Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1584 of 1771

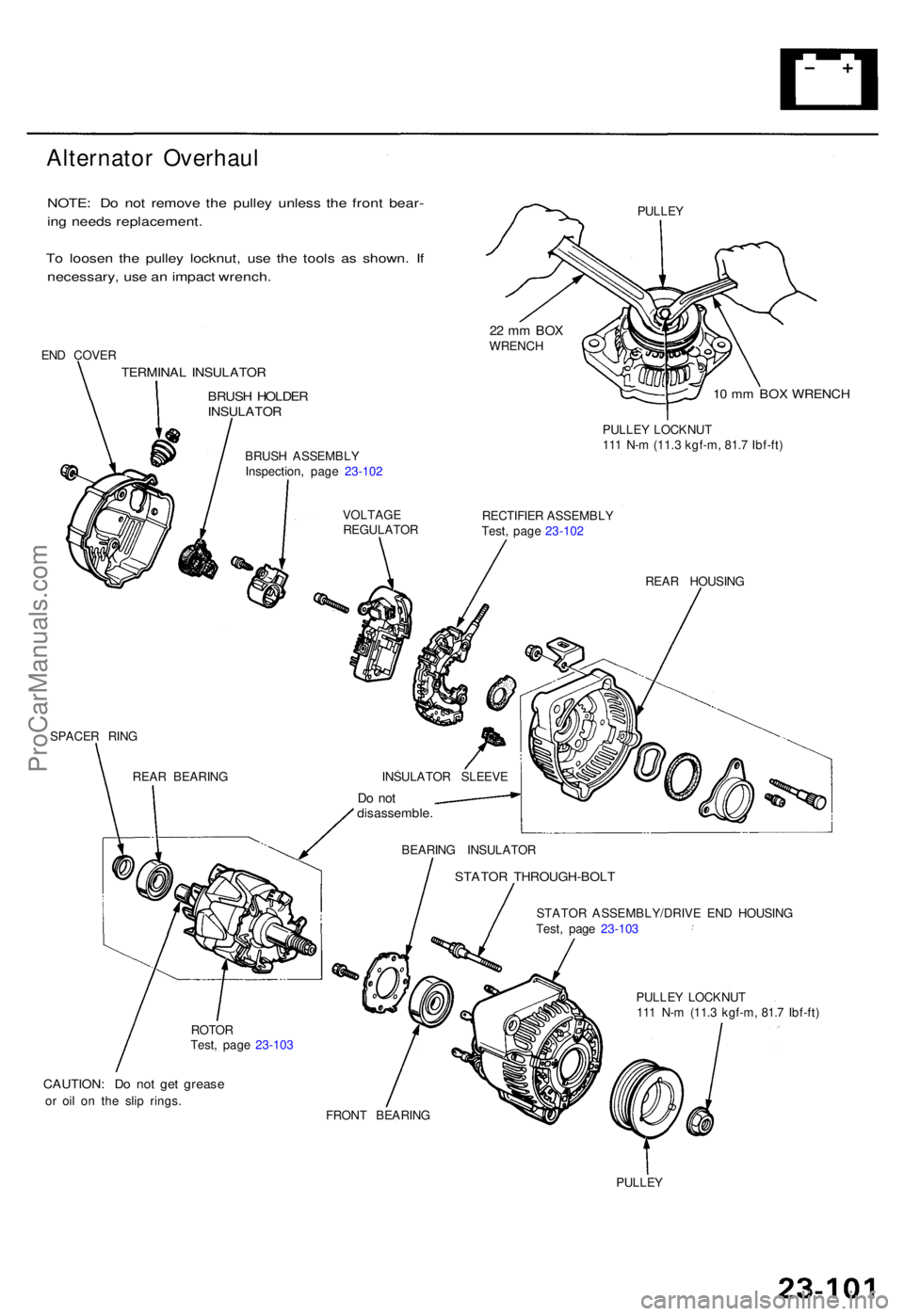

Alternator Overhau l

NOTE: D o no t remov e th e pulle y unles s th e fron t bear -

in g need s replacement .

T o loose n th e pulle y locknut , us e th e tool s a s shown . I f

necessary , us e a n impac t wrench .

END COVE R

TERMINA L INSULATO R

BRUSH HOLDE RINSULATO R

BRUSH ASSEMBL Y

Inspection , pag e 23-10 2

VOLTAG E

REGULATO R

SPACER RIN G

REA R BEARIN G PULLE

Y

22 m m BO XWRENC H

10 m m BO X WRENC H

PULLEY LOCKNU T

11 1 N- m (11. 3 kgf-m , 81. 7 Ibf-ft )

RECTIFIE R ASSEMBL Y

Test , pag e 23-10 2

REAR HOUSIN G

Do no tdisassemble .

BEARING INSULATO R

STATOR THROUGH-BOL T

STATOR ASSEMBLY/DRIV E EN D HOUSIN G

Test , pag e 23-10 3

PULLE Y LOCKNU T

11 1 N- m (11. 3 kgf-m , 81. 7 Ibf-ft )

CAUTION : D o no t ge t greas e

or oi l o n th e sli p rings .

FRONT BEARIN G

PULLEY

ROTO

R

Test , pag e 23-10 3 INSULATO

R SLEEV E

ProCarManuals.com

Page 1585 of 1771

Charging System

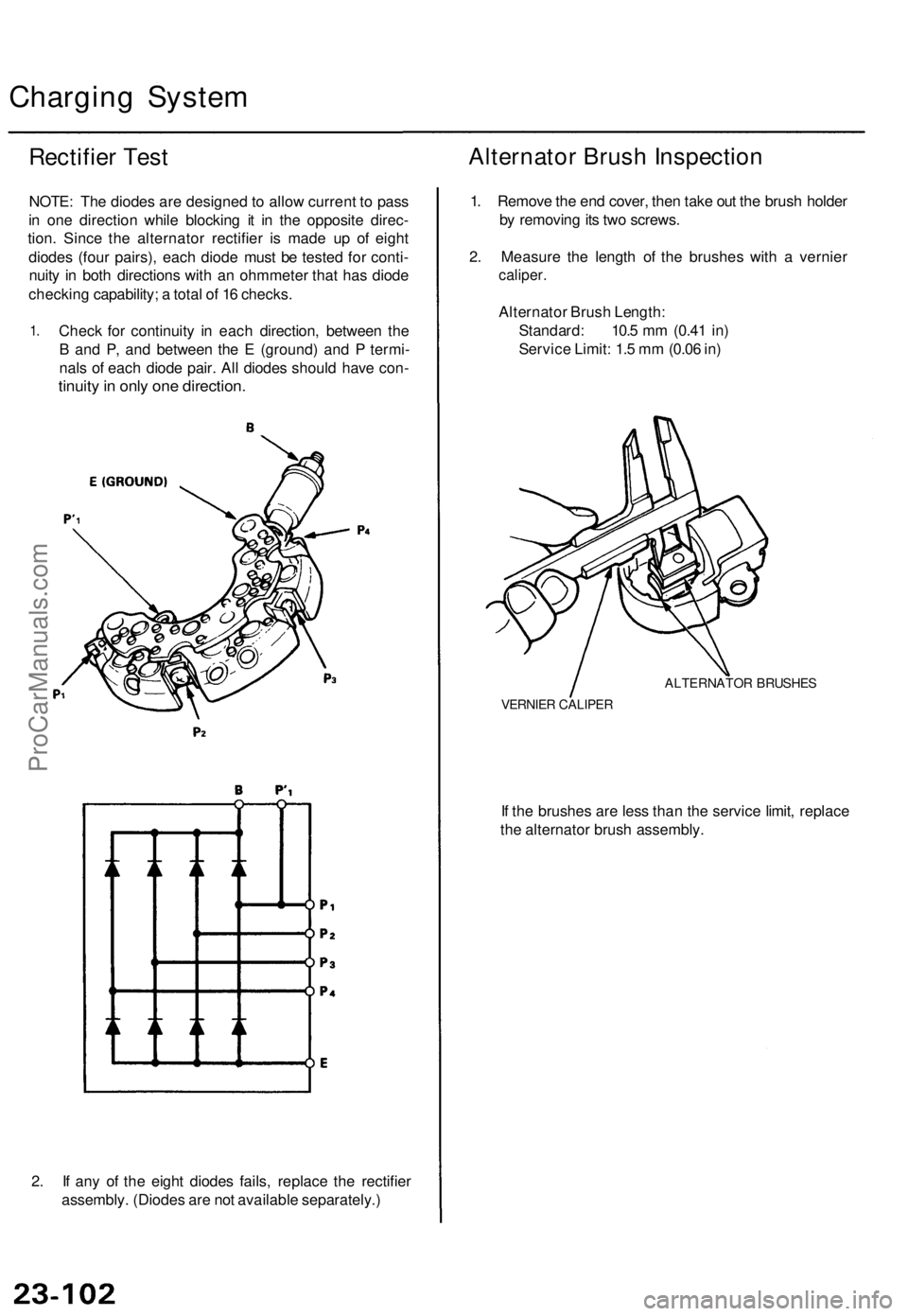

Rectifier Test

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-

tion. Since the alternator rectifier is made up of eight

diodes (four pairs), each diode must be tested for conti-

nuity in both directions with an ohmmeter that has diode

checking capability; a total of 16 checks.

1.

Check for continuity in each direction, between the

B and P, and between the E (ground) and P termi-

nals of each diode pair. All diodes should have con-

tinuity in only one direction.

2. If any of the eight diodes fails, replace the rectifier

assembly. (Diodes are not available separately.)

Alternator Brush Inspection

1. Remove the end cover, then take out the brush holder

by removing its two screws.

2. Measure the length of the brushes with a vernier

caliper.

Alternator Brush Length:

Standard: 10.5 mm (0.41 in)

Service Limit: 1.5 mm (0.06 in)

ALTERNATOR BRUSHES

VERNIER CALIPER

If the brushes are less than the service limit, replace

the alternator brush assembly.ProCarManuals.com

Page 1586 of 1771

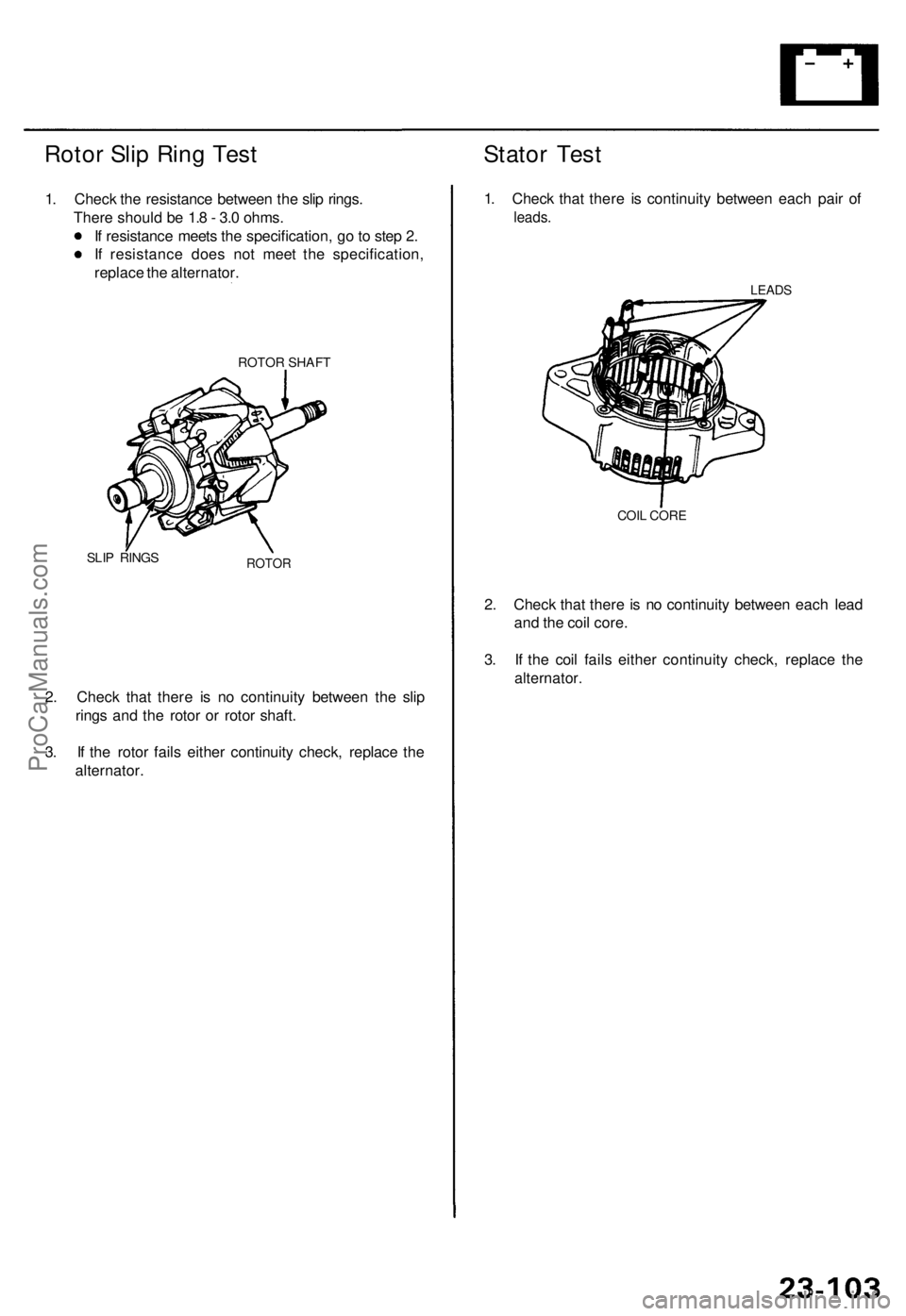

Rotor Slip Ring Test

1. Check the resistance between the slip rings.

There should be 1.8 - 3.0 ohms.

If resistance meets the specification, go to step 2.

If resistance does not meet the specification,

replace the alternator.

ROTOR SHAFT

SLIP RINGS

ROTOR

2. Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

3. If the rotor fails either continuity check, replace the

alternator.

Stator Test

1. Check that there is continuity between each pair of

leads.

LEADS

COIL CORE

2. Check that there is no continuity between each lead

and the coil core.

3. If the coil fails either continuity check, replace the

alternator.ProCarManuals.com

Page 1589 of 1771

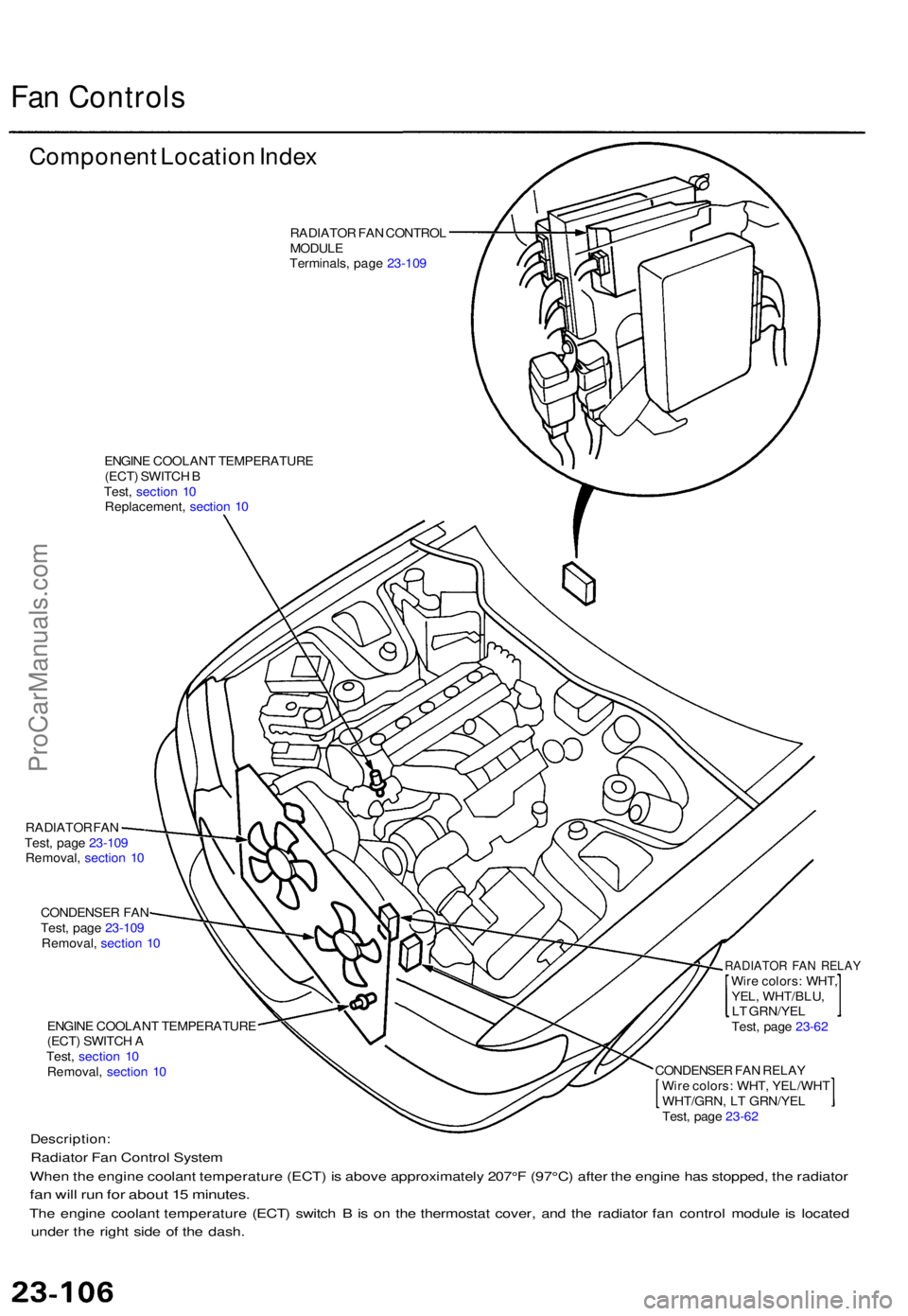

Fan Control s

Componen t Locatio n Inde x

RADIATO R FA N CONTRO L

MODUL E

Terminals , pag e 23-10 9

ENGIN E COOLAN T TEMPERATUR E

(ECT ) SWITC H B

Test , sectio n 1 0

Replacement , sectio n 1 0

RADIATO R FA N

Test , pag e 23-10 9

Removal , sectio n 1 0

CONDENSE R FA N

Test , pag e 23-10 9

Removal , sectio n 1 0

ENGIN E COOLAN T TEMPERATUR E

(ECT ) SWITC H A

Test , sectio n 1 0

Removal , sectio n 1 0

RADIATO R FA N RELA YWire colors : WHT ,

YEL , WHT/BLU ,

L T GRN/YE L

Test , pag e 23-6 2

Description :

Radiator Fa n Contro l Syste m

Whe n th e engin e coolan t temperatur e (ECT ) i s abov e approximatel y 207° F (97°C ) afte r th e engin e ha s stopped , th e radiato r

fan wil l ru n fo r abou t 1 5 minutes .

The engin e coolan t temperatur e (ECT ) switc h B is o n th e thermosta t cover , an d th e radiato r fa n contro l modul e is locate d

unde r th e righ t sid e o f th e dash .

CONDENSE R FA N RELA Y

Wir e colors : WHT , YEL/WH T

WHT/GRN , L T GRN/YE L

Test , pag e 23-6 2

ProCarManuals.com

Page 1591 of 1771

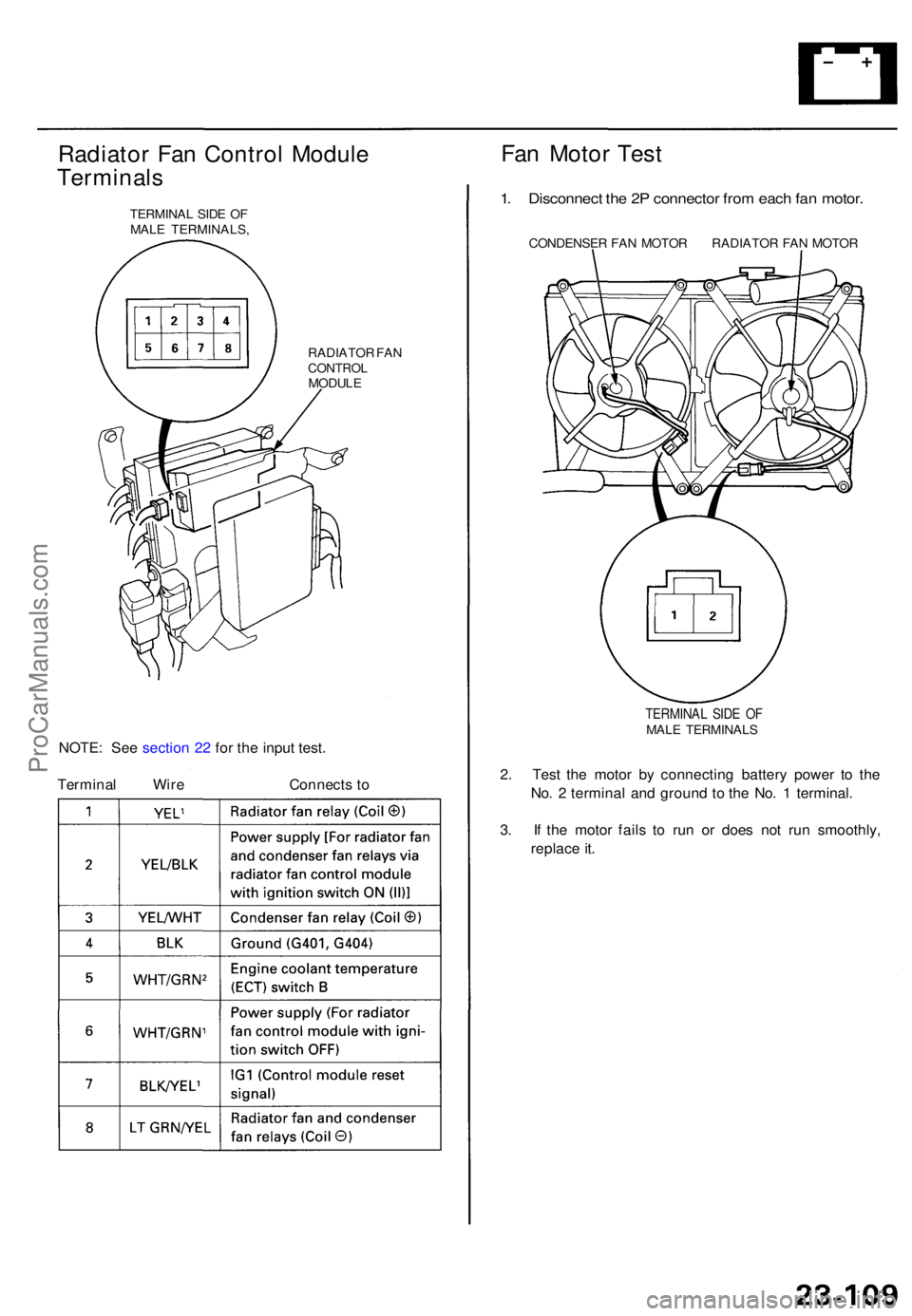

Radiator Fa n Contro l Modul e

Terminal s

TERMINA L SID E O F

MAL E TERMINALS ,

Fan Moto r Tes t

RADIATO R FA NCONTRO LMODULE

NOTE: Se e sectio n 2 2 fo r th e inpu t test .

Termina lWire Connects to

1. Disconnec t th e 2 P connecto r fro m eac h fa n motor .

CONDENSE R FA N MOTO R RADIATO R FA N MOTO R

TERMINA L SID E O FMAL E TERMINAL S

2. Tes t th e moto r b y connectin g batter y powe r t o th e

No . 2 termina l an d groun d t o th e No . 1 terminal .

3 . I f th e moto r fail s t o ru n o r doe s no t ru n smoothly ,

replac e it .

ProCarManuals.com

Page 1592 of 1771

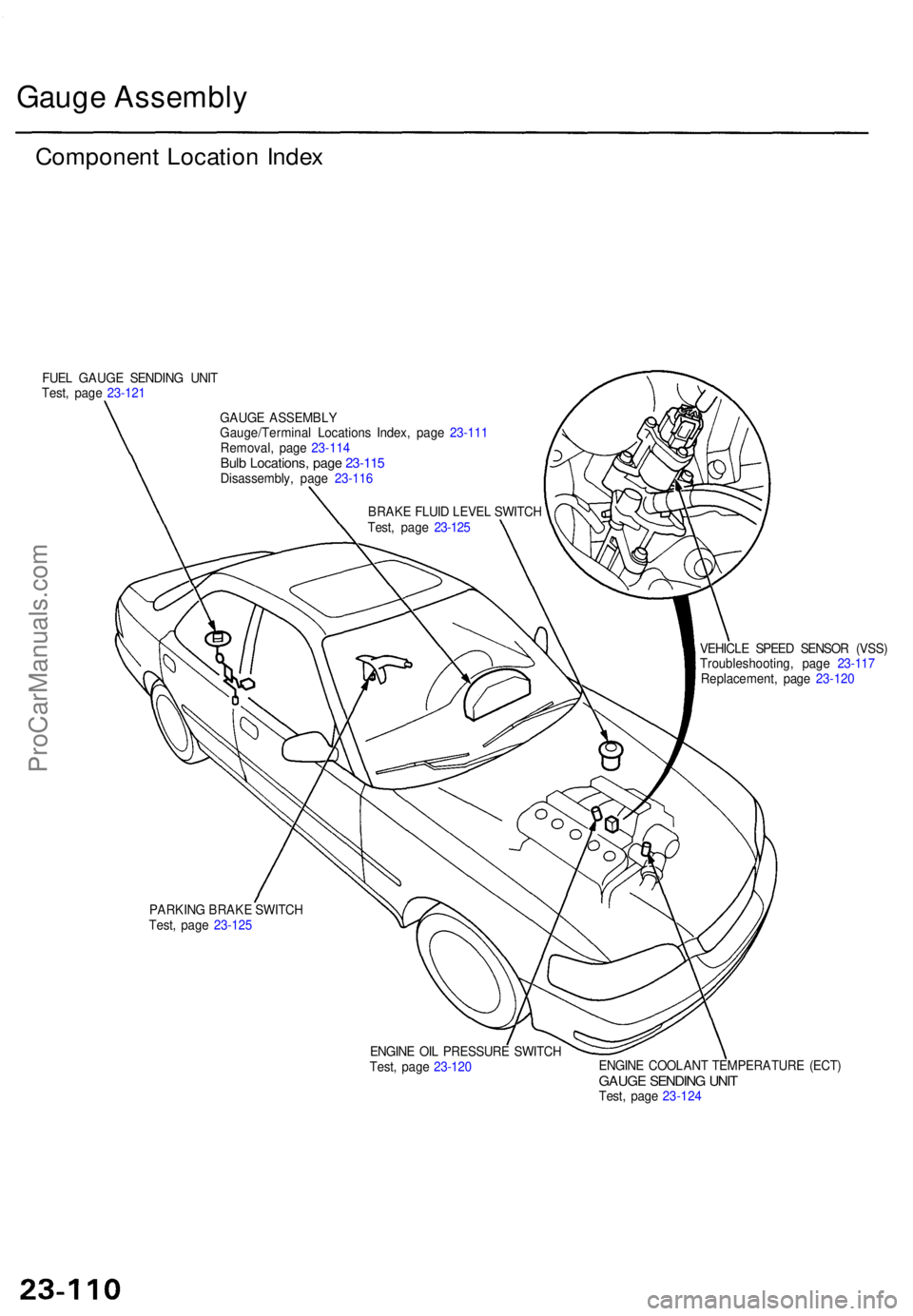

Gauge Assembl y

Componen t Locatio n Inde x

FUEL GAUG E SENDIN G UNI T

Test , pag e 23-12 1

VEHICLE SPEE D SENSO R (VSS )

Troubleshooting , pag e 23-11 7

Replacement , pag e 23-12 0

PARKIN G BRAK E SWITC H

Test , pag e 23-12 5

ENGINE OI L PRESSUR E SWITC H

Test , pag e 23-12 0 ENGIN

E COOLAN T TEMPERATUR E (ECT )

GAUG E SENDIN G UNI TTest , pag e 23-12 4

BRAK

E FLUI D LEVE L SWITC H

Test , pag e 23-12 5

GAUG

E ASSEMBL Y

Gauge/Termina l Location s Index , pag e 23-11 1

Removal , pag e 23-11 4

Bulb Locations , pag e 23-11 5Disassembly , pag e 23-11 6

ProCarManuals.com

Page 1593 of 1771

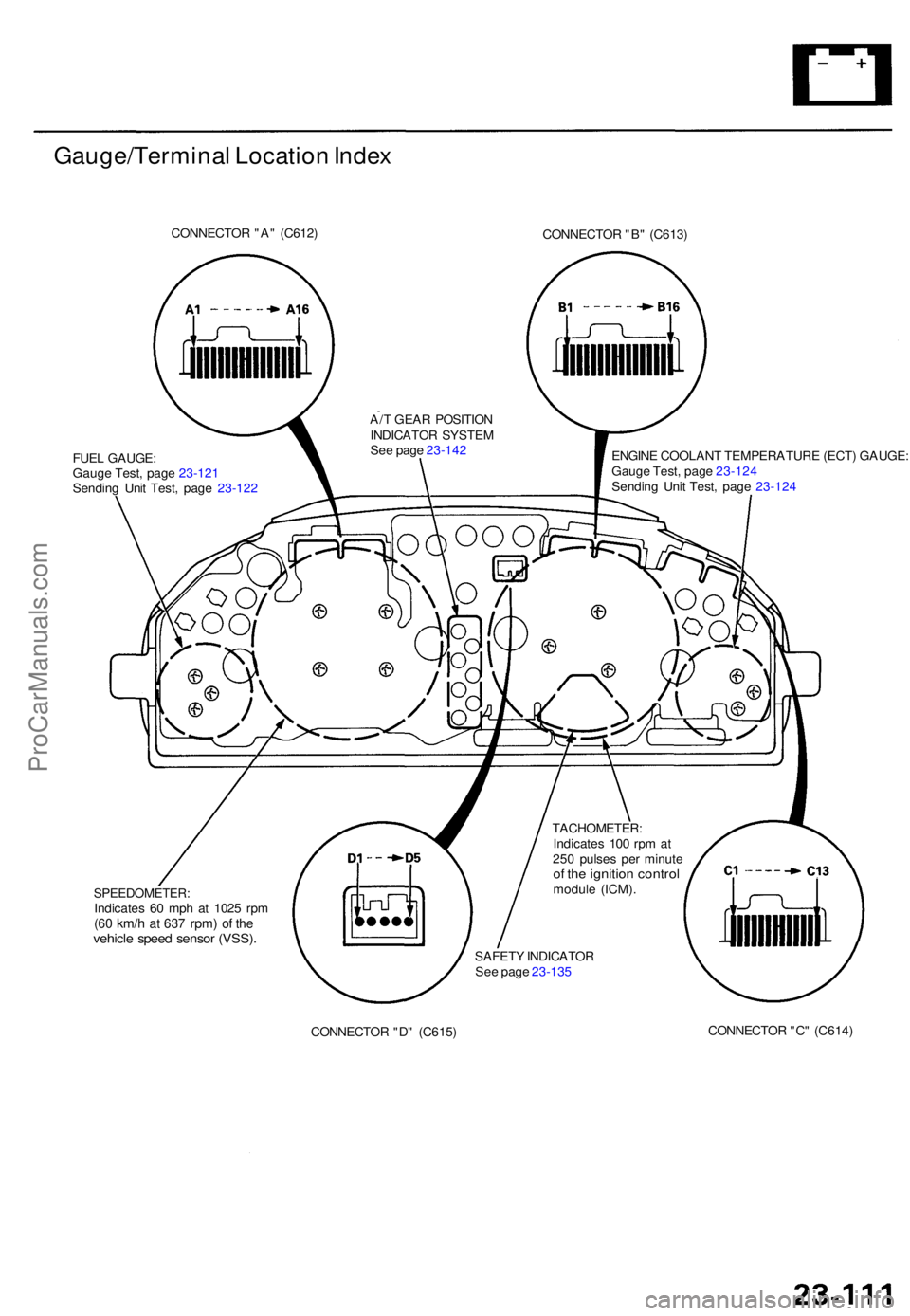

Gauge/Terminal Locatio n Inde x

CONNECTO R "A " (C612 )

CONNECTOR "B " (C613 )

FUE L GAUGE :

Gaug e Test , pag e 23-12 1

Sendin g Uni t Test , pag e 23-12 2 ENGIN

E COOLAN T TEMPERATUR E (ECT ) GAUGE :

Gaug e Test , pag e 23-12 4

Sendin g Uni t Test , pag e 23-12 4

SPEEDOMETER :Indicates 6 0 mp h a t 102 5 rp m(60 km/ h at 63 7 rpm ) of th evehicl e spee d senso r (VSS) .

CONNECTO R "D " (C615 ) CONNECTO

R "C " (C614 )

SAFET

Y INDICATO R

Se e pag e 23-13 5

TACHOMETER :Indicates 10 0 rp m a t

25 0 pulse s pe r minut e

of th e ignitio n contro lmodule (ICM) .

A/

T GEA R POSITIO N

INDICATO R SYSTE M

Se e pag e 23-14 2

ProCarManuals.com

Page 1596 of 1771

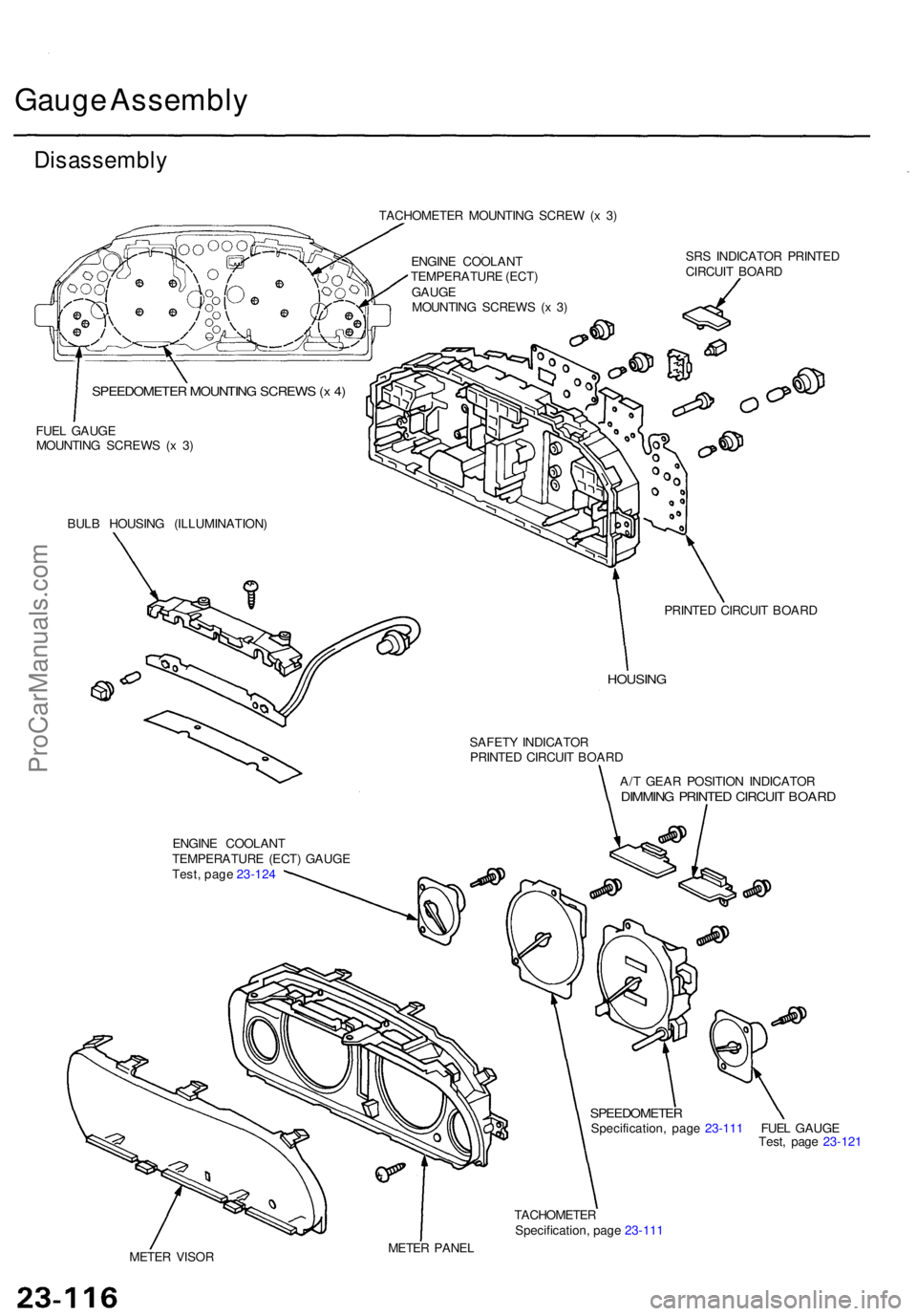

Gauge Assembl y

Disassembl y

TACHOMETE R MOUNTIN G SCRE W (x 3 )

ENGIN E COOLAN T

TEMPERATUR E (ECT )

GAUG E

MOUNTIN G SCREW S ( x 3 ) SR

S INDICATO R PRINTE D

CIRCUI T BOAR D

SPEEDOMETE R MOUNTIN G SCREW S (x 4 )

FUE L GAUG E

MOUNTIN G SCREW S ( x 3 )

BUL B HOUSIN G (ILLUMINATION )

PRINTED CIRCUI T BOAR D

HOUSIN G

SAFETY INDICATO R

PRINTE D CIRCUI T BOAR D

A/ T GEA R POSITIO N INDICATO R

DIMMING PRINTE D CIRCUI T BOAR D

ENGINE COOLAN T

TEMPERATUR E (ECT ) GAUG E

Test , pag e 23-12 4

SPEEDOMETE RSpecification, pag e 23-11 1 FUE L GAUG E

Test , pag e 23-12 1

TACHOMETE R

Specification, page 23-111

METE R VISO R METE

R PANE L

ProCarManuals.com

Page 1597 of 1771

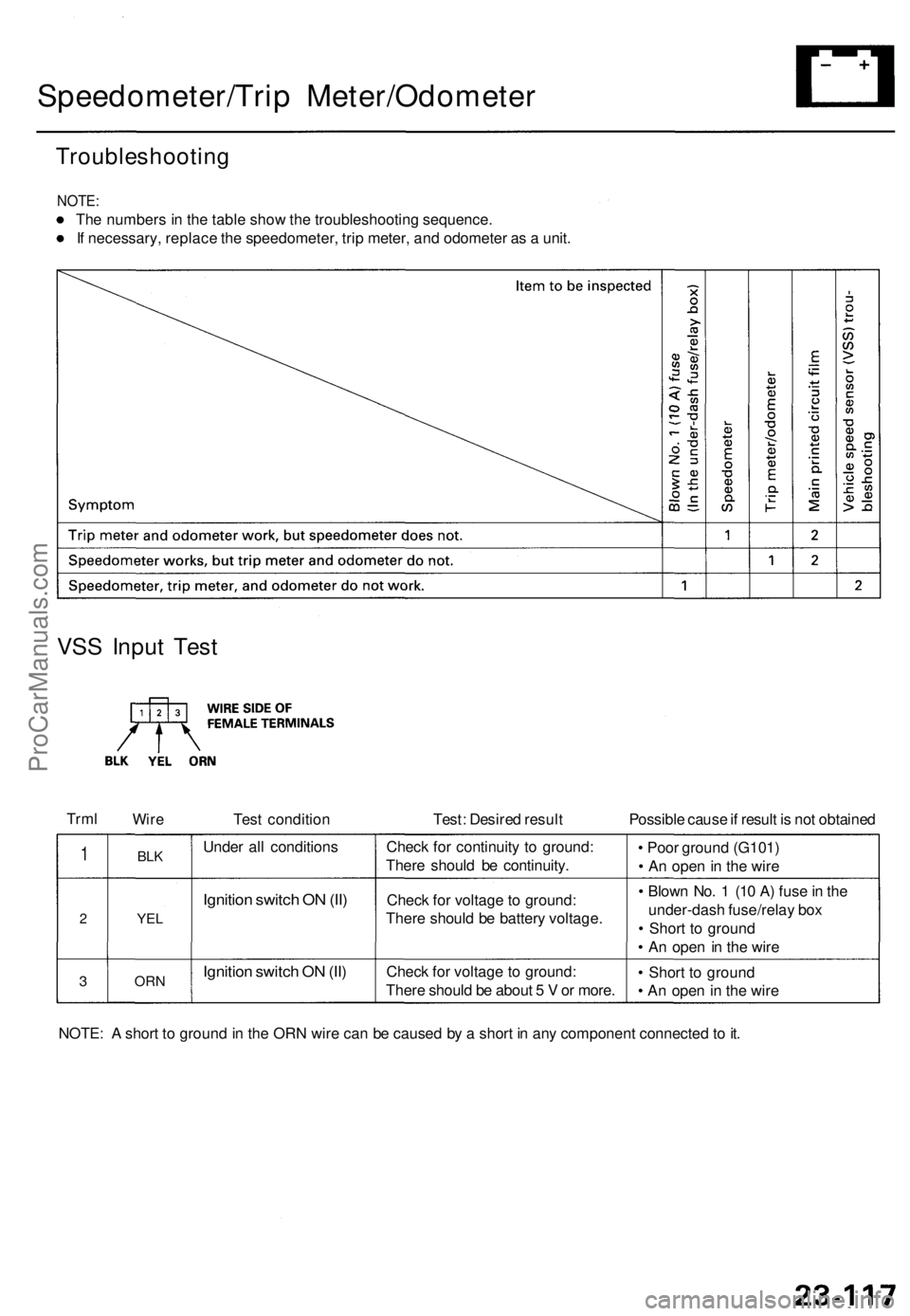

Speedometer/Trip Meter/Odometer

Troubleshooting

NOTE:

The numbers in the table show the troubleshooting sequence.

If necessary, replace the speedometer, trip meter, and odometer as a unit.

VSS Input Test

Trml

Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

1

2

3

BLK

YEL

ORN

Under all conditions

Ignition switch ON (II)

Ignition switch ON (II)

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be about 5 V or more.

• Poor ground (G101)

• An open in the wire

• Blown No. 1 (10 A) fuse in the

under-dash fuse/relay box

• Short to ground

• An open in the wire

• Short to ground

• An open in the wire

NOTE: A short to ground in the ORN wire can be caused by a short in any component connected to it.ProCarManuals.com

Page 1598 of 1771

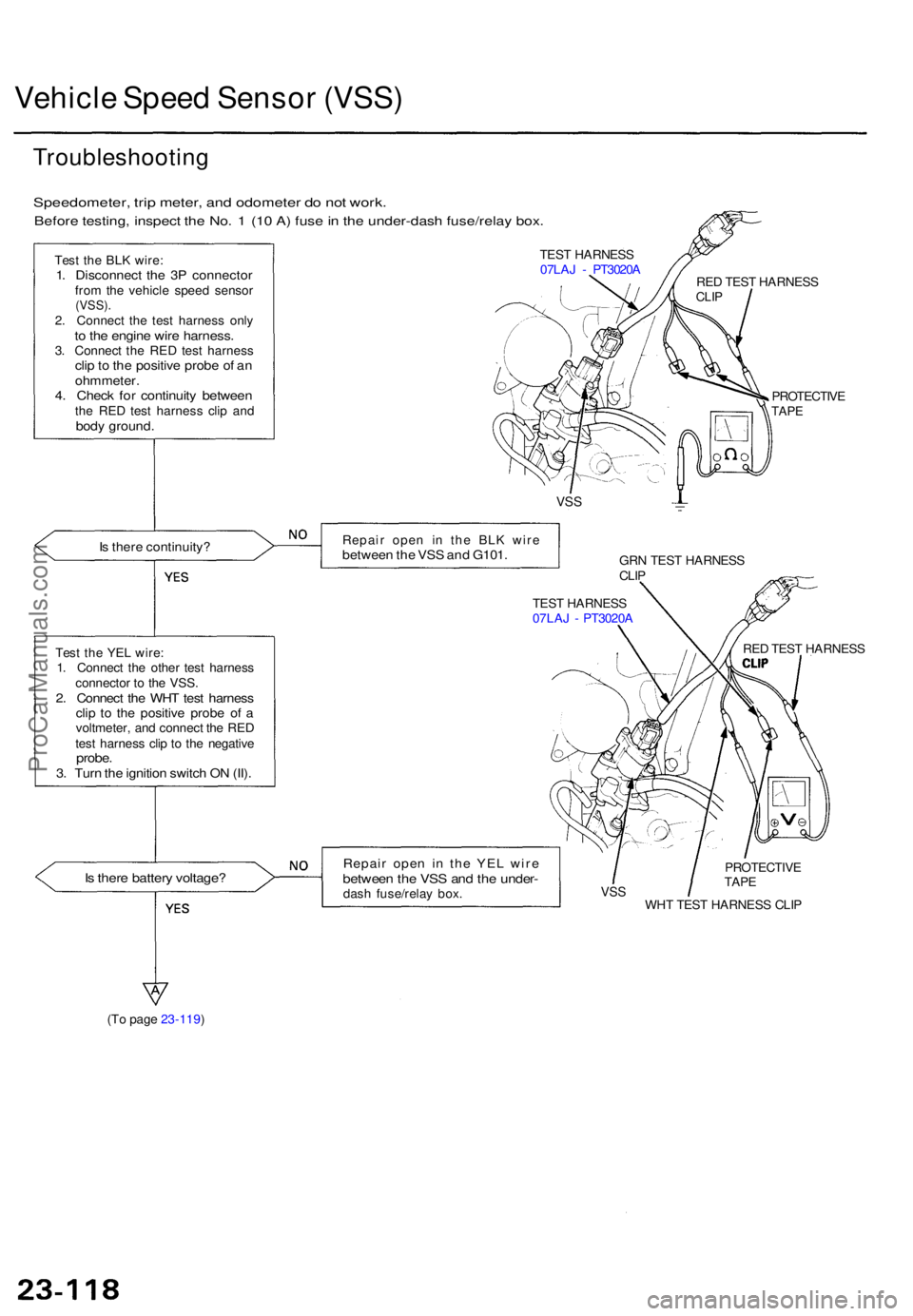

Vehicle Spee d Senso r (VSS )

Troubleshootin g

Speedometer, tri p meter , an d odomete r d o no t work .

Befor e testing , inspec t th e No . 1 (1 0 A ) fus e in th e under-das h fuse/rela y box .

TEST HARNES S

07LA J - PT3020 A

RED TES T HARNES S

CLIP

PROTECTIV ETAPE

VSS

Is ther e continuity ?Repair ope n i n th e BL K wir ebetwee n th e VS S an d G101 .GRN TES T HARNES S

CLI P

TES T HARNES S

07LA J - PT3020 A

Tes t th e YE L wire :

1 . Connec t th e othe r tes t harnes s

connecto r t o th e VSS .

2. Connec t th e WH T tes t harnes sclip t o th e positiv e prob e o f avoltmeter , an d connec t th e RE D

tes t harnes s cli p t o th e negativ e

probe.3. Tur n th e ignitio n switc h O N (II) .

RED TES T HARNES S

Is ther e batter y voltage ?Repair ope n i n th e YE L wir ebetwee n th e VS S an d th e under -dash fuse/rela y box .VSS

PROTECTIV ETAPE

WH T TES T HARNES S CLI P

(T o pag e 23-119 )

Tes

t th e BL K wire :

1. Disconnec t th e 3 P connecto rfrom th e vehicl e spee d senso r(VSS).2. Connec t th e tes t harnes s onl yto th e engin e wir e harness .3. Connec t th e RE D tes t harnes sclip to th e positiv e prob e o f a nohmmeter .4. Chec k fo r continuit y betwee nthe RE D tes t harnes s cli p an dbod y ground .

ProCarManuals.com