Test ACURA TL 1995 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 333 of 1771

Pressure Testin g — '97 - '9 8 Model s

While testing , b e carefu l o f th e rotatin g fron t wheels .

Mak e sur e lifts , jack s an d safet y stand s ar e place d properl y (se e sectio n 1 ).

CAUTION :

Befor e testing , b e sur e th e transmissio n flui d is fille d to th e prope r level .

War m u p th e engin e befor e testing .

1 . Rais e th e fron t o f th e vehicle , an d suppor t i t wit h safet y stands .

2 . Se t th e parkin g brake , an d bloc k rea r wheel s securely .

3 . Allo w th e fron t wheel s t o rotat e freely .

4 . War m u p th e engin e (th e radiato r fa n come s on) , the n sto p an d connec t a tachometer .

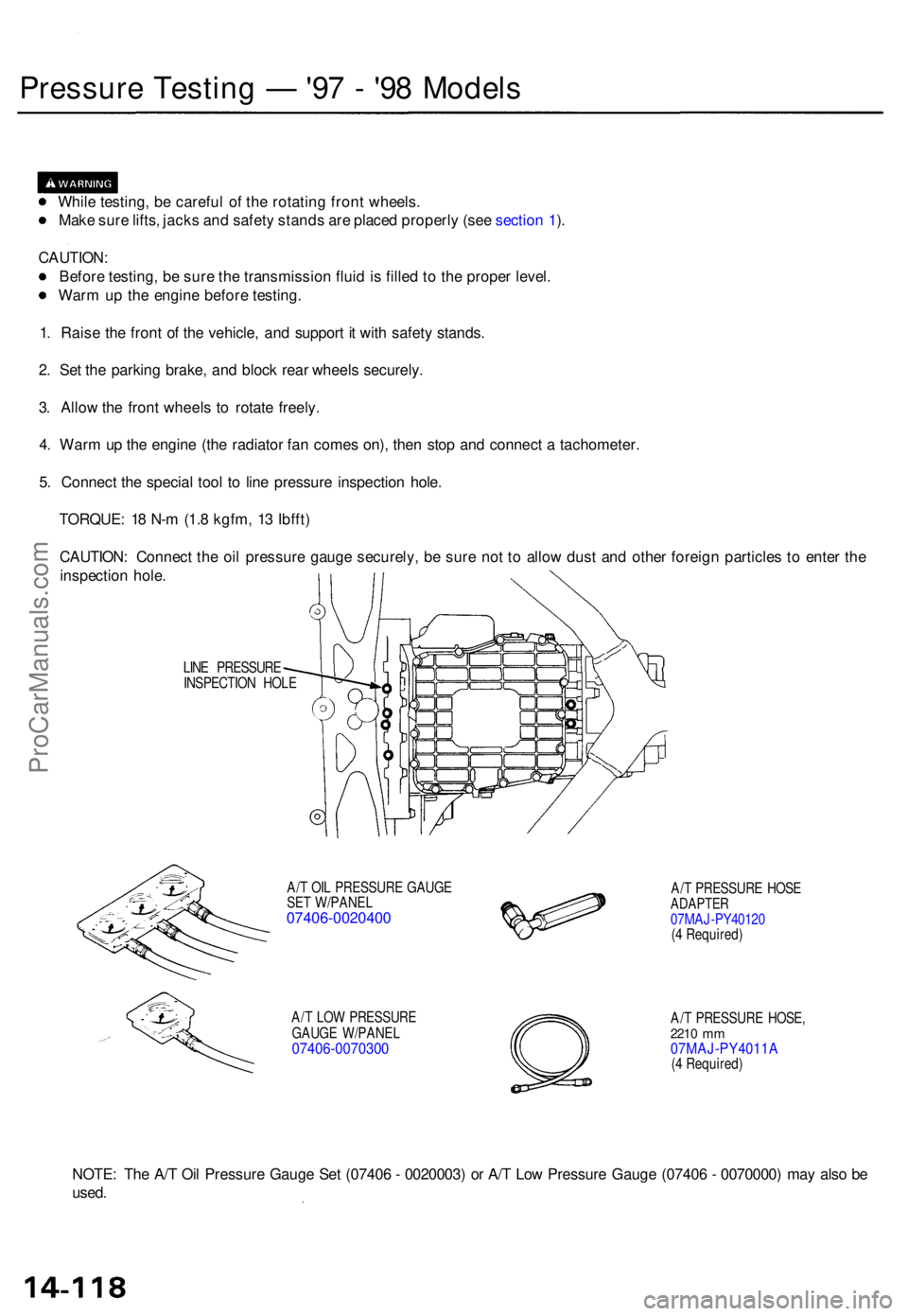

5 . Connec t th e specia l too l t o lin e pressur e inspectio n hole .

TORQUE : 1 8 N- m (1. 8 kgfm , 1 3 Ibfft )

CAUTION : Connec t th e oi l pressur e gaug e securely , b e sur e no t t o allo w dus t an d othe r foreig n particle s t o ente r th e

inspectio n hole .

LINE PRESSUR E

INSPECTIO N HOL E

A/ T OI L PRESSUR E GAUG E

SE T W/PANE L

07406-0020400

A/T LO W PRESSUR E

GAUG E W/PANE L

07406-007030 0

A/T PRESSUR E HOS EADAPTE R07MAJ-PY4012 0

( 4 Required )

A/ T PRESSUR E HOSE ,

2210 mm07MAJ-PY4011 A(4 Required )

NOTE: Th e A/ T Oi l Pressur e Gaug e Se t (0740 6 - 0020003 ) o r A/ T Lo w Pressur e Gaug e (0740 6 - 0070000 ) ma y als o b e

used .

ProCarManuals.com

Page 335 of 1771

Pressure Testin g — '97 - '9 8 Model s

(cont'd )

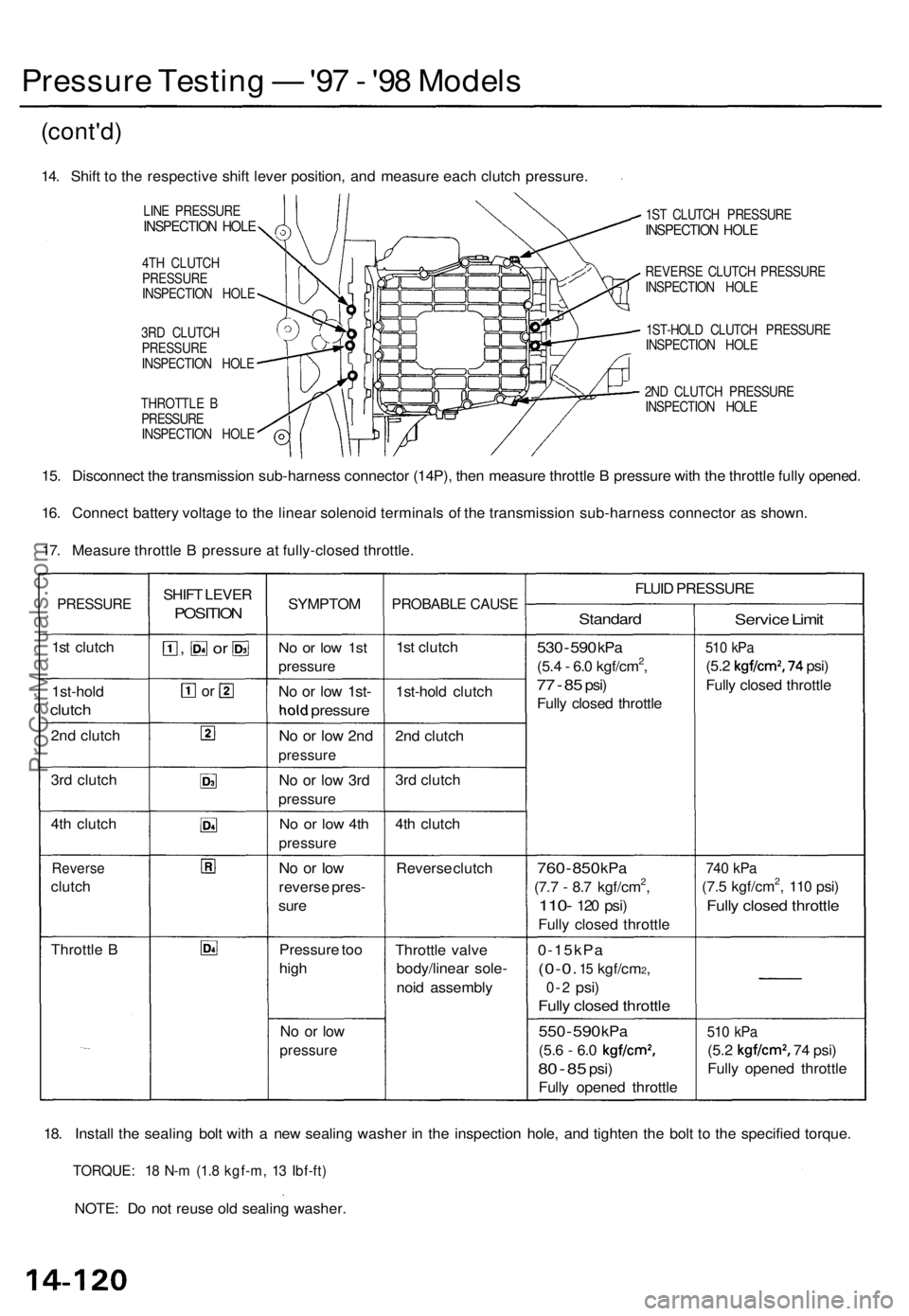

14. Shif t t o th e respectiv e shif t leve r position , an d measur e eac h clutc h pressure .

LINE PRESSUR EINSPECTION HOL E

4TH CLUTC H

PRESSUR E

INSPECTIO N HOL E

3R D CLUTC H

PRESSUR E

INSPECTIO N HOL E

THROTTL E B

PRESSUR E

INSPECTIO N HOL E 1S

T CLUTC H PRESSUR E

INSPECTION HOL E

REVERS E CLUTC H PRESSUR E

INSPECTIO N HOL E

1ST-HOL D CLUTC H PRESSUR E

INSPECTIO N HOL E

2N D CLUTC H PRESSUR E

INSPECTIO N HOL E

15. Disconnec t th e transmissio n sub-harnes s connecto r (14P) , the n measur e throttl e B pressur e wit h th e throttl e full y opened .

16 . Connec t batter y voltag e to th e linea r solenoi d terminal s o f th e transmissio n sub-harnes s connecto r a s shown .

17 . Measur e throttl e B pressur e a t fully-close d throttle .

PRESSUR E

1st clutc h

1st-hol d

clutch

2nd clutc h

3r d clutc h

4t h clutc h

Revers e

clutch

Throttl e B SHIF

T LEVE R

POSITIO N

, o r

or

SYMPTO M

No o r lo w 1s t

pressur e

No o r lo w 1st -

hold pressur e

No o r lo w 2n d

pressur e

No o r lo w 3r d

pressur e

No o r lo w 4t h

pressur e

No o r lo w

revers e pres -

sur e

Pressur e to o

hig h

No o r lo w

pressur e

PROBABL E CAUS E

1st clutc h

1st-hol d clutc h

2n d clutc h

3r d clutc h

4t h clutc h

Revers e clutc h

Throttl e valv e

body/linea r sole -

noi d assembl y FLUI

D PRESSUR E

Standard

530 - 59 0 kP a

(5.4 - 6. 0 kgf/cm2,

77 - 8 5 psi )

Full y close d throttl e

760 - 85 0 kP a

(7.7 - 8. 7 kgf/cm2,

110 - 120 psi )

Full y close d throttl e

0-15kP a

(0-0. 15 kgf/cm2,

0-2 psi )

Fully close d throttl e

550 - 59 0 kP a

(5.6 - 6. 0 kgf/cm2,

80 - 8 5 psi )

Full y opene d throttl e

Service Limi t

510 kP a

(5.2 kgf/cm2, 74 psi )

Full y close d throttl e

740 kP a

(7.5 kgf/cm2, 11 0 psi )

Full y close d throttl e

510 kP a

(5.2 kgf/cm2, 74 psi )

Full y opene d throttl e

18 . Instal l th e sealin g bol t wit h a ne w sealin g washe r i n th e inspectio n hole , an d tighte n th e bol t t o th e specifie d torque .

TORQUE : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

NOTE : D o no t reus e ol d sealin g washer .

ProCarManuals.com

Page 339 of 1771

Throttle Valv e Body/Linea r Solenoi d Assembl y

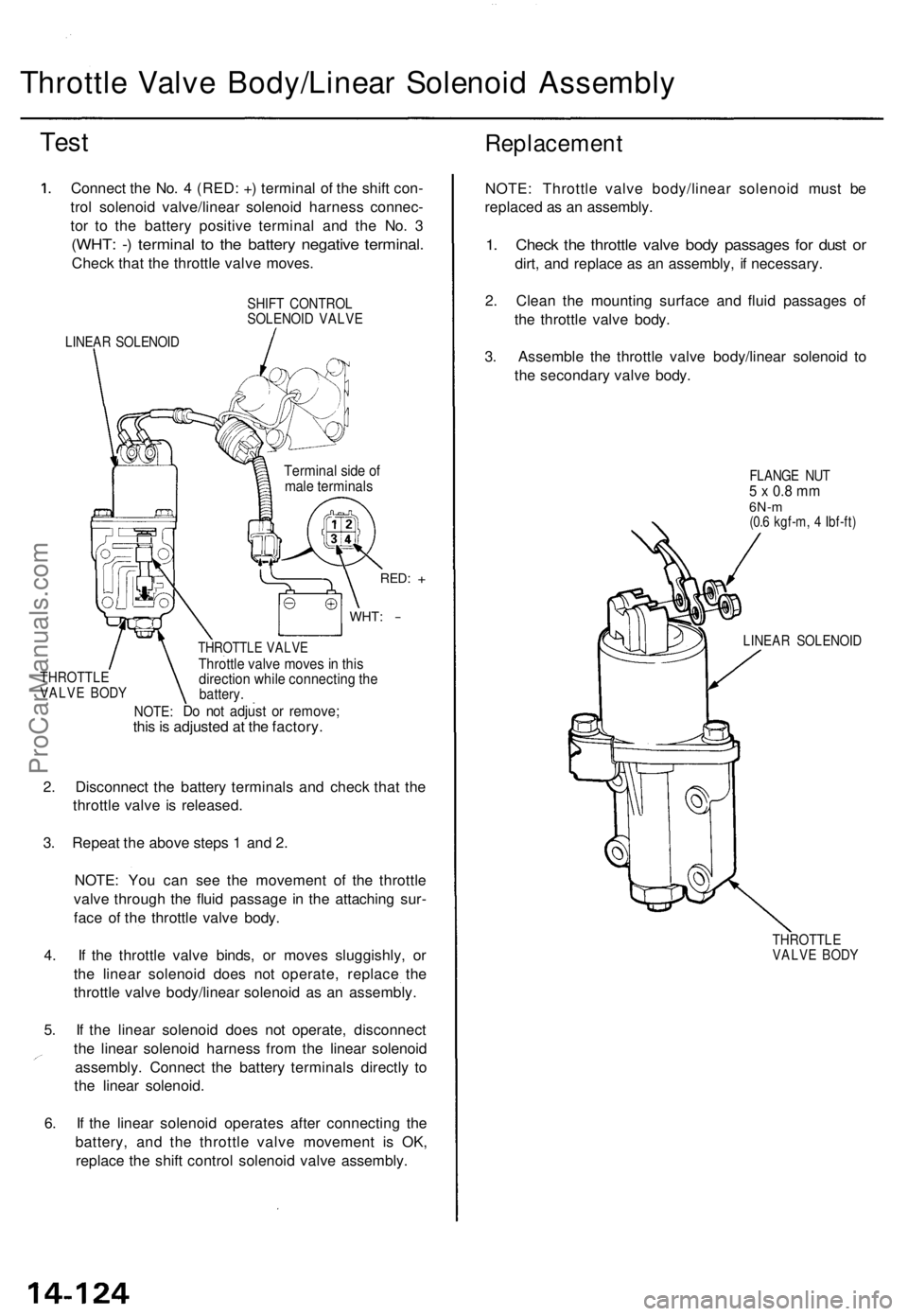

Test

Connec t th e No . 4 (RED : + ) termina l o f th e shif t con -

tro l solenoi d valve/linea r solenoi d harnes s connec -

to r t o th e batter y positiv e termina l an d th e No . 3

(WHT : - ) termina l t o th e batter y negativ e terminal .

Check tha t th e throttl e valv e moves .

SHIFT CONTRO LSOLENOID VALV E

LINEAR SOLENOI D

THROTTL EVALVE BOD Y

Termina l sid e o fmal e terminal s

RED: +

WHT : -

NOTE :

THROTTL E VALV EThrottle valv e move s i n thi sdirectio n whil e connectin g th ebattery .

Do no t adjus t o r remove ;this is adjuste d a t th e factory .

2 . Disconnec t th e batter y terminal s an d chec k tha t th e

throttl e valv e i s released .

3 . Repea t th e abov e step s 1 an d 2 .

NOTE : Yo u ca n se e th e movemen t o f th e throttl e

valv e throug h th e flui d passag e i n th e attachin g sur -

fac e o f th e throttl e valv e body .

4 . I f th e throttl e valv e binds , o r move s sluggishly , o r

th e linea r solenoi d doe s no t operate , replac e th e

throttl e valv e body/linea r solenoi d a s a n assembly .

5 . I f th e linea r solenoi d doe s no t operate , disconnec t

th e linea r solenoi d harnes s fro m th e linea r solenoi d

assembly . Connec t th e batter y terminal s directl y t o

th e linea r solenoid .

6 . I f th e linea r solenoi d operate s afte r connectin g th e

battery , an d th e throttl e valv e movemen t i s OK ,

replac e th e shif t contro l solenoi d valv e assembly .

Replacemen t

NOTE: Throttl e valv e body/linea r solenoi d mus t b e

replace d a s a n assembly .

1. Chec k th e throttl e valv e bod y passage s fo r dus t o r

dirt , an d replac e a s a n assembly , i f necessary .

2 . Clea n th e mountin g surfac e an d flui d passage s o f

th e throttl e valv e body .

3 . Assembl e th e throttl e valv e body/linea r solenoi d t o

th e secondar y valv e body .

FLANG E NU T5 x 0. 8 m m6N- m(0.6 kgf-m , 4 Ibf-ft )

LINEA R SOLENOI D

THROTTLEVALVE BOD Y

ProCarManuals.com

Page 361 of 1771

Valve Body

Repair

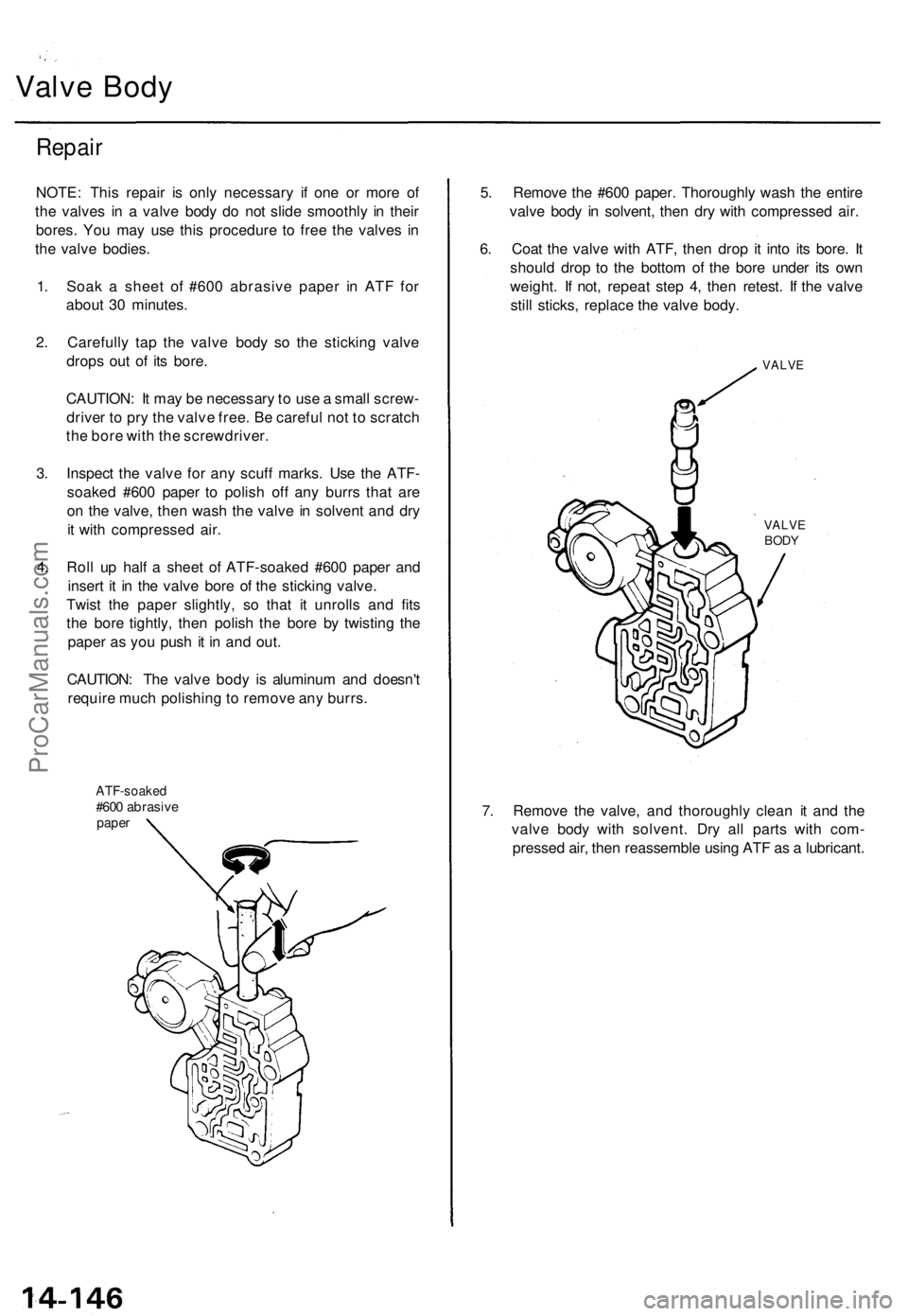

NOTE: This repair is only necessary if one or more of

the valves in a valve body do not slide smoothly in their

bores. You may use this procedure to free the valves in

the valve bodies.

1. Soak a sheet of #600 abrasive paper in ATF for

about 30 minutes.

2. Carefully tap the valve body so the sticking valve

drops out of its bore.

CAUTION: It may be necessary to use a small screw-

driver to pry the valve free. Be careful not to scratch

the bore with the screwdriver.

3. Inspect the valve for any scuff marks. Use the ATF-

soaked #600 paper to polish off any burrs that are

on the valve, then wash the valve in solvent and dry

it with compressed air.

4. Roll up half a sheet of ATF-soaked #600 paper and

insert it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits

the bore tightly, then polish the bore by twisting the

paper as you push it in and out.

CAUTION: The valve body is aluminum and doesn't

require much polishing to remove any burrs.

ATF-soaked

#600 abrasive

paper

5. Remove the #600 paper. Thoroughly wash the entire

valve body in solvent, then dry with compressed air.

6. Coat the valve with ATF, then drop it into its bore. It

should drop to the bottom of the bore under its own

weight. If not, repeat step 4, then retest. If the valve

still sticks, replace the valve body.

VALVE

VALVE

BODY

7. Remove the valve, and thoroughly clean it and the

valve body with solvent. Dry all parts with com-

pressed air, then reassemble using ATF as a lubricant.ProCarManuals.com

Page 501 of 1771

Front Dampe r

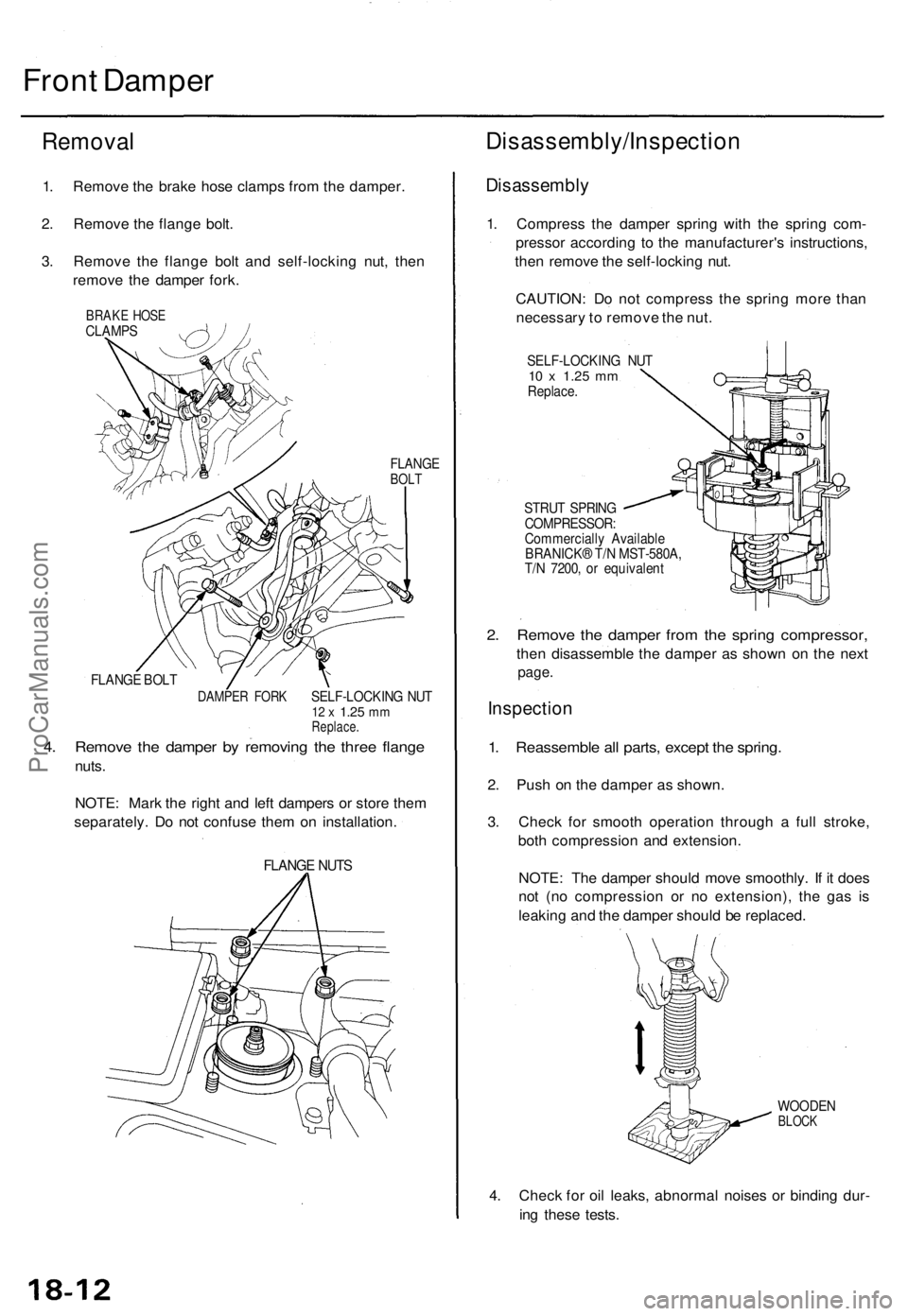

Remova l

1. Remov e th e brak e hos e clamp s fro m th e damper .

2 . Remov e th e flang e bolt .

3 . Remov e th e flang e bol t an d self-lockin g nut , the n

remov e th e dampe r fork .

BRAK E HOS ECLAMP S

FLANGEBOLT

SELF-LOCKIN G NU T12 x 1.2 5 mmReplace .

4. Remov e th e dampe r b y removin g th e thre e flang e

nuts.

NOTE : Mar k th e righ t an d lef t damper s o r stor e the m

separately . D o no t confus e the m o n installation .

FLANGE NUT S

Disassembly/Inspectio n

Disassembly

1. Compres s th e dampe r sprin g wit h th e sprin g com -

presso r accordin g t o th e manufacturer' s instructions ,

the n remov e th e self-lockin g nut .

CAUTION : D o no t compres s th e sprin g mor e tha n

necessar y to remov e th e nut .

SELF-LOCKIN G NU T10 x 1.2 5 mmReplace .

STRU T SPRIN G

COMPRESSOR :Commercially Availabl e

BRANICK ® T/ N MST-580A ,

T/ N 7200 , o r equivalen t

2. Remov e th e dampe r fro m th e sprin g compressor ,

then disassemble the dampe r a s show n o n th e nex t

page .

Inspectio n

1. Reassembl e al l parts , excep t th e spring .

2. Pus h o n th e dampe r a s shown .

3 . Chec k fo r smoot h operatio n throug h a ful l stroke ,

bot h compressio n an d extension .

NOTE : Th e dampe r shoul d mov e smoothly . I f i t doe s

no t (n o compressio n o r n o extension) , th e ga s i s

leakin g an d th e dampe r shoul d b e replaced .

WOODENBLOCK

4. Chec k fo r oi l leaks , abnorma l noise s o r bindin g dur -

in g thes e tests .

FLANG E BOL TDAMPE R FOR K

ProCarManuals.com

Page 509 of 1771

Kickback and Pump Operation:

• When the engine is started, the ABS control unit begins the initial diagnosis and operates the solenoid valve one time.

The kickback may be felt when the brake pedal is depressed.

• When the ABS control unit detects the pressure switch OFF signal during the initial diagnosis, it operates the pump

motor, and performs the pump motor over-run diagnosis and pump motor diagnosis. Therefore, there are two cases

where the pump motor operates or does not operate after the engine is started.

• Normally, after the initial diagnosis, the pump motor operates based on the pressure switch signal, regardless of the

vehicle speed.

Troubleshooting:

• When two or three DTCs are stored in the control unit, perform troubleshooting for the DTC that appears first.

• When a customer's reported problem cannot be verified on the car, ask the customer about the conditions when the

ABS indicator light came ON, and test-drive the car under those conditions, if possible. When the ABS indicator light

does not come ON during the test, check for loose terminals and check by shaking the harnesses and connectors while

following the flowchart.

• The connector terminal numbers are viewed from the wire side for the female terminals, and from the terminal side for

the male terminals.

• After the repair is completed, test-drive the car and check that the ABS indicator light does not come ON again during

the test. (Refer to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 514 of 1771

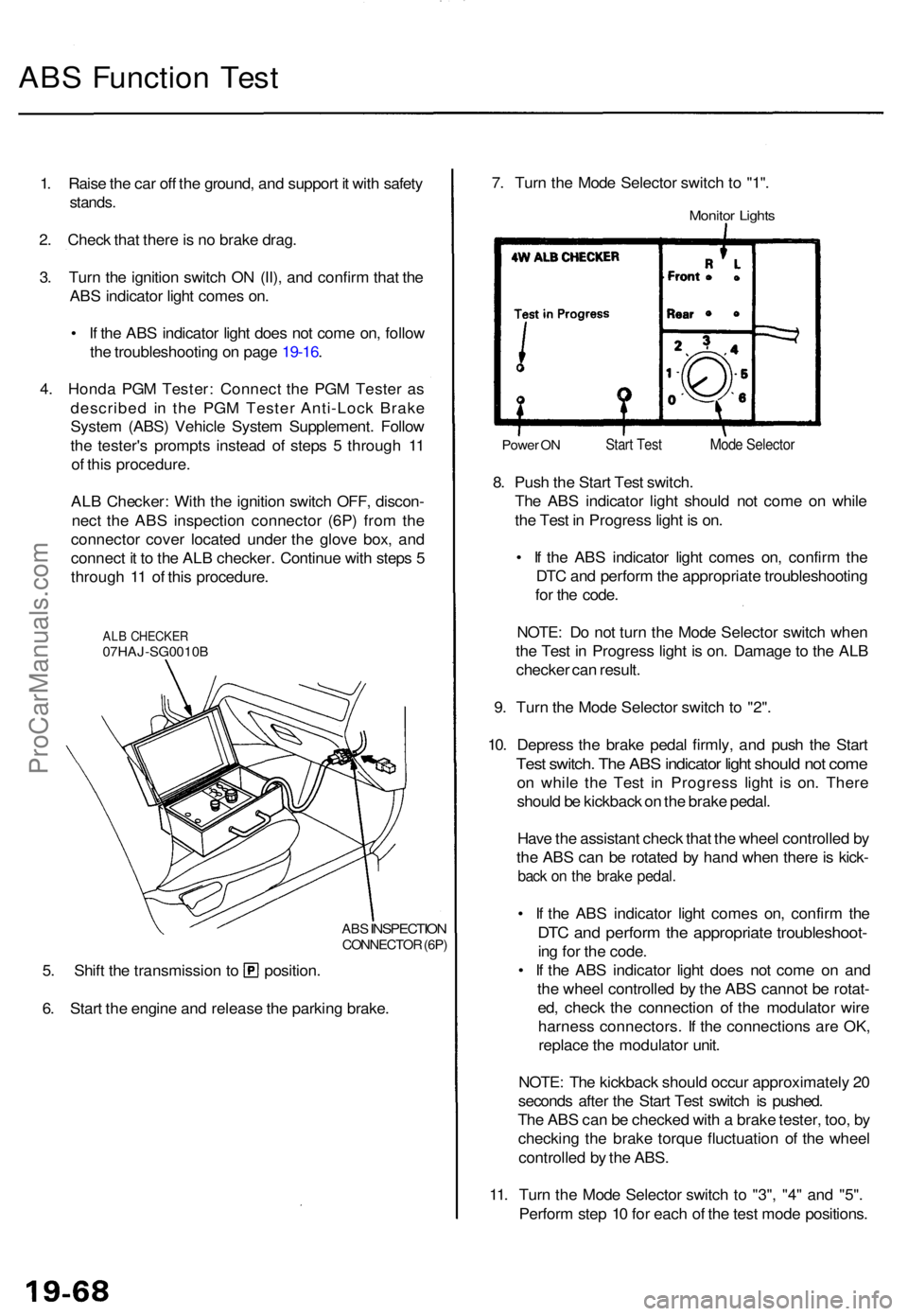

ABS Functio n Tes t

1. Rais e th e ca r of f th e ground , an d suppor t i t wit h safet y

stands .

2. Chec k tha t ther e is n o brak e drag .

3 . Tur n th e ignitio n switc h O N (II) , an d confir m tha t th e

AB S indicato r ligh t come s on .

• I f th e AB S indicato r ligh t doe s no t com e on , follo w

th e troubleshootin g o n pag e 19-16 .

4 . Hond a PG M Tester : Connec t th e PG M Teste r a s

describe d i n th e PG M Teste r Anti-Loc k Brak e

Syste m (ABS ) Vehicl e Syste m Supplement . Follo w

th e tester' s prompt s instea d o f step s 5 throug h 1 1

o f thi s procedure .

AL B Checker : Wit h th e ignitio n switc h OFF , discon -

nec t th e AB S inspectio n connecto r (6P ) fro m th e

connecto r cove r locate d unde r th e glov e box , an d

connec t i t t o th e AL B checker . Continu e wit h step s 5

throug h 1 1 o f thi s procedure .

ALB CHECKE R07HAJ-SG0010 B

ABS

INSPECTIO NCONNECTO R (6P )

5. Shif t th e transmissio n t o position .

6 . Star t th e engin e an d releas e th e parkin g brake . 7

. Tur n th e Mod e Selecto r switc h t o "1" .

Monito r Light s

Powe r O NStar t Tes t

8. Pus h th e Star t Tes t switch .

Th e AB S indicato r ligh t shoul d no t com e o n whil e

th e Tes t i n Progres s ligh t i s on .

• I f th e AB S indicato r ligh t come s on , confir m th e

DT C an d perfor m th e appropriat e troubleshootin g

fo r th e code .

NOTE : D o no t tur n th e Mod e Selecto r switc h whe n

th e Tes t i n Progres s ligh t i s on . Damag e to th e AL B

checke r ca n result .

9 . Tur n th e Mod e Selecto r switc h t o "2" .

10 . Depres s th e brak e peda l firmly , an d pus h th e Star t

Test switch . Th e AB S indicato r ligh t shoul d no t com e

on whil e th e Tes t i n Progres s ligh t i s on . Ther e

shoul d b e kickbac k o n th e brak e pedal .

Hav e th e assistan t chec k tha t th e whee l controlle d b y

th e AB S ca n b e rotate d b y han d whe n ther e is kick -

back o n th e brak e pedal .

• I f th e AB S indicato r ligh t come s on , confir m th e

DT C an d perfor m th e appropriat e troubleshoot -

ing fo r th e code .

• I f th e AB S indicato r ligh t doe s no t com e o n an d

th e whee l controlle d b y th e AB S canno t b e rotat -

ed , chec k th e connectio n o f th e modulato r wir e

harnes s connectors . I f th e connection s ar e OK ,

replac e th e modulato r unit .

NOTE : Th e kickbac k shoul d occu r approximatel y 2 0

second s afte r th e Star t Tes t switc h i s pushed .

Th e AB S can be checke d wit h a brak e tester , too , b y

checkin g th e brak e torqu e fluctuatio n o f th e whee l

controlle d b y th e ABS .

11 . Tur n th e Mod e Selecto r switc h t o "3" , "4 " an d "5" .

Perfor m ste p 1 0 fo r eac h o f th e tes t mod e positions .

Mode Selecto r

ProCarManuals.com

Page 523 of 1771

Troubleshooting Precaution s

Kickback

1. Th e moto r operate s whe n th e AB S is functioning , an d flui d i n th e reservoi r i s force d ou t t o th e maste r cylinde r caus -

in g kickbac k a t th e brak e pedal .

Pum p Moto r

1 . Th e pum p moto r operate s whe n th e AB S is functioning .

2 . Th e AB S contro l uni t check s th e pum p moto r operatio n durin g initia l diagnosi s an d vehicl e starts . Yo u ma y hea r th e

fain t operatio n soun d a t thi s time , bu t i t i s normal .

Brak e Flui d Replacement/Ai r Bleedin g

1 . Brak e flui d replacemen t an d ai r bleedin g procedure s ar e th e sam e a s vehicle s withou t ABS . T o cas e bleeding , star t

wit h th e fron t wheels .

Troubleshootin g

1 . Th e troubleshootin g flowchart s procedure s assum e tha t th e caus e o f th e proble m is stil l presen t an d th e AB S indica -

to r ligh t i s stil l on . Followin g th e flowchar t whe n th e AB S indicator light doe s no t com e o n ca n resul t i n incorrec t

judgment.

2. Questio n th e custome r abou t th e condition s whe n th e proble m occurred , an d tr y t o reproduc e th e sam e condition s

fo r troubleshooting .

Fin d ou t whe n th e AB S indicato r ligh t cam e on , suc h a s durin g initia l diagnosis , durin g AB S control , afte r AB S con -

trol , whe n th e vehicl e started , whe n vehicl e spee d wa s a t 1 9 mp h (3 0 km/h) , whe n th e proble m continue d fo r a fe w

second s o r a fe w minutes , etc .

3 . Whe n th e AB S indicato r ligh t doe s no t com e o n durin g th e test-drive , bu t th e troubleshootin g i s performe d base d o n

th e DTC , chec k fo r th e loos e connectors , poo r contac t o f terminals , etc , befor e troubleshooting .

4 . Afte r troubleshooting , eras e th e DT C an d test-driv e th e vehicle . B e sur e tha t th e AB S indicato r ligh t doe s no t com e on .

5 . Th e connecto r illustration s sho w th e femal e connector s wit h a singl e outlin e an d th e mal e connector s wit h a doubl e

outline .

ProCarManuals.com

Page 524 of 1771

Diagnostic Troubl e Cod e (DTC )

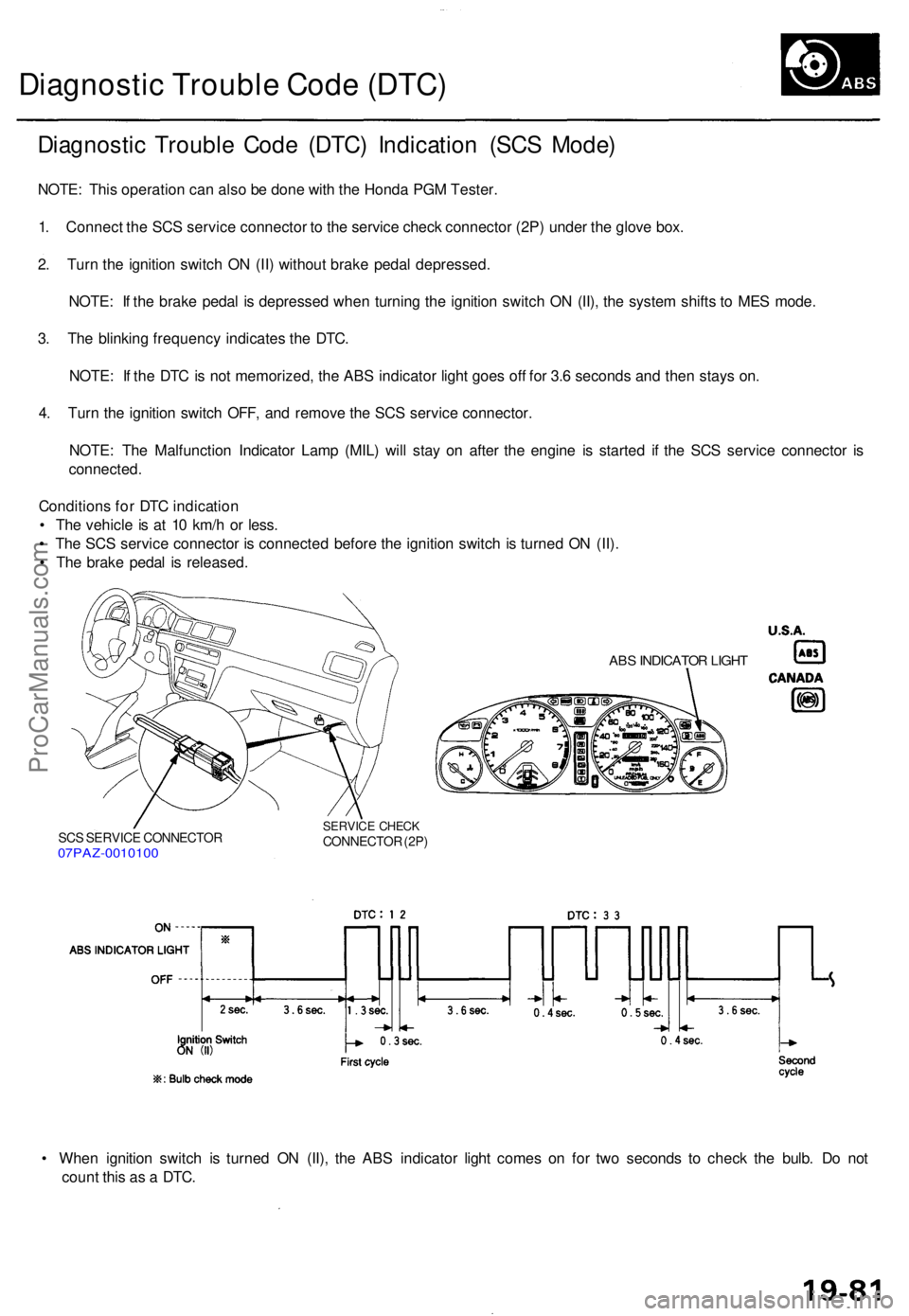

Diagnosti c Troubl e Cod e (DTC ) Indicatio n (SC S Mode )

NOTE: Thi s operatio n ca n als o b e don e wit h th e Hond a PG M Tester .

1 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r (2P ) unde r th e glov e box .

2 . Tur n th e ignitio n switc h O N (II ) withou t brak e peda l depressed .

NOTE : I f th e brak e peda l i s depresse d whe n turnin g th e ignitio n switc h O N (II) , th e syste m shift s t o ME S mode .

3 . Th e blinkin g frequenc y indicate s th e DTC .

NOTE : I f th e DT C is no t memorized , th e AB S indicato r ligh t goe s of f fo r 3. 6 second s an d the n stay s on .

4 . Tur n th e ignitio n switc h OFF , an d remov e th e SC S servic e connector .

NOTE : Th e Malfunctio n Indicato r Lam p (MIL ) wil l sta y o n afte r th e engin e i s starte d i f th e SC S servic e connecto r i s

connected .

Condition s fo r DT C indicatio n

• Th e vehicl e is a t 1 0 km/ h o r less .

• Th e SC S servic e connecto r i s connecte d befor e th e ignitio n switc h i s turne d O N (II) .

• Th e brak e peda l i s released .

SCS SERVIC E CONNECTO R07PAZ-001010 0

SERVICE CHEC KCONNECTO R (2P )

ABS INDICATO R LIGH T

• Whe n ignitio n switc h i s turne d O N (II) , th e AB S indicato r ligh t come s o n fo r tw o second s t o chec k th e bulb . D o no t

coun t thi s a s a DTC .

ProCarManuals.com

Page 525 of 1771

Diagnostic Troubl e Cod e (DTC )

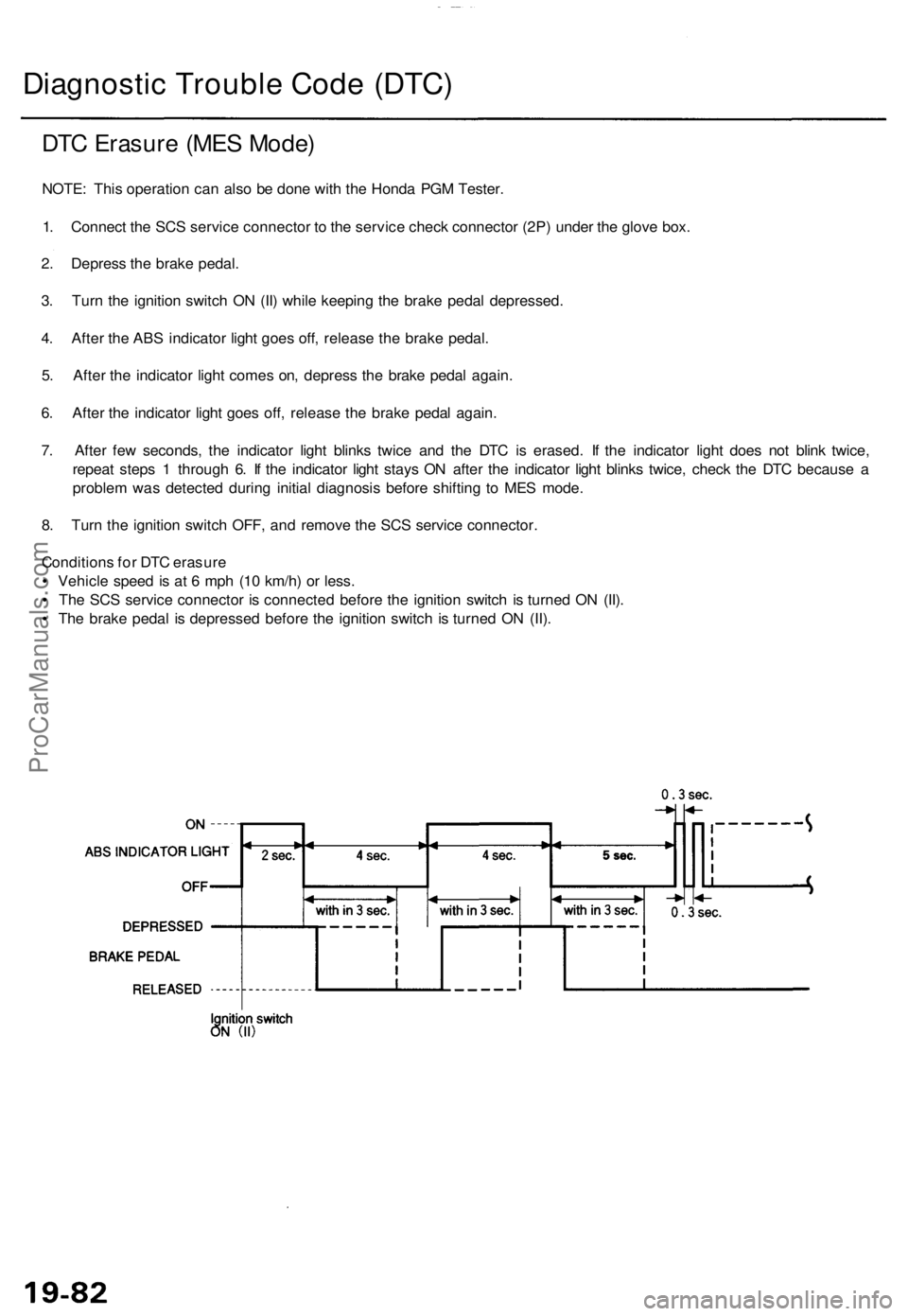

DTC Erasur e (ME S Mode )

NOTE: Thi s operatio n ca n als o b e don e wit h th e Hond a PG M Tester .

1 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r (2P ) unde r th e glov e box .

2 . Depres s th e brak e pedal .

3 . Tur n th e ignitio n switc h O N (II ) whil e keepin g th e brak e peda l depressed .

4 . Afte r th e AB S indicator light goe s off , releas e th e brak e pedal .

5 . Afte r th e indicato r ligh t come s on , depres s th e brak e peda l again .

6 . Afte r th e indicato r ligh t goe s off , releas e th e brak e peda l again .

7 . Afte r fe w seconds , th e indicato r ligh t blink s twic e an d th e DT C is erased . I f th e indicato r ligh t doe s no t blin k twice ,

repea t step s 1 throug h 6 . I f th e indicato r ligh t stay s O N afte r th e indicato r ligh t blink s twice , chec k th e DT C becaus e a

proble m wa s detecte d durin g initia l diagnosi s befor e shiftin g t o ME S mode .

8 . Tur n th e ignitio n switc h OFF , an d remov e th e SC S servic e connector .

Condition s fo r DT C erasur e

• Vehicl e spee d i s a t 6 mp h (1 0 km/h ) o r less .

• Th e SC S servic e connecto r i s connecte d befor e th e ignitio n switc h i s turne d O N (II) .

• Th e brak e peda l i s depresse d befor e th e ignitio n switc h i s turne d O N (II) .

ProCarManuals.com