Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1655 of 1771

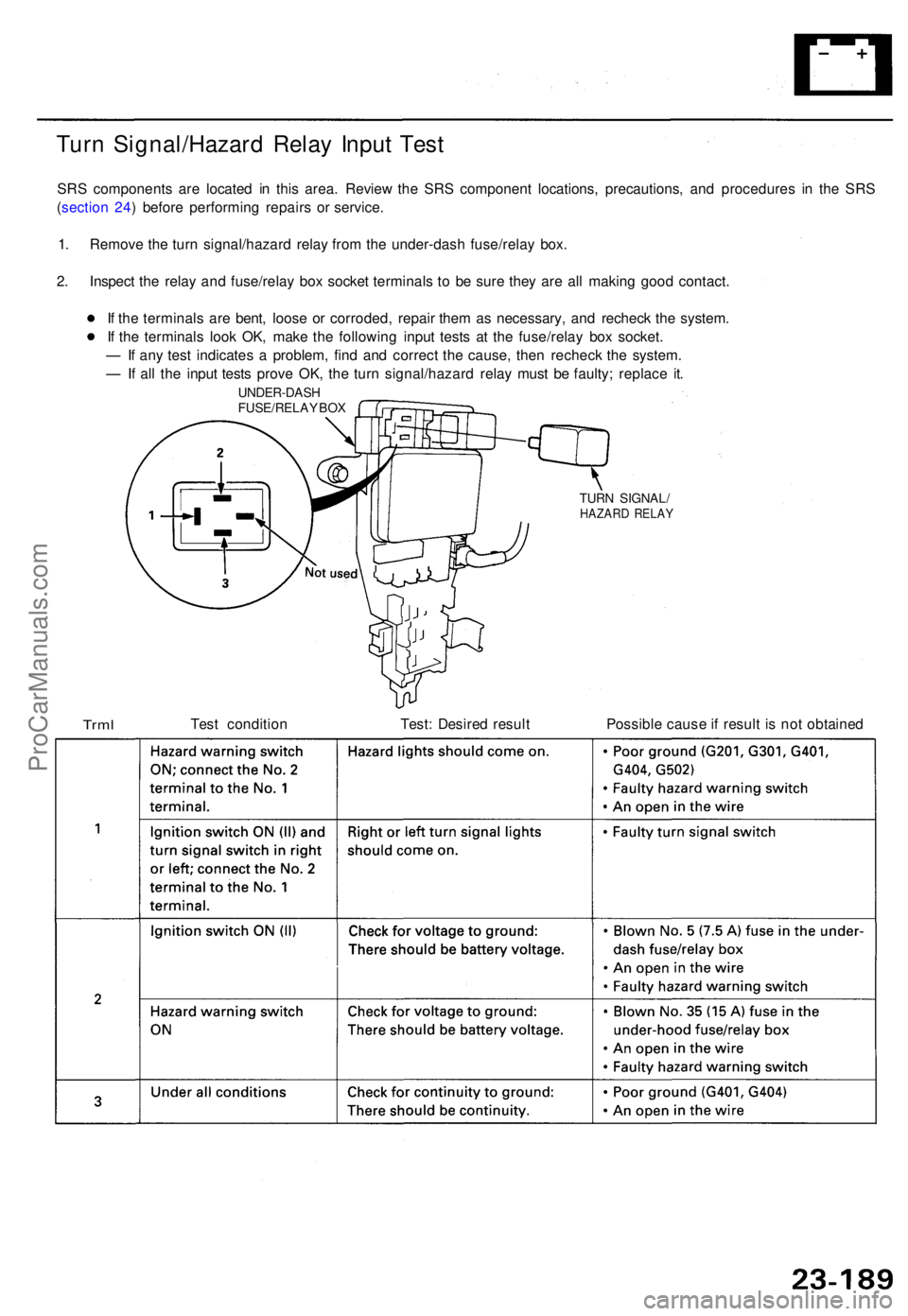

Turn Signal/Hazar d Rela y Inpu t Tes t

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

1 . Remov e th e tur n signal/hazar d rela y fro m th e under-das h fuse/rela y box .

2 . Inspec t th e rela y an d fuse/rela y bo x socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

I f th e terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e fuse/rela y bo x socket .

— If an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e tur n signal/hazar d rela y mus t b e faulty ; replac e it .

UNDER-DAS H

FUSE/RELA Y BO X

TUR N SIGNAL /HAZARD RELA Y

TrmlTest conditio n Test: Desire d resul t Possible caus e if resul t i s no t obtaine d

ProCarManuals.com

Page 1657 of 1771

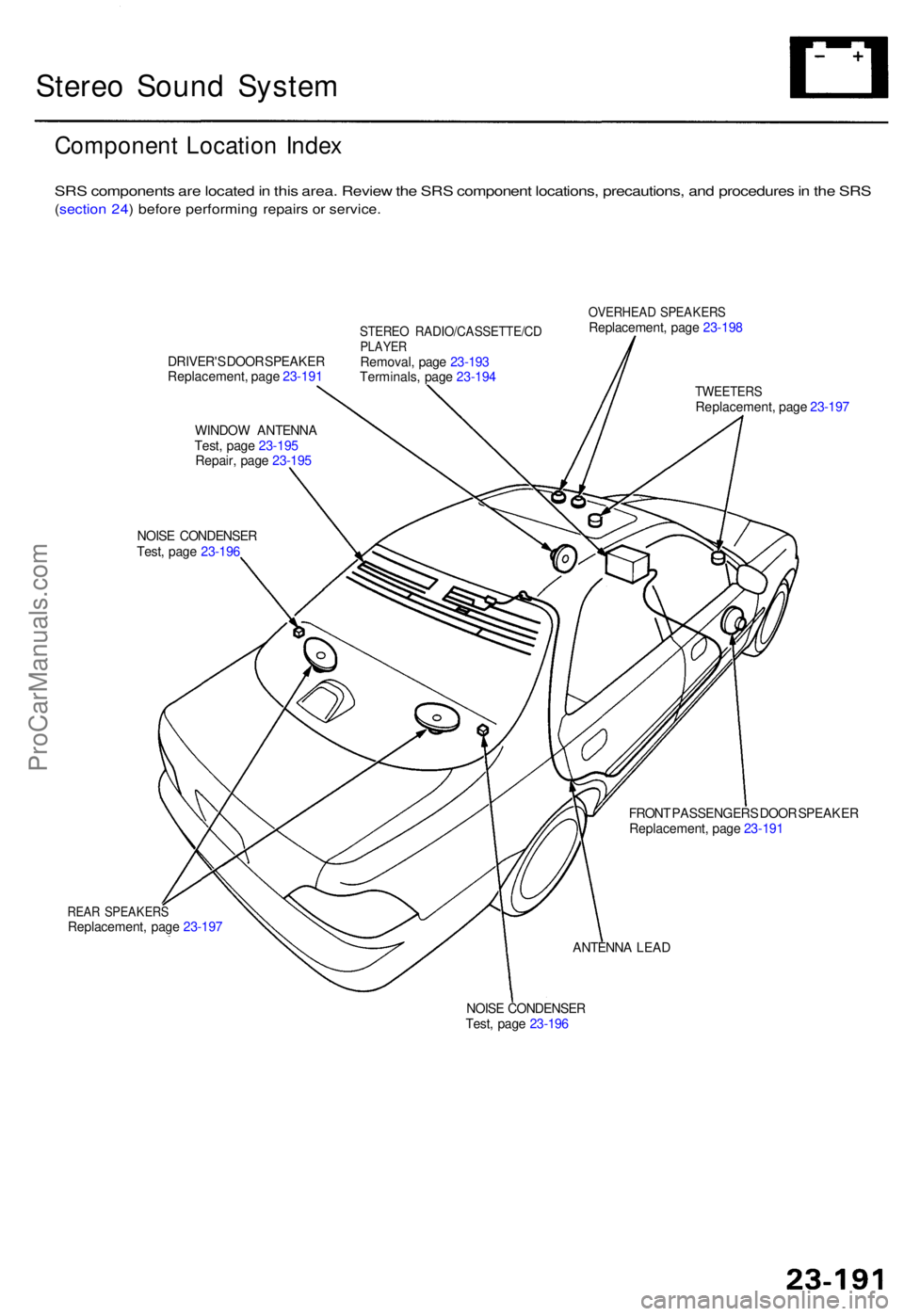

Stereo Soun d Syste m

Componen t Locatio n Inde x

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

(sectio n 24 ) befor e performin g repair s o r service .

DRIVER' S DOO R SPEAKE R

Replacement , pag e 23-19 1

WINDO W ANTENN A

Test , pag e 23-19 5

Repair , pag e 23-19 5

NOIS E CONDENSE R

Test , pag e 23-19 6

STERE O RADIO/CASSETTE/C DPLAYERRemoval , pag e 23-19 3

Terminals , pag e 23-19 4

OVERHEA D SPEAKER SReplacement , pag e 23-19 8

REAR SPEAKER SReplacement , pag e 23-19 7

TWEETER SReplacement , pag e 23-19 7

FRON T PASSENGER S DOO R SPEAKE R

Replacement , pag e 23-19 1

ANTENN A LEA D

NOIS E CONDENSE R

Test , pag e 23-19 6

ProCarManuals.com

Page 1660 of 1771

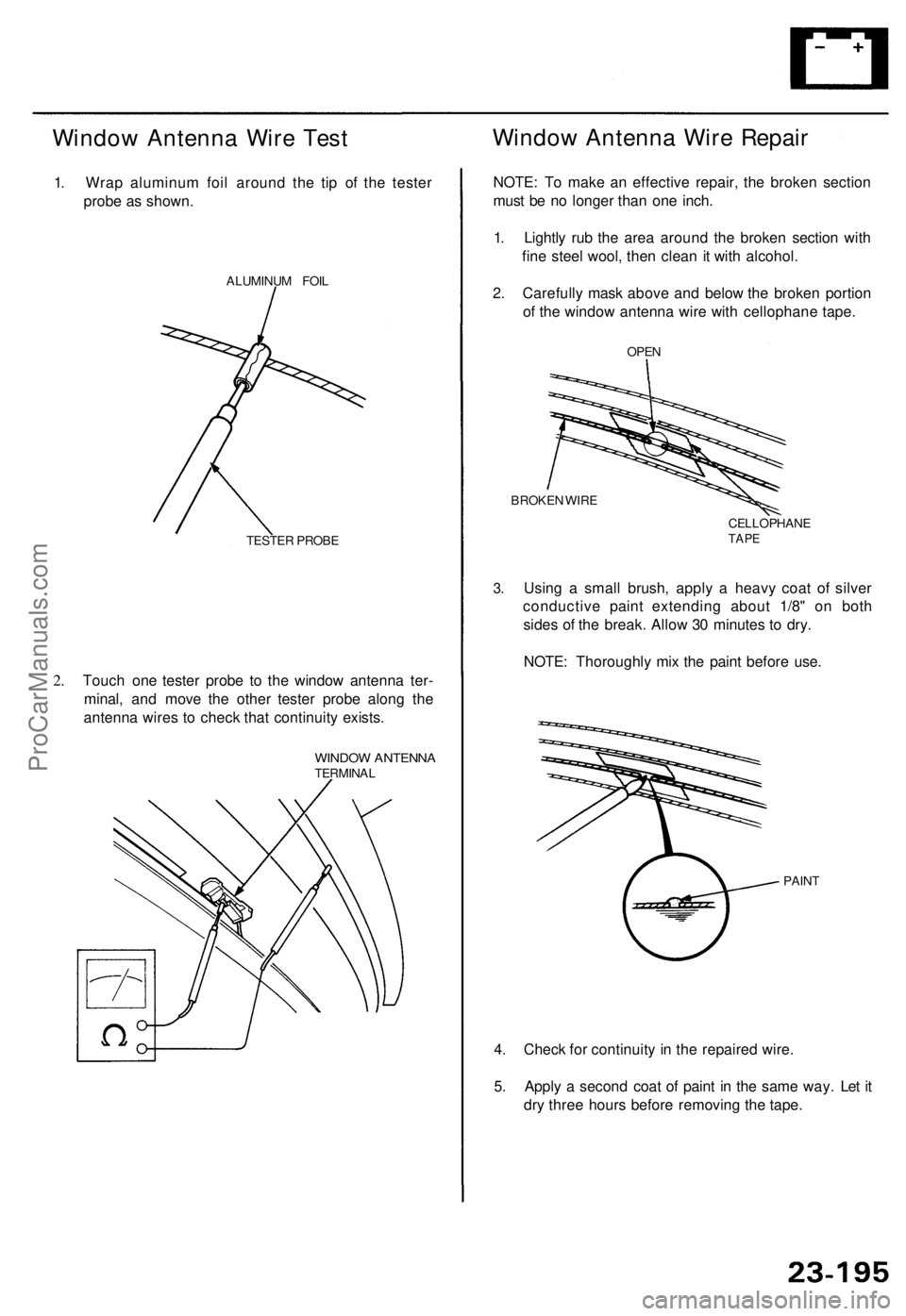

Window Antenn a Wir e Tes t

1. Wra p aluminu m foi l aroun d th e ti p of the teste r

prob e a s shown .

ALUMINU M FOI L

TESTE R PROB E

2.Touc h on e teste r prob e t o th e windo w antenn a ter -

minal , an d mov e th e othe r teste r prob e alon g th e

antenn a wire s t o chec k tha t continuit y exists .

WINDO W ANTENN ATERMINA L

Window Antenn a Wir e Repai r

NOTE: T o mak e a n effectiv e repair , th e broke n sectio n

mus t b e n o longe r tha n on e inch .

1 . Lightl y ru b th e are a aroun d th e broke n sectio n wit h

fin e stee l wool , the n clea n i t wit h alcohol .

2 . Carefull y mas k abov e an d belo w th e broke n portio n

o f th e windo w antenn a wir e wit h cellophan e tape .

OPEN

BROKE N WIR E

CELLOPHANE

TAPE

3.Usin g a smal l brush , appl y a heav y coa t of silve r

conductiv e pain t extendin g abou t 1/8 " o n bot h

side s o f th e break . Allo w 3 0 minute s t o dry .

NOTE : Thoroughl y mi x th e pain t befor e use .

PAIN T

4. Chec k fo r continuit y i n th e repaire d wire .

5 . Appl y a secon d coa t o f pain t i n th e sam e way . Le t i t

dr y thre e hour s befor e removin g th e tape .

ProCarManuals.com

Page 1661 of 1771

Stereo Soun d Syste m

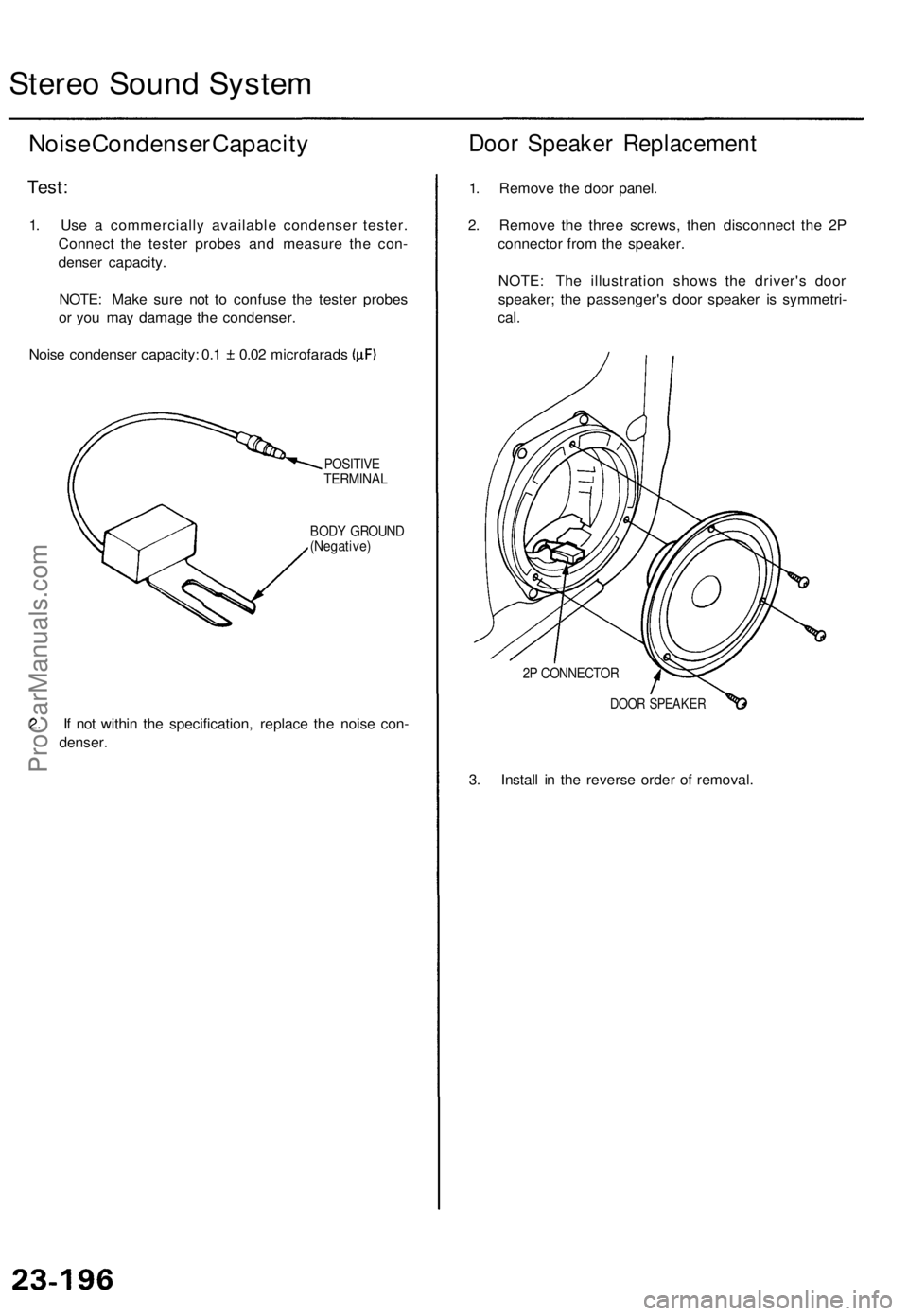

Noise Condense r Capacit y

Test:

1. Us e a commerciall y availabl e condense r tester .

Connec t th e teste r probe s an d measur e th e con -

dense r capacity .

NOTE : Mak e sur e no t t o confus e th e teste r probe s

o r yo u ma y damag e th e condenser .

Noise condense r capacity: 0.1 0.0 2 microfarad s

POSITIVETERMINA L

BODY GROUN D(Negative )

2. I f no t withi n th e specification , replac e th e nois e con -

denser .

Door Speake r Replacemen t

1. Remov e th e doo r panel .

2 . Remov e th e thre e screws , the n disconnec t th e 2 P

connecto r fro m th e speaker .

NOTE : Th e illustratio n show s th e driver' s doo r

speaker ; th e passenger' s doo r speake r i s symmetri -

cal.

2P CONNECTO R

DOOR SPEAKE R

3. Instal l i n th e revers e orde r o f removal .

ProCarManuals.com

Page 1664 of 1771

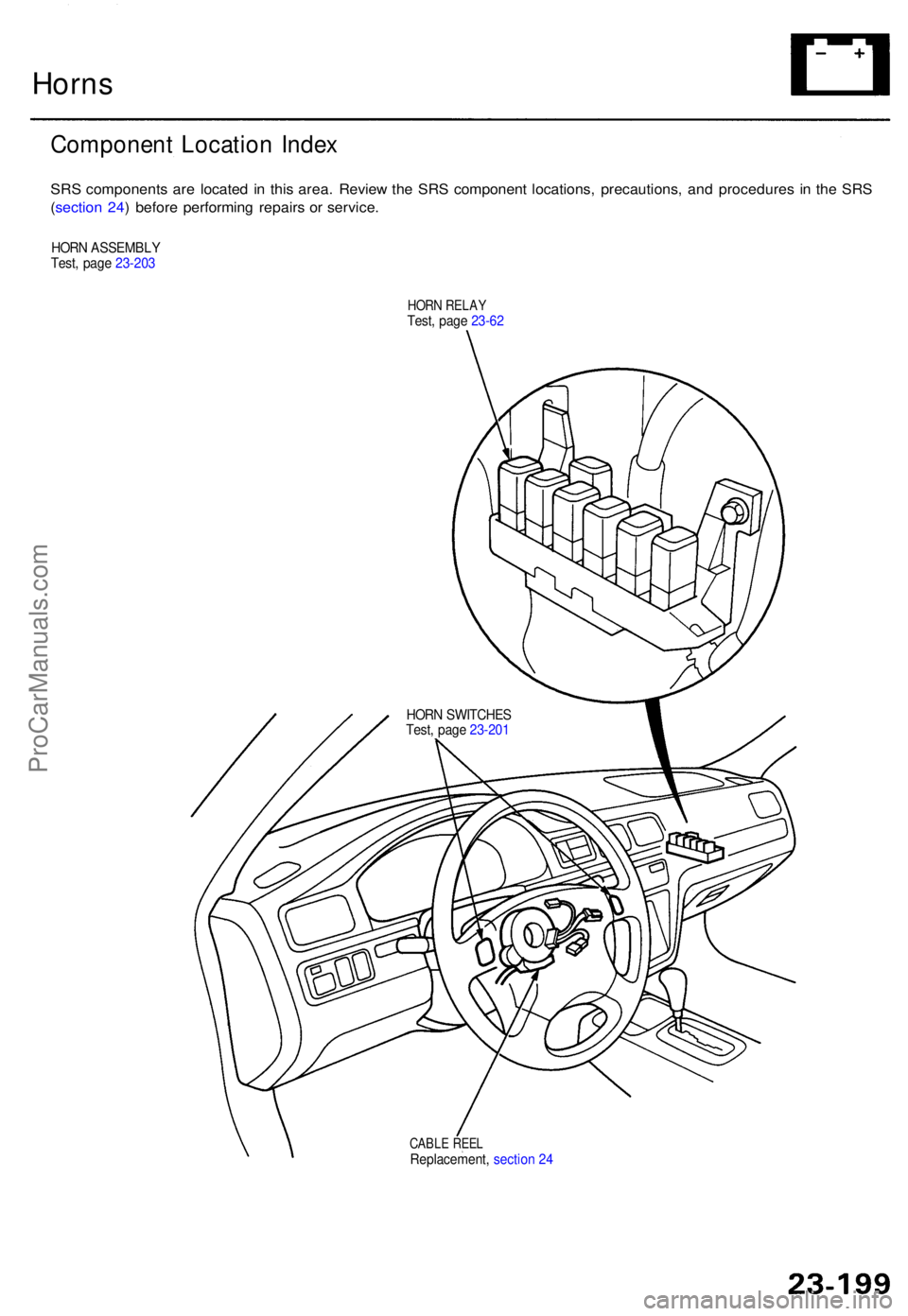

Horns

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

HORN ASSEMBL Y

Test , pag e 23-20 3

HORN RELA YTest, pag e 23-6 2

CABL E REE LReplacement , sectio n 2 4

HOR

N SWITCHE S

Test , pag e 23-20 1

ProCarManuals.com

Page 1666 of 1771

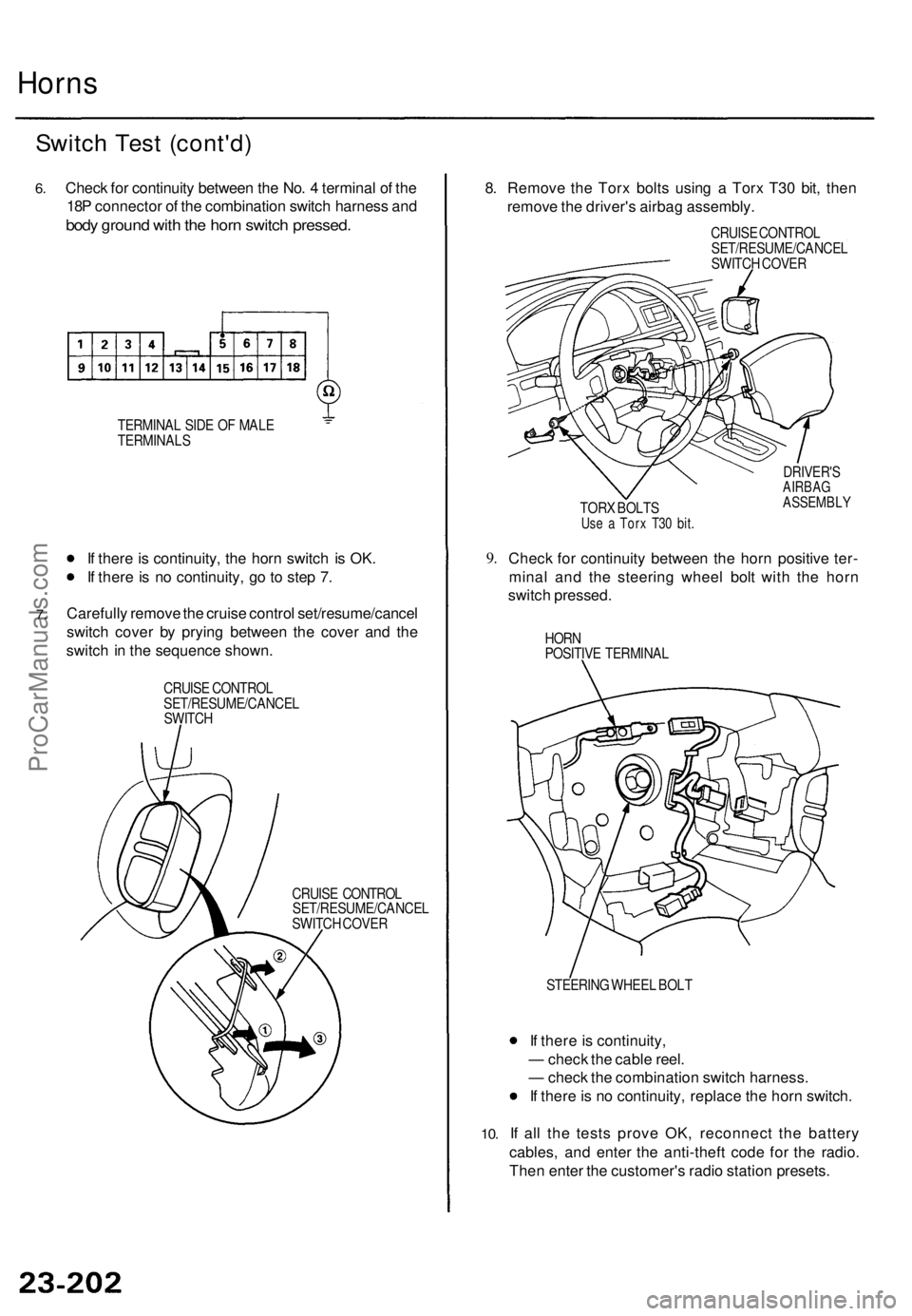

Horns

Switc h Tes t (cont'd )

6.Chec k fo r continuit y betwee n th e No . 4 termina l o f th e

18 P connecto r o f th e combinatio n switc h harnes s an d

bod y groun d wit h th e hor n switc h pressed .

TERMINA L SID E O F MAL E

TERMINAL S

7.

If ther e is continuity , th e hor n switc h i s OK .

I f ther e is n o continuity , g o to ste p 7 .

Carefull y remov e th e cruis e contro l set/resume/cance l

switc h cove r b y pryin g betwee n th e cove r an d th e

switc h in th e sequenc e shown .

CRUISE CONTRO L

SET/RESUME/CANCE L

SWITC H

CRUISE CONTRO L

SET/RESUME/CANCE L

SWITC H COVE R

8. Remov e th e Tor x bolt s usin g a Tor x T3 0 bit , the n

remov e th e driver' s airba g assembly .

CRUISE CONTRO L

SET/RESUME/CANCE L

SWITC H COVE R

TOR X BOLT S

Use a Tor x T3 0 bit .

DRIVER' SAIRBAGASSEMBL Y

9.Chec k fo r continuit y betwee n th e hor n positiv e ter -

mina l an d th e steerin g whee l bol t wit h th e hor n

switc h pressed .

HORN

POSITIV E TERMINA L

10.

STEERIN G WHEE L BOL T

If ther e is continuity ,

— chec k th e cabl e reel .

— chec k th e combinatio n switc h harness .

I f ther e is n o continuity , replac e th e hor n switch .

I f al l th e test s prov e OK , reconnec t th e batter y

cables , an d ente r th e anti-thef t cod e fo r th e radio .

The n ente r th e customer' s radi o statio n presets .

ProCarManuals.com

Page 1669 of 1771

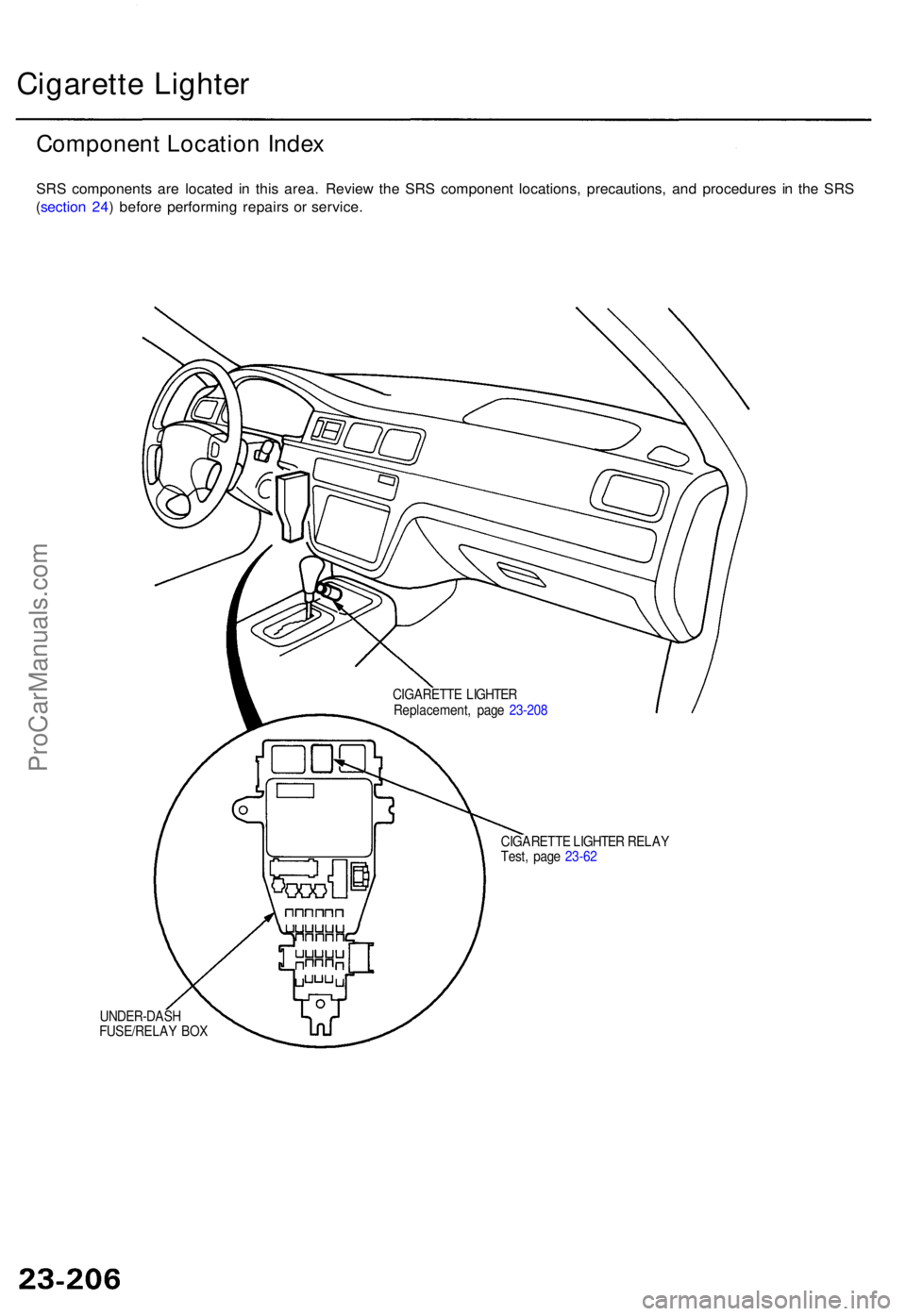

Cigarette Lighte r

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

CIGARETT E LIGHTE R RELA Y

Test , pag e 23-6 2

UNDER-DAS H

FUSE/RELA Y BO X CIGARETT

E LIGHTE R

Replacement , pag e 23-20 8

ProCarManuals.com

Page 1670 of 1771

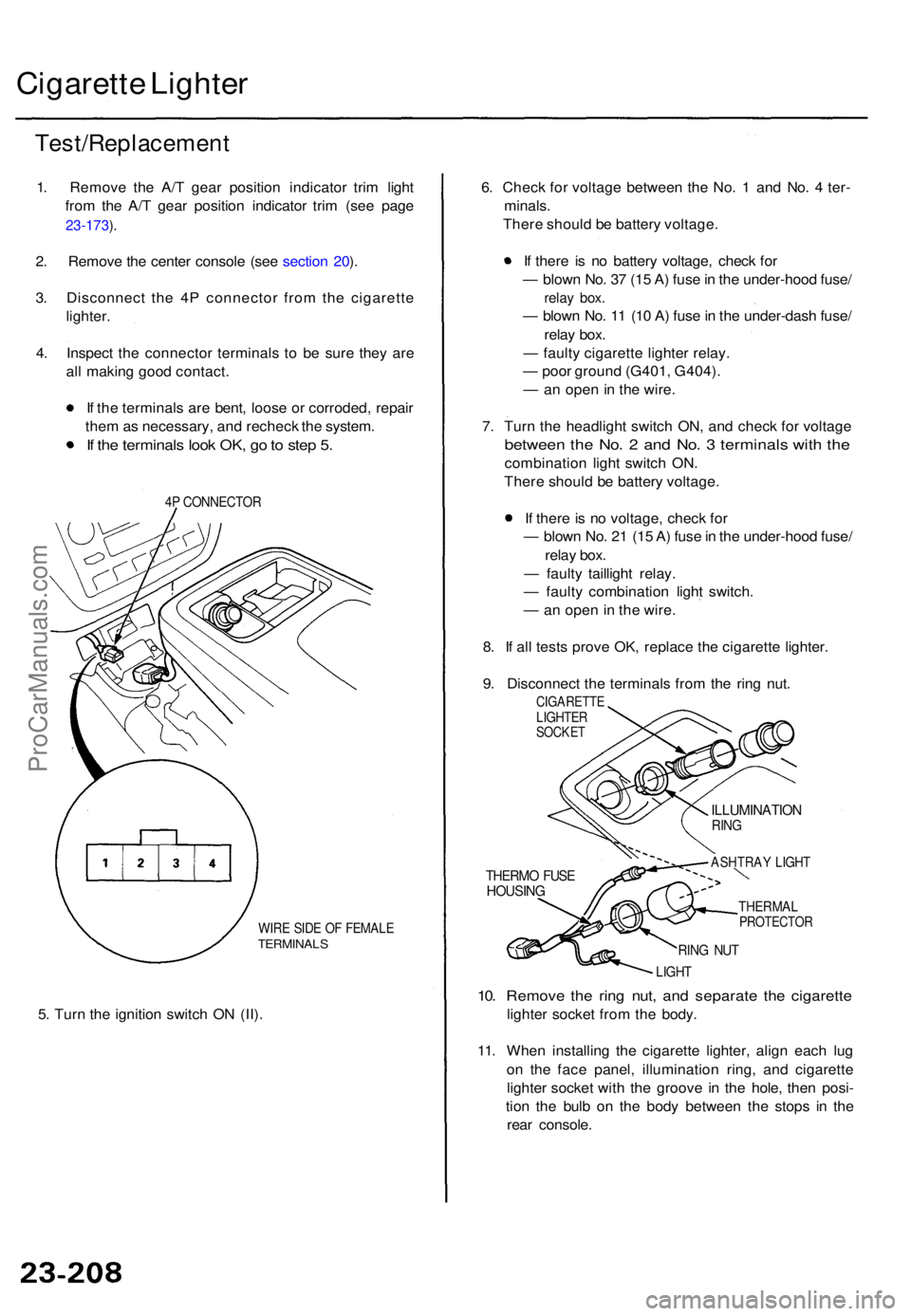

Cigarette Lighte r

Test/Replacemen t

1. Remov e th e A/ T gea r positio n indicato r tri m ligh t

fro m th e A/ T gea r positio n indicato r tri m (se e pag e

23-173 ).

2 . Remov e th e cente r consol e (se e sectio n 20 ).

3 . Disconnec t th e 4 P connecto r fro m th e cigarett e

lighter .

4 . Inspec t th e connecto r terminal s t o b e sur e the y ar e

al l makin g goo d contact .

I f th e terminal s ar e bent , loos e o r corroded , repai r

the m as necessary , an d rechec k th e system .

If th e terminal s loo k OK , g o to ste p 5 .

4P CONNECTO R

WIRE SID E O F FEMAL ETERMINAL S

5. Tur n th e ignitio n switc h O N (II) . 6

. Chec k fo r voltag e betwee n th e No . 1 an d No . 4 ter -

minals .

Ther e shoul d b e batter y voltage .

I f ther e i s n o batter y voltage , chec k fo r

— blow n No . 3 7 (1 5 A ) fus e in th e under-hoo d fuse /

relay box .

— blow n No . 1 1 (1 0 A ) fus e in th e under-das h fuse /

rela y box .

— fault y cigarett e lighte r relay .

— poo r groun d (G401 , G404) .

— an ope n in th e wire .

7 . Tur n th e headligh t switc h ON , an d chec k fo r voltag e

betwee n th e No . 2 an d No . 3 terminal s wit h th e

combinatio n ligh t switc h ON .

Ther e shoul d b e batter y voltage .

I f ther e is n o voltage , chec k fo r

— blow n No . 2 1 (1 5 A ) fus e in th e under-hoo d fuse /

rela y box .

— fault y tailligh t relay .

— fault y combinatio n ligh t switch .

— an ope n in th e wire .

8 . I f al l test s prov e OK , replac e th e cigarett e lighter .

9 . Disconnec t th e terminal s fro m th e rin g nut .

CIGARETT ELIGHTERSOCKE T

THERMO FUS EHOUSIN GTHERMA LPROTECTO R

RING NU T

LIGH T

10. Remov e th e rin g nut , an d separat e th e cigarett e

lighter socke t fro m th e body .

11 . Whe n installin g th e cigarett e lighter , alig n eac h lu g

o n th e fac e panel , illuminatio n ring , an d cigarett e

lighte r socke t wit h th e groov e i n th e hole , the n posi -

tio n th e bul b o n th e bod y betwee n th e stop s i n th e

rea r console .

ASHTRAY LIGHT

ILLUMINATIO NRING

ProCarManuals.com

Page 1671 of 1771

Rear Windo w Defogge r

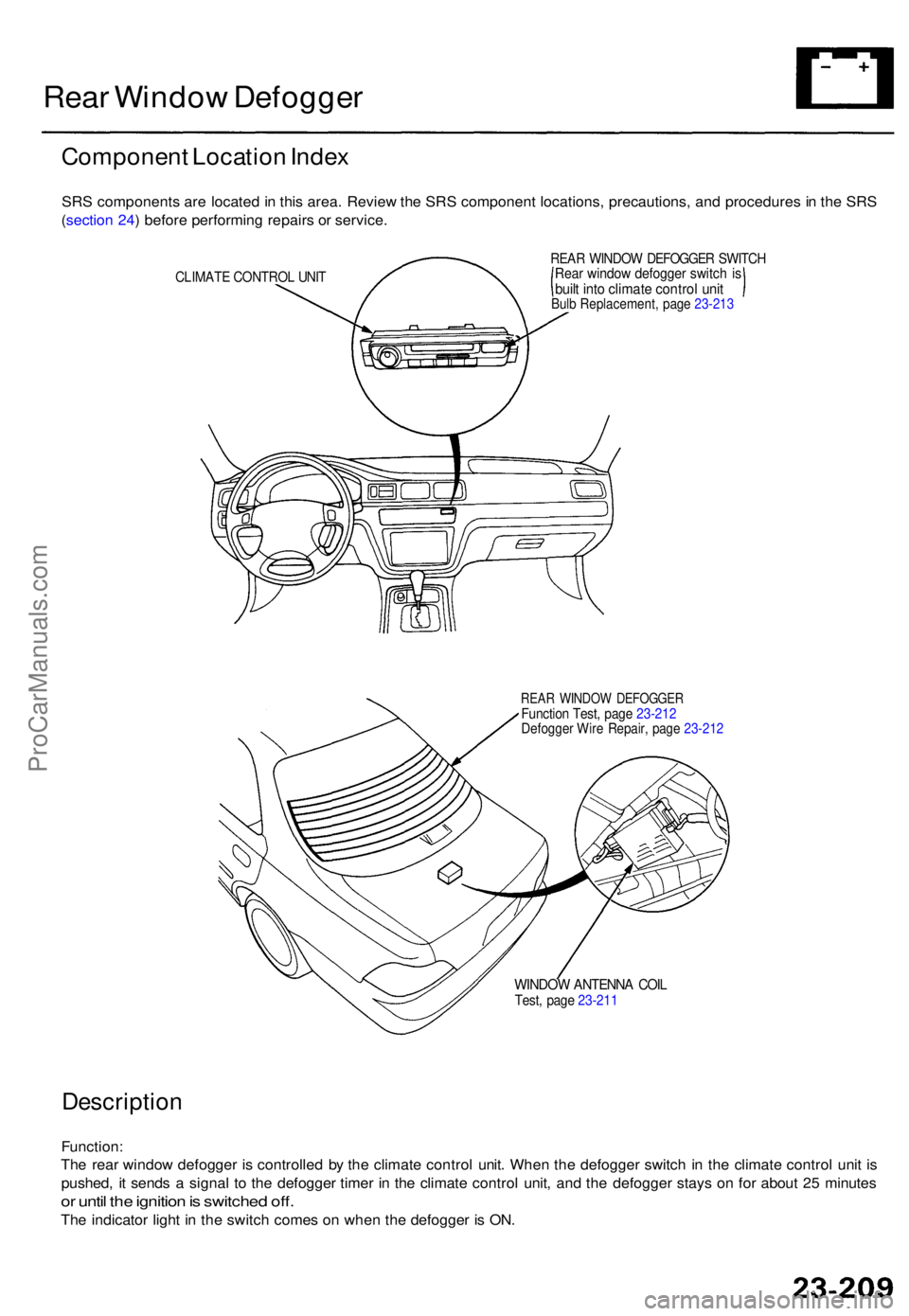

Componen t Locatio n Inde x

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

CLIMAT E CONTRO L UNI T

REA R WINDO W DEFOGGE R SWITC HRear windo w defogge r switc h i sbuil t int o climat e contro l uni tBulb Replacement , pag e 23-21 3

REAR WINDO W DEFOGGE RFunction Test , pag e 23-21 2Defogge r Wir e Repair , pag e 23-21 2

WINDO W ANTENN A COI LTest , pag e 23-21 1

Descriptio n

Function:

Th e rea r windo w defogge r i s controlle d b y th e climat e contro l unit . Whe n th e defogge r switc h i n th e climat e contro l uni t i s

pushed , i t send s a signa l t o th e defogge r time r i n th e climat e contro l unit , an d th e defogge r stay s o n fo r abou t 2 5 minute s

or unti l th e ignitio n is switche d off .

The indicato r ligh t i n th e switc h come s o n whe n th e defogge r i s ON .

ProCarManuals.com

Page 1673 of 1771

Rear Windo w Defogge r

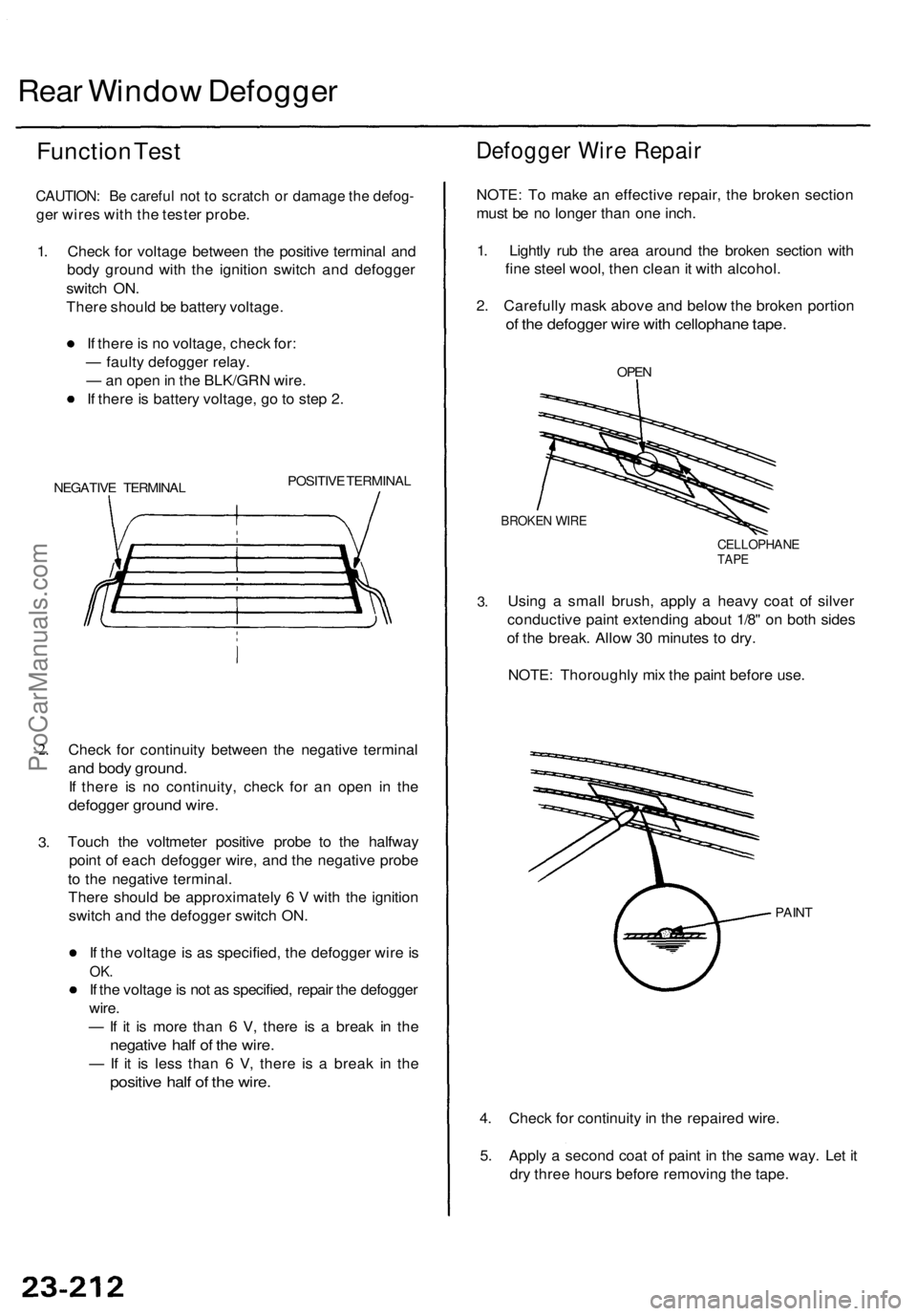

Function Tes t

CAUTION : B e carefu l no t t o scratc h o r damag e th e defog -

ger wire s wit h th e teste r probe .

1 . Chec k fo r voltag e betwee n th e positiv e termina l an d

bod y groun d wit h th e ignitio n switc h an d defogge r

switc h ON .

Ther e shoul d b e batter y voltage .

I f ther e is n o voltage , chec k for :

— fault y defogge r relay .

— an ope n in th e BLK/GR N wire .

I f ther e is batter y voltage , g o to ste p 2 .

NEGATIV E TERMINA L POSITIV

E TERMINA L

2.

3 .

Chec k fo r continuit y betwee n th e negativ e termina l

and bod y ground .

If ther e i s n o continuity , chec k fo r a n ope n i n th e

defogge r groun d wire .

Touc h th e voltmete r positiv e prob e t o th e halfwa y

poin t o f eac h defogge r wire , an d th e negativ e prob e

t o th e negativ e terminal .

Ther e shoul d b e approximatel y 6 V with th e ignitio n

switc h an d th e defogge r switc h ON .

I f th e voltag e is a s specified , th e defogge r wir e is

OK .

If th e voltag e is no t a s specified , repai r th e defogge r

wire .

— If i t i s mor e tha n 6 V , ther e i s a brea k i n th e

negativ e hal f o f th e wire .

— If i t i s les s tha n 6 V , ther e i s a brea k i n th e

positiv e hal f o f th e wire .

Defogge r Wir e Repai r

NOTE: T o mak e a n effectiv e repair , th e broke n sectio n

mus t b e n o longe r tha n on e inch .

1 . Lightl y ru b th e are a aroun d th e broke n sectio n wit h

fin e stee l wool , the n clea n it wit h alcohol .

2 . Carefull y mas k abov e an d belo w th e broke n portio n

of th e defogge r wir e wit h cellophan e tape .

OPEN

BROKE N WIR E

CELLOPHAN ETAPE

3.Usin g a smal l brush , apply a heav y coa t o f silve r

conductiv e pain t extendin g abou t 1/8 " o n bot h side s

o f th e break . Allo w 3 0 minute s t o dry .

NOTE : Thoroughl y mi x th e pain t befor e use .

PAIN T

4. Chec k fo r continuit y in th e repaire d wire .

5 . Appl y a secon d coa t o f pain t i n th e sam e way . Le t i t

dr y thre e hour s befor e removin g th e tape .

ProCarManuals.com