Test ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 308 of 1771

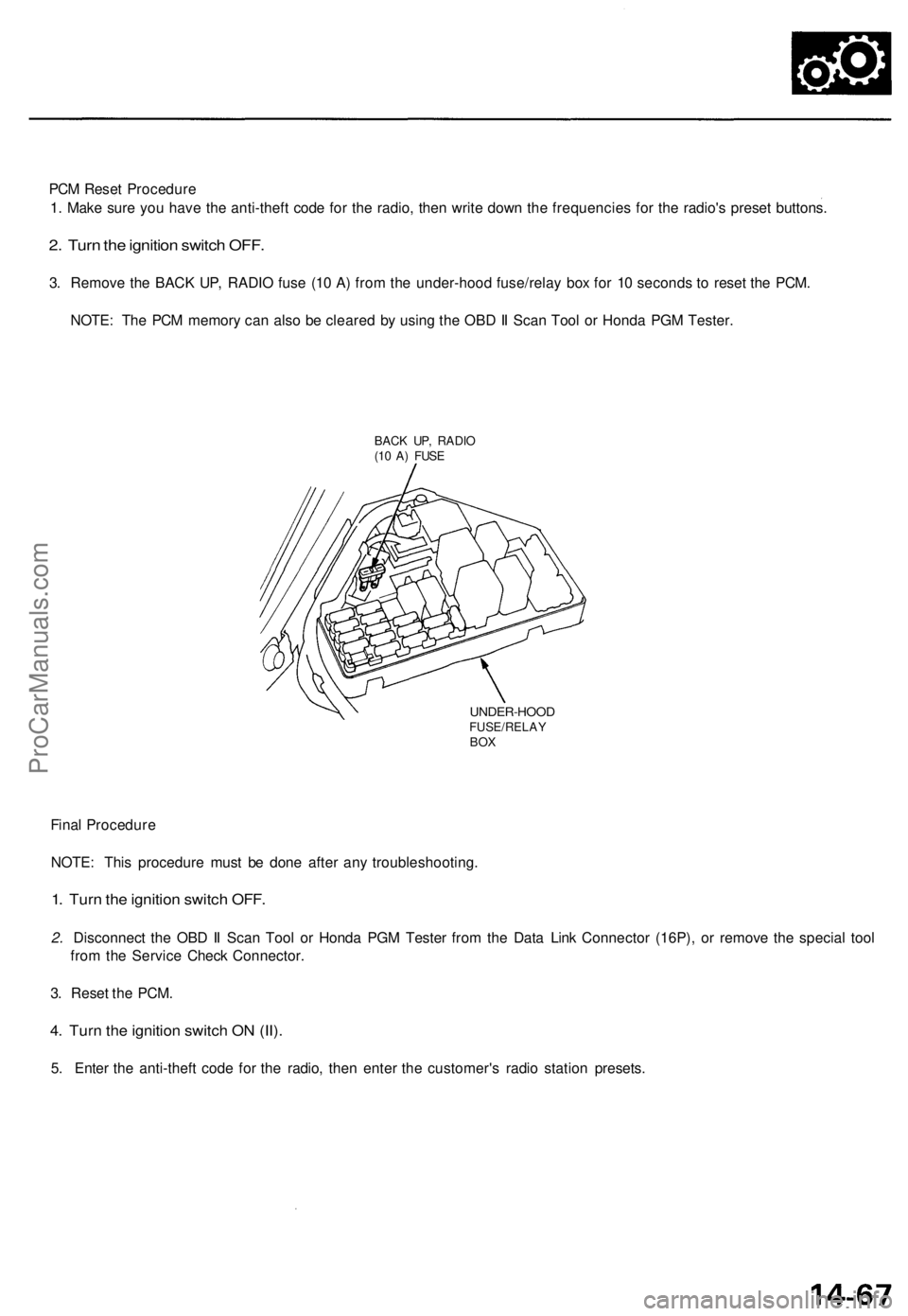

PCM Reset Procedure

1. Make sure you have the anti-theft code for the radio, then write down the frequencies for the radio's preset buttons.

2. Turn the ignition switch OFF.

3. Remove the BACK UP, RADIO fuse (10 A) from the under-hood fuse/relay box for 10 seconds to reset the PCM.

NOTE: The PCM memory can also be cleared by using the OBD II Scan Tool or Honda PGM Tester.

BACK UP, RADIO

(10 A) FUSE

UNDER-HOOD

FUSE/RELAY

BOX

Final Procedure

NOTE: This procedure must be done after any troubleshooting.

1. Turn the ignition switch OFF.

2. Disconnect the OBD II Scan Tool or Honda PGM Tester from the Data Link Connector (16P), or remove the special tool

from the Service Check Connector.

3. Reset the PCM.

4. Turn the ignition switch ON (II).

5. Enter the anti-theft code for the radio, then enter the customer's radio station presets.ProCarManuals.com

Page 313 of 1771

Shift Contro l Solenoi d

Test

1. Disconnec t th e transmissio n sub-harnes s connecto r

(14P).

2. Measur e th e resistanc e betwee n th e No . 4 termina l

of th e transmissio n sub-harnes s connecto r an d

bod y ground , an d betwee n th e No . 5 termina l an d

bod y ground .

TRANSMISSIO NSUB-HARNESSCONNECTOR (10P )

3. I f th e resistanc e i s ou t o f specification , remov e th e

shif t cabl e cover , an d disconnec t th e shif t contro l

solenoi d valve/linea r solenoi d harnes s connector .

6x 1. 0 m m12N-m(1. 2 kgfm ,8.7 Ibf-ft )

CLAM P

SHIFT CABL ECOVER

4. Measur e th e resistanc e betwee n th e No . 1 termina l

o f th e shif t contro l solenoi d valve/linea r solenoi d

harnes s connecto r an d bod y ground , an d betwee n

the No . 2 termina l an d bod y ground .

SHIFT CONTRO L SOLENOI DVALVE/LINEA R SOLENOI DHARNESS CONNECTO R

Terminal sid e o f

mal e terminal s

• Replac e th e transmissio n sub-harnes s i f th e

resistanc e is withi n specification .

• Replac e th e shif t contro l solenoi d valv e assem -

bl y i f th e resistanc e is ou t o f specification .

5 . I f th e resistanc e i s withi n th e standard , connec t th e

No . 2 termina l o f th e shif t contro l solenoi d valve/lin -

ea r solenoi d harnes s connecto r t o th e batter y posi -

tiv e terminal . A clickin g soun d shoul d b e heard .

Connec t th e No . 1 termina l t o th e batter y positiv e

terminal . A clickin g soun d shoul d b e heard . I f n o

clickin g soun d i s heard , replac e th e shif t contro l

solenoi d valv e assembly .

NOTE : I f solenoi d valv e replacemen t i s required ,

se e th e followin g headings :

• Lowe r Valv e Bod y

Removal/Installatio n

................................... 14-12 1

Disassembly/Reassembl y

'96 Mode l ................................................... . 14-12 2

'97 -'9 8 Model s ......................................... . 14-12 3

• Shif t Contro l Solenoi d Valv e A/ B

Tes t

............................................................. . 14-12 5

Replacemen t

.............................................. . 14-12 5

STANDARD

: 1 2-2 5 W

TRANSMISSIO N SUB-HARNES SCONNECTOR (14P )

STANDARD: 12-25 W

ProCarManuals.com

Page 314 of 1771

Linear Solenoi d

Test

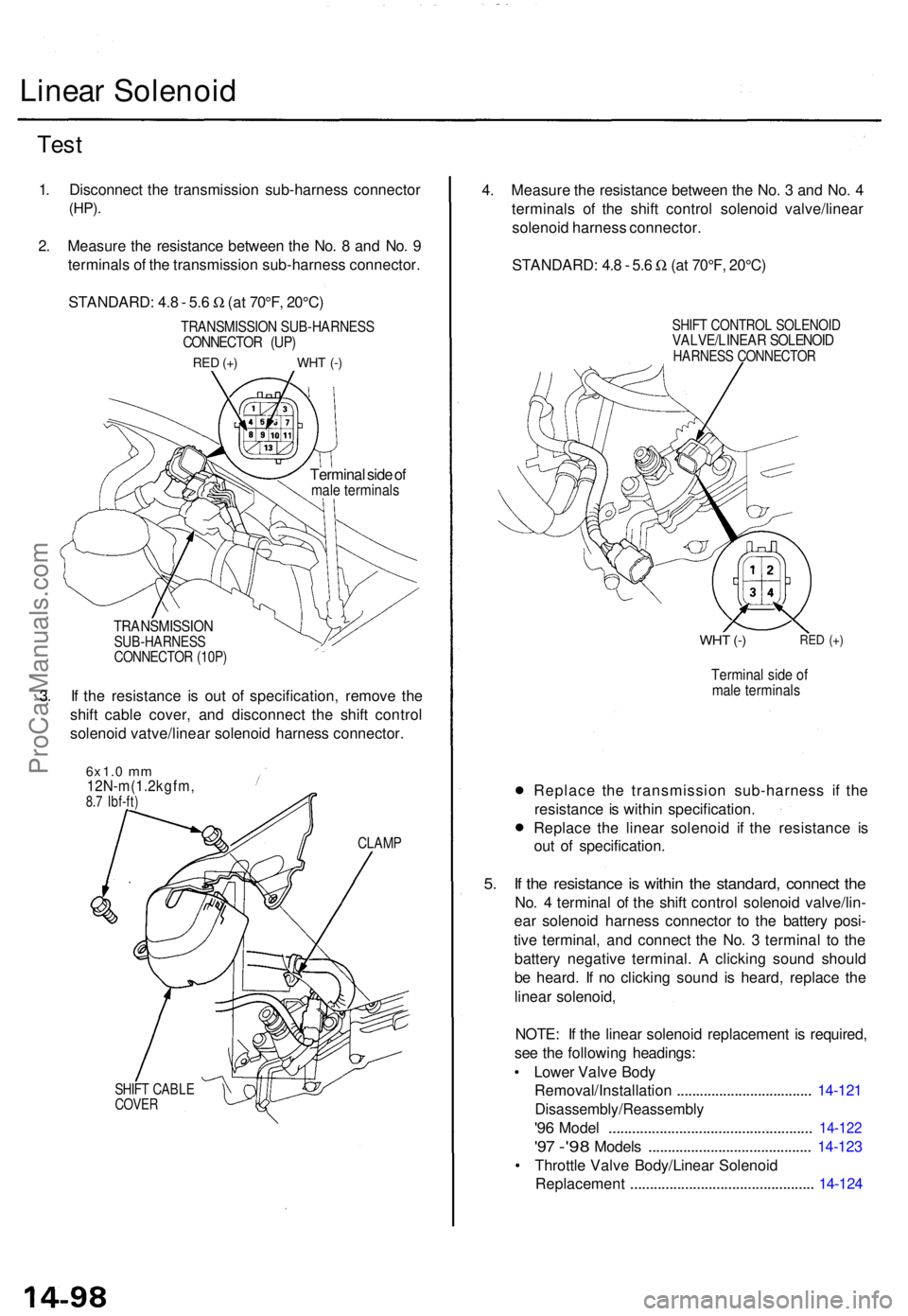

1. Disconnec t th e transmissio n sub-harnes s connecto r

(HP).

2. Measur e th e resistanc e betwee n th e No . 8 an d No . 9

terminal s o f th e transmissio n sub-harnes s connector .

STANDARD : 4. 8 - 5. 6 W (a t 70°F , 20°C )

TRANSMISSIO N SUB-HARNES SCONNECTOR (UP )

RED (+ ) WH T (- )

Termina l sid e o fmal e terminal s

TRANSMISSIO NSUB-HARNESSCONNECTOR (10P )

3. I f th e resistanc e i s ou t o f specification , remov e th e

shif t cabl e cover , an d disconnec t th e shif t contro l

solenoi d vatve/linea r solenoi d harnes s connector .

6x1.0 mm12N-m(1.2kgfm ,8.7 Ibf-ft )

CLAM P

SHIFT CABL ECOVER

4. Measur e th e resistanc e betwee n th e No . 3 an d No . 4

terminal s o f th e shif t contro l solenoi d valve/linea r

solenoi d harnes s connector .

STANDARD : 4. 8 - 5. 6 W (a t 70°F , 20°C )

SHIFT CONTRO L SOLENOI DVALVE/LINEA R SOLENOI DHARNESS CONNECTO R

WHT (- )RE D (+ )

Termina l sid e o fmal e terminal s

• Replac

e th e transmissio n sub-harnes s i f th e

resistanc e is withi n specification .

• Replac

e th e linea r solenoi d i f th e resistanc e i s

ou t o f specification .

5. I f th e resistanc e is withi n th e standard , connec t th e

No . 4 termina l o f th e shif t contro l solenoi d valve/lin -

ea r solenoi d harnes s connecto r t o th e batter y posi -

tiv e terminal , an d connec t th e No . 3 termina l t o th e

batter y negativ e terminal . A clickin g soun d shoul d

b e heard . I f n o clickin g soun d i s heard , replac e th e

linea r solenoid ,

NOTE : I f th e linea r solenoi d replacemen t i s required ,

se e th e followin g headings :

• Lowe r Valv e Bod y

Removal/Installatio n

................................... 14-12 1

Disassembly/Reassembl y

'96 Mode l ................................................... . 14-12 2

'97 -'9 8 Model s ......................................... . 14-12 3

• Throttl e Valv e Body/Linea r Solenoi d

Replacemen t

.............................................. . 14-12 4

ProCarManuals.com

Page 324 of 1771

Road Tes t

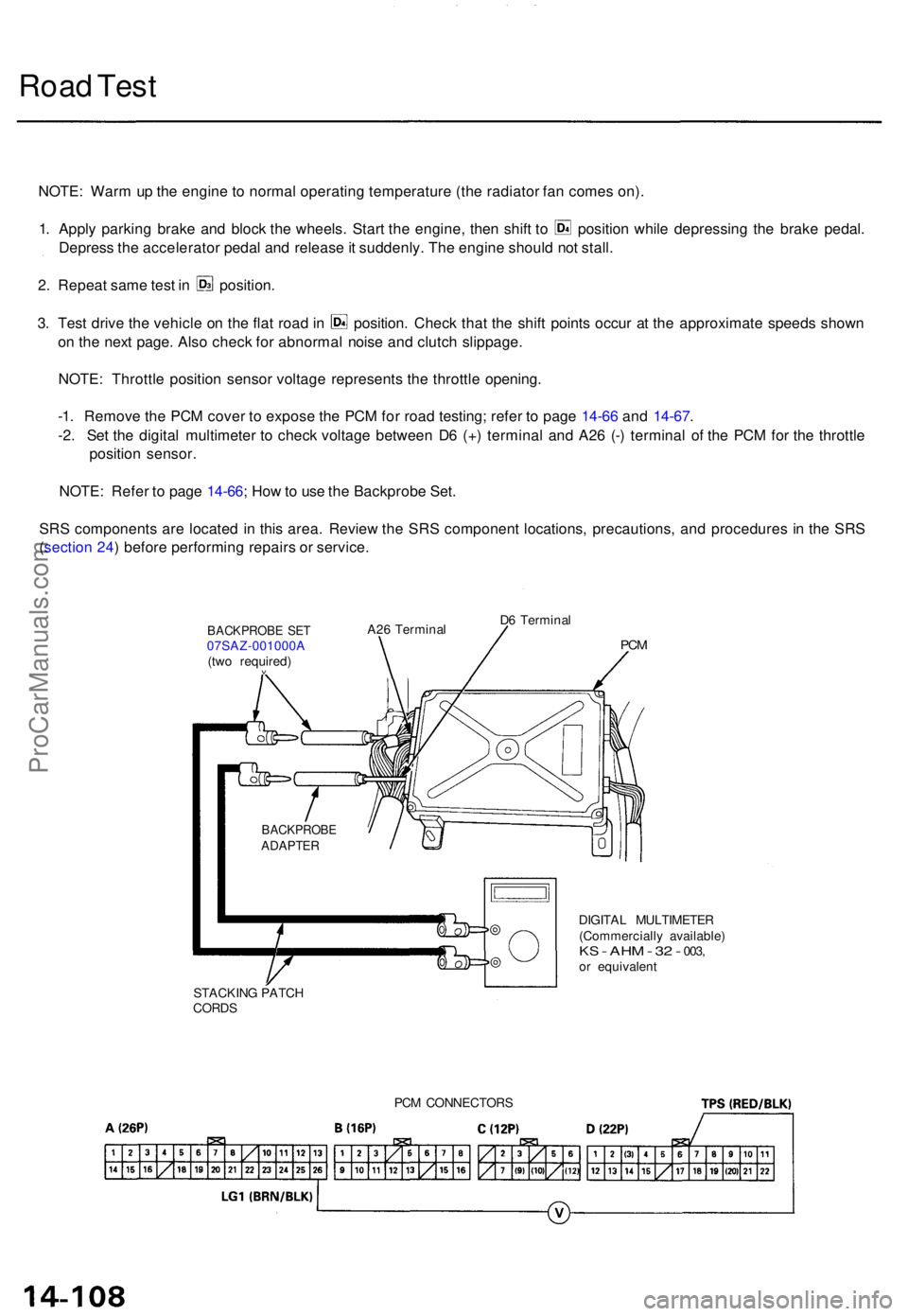

NOTE : War m u p th e engin e t o norma l operatin g temperatur e (th e radiato r fa n come s on) .

1. Appl y parkin g brak e an d bloc k th e wheels . Star t th e engine , the n shif t t o positio n whil e depressin g th e brak e pedal .

Depres s th e accelerato r peda l an d releas e it suddenly . Th e engin e shoul d no t stall .

2. Repea t sam e tes t i n position .

3. Tes t driv e th e vehicl e o n th e fla t roa d in position . Chec k tha t th e shif t point s occu r a t th e approximat e speed s show n

o n th e nex t page . Als o chec k fo r abnorma l nois e an d clutc h slippage .

NOTE : Throttl e positio n senso r voltag e represent s th e throttl e opening .

-1 . Remov e th e PC M cove r t o expos e th e PC M fo r roa d testing ; refe r t o pag e 14-6 6 an d 14-67 .

-2 . Se t th e digita l multimete r t o chec k voltag e betwee n D 6 (+ ) termina l an d A2 6 (- ) termina l o f th e PC M fo r th e throttl e

positio n sensor .

NOTE : Refe r t o pag e 14-66 ; Ho w to us e th e Backprob e Set .

SR S component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

DIGITAL MULTIMETE R

(Commerciall y available )

KS - AH M - 32 - 003 ,or equivalen t

STACKIN G PATC H

CORDS

BACKPROB EADAPTER

BACKPROB E SE T07SAZ-001000 A

(tw o required )

v

A26 Termina l D

6 Termina lPCM

PC M CONNECTOR S

ProCarManuals.com

Page 326 of 1771

Road Test

(cont'd)

4. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th, then shift from position to position. The vehi-

cle should immediately begin slowing down from engine braking.

CAUTION: Do not shift from or position to or position at speeds over 63 mph (100 km/h); you may dam-

age the transmission.

5. Check for abnormal noise and clutch slippage in the following positions.

(1st Gear) Position

a. Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage,

b. Upshifts should not occur with the shift lever in this position.

(2nd Gear) Position

a. Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage,

b. Upshifts and downshifts should not occur with the shift lever in this position.

(Reverse) Position

Accelerate from a stop at full throttle, and check for abnormal noise and clutch slippage.

6. Test in (Parking) Position

Park the vehicle on slope (approx. 16°), apply the parking brake, and shift into position. Release the brake; the vehi-

cle should not move.ProCarManuals.com

Page 327 of 1771

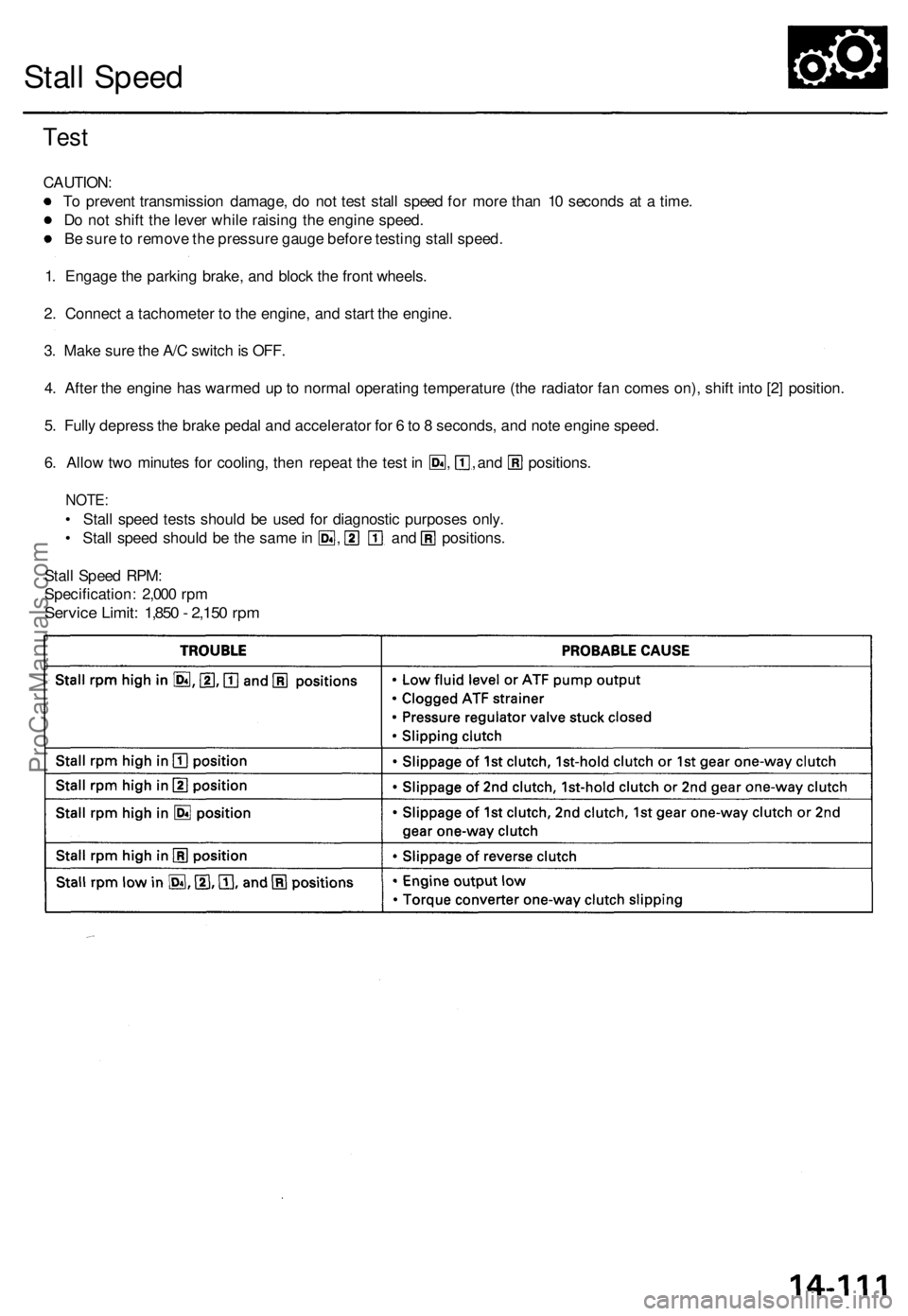

Stall Speed

Test

CAUTION:

To prevent transmission damage, do not test stall speed for more than 10 seconds at a time.

Do not shift the lever while raising the engine speed.

Be sure to remove the pressure gauge before testing stall speed.

1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into [2] position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in , , and positions.

NOTE:

• Stall speed tests should be used for diagnostic purposes only.

• Stall speed should be the same in , and positions.

Stall Speed RPM:

Specification: 2,000 rpm

Service Limit: 1,850 - 2,150 rpmProCarManuals.com

Page 329 of 1771

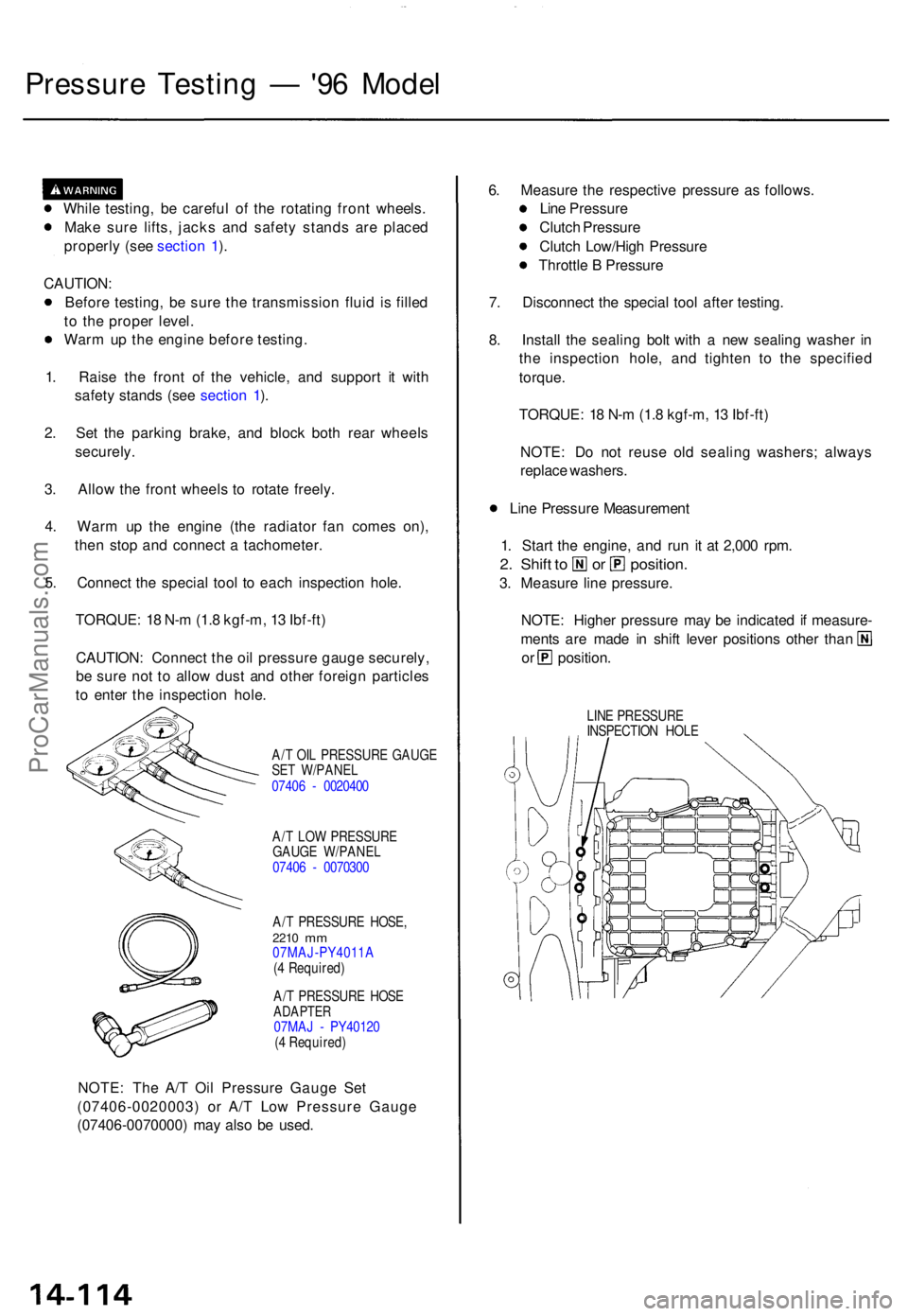

Pressure Testin g — '96 Mode l

While testing , b e carefu l o f th e rotatin g fron t wheels .

Mak e sur e lifts , jack s an d safet y stand s ar e place d

properl y (se e sectio n 1 ).

CAUTION :

Befor e testing , b e sur e th e transmissio n flui d i s fille d

t o th e prope r level .

War m u p th e engin e befor e testing .

1 . Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s

securely .

3 . Allo w th e fron t wheel s t o rotat e freely .

4 . War m u p th e engin e (th e radiato r fa n come s on) ,

the n sto p an d connec t a tachometer .

5 . Connec t th e specia l too l t o eac h inspectio n hole .

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

CAUTION : Connec t th e oi l pressur e gaug e securely ,

b e sur e no t t o allo w dus t an d othe r foreig n particle s

t o ente r th e inspectio n hole .

A/T OI L PRESSUR E GAUG E

SE T W/PANE L

0740 6 - 002040 0

A/ T LO W PRESSUR E

GAUG E W/PANE L

0740 6 - 007030 0

A/ T PRESSUR E HOSE ,

2210 mm07MAJ-PY4011 A

( 4 Required )

A/ T PRESSUR E HOS E

ADAPTE R07MAJ - PY4012 0

( 4 Required )

NOTE: Th e A/ T Oi l Pressur e Gaug e Se t

(07406-0020003 ) o r A/ T Lo w Pressur e Gaug e

(07406-0070000 ) ma y als o b e used . 6

. Measur e th e respectiv e pressur e a s follows .

Lin e Pressur e

Clutc h Pressur e

Clutc h Low/Hig h Pressur e

Throttl e B Pressur e

7 . Disconnec t th e specia l too l afte r testing .

8 . Instal l th e sealin g bol t wit h a ne w sealin g washe r i n

th e inspectio n hole , an d tighte n t o th e specifie d

torque .

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

NOTE : D o no t reus e ol d sealin g washers ; alway s

replac e washers .

Lin e Pressur e Measuremen t

1 . Star t th e engine , an d ru n i t a t 2,00 0 rpm .

2. Shif t t o o r position .

3. Measur e lin e pressure .

NOTE : Highe r pressur e ma y b e indicate d if measure -

ments ar e mad e i n shif t leve r position s othe r tha n

or position .

LINE PRESSUR E

INSPECTIO N HOL E

ProCarManuals.com

Page 330 of 1771

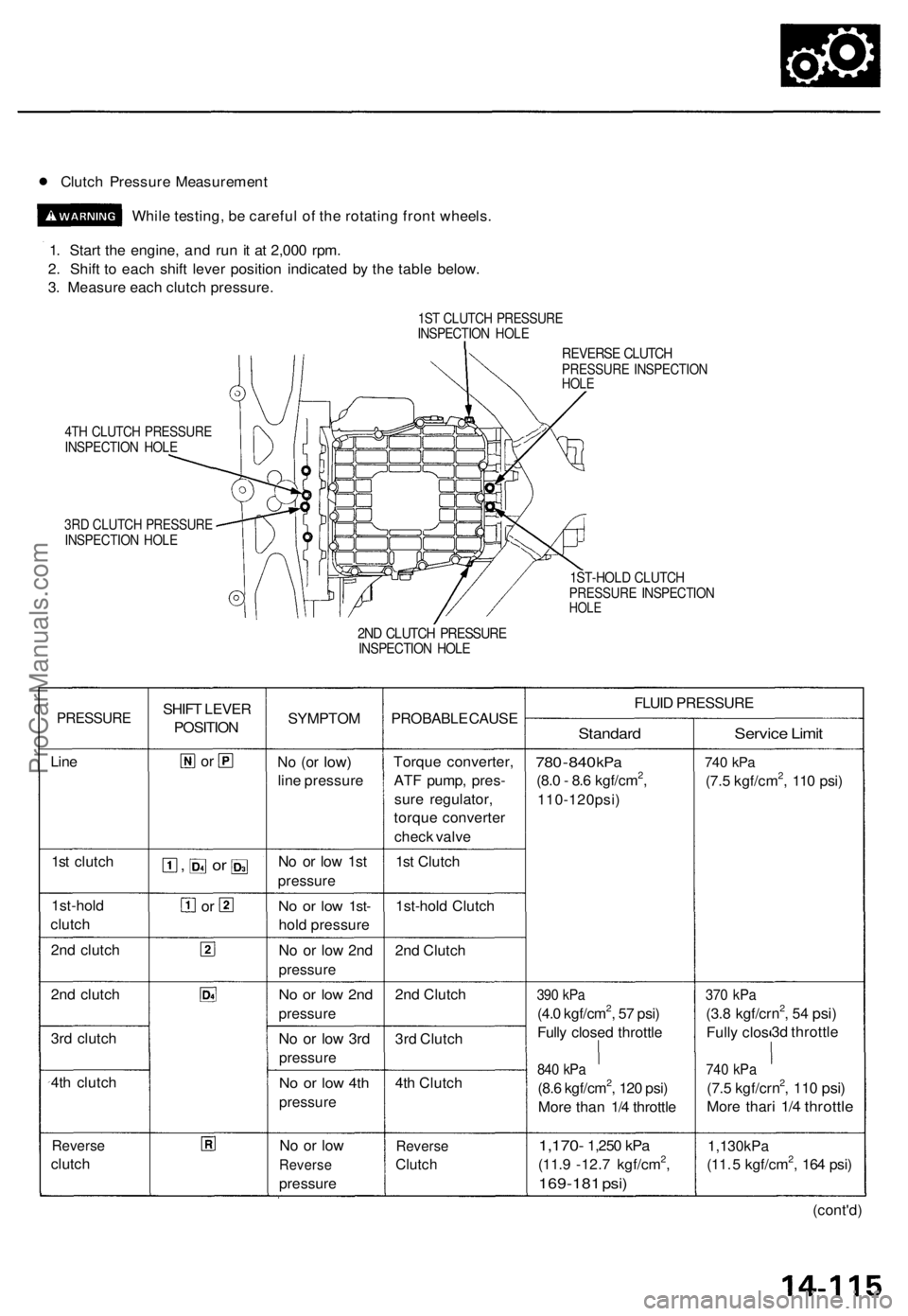

• Clutch Pressur e Measuremen t

Whil e testing , b e carefu l o f th e rotatin g fron t wheels .

1 . Star t th e engine , an d ru n i t a t 2,00 0 rpm .

2 . Shif t t o eac h shif t leve r positio n indicate d b y th e tabl e below .

3 . Measur e eac h clutc h pressure .

1ST CLUTC H PRESSUR EINSPECTIO N HOL E

4TH CLUTC H PRESSUR EINSPECTIO N HOL E

3RD CLUTC H PRESSUR EINSPECTIO N HOL E

REVERS E CLUTC HPRESSUR E INSPECTIO NHOLE

1ST-HOL D CLUTC HPRESSUR E INSPECTIO NHOLE

2ND CLUTC H PRESSUR EINSPECTIO N HOL E

PRESSUR E

Line

1s t clutc h

1st-hol d

clutc h

2n d clutc h

2n d clutc h

3r d clutc h

4t h clutc h

Revers e

clutch SHIF

T LEVE R

POSITIO N

or

, or

or

SYMPTO M

No (o r low )

line pressur e

No o r lo w 1s t

pressur e

No o r lo w 1st -

hold pressur e

No o r lo w 2n d

pressur e

No o r lo w 2n d

pressur e

No o r lo w 3r d

pressur e

No o r lo w 4t h

pressur e

No o r lo w

Revers e

pressur e

PROBABL E CAUS E

Torqu e converter ,

AT F pump , pres -

sur e regulator ,

torqu e converte r

chec k valv e

1s t Clutc h

1st-hol d Clutc h

2n d Clutc h

2n d Clutc h

3r d Clutc h

4t h Clutc h

Revers e

Clutch

FLUID PRESSUR E

Standard

780 - 84 0 kP a

(8.0 - 8. 6 kgf/cm2,

110-120psi )

390 kP a

(4.0 kgf/cm2, 5 7 psi )

Full y close d throttl e

840 kP a

(8.6 kgf/cm2, 12 0 psi )

Mor e tha n 1/ 4 throttl e

1,170- 1,250 kPa

(11. 9 -12. 7 kgf/cm2,

169-18 1 psi )

Servic e Limi t

740 kP a

(7.5 kgf/cm2, 11 0 psi )

370 kP a

(3.8 kgf/c r

Full y clo s

740 kP a

(7.5 kgf/c r

Mor e tha r

n2, 5 4 psi )

3d throttl e

n2, 11 0 psi )

i 1/ 4 throttl e

1,130kP a

(11. 5 kgf/cm2, 16 4 psi )

(cont'd )

ProCarManuals.com

Page 331 of 1771

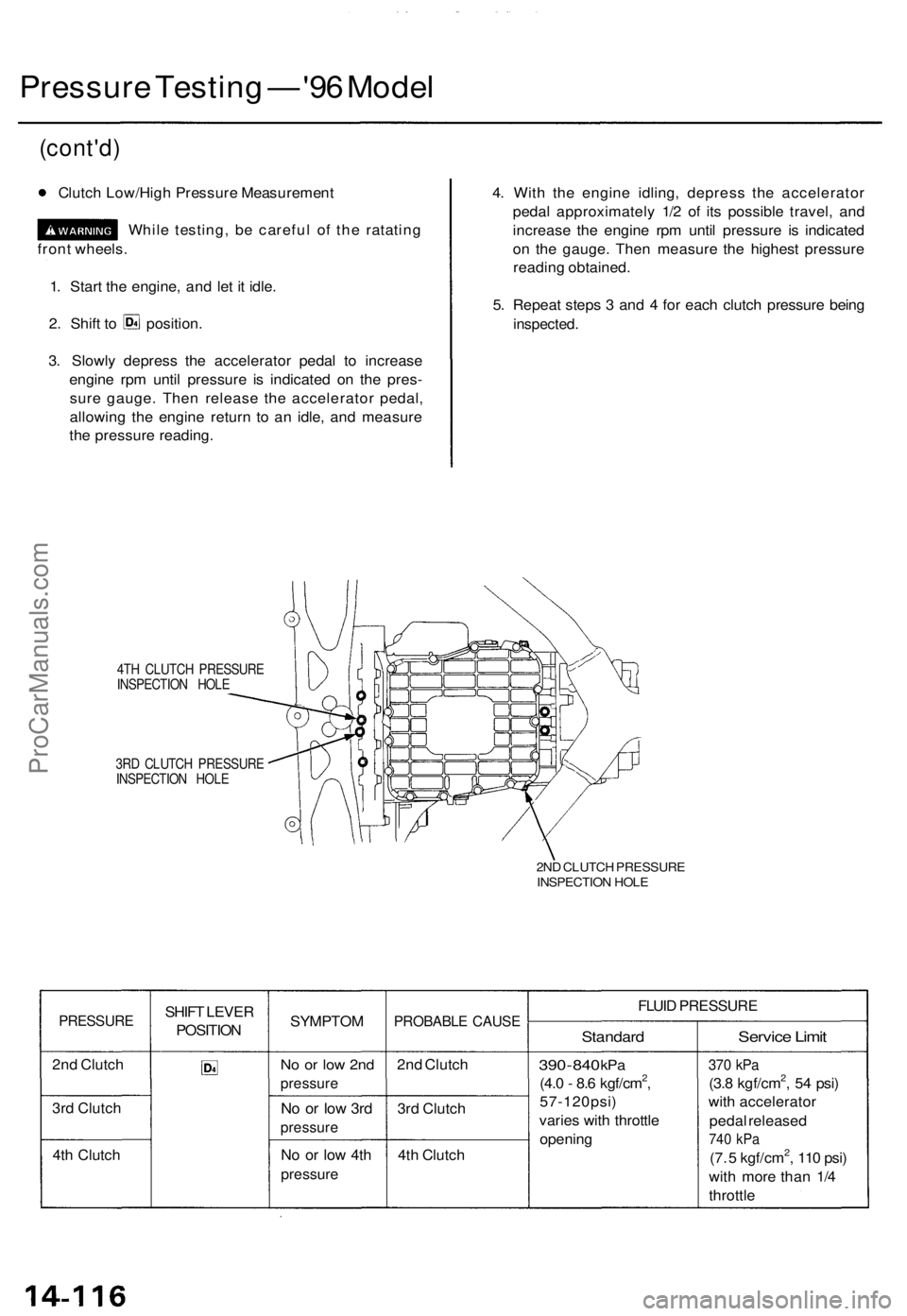

Pressure Testing — '96 Model

3. Slowly depress the accelerator pedal to increase

engine rpm until pressure is indicated on the pres-

sure gauge. Then release the accelerator pedal,

allowing the engine return to an idle, and measure

the pressure reading.

4. With the engine idling, depress the accelerator

pedal approximately 1/2 of its possible travel, and

increase the engine rpm until pressure is indicated

on the gauge. Then measure the highest pressure

reading obtained.

5. Repeat steps 3 and 4 for each clutch pressure being

inspected.

4TH CLUTCH PRESSURE

INSPECTION HOLE

3RD CLUTCH PRESSURE

INSPECTION HOLE

2ND CLUTCH PRESSURE

INSPECTION HOLE

PRESSURE

2nd Clutch

3rd Clutch

4th Clutch

SHIFT LEVER

POSITION

SYMPTOM

No or low 2nd

pressure

No or low 3rd

pressure

No or low 4th

pressure

PROBABLE CAUSE

2nd Clutch

3rd Clutch

4th Clutch

FLUID PRESSURE

Standard

390

-

840

kPa

(4.0 - 8.6 kgf/cm2,

57-120psi)

varies with throttle

opening

Service Limit

370 kPa

(3.8 kgf/cm2, 54 psi)

with accelerator

pedal released

740 kPa

(7. 5 kgf/cm2, 110 psi)

with more than 1/4

throttle

1. Start the engine, and let it idle.

(cont'd)

Clutch Low/High Pressure Measurement

2. Shift to position.

front wheels.

While testing, be careful of the ratatingProCarManuals.com

Page 332 of 1771

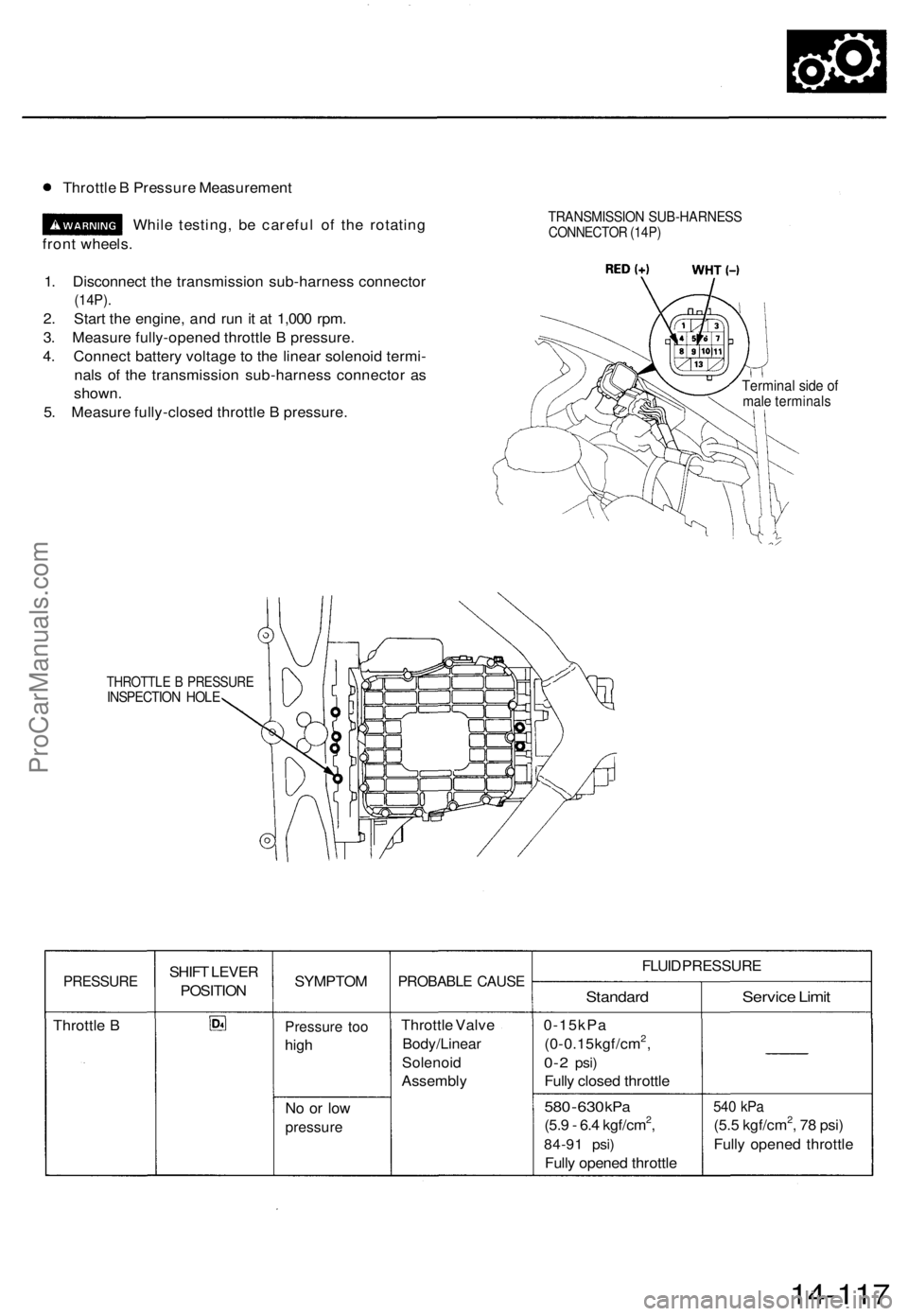

Throttle B Pressure Measurement

While testing, be careful of the rotating

front wheels.

1. Disconnect the transmission sub-harness connector

(14P).

2. Start the engine, and run it at 1,000 rpm.

3. Measure fully-opened throttle B pressure.

4. Connect battery voltage to the linear solenoid termi-

nals of the transmission sub-harness connector as

shown.

5. Measure fully-closed throttle B pressure.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

Terminal side of

male terminals

THROTTLE B PRESSURE

INSPECTION HOLE

PRESSURE

Throttle B

SHIFT LEVER

POSITION

SYMPTOM

Pressure too

high

No or low

pressure

PROBABLE CAUSE

Throttle Valve

Body/Linear

Solenoid

Assembly

FLUID PRESSURE

Standard

0-15kPa

(0-0.15kgf/cm2,

0-2

psi)

Fully closed throttle

580

-

630

kPa

(5.9 - 6.4 kgf/cm2,

84-91 psi)

Fully opened throttle

Service Limit

540 kPa

(5.5 kgf/cm2, 78 psi)

Fully opened throttle

14-117ProCarManuals.com