Test ACURA TL 1995 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 810 of 1771

Oil Pressur e

Testing

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engine oil level . I f th e oi l leve l i s cor -

rect :

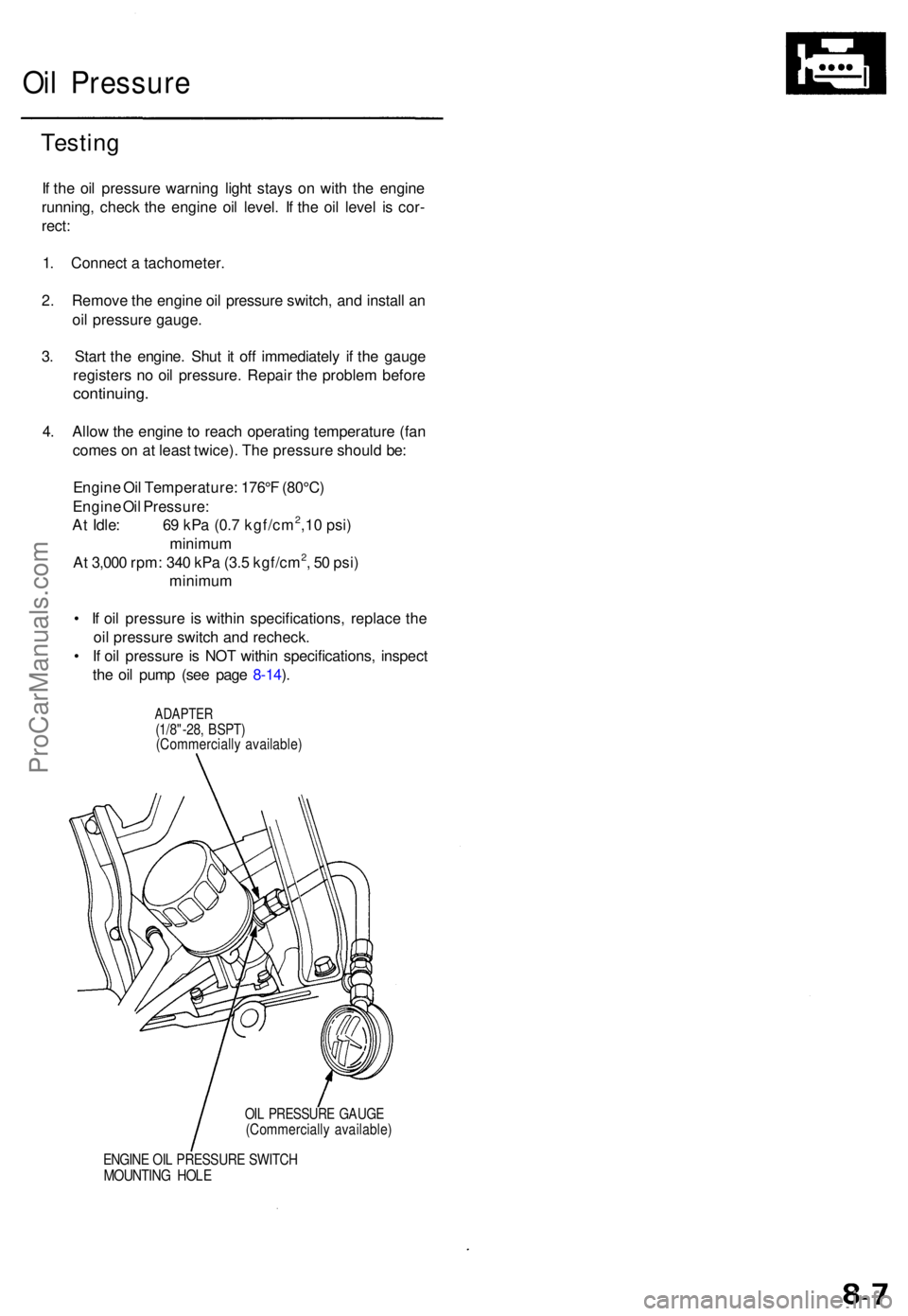

1 . Connec t a tachometer .

2 . Remov e th e engin e oi l pressur e switch , an d instal l a n

oi l pressur e gauge .

3 . Star t th e engine . Shu t i t of f immediatel y i f th e gaug e

register s n o oi l pressure . Repai r th e proble m befor e

continuing .

4. Allo w th e engin e to reac h operatin g temperatur e (fa n

come s o n a t leas t twice) . Th e pressur e shoul d be :

Engin e Oi l Temperature : 176° F (80°C )

Engin e Oi l Pressure :

A t Idle : 6 9 kP a (0. 7 kgf/cm

2,1 0 psi )

minimu m

A t 3,00 0 rpm : 34 0 kP a (3. 5 kgf/cm

2, 5 0 psi )

minimu m

• I f oi l pressur e i s withi n specifications , replac e th e

oi l pressur e switc h an d recheck .

• I f oi l pressur e is NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-14 ).

ADAPTE R(1/8"-28, BSPT )(Commerciall y available )

OIL PRESSUR E GAUG E(Commerciall y available )

ENGINE OI L PRESSUR E SWITC HMOUNTIN G HOL E

ProCarManuals.com

Page 822 of 1771

Radiator

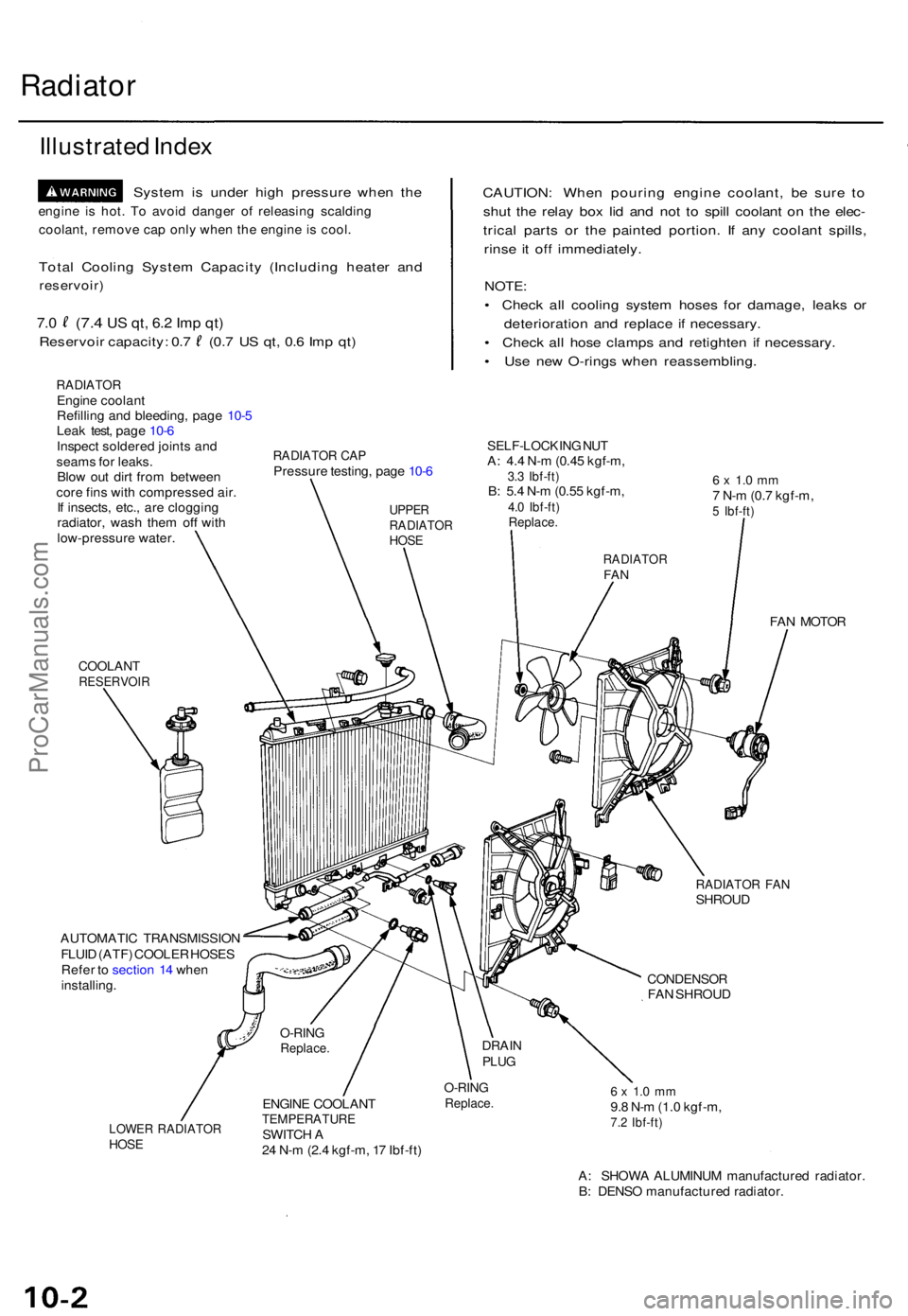

Illustrate d Inde x

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

coolant , remov e ca p onl y whe n th e engin e i s cool .

Total Coolin g Syste m Capacit y (Includin g heate r an d

reservoir )

7.0 (7. 4 US qt , 6. 2 Im p qt )

Reservoi r capacity : 0. 7 (0. 7 U S qt , 0. 6 Im p qt )

RADIATO REngine coolan t

Refillin g an d bleeding , pag e 10- 5

Lea k test , pag e 10- 6

Inspec t soldere d joint s an d

seam s fo r leaks .

Blo w ou t dir t fro m betwee n

cor e fin s wit h compresse d air .

I f insects , etc. , ar e cloggin g

radiator , was h the m of f wit h

low-pressur e water .

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o spil l coolan t o n th e elec -

trica l part s o r th e painte d portion . I f an y coolan t spills ,

rins e i t of f immediately .

NOTE:

• Chec k al l coolin g syste m hose s fo r damage , leak s o r

deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f necessary .

• Us e ne w O-ring s whe n reassembling .

RADIATOR CA PPressur e testing , pag e 10- 6

SELF-LOCKIN G NU TA: 4. 4 N- m (0.4 5 kgf-m ,3.3 Ibf-ft )B: 5. 4 N- m (0.5 5 kgf-m ,4.0 Ibf-ft )Replace .

6 x 1. 0 m m7 N- m (0. 7 kgf-m ,5 Ibf-ft )

COOLAN TRESERVOI R

FAN MOTO R

RADIATO R FA NSHROU D

AUTOMATI C TRANSMISSIO N

FLUI D (ATF ) COOLE R HOSE S

Refe r t o sectio n 1 4 whe n

installing .

CONDENSO RFAN SHROU D

LOWER RADIATO RHOSE

ENGIN E COOLAN TTEMPERATUR ESWITCH A

2 4 N- m (2. 4 kgf-m , 1 7 Ibf-ft )

O-RIN GReplace .6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,7.2 Ibf-ft )

A: SHOW A ALUMINU M manufacture d radiator .

B : DENS O manufacture d radiator .

O-RINGReplace .DRAINPLUG

UPPE RRADIATO RHOSE

RADIATO RFAN

ProCarManuals.com

Page 826 of 1771

Radiator

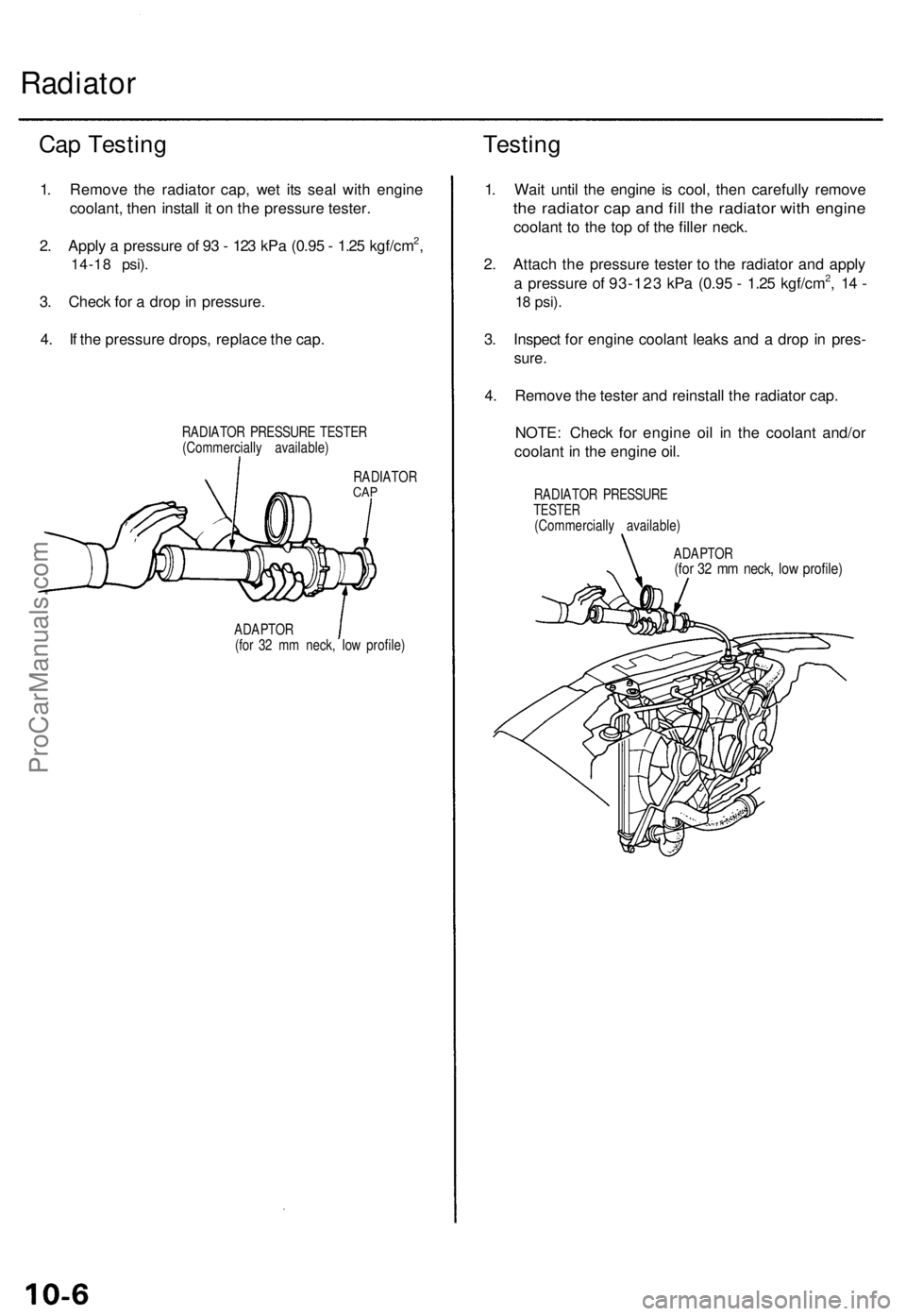

Cap Testin g

1. Remov e th e radiato r cap , we t it s sea l wit h engin e

coolant , the n instal l i t o n th e pressur e tester .

2 . Appl y a pressur e o f 9 3 - 12 3 kP a (0.9 5 - 1.2 5 kgf/cm

2,

14-1 8 psi) .

3. Chec k fo r a dro p in pressure .

4 . I f th e pressur e drops , replac e th e cap .

RADIATO R PRESSUR E TESTE R

(Commerciall y available )

RADIATO R

CAP

ADAPTO R

(fo r 3 2 m m neck , lo w profile )

Testing

1. Wai t unti l th e engin e i s cool , the n carefull y remov e

the radiato r ca p an d fil l th e radiato r wit h engin e

coolan t t o th e to p o f th e fille r neck .

2 . Attac h th e pressur e teste r t o th e radiato r an d appl y

a pressur e o f 93-12 3 kP a (0.9 5 - 1.2 5 kgf/cm

2, 1 4 -

18 psi) .

3. Inspec t fo r engin e coolan t leak s an d a dro p i n pres -

sure.

4. Remov e th e teste r an d reinstal l th e radiato r cap .

NOTE : Chec k fo r engin e oi l i n th e coolan t and/o r

coolan t i n th e engine oil.

RADIATO R PRESSUR ETESTER(Commerciall y available )

ADAPTO R

(for 3 2 m m neck , lo w profile )

ProCarManuals.com

Page 828 of 1771

Thermostat Radiato

r Fa n Switche s

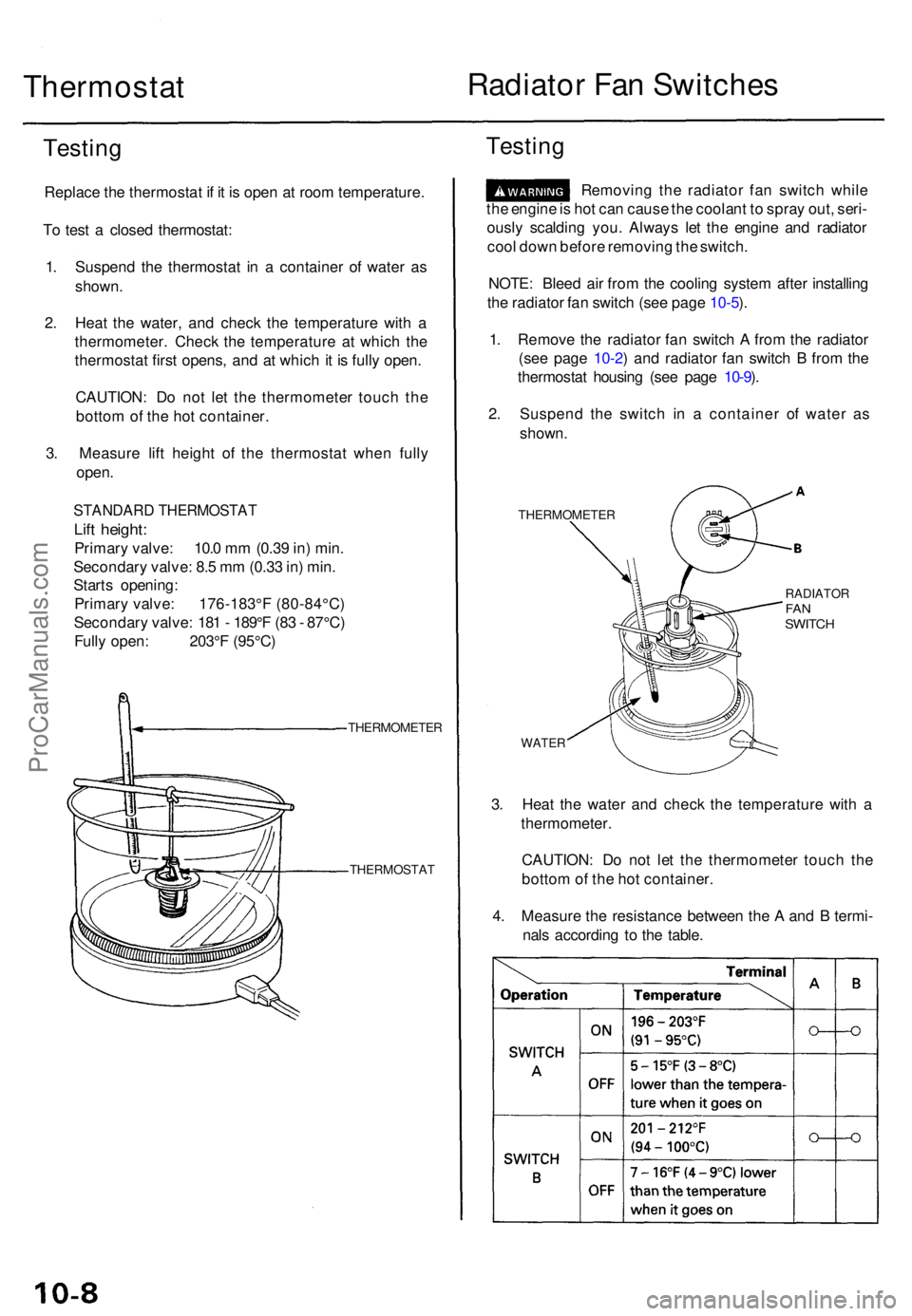

Testing

Replac e th e thermosta t i f i t i s ope n a t roo m temperature .

T o tes t a close d thermostat :

1 . Suspen d th e thermosta t i n a containe r o f wate r a s

shown .

2 . Hea t th e water , an d chec k th e temperatur e wit h a

thermometer . Chec k th e temperatur e a t whic h th e

thermosta t firs t opens , an d a t whic h i t i s full y open .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m of th e ho t container .

3 . Measur e lif t heigh t of the thermosta t whe n full y

open .

STANDAR D THERMOSTA T

Lift height :

Primar y valve : 10. 0 m m (0.3 9 in ) min .

Secondar y valve : 8. 5 m m (0.3 3 in ) min .

Start s opening :

Primar y valve : 176-183° F (80-84°C )

Secondar y valve : 18 1 - 189° F (8 3 - 87°C )

Full y open : 203° F (95°C )

THERMOMETE R

THERMOSTA T

Testing

Removin g th e radiato r fa n switc h whil e

th e engin e is ho t ca n caus e th e coolan t t o spra y out , seri -

ousl y scaldin g you . Alway s le t th e engin e an d radiato r

coo l dow n befor e removin g th e switch .

NOTE : Blee d ai r fro m th e coolin g syste m afte r installin g

th e radiato r fa n switc h (se e pag e 10-5 ).

1 . Remov e th e radiato r fa n switc h A fro m th e radiato r

(se e pag e 10-2 ) an d radiato r fa n switc h B fro m th e

thermosta t housin g (se e pag e 10-9 ).

2 . Suspen d th e switc h i n a containe r of wate r a s

shown .

THERMOMETE R

RADIATORFANSWITC H

WATER

3. Hea t th e wate r an d chec k th e temperatur e wit h a

thermometer .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m of th e ho t container .

4 . Measur e th e resistanc e betwee n th e A an d B termi -

nal s accordin g t o th e table .

ProCarManuals.com

Page 832 of 1771

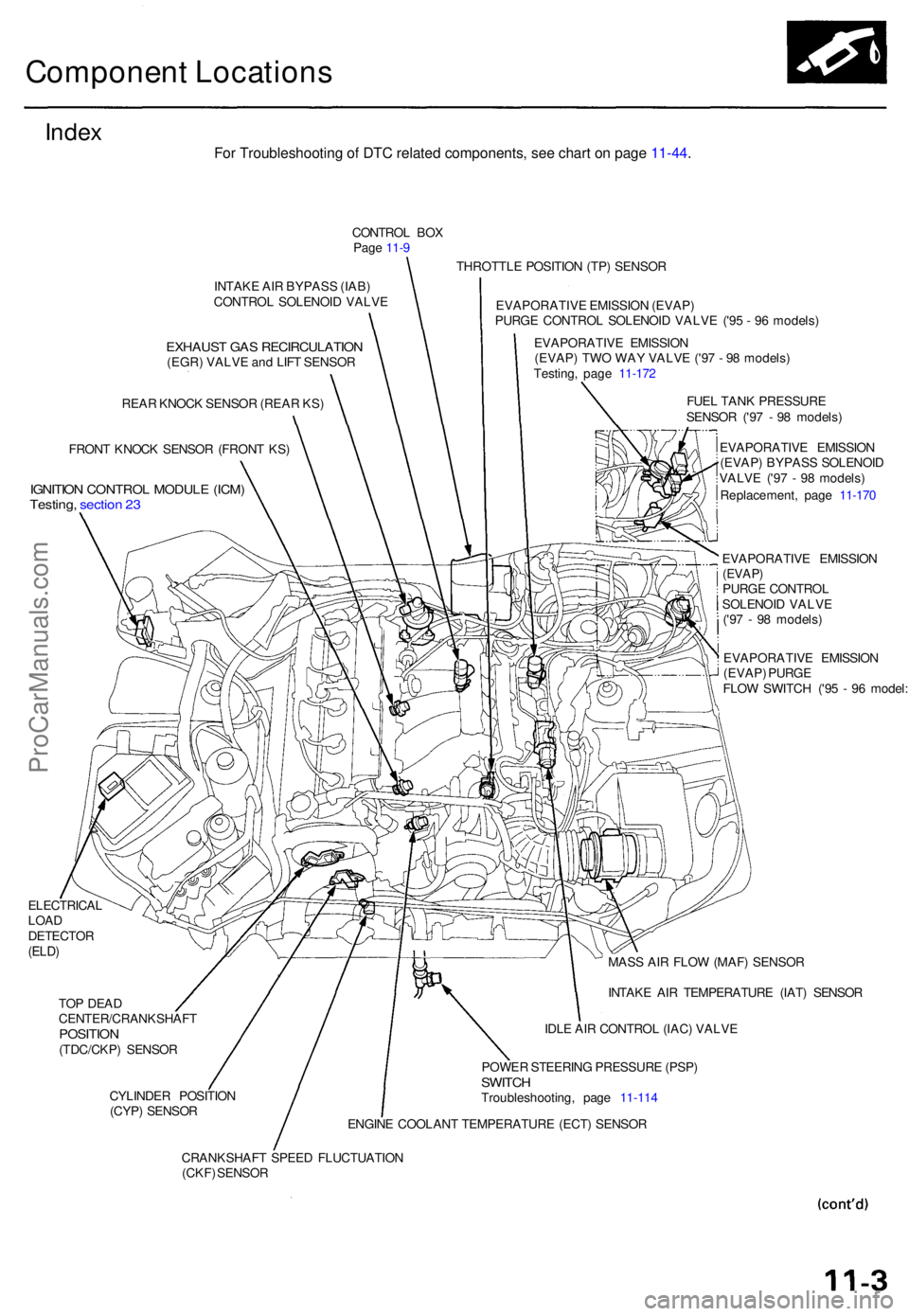

Component Location s

Index

CONTRO L BO X

Pag e 11- 9

INTAK E AI R BYPAS S (IAB )

CONTRO L SOLENOI D VALV E

EXHAUS T GA S RECIRCULATIO N(EGR) VALV E an d LIF T SENSO R

REA R KNOC K SENSO R (REA R KS )

FRON T KNOC K SENSO R (FRON T KS )

IGNITIO N CONTRO L MODUL E (ICM )Testing , sectio n 2 3

THROTTL E POSITIO N (TP ) SENSO R

EVAPORATIV E EMISSIO N (EVAP )

PURG E CONTRO L SOLENOI D VALV E ('9 5 - 9 6 models )

EVAPORATIV E EMISSIO N

(EVAP ) TW O WA Y VALV E ('9 7 - 9 8 models )

Testing , pag e 11-17 2

FUEL TAN K PRESSUR E

SENSO R ('9 7 - 9 8 models )

EVAPORATIV E EMISSIO N

(EVAP ) BYPAS S SOLENOI D

VALV E ('9 7 - 9 8 models )

Replacement , pag e 11-17 0

EVAPORATIV E EMISSIO N

(EVAP)PURGE CONTRO L

SOLENOI D VALV E

('9 7 - 9 8 models )

EVAPORATIV E EMISSIO N

(EVAP ) PURG E

FLO W SWITC H ('9 5 - 9 6 model :

ELECTRICA LLOADDETECTO R(ELD)

TOP DEA D

CENTER/CRANKSHAF T

POSITION(TDC/CKP ) SENSO R

CYLINDE R POSITIO N

(CYP ) SENSO R MAS

S AI R FLO W (MAF ) SENSO R

INTAK E AI R TEMPERATUR E (IAT ) SENSO R

IDL E AI R CONTRO L (IAC ) VALV E

POWE R STEERIN G PRESSUR E (PSP )

SWITC HTroubleshooting , pag e 11-11 4

ENGIN E COOLAN T TEMPERATUR E (ECT ) SENSO R

CRANKSHAF T SPEE D FLUCTUATIO N

(CKF ) SENSO R

For Troubleshooting of DTC related components, see chart on page 11-44.

ProCarManuals.com

Page 833 of 1771

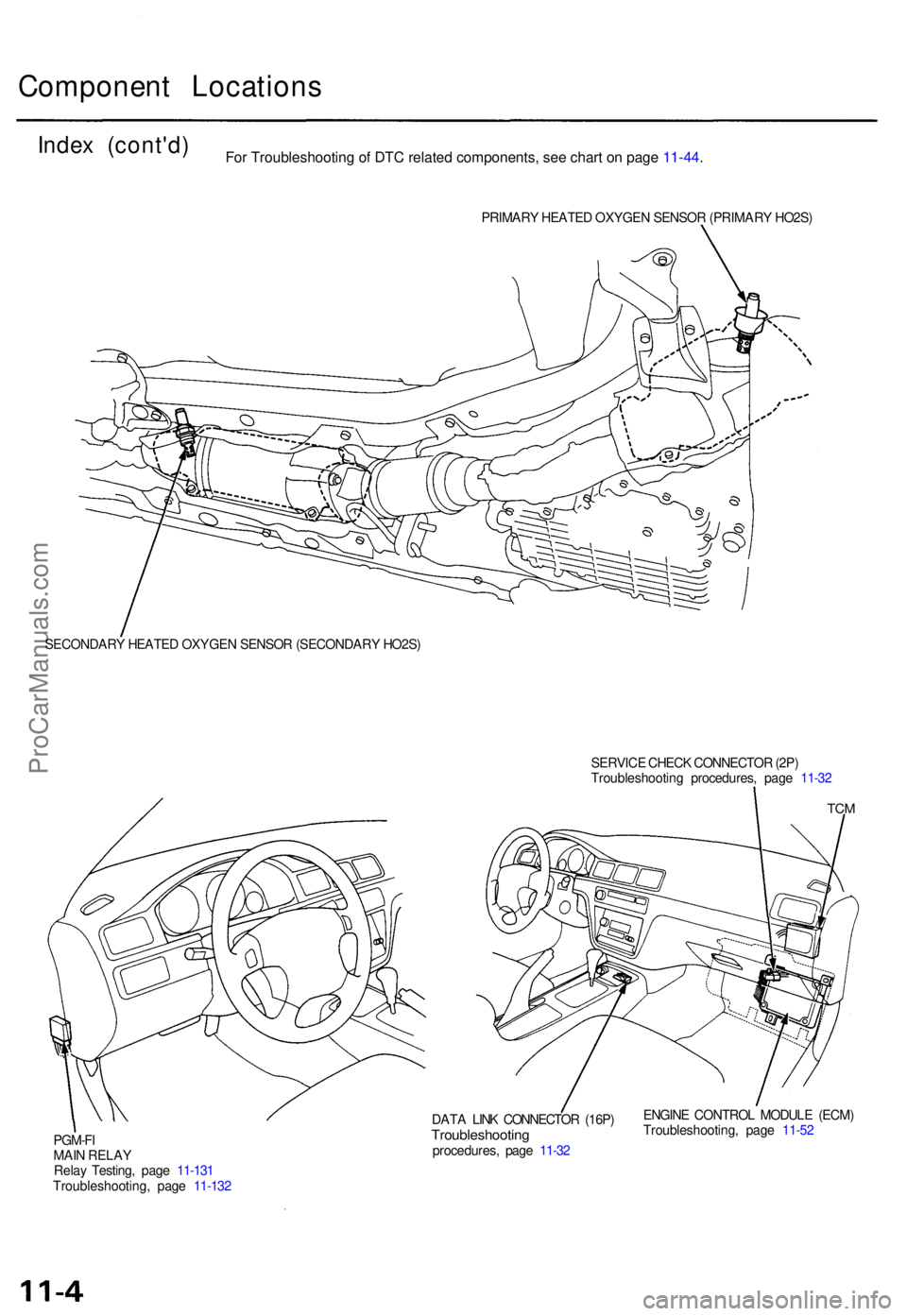

Component Location s

Index (cont'd )

PRIMARY HEATE D OXYGE N SENSO R (PRIMAR Y HO2S )

SECONDAR Y HEATE D OXYGE N SENSO R (SECONDAR Y HO2S )

SERVICE CHEC K CONNECTO R (2P )

Troubleshootin g procedures , pag e 11-3 2

PGM-F I

MAI N RELA Y

Rela y Testing , pag e 11-13 1

Troubleshooting , pag e 11-13 2

TCM

ENGIN E CONTRO L MODUL E (ECM )

Troubleshooting , pag e 11-5 2

DAT

A LIN K CONNECTO R (16P )

Troubleshootin gprocedures, pag e 11-3 2

For Troubleshooting of DTC related components, see chart on page 11-44.

ProCarManuals.com

Page 834 of 1771

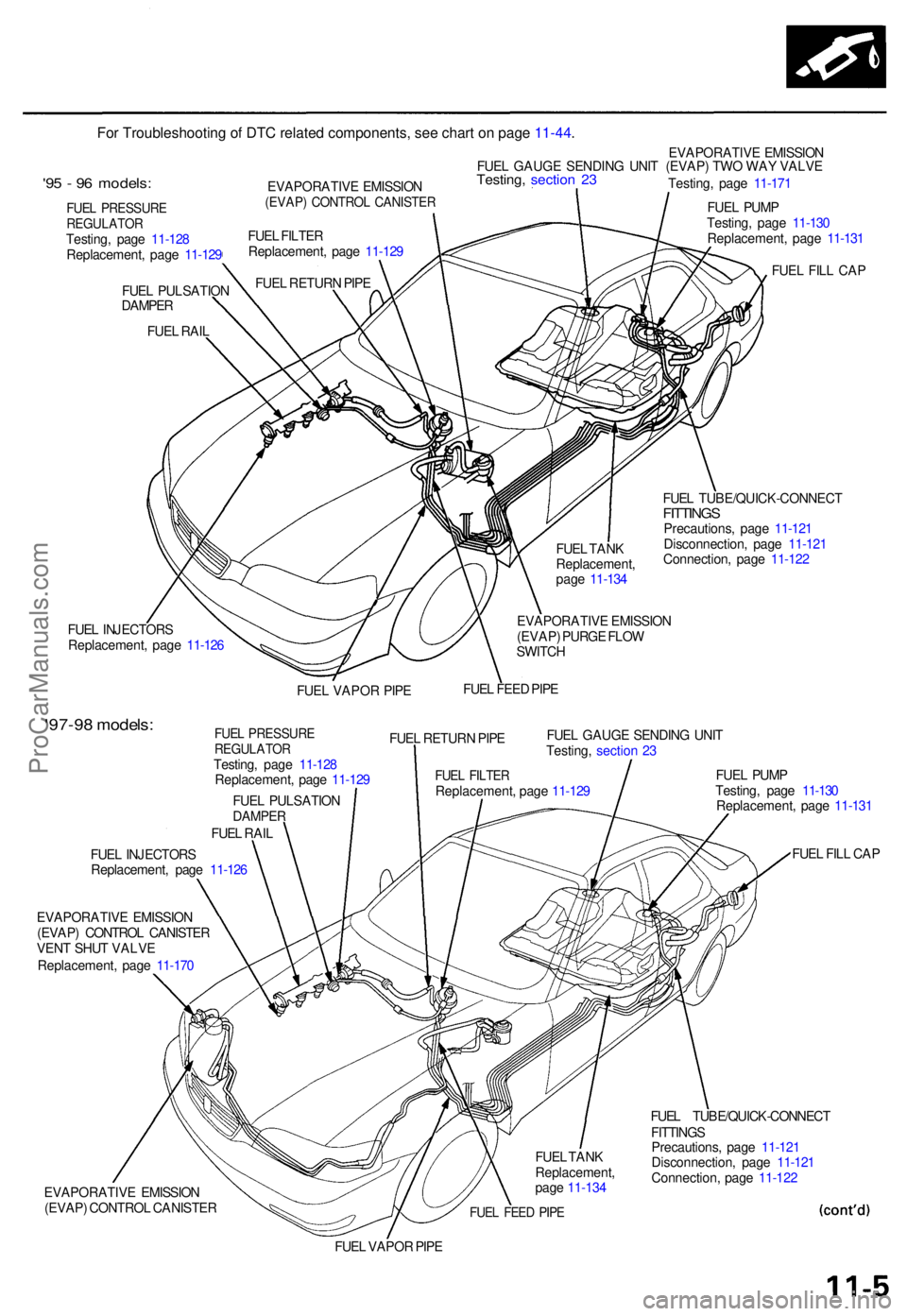

'95 - 9 6 models :

FUEL PRESSUR EREGULATO RTesting, pag e 11-12 8

Replacement , pag e 11-12 9

FUE L PULSATIO N

DAMPE R

FUE L RAI L EVAPORATIV

E EMISSIO N

(EVAP) CONTRO L CANISTE R

FUEL FILTE R

Replacement , pag e 11-12 9 EVAPORATIV

E EMISSIO N

FUE L GAUG E SENDIN G UNI T (EVAP ) TW O WA Y VALV E

Testing , sectio n 2 3

FUE L INJECTOR S

Replacement , pag e 11-12 6 Testing

, pag e 11-17 1

FUE L PUM P

Testing , pag e 11-13 0

Replacement , pag e 11-13 1

FUE L FIL L CA P

FUE L TUBE/QUICK-CONNEC T

FITTINGSPrecautions , pag e 11-12 1

Disconnection , pag e 11-12 1

Connection , pag e 11-12 2

FUE L VAPO R PIP E EVAPORATIV

E EMISSIO N

(EVAP ) PURG E FLO W

SWITC H

FUE L FEE D PIP E

'97-9 8 models :FUEL PRESSUR EREGULATO RTesting, pag e 11-12 8

Replacement , pag e 11-12 9

FUE L PULSATIO N

DAMPER

FUEL RAI L FUE

L RETUR N PIP E FUE

L GAUG E SENDIN G UNI T

Testing , sectio n 2 3

FUE L INJECTOR S

Replacement , pag e 11-12 6

EVAPORATIV E EMISSIO N

(EVAP ) CONTRO L CANISTE R

VEN T SHU T VALV E

Replacement , pag e 11-17 0 FUE

L PUM P

Testing , pag e 11-13 0

Replacement , pag e 11-13 1

FUE L FIL L CA P

EVAPORATIV E EMISSIO N

(EVAP ) CONTRO L CANISTE R FUE

L TAN K

Replacement ,

pag e 11-13 4 FUE

L TUBE/QUICK-CONNEC T

FITTING S

Precautions , pag e 11-12 1

Disconnection , pag e 11-12 1

Connection , pag e 11-12 2

FUEL FEE D PIP E

FUE L VAPO R PIP E

FUE L FILTE RReplacement , pag e 11-12 9

FUE

L TAN K

Replacement ,

pag e 11-13 4

FUE

L RETUR N PIP E

For Troubleshooting of DTC related components, see chart on page 11-44.

ProCarManuals.com

Page 861 of 1771

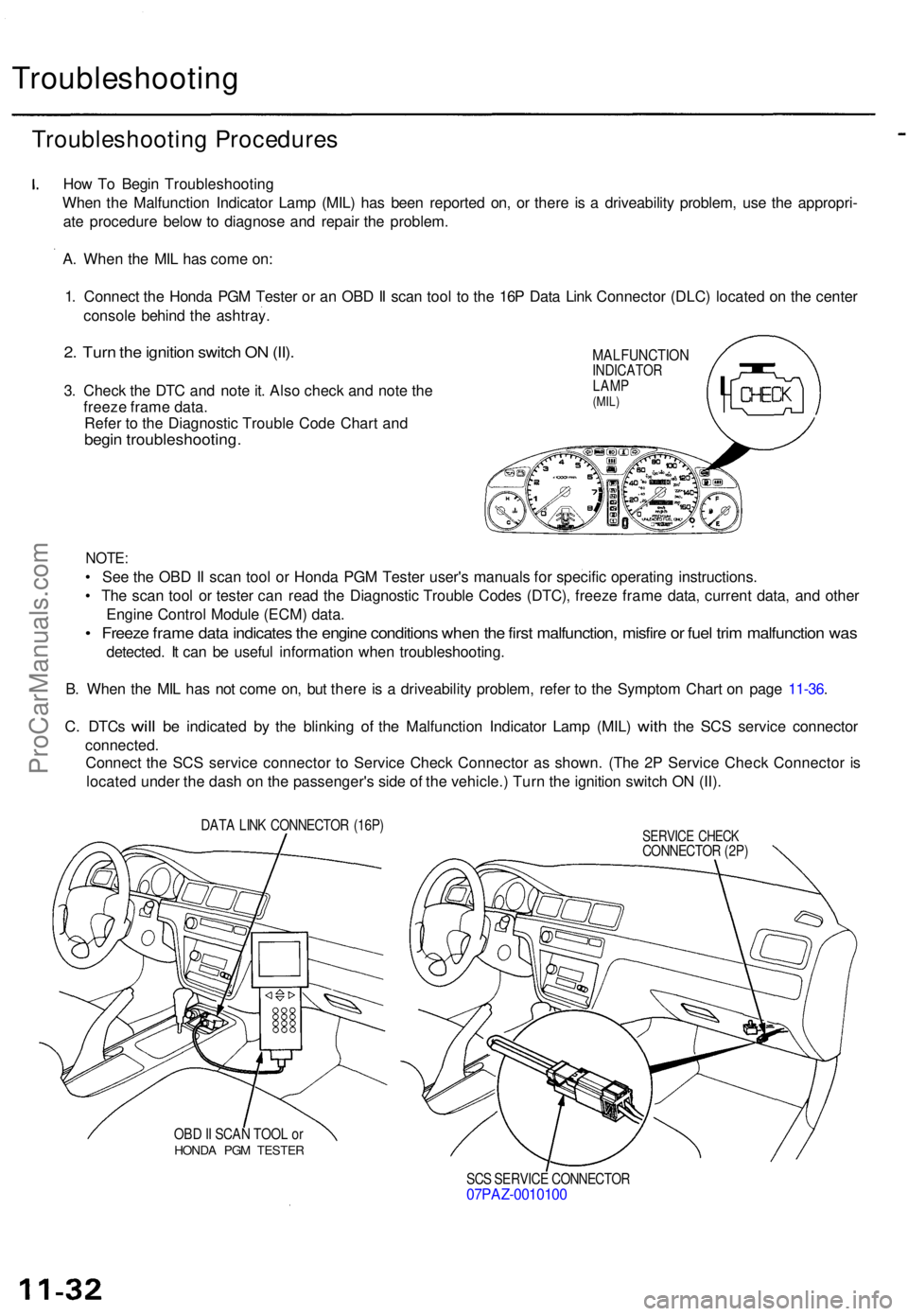

Troubleshooting

Troubleshootin g Procedure s

How T o Begi n Troubleshootin g

Whe n th e Malfunctio n Indicato r Lam p (MIL ) ha s bee n reporte d on , o r ther e i s a driveabilit y problem , us e th e appropri -

at e procedur e belo w to diagnos e an d repai r th e problem .

A . Whe n th e MI L ha s com e on :

1 . Connec t th e Hond a PG M Teste r o r a n OB D II sca n too l t o th e 16 P Dat a Lin k Connecto r (DLC ) locate d o n th e cente r

consol e behin d th e ashtray .

2. Tur n th e ignitio n switc h O N (II) .

3. Chec k th e DT C an d not e it . Als o chec k an d not e th e

freez e fram e data .

Refe r t o th e Diagnosti c Troubl e Cod e Char t an d

begi n troubleshooting .

MALFUNCTIONINDICATOR

LAM P

(MIL)

NOTE :

• Se e th e OB D II sca n too l o r Hond a PG M Teste r user' s manual s fo r specifi c operatin g instructions .

• Th e sca n too l o r teste r ca n rea d th e Diagnosti c Troubl e Code s (DTC) , freez e fram e data , curren t data , an d othe r

Engin e Contro l Modul e (ECM ) data .

• Freez e fram e dat a indicate s th e engin e condition s whe n th e firs t malfunction , misfir e o r fue l tri m malfunctio n wa s

detected . I t ca n b e usefu l informatio n whe n troubleshooting .

B . Whe n th e MI L ha s no t com e on , bu t ther e i s a driveabilit y problem , refe r t o th e Sympto m Char t o n pag e 11-36 .

C. DTC s will be indicate d by th e blinkin g of th e Malfunctio n Indicato r Lam p (MIL ) with the SC S servic e connecto r

connected .

Connec t th e SC S servic e connecto r t o Servic e Chec k Connecto r a s shown . (Th e 2 P Servic e Chec k Connecto r i s

locate d unde r th e das h o n th e passenger' s sid e o f th e vehicle. ) Tur n th e ignitio n switc h O N (II) .

DAT A LIN K CONNECTO R (16P )

OB D II SCA N TOO L o r

HOND A PG M TESTE R

SERVICE CHEC KCONNECTO R (2P )

SC S SERVIC E CONNECTO R

07PAZ-001010 0

ProCarManuals.com

Page 862 of 1771

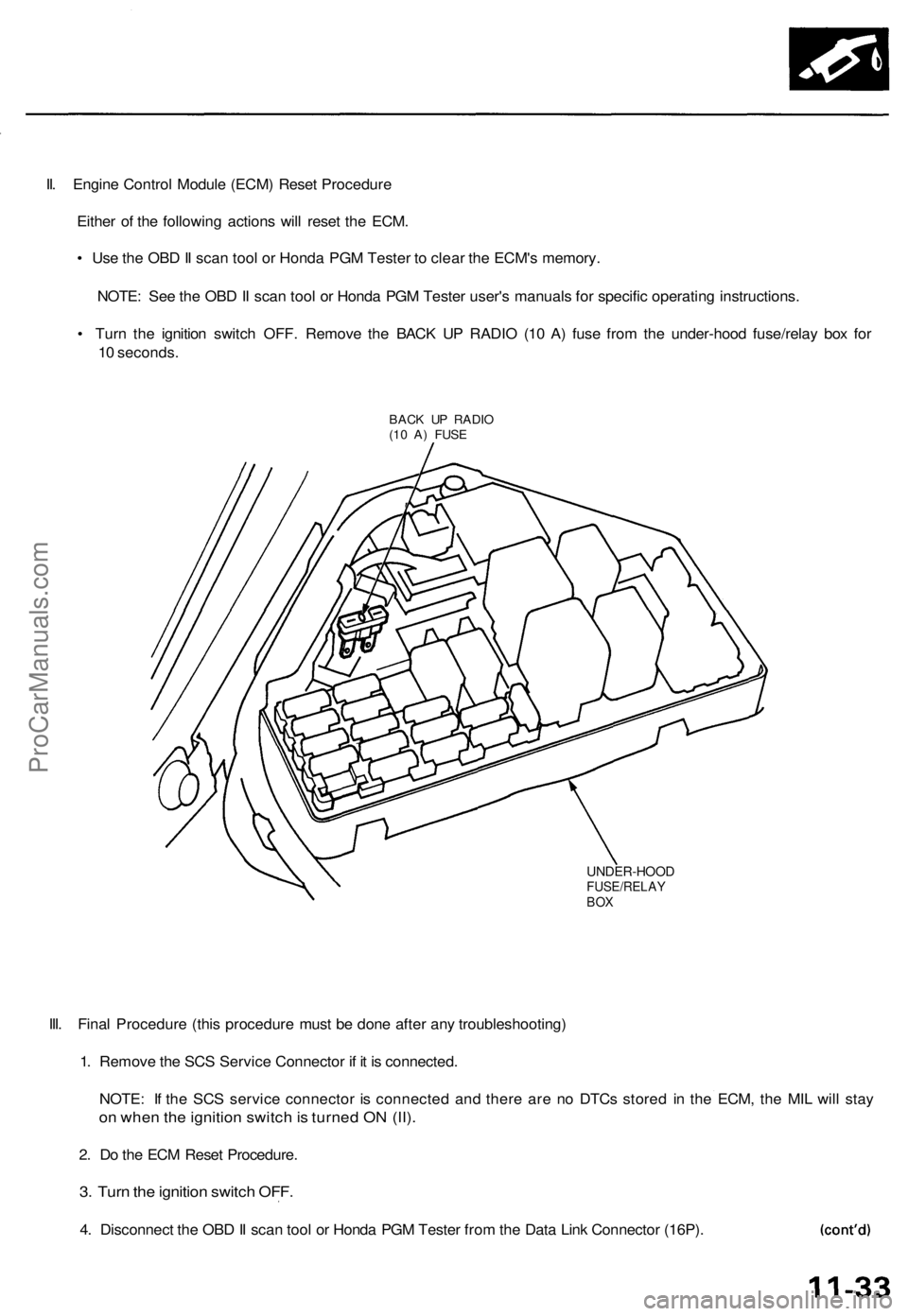

II. Engine Control Module (ECM) Reset Procedure

Either of the following actions will reset the ECM.

• Use the OBD II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

• Turn the ignition switch OFF. Remove the BACK UP RADIO (10 A) fuse from the under-hood fuse/relay box for

10 seconds.

BACK UP RADIO

(10 A) FUSE

UNDER-HOOD

FUSE/RELAY

BOX

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected.

NOTE: If the SCS service connector is connected and there are no DTCs stored in the ECM, the MIL will stay

on when the ignition switch is turned ON (II).

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD II scan tool or Honda PGM Tester from the Data Link Connector (16P).ProCarManuals.com

Page 864 of 1771

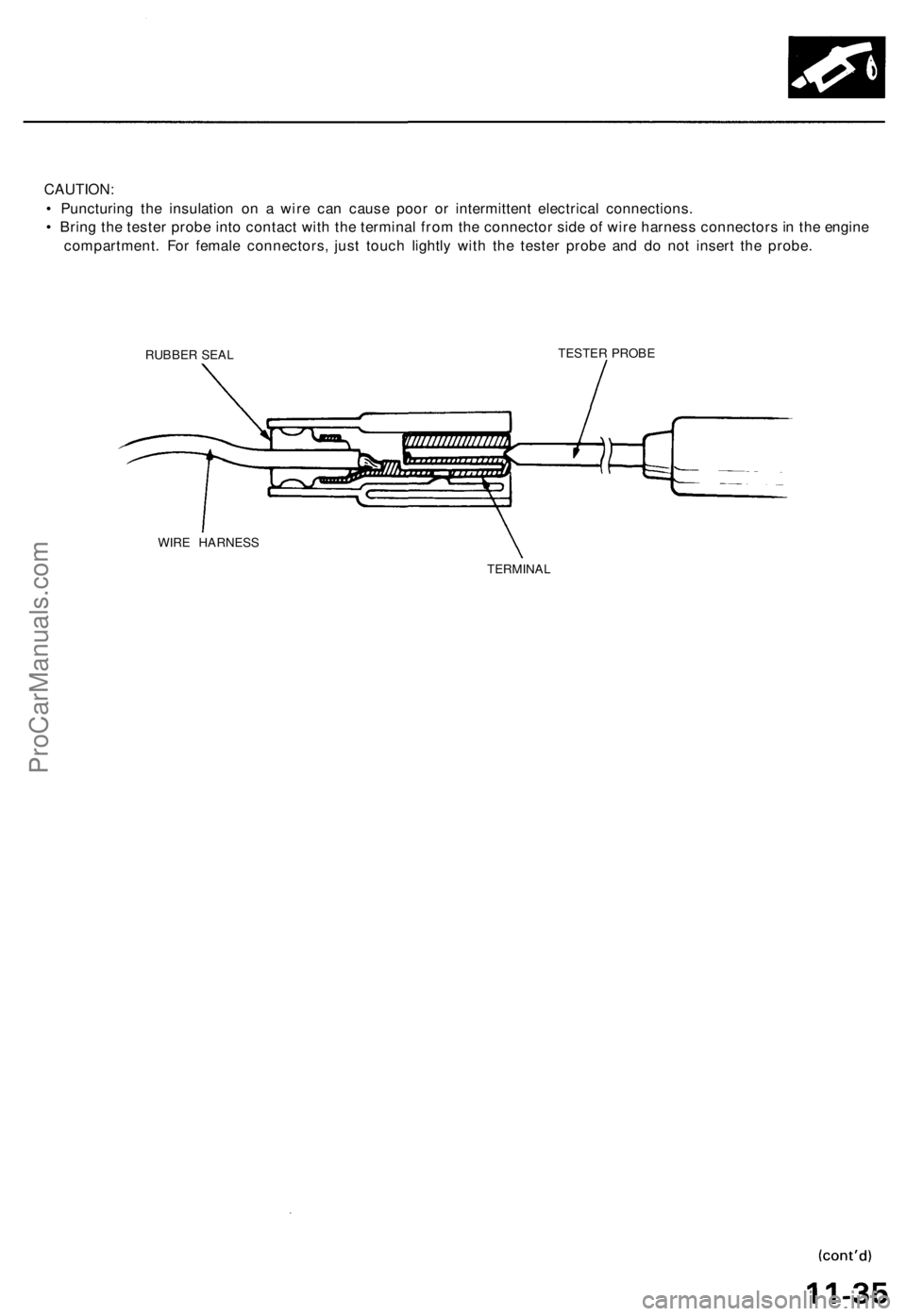

CAUTION:

• Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

• Bring the tester probe into contact with the terminal from the connector side of wire harness connectors in the engine

compartment. For female connectors, just touch lightly with the tester probe and do not insert the probe.

RUBBER SEAL

TESTER PROBE

WIRE HARNESS

TERMINALProCarManuals.com