sensor ACURA NSX 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 579 of 1503

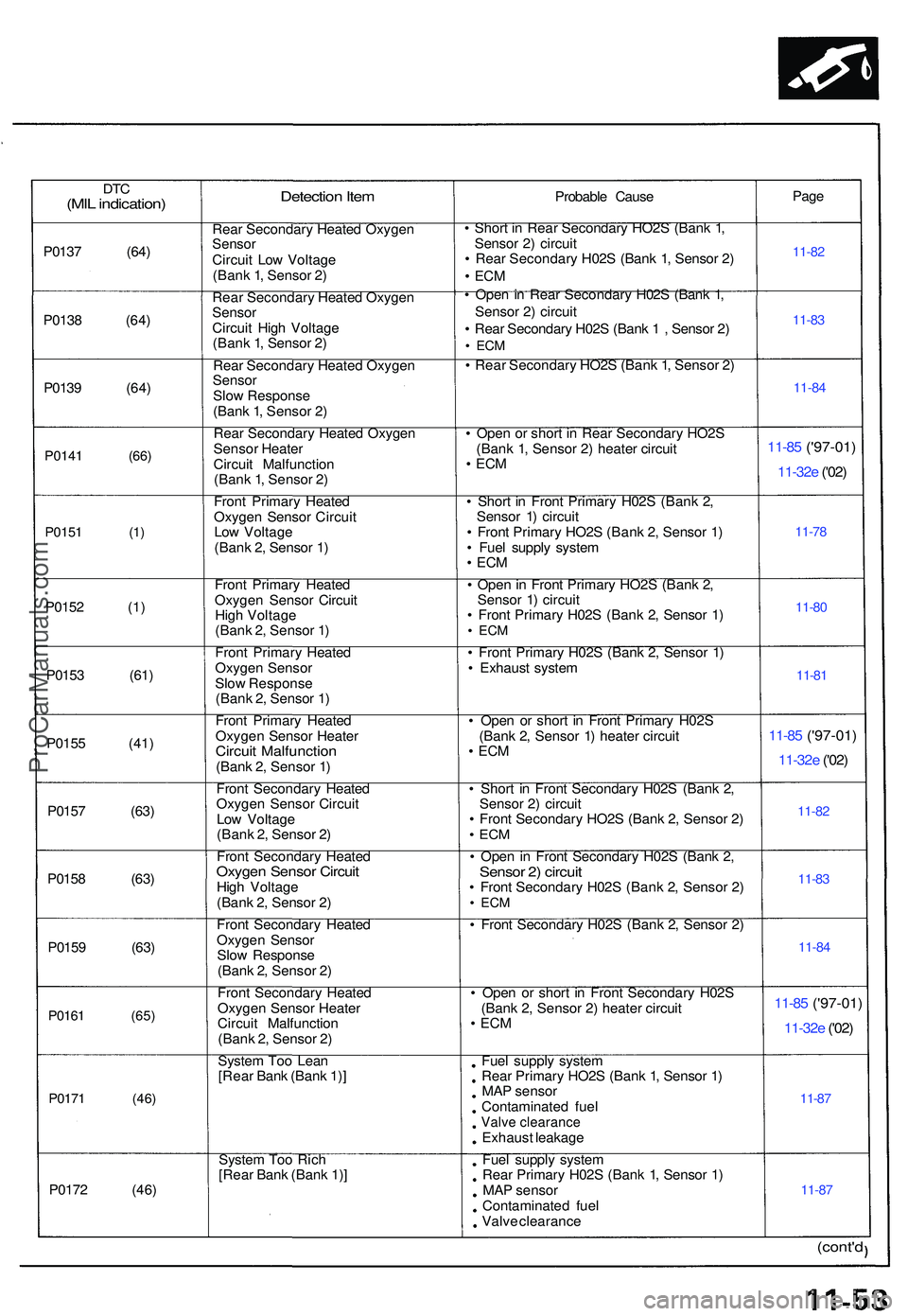

DTC(MI L indication )

P0137 (64 )

P013 8 (64 )

P013 9 (64 )

P0141 (66 )

P015 1

(1 )

P0152 (1 )

P015 3 (61 )

P015 5 (41 )

P015 7 (63 )

P015 8 (63 )

P015 9 (63 )

P0161 (65 )

P017 1 (46 )

P0172 (46 )

Detection Ite m

Rea r Secondar y Heate d Oxyge nSensorCircuit Lo w Voltag e

(Ban k 1 , Senso r 2 )

Rea r Secondar y Heate d Oxyge n

Senso r

Circui t Hig h Voltag e

(Ban k 1 , Senso r 2 )

Rea r Secondar y Heate d Oxyge n

Senso r

Slo w Respons e

(Ban k 1 , Senso r 2 )

Rea r Secondar y Heate d Oxyge n

Senso r Heate r

Circui t Malfunctio n

(Ban k 1 , Senso r 2 )

Fron t Primar y Heate d

Oxyge n Senso r Circui t

Lo w Voltag e

(Ban k 2 , Senso r 1 )

Fron t Primar y Heate d

Oxyge n Senso r Circui t

Hig h Voltag e

(Ban k 2 , Senso r 1 )

Fron t Primar y Heate d

Oxyge n Senso r

Slo w Respons e

(Ban k 2 , Senso r 1 )

Fron t Primar y Heate d

Oxyge n Senso r Heate r

Circuit Malfunctio n(Bank 2 , Senso r 1 )

Fron t Secondar y Heate d

Oxyge n Senso r Circui t

Lo w Voltag e

(Ban k 2 , Senso r 2 )

Fron t Secondar y Heate d

Oxygen Senso r Circui tHigh Voltag e

(Ban k 2 , Senso r 2 )

Fron t Secondar y Heate d

Oxyge n Senso r

Slo w Respons e

(Ban k 2 , Senso r 2 )

Fron t Secondar y Heate d

Oxyge n Senso r Heate r

Circui t Malfunctio n

(Ban k 2 , Senso r 2 )

Syste m To o Lea n

[Rea r Ban k (Ban k 1) ]

Syste m To o Ric h

[Rea r Ban k (Ban k 1) ] Probabl

e Caus e

• Shor t i n Rea r Secondar y HO2 S (Ban k 1 ,

Senso r 2 ) circui t

• Rea r Secondar y H02 S (Ban k 1 , Senso r 2 )

• EC M

• Ope n in Rea r Secondar y H02 S (Ban k 1 ,

Senso r 2 ) circui t

• Rea r Secondar y H02 S (Ban k 1 , Senso r 2 )

• EC M

• Rea r Secondar y HO2 S (Ban k 1 , Senso r 2 )

• Ope n o r shor t i n Rea r Secondar y HO2 S

(Ban k 1 , Senso r 2 ) heate r circui t

• EC M

• Shor t i n Fron t Primar y H02 S (Ban k 2 ,

Senso r 1 ) circui t

• Fron t Primar y HO2 S (Ban k 2 , Senso r 1 )

• Fue l suppl y syste m

• EC M

• Ope n in Fron t Primar y HO2 S (Ban k 2 ,

Senso r 1 ) circui t

• Fron t Primar y H02 S (Ban k 2 , Senso r 1 )

• EC M

• Fron t Primar y H02 S (Ban k 2 , Senso r 1 )

• Exhaus t syste m

• Ope n o r shor t i n Fron t Primar y H02 S

(Ban k 2 , Senso r 1 ) heate r circui t

• EC M

• Shor t i n Fron t Secondar y H02 S (Ban k 2 ,

Senso r 2 ) circui t

• Fron t Secondar y HO2 S (Ban k 2 , Senso r 2 )

• EC M

• Ope n i n Fron t Secondar y H02 S (Ban k 2 ,Senso r 2 ) circui t• Fron t Secondar y H02 S (Ban k 2 , Senso r 2 )• EC M

• Fron t Secondar y H02 S (Ban k 2 , Senso r 2 )

• Ope n o r shor t i n Fron t Secondar y H02 S

(Ban k 2 , Senso r 2 ) heate r circui t

• EC M

Fuel suppl y syste m

Rea r Primar y HO2 S (Ban k 1 , Senso r 1 )

MA P senso r

Contaminate d fue l

Valv e clearanc eExhaust leakag e

Fue l suppl y syste m

Rea r Primar y H02 S (Ban k 1 , Senso r 1 )

MA P senso r

Contaminate d fue l

Valv e clearanc e Pag

e

11-8 2

11-8 3

11-8 4

11-7 8

11-8 0

11-8 1

11-8 2

11-8 3

11-8 4

11-8 7

11-8 7

(cont' d

11-85 ('97-01)

11-32e ('02)

11-8 5 ('97-01)

11-32e ('02)

11-8 5 ('97-01)

11-32e ('02)

ProCarManuals.com

Page 580 of 1503

Troubleshooting

Diagnostic Troubl e Cod e (DTC ) Char t (cont'd )

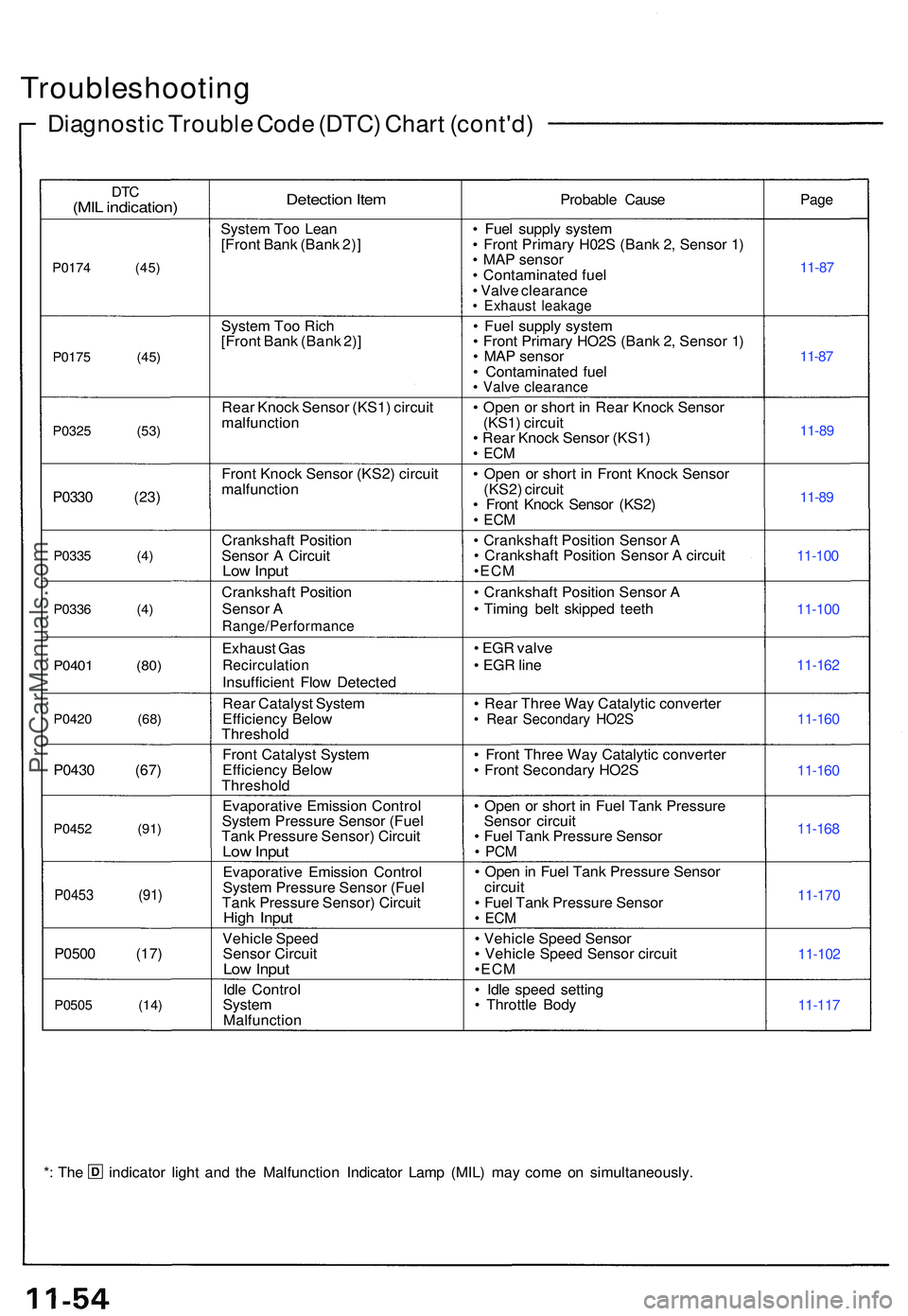

DTC(MI L indication )

P0174 (45 )

P017 5 (45 )

P032 5 (53 )

P0330 (23 )

P0335 (4 )

P033 6 (4 )

P0401 (80 )

P0420 (68 )

P0430 (67 )

P0452 (91 )

P0453 (91 )

P0500 (17 )

P0505 (14 )

Detection Ite m

Syste m To o Lea n

[Fron t Ban k (Ban k 2) ]

Syste m To o Ric h

[Fron t Ban k (Ban k 2) ]

Rea r Knoc k Senso r (KS1 ) circui t

malfunctio n

Fron t Knoc k Senso r (KS2 ) circui t

malfunctio n

Crankshaf t Positio n

Senso r A Circui t

Low Inpu t

Crankshaf t Positio n

Senso r A

Range/Performanc e

Exhaust Ga sRecirculatio n

Insufficient Flo w Detecte d

Rea r Catalys t Syste m

Efficienc y Belo w

Threshol d

Fron t Catalys t Syste m

Efficienc y Belo w

Threshol d

Evaporativ e Emissio n Contro l

Syste m Pressur e Senso r (Fue l

Tan k Pressur e Sensor ) Circui t

Low Inpu t

Evaporativ e Emissio n Contro l

Syste m Pressur e Senso r (Fue l

Tan k Pressur e Sensor ) Circui t

High Inpu t

Vehicl e Spee d

Senso r Circui t

Low Inpu t

Idle Contro l

Syste m

Malfunctio n Probabl

e Caus e

• Fue l suppl y syste m

• Fron t Primar y H02 S (Ban k 2 , Senso r 1 )

• MA P senso r

• Contaminate d fue l

• Valv e clearanc e

• Exhaus t leakag e

• Fue l suppl y syste m

• Fron t Primar y HO2 S (Ban k 2 , Senso r 1 )

• MA P senso r

• Contaminate d fue l

• Valv e clearanc e

• Ope n o r shor t i n Rea r Knoc k Senso r

(KS1 ) circui t

• Rea r Knoc k Senso r (KS1 )

• EC M

• Ope n o r shor t i n Fron t Knoc k Senso r

(KS2 ) circui t

• Fron t Knoc k Senso r (KS2 )

• EC M

• Crankshaf t Positio n Senso r A

• Crankshaf t Positio n Senso r A circui t

•ECM

• Crankshaf t Positio n Senso r A

• Timin g bel t skippe d teet h

• EG R valv e

• EG R lin e

• Rea r Thre e Wa y Catalyti c converte r

• Rea r Secondar y HO2 S

• Fron t Thre e Wa y Catalyti c converte r

• Fron t Secondar y HO2 S

• Ope n o r shor t i n Fue l Tan k Pressur e

Senso r circui t

• Fue l Tan k Pressur e Senso r

• PC M

• Ope n in Fue l Tan k Pressur e Senso r

circui t

• Fue l Tan k Pressur e Senso r

• EC M

• Vehicl e Spee d Senso r

• Vehicl e Spee d Senso r circui t

•EC M

• Idl e spee d settin g

• Throttl e Bod y

Page

11-8 7

11-8 7

11-8 9

11-8 9

11-10 0

11-10 0

11-16 2

11-160

11-16 0

11-16 8

11-17 0

11-102

11-117

*: Th e indicato r ligh t an d th e Malfunctio n Indicato r Lam p (MIL ) ma y com e o n simultaneously .

ProCarManuals.com

Page 581 of 1503

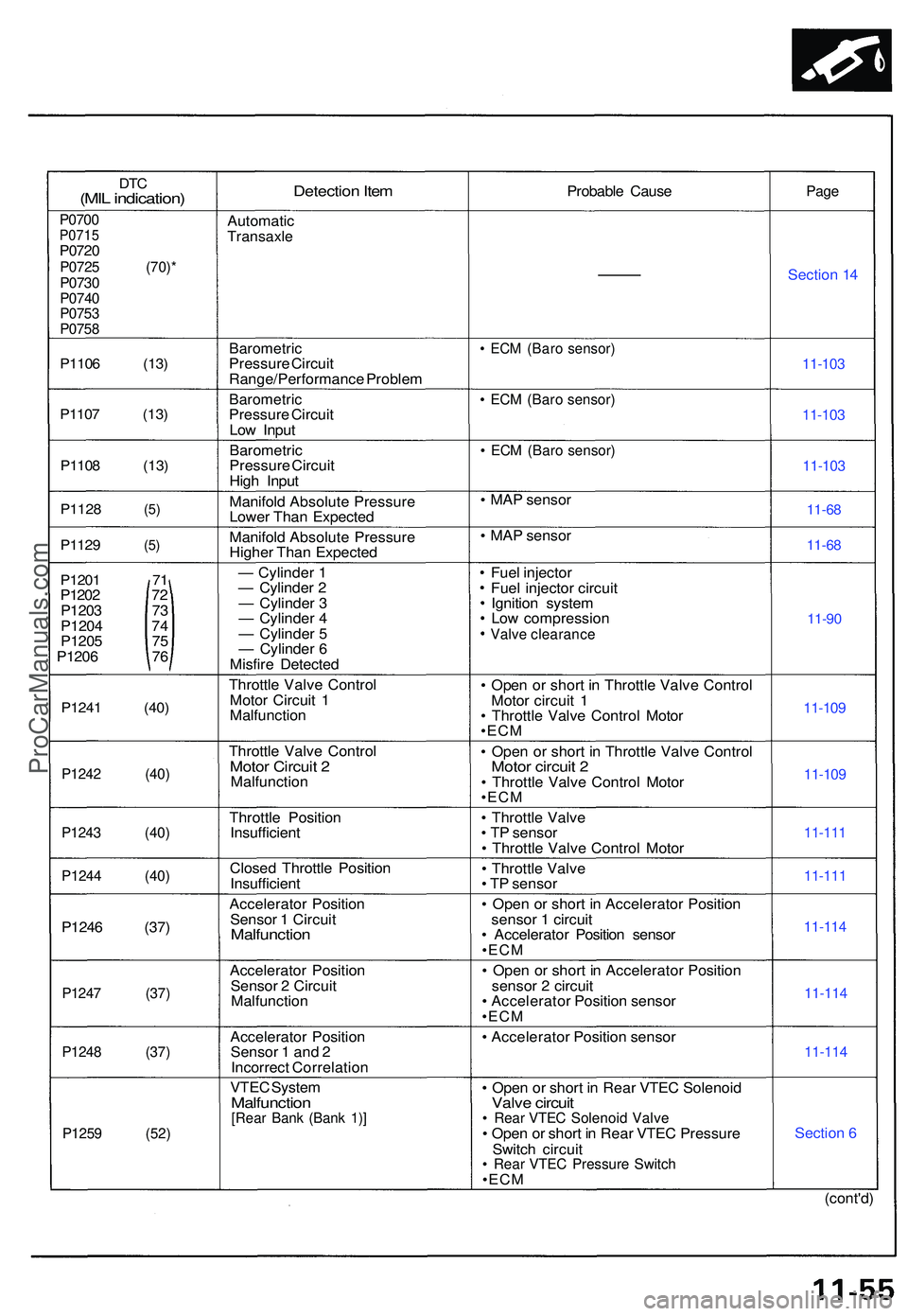

DTC(MI L indication )

P0700P071 5P0720P072 5 (70) *P0730P074 0P0753P075 8

P1106 (13 )

P110 7 (13 )

P110 8 (13 )

P112 8

(5 )

P1129 (5 )

P1201 7 1P1202 7 2

P120 3 7 3

P120 4 7 4

P120 5 7 5

P1206 7 6

P1241 (40 )

P1242 (40 )

P1243 (40 )

P1244 (40 )

P1246 (37 )

P1247 (37 )

P1248 (37 )

P1259 (52 )

Detection Ite m

Automati cTransaxle

Barometri cPressure Circui t

Range/Performanc e Proble m

Barometri cPressure Circui t

Lo w Inpu t

Barometri cPressure Circui t

Hig h Inpu t

Manifol d Absolut e Pressur e

Lowe r Tha n Expecte d

Manifol d Absolut e Pressur e

Highe r Tha n Expecte d

— Cylinde r 1

— Cylinde r 2

— Cylinde r 3

— Cylinde r 4

— Cylinde r 5

— Cylinde r 6

Misfir e Detecte d

Throttl e Valv e Contro l

Moto r Circui t 1

Malfunctio n

Throttl e Valv e Contro l

Motor Circui t 2Malfunctio n

Throttl e Positio n

Insufficien t

Close d Throttl e Positio n

Insufficien t

Accelerato r Positio n

Senso r 1 Circui t

Malfunctio n

Accelerato r Positio n

Senso r 2 Circui t

Malfunctio n

Accelerato r Positio n

Senso r 1 an d 2

Incorrec t Correlatio n

VTE C Syste m

Malfunctio n[Rear Ban k (Ban k 1) ]

Probabl e Caus e

• EC M (Bar o sensor )

• EC M (Bar o sensor )

• EC M (Bar o sensor )

• MA P senso r

• MA P senso r

Fue l injecto r

Fue l injecto r circui t

Ignitio n syste m

Lo w compressio n

Valve clearanc e

• Ope n o r shor t i n Throttl e Valv e Contro l

Moto r circui t 1

• Throttl e Valv e Contro l Moto r

•ECM

• Ope n o r shor t i n Throttl e Valv e Contro lMotor circui t 2• Throttl e Valv e Contro l Moto r•ECM

• Throttl e Valv e

• T P senso r

• Throttl e Valv e Contro l Moto r

• Throttl e Valv e

• T P senso r

• Ope n o r shor t i n Accelerato r Positio n

senso r 1 circui t

• Accelerato r Positio n senso r

•ECM

• Ope n o r shor t i n Accelerato r Positio n

senso r 2 circui t

• Accelerato r Positio n senso r

•ECM

• Accelerato r Positio n senso r

• Ope n o r shor t i n Rea r VTE C Solenoi d

Valve circui t• Rea r VTE C Solenoi d Valv e• Ope n o r shor t i n Rea r VTE C Pressur e

Switc h circui t

• Rea r VTE C Pressur e Switc h•ECM

Page

Sectio n 1 4

11-10 3

11-103

11-10 3

11-68

11-6 8

11-90

11-10 9

11-10 9

11-111

11-11 1

11-11 4

11-114

11-114

Sectio n 6

(cont'd )

ProCarManuals.com

Page 582 of 1503

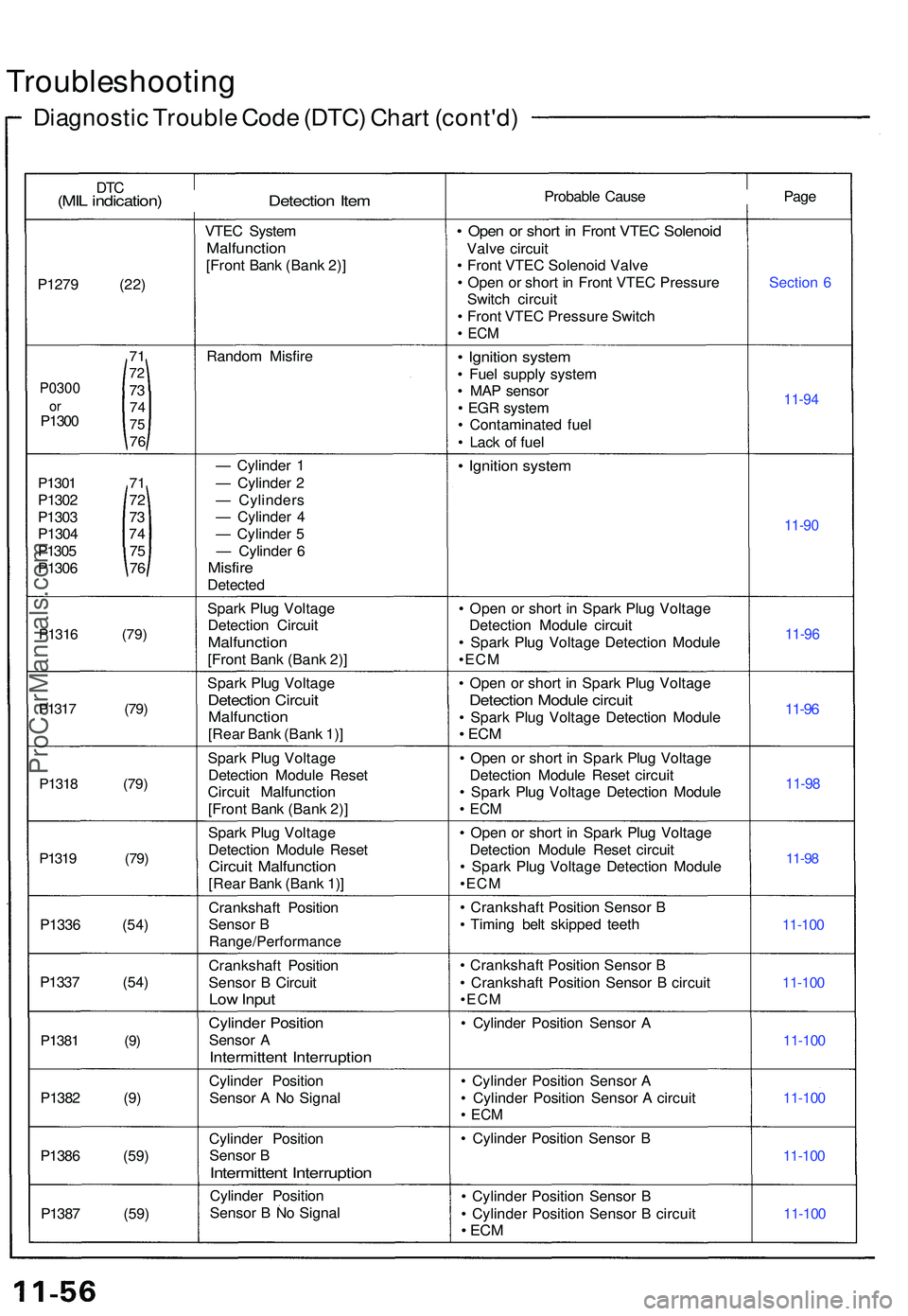

DTC(MI L indication ) Detectio n Ite m

P127 9 (22 )

717 2

P130 0 7

374

7 5

76

P130 1 7 1

P1302 7 2

P130 3 7 3

P130 4 7 4

P130 5 7 5

P1306 7 6

P1316 (79 )

P131 7 (79 )

P131 8 (79 )

P131 9 (79 )

P1336 (54 )

P133 7 (54 )

P1381 (9 )

P1382 (9 )

P138 6 (59 )

P138 7 (59 )VTE

C Syste m

Malfunctio n

[Front Ban k (Ban k 2) ]

Rando m Misfir e

— Cylinde r 1

— Cylinde r 2

— Cylinder s

— Cylinde r 4

— Cylinde r 5

— Cylinde r 6

Misfir e

Detecte d

Spar k Plu g Voltag e

Detectio n Circui t

Malfunctio n

[Front Ban k (Ban k 2) ]

Spar k Plu g Voltag e

Detectio n Circui tMalfunctio n

[Rear Ban k (Ban k 1) ]

Spar k Plu g Voltag e

Detectio n Modul e Rese t

Circui t Malfunctio n

[Fron t Ban k (Ban k 2) ]

Spar k Plu g Voltag e

Detectio n Modul e Rese t

Circuit Malfunctio n

[Rear Ban k (Ban k 1) ]

Crankshaf t Positio n

Senso r B

Range/Performanc e

Crankshaft Positio n

Senso r B Circui t

Low Inpu t

Cylinde r Positio n

Sensor A

Intermitten t Interruptio n

Cylinder Positio n

Senso r A N o Signa l

Cylinde r Positio n

Senso r B

Intermitten t Interruptio n

Cylinder Positio n

Senso r B N o Signa l Probabl

e Caus e Pag e

• Ope n o r shor t i n Fron t VTE C Solenoi d

Valve circui t

• Fron t VTE C Solenoi d Valv e

• Ope n o r shor t i n Fron t VTE C Pressur e

Switc h circui t

• Fron t VTE C Pressur e Switc h

• EC M

• Ignitio n syste m

• Fue l suppl y syste m

• MA P senso r

• EG R syste m

• Contaminate d fue l

• Lac k o f fue l

• Ignitio n syste m

• Ope n o r shor t i n Spar k Plu g Voltag e

Detectio n Modul e circui t

• Spar k Plu g Voltag e Detectio n Modul e

•EC M

• Ope n o r shor t i n Spar k Plu g Voltag e

Detectio n Modul e circui t

• Spar k Plu g Voltag e Detectio n Modul e• EC M

• Ope n o r shor t i n Spar k Plu g Voltag e

Detectio n Modul e Rese t circui t

• Spar k Plu g Voltag e Detectio n Modul e

• EC M

• Ope n o r shor t i n Spar k Plu g Voltag e

Detectio n Modul e Rese t circui t

• Spar k Plu g Voltag e Detectio n Modul e

•EC M

• Crankshaf t Positio n Senso r B

• Timin g bel t skippe d teet h

• Crankshaf t Positio n Senso r B

• Crankshaf t Positio n Senso r B circui t

•ECM

• Cylinde r Positio n Senso r A

• Cylinde r Positio n Senso r A

• Cylinde r Positio n Senso r A circui t

• EC M

• Cylinde r Positio n Senso r B

• Cylinde r Positio n Senso r B

• Cylinde r Positio n Senso r B circui t

• EC M

Sectio n 6

11-9 4

11-90

11-9 6

11-96

11-9 8

11-98

11-10 0

11-10 0

11-10 0

11-10 0

11-10 0

11-10 0

Troubleshootin g

Diagnostic Troubl e Cod e (DTC ) Char t (cont'd )

or

P0300

ProCarManuals.com

Page 583 of 1503

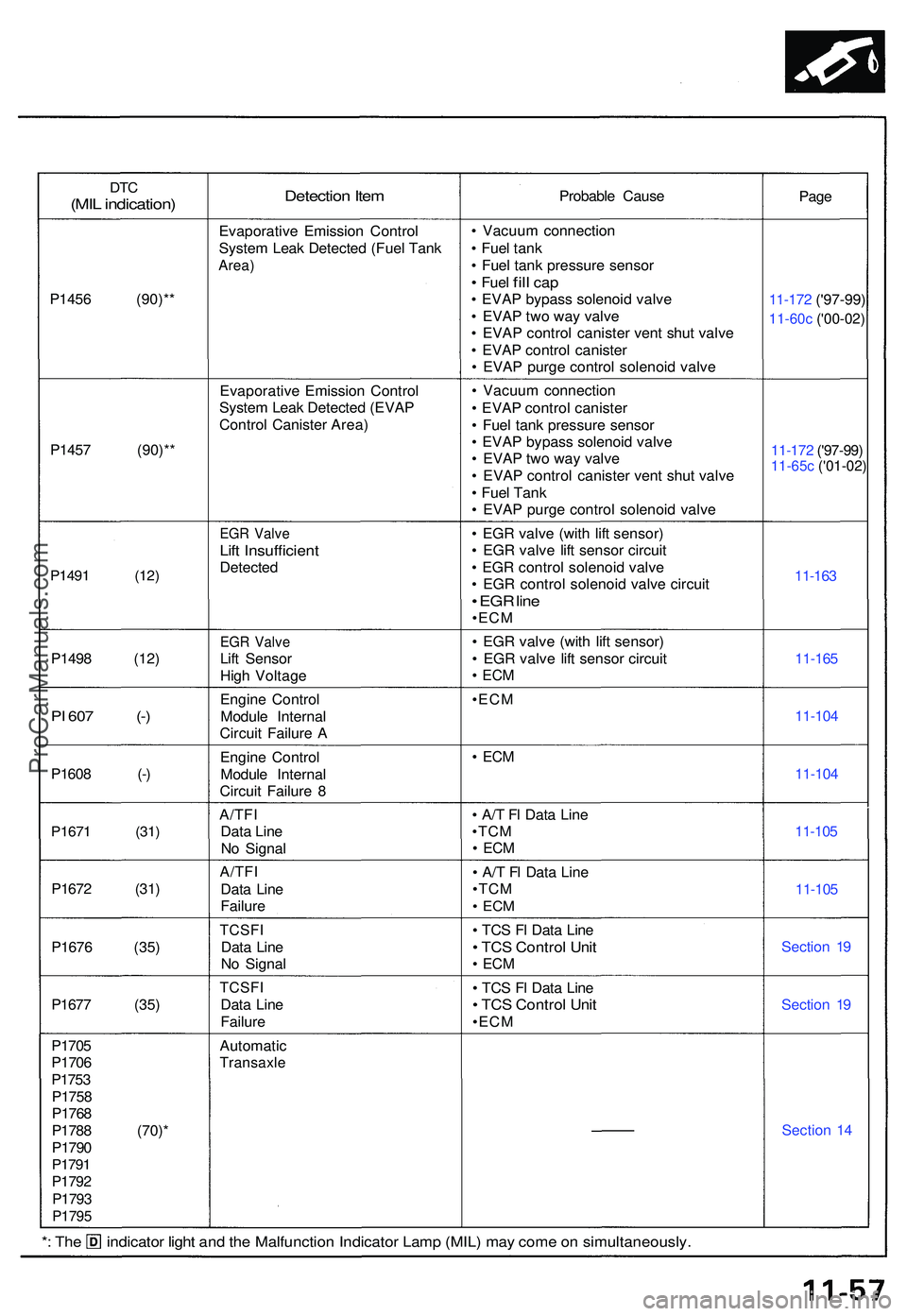

DTC(MI L indication )

P1456 (90)* *

P145 7 (90)* *

P1491 (12 )

P1498 (12 )

PI 60 7 (- )

P1608 (- )

P1671 (31 )

P1672 (31 )

P167 6 (35 )

P167 7 (35 )

P1705P1706

P175 3

P175 8P1768

P178 8 (70) *

P179 0

P1791

P179 2

P179 3

P179 5

Detectio n Ite m

Evaporativ e Emissio n Contro l

Syste m Lea k Detecte d (Fue l Tan k

Area )

Evaporativ e Emissio n Contro l

Syste m Lea k Detecte d (EVA P

Contro l Caniste r Area )

EGR Valv e

Lift Insufficien tDetected

EGR Valv eLift Senso r

Hig h Voltag e

Engin e Contro l

Modul e Interna l

Circui t Failur e A

Engin e Contro l

Modul e Interna l

Circui t Failur e 8

A/TF I

Dat a Lin e

N o Signa l

A/TF I

Dat a Lin e

Failur e

TCSF I

Data Lin e

N o Signa l

TCSFI

Data Lin e

Failur e

Automati c

Transaxle

Probable Caus e

• Vacuu m connectio n

• Fue l tan k

• Fue l tan k pressur e senso r

• Fuel fill ca p• EVA P bypas s solenoi d valv e

• EVA P tw o wa y valv e

• EVA P contro l caniste r ven t shu t valv e

• EVA P contro l caniste r

• EVA P purg e contro l solenoi d valv e

• Vacuu m connectio n

• EVA P contro l caniste r

• Fue l tan k pressur e senso r

• EVA P bypas s solenoi d valv e

• EVA P tw o wa y valv e

• EVA P contro l caniste r ven t shu t valv e

• Fue l Tan k

• EVA P purg e contro l solenoi d valv e

• EG R valv e (wit h lif t sensor )

• EG R valv e lif t senso r circui t

• EG R contro l solenoi d valv e

• EG R contro l solenoi d valv e circui t

• EG R lin e•EC M

• EG R valv e (wit h lif t sensor )

• EG R valv e lif t senso r circui t

• EC M

•EC M

• EC M

• A/ T F l Dat a Lin e

•TC M

• EC M

• A/ T F l Dat a Lin e

•TC M

• EC M

• TC S F l Dat a Lin e

• TC S Contro l Uni t• EC M

• TC S F l Dat a Lin e• TC S Contro l Uni t

•EC M Pag

e

11-172 ('97-99)

11-172 ('97-99)

11-163

11-16 5

11-10 4

11-10 4

11-105

11-10 5

Sectio n 1 9

Sectio n 1 9

Sectio n 1 4

*: Th e indicato r ligh t an d th e Malfunctio n Indicato r Lam p (MIL ) ma y com e o n simultaneously .

11-60c ('00-02)

11-65c ('01-02)

ProCarManuals.com

Page 585 of 1503

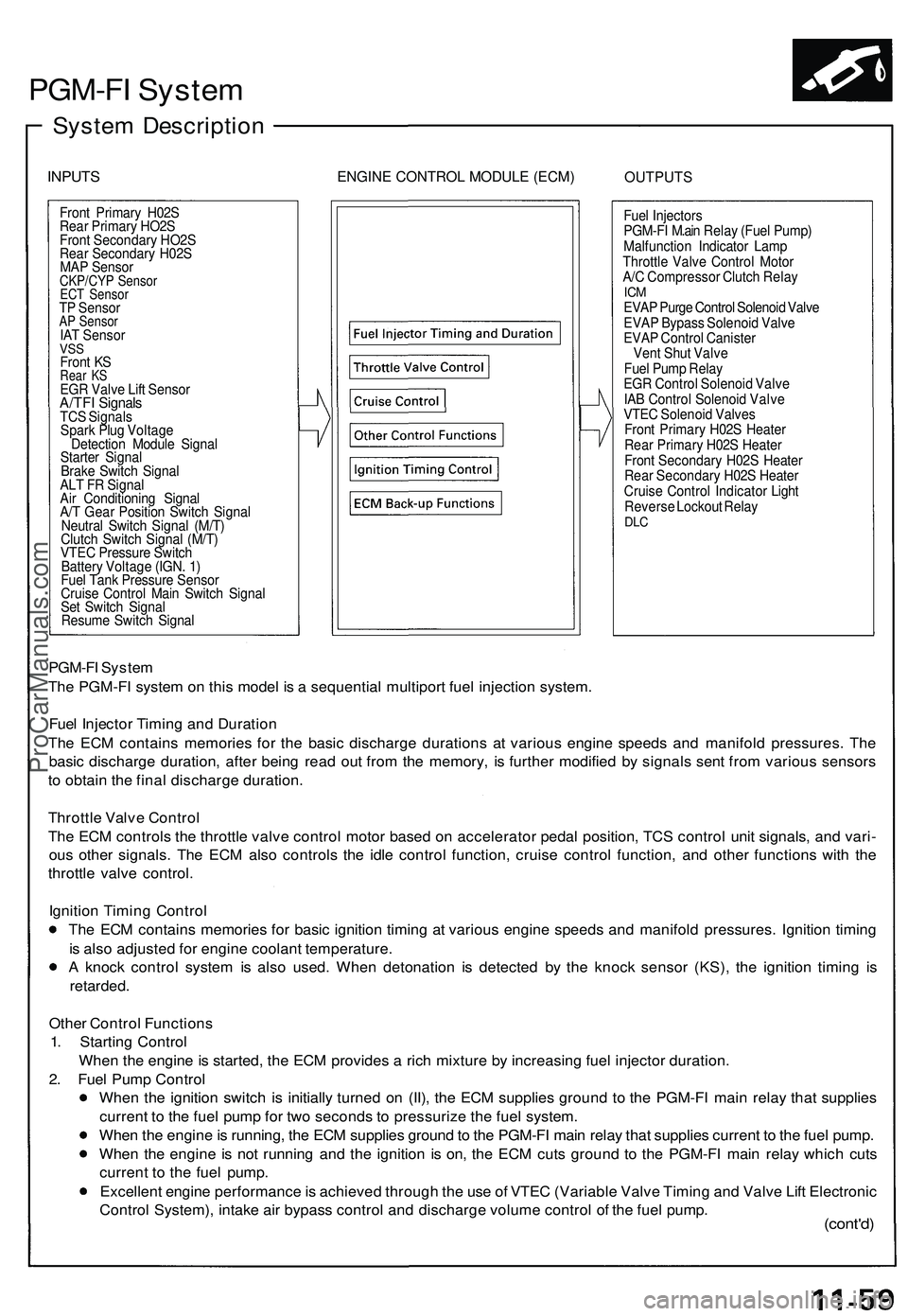

PGM-FI Syste m

System Descriptio n

INPUTSENGIN E CONTRO L MODUL E (ECM )OUTPUT S

Front Primar y H02 S

Rea r Primar y HO2 S

Fron t Secondar y HO2 S

Rea r Secondar y H02 S

MA P Senso r

CKP/CY P Senso rECT Senso rTP Senso rAP Senso rIAT Senso rVSSFron t K SRea r K SEG R Valv e Lif t Senso rA/TFI Signal sTCS Signal s

Spar k Plu g Voltag e

Detectio n Modul e Signa l

Starte r Signa l

Brak e Switc h Signa l

AL T F R Signa l

Ai r Conditionin g Signa l

A/ T Gea r Positio n Switc h Signa l

Neutra l Switc h Signa l (M/T )

Clutc h Switc h Signa l (M/T )

VTE C Pressur e Switc h

Batter y Voltag e (IGN . 1 )

Fue l Tan k Pressur e Senso r

Cruis e Contro l Mai n Switc h Signa l

Se t Switc h Signa l

Resum e Switc h Signa l Fue

l Injector s

PGM-F I M.ai n Rela y (Fue l Pump )

Malfunctio n Indicato r Lam p

Throttl e Valv e Contro l Moto r

A/ C Compresso r Clutc h Rela y

ICMEVA P Purg e Contro l Solenoi d Valv e

EVA P Bypas s Solenoi d Valv e

EVA P Contro l Caniste r

Ven t Shu t Valv e

Fue l Pum p Rela y

EG R Contro l Solenoi d Valv e

IA B Contro l Solenoi d Valv e

VTE C Solenoi d Valve s

Fron t Primar y H02 S Heate r

Rea r Primar y H02 S Heate r

Fron t Secondar y H02 S Heate r

Rea r Secondar y H02 S Heate r

Cruis e Contro l Indicato r Ligh t

Revers e Lockou t Rela y

DLC

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Fue l Injecto r Timin g an d Duratio n

Th e EC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Throttl e Valv e Contro l

Th e EC M control s th e throttl e valv e contro l moto r base d o n accelerato r peda l position , TC S contro l uni t signals , an d vari -

ou s othe r signals . Th e EC M als o control s th e idl e contro l function , cruis e contro l function , an d othe r function s wit h th e

throttl e valv e control .

Ignitio n Timin g Contro l

Th e EC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d pressures . Ignitio n timin g

i s als o adjuste d fo r engin e coolan t temperature .

A knoc k contro l syste m is als o used . Whe n detonatio n i s detecte d b y th e knoc k senso r (KS) , th e ignitio n timin g i s

retarded .

Other Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e EC M provide s a ric h mixtur e b y increasin g fue l injecto r duration .

2 . Fue l Pum p Contro l

Whe n th e ignitio n switc h i s initiall y turne d o n (II) , th e EC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s

curren t t o th e fue l pum p fo r tw o second s t o pressuriz e th e fue l system .

Whe n th e engin e is running , th e EC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s curren t t o th e fue l pump .

Whe n th e engin e i s no t runnin g an d th e ignitio n i s on , th e EC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

Excellen t engin e performanc e is achieve d throug h th e us e o f VTE C (Variabl e Valv e Timin g an d Valv e Lif t Electroni c

Contro l System) , intak e ai r bypas s contro l an d discharg e volum e contro l o f th e fue l pump .

(cont'd )

ProCarManuals.com

Page 586 of 1503

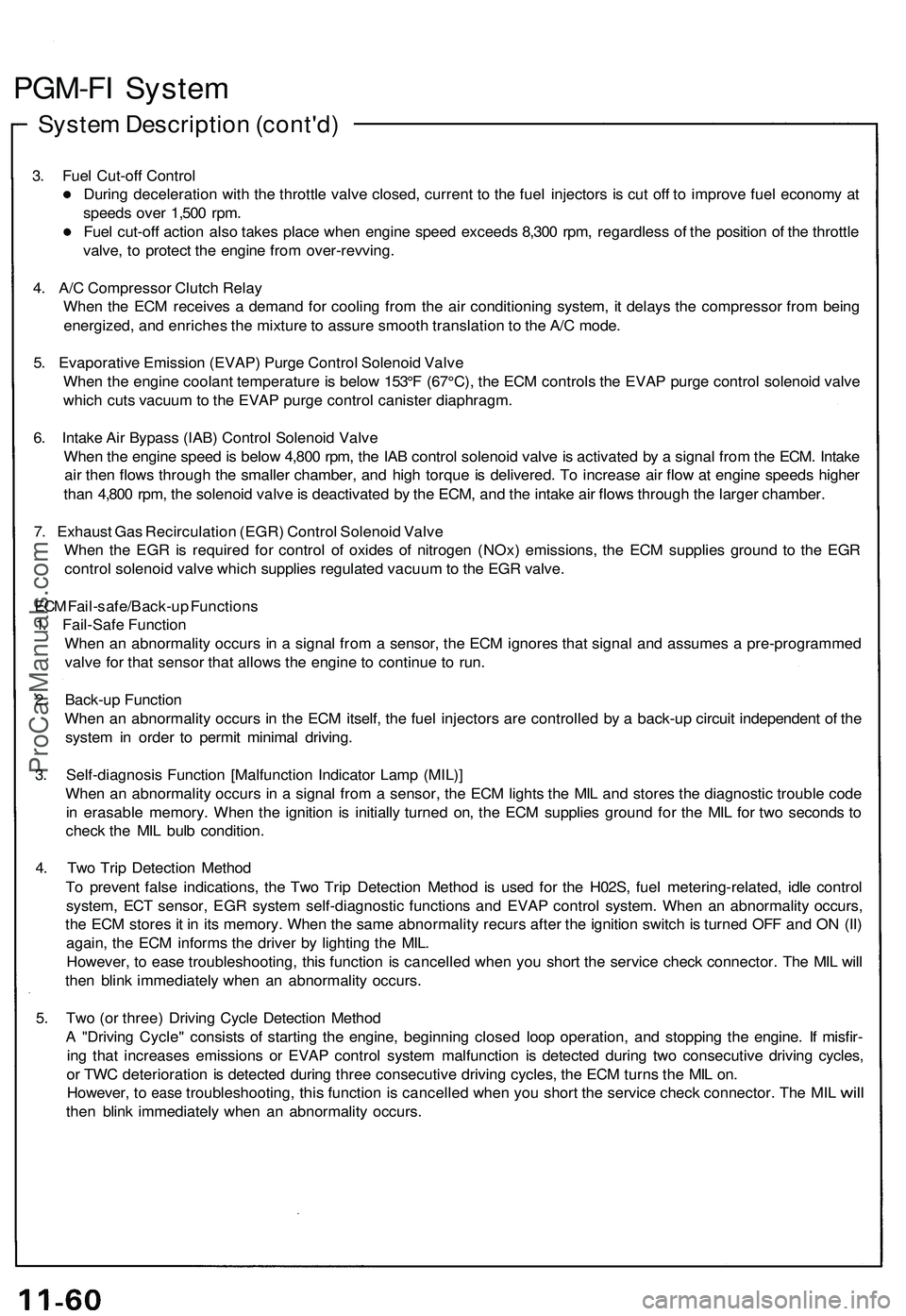

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 588 of 1503

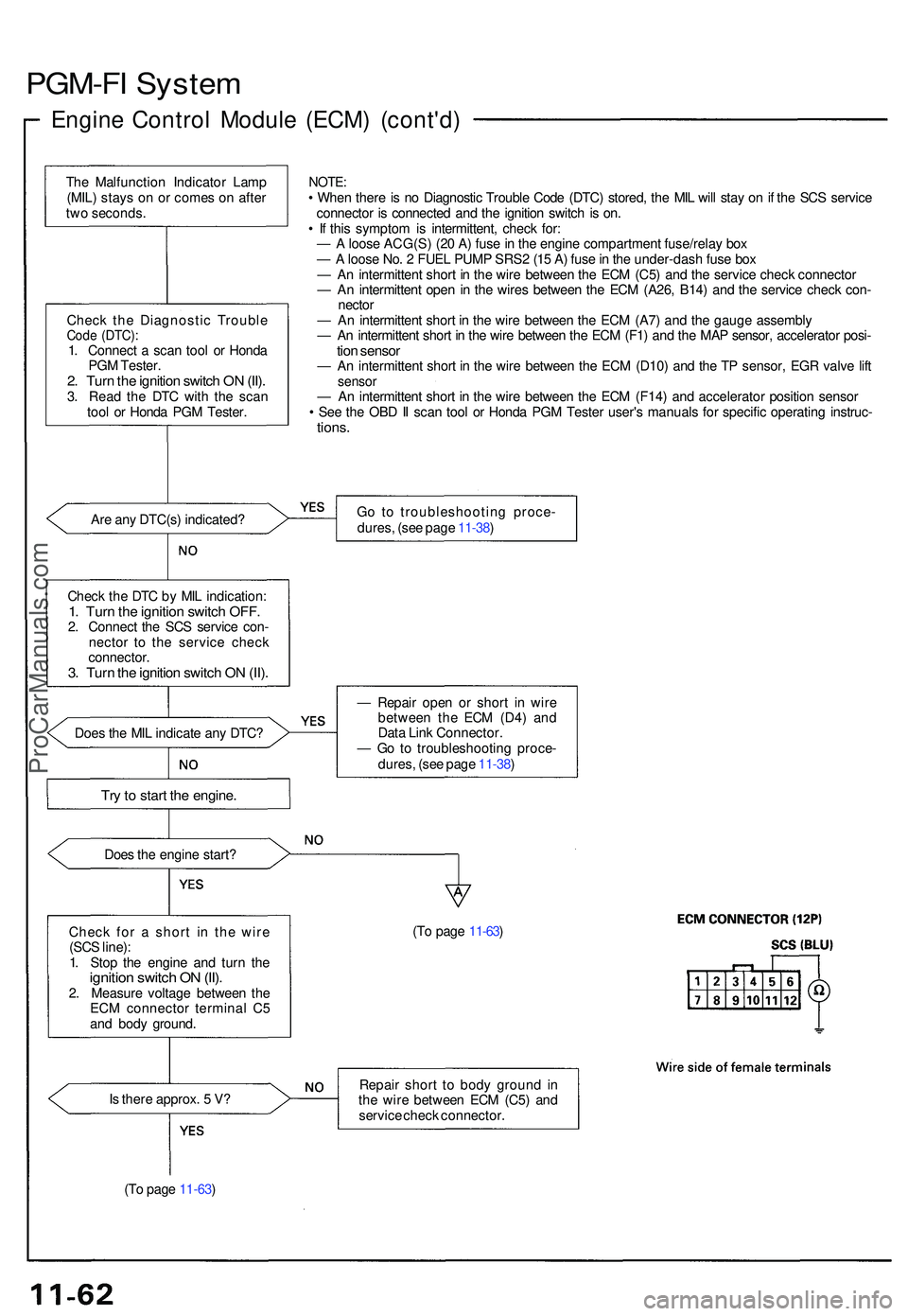

PGM-FI Syste m

Engine Contro l Modul e (ECM ) (cont'd )

The Malfunctio n Indicato r Lam p

(MIL ) stay s o n o r come s o n afte r

tw o seconds .

Chec k th e Diagnosti c Troubl e

Code (DTC) :1. Connec t a sca n too l o r Hond a

PG M Tester .

2. Tur n th e ignitio n switc h O N (II) .3. Rea d th e DT C wit h th e sca n

too l o r Hond a PG M Tester .

NOTE:• Whe n ther e is n o Diagnosti c Troubl e Cod e (DTC ) stored , th e MI L wil l sta y o n if th e SC S servic e

connecto r i s connecte d an d th e ignitio n switc h i s on .

• I f thi s sympto m is intermittent , chec k for :

— A loos e ACG(S ) (2 0 A ) fus e in th e engin e compartmen t fuse/rela y bo x

— A loos e No . 2 FUE L PUM P SRS 2 (1 5 A ) fus e in th e under-das h fus e bo x

— A n intermitten t shor t i n th e wire betwee n th e EC M (C5 ) an d th e servic e chec k connecto r

— A n intermitten t ope n i n th e wire s betwee n th e EC M (A26 , B14 ) an d th e servic e chec k con -

necto r

— A n intermitten t shor t i n th e wire betwee n th e EC M (A7 ) an d th e gaug e assembl y

— A n intermitten t shor t i n th e wir e betwee n th e EC M (F1 ) an d th e MA P sensor , accelerato r posi -

tion senso r— A n intermitten t shor t i n th e wir e betwee n th e EC M (D10 ) an d th e T P sensor , EG R valv e lif tsenso r— A n intermitten t shor t i n th e wire betwee n th e EC M (F14 ) an d accelerato r positio n senso r

• Se e th e OB D II sca n too l o r Hond a PG M Teste r user' s manual s fo r specifi c operatin g instruc -

tions.

Are an y DTC(s ) indicated ? G

o t o troubleshootin g proce -

dures , (se e pag e 11-38 )

Chec k th e DT C b y MI L indication :

1. Tur n th e ignitio n switc h OFF .2. Connec t th e SC S servic e con -

necto r t o th e servic e chec k

connector .

3. Tur n th e ignitio n switc h O N (II) .

Doe s th e MI L indicat e an y DTC ? —

Repai r ope n o r shor t i n wir e

betwee n the ECM (D4 ) an d

Dat a Lin k Connector .

— G o t o troubleshootin g proce -

dures , (se e pag e 11-38 )

Try t o star t th e engine .

Does th e engin e start ?

Chec k fo r a shor t i n th e wir e

(SC S line) :

1 . Sto p th e engin e an d tur n th e

ignitio n switc h O N (II) .2. Measur e voltag e betwee n th e

EC M connecto r termina l C 5

an d bod y ground . (T

o pag e 11-63 )

I s ther e approx . 5 V ?

(T o pag e 11-63 ) Repai

r shor t t o bod y groun d i n

th e wir e betwee n EC M (C5 ) an d

servic e chec k connector .

ProCarManuals.com

Page 589 of 1503

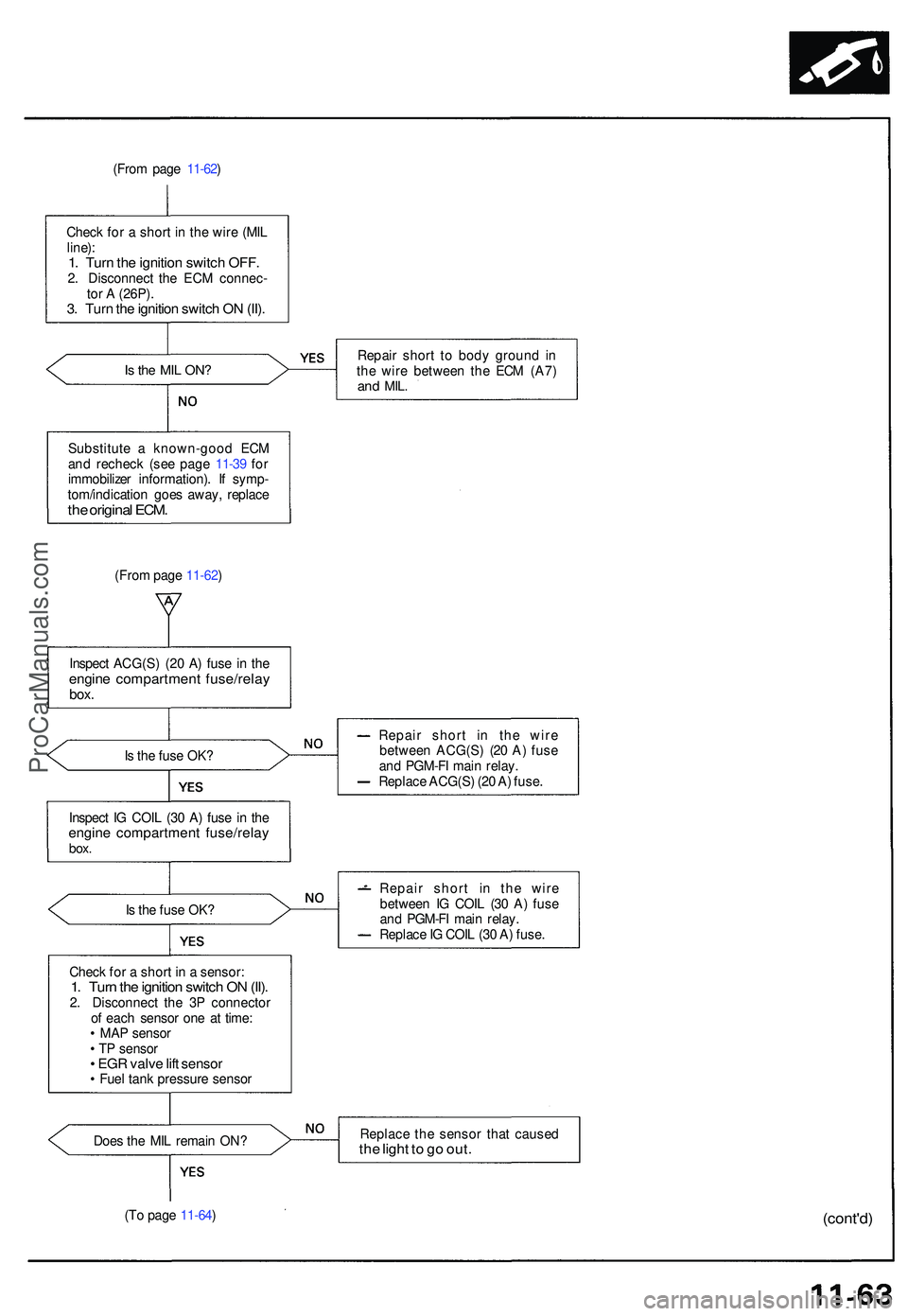

(From pag e 11-62 )

Chec k fo r a shor t i n th e wir e (MI L

line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e EC M connec -

to r A (26P) .

3. Tur n th e ignitio n switc h O N (II) .

Is th e MI L ON ?Repai r shor t t o bod y groun d i n

th e wir e betwee n th e EC M (A7 )

and MIL .

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

the origina l ECM .

(From pag e 11-62 )

Inspec t ACG(S ) (2 0 A ) fus e i n th e

engin e compartmen t fuse/rela ybox.

Is th e fus e OK ? Repai

r shor t i n th e wir e

betwee n ACG(S ) (2 0 A ) fus e

an d PGM-F I mai n relay .

Replac e ACG(S ) (2 0 A ) fuse .

Inspec t I G COI L (3 0 A ) fus e i n th e

engin e compartmen t fuse/rela ybox.

Is th e fus e OK ? Repai

r shor t i n th e wir e

betwee n I G COI L (3 0 A ) fus e

an d PGM-F I mai n relay .

Replac e IG COI L (3 0 A ) fuse .

Chec k fo r a shor t i n a sensor :

1. Tur n th e ignitio n switc h O N (II) .2. Disconnec t th e 3 P connecto r

o f eac h senso r on e a t time :

• MA P senso r

• T P senso r

• EG R valv e lif t senso r• Fue l tan k pressur e senso r

Doe s th e MI L remai n ON ? Replac

e th e senso r tha t cause d

the ligh t t o g o out .

(To pag e 11-64 )(cont'd )

ProCarManuals.com

Page 590 of 1503

PGM-FI Syste m

Engine Contro l Modul e (ECM ) (cont'd )

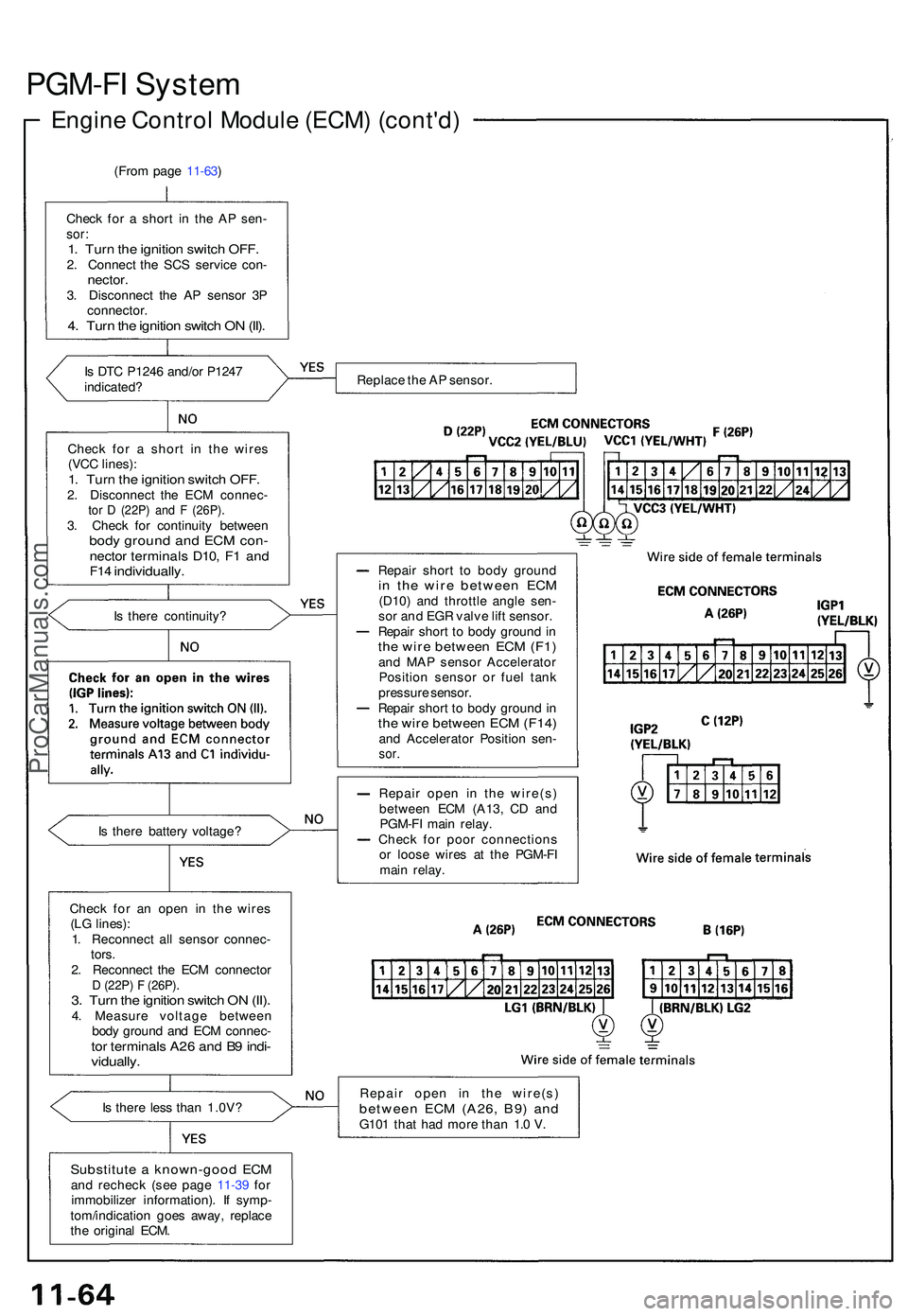

(From pag e 11-63 )

Chec k fo r a shor t i n th e A P sen -

sor:1. Tur n th e ignitio n switc h OFF .2. Connec t th e SC S servic e con -nector .3. Disconnec t th e A P senso r 3 P

connector .

4. Tur n th e ignitio n switc h O N (II) .

Is DT C P124 6 and/o r P124 7

indicated ?

Chec k fo r a shor t i n th e wire s

(VC C lines) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e EC M connec -tor D (22P ) an d F (26P) .3. Chec k fo r continuit y betwee nbody groun d an d EC M con -necto r terminal s D10 , F 1 an dF14 individually .

Is ther e continuity ?

I s ther e batter y voltage ?

Chec k fo r a n ope n i n th e wire s

(L G lines) :

1 . Reconnec t al l senso r connec -

tors .

2 . Reconnec t th e EC M connecto r

D (22P ) F (26P) .3. Tur n th e ignitio n switc h O N (II) .4. Measur e voltag e betwee n

bod y groun d an d EC M connec -

tor terminal s A2 6 an d B 9 indi -vidually .

Is ther e les s tha n 1.0V ?

Substitut e a known-goo d EC Mand rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

th e origina l ECM . Replac

e th e A P sensor .

Repai r shor t t o bod y groun d

in th e wir e betwee n EC M(D10 ) an d throttl e angl e sen -

so r an d EG R valv e lif t sensor .

Repai r shor t t o bod y groun d in

th e wir e betwee n EC M (F1 )and MA P senso r Accelerato r

Positio n senso r o r fue l tan k

pressur e sensor .

Repai r shor t t o bod y groun d in

th e wir e betwee n EC M (F14 )and Accelerato r Positio n sen -sor.

Repai r ope n i n th e wire(s )

betwee n EC M (A13 , C D an d

PGM-F I mai n relay .

Chec k fo r poo r connection s

o r loos e wire s a t th e PGM-F I

mai n relay .

Repai r ope n i n th e wire(s )

between EC M (A26 , B9 ) an dG10 1 tha t ha d mor e tha n 1. 0 V .

ProCarManuals.com