Test ACURA TL 1995 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 610 of 1771

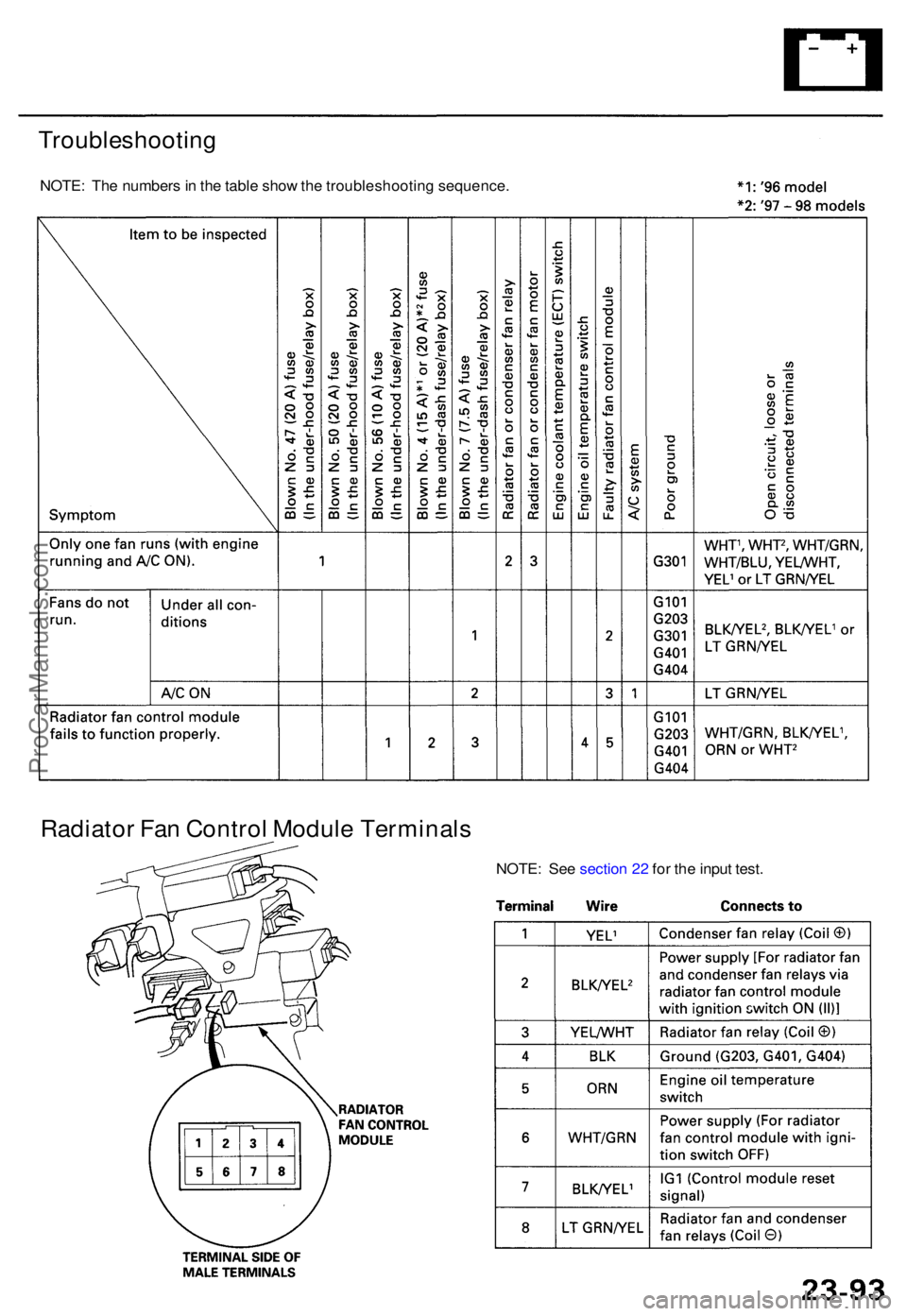

Troubleshooting

NOTE: Th e number s in th e tabl e sho w th e troubleshootin g sequence .

Radiator Fa n Contro l Modul e Terminal s

NOTE: Se e sectio n 2 2 fo r th e inpu t test .

ProCarManuals.com

Page 611 of 1771

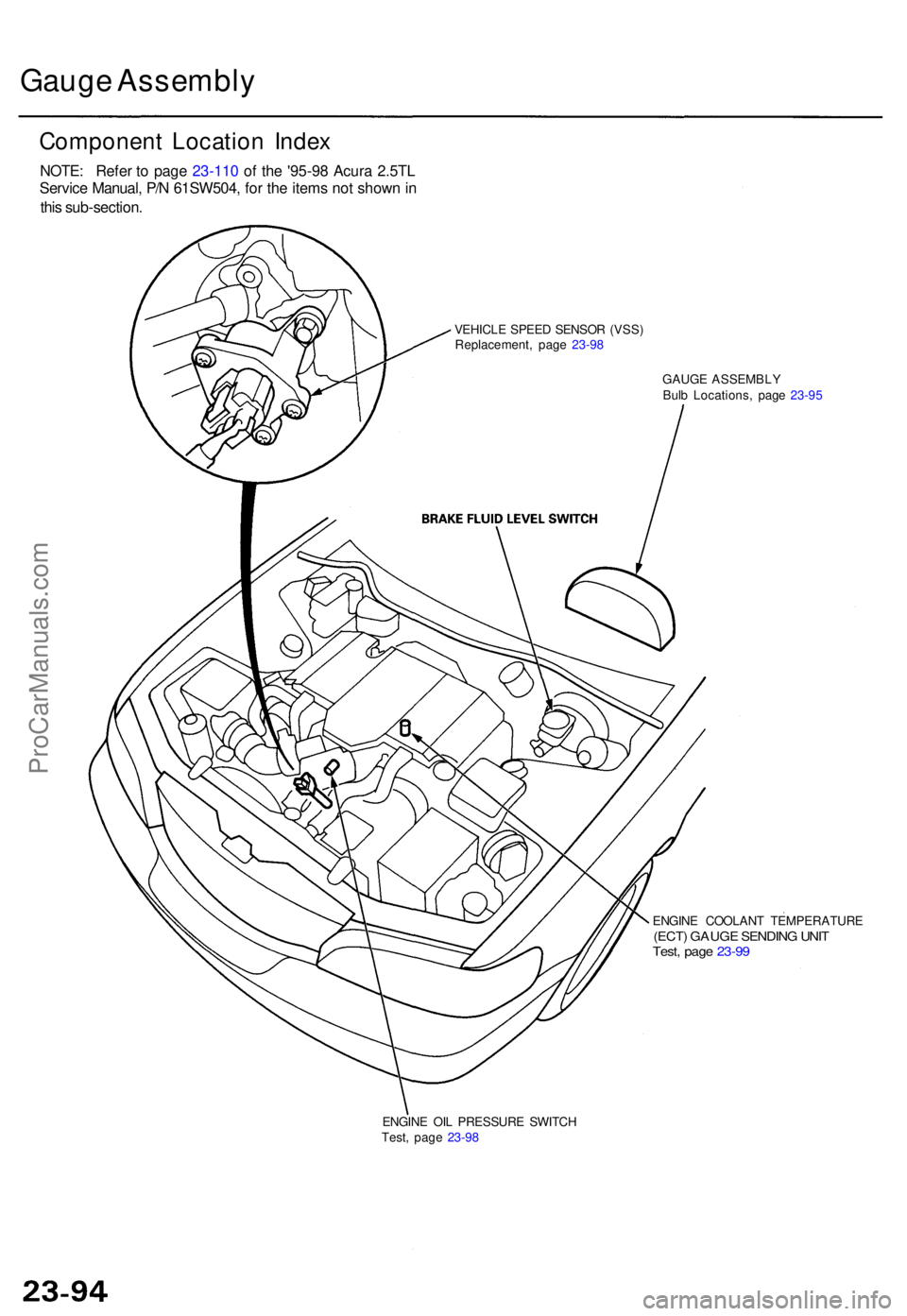

Gauge Assembl y

Componen t Locatio n Inde x

VEHICL E SPEE D SENSO R (VSS )

Replacement , pag e 23-9 8

GAUGE ASSEMBL Y

Bul b Locations , pag e 23-9 5

ENGIN E COOLAN T TEMPERATUR E

(ECT) GAUG E SENDIN G UNI TTest , pag e 23-9 9

ENGIN E OI L PRESSUR E SWITC H

Test , pag e 23-9 8

NOTE : Refer to page 23-110 of the '95-98 Acura 2.5TL

Servic e Manual , P/ N 61SW504 , for the items not shown in

thi s sub-section .

ProCarManuals.com

Page 613 of 1771

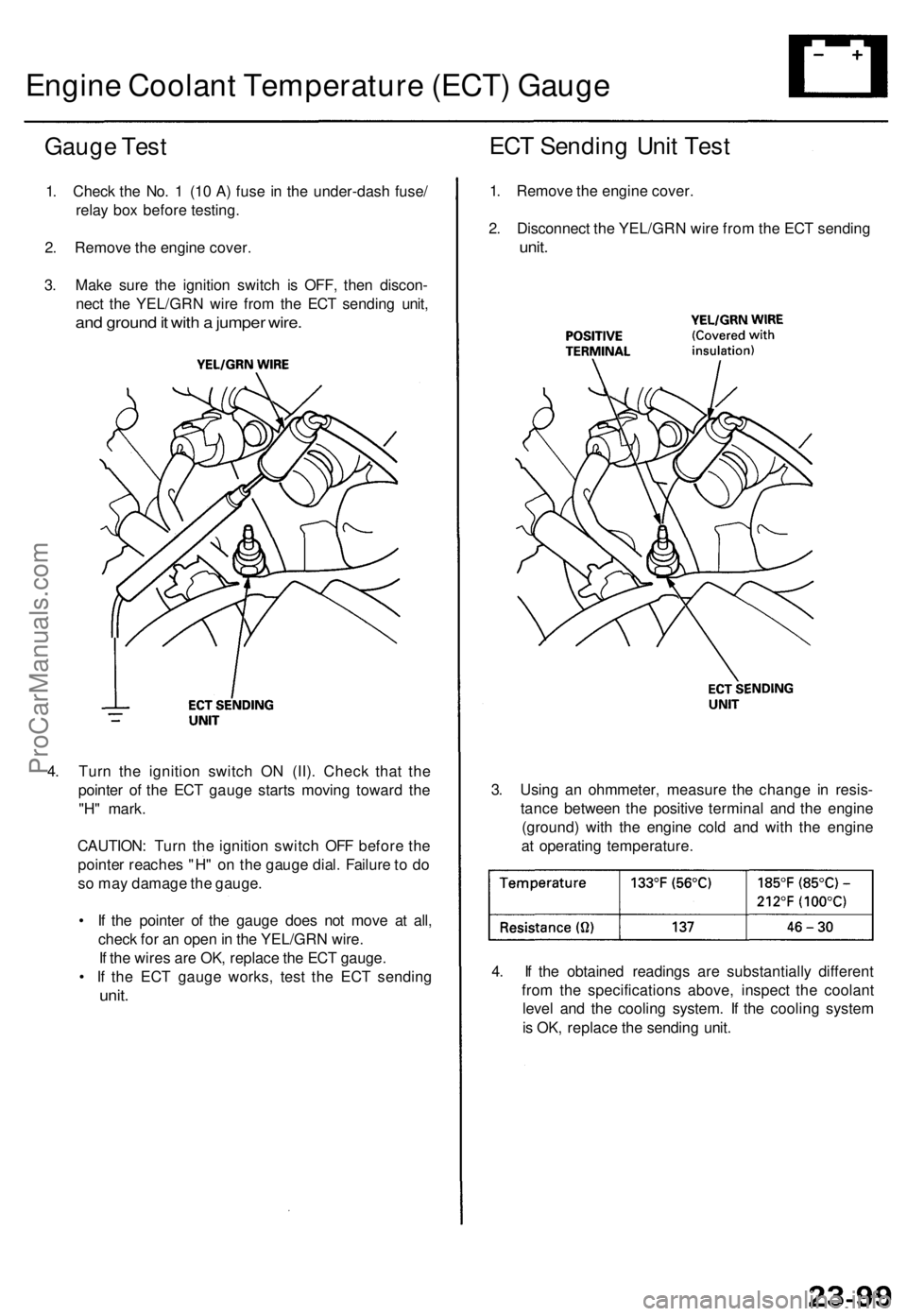

Engine Coolan t Temperatur e (ECT ) Gaug e

Gauge Tes t

1. Chec k th e No . 1 (1 0 A ) fus e i n th e under-das h fuse /

rela y bo x befor e testing .

2 . Remov e th e engin e cover .

3 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e EC T sendin g unit ,

and groun d it wit h a jumpe r wire .

4. Tur n th e ignitio n switc h O N (II) . Chec k tha t th e

pointe r o f th e EC T gaug e start s movin g towar d th e

"H " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s "H " o n th e gaug e dial . Failur e to d o

s o ma y damag e th e gauge .

• I f th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k fo r a n ope n in th e YEL/GR N wire .

I f th e wire s ar e OK , replac e th e EC T gauge .

• I f th e EC T gaug e works , tes t th e EC T sendin g

unit.

4. I f th e obtaine d reading s ar e substantiall y differen t

fro m th e specification s above , inspec t th e coolan t

leve l an d th e coolin g system . I f th e coolin g syste m

i s OK , replac e th e sendin g unit .

3

. Usin g a n ohmmeter , measur e th e chang e i n resis -

tanc e betwee n th e positiv e termina l an d th e engine

(ground ) wit h th e engin e col d an d wit h th e engin e

a t operatin g temperature .

ECT Sendin g Uni t Tes t

1. Remov e th e engin e cover .

2 . Disconnec t th e YEL/GR N wir e fro m th e EC T sendin g

unit.

ProCarManuals.com

Page 614 of 1771

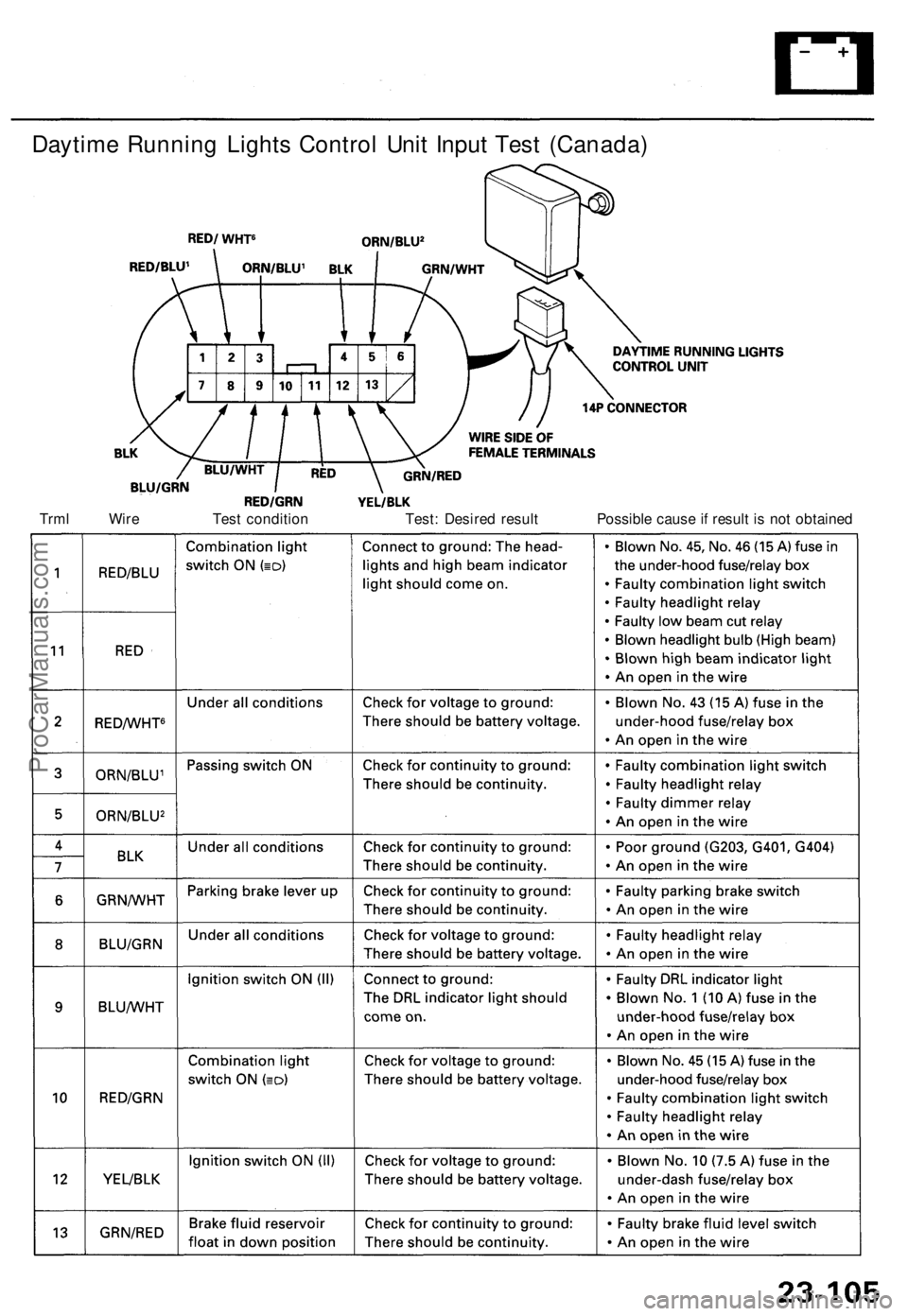

Daytime Runnin g Light s Contro l Uni t Inpu t Tes t (Canada )

Trml Wir e Tes t conditio n Test : Desire d resul t Possibl e caus e if resul t i s no t obtaine d

ProCarManuals.com

Page 616 of 1771

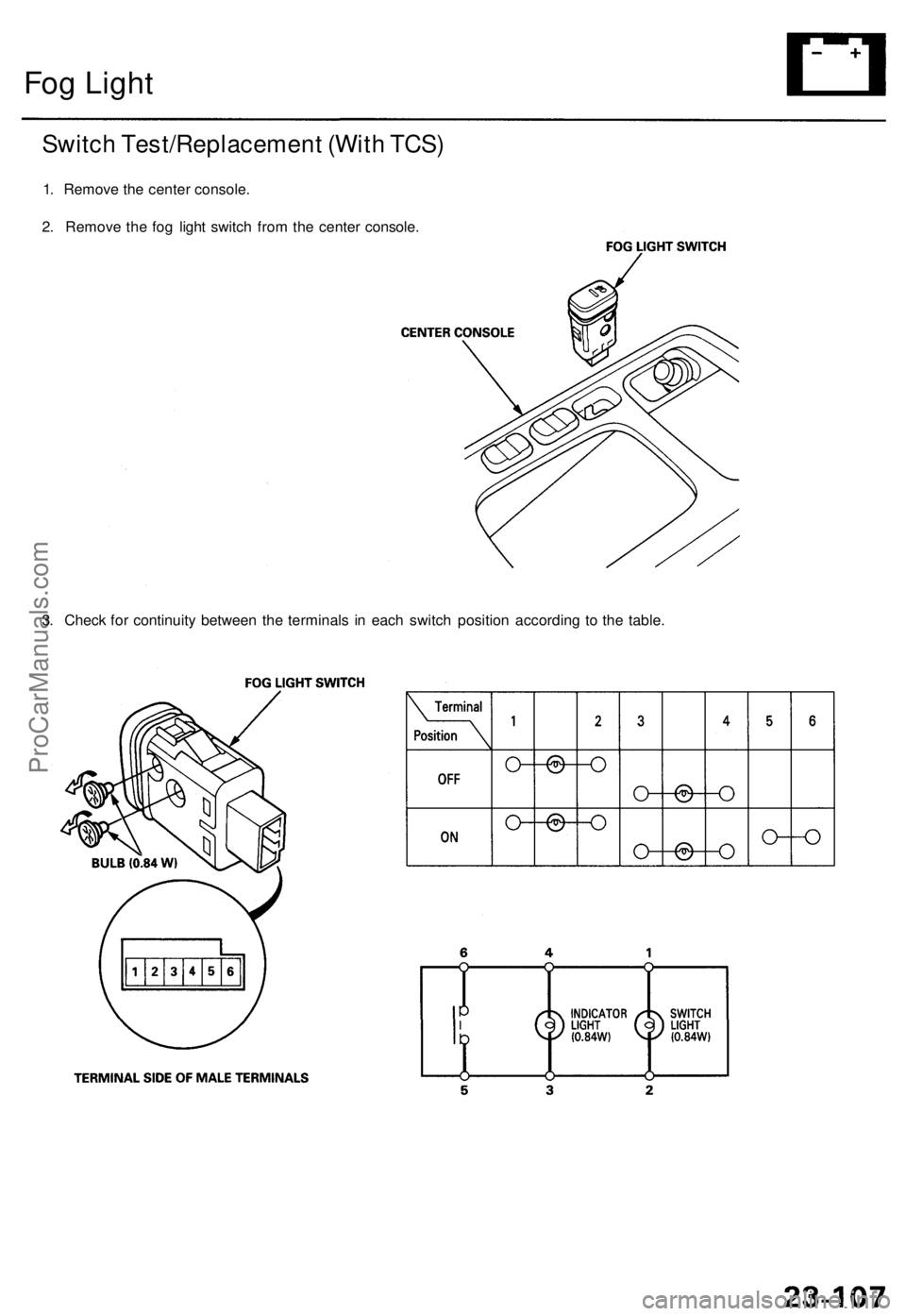

Fog Ligh t

Switc h Test/Replacemen t (Wit h TCS )

1. Remov e th e cente r console .

2 . Remov e th e fo g ligh t switc h fro m th e cente r console .

3 . Chec k fo r continuit y betwee n th e terminal s i n eac h switc h positio n accordin g t o th e table .

ProCarManuals.com

Page 618 of 1771

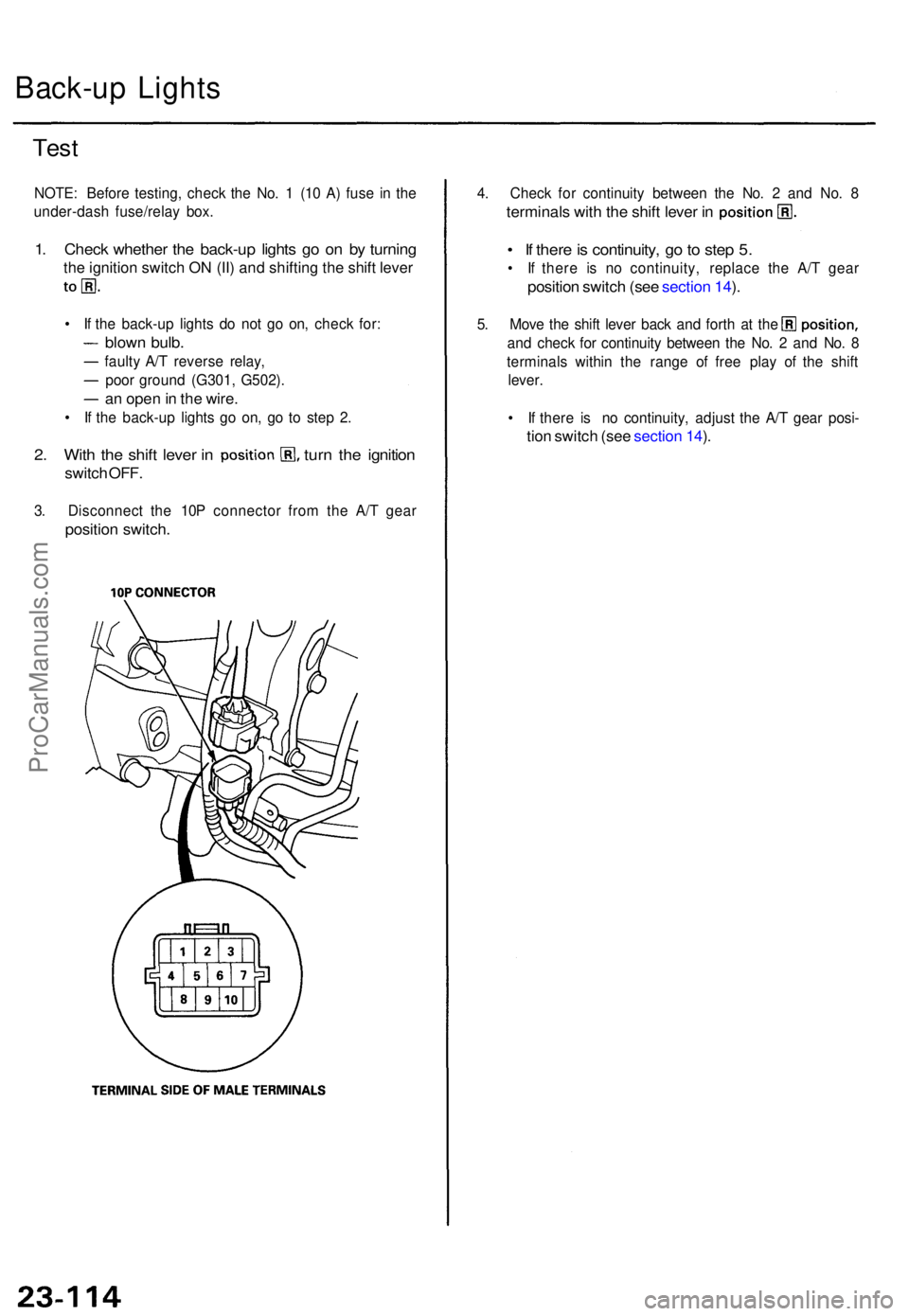

Back-up Light s

Test

NOTE : Befor e testing , chec k th e No . 1 (1 0 A ) fus e i n th e

under-das h fuse/rela y box .

1. Chec k whethe r th e back-u p light s g o o n b y turnin g

the ignitio n switc h O N (II ) an d shiftin g th e shif t leve r

• I f th e back-u p light s d o no t g o on , chec k for :

blow n bulb .

faulty A/ T revers e relay ,

poo r groun d (G301 , G502) .

an ope n in th e wire .

• I f th e back-u p light s g o on , g o t o ste p 2 .

2. Wit h th e shif t leve r i n tur n th e ignitio n

switch OFF .

3. Disconnec t th e 10 P connecto r fro m th e A/ T gea r

positio n switch .

4. Chec k fo r continuit y betwee n th e No . 2 an d No . 8

terminal s wit h th e shif t leve r i n

• I f ther e is continuity , g o to ste p 5.

• I f ther e i s n o continuity , replac e th e A/ T gea r

positio n switc h (se e sectio n 14 ).

5 . Mov e th e shif t leve r bac k an d fort h a t th e

an d chec k fo r continuit y betwee n th e No . 2 an d No . 8

terminal s withi n th e rang e o f fre e pla y o f th e shif t

lever .

• I f ther e i s n o continuity , adjus t th e A/ T gea r posi -

tion switc h (se e sectio n 14 ).

ProCarManuals.com

Page 619 of 1771

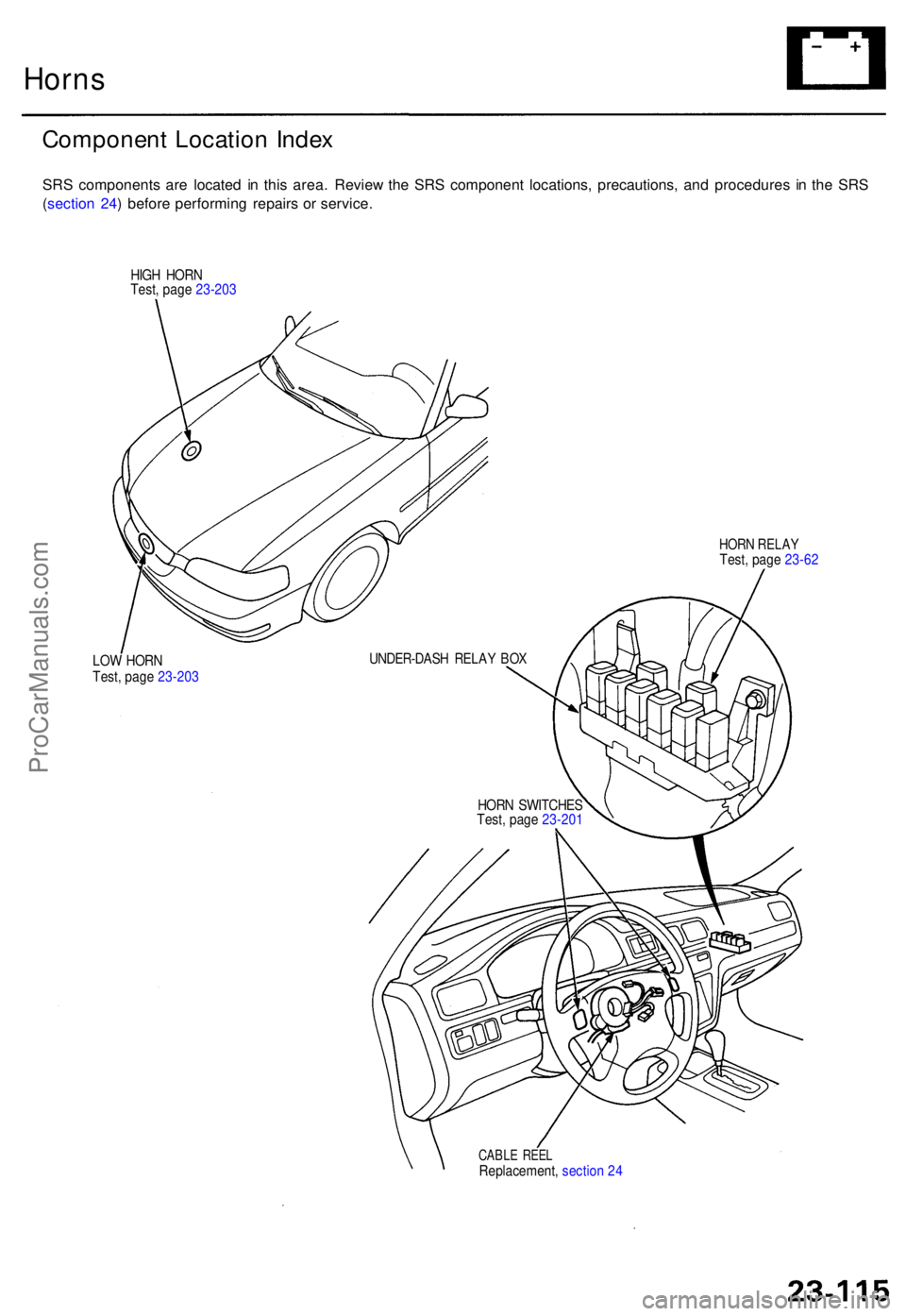

Horns

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

HIGH HOR N

HORN RELA Y

CABLE REE LReplacement , sectio n 2 4

HOR

N SWITCHE S

UNDER-DAS H RELA Y BO XLOW HOR N

Test, page 23-201

Test

, page 23-20 3

Test

, page 23-203

Test, page 23-62

ProCarManuals.com

Page 621 of 1771

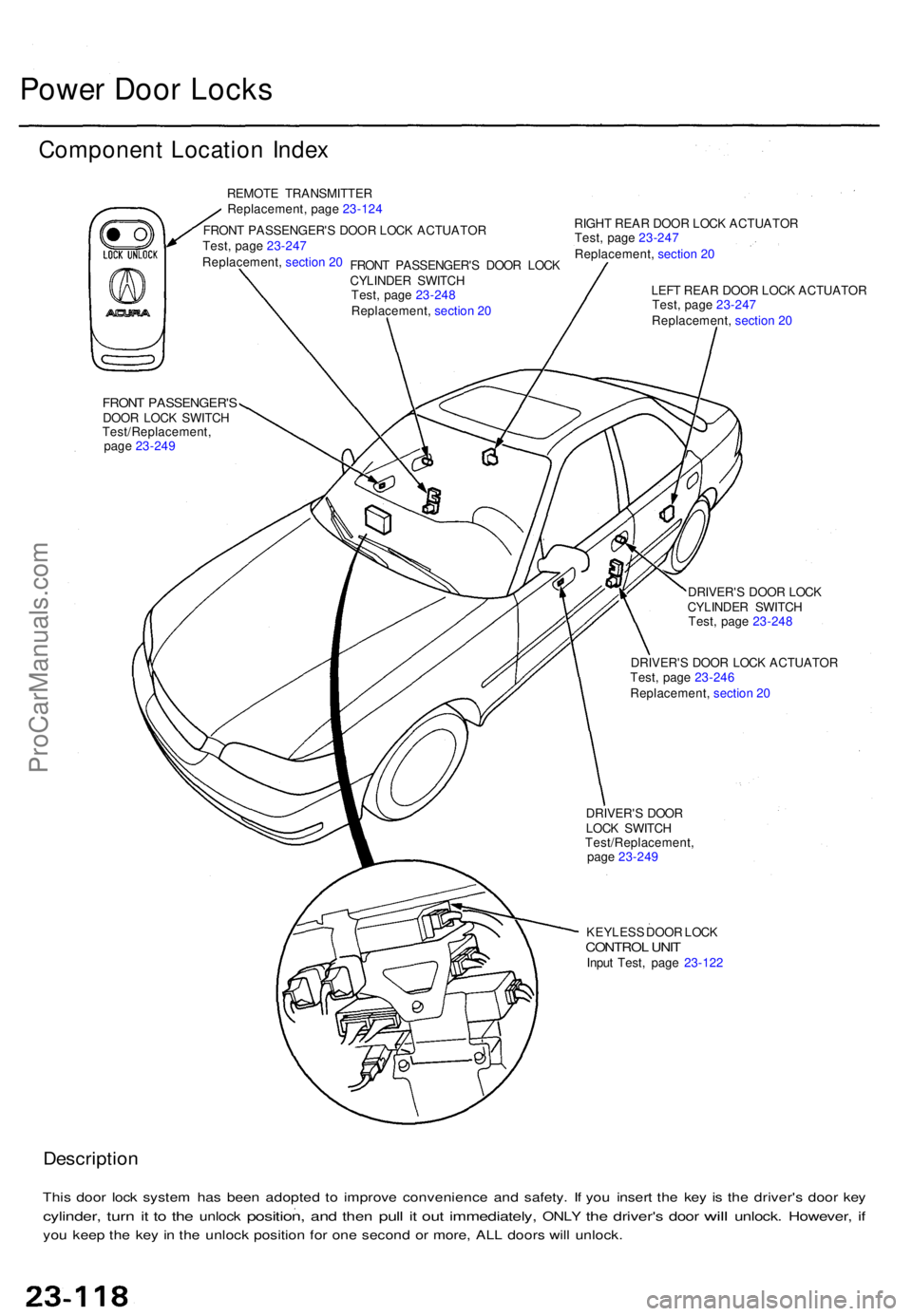

Power Doo r Lock s

Componen t Locatio n Inde x

REMOT E TRANSMITTE R

Replacement , pag e 23-12 4

FRON T PASSENGER' S DOO R LOC K ACTUATO R RIGH

T REA R DOO R LOC K ACTUATO R

FRONT PASSENGER' SDOOR LOC K SWITC H

DRIVER'S DOO R LOC K

CYLINDE R SWITC H

DRIVER' S DOO R LOC K ACTUATO R

LEF

T REA R DOO R LOC K ACTUATO R

DRIVER' S DOO R

LOC K SWITC H

KEYLES S DOO R LOC K

CONTRO L UNI TInpu t Test , pag e 23-12 2

Descriptio n

This doo r loc k syste m ha s bee n adopte d t o improv e convenienc e an d safety . I f yo u inser t th e ke y i s th e driver' s doo r ke y

cylinder , turn it t o th e unloc k position , and the n pull it ou t immediately , ONLY the driver' s door will unlock . However , if

yo u kee p th e ke y i n th e unloc k positio n fo r on e secon d o r more , AL L door s wil l unlock .

FRONT PASSENGER' S DOO R LOC K

CYLINDE R SWITC H

Test

, pag e 23- 247

Replacement , section 20

Test /Replacement ,

pag e 23-24 9 Test

, pag e 23-24 8

Replacement , section 20 Test

, pag e 23-247

Replacement , section 20

Test , pag e 23-247

Replacement , section 20

Test , pag e 23-24 8

Test , pag e 23-24 6

Replacement , section 20

Test/Replacement ,

pag e 23-249

ProCarManuals.com

Page 623 of 1771

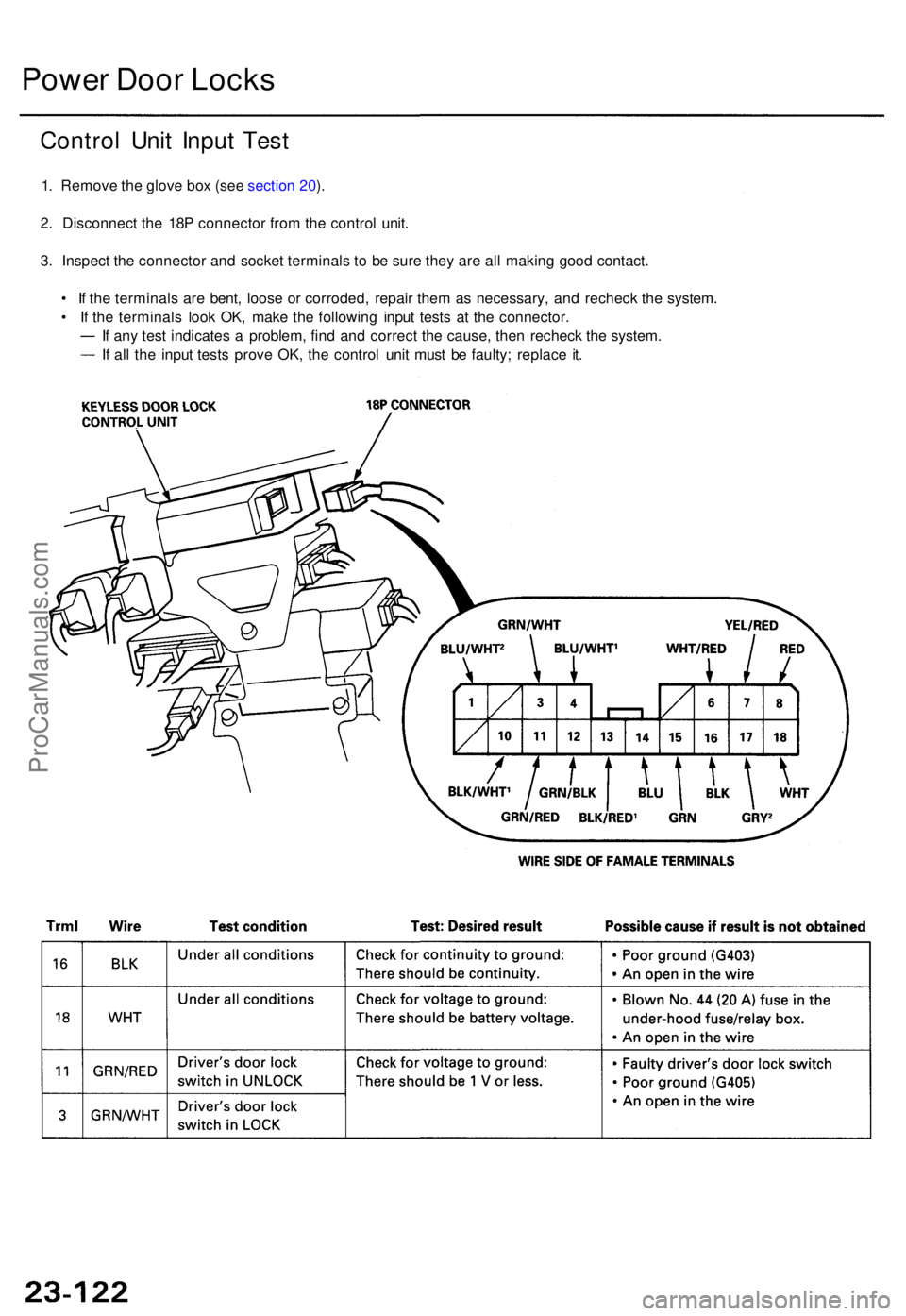

Power Doo r Lock s

Contro l Uni t Inpu t Tes t

1. Remov e th e glov e bo x (se e sectio n 20 ).

2 . Disconnec t th e 18 P connecto r fro m th e contro l unit .

3 . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

• I f th e terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

• I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

I f an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

I f al l th e inpu t test s prov e OK , th e contro l uni t mus t b e faulty ; replac e it .

ProCarManuals.com

Page 624 of 1771

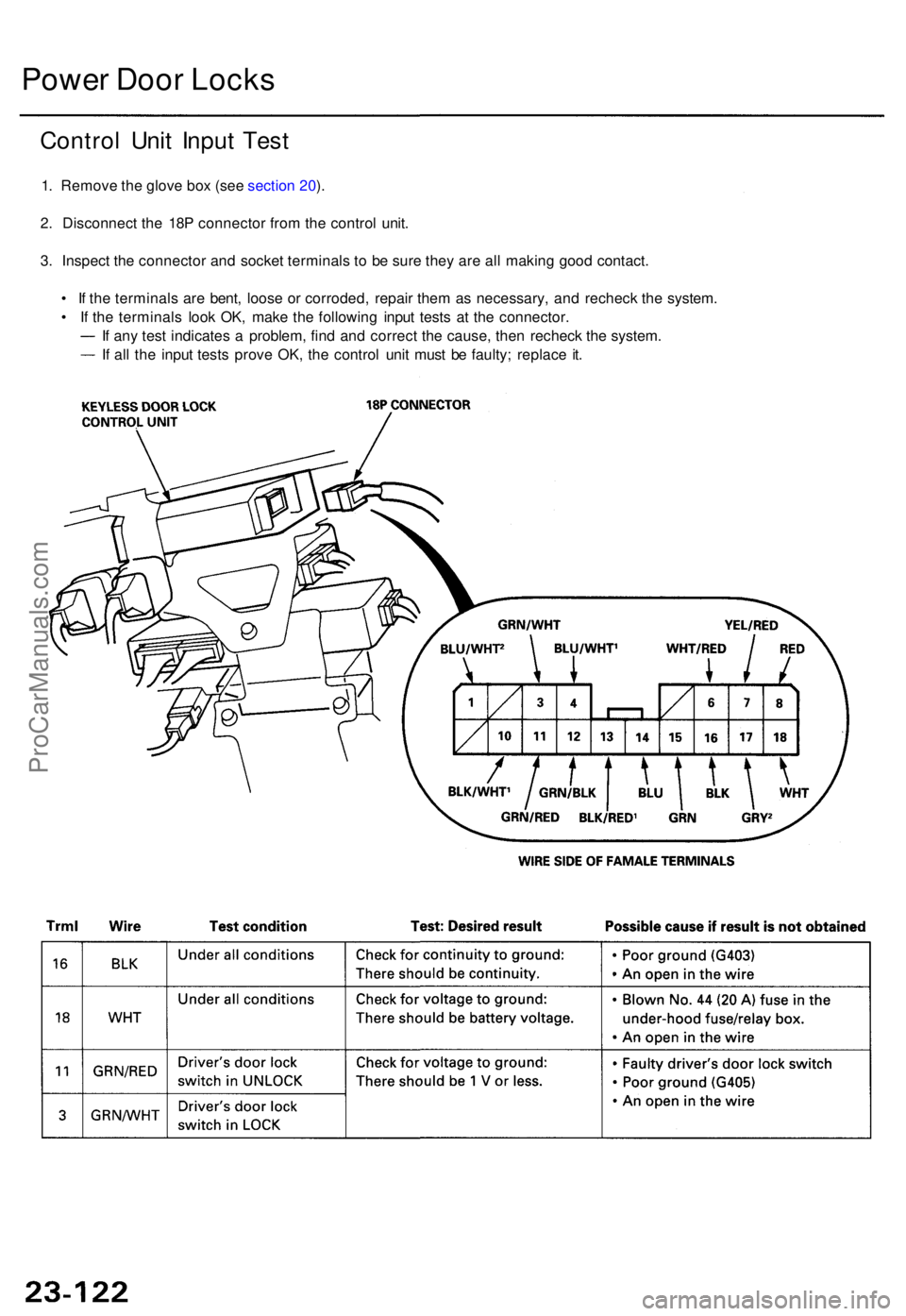

Power Doo r Lock s

Contro l Uni t Inpu t Tes t

1. Remov e th e glov e bo x (se e sectio n 20 ).

2 . Disconnec t th e 18 P connecto r fro m th e contro l unit .

3 . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

• I f th e terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

• I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

I f an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

I f al l th e inpu t test s prov e OK , th e contro l uni t mus t b e faulty ; replac e it .

ProCarManuals.com