Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 975 of 1771

Troubleshooting Procedures

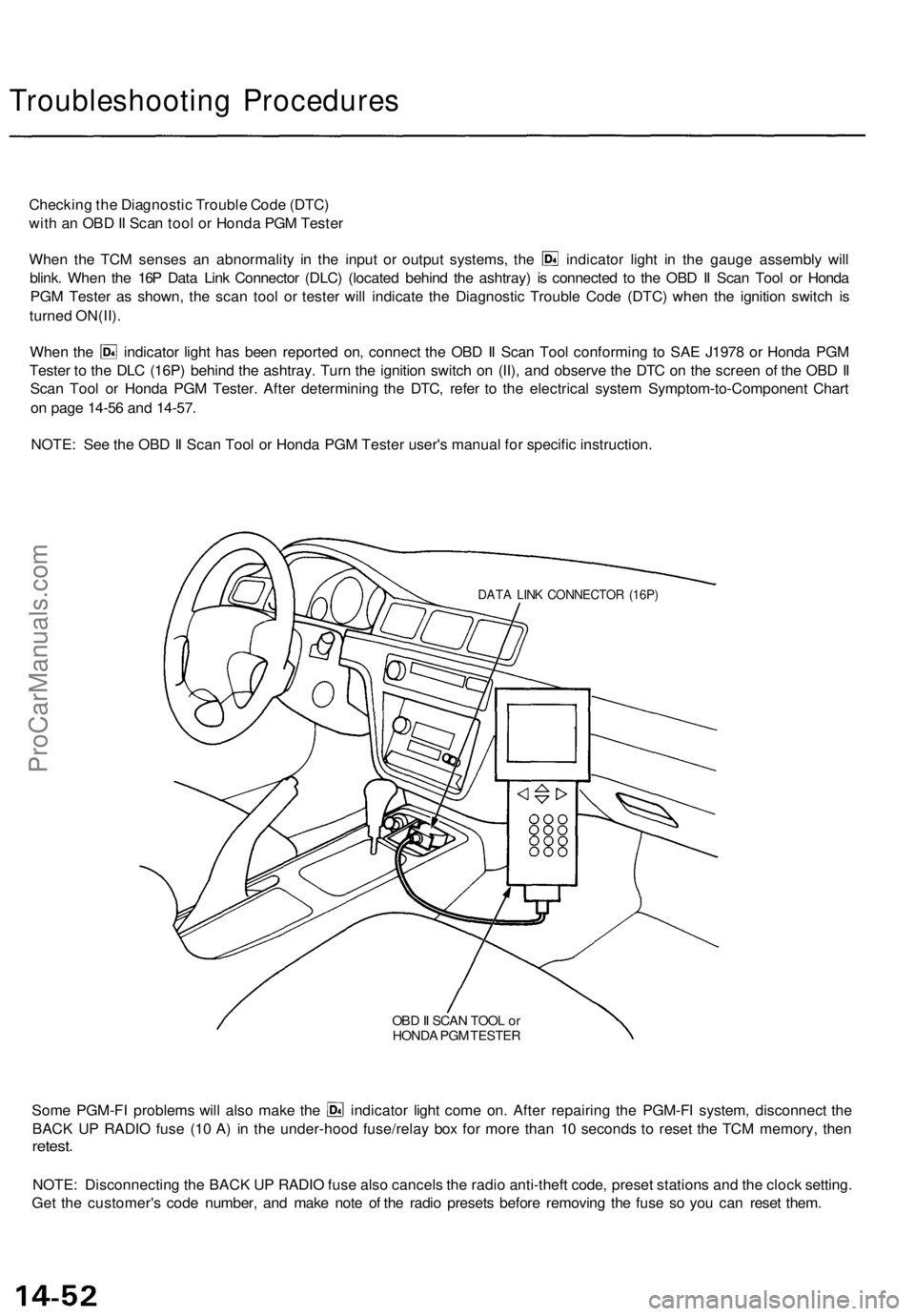

Checking the Diagnostic Trouble Code (DTC)

with an OBD II Scan tool or Honda PGM Tester

When the TCM senses an abnormality in the input or output systems, the indicator light in the gauge assembly will

blink. When the 16P Data Link Connector (DLC) (located behind the ashtray) is connected to the OBD II Scan Tool or Honda

PGM Tester as shown, the scan tool or tester will indicate the Diagnostic Trouble Code (DTC) when the ignition switch is

turned ON(II).

When the indicator light has been reported on, connect the OBD II Scan Tool conforming to SAE J1978 or Honda PGM

Tester to the DLC (16P) behind the ashtray. Turn the ignition switch on (II), and observe the DTC on the screen of the OBD II

Scan Tool or Honda PGM Tester. After determining the DTC, refer to the electrical system Symptom-to-Component Chart

on page 14-56 and 14-57.

NOTE: See the OBD II Scan Tool or Honda PGM Tester user's manual for specific instruction.

OBD II SCAN TOOL or

HONDA PGM TESTER

Some PGM-FI problems will also make the indicator light come on. After repairing the PGM-FI system, disconnect the

BACK UP RADIO fuse (10 A) in the under-hood fuse/relay box for more than 10 seconds to reset the TCM memory, then

retest.

NOTE: Disconnecting the BACK UP RADIO fuse also cancels the radio anti-theft code, preset stations and the clock setting.

Get the customer's code number, and make note of the radio presets before removing the fuse so you can reset them.

DATA LINK CONNECTOR (16P)ProCarManuals.com

Page 978 of 1771

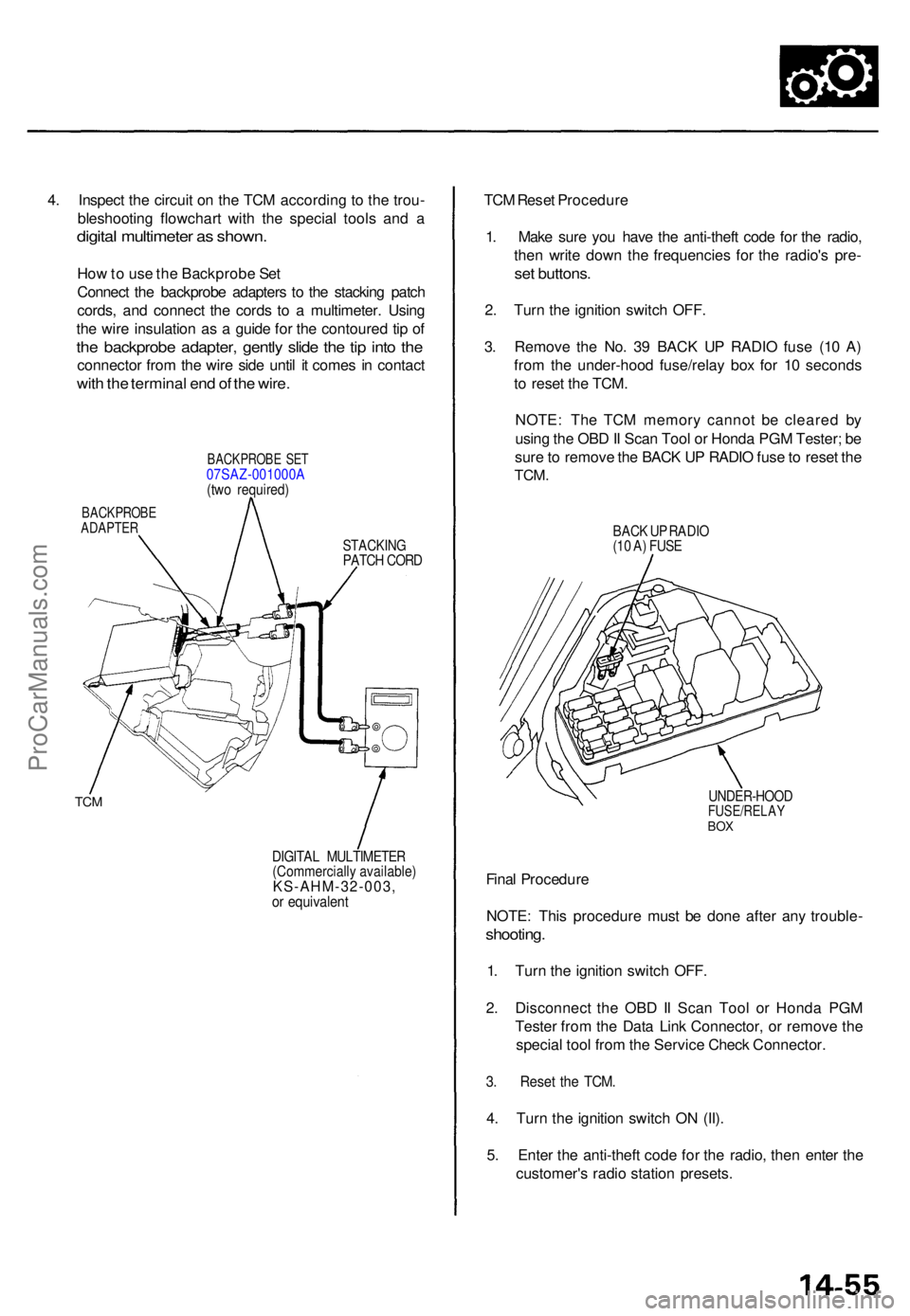

4. Inspec t th e circui t o n th e TC M accordin g t o th e trou -

bleshootin g flowchar t wit h th e specia l tool s an d a

digita l multimete r a s shown .

How to us e th e Backprob e Se t

Connec t th e backprob e adapter s t o th e stackin g patc h

cords , an d connec t th e cord s t o a multimeter . Usin g

th e wir e insulatio n a s a guid e fo r th e contoure d ti p o f

the backprob e adapter , gentl y slid e th e ti p int o th e

connecto r fro m th e wir e sid e unti l i t come s i n contac t

with th e termina l en d o f th e wire .

BACKPROB E SE T07SAZ-001000 A

(tw o required )

BACKPROB EADAPTER

STACKIN GPATCH COR D

TCM

DIGITA L MULTIMETE R

(Commerciall y available )

KS-AHM-32-003 ,or equivalen t

TCM Rese t Procedur e

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

set buttons .

2. Tur n th e ignitio n switc h OFF .

3 . Remov e th e No . 3 9 BAC K U P RADI O fus e (1 0 A )

fro m th e under-hoo d fuse/rela y bo x fo r 1 0 second s

t o rese t th e TCM .

NOTE : Th e TC M memor y canno t b e cleare d b y

usin g th e OB D II Sca n Too l o r Hond a PG M Tester ; b e

sur e to remov e th e BAC K U P RADI O fus e to rese t th e

TCM .

BACK U P RADI O

(1 0 A ) FUS E

UNDER-HOO D

FUSE/RELAYBOX

Fina l Procedur e

NOTE : Thi s procedur e mus t b e don e afte r an y trouble -

shooting.

1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e OB D II Sca n Too l o r Hond a PG M

Teste r fro m th e Dat a Lin k Connector , o r remov e th e

specia l too l fro m th e Servic e Chec k Connector .

3. Rese t th e TCM .

4. Tur n th e ignitio n switc h O N (II) .

5 . Ente r th e anti-thef t cod e fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

ProCarManuals.com

Page 980 of 1771

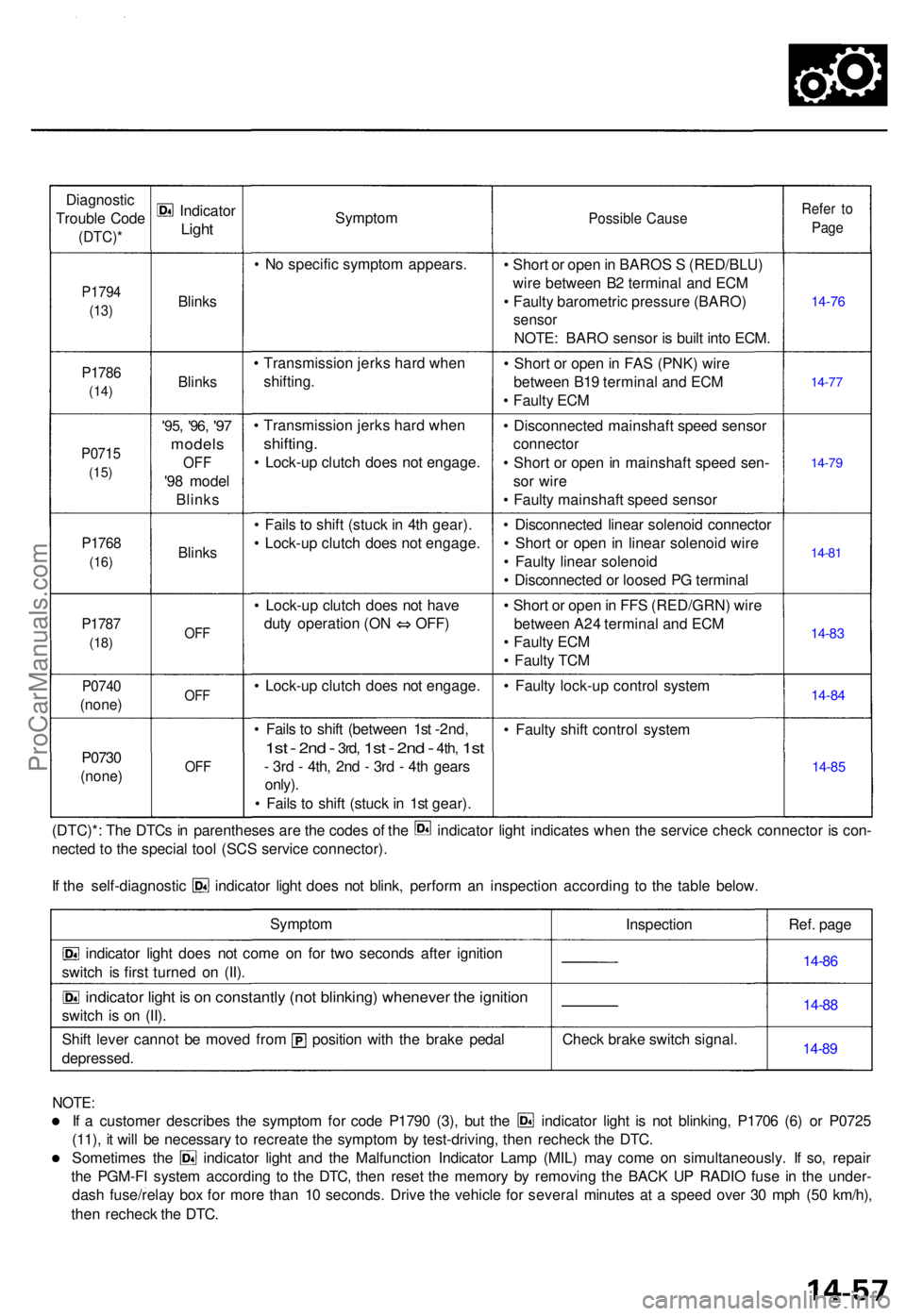

Diagnostic

Troubl e Cod e

(DTC) *

P1794

(13)

P178 6

(14)

P071 5

(15)

P176 8

(16)

P178 7

(18)

P074 0

(none )

P0730

(none )

Indicato r

Light

Blink s

Blinks

'95, '96 , '97

model s

OFF

'98 mode l

Blink s

Blinks

OFF

OF F

OFF

Sympto m

• N o specifi c sympto m appears .

• Transmissio n jerk s har d whe n

shifting .

• Transmissio n jerk s har d whe n

shifting .

• Lock-u p clutc h doe s no t engage .

• Fail s t o shif t (stuc k in 4t h gear) .

• Lock-u p clutc h doe s no t engage .

• Lock-u p clutc h doe s no t hav e

duty operatio n (O N OFF )

• Lock-u p clutc h doe s no t engage .

• Fail s t o shif t (betwee n 1s t -2nd,

1s t - 2n d - 3rd , 1st - 2nd - 4th , 1st

- 3r d - 4th , 2n d - 3r d - 4t h gear s

only) .

• Fail s t o shif t (stuc k in 1s t gear) .

Possibl e Caus e

• Shor t o r ope n in BARO S S (RED/BLU )

wir e betwee n B 2 termina l an d EC M

• Fault y barometri c pressur e (BARO )

sensor

NOTE : BAR O senso r i s buil t int o ECM .

• Shor t o r ope n in FA S (PNK ) wir e

betwee n B1 9 termina l an d EC M

• Fault y EC M

• Disconnecte d mainshaf t spee d senso r

connecto r

• Shor t o r ope n in mainshaf t spee d sen -

so r wir e

• Fault y mainshaf t spee d senso r

• Disconnecte d linea r solenoi d connecto r

• Shor t o r ope n in linea r solenoi d wir e

• Fault y linea r solenoi d

• Disconnecte d o r loose d P G termina l

• Shor t o r ope n in FF S (RED/GRN ) wir e

betwee n A2 4 termina l an d EC M

• Fault y EC M

• Fault y TC M

• Fault y lock-u p contro l syste m

• Fault y shif t contro l syste m

Refer t o

Pag e

14-7 6

14-77

14-7 9

14-8 1

14-8 3

14-8 4

14-8 5

(DTC)* : Th e DTC s i n parenthese s ar e th e code s o f th e indicato r ligh t indicate s whe n th e servic e chec k connecto r i s con -

necte d t o th e specia l too l (SC S servic e connector) .

If th e self-diagnosti c indicato r ligh t doe s no t blink , perfor m a n inspectio n accordin g t o th e tabl e below .

Sympto m

indicator ligh t doe s no t com e o n fo r tw o second s afte r ignitio n

switc h i s firs t turne d o n (II) .

indicato r ligh t i s o n constantl y (no t blinking ) wheneve r th e ignitio n

switch i s o n (II) .

Shif t leve r canno t b e move d fro m positio n wit h th e brak e peda l

depressed . Inspectio

n

Chec k brak e switc h signal . Ref

. pag e

14-86

14-8 8

14-8 9

NOTE :

If a custome r describe s th e sympto m fo r cod e P179 0 (3) , bu t th e indicato r ligh t i s no t blinking , P170 6 (6 ) o r P072 5

(11) , i t wil l b e necessar y t o recreat e th e sympto m b y test-driving , the n rechec k th e DTC .

Sometime s th e indicato r ligh t an d th e Malfunctio n Indicato r Lam p (MIL ) ma y com e o n simultaneously . I f so , repai r

th e PGM-F I syste m accordin g t o th e DTC , the n rese t th e memor y b y removin g th e BAC K U P RADI O fus e i n th e under -

das h fuse/rela y bo x fo r mor e tha n 1 0 seconds . Driv e th e vehicl e fo r severa l minute s a t a spee d ove r 3 0 mp h (5 0 km/h) ,

the n rechec k th e DTC .

ProCarManuals.com

Page 983 of 1771

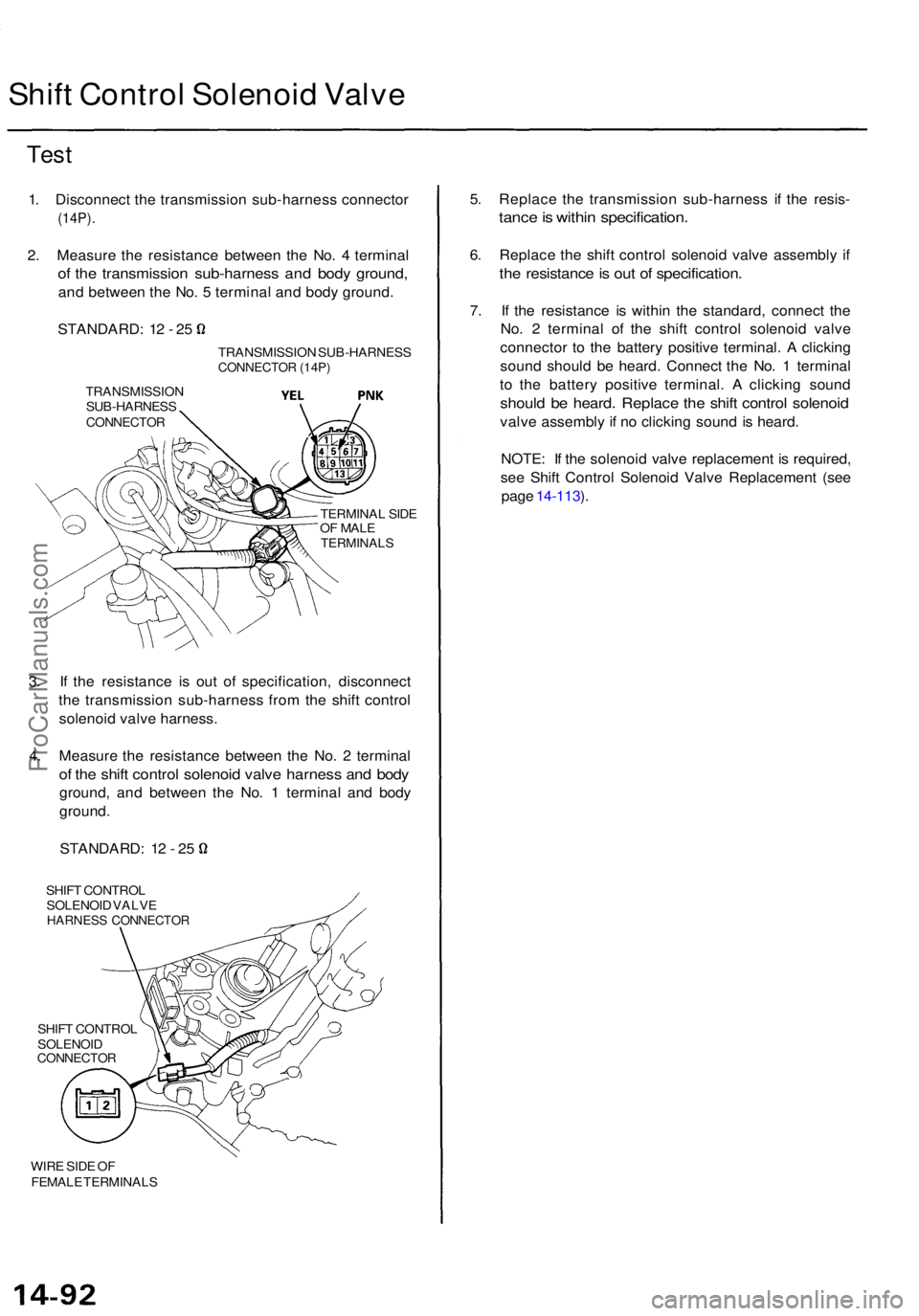

Shift Contro l Solenoi d Valv e

Test

1. Disconnec t th e transmissio n sub-harnes s connecto r

(14P).

2. Measur e th e resistanc e betwee n th e No . 4 termina l

of th e transmissio n sub-harnes s an d bod y ground ,

and betwee n th e No . 5 termina l an d bod y ground .

STANDARD : 1 2 - 2 5

TRANSMISSIO N

SUB-HARNES S

CONNECTOR

TRANSMISSIO N SUB-HARNES SCONNECTOR (14P )

TERMINA L SID E

O F MAL E

TERMINAL S

3. I f th e resistanc e i s ou t o f specification , disconnec t

th e transmissio n sub-harnes s fro m th e shif t contro l

solenoi d valv e harness .

4 . Measur e th e resistanc e betwee n th e No . 2 termina l

of th e shif t contro l solenoi d valv e harnes s an d bod y

ground , an d betwee n th e No . 1 termina l an d bod y

ground .

STANDARD : 1 2 - 2 5

SHIF T CONTRO L

SOLENOI D VALV E

HARNES S CONNECTO R

SHIFT CONTRO L

SOLENOI D

CONNECTO R

WIRE SID E O F

FEMAL E TERMINAL S

5. Replac e th e transmissio n sub-harnes s i f th e resis -

tance is withi n specification .

6. Replac e th e shif t contro l solenoi d valv e assembl y i f

th e resistanc e is ou t o f specification .

7. I f th e resistanc e i s withi n th e standard , connec t th e

No . 2 termina l o f th e shif t contro l solenoi d valv e

connecto r t o th e batter y positiv e terminal . A clickin g

soun d shoul d b e heard . Connec t th e No . 1 termina l

t o th e batter y positiv e terminal . A clickin g soun d

should b e heard . Replac e th e shif t contro l solenoi d

valve assembl y if n o clickin g soun d is heard .

NOTE : I f th e solenoi d valv e replacemen t i s required ,

se e Shif t Contro l Solenoi d Valv e Replacemen t (se e

pag e 14-113 ).

ProCarManuals.com

Page 984 of 1771

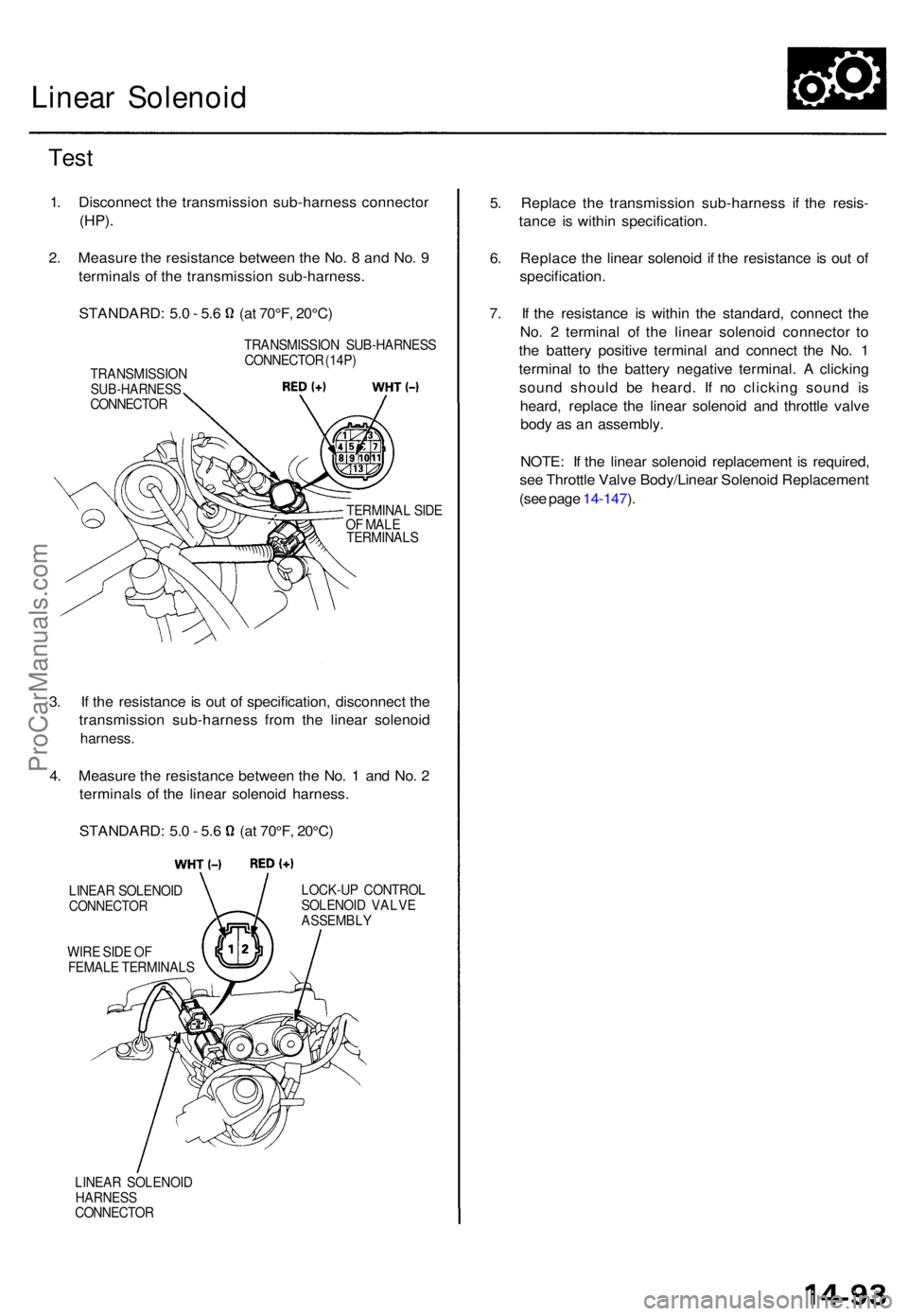

Linear Solenoi d

Test

1. Disconnec t th e transmissio n sub-harnes s connecto r

(HP).

2. Measur e th e resistanc e betwee n th e No . 8 an d No . 9

terminal s o f th e transmissio n sub-harness .

STANDARD: 5. 0 - 5. 6 (a t 70°F , 20°C )

TRANSMISSIO NSUB-HARNESSCONNECTOR TRANSMISSIO

N SUB-HARNES S

CONNECTO R (14P )

TERMINA L SID E

O F MAL E

TERMINAL S

3. I f th e resistanc e is ou t o f specification , disconnec t th e

transmissio n sub-harnes s fro m th e linea r solenoi d

harness.

4. Measur e th e resistanc e betwee n th e No . 1 an d No . 2

terminal s of the linea r solenoi d harness .

STANDARD : 5. 0 - 5. 6 (a t 70°F , 20°C )

LINEA R SOLENOI DCONNECTO R

WIRE SID E O F

FEMAL E TERMINAL S LOCK-U

P CONTRO L

SOLENOI D VALV E

ASSEMBL Y

LINEA R SOLENOI D

HARNESSCONNECTO R

5. Replac e th e transmissio n sub-harnes s i f th e resis -

tanc e i s withi n specification .

6 . Replac e th e linea r solenoi d i f th e resistanc e is ou t o f

specification .

7 . I f th e resistanc e i s withi n th e standard , connec t th e

No . 2 termina l o f th e linea r solenoi d connecto r t o

th e batter y positiv e termina l an d connec t th e No . 1

termina l t o th e batter y negativ e terminal . A clickin g

soun d shoul d b e heard . I f n o clickin g soun d i s

heard , replac e th e linea r solenoi d an d throttl e valv e

bod y a s a n assembly .

NOTE : I f th e linea r solenoi d replacemen t i s required ,

se e Throttl e Valv e Body/Linea r Solenoi d Replacemen t

(se e pag e 14-147 ).

ProCarManuals.com

Page 993 of 1771

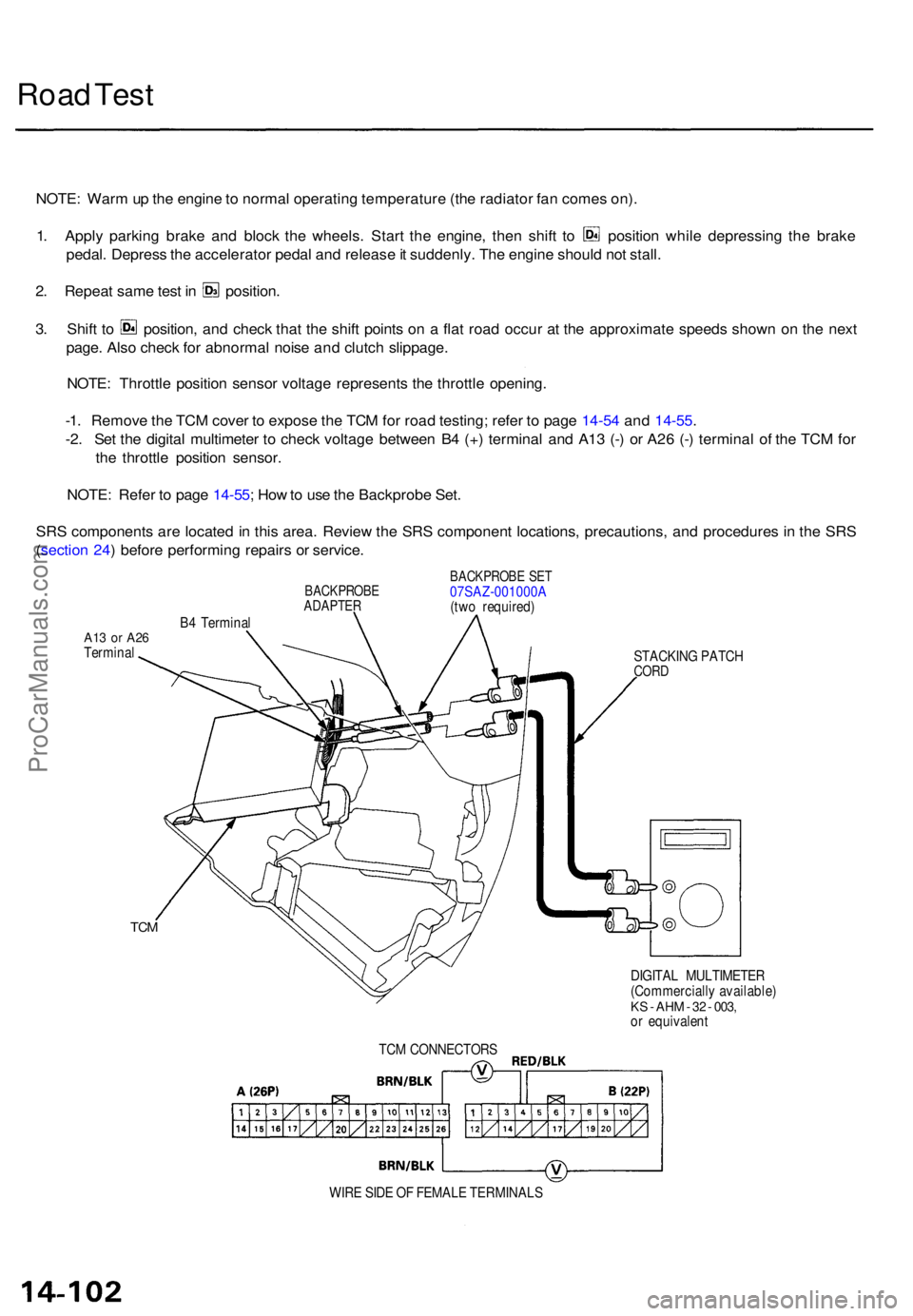

Road Tes t

NOTE : War m u p th e engin e to norma l operatin g temperatur e (th e radiato r fa n come s on) .

1. Appl y parkin g brak e an d bloc k th e wheels . Star t th e engine , the n shif t t o positio n whil e depressin g th e brak e

pedal . Depres s th e accelerato r peda l an d releas e it suddenly . Th e engine should no t stall .

2. Repea t sam e tes t i n position .

3. Shif t t o position , an d chec k tha t th e shif t point s o n a fla t roa d occu r a t th e approximat e speed s show n o n th e nex t

page . Als o chec k fo r abnorma l nois e an d clutc h slippage .

NOTE : Throttl e positio n senso r voltag e represent s th e throttl e opening .

-1 . Remov e th e TC M cove r t o expos e th e TC M fo r roa d testing ; refe r t o pag e 14-5 4 an d 14-55 .

-2 . Se t th e digita l multimete r t o chec k voltag e betwee n B 4 (+ ) termina l an d A1 3 (- ) o r A2 6 (- ) termina l o f th e TC M fo r

th e throttl e positio n sensor .

NOTE : Refe r t o pag e 14-55 ; Ho w to us e th e Backprob e Set .

SR S component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

BACKPROB EADAPTER

B4 Termina l

BACKPROB E SE T07SAZ-001000 A

(tw o required )

A13 o r A2 6Termina l

STACKING PATC H

CORD

TCM

DIGITA L MULTIMETE R

(Commerciall y available )

KS - AH M - 3 2 - 003 ,or equivalen t

TC M CONNECTOR S

WIR E SID E O F FEMAL E TERMINAL S

ProCarManuals.com

Page 994 of 1771

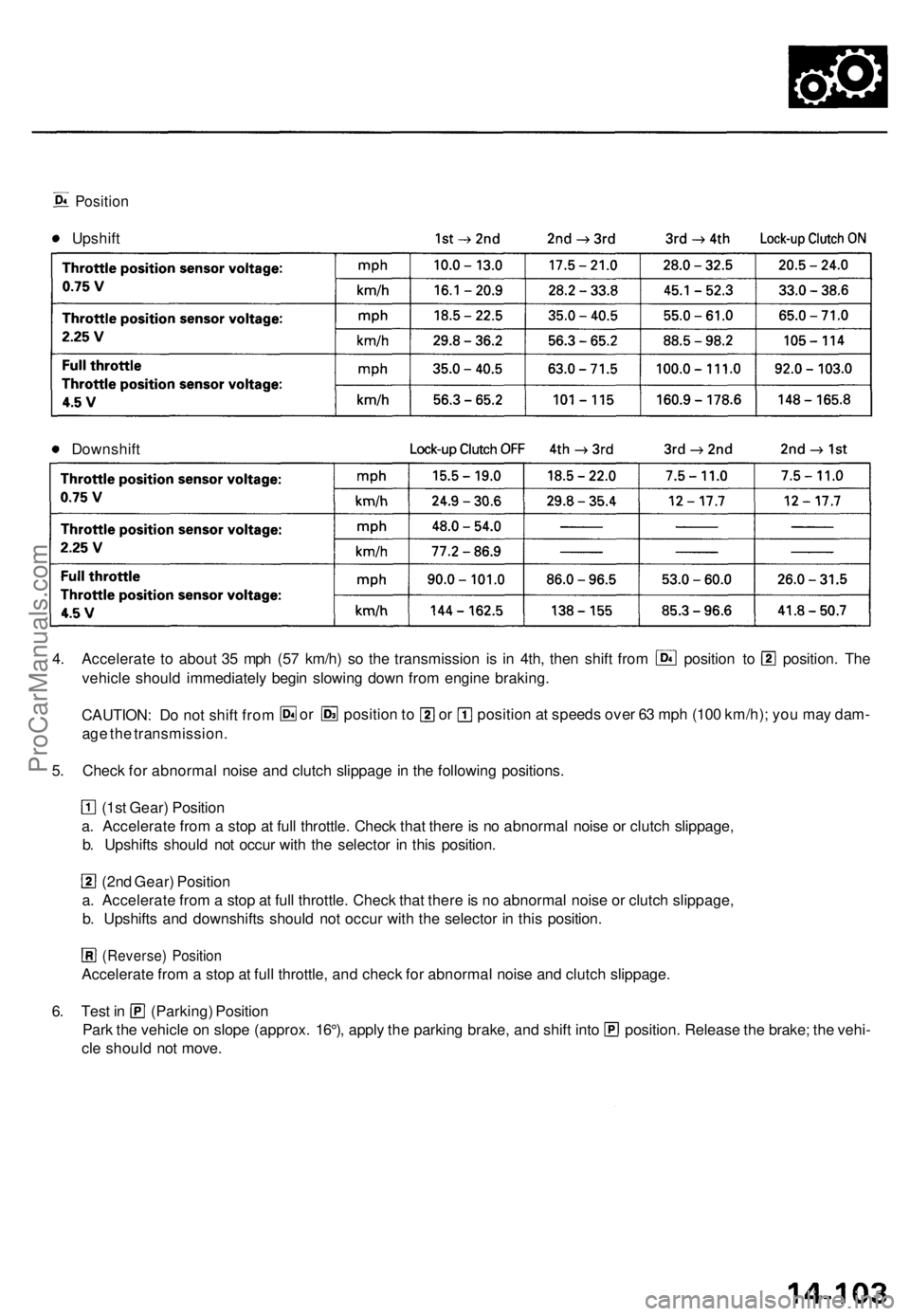

Position

Upshift

Downshift

4. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th, then shift from position to position. The

vehicle should immediately begin slowing down from engine braking.

CAUTION: Do not shift from

age the transmission.

or position to or position at speeds over 63 mph (100 km/h); you may dam-

5. Check for abnormal noise and clutch slippage in the following positions.

(1st Gear) Position

a. Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage,

b. Upshifts should not occur with the selector in this position.

(2nd Gear) Position

a. Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage,

b. Upshifts and downshifts should not occur with the selector in this position.

(Reverse) Position

Accelerate from a stop at full throttle, and check for abnormal noise and clutch slippage.

6. Test in (Parking) Position

Park the vehicle on slope (approx. 16°), apply the parking brake, and shift into position. Release the brake; the vehi-

cle should not move.ProCarManuals.com

Page 995 of 1771

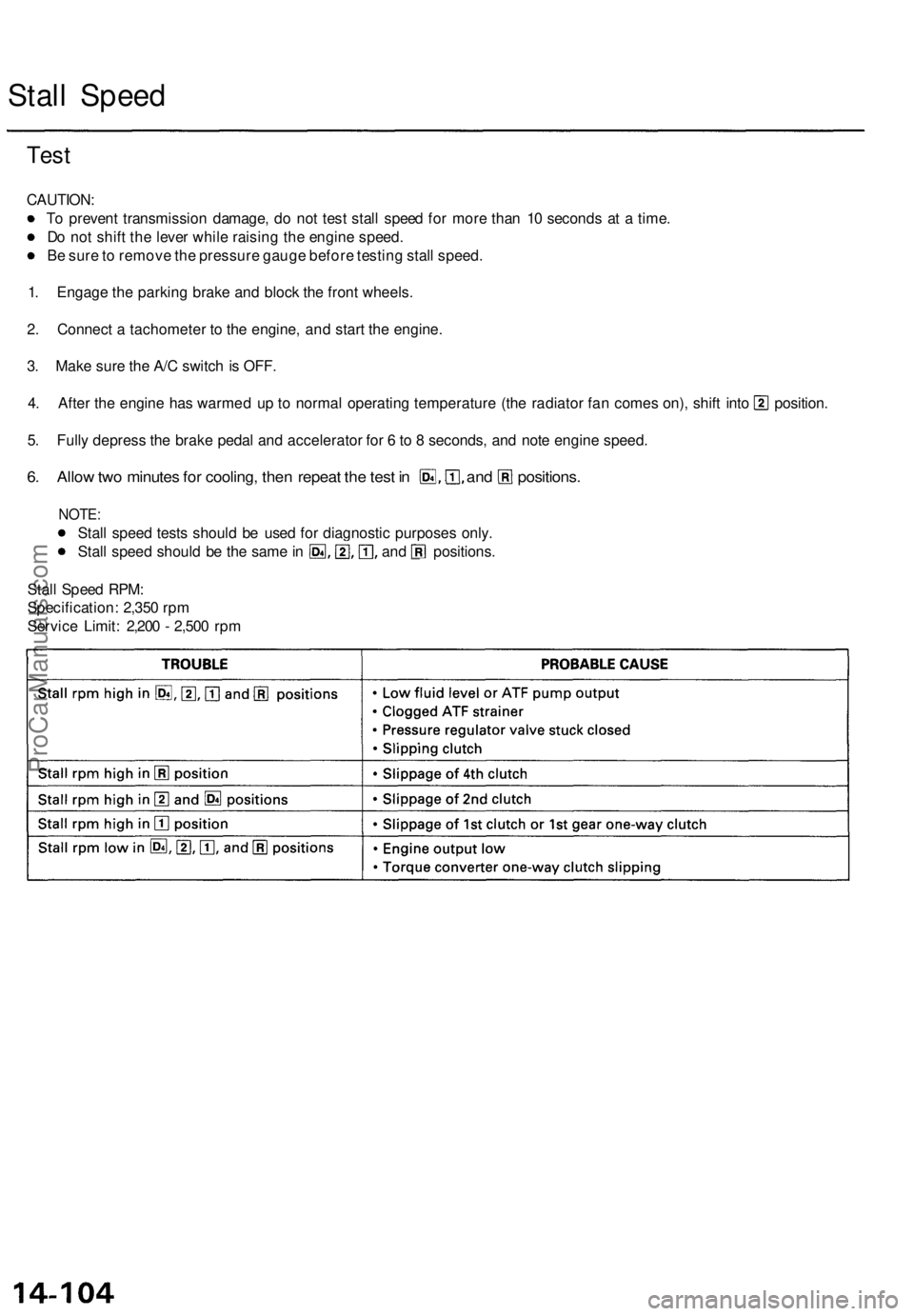

Stall Spee d

Test

CAUTION :

T o preven t transmissio n damage , d o no t tes t stal l spee d fo r mor e tha n 1 0 second s a t a time .

D o no t shif t th e leve r whil e raisin g th e engin e speed .

B e sur e to remov e th e pressur e gaug e befor e testin g stal l speed .

1 . Engag e th e parkin g brak e an d bloc k th e fron t wheels .

2 . Connec t a tachomete r t o th e engine , an d star t th e engine .

3 . Mak e sur e th e A/ C switc h is OFF .

4. Afte r th e engin e ha s warme d u p t o norma l operatin g temperatur e (th e radiato r fa n come s on) , shif t int o position .

5 . Full y depres s th e brak e peda l an d accelerato r fo r 6 to 8 seconds , an d not e engin e speed .

6. Allo w tw o minute s fo r cooling , the n repea t th e tes t i n and positions .

NOTE:

Stall spee d test s shoul d b e use d fo r diagnosti c purpose s only .

Stall spee d shoul d b e th e sam e in an d _ positions .

Stal l Spee d RPM :

Specification : 2,35 0 rp m

Servic e Limit : 2,20 0 - 2,50 0 rp m

ProCarManuals.com

Page 997 of 1771

Pressure Testin g

While testing , b e carefu l o f th e rotatin g fron t wheels .

Mak e sur e lifts , jack s an d safet y stand s ar e place d

properl y (se e sectio n 1 ).

CAUTION :

Befor e testing , b e sur e th e transmissio n flui d is fille d

t o th e prope r level .

War m u p th e engin e befor e testing .

1. Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s

securely .

3. Allo w th e fron t wheel s t o rotat e freely .

4 . War m u p th e engin e (th e radiato r fa n come s on) ,

the n sto p an d connec t a tachometer .

5 . Connec t th e specia l too l t o eac h inspectio n hole .

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

CAUTION : Connec t th e oi l pressur e gaug e securely ,

b e sur e no t t o allo w dus t an d othe r foreig n particle s

t o ente r th e inspectio n hole .

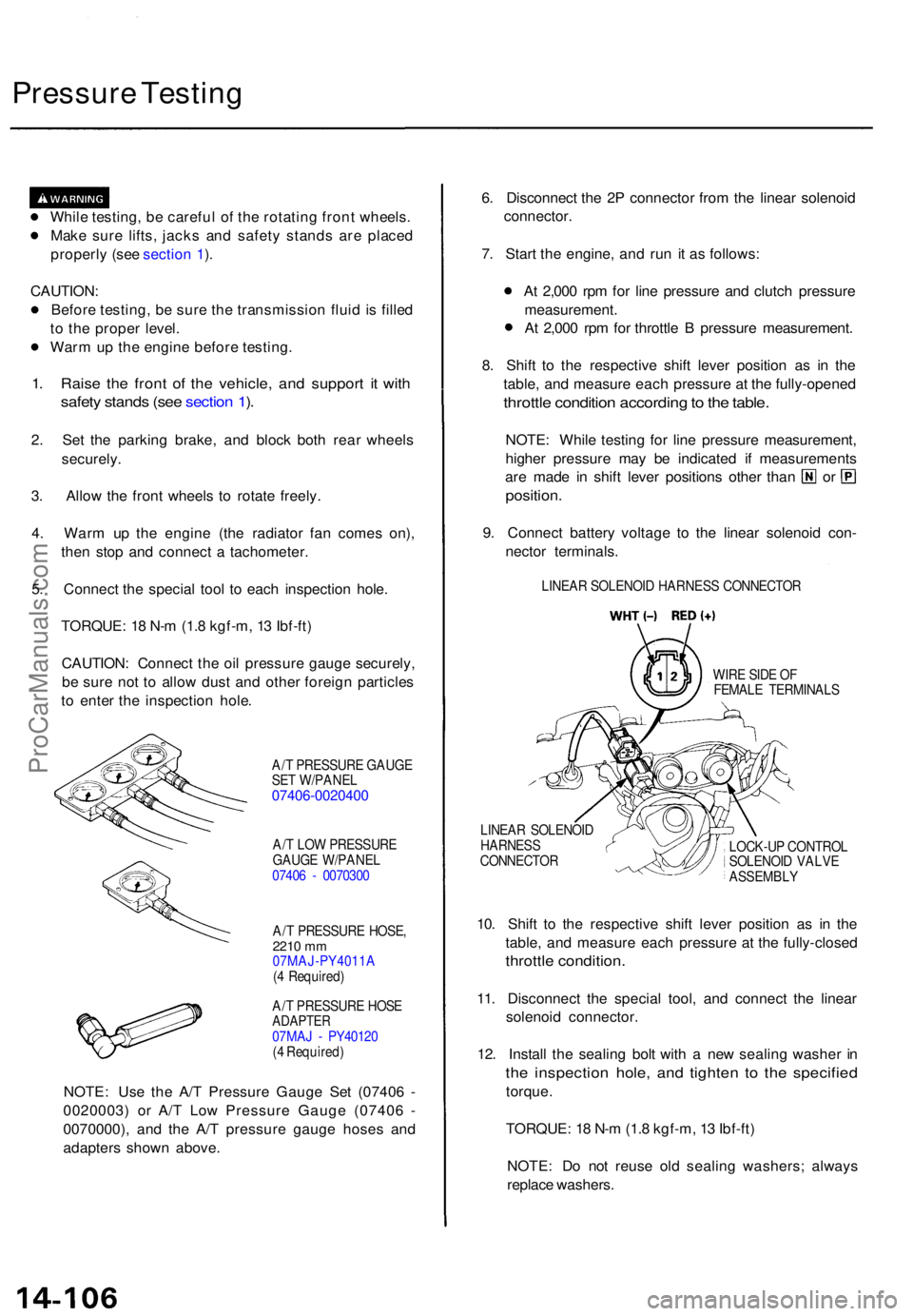

A/T PRESSUR E GAUG E

SE T W/PANE L

07406-002040 0

A/T LO W PRESSUR E

GAUG E W/PANE L

0740 6 - 007030 0

A/ T PRESSUR E HOSE ,

2210 mm07MAJ-PY4011 A

( 4 Required )

A/ T PRESSUR E HOS E

ADAPTE R07MAJ - PY4012 0

( 4 Required )

NOTE: Us e th e A/ T Pressur e Gaug e Se t (0740 6 -

0020003 ) o r A/ T Lo w Pressur e Gaug e (0740 6 -

0070000) , an d th e A/ T pressur e gaug e hose s an d

adapter s show n above . 6

. Disconnec t th e 2 P connecto r fro m th e linea r solenoi d

connector .

7 . Star t th e engine , an d ru n i t a s follows :

A t 2,00 0 rp m fo r lin e pressur e an d clutc h pressur e

measurement .

A t 2,00 0 rp m fo r throttl e B pressur e measurement .

8 . Shif t t o th e respectiv e shif t leve r positio n a s i n th e

table , an d measur e eac h pressur e a t th e fully-opene d

throttle conditio n accordin g to th e table .

NOTE : Whil e testin g fo r lin e pressur e measurement ,

highe r pressur e ma y b e indicate d i f measurement s

are mad e i n shif t leve r position s othe r tha n o r

position .

9. Connec t batter y voltag e t o th e linea r solenoi d con -

necto r terminals .

LINEAR SOLENOI D HARNES S CONNECTO R

WIR E SID E O F

FEMAL E TERMINAL S

LINEA R SOLENOI D

HARNES S

CONNECTO R LOCK-U

P CONTRO L

SOLENOI D VALV E

ASSEMBL Y

10. Shif t t o th e respectiv e shif t leve r positio n a s i n th e

table , an d measur e eac h pressur e a t th e fully-close d

throttle condition .

11. Disconnec t th e specia l tool , an d connec t th e linea r

solenoi d connector .

12 . Instal l th e sealin g bol t wit h a ne w sealin g washe r i n

th e inspectio n hole , an d tighte n t o th e specifie d

torque.

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

NOTE : D o no t reus e ol d sealin g washers ; alway s

replac e washers .

ProCarManuals.com

Page 1027 of 1771

Valve Body

Repair

NOTE: This repair is only necessary if one or more of

the valves in a valve body do not slide smoothly in their

bores. You may use this procedure to free the valves in

the valve bodies.

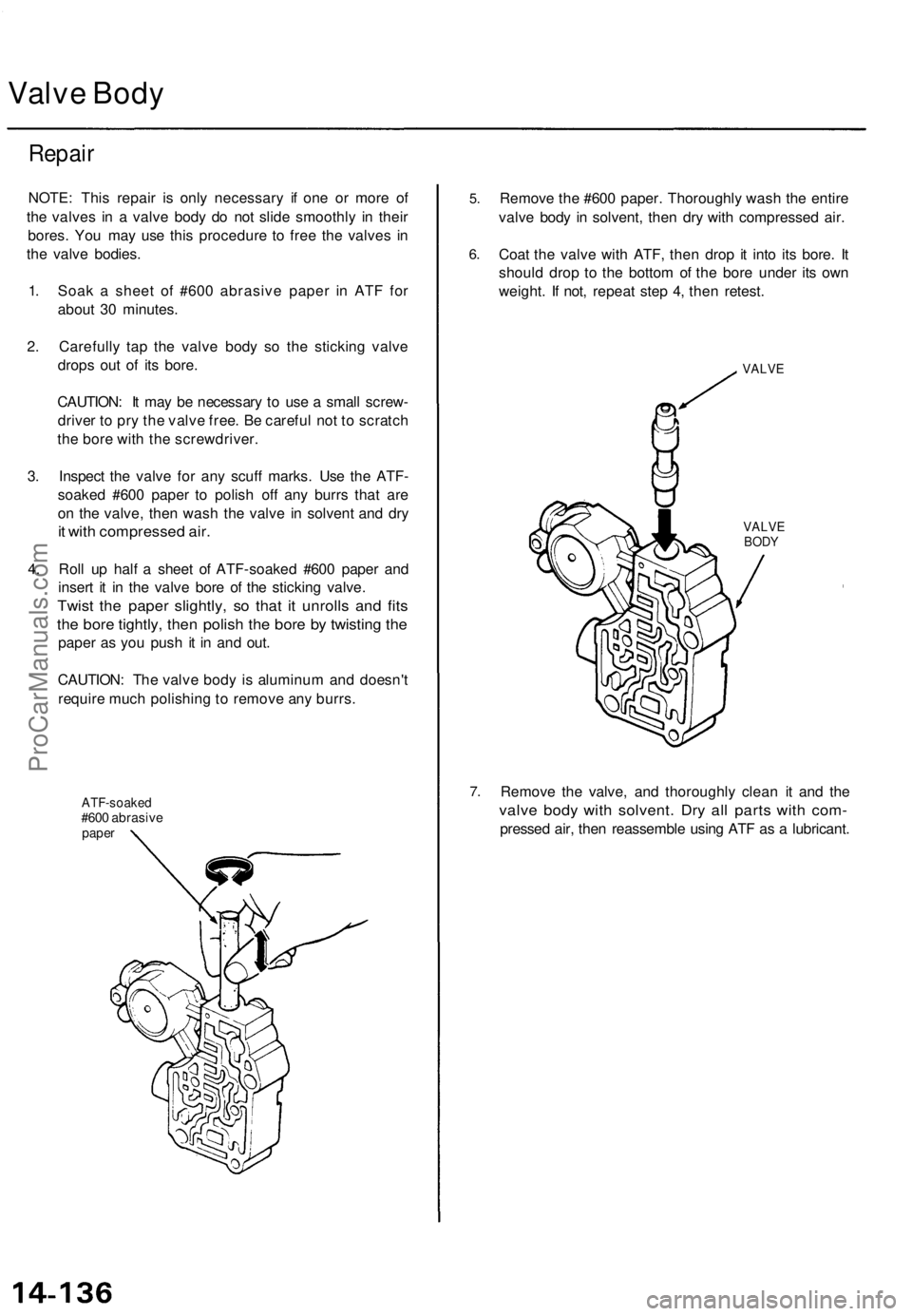

1. Soak a sheet of #600 abrasive paper in ATF for

about 30 minutes.

2. Carefully tap the valve body so the sticking valve

drops out of its bore.

CAUTION: It may be necessary to use a small screw-

driver to pry the valve free. Be careful not to scratch

the bore with the screwdriver.

3. Inspect the valve for any scuff marks. Use the ATF-

soaked #600 paper to polish off any burrs that are

on the valve, then wash the valve in solvent and dry

it with compressed air.

4. Roll up half a sheet of ATF-soaked #600 paper and

insert it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits

the bore tightly, then polish the bore by twisting the

paper as you push it in and out.

CAUTION: The valve body is aluminum and doesn't

require much polishing to remove any burrs.

ATF-soaked

#600 abrasive

paper

5.

6.

Remove the #600 paper. Thoroughly wash the entire

valve body in solvent, then dry with compressed air.

Coat the valve with ATF, then drop it into its bore. It

should drop to the bottom of the bore under its own

weight. If not, repeat step 4, then retest.

VALVE

VALVE

BODY

7.

Remove the valve, and thoroughly clean it and the

valve body with solvent. Dry all parts with com-

pressed air, then reassemble using ATF as a lubricant.ProCarManuals.com