Test ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1601 of 1771

Fuel Gaug e

Gauge Tes t

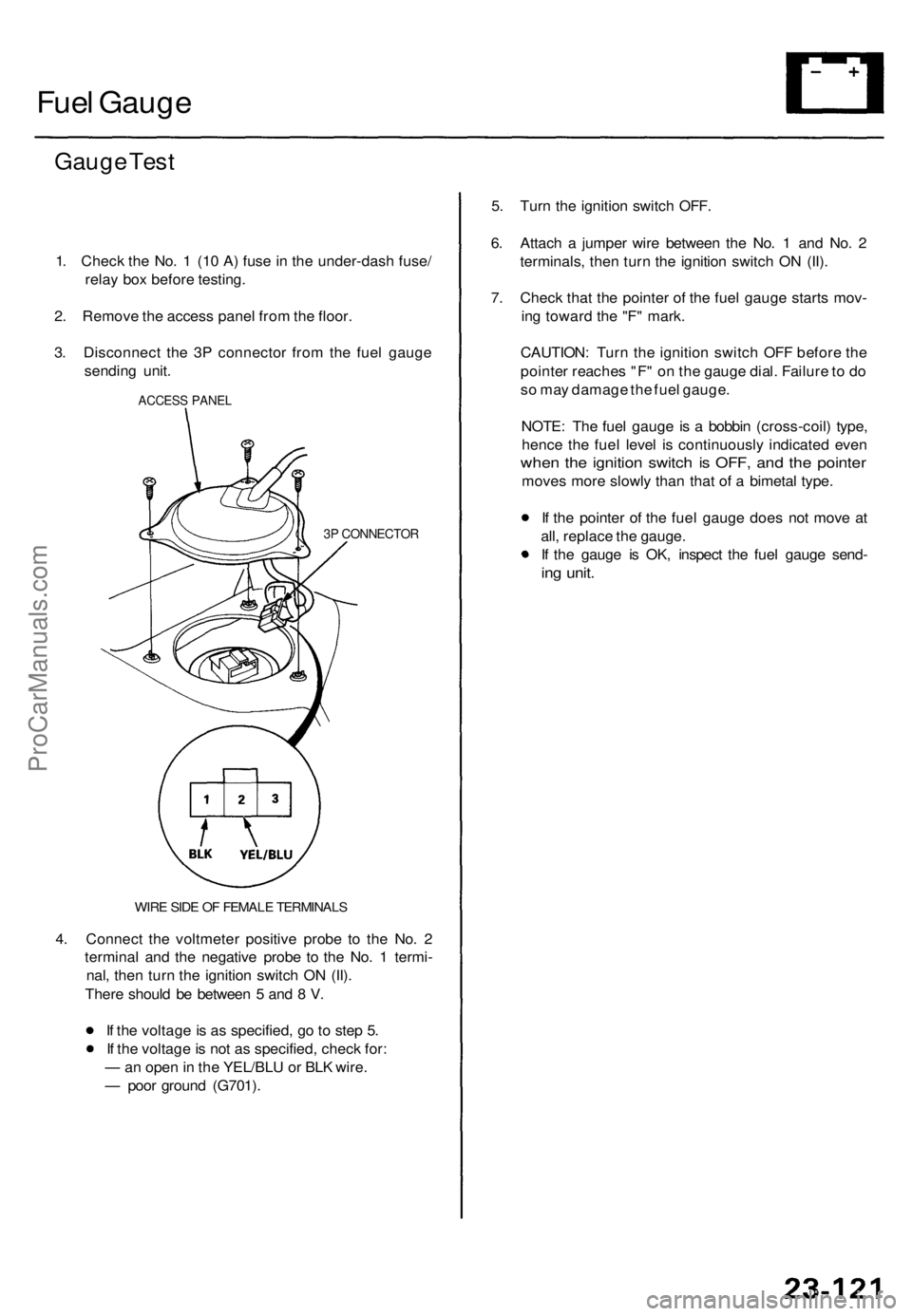

1. Chec k th e No . 1 (1 0 A ) fus e in th e under-das h fuse /

rela y bo x befor e testing .

2 . Remov e th e acces s pane l fro m th e floor .

3 . Disconnec t th e 3 P connecto r fro m th e fue l gaug e

sendin g unit .

ACCES S PANE L

3P CONNECTO R

WIRE SID E O F FEMAL E TERMINAL S

4. Connec t th e voltmete r positiv e prob e t o th e No . 2

termina l an d th e negativ e prob e t o th e No . 1 termi -

nal , the n tur n th e ignitio n switc h O N (II) .

Ther e shoul d b e betwee n 5 an d 8 V .

I f th e voltag e is a s specified , g o to ste p 5 .

I f th e voltag e is no t a s specified , chec k for :

— an ope n in th e YEL/BL U o r BL K wire .

— poo r groun d (G701) . 5

. Tur n th e ignitio n switc h OFF .

6 . Attac h a jumpe r wir e betwee n th e No . 1 an d No . 2

terminals , the n tur n th e ignitio n switc h O N (II) .

7 . Chec k tha t th e pointe r o f th e fue l gaug e start s mov -

in g towar d th e "F " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s "F " o n th e gaug e dial . Failur e to d o

s o ma y damag e th e fue l gauge .

NOTE : Th e fue l gaug e is a bobbi n (cross-coil ) type ,

henc e th e fue l leve l i s continuousl y indicate d eve n

when th e ignitio n switc h i s OFF , an d th e pointe r

moves mor e slowl y tha n tha t o f a bimeta l type .

I f th e pointe r o f th e fue l gaug e doe s no t mov e a t

all , replac e th e gauge .

I f th e gaug e i s OK , inspec t th e fue l gaug e send -

ing unit .

ProCarManuals.com

Page 1603 of 1771

Low Fue l Indicato r Syste m

Indicato r Ligh t Tes t

1. Chec k th e No . 1 (1 0 A ) fus e i n th e under-das h fuse /

rela y bo x befor e testing .

2 . Par k th e ca r o n leve l ground .

D o no t smok e whil e workin g o n th e

fue l system . Kee p ope n flam e awa y fro m th e wor k

area . Drai n fue l onl y int o a n approve d container .

3 . Drai n th e fue l int o a n approve d container . The n

instal l th e drai n bol t wit h a ne w washer .

4. Ad d les s tha n 8. 5 (2. 2 U.S.Gal , 1. 8 Imp . Gal ) o f fuel ,

and tur n th e ignitio n switc h O N (II) . Th e low fuel

indicato r ligh t shoul d com e o n withi n fou r minutes .

LOW FUE L INDICATO R LIGH T

If th e ligh t come s o n withi n fou r minutes , g o t o

ste p 7 .

I f th e ligh t doe s no t com e o n withi n fou r min -

utes , g o t o ste p 5 .

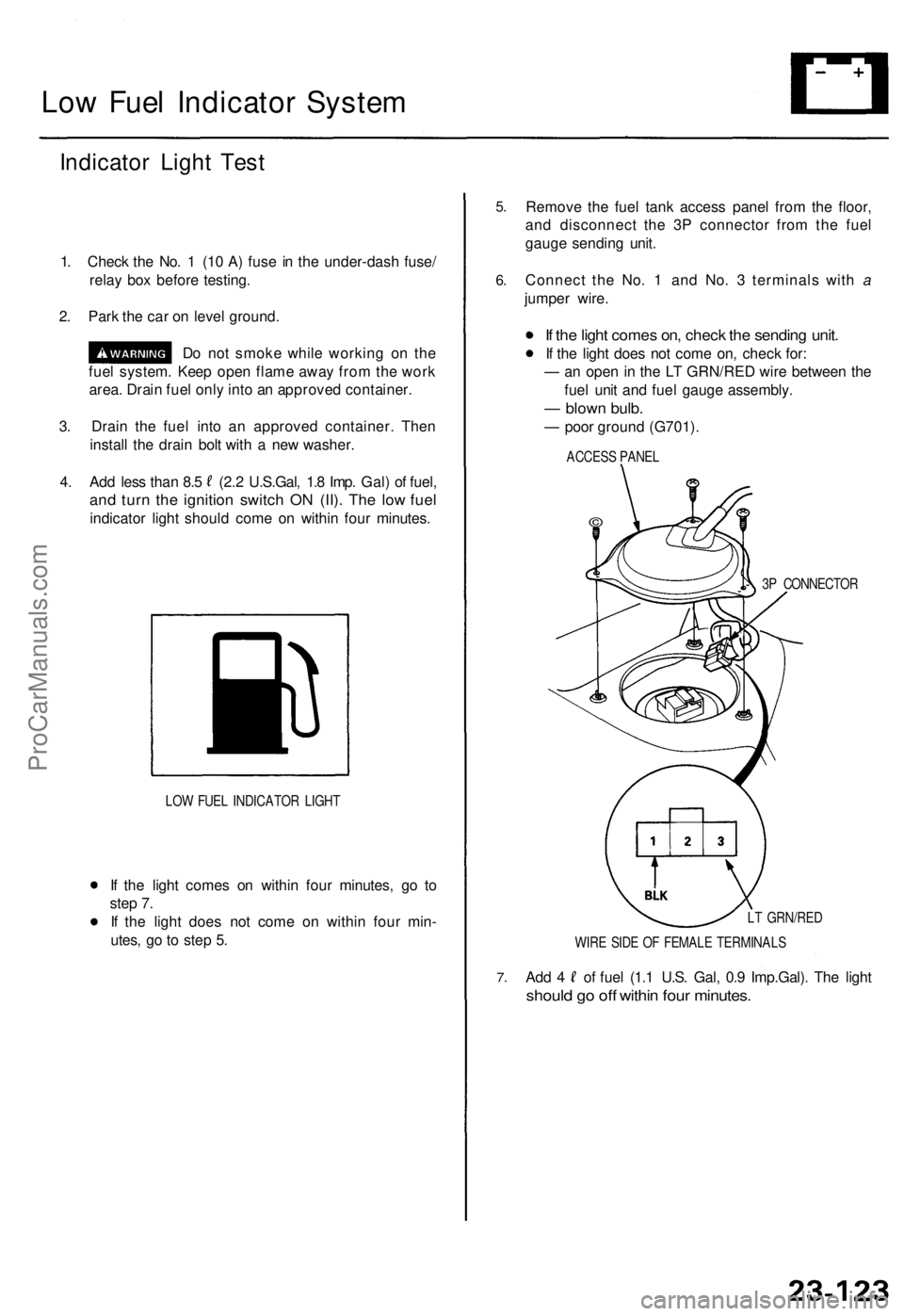

5.

6.

Remov e th e fue l tan k acces s pane l fro m th e floor ,

an d disconnec t th e 3 P connecto r fro m th e fue l

gaug e sendin g unit .

Connec t th e No . 1 an d No . 3 terminal s wit h a

jumpe r wire .

If th e ligh t come s on , chec k th e sendin g unit .

If th e ligh t doe s no t com e on , chec k for :

— an ope n i n th e L T GRN/RE D wir e betwee n th e

fue l uni t an d fue l gaug e assembly .

— blow n bulb .

— poo r groun d (G701) .

ACCESS PANE L

©

3P CONNECTO R

7.

L T GRN/RE D

WIR E SID E O F FEMAL E TERMINAL S

Add 4 o f fue l (1. 1 U.S . Gal , 0. 9 Imp.Gal) . Th e ligh t

shoul d g o of f withi n fou r minutes .

ProCarManuals.com

Page 1604 of 1771

Engine Coolan t Temperatur e (ECT ) Gaug e

Gauge Tes t

1. Chec k th e No . 1 (1 0 A ) fus e in th e under-das h fuse /

rela y bo x befor e testing .

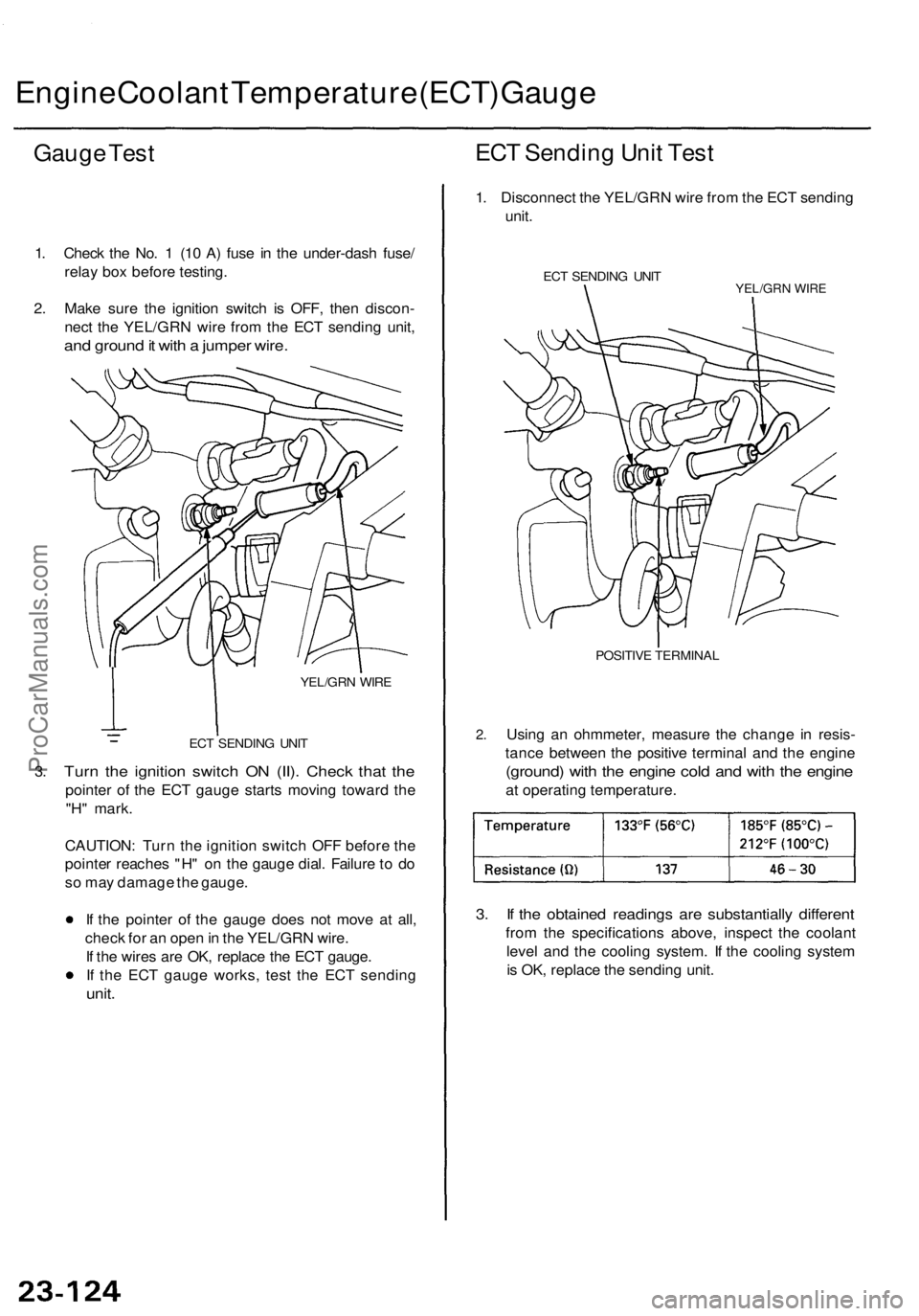

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e EC T sendin g unit ,

and groun d it wit h a jumpe r wire .

3.

YEL/GR N WIR E

EC T SENDIN G UNI T

Turn th e ignitio n switc h O N (II) . Chec k tha t th e

pointe r o f th e EC T gaug e start s movin g towar d th e

"H " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s "H " o n th e gaug e dial . Failur e t o d o

s o ma y damag e th e gauge .

I f th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k fo r a n ope n in th e YEL/GR N wire .

I f th e wire s ar e OK , replac e th e EC T gauge .

I f th e EC T gaug e works , tes t th e EC T sendin g

unit.

ECT Sendin g Uni t Tes t

1. Disconnec t th e YEL/GR N wir e fro m th e EC T sendin g

unit .

ECT SENDIN G UNI TYEL/GR N WIR E

2.

POSITIV E TERMINA L

Using a n ohmmeter , measur e th e chang e i n resis -

tanc e betwee n th e positiv e termina l an d th e engin e

(ground ) wit h th e engin e col d an d wit h th e engin e

at operatin g temperature .

3. I f th e obtaine d reading s ar e substantiall y differen t

from th e specification s above , inspec t th e coolan t

leve l an d th e coolin g system . I f th e coolin g syste m

i s OK , replac e th e sendin g unit .

ProCarManuals.com

Page 1605 of 1771

Brake System Indicator

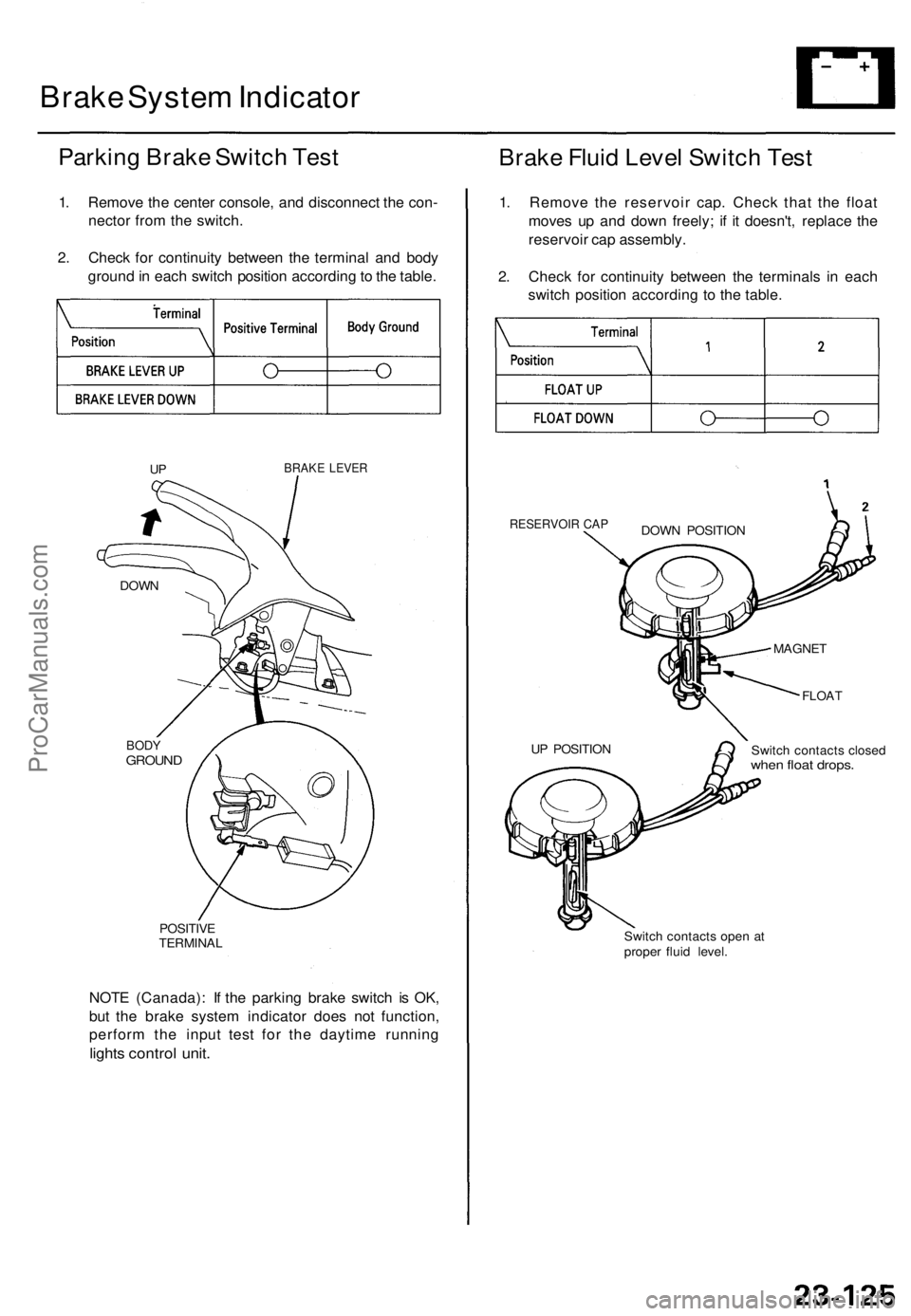

Parking Brake Switch Test

1. Remove the center console, and disconnect the con-

nector from the switch.

2. Check for continuity between the terminal and body

ground in each switch position according to the table.

BRAKE LEVER

BODY

GROUND

POSITIVE

TERMINAL

NOTE (Canada): If the parking brake switch is OK,

but the brake system indicator does not function,

perform the input test for the daytime running

lights control unit.

Brake Fluid Level Switch Test

1. Remove the reservoir cap. Check that the float

moves up and down freely; if it doesn't, replace the

reservoir cap assembly.

2. Check for continuity between the terminals in each

switch position according to the table.

RESERVOIR CAP

FLOAT

Switch contacts closed

when float drops.

Switch contacts open at

proper fluid level.

UP POSITION

MAGNET

DOWN POSITION

DOWN

UPProCarManuals.com

Page 1606 of 1771

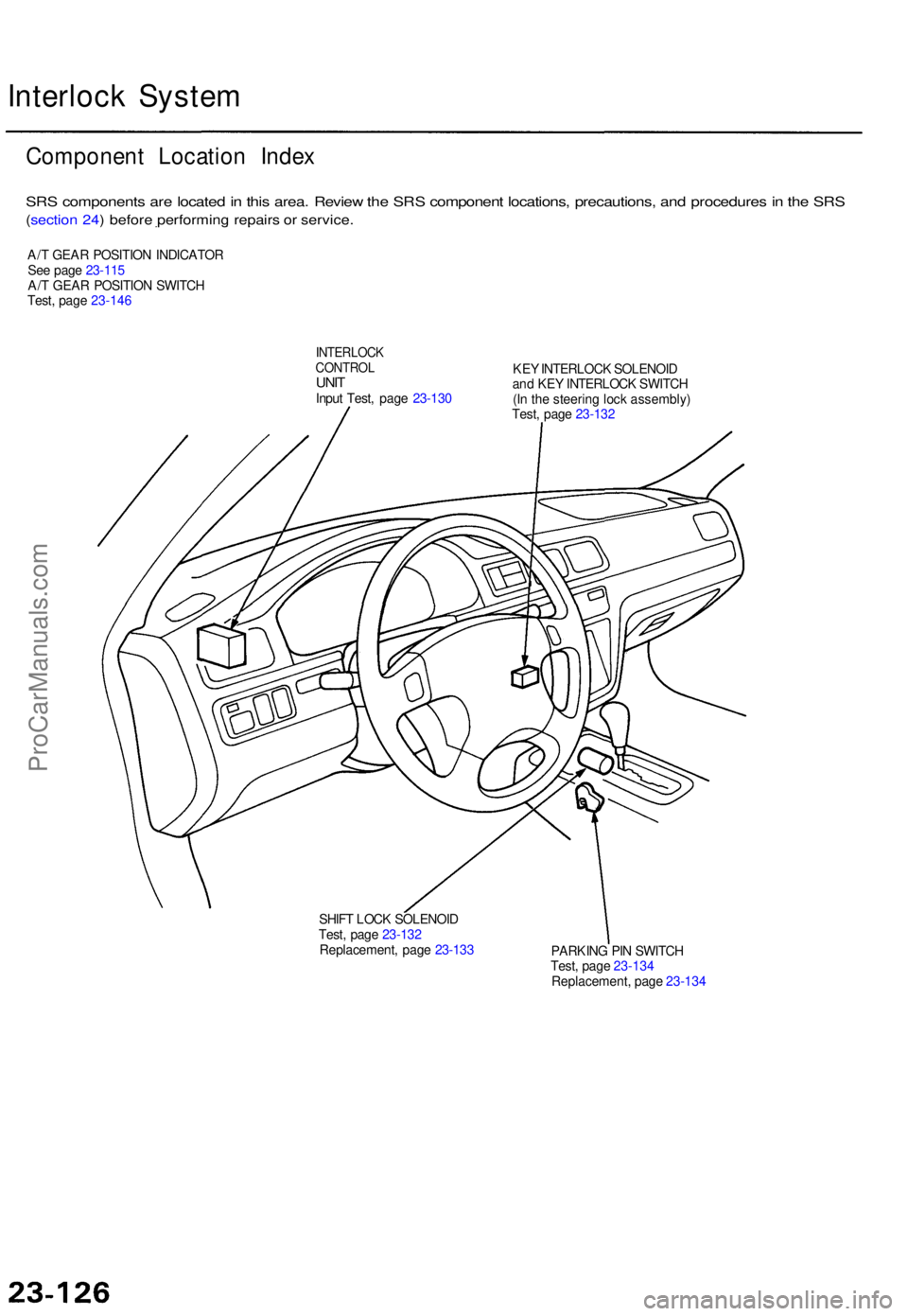

Interlock Syste m

Componen t Locatio n Inde x

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

(sectio n 24 ) befor e performin g repair s o r service .

A/T GEA R POSITIO N INDICATO R

Se e pag e 23-11 5

A/ T GEA R POSITIO N SWITC H

Test , pag e 23-14 6

INTERLOC KCONTROLUNITInpu t Test , pag e 23-13 0 KE

Y INTERLOC K SOLENOI D

an d KE Y INTERLOC K SWITC H

(I n th e steerin g loc k assembly )

Test , pag e 23-13 2

SHIF T LOC K SOLENOI D

Test , pag e 23-13 2

Replacement , pag e 23-13 3

PARKING PI N SWITC H

Test , pag e 23-13 4

Replacement , pag e 23-13 4

ProCarManuals.com

Page 1609 of 1771

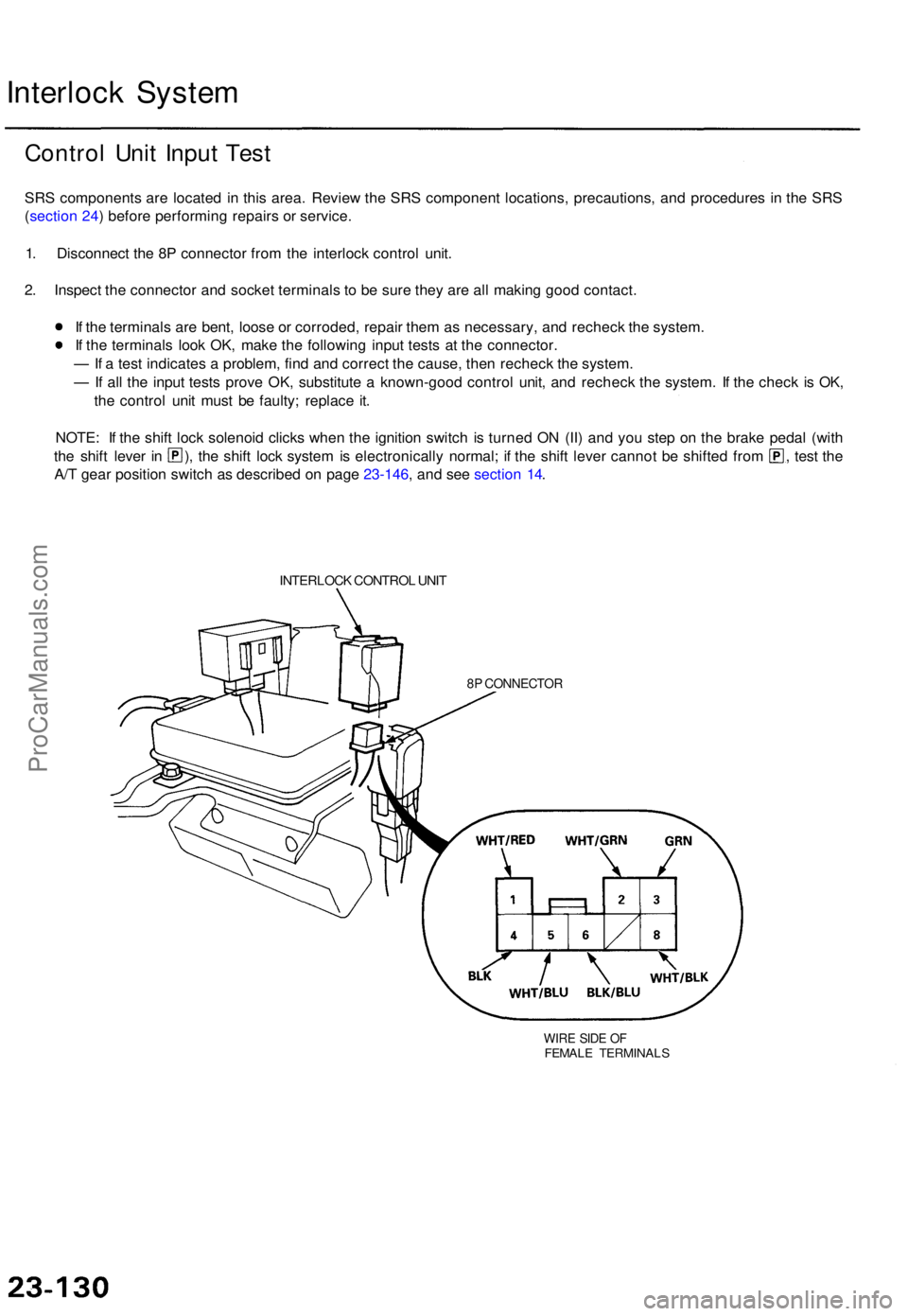

Interlock Syste m

Contro l Uni t Inpu t Tes t

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

1 . Disconnec t th e 8 P connecto r fro m th e interloc k contro l unit .

2 . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

I f th e terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

— If a tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , substitut e a known-goo d contro l unit , an d rechec k th e system . I f th e chec k i s OK ,

th e contro l uni t mus t b e faulty ; replac e it .

NOTE : I f th e shif t loc k solenoi d click s whe n th e ignitio n switc h i s turne d O N (II ) an d yo u ste p o n th e brak e peda l (wit h

the shif t leve r i n ) , th e shif t loc k syste m is electronicall y normal ; i f th e shif t leve r canno t b e shifte d fro m , test th e

A/ T gea r positio n switc h a s describe d o n pag e 23-146 , an d se e sectio n 14 .

INTERLOC K CONTRO L UNI T

8P CONNECTO R

WIRE SID E O FFEMAL E TERMINAL S

ProCarManuals.com

Page 1610 of 1771

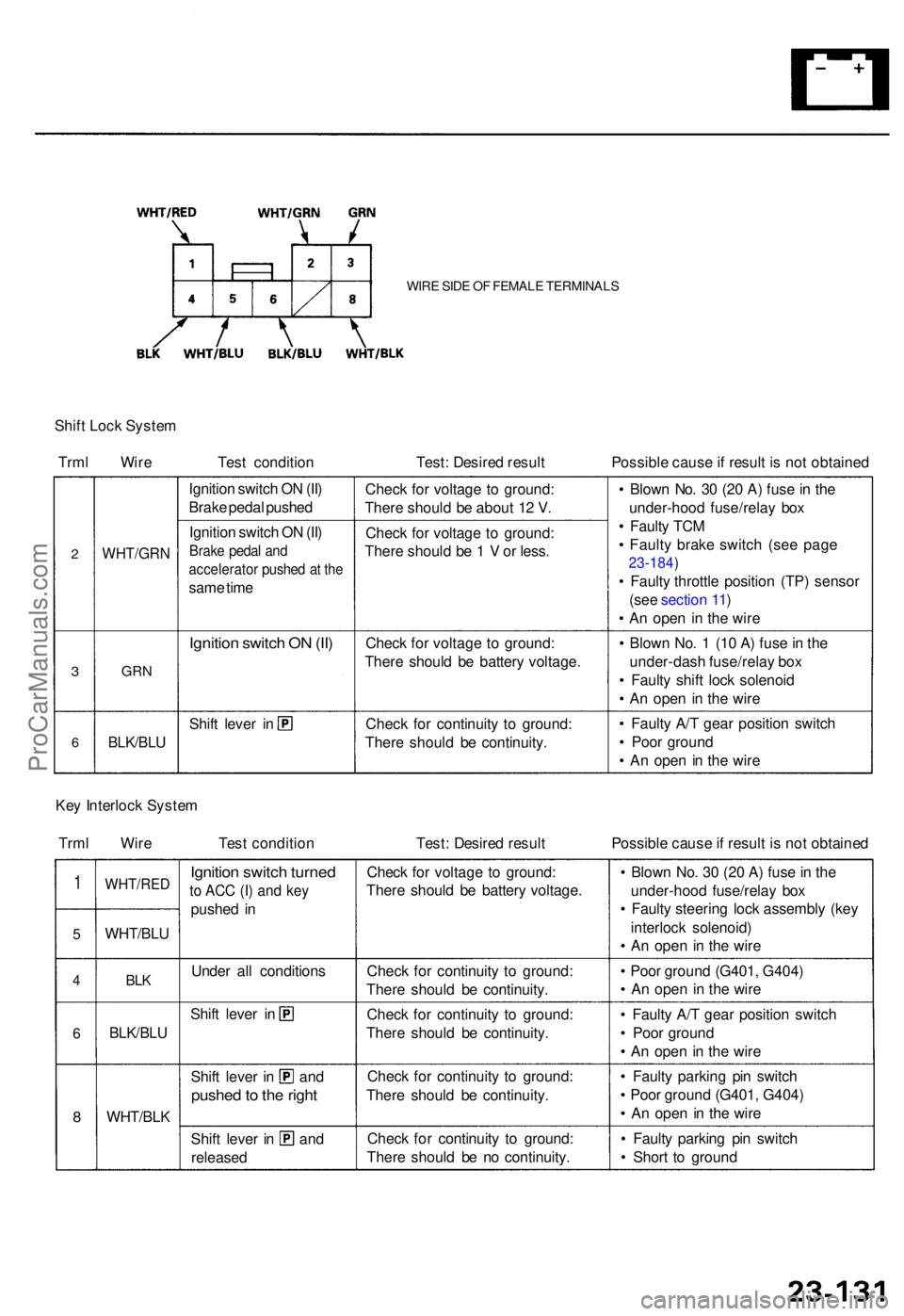

WIRE SID E O F FEMAL E TERMINAL S

Shift Loc k Syste m

Trm l Wir e Test conditio n Test: Desire d resul t Possible caus e if resul t i s no t obtaine d

2

3

6

WHT/GR N

GRN

BLK/BL U

Ignition switc h O N (II )

Brak e peda l pushe d

Ignitio n switc h O N (II )

Brak e peda l an d

accelerato r pushe d a t th e

sam e tim e

Ignitio n switc h O N (II )

Shif t leve r i n Chec

k fo r voltag e t o ground :

Ther e shoul d b e abou t 1 2 V .

Chec k fo r voltag e t o ground :

Ther e shoul d b e 1 V or less .

Chec k fo r voltag e t o ground :

Ther e shoul d b e batter y voltage .

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity . •

Blow n No . 3 0 (2 0 A ) fus e in th e

under-hoo d fuse/rela y bo x

• Fault y TC M

• Fault y brak e switc h (se e pag e

23-184 )

• Fault y throttl e positio n (TP ) senso r

(se e sectio n 11 )

• A n ope n i n th e wir e

• Blow n No . 1 (1 0 A ) fus e in th e

under-das h fuse/rela y bo x

• Fault y shif t loc k solenoi d

• A n ope n i n th e wir e

• Fault y A/ T gea r positio n switc h

• Poo r groun d

• A n ope n i n th e wir e

Ke y Interloc k Syste m

Trm l Wir e Tes t conditio n Test: Desire d resul t Possible caus e if resul t i s no t obtaine d

1

5

4

6

8

WHT/RE D

WHT/BLU

BLK

BLK/BL U

WHT/BL K

Ignition switc h turne d

to AC C (I ) an d ke y

pushe d i n

Unde r al l condition s

Shift leve r i n

Shif t leve r i n an d

pushed to th e righ t

Shift leve r i n an d

release d

Check fo r voltag e t o ground :

Ther e shoul d b e batter y voltage .

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity .

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity .

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity .

Chec k fo r continuit y t o ground :

Ther e shoul d b e n o continuity .•

Blow n No . 3 0 (2 0 A ) fus e in th e

under-hoo d fuse/rela y bo x

• Fault y steerin g loc k assembl y (ke y

interloc k solenoid )

• A n ope n i n th e wir e

• Poo r groun d (G401 , G404 )

• A n ope n i n th e wir e

• Fault y A/ T gea r positio n switc h

• Poo r groun d

• A n ope n i n th e wir e

• Fault y parkin g pi n switc h

• Poo r groun d (G401 , G404 )

• A n ope n in th e wir e

• Fault y parkin g pi n switc h

• Shor t t o groun d

ProCarManuals.com

Page 1613 of 1771

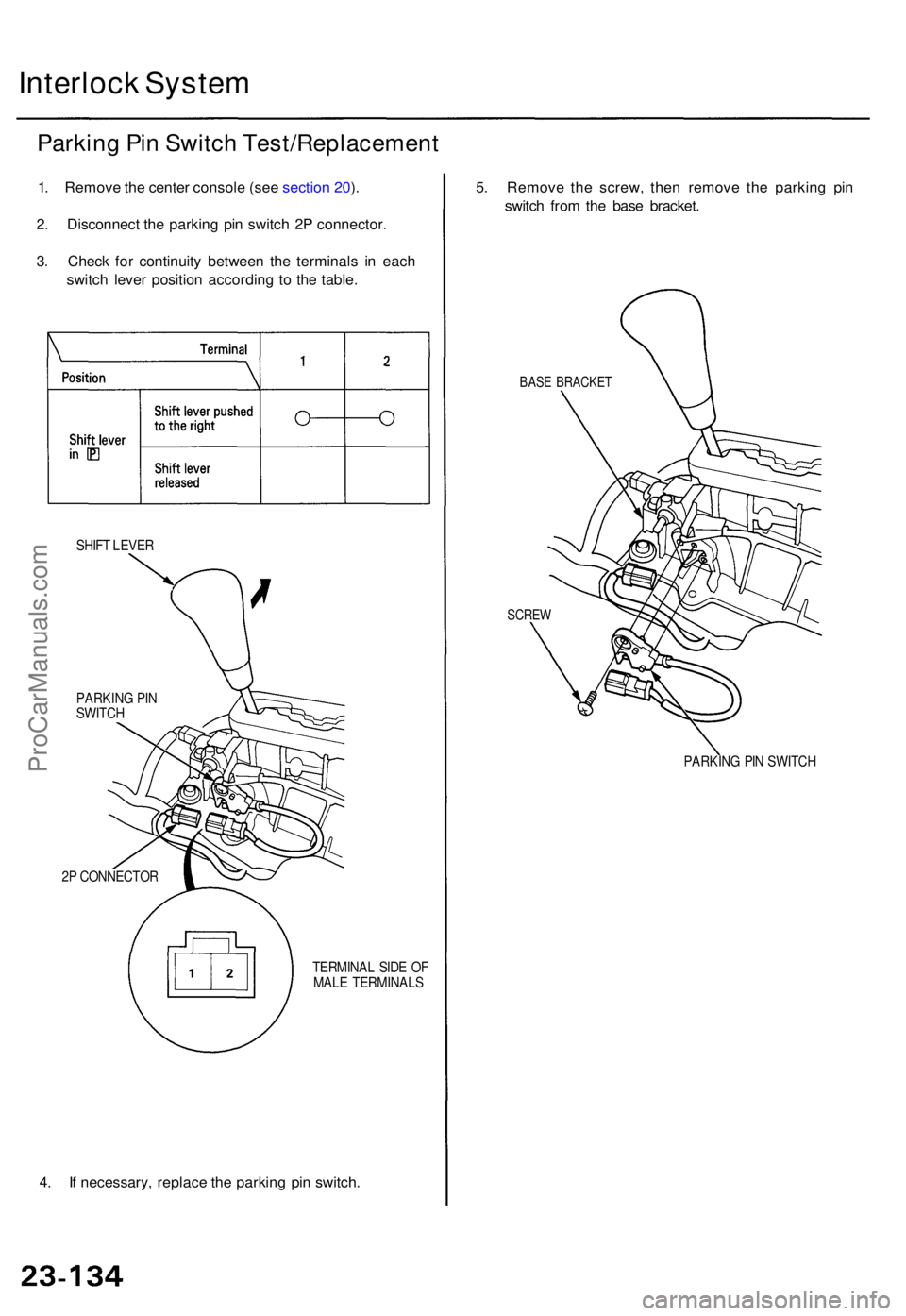

Interlock Syste m

Parkin g Pi n Switc h Test/Replacemen t

1. Remov e th e cente r consol e (se e sectio n 20 ).

2 . Disconnec t th e parkin g pi n switc h 2 P connector .

3 . Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h leve r positio n accordin g t o th e table .

SHIFT LEVE R

PARKIN G PI N

SWITC H

2 P CONNECTO R

TERMINAL SID E O F

MAL E TERMINAL S

4. I f necessary, replace th e parkin g pi n switch . 5

. Remov e th e screw , the n remov e th e parkin g pi n

switc h fro m th e bas e bracket .

BASE BRACKE T

SCREW

PARKIN G PI N SWITC H

ProCarManuals.com

Page 1614 of 1771

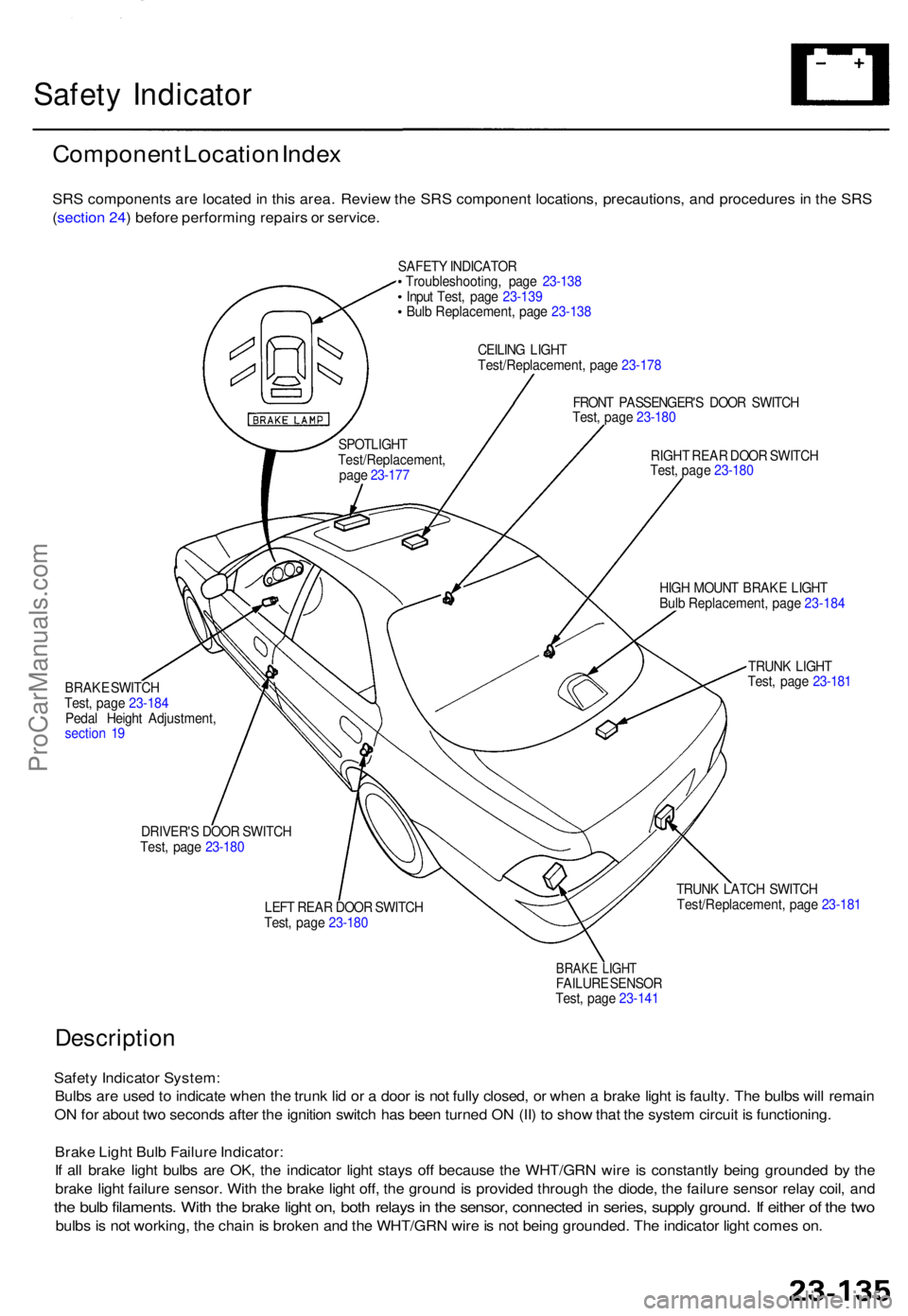

Safety Indicato r

Componen t Locatio n Inde x

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

SAFETY INDICATO R

Troubleshooting , pag e 23-13 8

Inpu t Test , pag e 23-13 9

Bul b Replacement , pag e 23-13 8

CEILIN G LIGH T

Test/Replacement , pag e 23-17 8

FRON T PASSENGER' S DOO R SWITC H

Test , pag e 23-18 0

RIGH T REA R DOO R SWITC H

Test , pag e 23-18 0

BRAK E SWITC H

Test , pag e 23-18 4

Peda l Heigh t Adjustment ,

sectio n 1 9 HIG

H MOUN T BRAK E LIGH T

Bul b Replacement , pag e 23-18 4

TRUN K LIGH T

Test , pag e 23-18 1

DRIVER' S DOO R SWITC H

Test , pag e 23-18 0

LEFT REA R DOO R SWITC H

Test , pag e 23-18 0 TRUN

K LATC H SWITC H

Test/Replacement , pag e 23-18 1

BRAKE LIGH TFAILUR E SENSO R

Test , pag e 23-14 1

Descriptio n

Safety Indicato r System :

Bulb s ar e use d to indicat e whe n th e trun k li d o r a doo r i s no t full y closed , o r whe n a brak e ligh t i s faulty . Th e bulb s wil l remai n

O N fo r abou t tw o second s afte r th e ignitio n switc h ha s bee n turne d O N (II ) t o sho w tha t th e syste m circui t i s functioning .

Brak e Ligh t Bul b Failur e Indicator :

I f al l brak e ligh t bulb s ar e OK , th e indicato r ligh t stay s of f becaus e th e WHT/GR N wir e i s constantl y bein g grounde d b y th e

brak e ligh t failur e sensor . Wit h th e brak e ligh t off , th e ground is provide d throug h th e diode , th e failur e senso r rela y coil , an d

the bul b filaments . Wit h th e brak e ligh t on , bot h relay s in th e sensor , connecte d in series , suppl y ground . I f eithe r o f th e tw o

bulb s is no t working , th e chai n is broke n an d th e WHT/GR N wir e is no t bein g grounded . Th e indicato r ligh t come s on .

SPOTLIGH T

Test/Replacement ,

pag e 23-17 7

ProCarManuals.com

Page 1616 of 1771

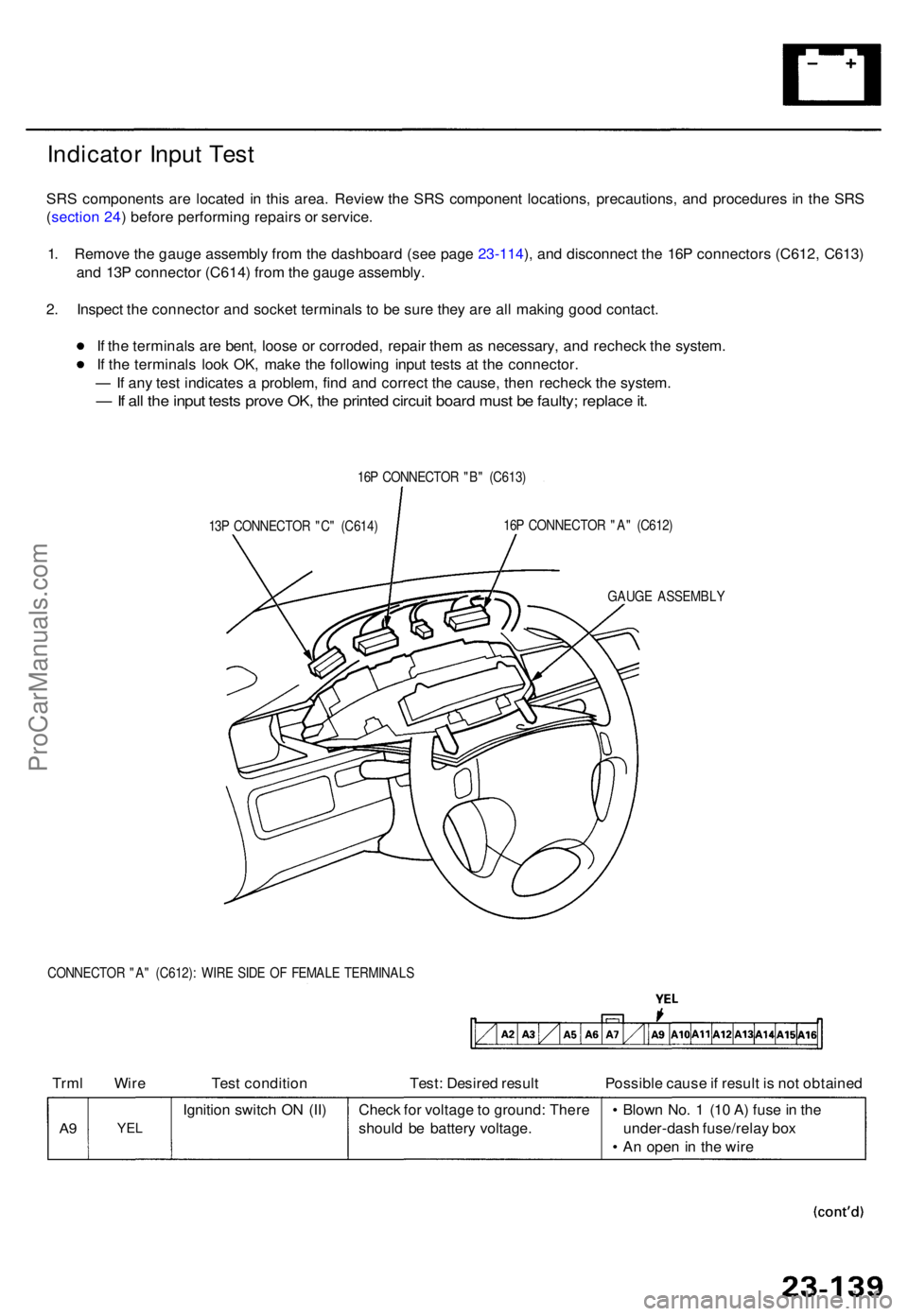

Indicator Inpu t Tes t

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

1 . Remov e th e gaug e assembl y fro m th e dashboar d (se e pag e 23-114 ), an d disconnec t th e 16 P connector s (C612 , C613 )

an d 13 P connecto r (C614 ) fro m th e gaug e assembly .

2 . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

I f th e terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

— If an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e printe d circui t boar d mus t b e faulty ; replac e it .

16 P CONNECTO R "B " (C613 )

13 P CONNECTO R "C " (C614 ) 16

P CONNECTO R "A " (C612 )

GAUG E ASSEMBL Y

CONNECTO R "A " (C612) : WIR E SID E O F FEMAL E TERMINAL S

Trml Wir e Test conditio n Test: Desire d resul t Possible caus e if resul t i s no t obtaine d

A9YE L

Ignitio n switc h O N (II ) Check fo r voltag e to ground : Ther e

shoul d b e batter y voltage . •

Blow n No . 1 (1 0 A ) fus e in th e

under-das h fuse/rela y bo x

• A n ope n i n th e wir e

ProCarManuals.com