Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 867 of 1771

Troubleshooting

Troubleshooting Procedures (cont'd)

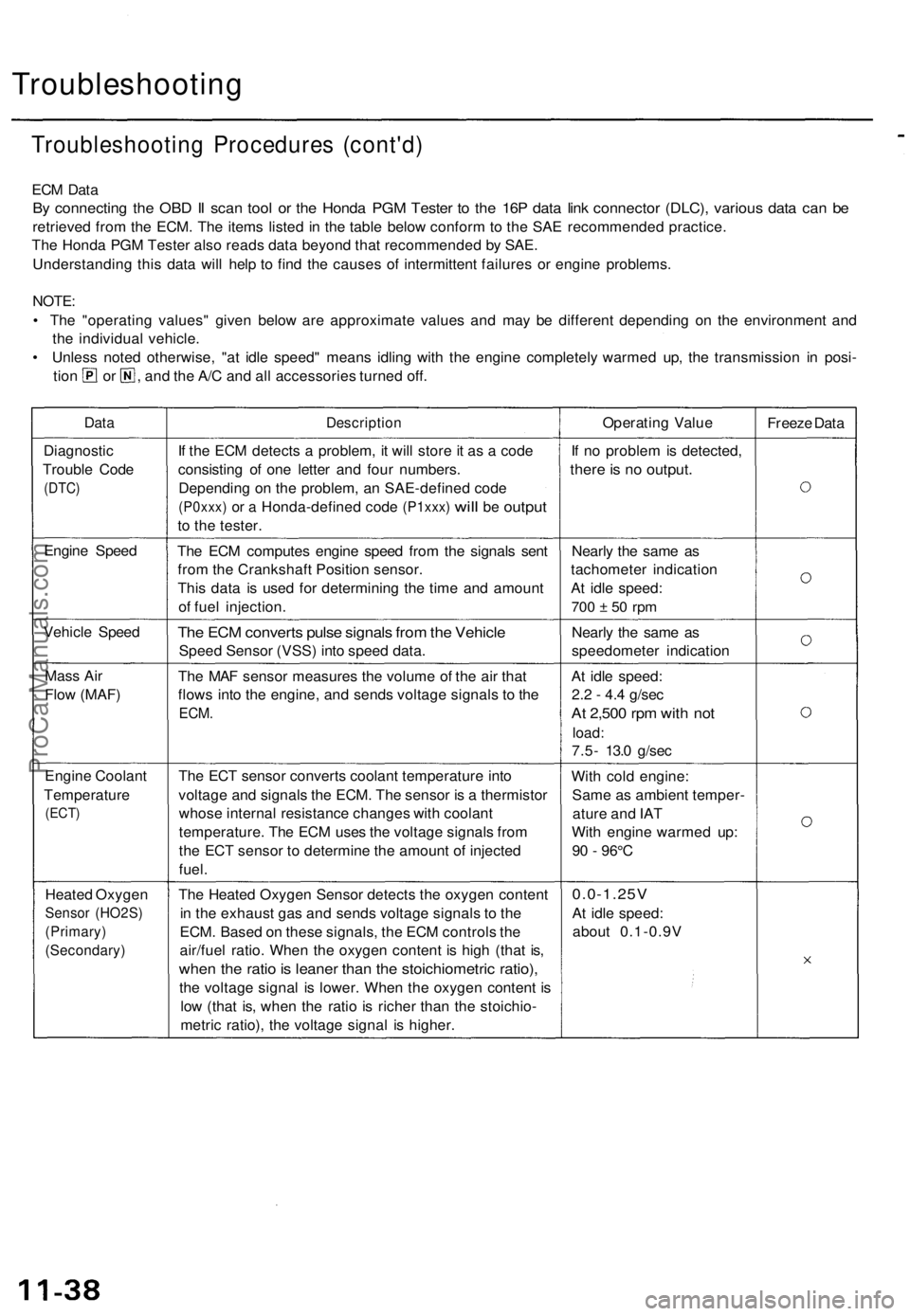

ECM Data

By connecting the OBD II scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can be

retrieved from the ECM. The items listed in the table below conform to the SAE recommended practice.

The Honda PGM Tester also reads data beyond that recommended by SAE.

Understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

• The "operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

• Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up, the transmission in posi-

tion or , and the A/C and all accessories turned off.

Data

Description

Operating Value

Freeze Data

Diagnostic

Trouble Code

(DTC)

If the ECM detects a problem, it will store it as a code

consisting of one letter and four numbers.

Depending on the problem, an SAE-defined code

(P0xxx)

or a

Honda-defined code

(P1xxx)

will

be

output

to the tester.

If no problem is detected,

there is no output.

Engine Speed

The ECM computes engine speed from the signals sent

from the Crankshaft Position sensor.

This data is used for determining the time and amount

of fuel injection.

Nearly the same as

tachometer indication

At idle speed:

700 ± 50 rpm

Vehicle Speed

The ECM converts pulse signals from the Vehicle

Speed Sensor (VSS) into speed data.

Nearly the same as

speedometer indication

Mass Air

Flow (MAF)

The MAF sensor measures the volume of the air that

flows into the engine, and sends voltage signals to the

ECM.

At idle speed:

2.2 - 4.4 g/sec

At 2,500 rpm with not

load:

7.5- 13.0 g/sec

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature into

voltage and signals the ECM. The sensor is a thermistor

whose internal resistance changes with coolant

temperature. The ECM uses the voltage signals from

the ECT sensor to determine the amount of injected

fuel.

With cold engine:

Same as ambient temper-

ature and IAT

With engine warmed up:

90 - 96°C

Heated Oxygen

Sensor (HO2S)

(Primary)

(Secondary)

The Heated Oxygen Sensor detects the oxygen content

in the exhaust gas and sends voltage signals to the

ECM. Based on these signals, the ECM controls the

air/fuel ratio. When the oxygen content is high (that is,

when the ratio is leaner than the stoichiometric ratio),

the voltage signal is lower. When the oxygen content is

low (that is, when the ratio is richer than the stoichio-

metric ratio), the voltage signal is higher.

0.0-1.25V

At idle speed:

about 0.1-0.9VProCarManuals.com

Page 876 of 1771

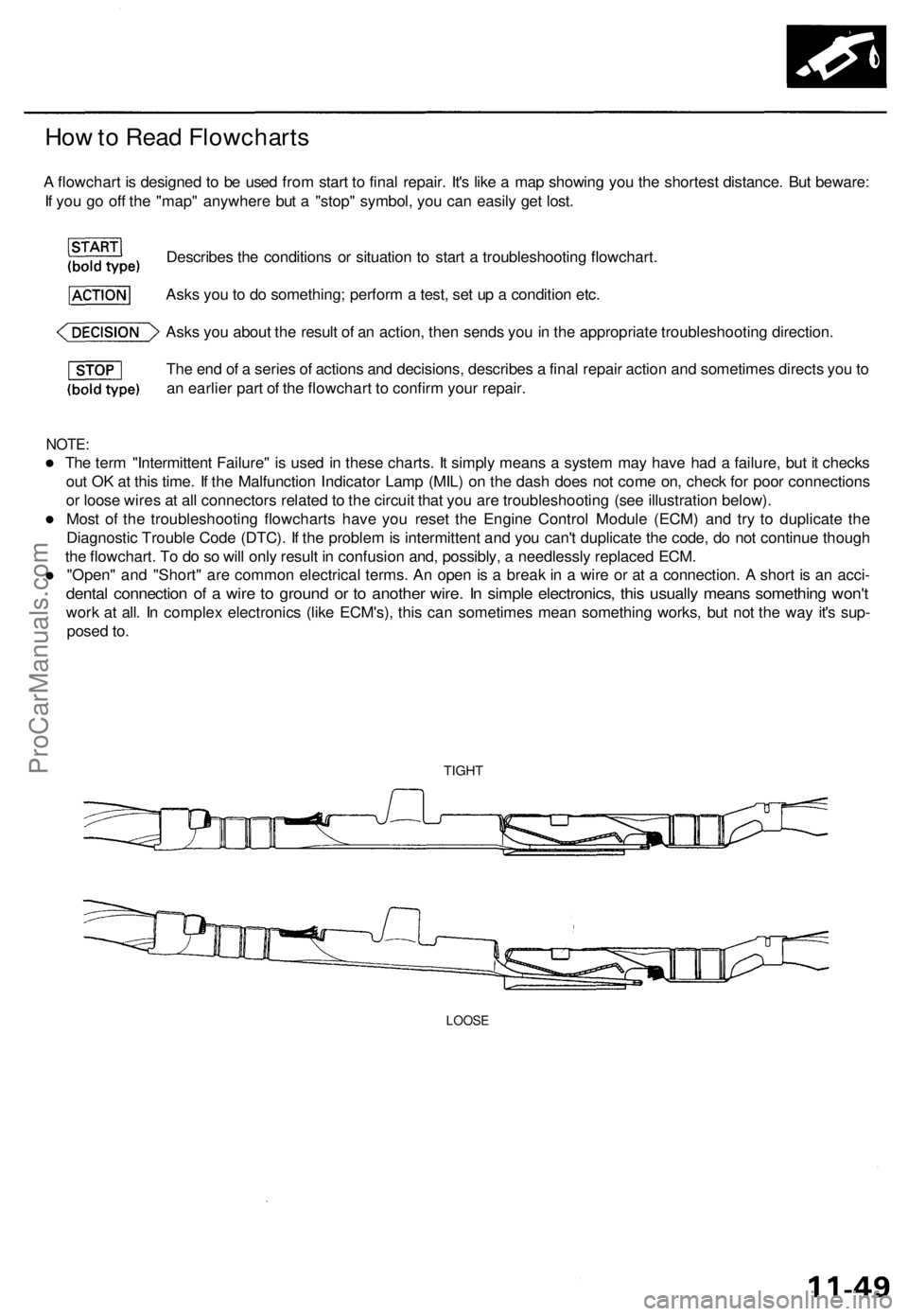

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. It's like a map showing you the shortest distance. But beware:

If you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

Describes the conditions or situation to start a troubleshooting flowchart.

Asks you to do something; perform a test, set up a condition etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

an earlier part of the flowchart to confirm your repair.

NOTE:

The term "Intermittent Failure" is used in these charts. It simply means a system may have had a failure, but it checks

out OK at this time. If the Malfunction Indicator Lamp (MIL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

Most of the troubleshooting flowcharts have you reset the Engine Control Module (ECM) and try to duplicate the

Diagnostic Trouble Code (DTC). If the problem is intermittent and you can't duplicate the code, do not continue though

the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced ECM.

"Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like ECM's), this can sometimes mean something works, but not the way it's sup-

posed to.

TIGHT

LOOSEProCarManuals.com

Page 880 of 1771

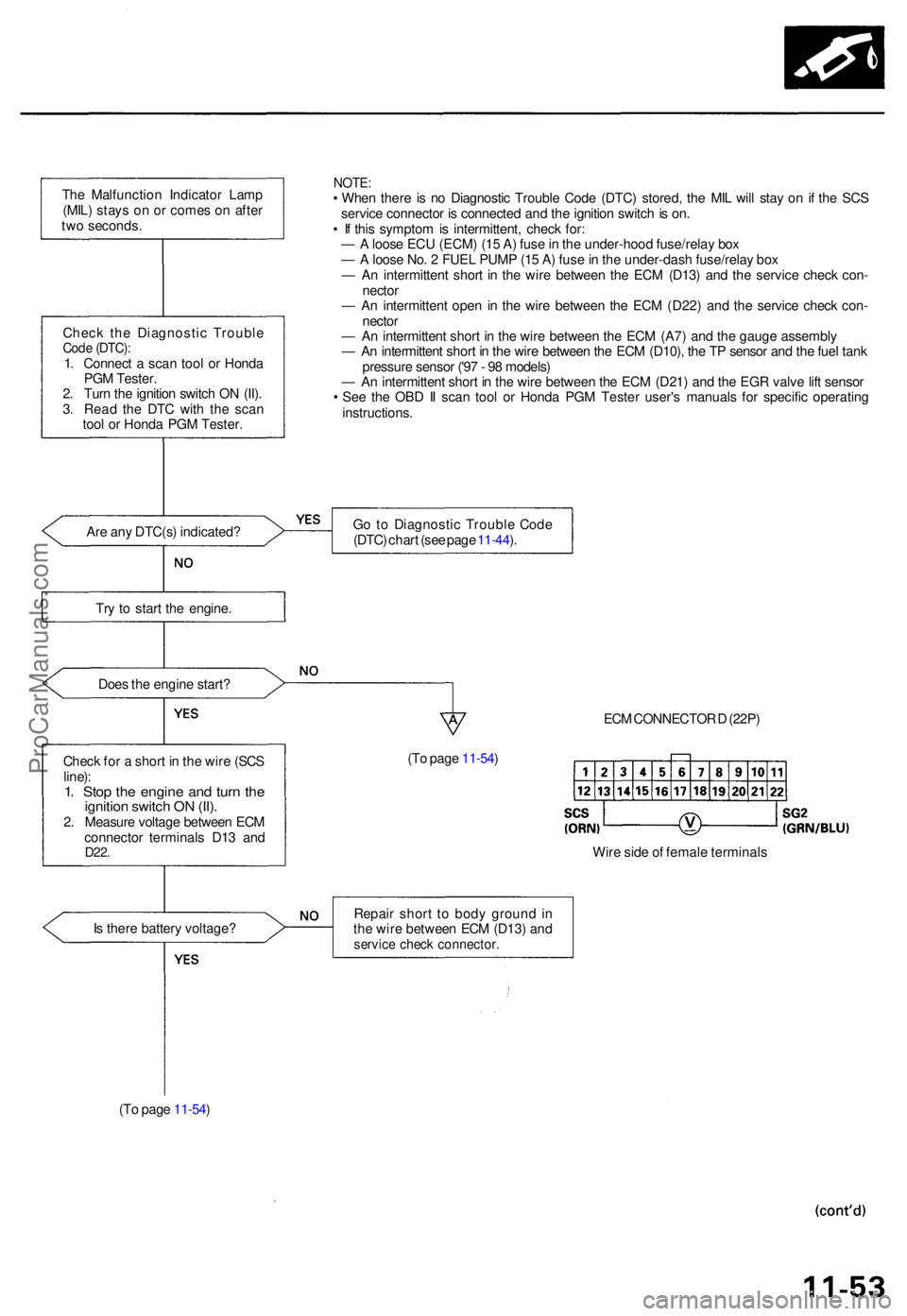

The Malfunctio n Indicato r Lam p

(MIL ) stay s o n o r come s o n afte r

tw o seconds .

Chec k th e Diagnosti c Troubl e

Code (DTC) :1. Connec t a sca n too l o r Hond a

PG M Tester .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Rea d th e DT C wit h th e sca n

too l o r Hond a PG M Tester .

NOTE:• Whe n ther e i s n o Diagnosti c Troubl e Cod e (DTC ) stored , th e MI L wil l sta y o n i f th e SC S

servic e connecto r i s connecte d an d th e ignitio n switc h is on .

• I f thi s sympto m is intermittent , chec k for :

— A loos e EC U (ECM ) (1 5 A ) fus e in th e under-hoo d fuse/rela y bo x

— A loos e No . 2 FUE L PUM P (1 5 A ) fus e in th e under-das h fuse/rela y bo x

— A n intermitten t shor t i n th e wir e betwee n th e EC M (D13 ) an d th e servic e chec k con -

necto r

— A n intermitten t ope n i n th e wir e betwee n th e EC M (D22 ) an d th e servic e chec k con -

necto r

— A n intermitten t shor t i n th e wire betwee n th e EC M (A7 ) an d th e gaug e assembl y

— A n intermitten t shor t i n th e wir e betwee n th e EC M (D10) , th e T P senso r an d th e fue l tan k

pressur e senso r ('9 7 - 9 8 models )

— A n intermitten t shor t i n th e wir e betwee n th e EC M (D21 ) an d th e EG R valv e lif t senso r

• Se e th e OB D II sca n too l o r Hond a PG M Teste r user' s manual s fo r specifi c operatin g

instructions .

Ar e an y DTC(s ) indicated ? G

o t o Diagnosti c Troubl e Cod e

(DTC ) char t (se e pag e 11-44 ).

Tr y t o star t th e engine .

Doe s th e engin e start ?

Chec k fo r a shor t i n th e wir e (SC S

line) :

1. Sto p th e engin e an d tur n th eignitio n switc h O N (II) .2. Measur e voltag e betwee n EC M

connecto r terminal s D1 3 an d

D22 .

(To pag e 11-54 ) EC

M CONNECTO R D (22P )

Wir e sid e o f femal e terminal s

I s ther e batter y voltage ? Repai

r shor t t o bod y groun d in

th e wir e betwee n EC M (D13 ) an d

servic e chec k connector .

(To pag e 11-54 )

ProCarManuals.com

Page 894 of 1771

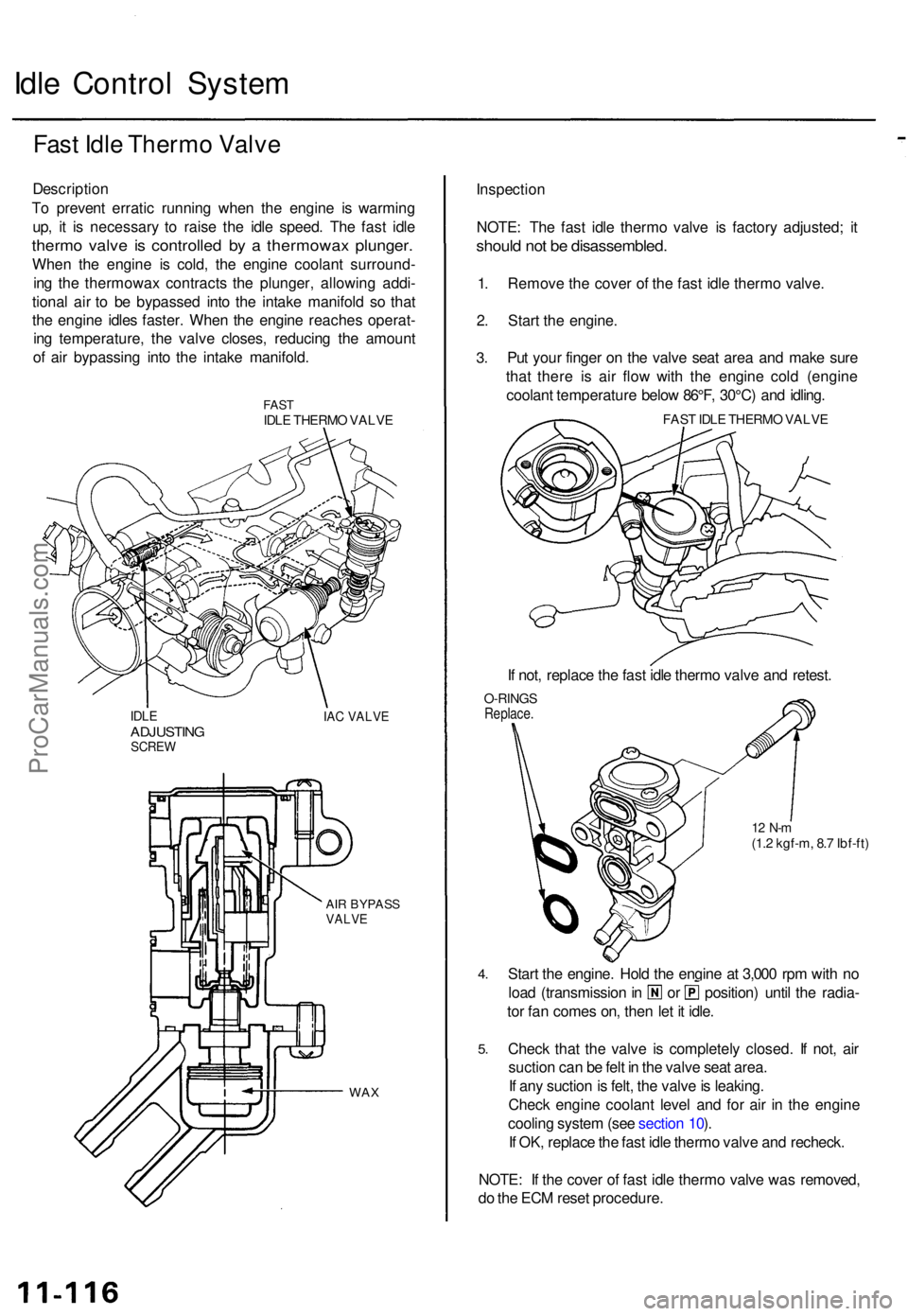

Idle Contro l Syste m

Fast Idl e Therm o Valv e

Descriptio n

T o preven t errati c runnin g whe n th e engin e i s warmin g

up , i t i s necessar y t o rais e th e idl e speed . Th e fas t idl e

therm o valv e i s controlle d b y a thermowa x plunger .

When th e engin e i s cold , th e engin e coolan t surround -

in g th e thermowa x contract s th e plunger , allowin g addi -

tiona l ai r t o b e bypasse d int o th e intak e manifol d s o tha t

th e engin e idle s faster . Whe n th e engin e reache s operat -

in g temperature , th e valv e closes , reducin g th e amoun t

o f ai r bypassin g int o th e intak e manifold .

FASTIDLE THERM O VALV E

IDLEADJUSTIN GSCREW

IAC VALV E

AIR BYPAS SVALVE

WAX

Inspectio n

NOTE : Th e fas t idl e therm o valv e i s factor y adjusted ; i t

shoul d no t b e disassembled .

1. Remov e th e cove r o f th e fas t idl e therm o valve .

2 . Star t th e engine .

3.Pu t you r finge r o n th e valv e sea t are a an d mak e sur e

tha t ther e i s ai r flo w wit h th e engin e col d (engin e

coolan t temperatur e belo w 86°F , 30°C ) an d idling .

FAST IDL E THERM O VALV E

If not , replac e th e fas t idl e therm o valv e an d retest .

O-RING SReplace .

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

4.

5 .

Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h n o

loa d (transmissio n in o r position ) unti l th e radia -

to r fa n come s on , the n le t i t idle .

Chec k tha t th e valv e i s completel y closed . I f not , ai r

suctio n ca n b e fel t i n th e valv e sea t area .

I f an y suctio n is felt , th e valv e is leaking .

Chec k engin e coolan t leve l an d fo r ai r i n th e engin e

coolin g syste m (se e sectio n 10 ).

I f OK , replac e th e fas t idl e therm o valv e an d recheck .

NOTE : I f th e cove r o f fas t idl e therm o valv e wa s removed ,

d o th e EC M rese t procedure .

ProCarManuals.com

Page 908 of 1771

Fuel Suppl y Syste m

Fuel Pressur e Regulato r

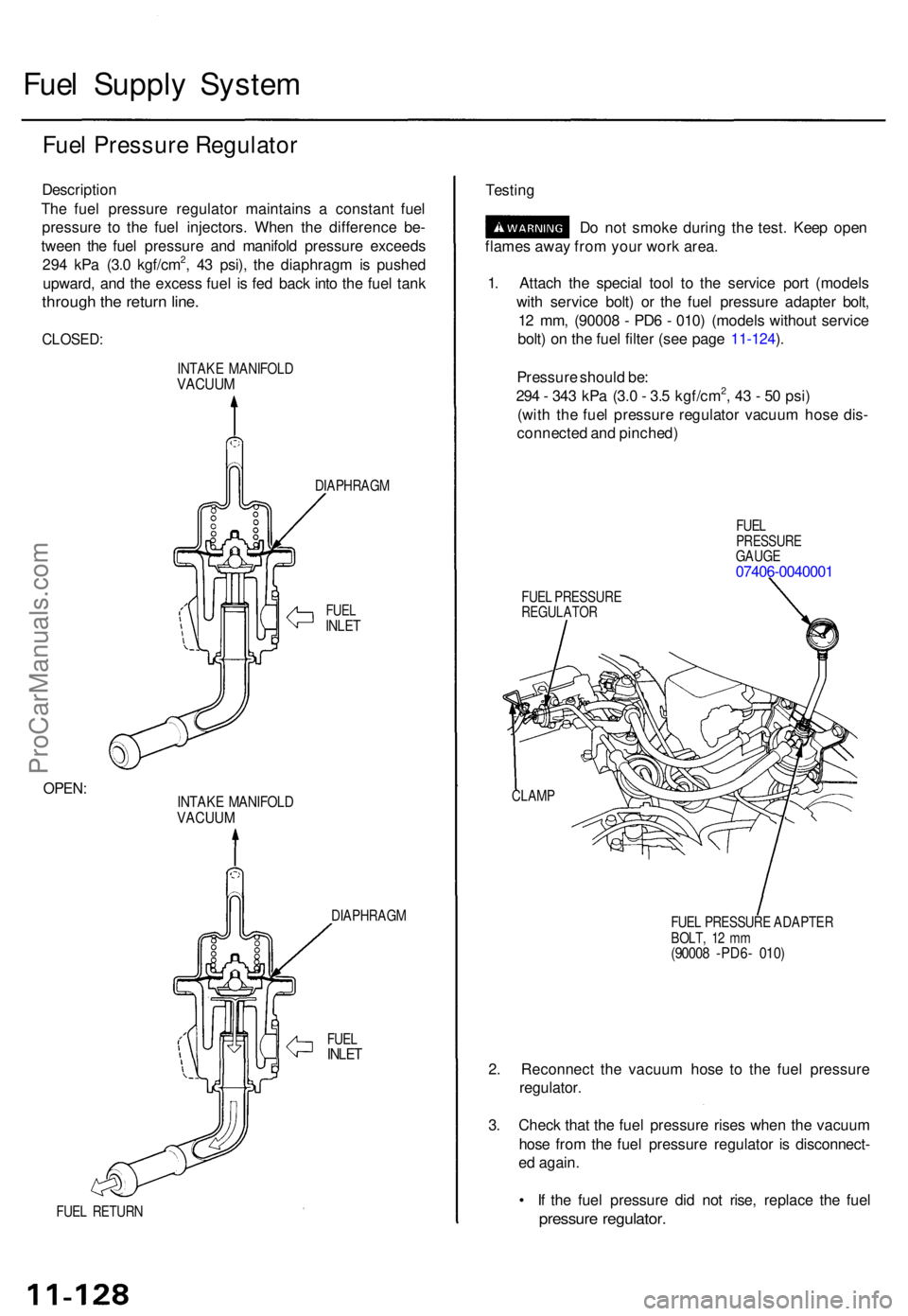

Descriptio n

Th e fue l pressur e regulato r maintain s a constan t fue l

pressur e t o th e fue l injectors . Whe n th e differenc e be -

twee n th e fue l pressur e an d manifol d pressur e exceed s

29 4 kP a (3. 0 kgf/cm

2, 4 3 psi) , th e diaphrag m is pushe d

upward , an d th e exces s fue l i s fe d bac k int o th e fue l tan k

throug h th e retur n line .

CLOSED :

INTAKE MANIFOL DVACUUM

DIAPHRAG M

FUELINLE T

OPEN :INTAK E MANIFOL DVACUUM

FUEL RETUR N DIAPHRAG

M

FUE L

INLE T

Testin g

Do no t smok e durin g th e test . Kee p ope n

flame s awa y fro m you r wor k area .

1 . Attac h th e specia l too l t o th e servic e por t (model s

wit h servic e bolt ) o r th e fue l pressur e adapte r bolt ,

1 2 mm , (9000 8 - PD 6 - 010 ) (model s withou t servic e

bolt ) o n th e fue l filte r (se e pag e 11-124 ).

Pressur e shoul d be :

29 4 - 34 3 kP a (3. 0 - 3. 5 kgf/cm

2, 4 3 - 5 0 psi )

(wit h th e fue l pressur e regulato r vacuu m hos e dis -

connecte d an d pinched )

FUELPRESSUR EGAUGE07406-004000 1

FUEL PRESSUR EREGULATO R

FUEL PRESSUR E ADAPTE R

BOLT , 1 2 m m

(9000 8 -PD6 - 010 )

2. Reconnec t th e vacuu m hos e t o th e fue l pressur e

regulator .

3 . Chec k tha t th e fue l pressur e rise s whe n th e vacuu m

hos e fro m th e fue l pressur e regulato r i s disconnect -

e d again .

• I f th e fue l pressur e di d no t rise , replac e th e fue l

pressur e regulator .

CLAMP

ProCarManuals.com

Page 912 of 1771

Fuel Suppl y Syste m

Fuel Pum p

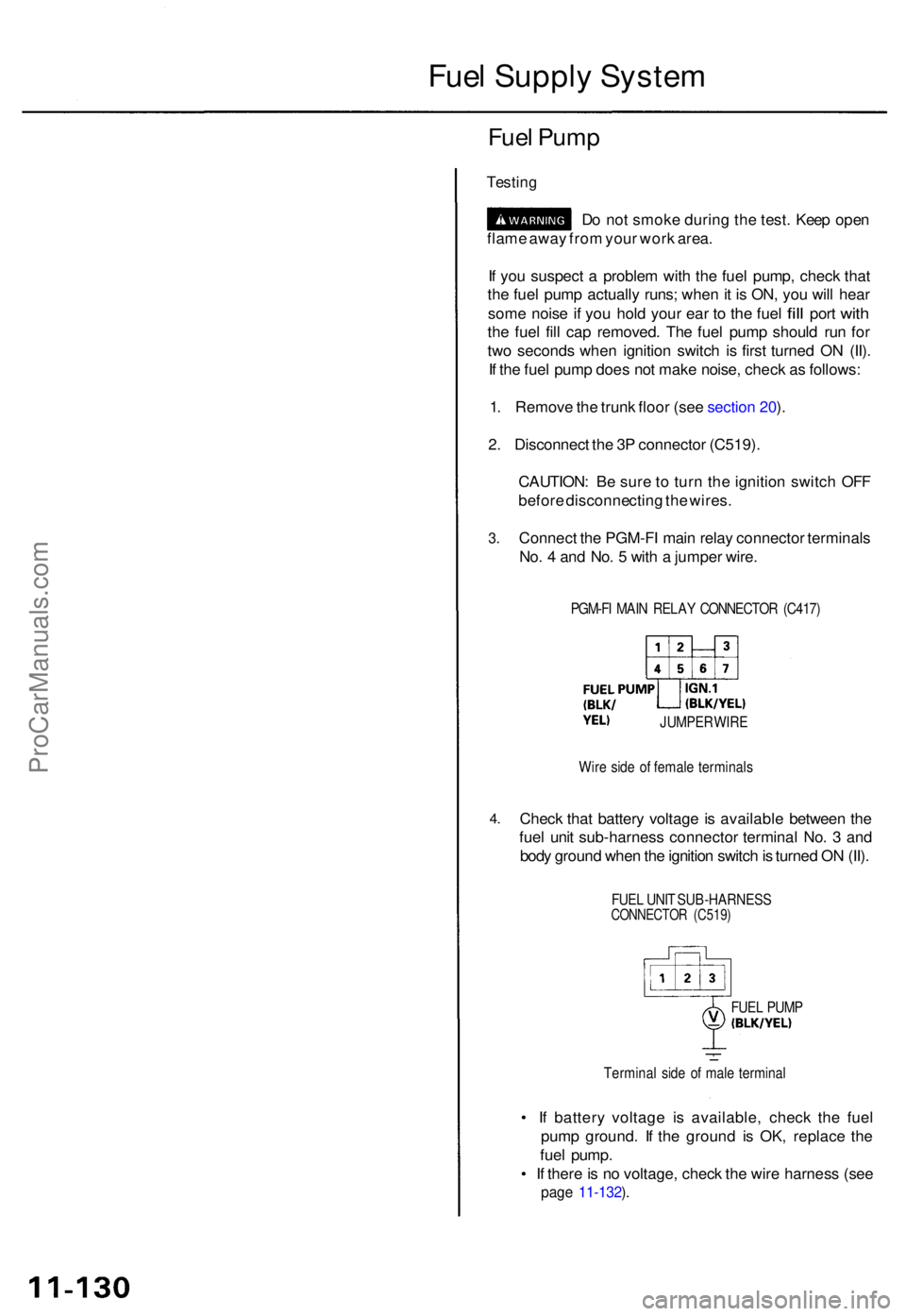

Testin g

Do no t smok e durin g th e test . Kee p ope n

flam e awa y fro m you r wor k area .

I f yo u suspec t a proble m wit h th e fue l pump , chec k tha t

th e fue l pum p actuall y runs ; whe n it i s ON , yo u wil l hea r

som e nois e

if yo u hol d you r ear t o th e fue l fill por t with

the fue l fil l ca p removed . Th e fue l pum p shoul d ru n fo r

tw o second s whe n ignitio n switc h i s firs t turne d O N (II) .

I f th e fue l pum p doe s no t mak e noise , chec k a s follows :

1 . Remov e th e trun k floo r (se e sectio n 20 ).

2 . Disconnec t th e 3 P connecto r (C519) .

CAUTION : B e sur e t o tur n th e ignitio n switc h OF F

befor e disconnectin g th e wires .

3.

4.

Connec t th e PGM-F I mai n rela y connecto r terminal s

No . 4 an d No . 5 wit h a jumpe r wire .

PGM-F I MAI N RELA Y CONNECTO R (C417 )

Wir e sid e o f femal e terminal s

Check tha t batter y voltag e i s availabl e betwee n th e

fue l uni t sub-harnes s connecto r termina l No . 3 an d

bod y groun d whe n th e ignitio n switc h is turne d O N (II) .

FUE L UNI T SUB-HARNES SCONNECTOR (C519 )

FUEL PUM P

Termina l sid e o f mal e termina l

• I f batter y voltag e i s available , chec k th e fue l

pum p ground . I f th e groun d i s OK , replac e th e

fue l pump .

• I f ther e is n o voltage , chec k th e wir e harnes s (se e

pag e 11-132 ).

JUMPE R WIR E

ProCarManuals.com

Page 914 of 1771

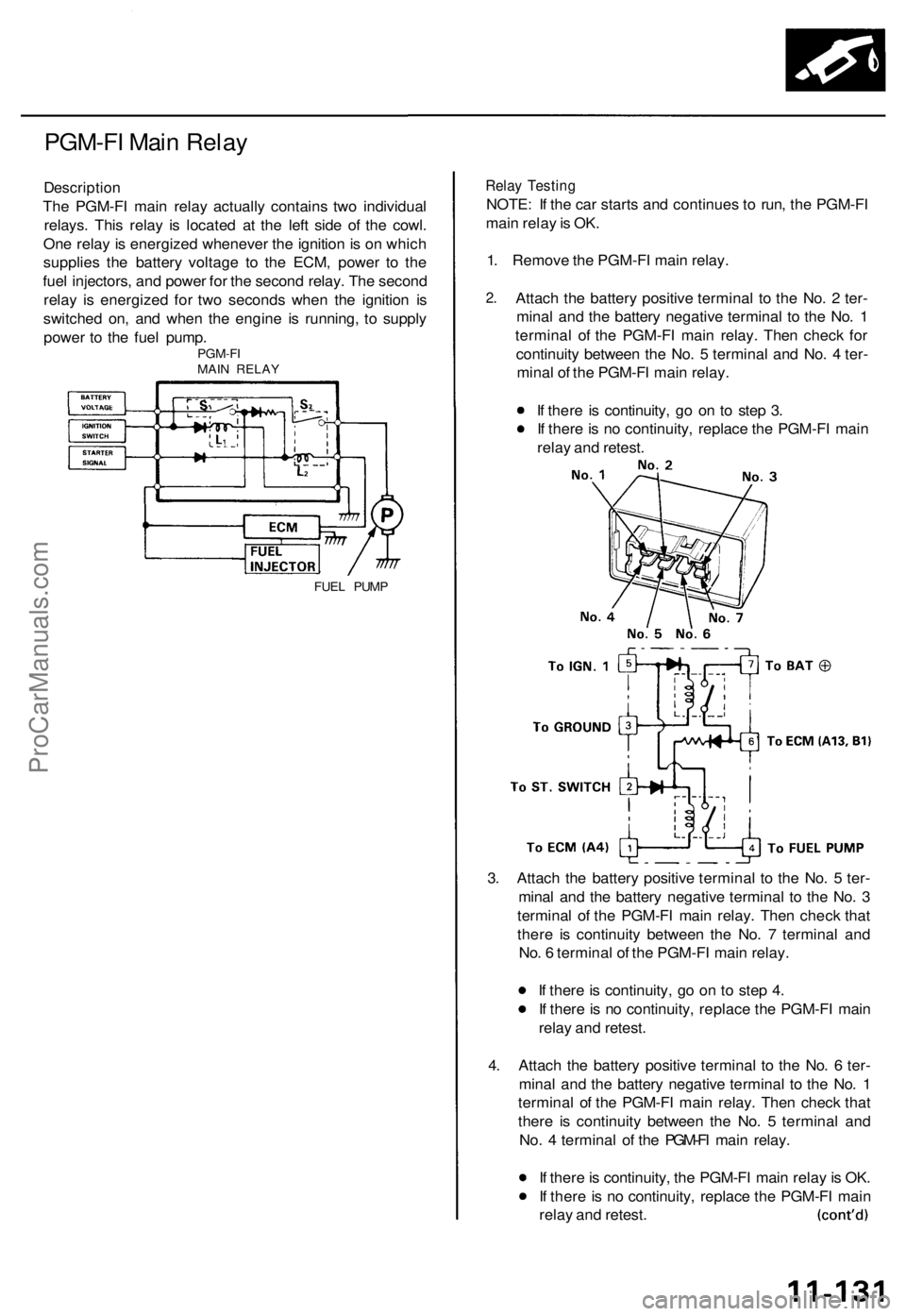

PGM-FI Main Relay

Description

The PGM-FI main relay actually contains two individual

relays. This relay is located at the left side of the cowl.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay. The second

relay is energized for two seconds when the ignition is

switched on, and when the engine is running, to supply

power to the fuel pump.

PGM-FI

MAIN RELAY

FUEL PUMP

Relay Testing

NOTE: If the car starts and continues to run, the PGM-FI

main relay is OK.

1. Remove the PGM-FI main relay.

2.

Attach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-FI main relay. Then check for

continuity between the No. 5 terminal and No. 4 ter-

minal of the PGM-FI main relay.

If there is continuity, go on to step 3.

If there is no continuity, replace the PGM-FI main

relay and retest.

3. Attach the battery positive terminal to the No. 5 ter-

minal and the battery negative terminal to the No. 3

terminal of the PGM-FI main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-FI main relay.

If there is continuity, go on to step 4.

If there is no continuity, replace the PGM-FI main

relay and retest.

4. Attach the battery positive terminal to the No. 6 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-FI main relay. Then check that

there is continuity between the No. 5 terminal and

No. 4 terminal of the PGM-FI main relay.

If there is continuity, the PGM-FI main relay is OK.

If there is no continuity, replace the PGM-FI main

relay and retest.ProCarManuals.com

Page 926 of 1771

Intake Ai r Syste m Emissio

n Contro l Syste m

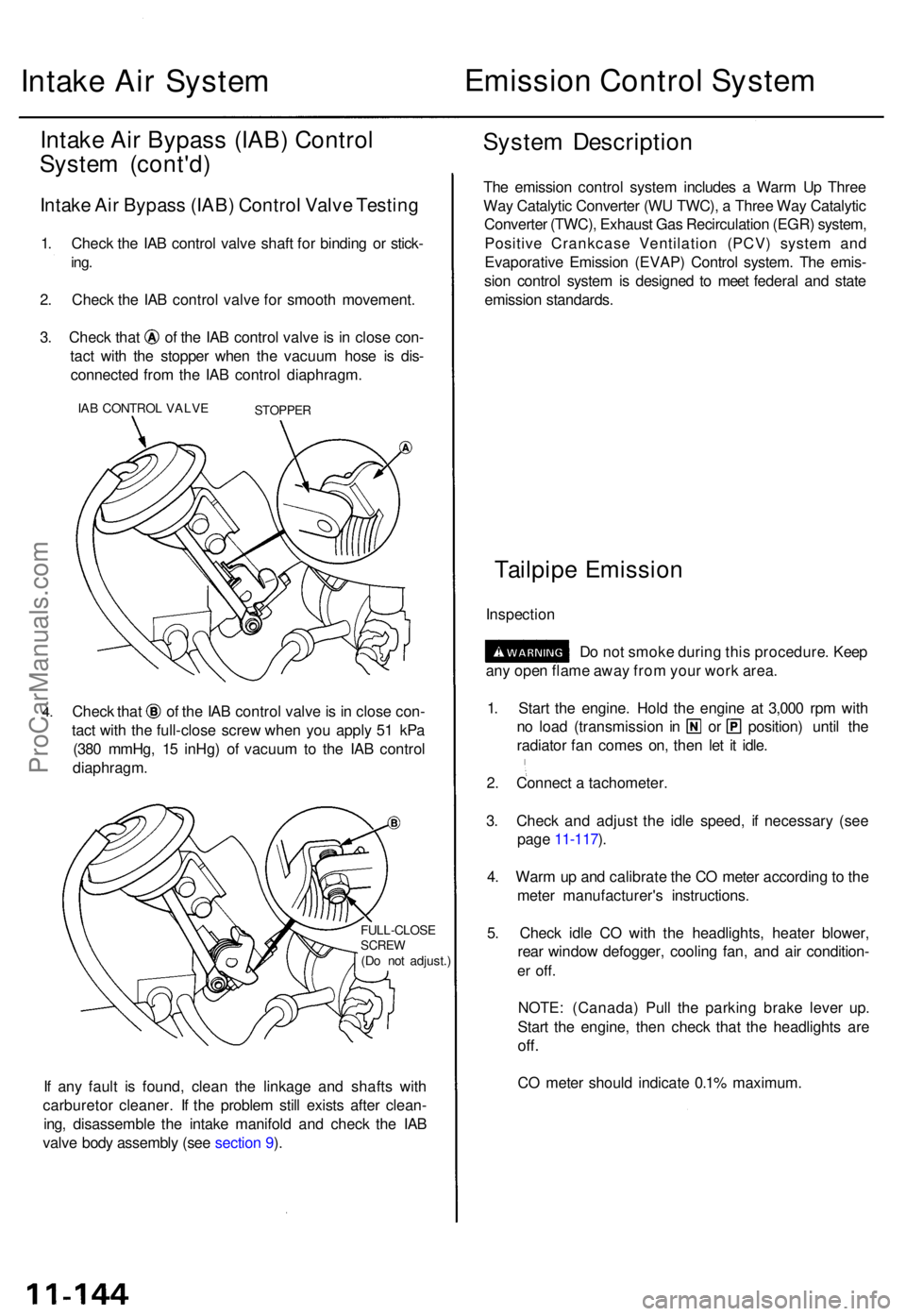

Intake Ai r Bypas s (IAB ) Contro l

Syste m (cont'd )

Intake Ai r Bypas s (IAB ) Contro l Valv e Testin g

1. Chec k th e IA B contro l valv e shaf t fo r bindin g o r stick -

ing.

2. Chec k th e IA B contro l valv e fo r smoot h movement .

3. Chec k tha t o f th e IA B contro l valv e is i n clos e con -

tac t wit h th e stoppe r whe n th e vacuu m hos e i s dis -

connecte d fro m th e IA B contro l diaphragm .

IAB CONTRO L VALV ESTOPPE R

4.Chec k tha t o f th e IA B contro l valv e is in clos e con -

tac t wit h th e full-clos e scre w whe n yo u appl y 5 1 kP a

(38 0 mmHg , 1 5 inHg ) o f vacuu m to th e IA B contro l

diaphragm .

FULL-CLOS ESCREW(Do no t adjust. )

If an y faul t i s found , clea n th e linkag e an d shaft s wit h

carbureto r cleaner . I f th e proble m stil l exist s afte r clean -

ing , disassembl e th e intak e manifol d an d chec k th e IA B

valv e bod y assembl y (se e sectio n 9 ).

Syste m Descriptio n

The emissio n contro l syste m include s a War m U p Thre e

Wa y Catalyti c Converte r (W U TWC) , a Thre e Wa y Catalyti c

Converte r (TWC) , Exhaus t Ga s Recirculatio n (EGR ) system ,

Positiv e Crankcas e Ventilatio n (PCV ) syste m an d

Evaporativ e Emissio n (EVAP ) Contro l system . Th e emis -

sio n contro l syste m is designe d t o mee t federa l an d stat e

emissio n standards .

Tailpipe Emissio n

Inspectio n

Do no t smok e durin g thi s procedure . Kee p

an y ope n flam e awa y fro m you r wor k area .

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (transmissio n i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Chec k an d adjus t th e idl e speed , i f necessar y (se e

pag e 11-117 ).

4 . War m u p an d calibrat e th e C O mete r accordin g to th e

mete r manufacturer' s instructions .

5 . Chec k idl e C O wit h th e headlights , heate r blower ,

rea r windo w defogger , coolin g fan , an d ai r condition -

er off .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

CO mete r shoul d indicat e 0.1 % maximum .

ProCarManuals.com

Page 933 of 1771

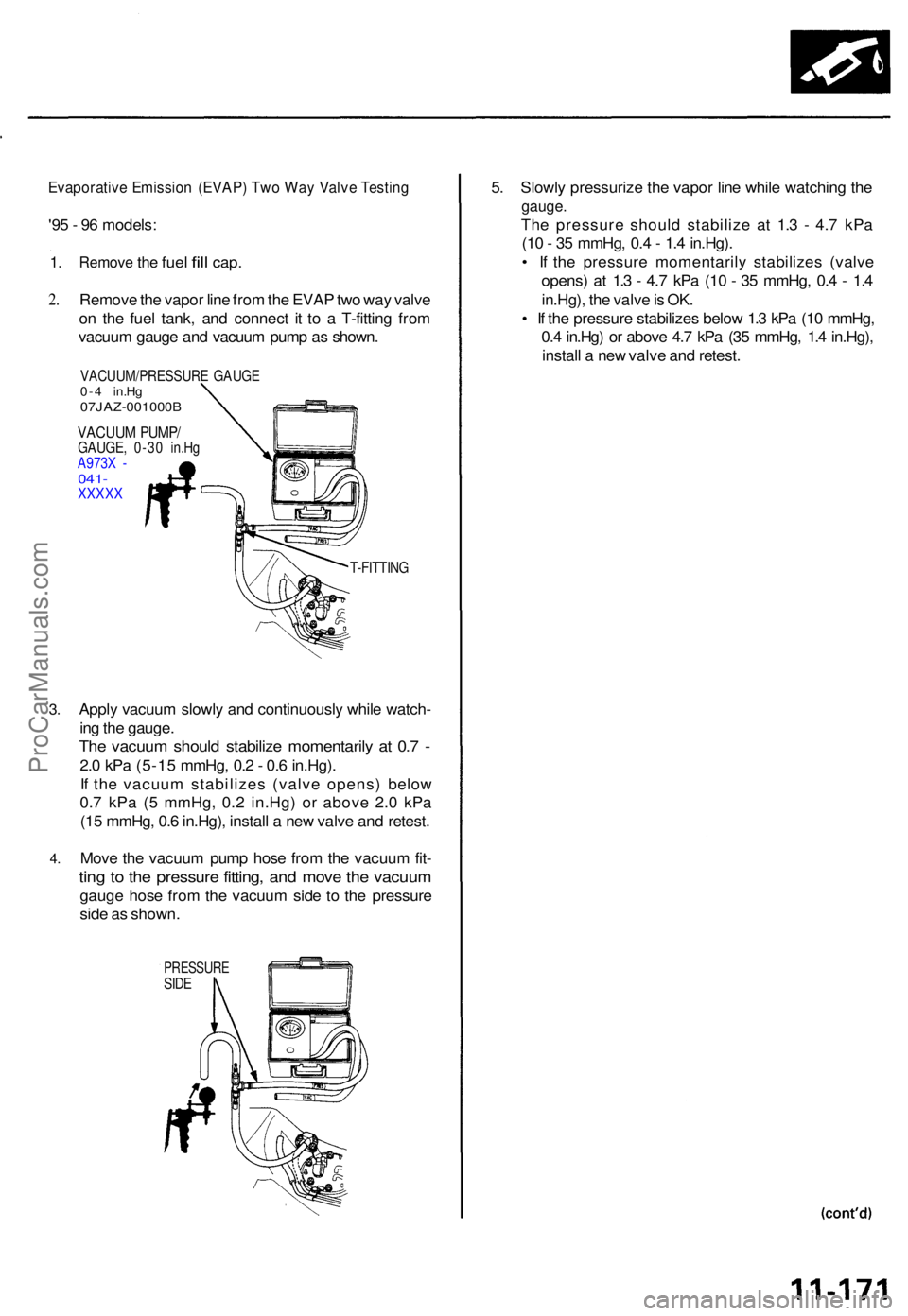

Evaporative Emissio n (EVAP ) Tw o Wa y Valv e Testin g

'95 - 9 6 models :

1. Remov e the fue l fill cap .

2.

3 .

4 .

Remov e th e vapo r lin e fro m th e EVA P tw o wa y valv e

o n th e fue l tank , an d connec t i t t o a T-fittin g fro m

vacuu m gaug e an d vacuu m pum p a s shown .

VACUUM/PRESSUR E GAUG E0-4 in.H g07JAZ-001000 B

VACUUM PUMP /GAUGE , 0-3 0 in.H g

A973 X -

041 -XXXX X

T-FITTING

Apply vacuu m slowl y an d continuousl y whil e watch -

in g th e gauge .

The vacuu m shoul d stabiliz e momentaril y a t 0. 7 -

2. 0 kP a (5-1 5 mmHg , 0. 2 - 0. 6 in.Hg) .

I f th e vacuu m stabilize s (valv e opens ) belo w

0. 7 kP a ( 5 mmHg , 0. 2 in.Hg ) o r abov e 2. 0 kP a

(1 5 mmHg , 0. 6 in.Hg) , instal l a ne w valv e an d retest .

Mov e th e vacuu m pum p hos e fro m th e vacuu m fit -

ting to th e pressur e fitting , an d mov e th e vacuu m

gauge hos e fro m th e vacuu m sid e t o th e pressur e

sid e a s shown .

PRESSUR ESIDE

5. Slowl y pressuriz e th e vapo r lin e whil e watchin g th e

gauge .

The pressur e shoul d stabiliz e a t 1. 3 - 4. 7 kP a

(1 0 - 3 5 mmHg , 0. 4 - 1. 4 in.Hg) .

• I f th e pressur e momentaril y stabilize s (valv e

opens ) a t 1. 3 - 4. 7 kP a (1 0 - 3 5 mmHg , 0. 4 - 1. 4

in.Hg) , th e valv e is OK .

• I f th e pressur e stabilize s belo w 1. 3 kP a (1 0 mmHg ,

0. 4 in.Hg ) o r abov e 4. 7 kP a (3 5 mmHg , 1. 4 in.Hg) ,

instal l a ne w valv e an d retest .

ProCarManuals.com

Page 934 of 1771

Emission Contro l Syste m

Evaporativ e Emissio n (EVAP ) Control s (cont'd )

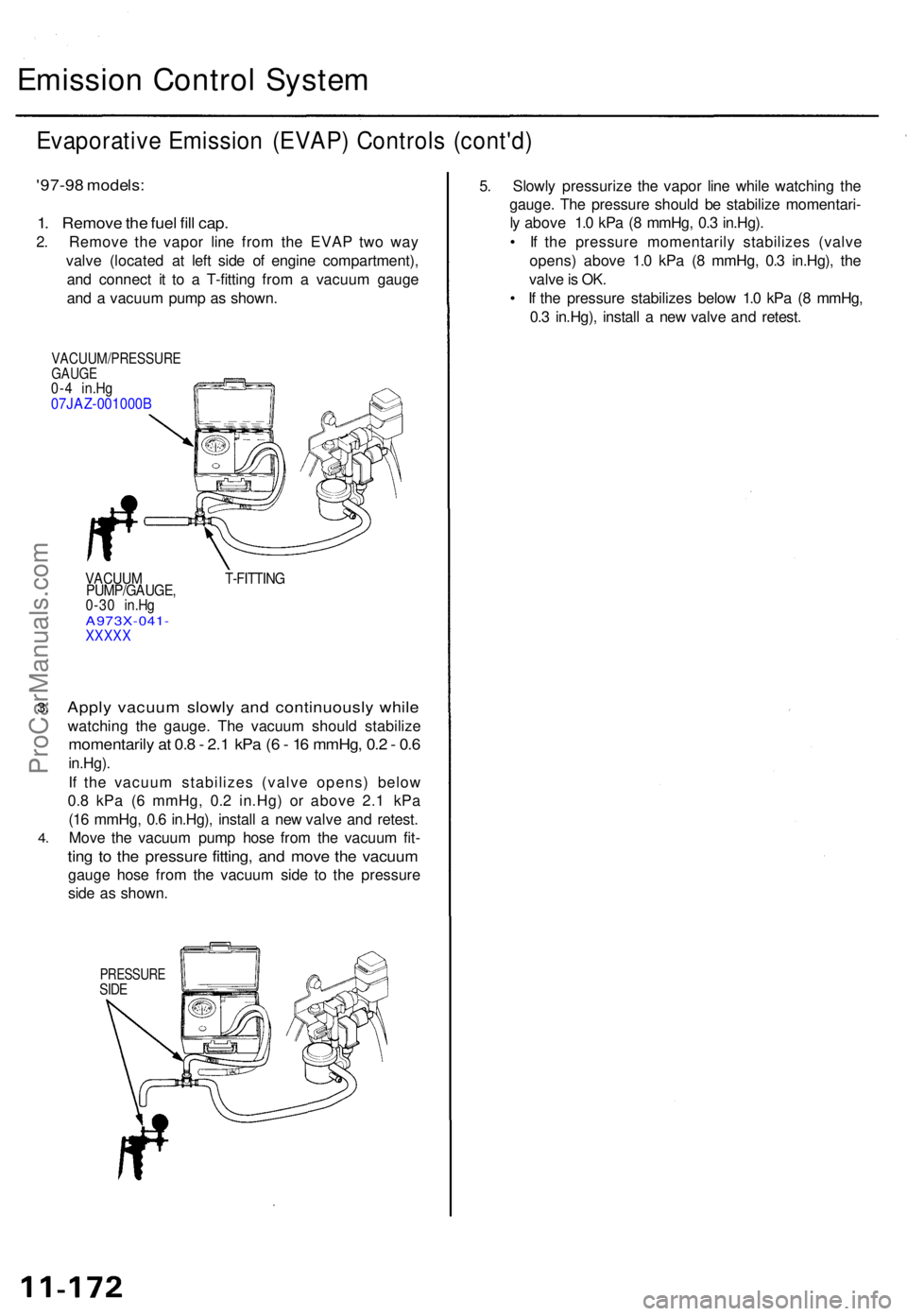

'97-98 models :

1. Remov e th e fue l fil l cap .

2. Remov e th e vapo r lin e fro m th e EVA P tw o wa y

valv e (locate d a t lef t sid e o f engin e compartment) ,

an d connec t i t t o a T-fittin g fro m a vacuu m gaug e

an d a vacuu m pum p a s shown .

VACUUM/PRESSUR EGAUGE0-4 in.H g07JAZ-001000 B

3.

4 .

VACUU M T-FITTIN G

PUMP/GAUGE ,

0-3 0 in.H g

A973X-041 -XXXXX

Apply vacuu m slowl y an d continuousl y whil e

watchin g th e gauge . Th e vacuu m shoul d stabiliz e

momentaril y a t 0. 8 - 2. 1 kP a ( 6 - 1 6 mmHg , 0. 2 - 0. 6

in.Hg) .

I f th e vacuu m stabilize s (valv e opens ) belo w

0. 8 kP a ( 6 mmHg , 0. 2 in.Hg ) o r abov e 2. 1 kP a

(1 6 mmHg , 0. 6 in.Hg) , instal l a ne w valv e an d retest .

Mov e th e vacuu m pum p hos e fro m th e vacuu m fit -

ting t o th e pressur e fitting , an d mov e th e vacuu m

gauge hos e fro m th e vacuu m sid e t o th e pressur e

sid e a s shown .

PRESSUR ESIDE

5. Slowl y pressuriz e th e vapo r lin e whil e watchin g th e

gauge . Th e pressur e shoul d b e stabiliz e momentari -

l y abov e 1. 0 kP a ( 8 mmHg , 0. 3 in.Hg) .

• I f th e pressur e momentaril y stabilize s (valv e

opens ) abov e 1. 0 kP a ( 8 mmHg , 0. 3 in.Hg) , th e

valv e is OK .

• I f th e pressur e stabilize s belo w 1. 0 kP a ( 8 mmHg ,

0. 3 in.Hg) , instal l a ne w valv e an d retest .

ProCarManuals.com