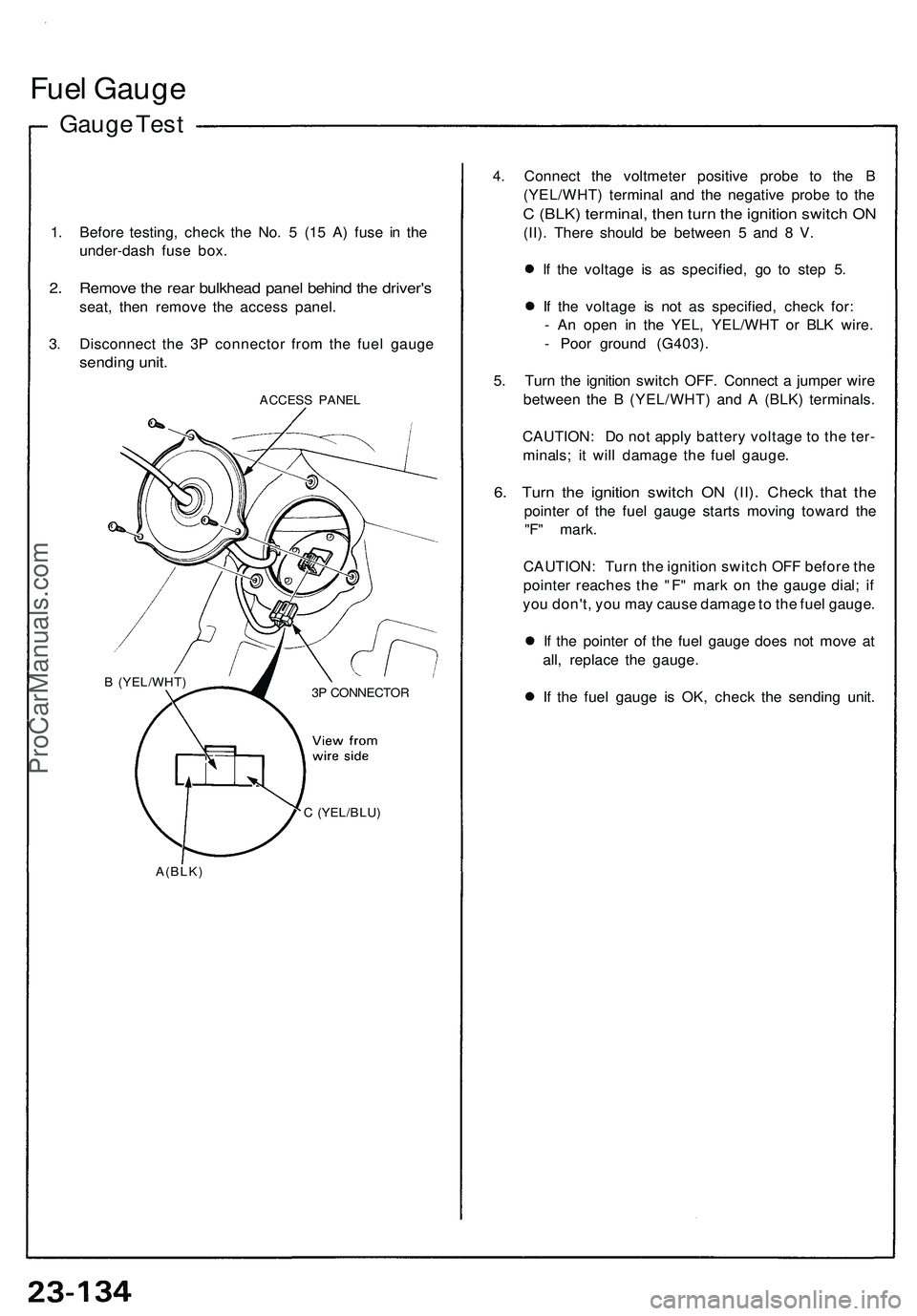

1. Befor e testing , chec k th e No . 5 (15 A ) fus e i n th e

under-das h fus e box .

2. Remov e th e rea r bulkhea d pane l behin d th e driver' s

seat, the n remov e th e acces s panel .

3 . Disconnec t th e 3 P connecto r fro m th e fue l gaug e

sendin g unit .

ACCES S PANE L

C (YEL/BLU )

A(BLK )

4. Connec t th e voltmete r positiv e prob e t o th e B

(YEL/WHT ) termina l an d th e negativ e prob e t o th e

C (BLK ) terminal , the n tur n th e ignitio n switc h O N

(II) . Ther e shoul d b e betwee n 5 an d 8 V .

I f th e voltag e i s a s specified , g o t o ste p 5 .

I f th e voltag e i s no t a s specified , chec k for :

- A n ope n i n th e YEL , YEL/WH T o r BL K wire .

- Poo r groun d (G403) .

5 . Tur n th e ignitio n switc h OFF . Connec t a jumpe r wir e

betwee n th e B (YEL/WHT ) an d A (BLK ) terminals .

CAUTION : D o no t appl y batter y voltag e t o th e ter -

minals ; i t wil l damag e th e fue l gauge .

6. Tur n th e ignitio n switc h O N (II) . Chec k tha t th e

pointe r o f th e fue l gaug e start s movin g towar d th e

"F " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "F" mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y caus e damag e to th e fue l gauge .

I f th e pointe r o f th e fue l gaug e doe s no t mov e a t

all , replac e th e gauge .

I f th e fue l gaug e i s OK , chec k th e sendin g unit .

B (YEL/WHT )

3P CONNECTO R

ProCarManuals.com

Page 1298 of 1503

Coolant Temperatur e Gaug e

Coolan t Temperatur e Gaug e Tes t

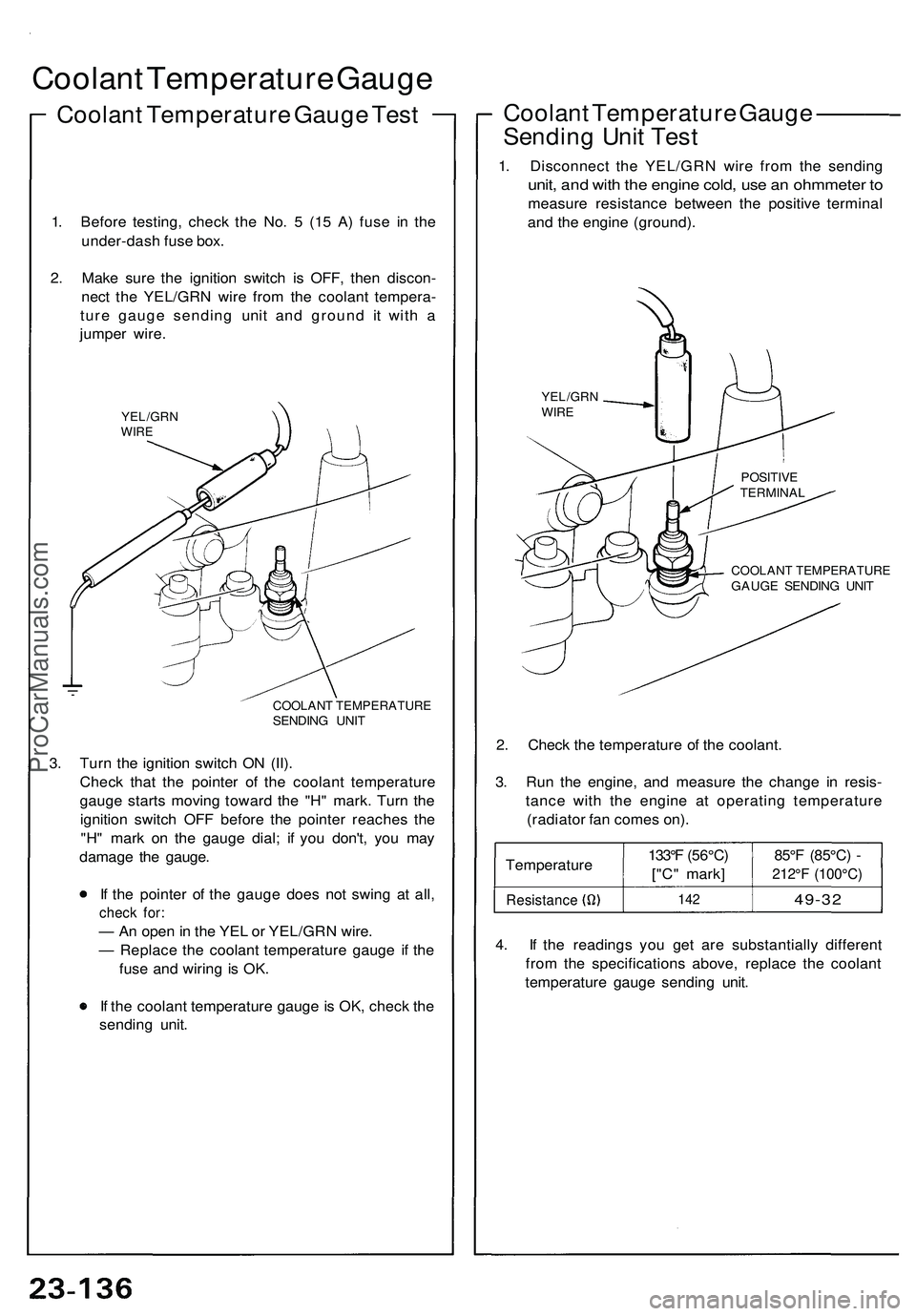

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e coolan t tempera -

tur e gaug e sendin g uni t an d groun d i t wit h a

jumpe r wire .

YEL/GR NWIRE

COOLAN T TEMPERATUR ESENDING UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e coolan t temperatur e

gaug e start s movin g towar d th e "H " mark . Tur n th e

ignitio n switc h OF F befor e th e pointe r reache s th e

"H " mar k o n th e gaug e dial ; i f yo u don't , yo u ma y

damag e th e gauge .

I f th e pointe r o f th e gaug e doe s no t swin g a t all ,

chec k for :

— An ope n in th e YE L o r YEL/GR N wire .

— Replac e th e coolan t temperatur e gaug e i f th e

fus e an d wirin g i s OK .

I f th e coolan t temperatur e gaug e is OK , chec k th e

sendin g unit .

Coolan t Temperatur e Gaug e ———

Sendin g Uni t Tes t

1. Disconnec t th e YEL/GR N wir e fro m th e sendin g

unit, an d wit h th e engin e cold , us e a n ohmmete r t o

measur e resistanc e betwee n th e positiv e termina l

an d th e engin e (ground) .

COOLAN T TEMPERATUR EGAUGE SENDIN G UNI T

2. Chec k th e temperatur e o f th e coolant .

3 . Ru n th e engine , an d measur e th e chang e i n resis -

tanc e wit h th e engin e a t operatin g temperatur e

(radiato r fa n come s on) .

Temperatur e

Resistance

133°F (56°C )

["C " mark ]

142

85° F (85°C ) -

212° F (100°C )

49-32

4. I f th e reading s yo u ge t ar e substantiall y differen t

fro m th e specification s above , replac e th e coolan t

temperatur e gaug e sendin g unit .

YEL/GR NWIRE

POSITIV ETERMINA L

ProCarManuals.com

Page 1299 of 1503

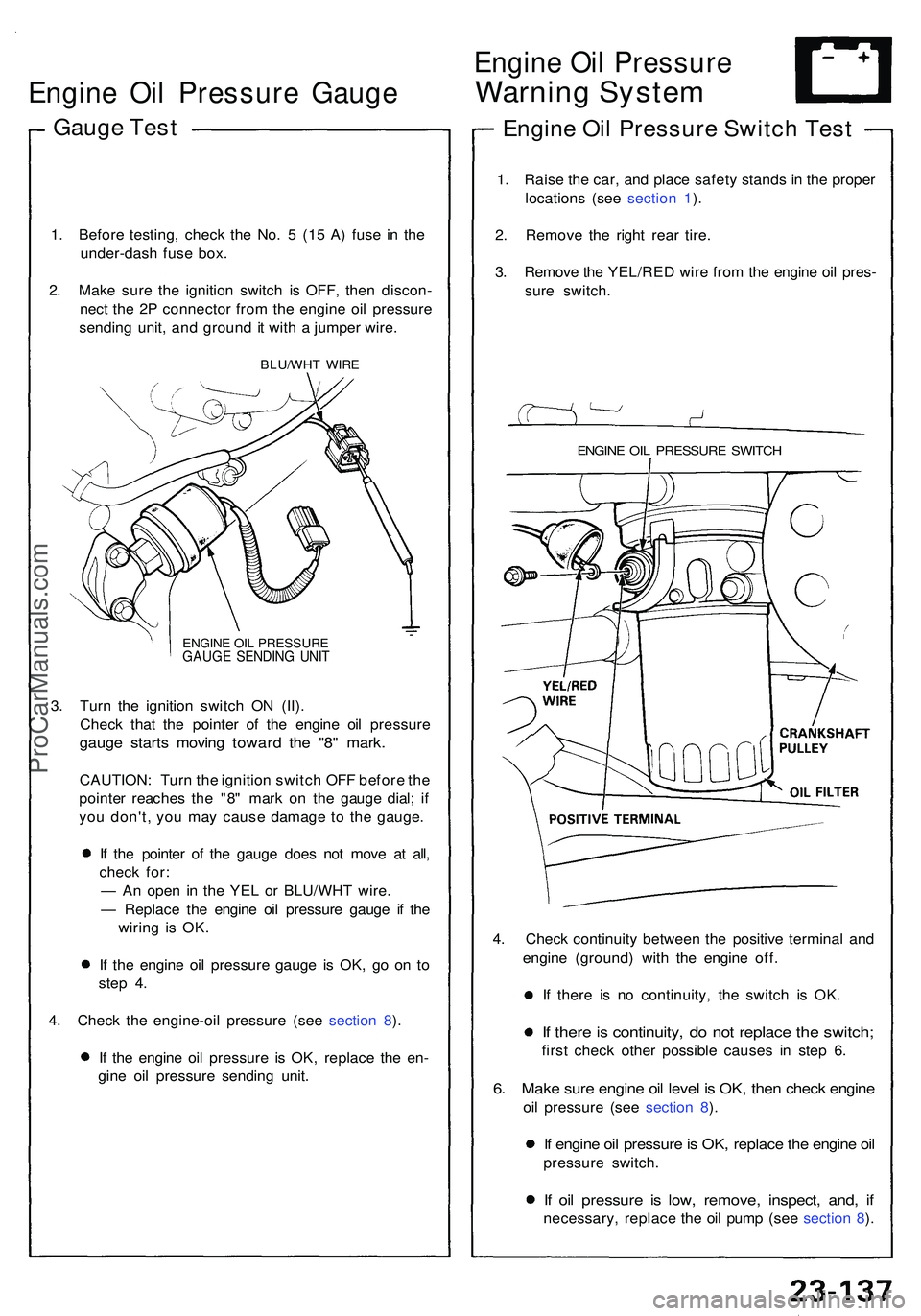

Engine Oi l Pressur e Gaug e

Gauge Tes t

1. Befor e testing , chec k th e No . 5 (15 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e 2 P connecto r fro m th e engin e oi l pressur e

sendin g unit , an d groun d i t wit h a jumpe r wire .

BLU/WH T WIR E

ENGIN E OI L PRESSUR E

GAUGE SENDIN G UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e engin e oi l pressur e

gauge start s movin g towar d th e "8 " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "8 " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y cause damag e t o th e gauge .

I f th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k for :

— A n ope n i n th e YE L o r BLU/WH T wire .

— Replac e th e engin e oi l pressur e gaug e i f th e

wirin g i s OK .

I f th e engin e oi l pressur e gaug e i s OK , g o o n t o

ste p 4 .

4 . Chec k th e engine-oi l pressur e (se e sectio n 8 ).

I f th e engin e oi l pressur e i s OK , replac e th e en -

gin e oi l pressur e sendin g unit .

Engin e Oi l Pressur e

Warning Syste m

Engine Oi l Pressur e Switc h Tes t

1. Rais e th e car , an d plac e safet y stand s i n th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e righ t rea r tire .

3 . Remov e th e YEL/RE D wir e fro m th e engin e oi l pres -

sur e switch .

ENGINE OI L PRESSUR E SWITC H

4. Chec k continuit y betwee n th e positiv e termina l an d

engin e (ground ) wit h th e engin e off .

I f ther e i s n o continuity , th e switc h i s OK .

If ther e is continuity , d o no t replac e th e switch ;

first chec k othe r possible causes i n ste p 6 .

6. Mak e sur e engin e oi l leve l i s OK , the n chec k engin e

oil pressur e (se e sectio n 8 ).

If engin e oi l pressur e is OK , replac e th e engin e oi l

pressur e switch .

If oi l pressur e i s low , remove , inspect , and , i f

necessary , replac e th e oi l pum p (se e sectio n 8 ).

ProCarManuals.com