sensor ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 99 of 1503

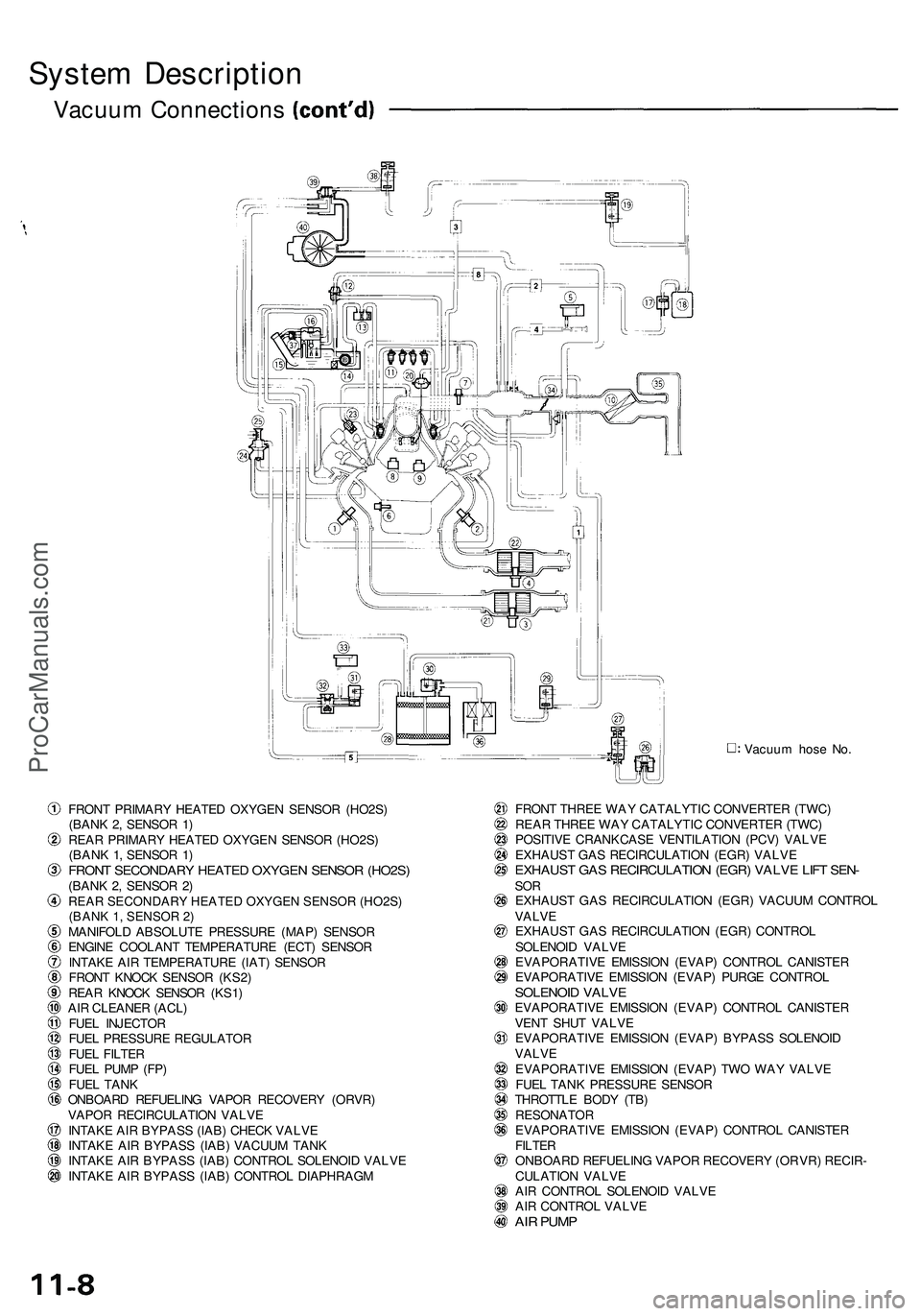

System Descriptio n

Vacuum Connection s

FRONT PRIMAR Y HEATE D OXYGE N SENSO R (HO2S )

(BAN K 2 , SENSO R 1 )

REA R PRIMAR Y HEATE D OXYGE N SENSO R (HO2S )

(BAN K 1 , SENSO R 1 )

FRON T SECONDAR Y HEATE D OXYGE N SENSO R (HO2S )(BANK 2 , SENSO R 2 )REAR SECONDARY HEATED OXYGEN SENSOR (HO2S)

(BANK 1, SENSOR 2)

MANIFOL D ABSOLUT E PRESSUR E (MAP ) SENSO R

ENGIN E COOLAN T TEMPERATUR E (ECT ) SENSO R

INTAK E AI R TEMPERATUR E (IAT ) SENSO R

FRON T KNOC K SENSO R (KS2 )

REA R KNOC K SENSO R (KS1 )

AI R CLEANE R (ACL )

FUE L INJECTO R

FUE L PRESSUR E REGULATO R

FUE L FILTE R

FUE L PUM P (FP )

FUE L TAN K

ONBOAR D REFUELIN G VAPO R RECOVER Y (ORVR )

VAPO R RECIRCULATIO N VALV E

INTAK E AI R BYPAS S (IAB ) CHEC K VALV E

INTAK E AI R BYPAS S (IAB ) VACUU M TAN K

INTAK E AI R BYPAS S (IAB ) CONTRO L SOLENOI D VALV E

INTAK E AI R BYPAS S (IAB ) CONTRO L DIAPHRAG M Vacuu

m hos e No .

FRON T THRE E WA Y CATALYTI C CONVERTE R (TWC )

REA R THRE E WA Y CATALYTI C CONVERTE R (TWC )

POSITIV E CRANKCAS E VENTILATIO N (PCV ) VALV E

EXHAUS T GA S RECIRCULATIO N (EGR ) VALV E

EXHAUS T GA S RECIRCULATIO N (EGR ) VALV E LIF T SEN -SOREXHAUS T GA S RECIRCULATIO N (EGR ) VACUU M CONTRO L

VALV E

EXHAUS T GA S RECIRCULATIO N (EGR ) CONTRO L

SOLENOI D VALV E

EVAPORATIV E EMISSIO N (EVAP ) CONTRO L CANISTE R

EVAPORATIV E EMISSIO N (EVAP ) PURG E CONTRO L

SOLENOID VALV EEVAPORATIV E EMISSIO N (EVAP ) CONTRO L CANISTE R

VEN T SHU T VALV E

EVAPORATIV E EMISSIO N (EVAP ) BYPAS S SOLENOI D

VALV E

EVAPORATIV E EMISSIO N (EVAP ) TW O WA Y VALV E

FUE L TAN K PRESSUR E SENSO R

THROTTL E BOD Y (TB )

RESONATO R

EVAPORATIV E EMISSIO N (EVAP ) CONTRO L CANISTE R

FILTERONBOAR D REFUELIN G VAPO R RECOVER Y (ORVR ) RECIR -

CULATIO N VALV E

AI R CONTRO L SOLENOI D VALV E

AI R CONTRO L VALV E

AIR PUM P

ProCarManuals.com

Page 141 of 1503

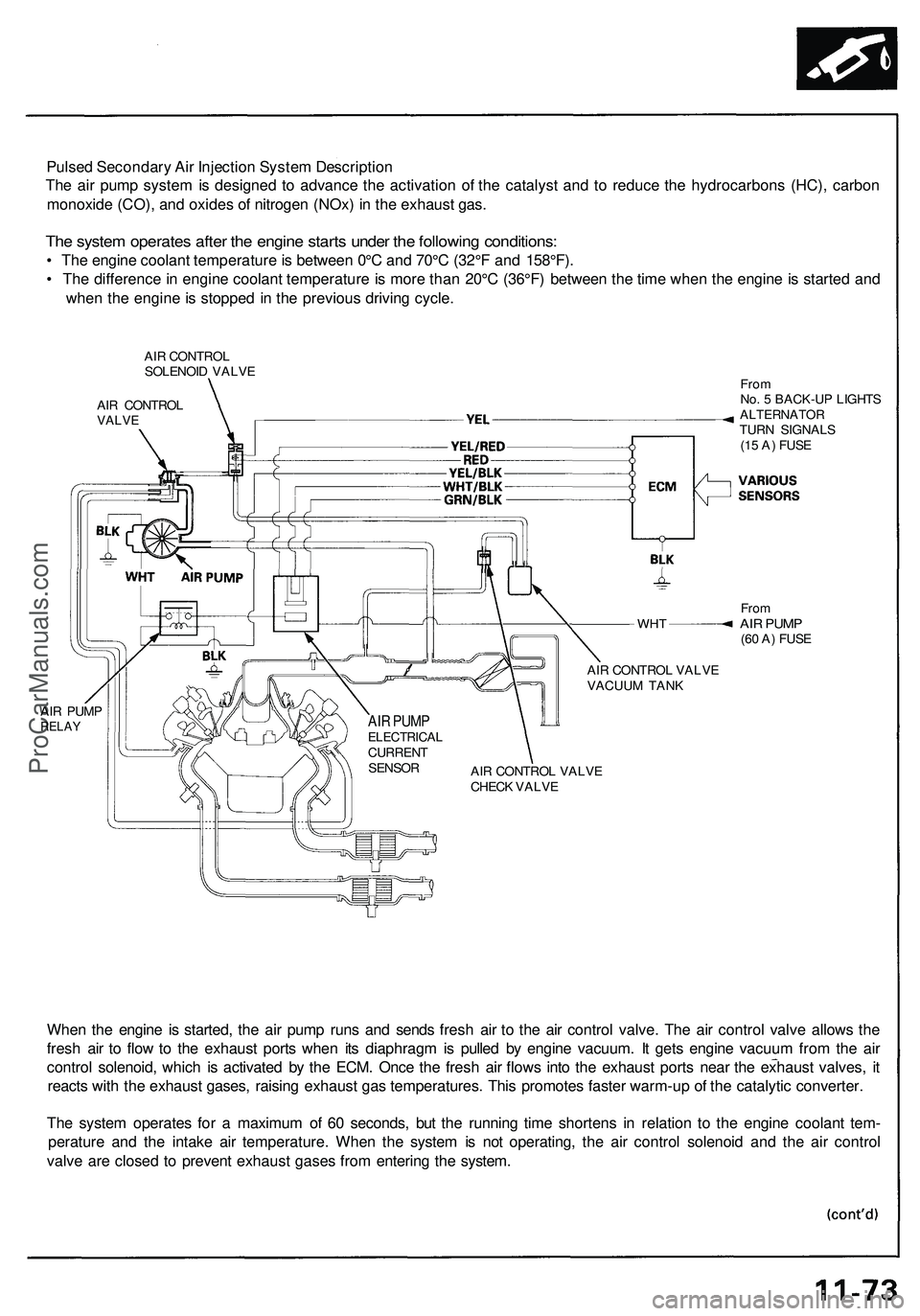

Pulsed Secondary Air Injection System Description

The air pump system is designed to advance the activation of the catalyst and to reduce the hydrocarbons (HC), carbon

monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas.

The system operates after the engine starts under the following conditions:

• The engine coolant temperature is between 0°C and 70°C (32°F and 158°F).

• The difference in engine coolant temperature is more than 20°C (36°F) between the time when the engine is started and

when the engine is stopped in the previous driving cycle.

AIR CONTROL

SOLENOID VALVE

AIR CONTROL

VALVE

WHT

AIR PUMP

RELAY

From

No. 5 BACK-UP LIGHTS

ALTERNATOR

TURN SIGNALS

(15 A) FUSE

From

AIR PUMP

(60 A) FUSE

AIR CONTROL VALVE

VACUUM TANK

AIR CONTROL VALVE

CHECK VALVE

When the engine is started, the air pump runs and sends fresh air to the air control valve. The air control valve allows the

fresh air to flow to the exhaust ports when its diaphragm is pulled by engine vacuum. It gets engine vacuum from the air

control solenoid, which is activated by the ECM. Once the fresh air flows into the exhaust ports near the exhaust valves, it

reacts with the exhaust gases, raising exhaust gas temperatures. This promotes faster warm-up of the catalytic converter.

The system operates for a maximum of 60 seconds, but the running time shortens in relation to the engine coolant tem-

perature and the intake air temperature. When the system is not operating, the air control solenoid and the air control

valve are closed to prevent exhaust gases from entering the system.

AIR PUMP

ELECTRICAL

CURRENT

SENSORProCarManuals.com

Page 157 of 1503

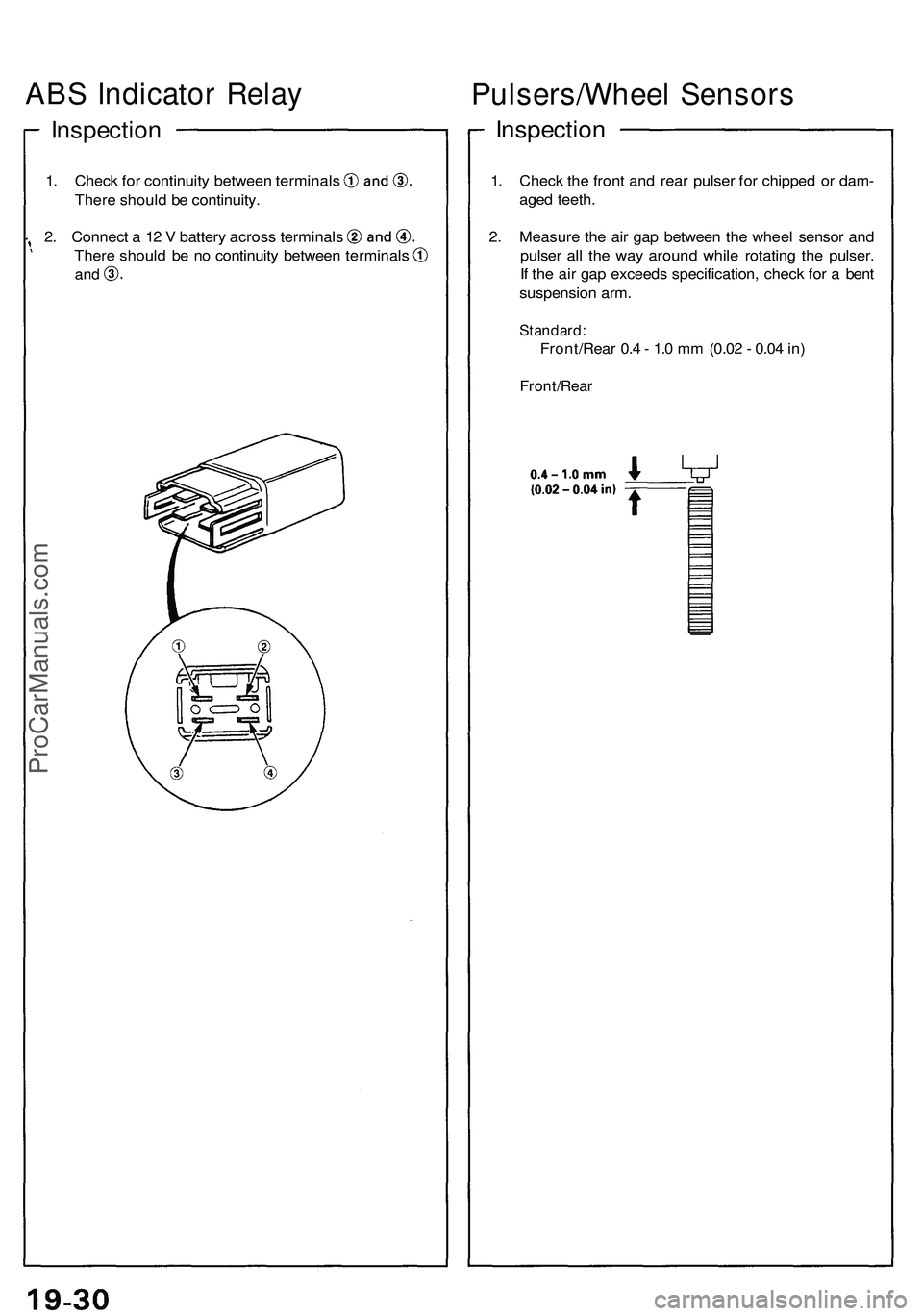

ABS Indicato r Rela y

Inspectio n

1. Chec k fo r continuit y betwee n terminal s

Ther e shoul d b e continuity .

2. Connec t a 1 2 V batter y acros s terminal s

There shoul d b e n o continuit y betwee n terminal s

and

Pulsers/Whee l Sensor s

Inspectio n

1. Chec k th e fron t an d rea r pulse r fo r chippe d o r dam -

age d teeth .

2 . Measur e th e ai r ga p betwee n th e whee l senso r an d

pulse r al l th e wa y aroun d whil e rotatin g th e pulser .

I f th e ai r ga p exceed s specification , chec k fo r a ben t

suspensio n arm .

Standard :

Front/Rea r 0. 4 - 1. 0 m m (0.0 2 - 0.0 4 in )

Front/Rea r

ProCarManuals.com

Page 158 of 1503

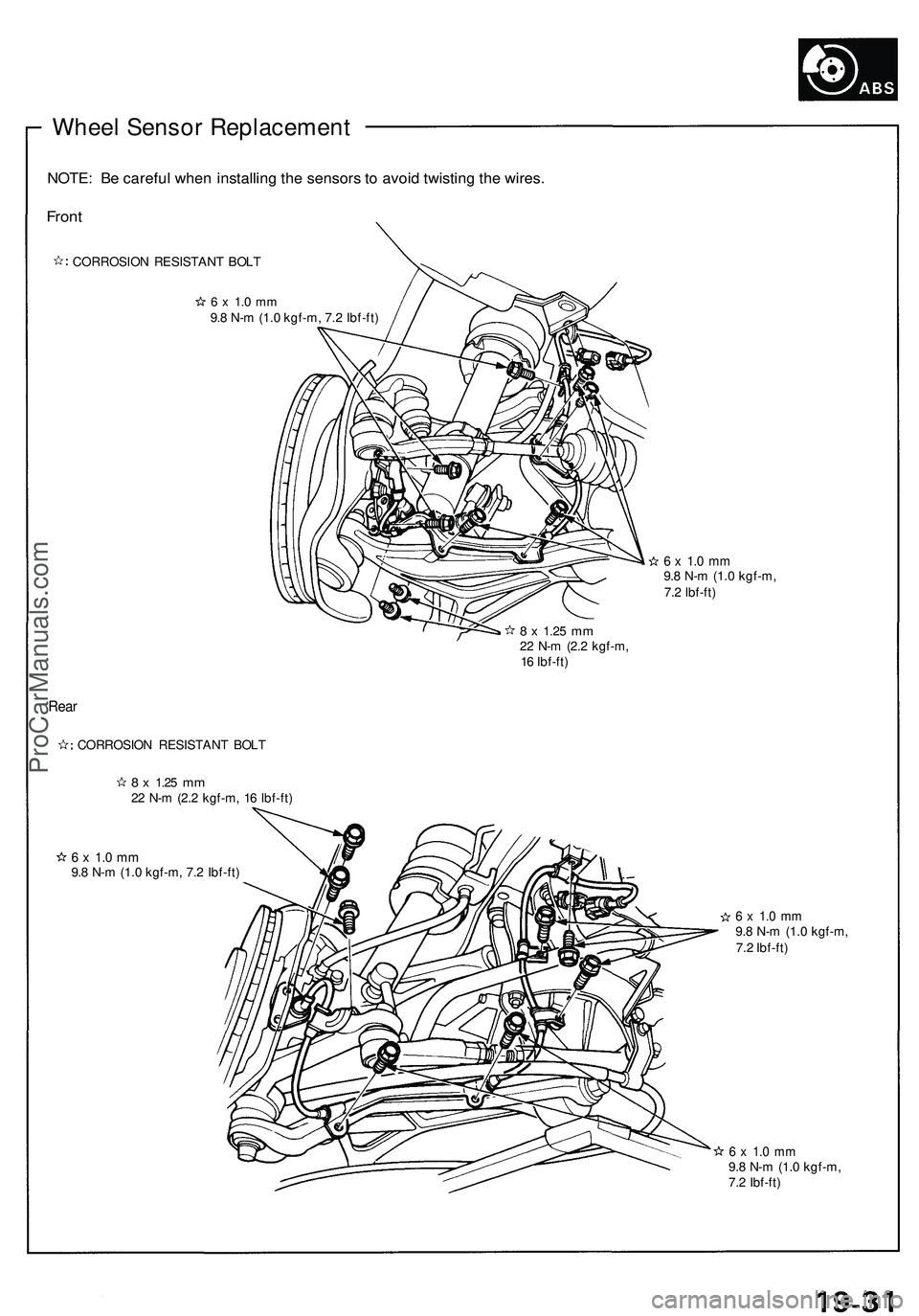

Wheel Senso r Replacemen t

NOTE: B e carefu l whe n installin g th e sensor s t o avoi d twistin g th e wires .

Front

CORROSIO N RESISTAN T BOL T

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Rear

CORROSIO N RESISTAN T BOL T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

ProCarManuals.com

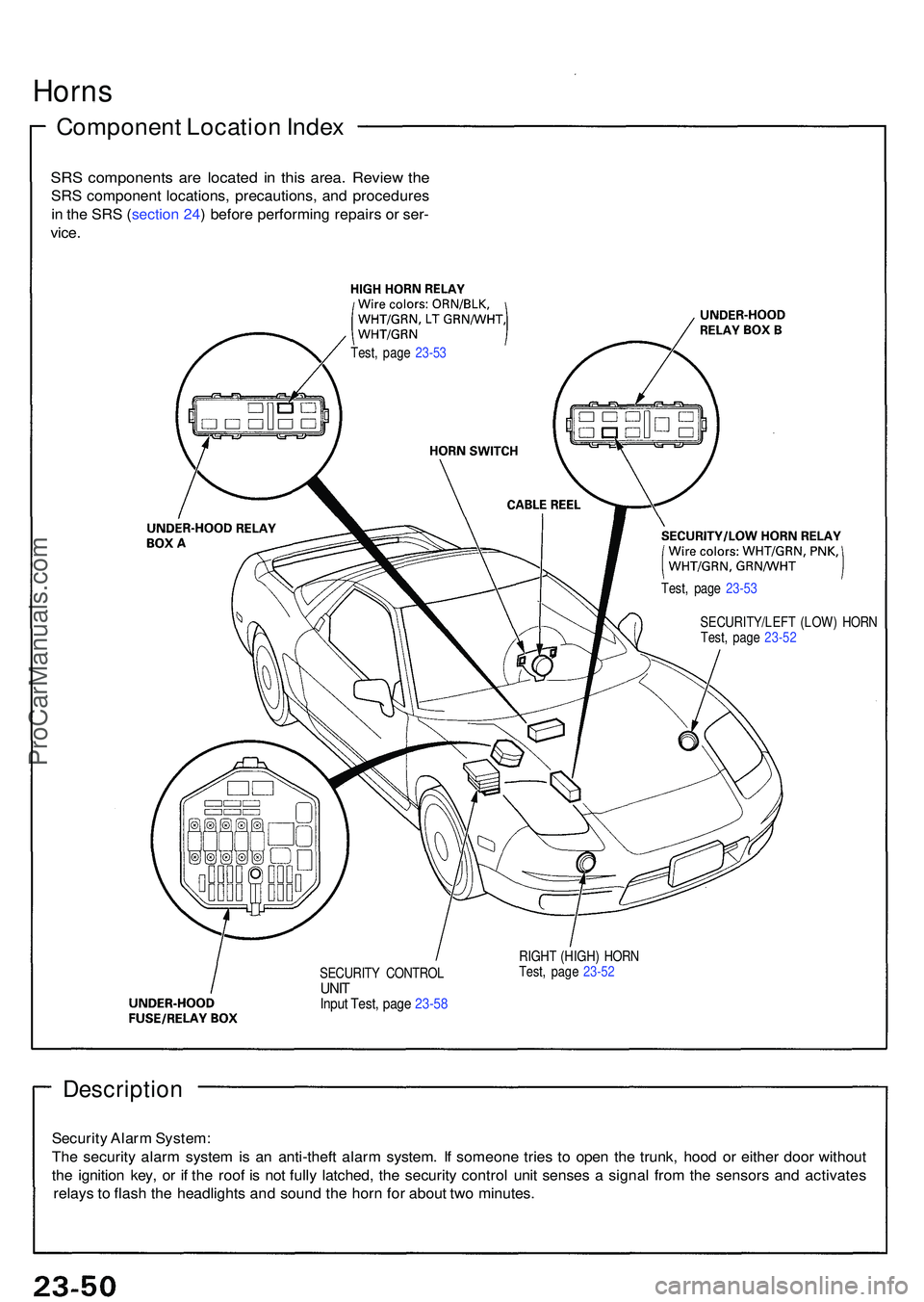

Page 277 of 1503

Description

Security Alar m System :

Th e securit y alar m syste m is a n anti-thef t alar m system . I f someon e trie s t o ope n th e trunk , hoo d o r eithe r doo r withou t

th e ignitio n key , o r i f th e roo f i s no t full y latched , th e securit y contro l uni t sense s a signa l fro m th e sensor s an d activate s

relay s t o flas h th e headlight s an d soun d th e hor n fo r abou t tw o minutes .

SECURIT Y CONTRO LUNITInpu t Test , pag e 23-5 8

RIGH T (HIGH ) HOR N

Test , pag e 23-5 2

Horn s

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

Test , pag e 23-5 3

Test, pag e 23-5 3

SECURITY/LEF T (LOW ) HOR N

Test , pag e 23-5 2

ProCarManuals.com

Page 342 of 1503

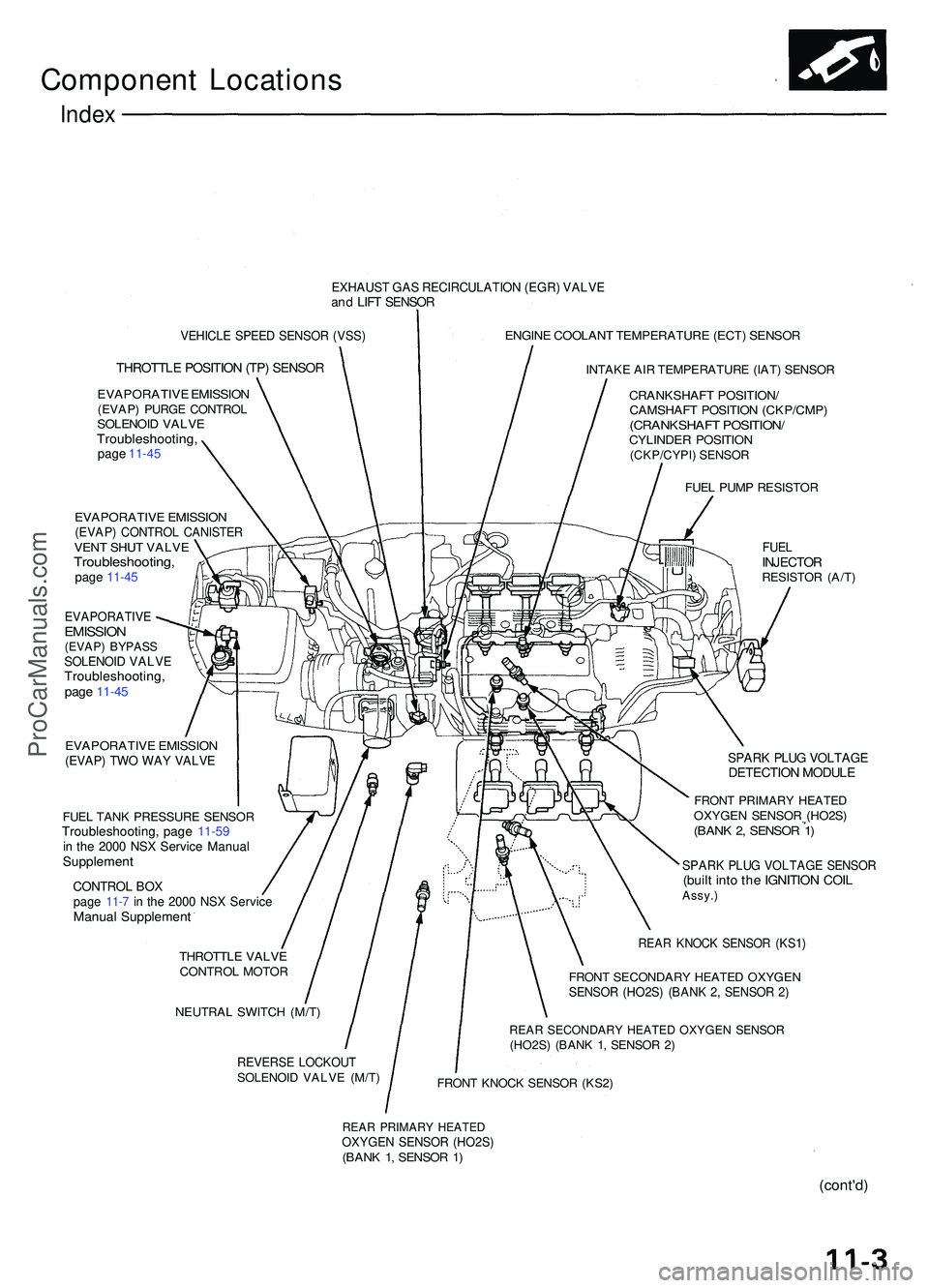

Component Location s

Index

EXHAUS T GA S RECIRCULATIO N (EGR ) VALV Eand LIF T SENSO R

FUELINJECTO RRESISTO R (A/T )

EVAPORATIV E EMISSIO N(EVAP) TW O WA Y VALV E

NEUTRA L SWITC H (M/T )

REAR KNOC K SENSO R (KS1 )

FRONT SECONDAR Y HEATE D OXYGE NSENSOR (HO2S ) (BAN K 2 , SENSO R 2 )

REA R SECONDAR Y HEATE D OXYGE N SENSO R(HO2S) (BAN K 1 , SENSO R 2 )

REVERS E LOCKOU TSOLENOID VALV E (M/T )FRON T KNOC K SENSO R (KS2 )

REAR PRIMAR Y HEATE DOXYGEN SENSO R (HO2S )(BANK 1 , SENSO R 1 )

(cont'd )

VEHICL E SPEE D SENSO R (VSS )

THROTTL E POSITIO N (TP ) SENSO R

EVAPORATIV E EMISSIO N(EVAP) PURG E CONTRO LSOLENOID VALV ETroubleshooting ,page 11-4 5

EVAPORATIV E EMISSIO N(EVAP) CONTRO L CANISTE RVENT SHU T VALV ETroubleshooting ,page 11-4 5

EVAPORATIV EEMISSION(EVAP) BYPAS SSOLENOI D VALV ETroubleshooting ,page 11-4 5

ENGIN E COOLAN T TEMPERATUR E (ECT ) SENSO R

INTAKE AI R TEMPERATUR E (IAT ) SENSO R

CRANKSHAF T POSITION /CAMSHAFT POSITIO N (CKP/CMP )(CRANKSHAF T POSITION /CYLINDER POSITIO N(CKP/CYPI ) SENSO R

FUEL PUM P RESISTO R

SPARK PLU G VOLTAG EDETECTIO N MODUL E

FRONT PRIMAR Y HEATE DOXYGEN SENSO R (HO2S )(BANK 2 , SENSO R 1 )

SPAR K PLU G VOLTAG E SENSO R(built int o th e IGNITIO N COI LAssy. )

FUEL TAN K PRESSUR E SENSO RTroubleshooting , pag e 11-5 9in th e 200 0 NS X Servic e Manua lSupplemen t

CONTROL BO Xpage 11- 7 in th e 200 0 NS X Servic eManual Supplemen t

THROTTLE VALV ECONTRO L MOTO R

ProCarManuals.com

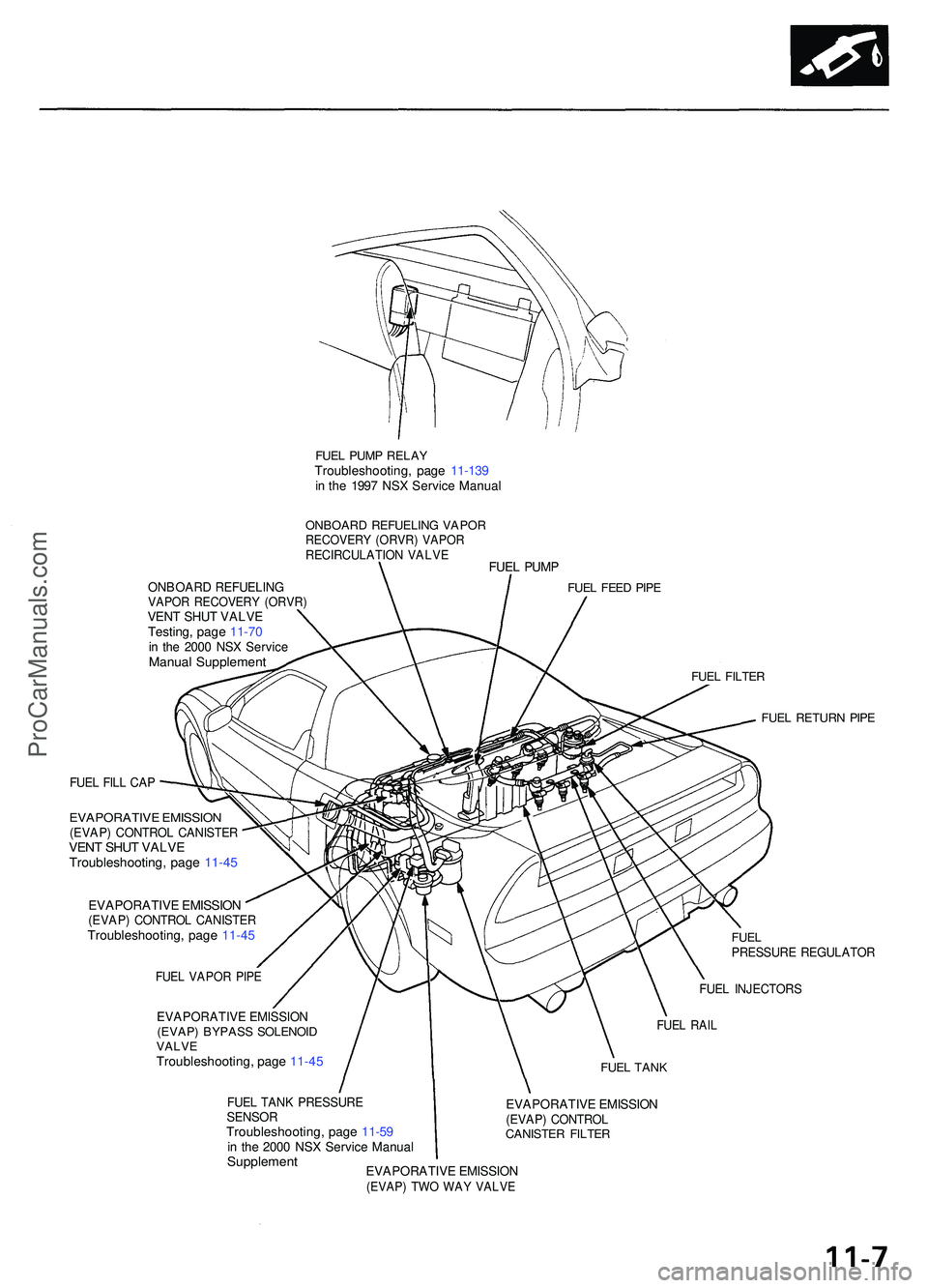

Page 346 of 1503

FUEL PUM P RELA YTroubleshooting , pag e 11-13 9in th e 199 7 NS X Servic e Manua l

ONBOAR D REFUELIN G VAPO RRECOVER Y (ORVR ) VAPO RRECIRCULATIO N VALV EFUEL PUM P

ONBOAR D REFUELIN GVAPOR RECOVER Y (ORVR )VENT SHU T VALV ETesting , pag e 11-7 0in th e 200 0 NS X Servic eManual Supplemen t

FUEL FEE D PIP E

FUE L FILTE R

FUEL RETUR N PIP E

FUE L FIL L CA P

EVAPORATIV E EMISSIO N(EVAP) CONTRO L CANISTE RVENT SHU T VALV ETroubleshooting , pag e 11-4 5

EVAPORATIV E EMISSIO N(EVAP) CONTRO L CANISTE RTroubleshooting , pag e 11-4 5

FUEL VAPO R PIP E

FUE LPRESSUR E REGULATO R

EVAPORATIV E EMISSIO N(EVAP) BYPAS S SOLENOI DVALVETroubleshooting , pag e 11-4 5

FUEL INJECTOR S

FUEL RAI L

FUEL TAN K PRESSUR ESENSORTroubleshooting , pag e 11-5 9in th e 200 0 NS X Servic e Manua lSupplemen t

FUEL TAN K

EVAPORATIV E EMISSIO N(EVAP) CONTRO LCANISTER FILTE R

EVAPORATIV E EMISSIO N(EVAP) TW O WA Y VALV E

ProCarManuals.com

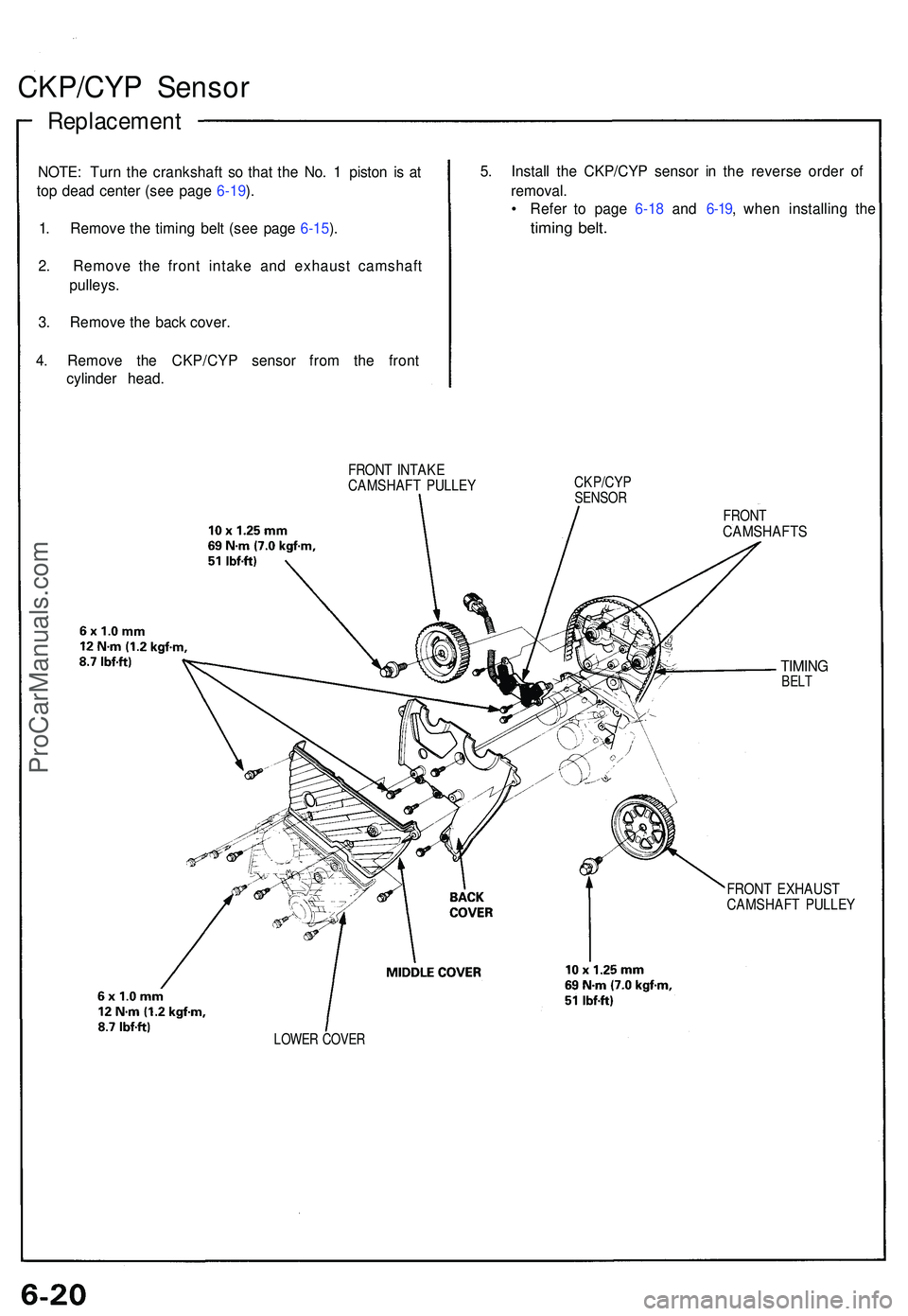

Page 437 of 1503

CKP/CYP Senso r

Replacemen t

NOTE: Tur n th e crankshaf t s o tha t th e No . 1 pisto n i s a t

to p dea d cente r (se e pag e 6-19 ).

1 . Remov e th e timin g bel t (se e pag e 6-15 ).

2 . Remov e th e fron t intak e an d exhaus t camshaf t

pulleys .

3 . Remov e th e bac k cover .

4 . Remov e th e CKP/CY P senso r fro m th e fron t

cylinde r head . 5

. Instal l th e CKP/CY P senso r i n th e revers e orde r o f

removal .

• Refe r t o pag e 6-1 8 an d 6-19 , whe n installin g th e

timin g belt .

FRON T INTAK ECAMSHAF T PULLE YCKP/CY PSENSOR

LOWER COVE R

FRONTCAMSHAFT S

TIMINGBELT

FRON T EXHAUS TCAMSHAF T PULLE Y

ProCarManuals.com

Page 438 of 1503

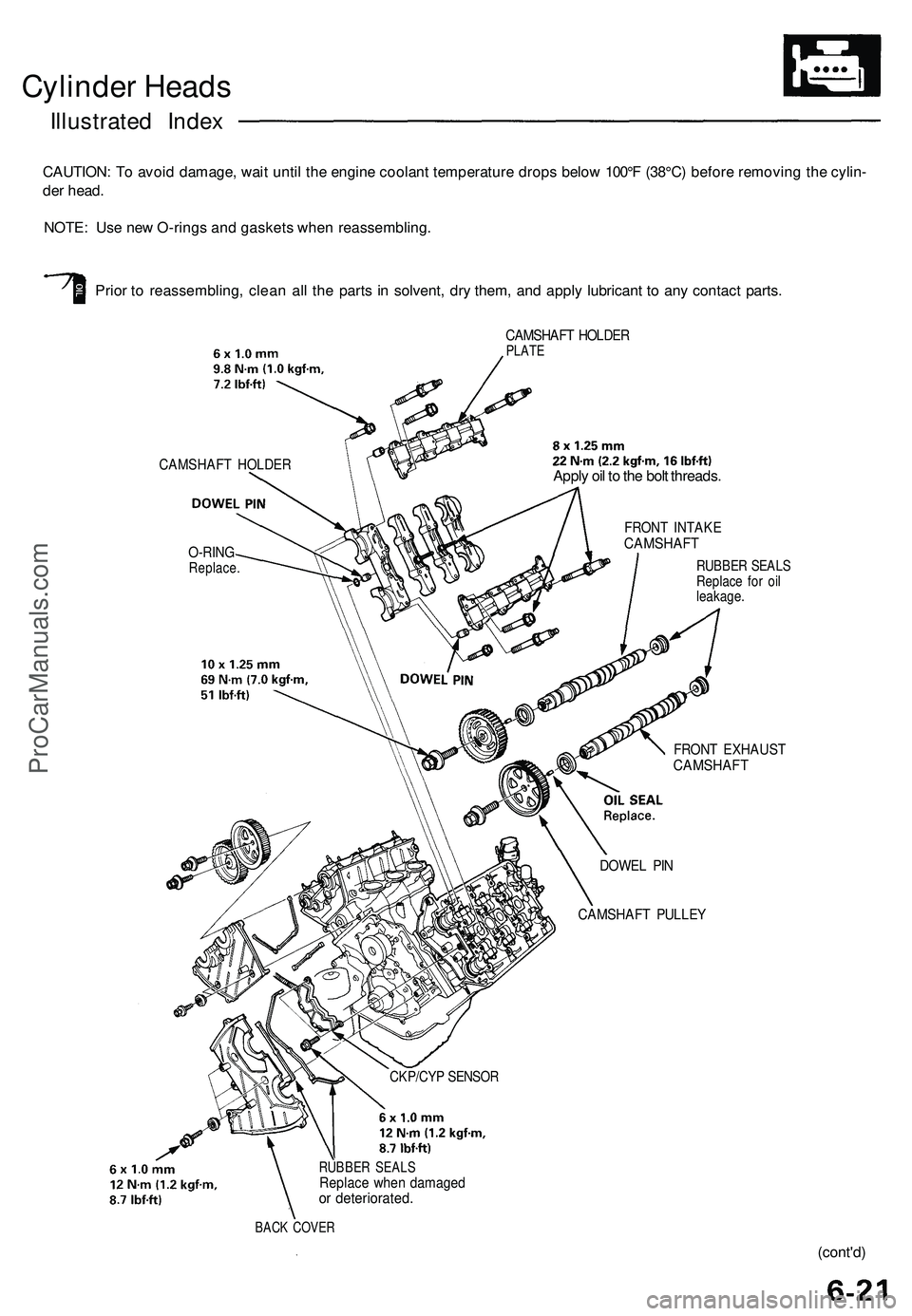

Cylinder Heads

Illustrated Index

CAUTION: To avoid damage, wait until the engine coolant temperature drops below 100°F (38°C) before removing the cylin-

der head.

NOTE: Use new O-rings and gaskets when reassembling.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

CAMSHAFT HOLDER

O-RING

Replace.

CAMSHAFT HOLDER

PLATE

CKP/CYP SENSOR

RUBBER SEALS

Replace when damaged

or deteriorated.

BACK COVER

Apply oil to the bolt threads.

FRONT INTAKE

CAMSHAFT

RUBBER SEALS

Replace for oil

leakage.

FRONT EXHAUST

CAMSHAFT

DOWEL PIN

CAMSHAFT PULLEY

(cont'd)ProCarManuals.com

Page 467 of 1503

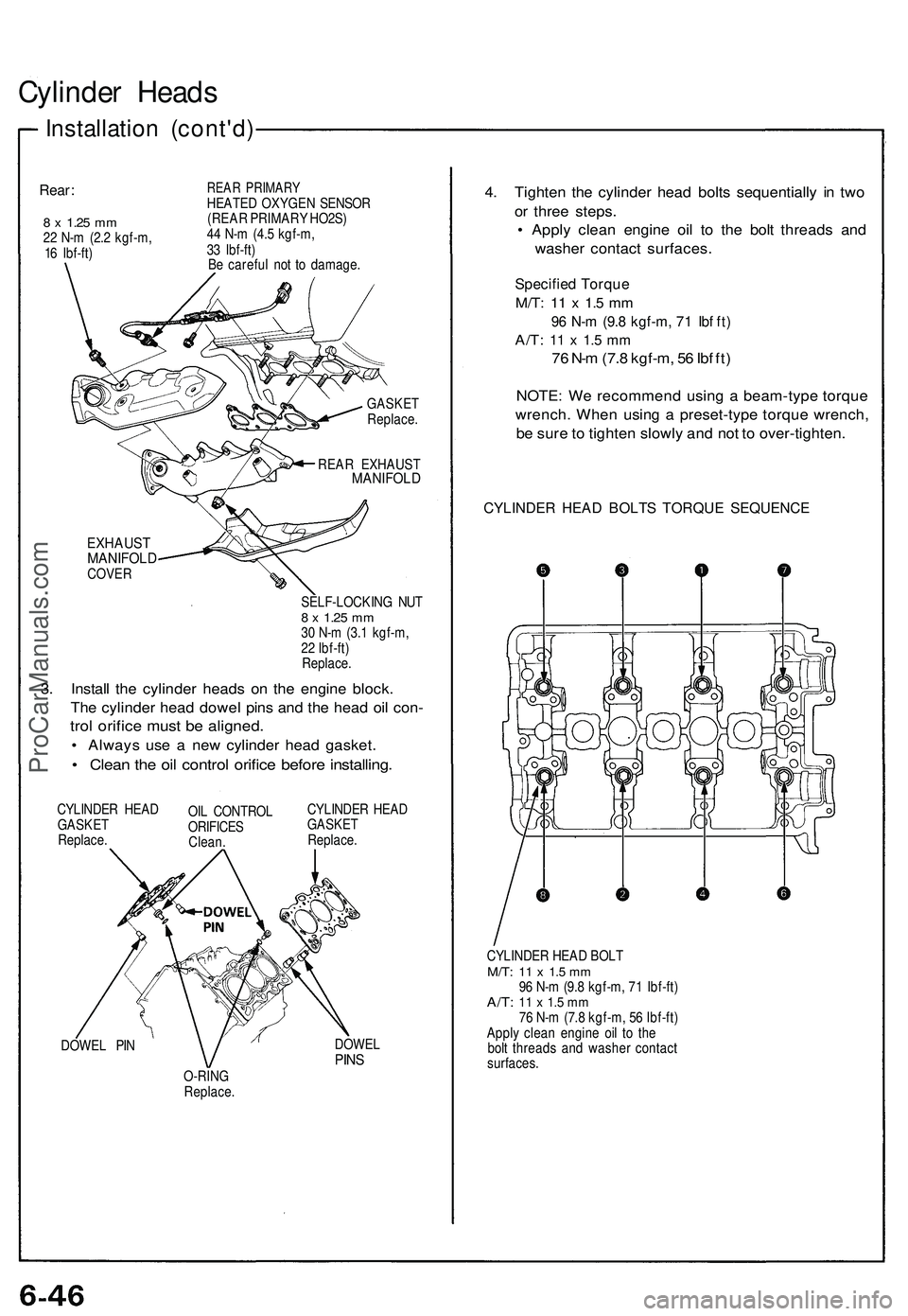

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

REAR PRIMARY

HEATED OXYGEN SENSOR

(REAR PRIMARY HO2S)

44 N-m (4.5 kgf-m,

33 Ibf-ft)

Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF-LOCKING NUT

8 x

1.25

mm

30 N-m (3.1 kgf-m,

22 Ibf-ft)

Replace.

3. Install the cylinder heads on the engine block.

The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

• Always use a new cylinder head gasket.

• Clean the oil control orifice before installing.

CYLINDER HEAD

GASKET

Replace.

OIL CONTROL

ORIFICES

Clean.

CYLINDER HEAD

GASKET

Replace.

DOWEL PIN

DOWEL

PINS

O-RING

Replace.

4. Tighten the cylinder head bolts sequentially in two

or three steps.

• Apply clean engine oil to the bolt threads and

washer contact surfaces.

Specified Torque

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

CYLINDER HEAD BOLT

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf-ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply clean engine oil to the

bolt threads and washer contact

surfaces.ProCarManuals.com