engine ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 53 of 1771

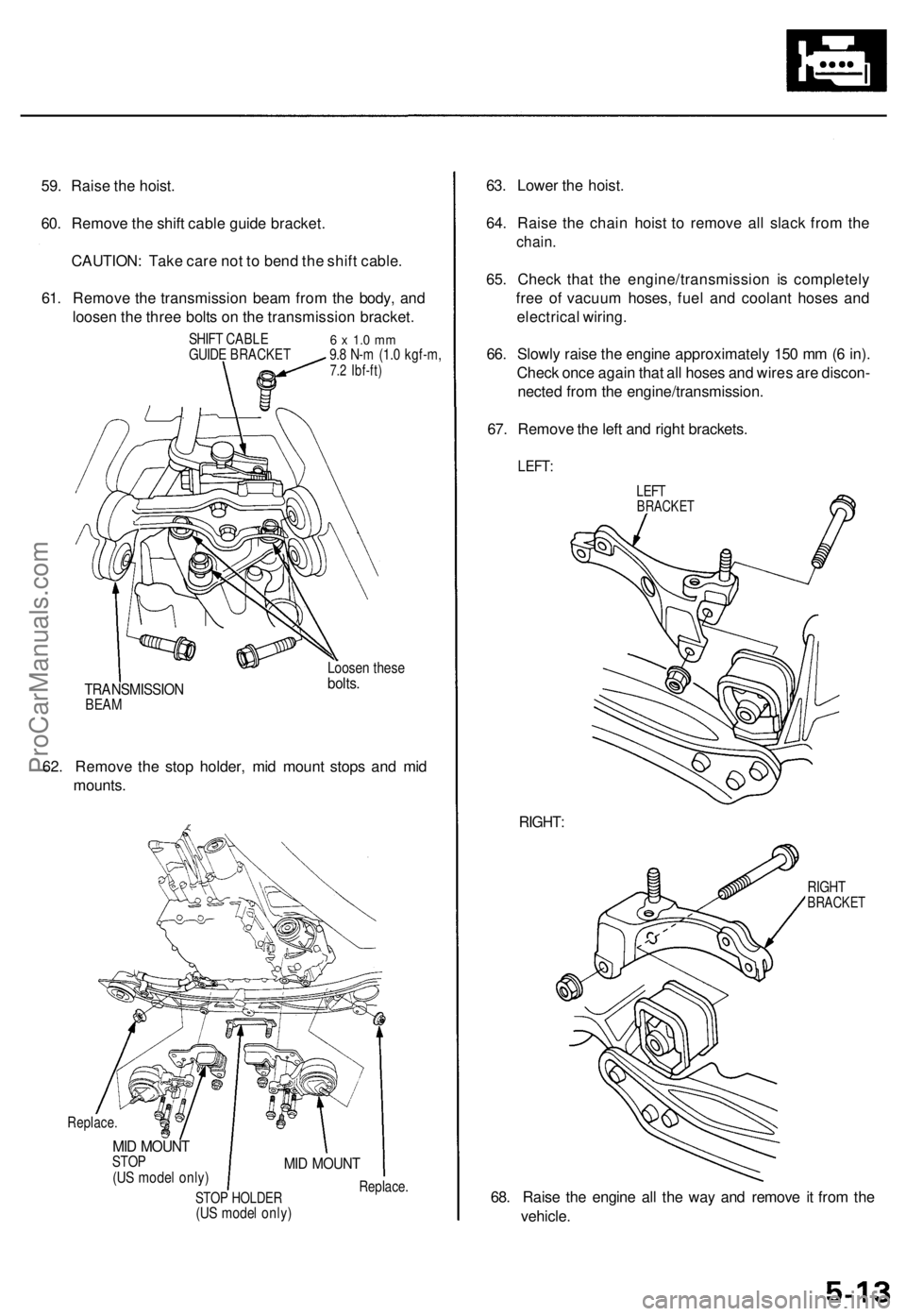

59. Raise the hoist.

60. Remove the shift cable guide bracket.

CAUTION: Take care not to bend the shift cable.

61. Remove the transmission beam from the body, and

loosen the three bolts on the transmission bracket.

SHIFT CABLE

GUIDE BRACKET

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

TRANSMISSION

BEAM

Loosen these

bolts.

62. Remove the stop holder, mid mount stops and mid

mounts.

Replace.

MID MOUNT

STOP

(US model only)

STOP HOLDER

(US model only)

MID MOUNT

Replace.

63. Lower the hoist.

64. Raise the chain hoist to remove all slack from the

chain.

65. Check that the engine/transmission is completely

free of vacuum hoses, fuel and coolant hoses and

electrical wiring.

66. Slowly raise the engine approximately 150 mm (6 in).

Check once again that all hoses and wires are discon-

nected from the engine/transmission.

67. Remove the left and right brackets.

LEFT:

LEFT

BRACKET

RIGHT:

RIGHT

BRACKET

68. Raise the engine all the way and remove it from the

vehicle.ProCarManuals.com

Page 54 of 1771

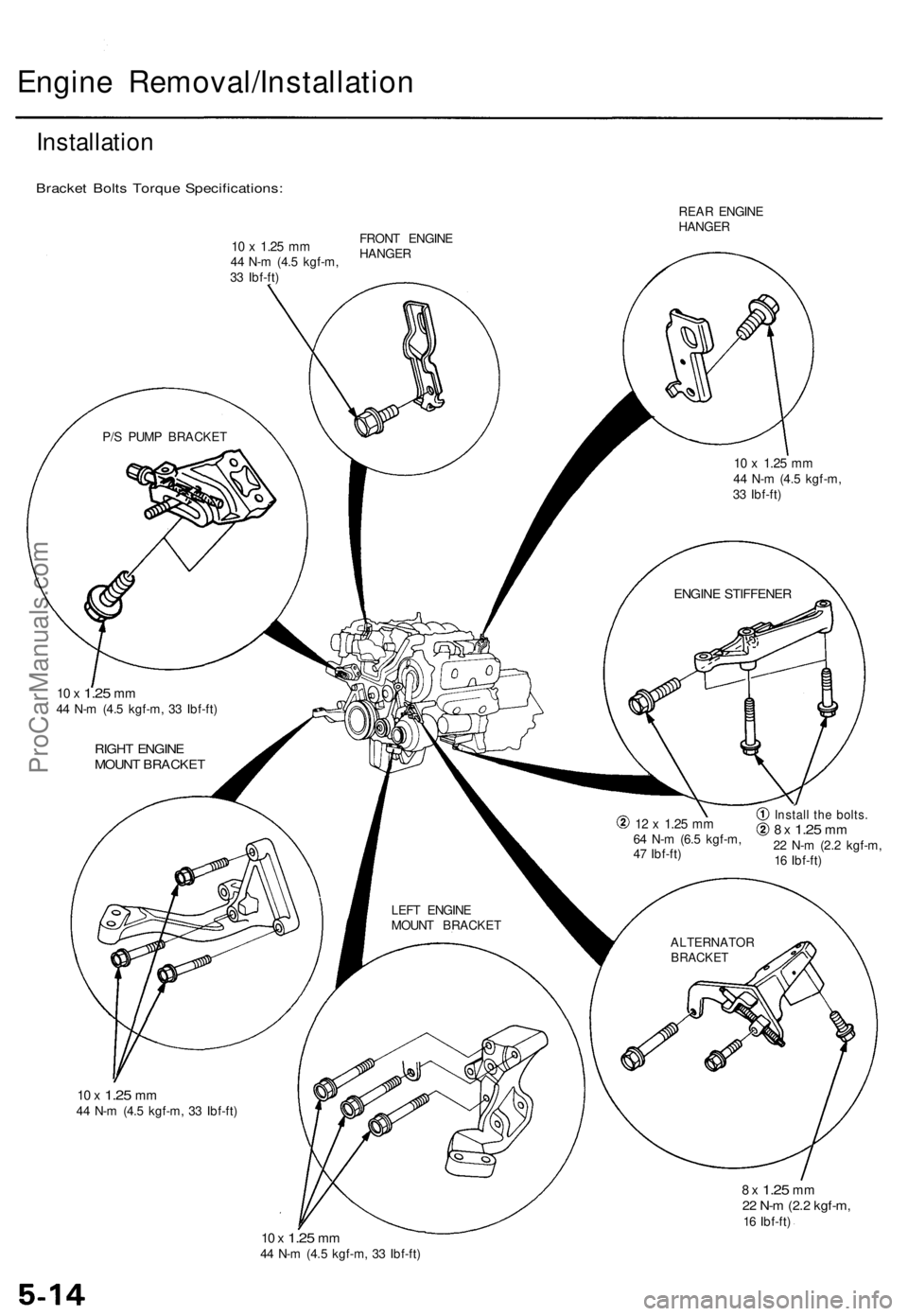

Engine Removal/Installation

Installation

Bracket Bolts Torque Specifications:

REAR ENGINE

HANGER

P/S PUMP BRACKET

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

ENGINE STIFFENER

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

RIGHT ENGINE

MOUNT BRACKET

LEFT ENGINE

MOUNT BRACKET

12 x

1.25

mm

64 N-m (6.5 kgf-m,

47 Ibf-ft)

Install the bolts.

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BRACKET

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

10 x

1.25

mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

FRONT ENGINE

HANGERProCarManuals.com

Page 55 of 1771

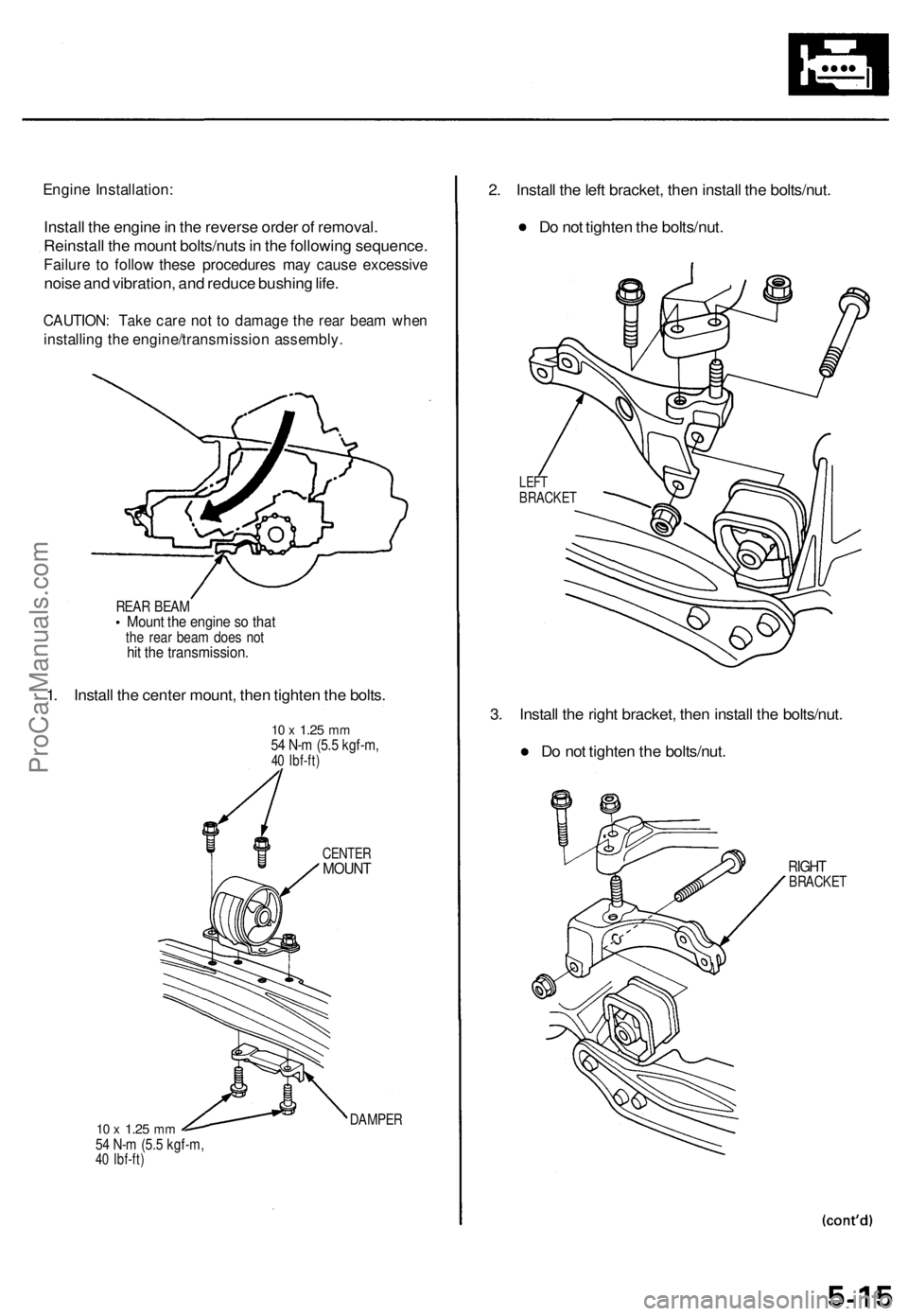

Engine Installation:

Install the engine in the reverse order of removal.

Reinstall the mount bolts/nuts in the following sequence.

Failure to follow these procedures may cause excessive

noise and vibration, and reduce bushing life.

CAUTION: Take care not to damage the rear beam when

installing the engine/transmission assembly.

REAR BEAM

Mount the engine so that

the rear beam does not

hit the transmission.

1. Install the center mount, then tighten the bolts.

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

CENTER

MOUNT

DAMPER

2. Install the left bracket, then install the bolts/nut.

Do not tighten the bolts/nut.

LEFT

BRACKET

3. Install the right bracket, then install the bolts/nut.

Do not tighten the bolts/nut.

RIGHT

BRACKETProCarManuals.com

Page 56 of 1771

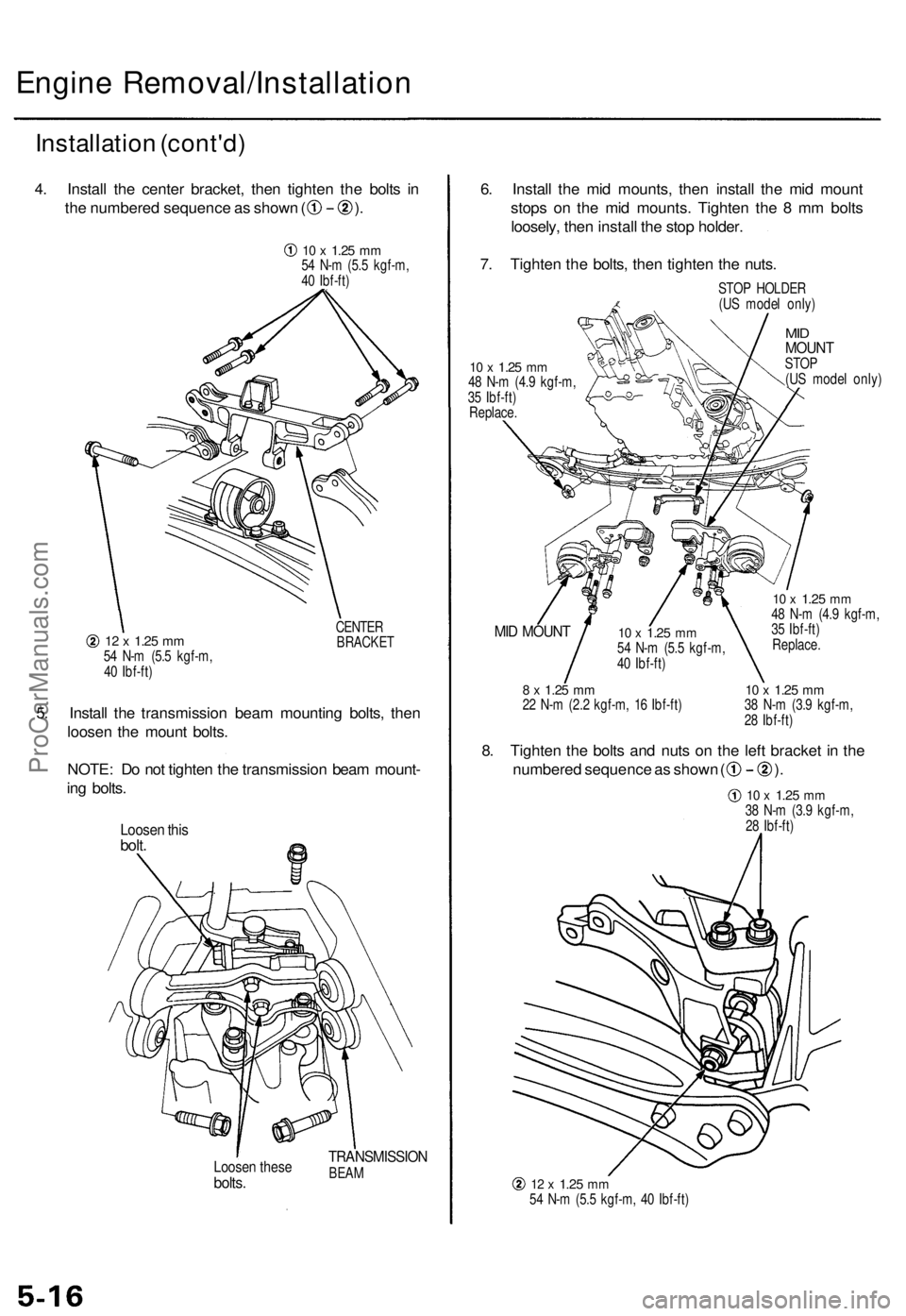

Engine Removal/Installatio n

Installation (cont'd )

4. Instal l th e cente r bracket , the n tighte n th e bolt s i n

th e numbere d sequenc e a s show n ( ) .

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft ) CENTE

RBRACKE T

5. Instal l th e transmissio n bea m mountin g bolts , the n

loose n th e moun t bolts .

NOTE : D o no t tighte n th e transmissio n bea m mount -

in g bolts .

Loose n thi sbolt .

Loose n thes ebolts.

TRANSMISSIO NBEAM

6. Instal l th e mi d mounts , the n instal l th e mi d moun t

stop s o n th e mi d mounts . Tighte n th e 8 m m bolt s

loosely , the n instal l th e sto p holder .

7 . Tighte n th e bolts , the n tighte n th e nuts .

STOP HOLDE R

(U S mode l only )

10 x 1.2 5 mm48 N- m (4. 9 kgf-m ,

3 5 Ibf-ft )

Replace .

MIDMOUN TSTOP

(U S mode l only )

MID MOUN T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

10 x 1.2 5 mm48 N- m (4. 9 kgf-m ,

3 5 Ibf-ft )

Replace .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

8. Tighte n th e bolt s an d nut s o n th e lef t bracke t i n th e

numbere d sequenc e a s show n ( ).

12 x 1.2 5 mm54 N- m (5. 5 kgf-m , 4 0 Ibf-ft )

10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

ProCarManuals.com

Page 57 of 1771

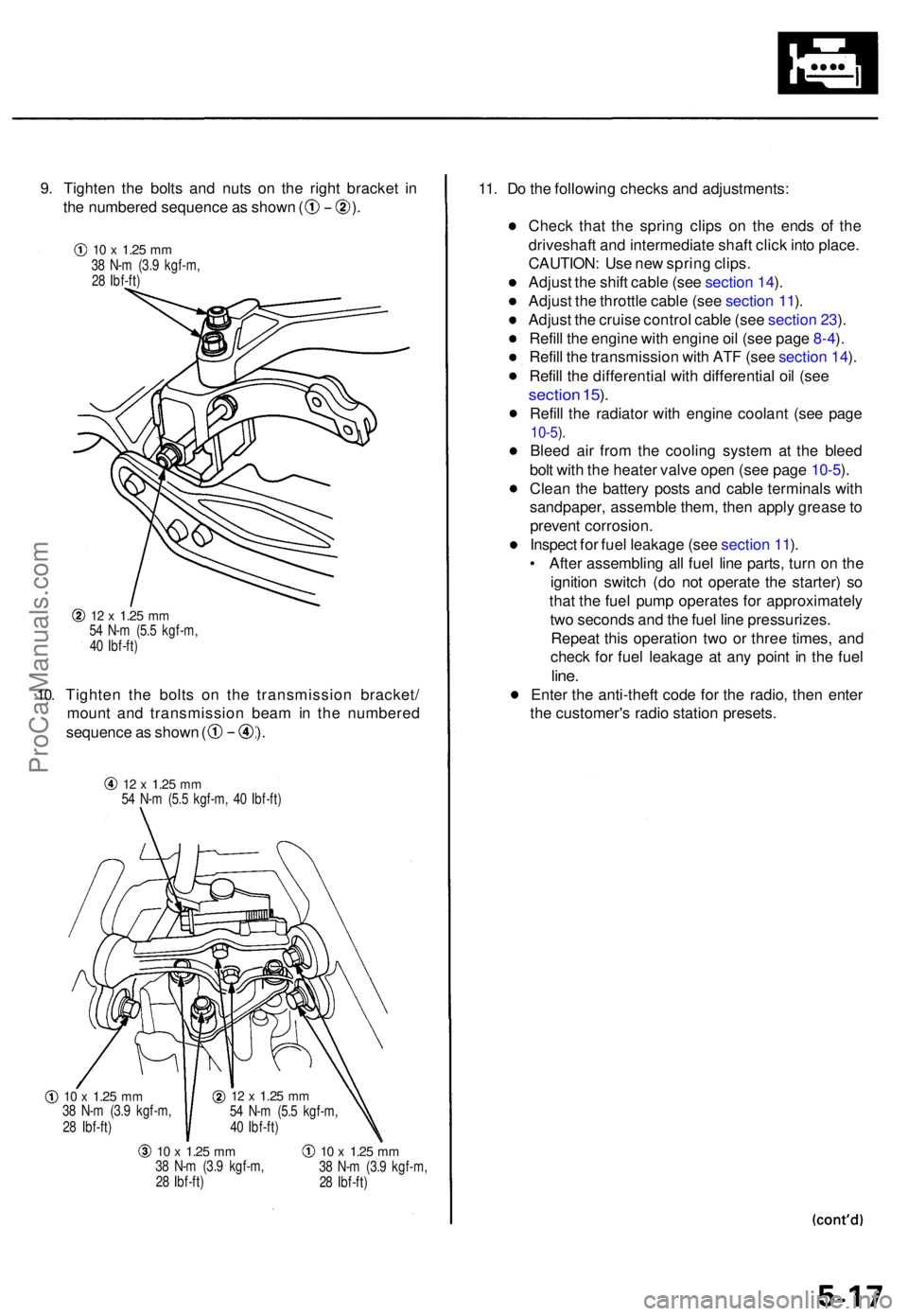

9. Tighte n th e bolt s an d nut s o n th e righ t bracke t i n

th e numbere d sequenc e a s show n ( ) .

10.

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Tighte n th e bolt s o n th e transmissio n bracket /

moun t an d transmissio n bea m in th e numbere d

sequence a s show n ( ) .

12 x 1.2 5 mm54 N- m (5. 5 kgf-m , 4 0 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

11. D o th e followin g check s an d adjustments :

Chec k tha t th e sprin g clip s o n th e end s o f th e

driveshaf t an d intermediat e shaf t clic k int o place .

CAUTION : Us e ne w sprin g clips .

Adjus t th e shif t cabl e (se e sectio n 14 ).

Adjus t th e throttl e cabl e (se e sectio n 11 ).

Adjus t th e cruis e contro l cabl e (se e sectio n 23 ).

Refil l th e engine with engin e oi l (se e pag e 8-4 ).

Refil l th e transmissio n wit h AT F (se e sectio n 14 ).

Refil l th e differentia l wit h differentia l oi l (se e

sectio n 15 ).

Refil l th e radiato r wit h engine coolant (se e pag e

10-5).

Blee d ai r fro m th e coolin g syste m a t th e blee d

bol t wit h th e heate r valv e ope n (se e pag e 10-5 ).

Clea n th e batter y post s an d cabl e terminal s wit h

sandpaper , assembl e them , the n appl y greas e to

preven t corrosion .

Inspec t fo r fue l leakag e (se e sectio n 11 ).

• Afte r assemblin g al l fue l lin e parts , tur n o n th e

ignitio n switc h (d o no t operat e th e starter ) s o

tha t th e fue l pum p operates for approximatel y

tw o second s an d th e fue l lin e pressurizes .

Repea t thi s operatio n tw o o r thre e times , an d

chec k fo r fue l leakag e a t an y poin t i n th e fue l

line.

Ente r th e anti-thef t cod e fo r th e radio , the n ente r

th e customer' s radi o statio n presets .

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

ProCarManuals.com

Page 58 of 1771

Engine Removal/Installation

Installation (cont'd)

Mount and Bracket Bolts/Nuts Torque Value Specifications:

TRANSMISSION

MOUNT BRACKET

TRANSMISSION

MOUNT

12 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

Replace.

RIGHT

MOUNT

DAMPER

8 x

1.25

mm

' 22 N-m (2.2 kgf-m,

16 Ibf-ft)

MID MOUNT

BRACKET

LEFT MOUNT

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

Replace.

MID MOUNT

BRACKET

10 x

1.25

mm

38 N-m (3.9 kgf-m, 28 Ibf-ft)ProCarManuals.com

Page 64 of 1771

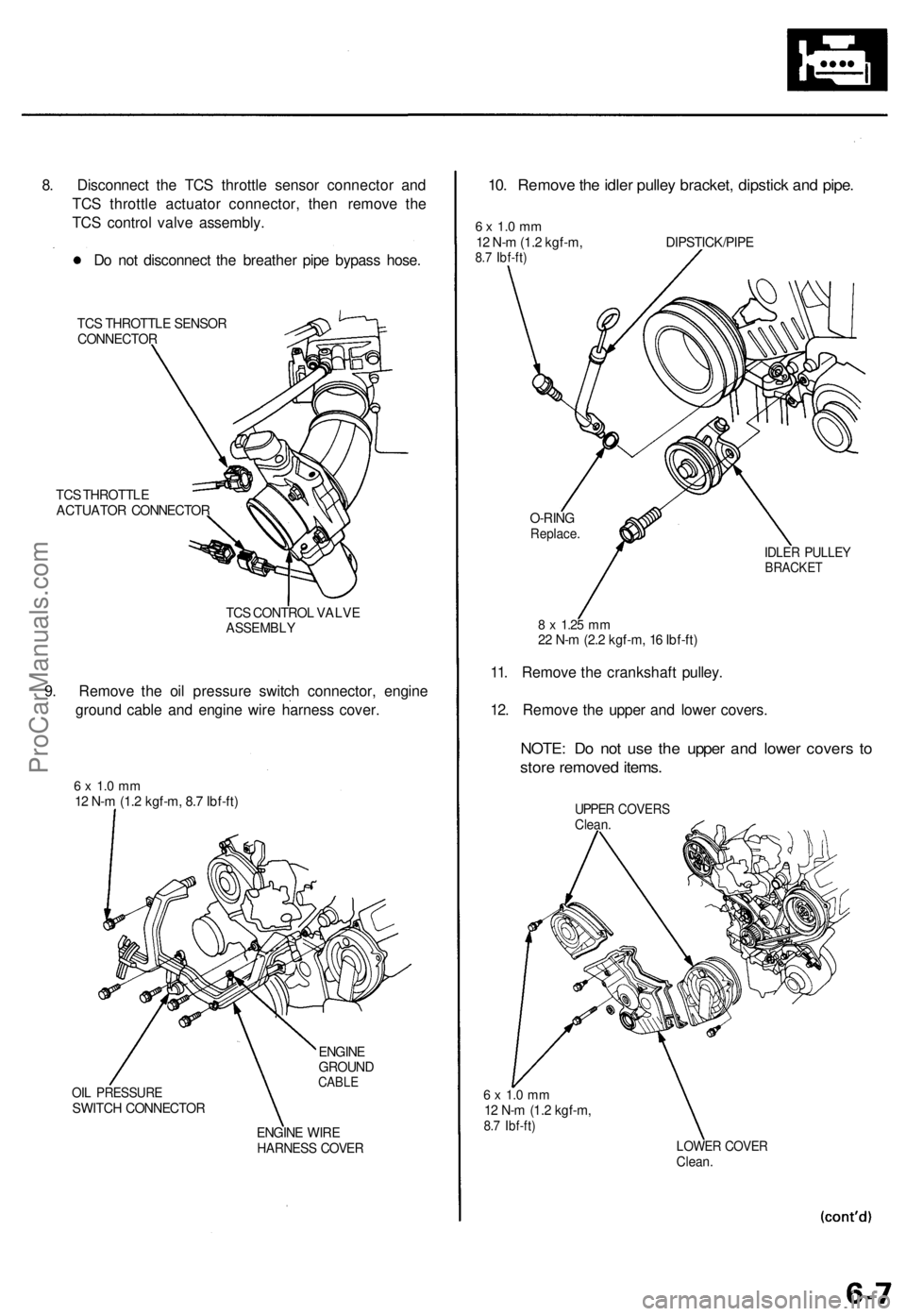

8. Disconnect the TCS throttle sensor connector and

TCS throttle actuator connector, then remove the

TCS control valve assembly.

Do not disconnect the breather pipe bypass hose.

TCS THROTTLE SENSOR

CONNECTOR

TCS THROTTLE

ACTUATOR CONNECTOR

TCS CONTROL VALVE

ASSEMBLY

9. Remove the oil pressure switch connector, engine

ground cable and engine wire harness cover.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

OIL PRESSURE

SWITCH CONNECTOR

ENGINE

GROUND

CABLE

ENGINE WIRE

HARNESS COVER

10. Remove the idler pulley bracket, dipstick and pipe.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

DIPSTICK/PIPE

8 x

1.25

mm

22 N-m (2.2 kgf-m, 16 Ibf-ft)

11. Remove the crankshaft pulley.

12. Remove the upper and lower covers.

NOTE: Do not use the upper and lower covers to

store removed items.

UPPER COVERS

Clean.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

LOWER COVER

Clean.

IDLER PULLEY

BRACKET

O-RING

Replace.ProCarManuals.com

Page 71 of 1771

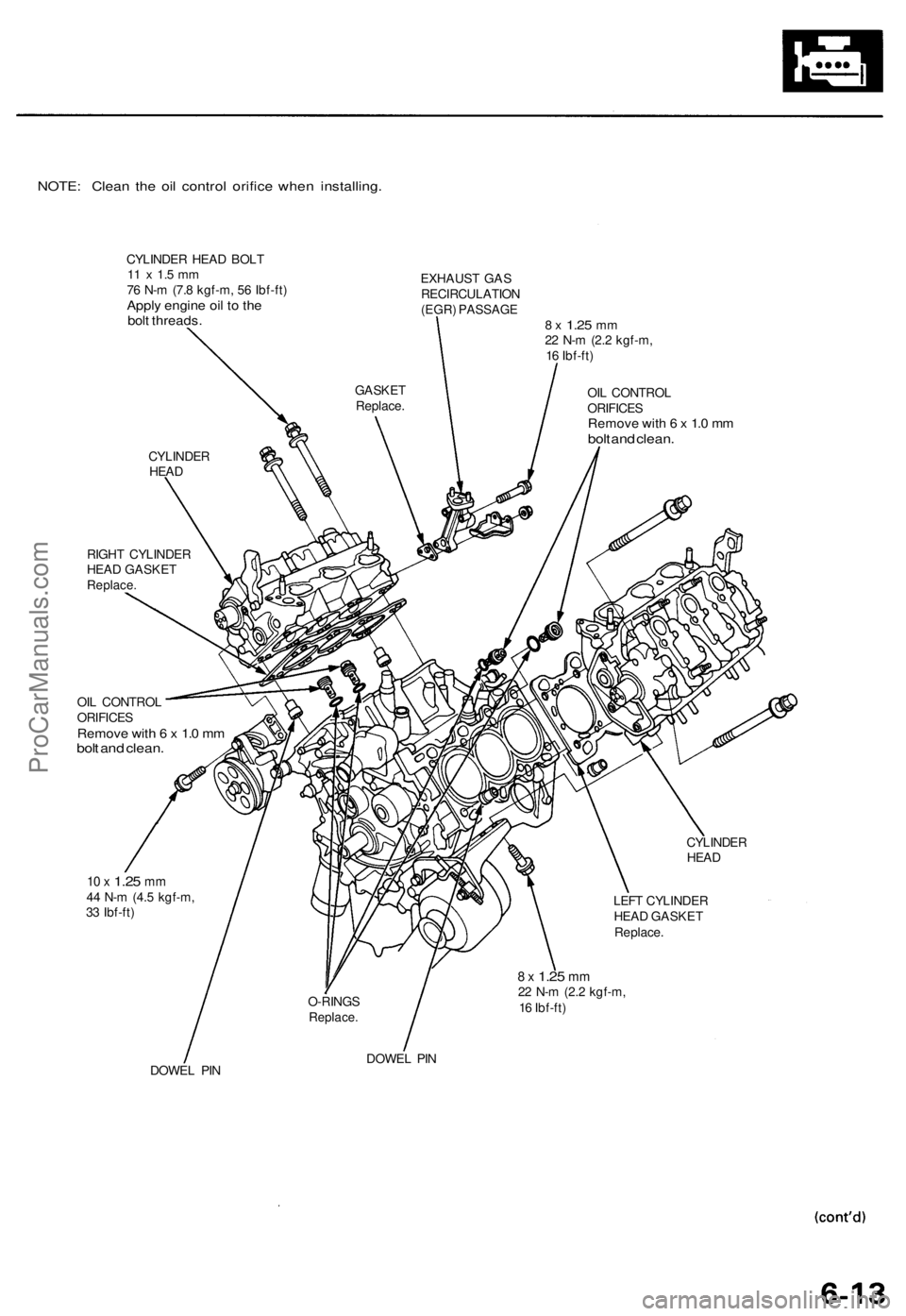

NOTE: Clean the oil control orifice when installing.

CYLINDER HEAD BOLT

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply engine oil to the

bolt threads.

EXHAUST GAS

RECIRCULATION

(EGR) PASSAGE

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

OIL CONTROL

ORIFICES

Remove with 6 x 1.0 mm

bolt and clean.

RIGHT CYLINDER

HEAD GASKET

Replace.

OIL CONTROL

ORIFICES

Remove with 6 x 1.0 mm

bolt and clean.

CYLINDER

HEAD

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

LEFT CYLINDER

HEAD GASKET

Replace.

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

DOWEL PIN

DOWEL PIN

O-RINGS

Replace.

GASKET

Replace.

CYLINDER

HEADProCarManuals.com

Page 73 of 1771

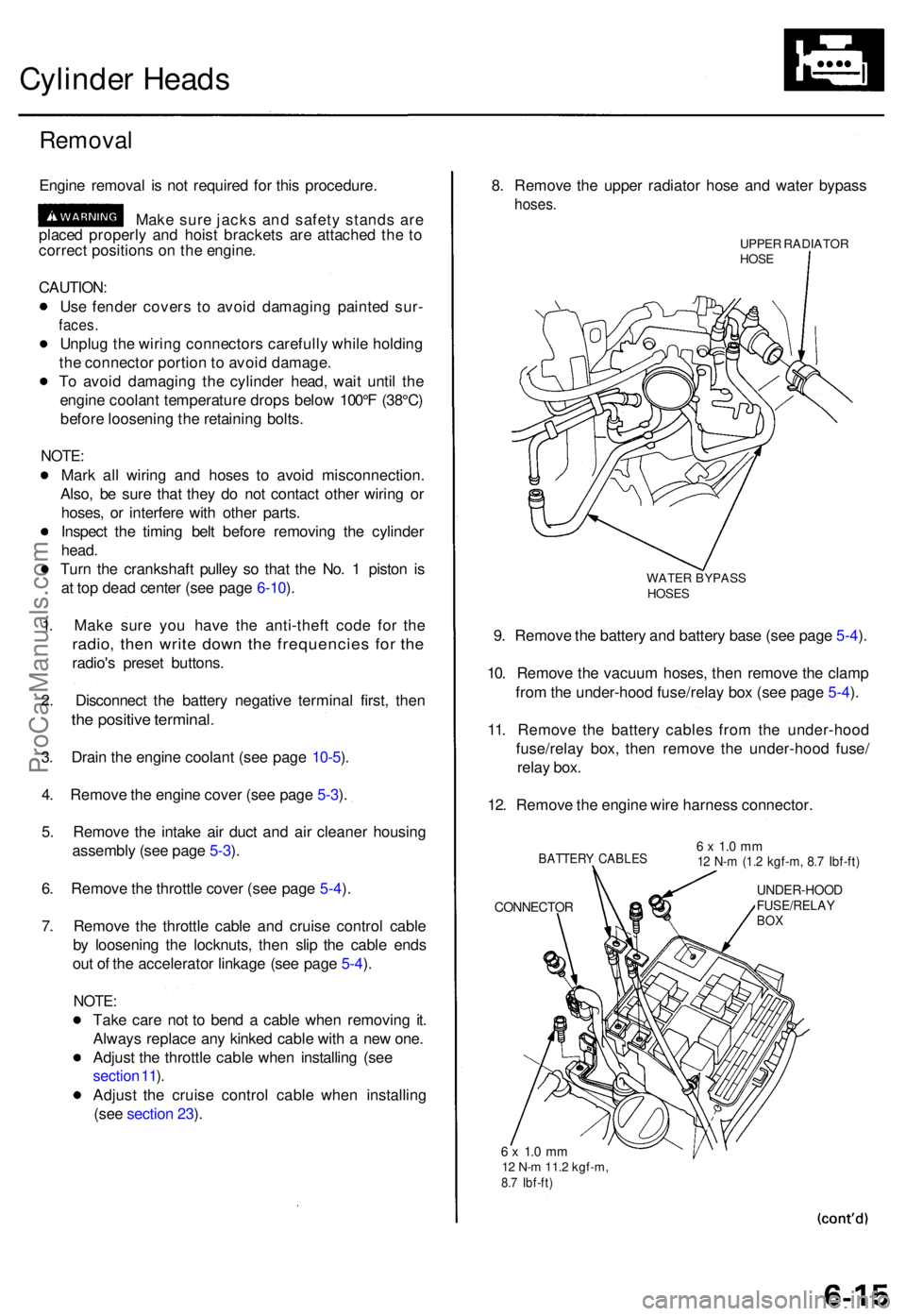

Cylinder Head s

Remova l

Engine remova l i s no t require d fo r thi s procedure .

Mak e sur e jack s an d safet y stand s ar e

place d properl y an d hois t bracket s ar e attache d th e t o

correc t position s o n th e engine .

CAUTION :

Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damage .

T o avoi d damagin g th e cylinde r head , wai t unti l th e

engin e coolan t temperatur e drop s belo w 100° F (38°C )

befor e loosenin g th e retainin g bolts .

NOTE :

Mark al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g o r

hoses , o r interfer e wit h othe r parts .

Inspec t th e timin g bel t befor e removin g th e cylinde r

head .

Tur n th e crankshaf t pulle y s o tha t th e No . 1 pisto n i s

a t to p dea d cente r (se e pag e 6-10 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e

radio , the n writ e dow n th e frequencie s fo r th e

radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e termina l first , the n

the positiv e terminal .

3. Drai n th e engin e coolan t (se e pag e 10-5 ).

4 . Remov e th e engin e cove r (se e pag e 5-3 ).

5 . Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembl y (se e pag e 5-3 ).

6 . Remov e th e throttl e cove r (se e pag e 5-4 ).

7 . Remov e th e throttl e cabl e an d cruis e contro l cabl e

b y loosenin g th e locknuts , the n sli p th e cabl e end s

ou t o f th e accelerato r linkag e (se e pag e 5-4 ).

NOTE :

Take car e no t t o ben d a cabl e whe n removin g it .

Alway s replac e an y kinke d cabl e wit h a ne w one .

Adjus t th e throttl e cabl e whe n installin g (se e

sectio n 11 ).

Adjus t th e cruis e contro l cabl e whe n installin g

(se e sectio n 23 ). 8

. Remov e th e uppe r radiato r hos e an d wate r bypas s

hoses.

UPPER RADIATO RHOSE

WATE R BYPAS SHOSES

9. Remov e th e batter y an d batter y bas e (se e pag e 5-4 ).

10 . Remov e th e vacuu m hoses , the n remov e th e clam p

fro m th e under-hoo d fuse/rela y bo x (se e pag e 5-4 ).

11 . Remov e th e batter y cable s fro m th e under-hoo d

fuse/rela y box , the n remov e th e under-hoo d fuse /

rela y box .

12 . Remov e th e engin e wir e harnes s connector .

BATTERY CABLE S

CONNECTO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

UNDER-HOO DFUSE/RELAYBOX

6 x 1. 0 m m12 N- m 11. 2 kgf-m ,8.7 Ibf-ft )

ProCarManuals.com

Page 74 of 1771

Cylinder Head s

Remova l (cont'd )

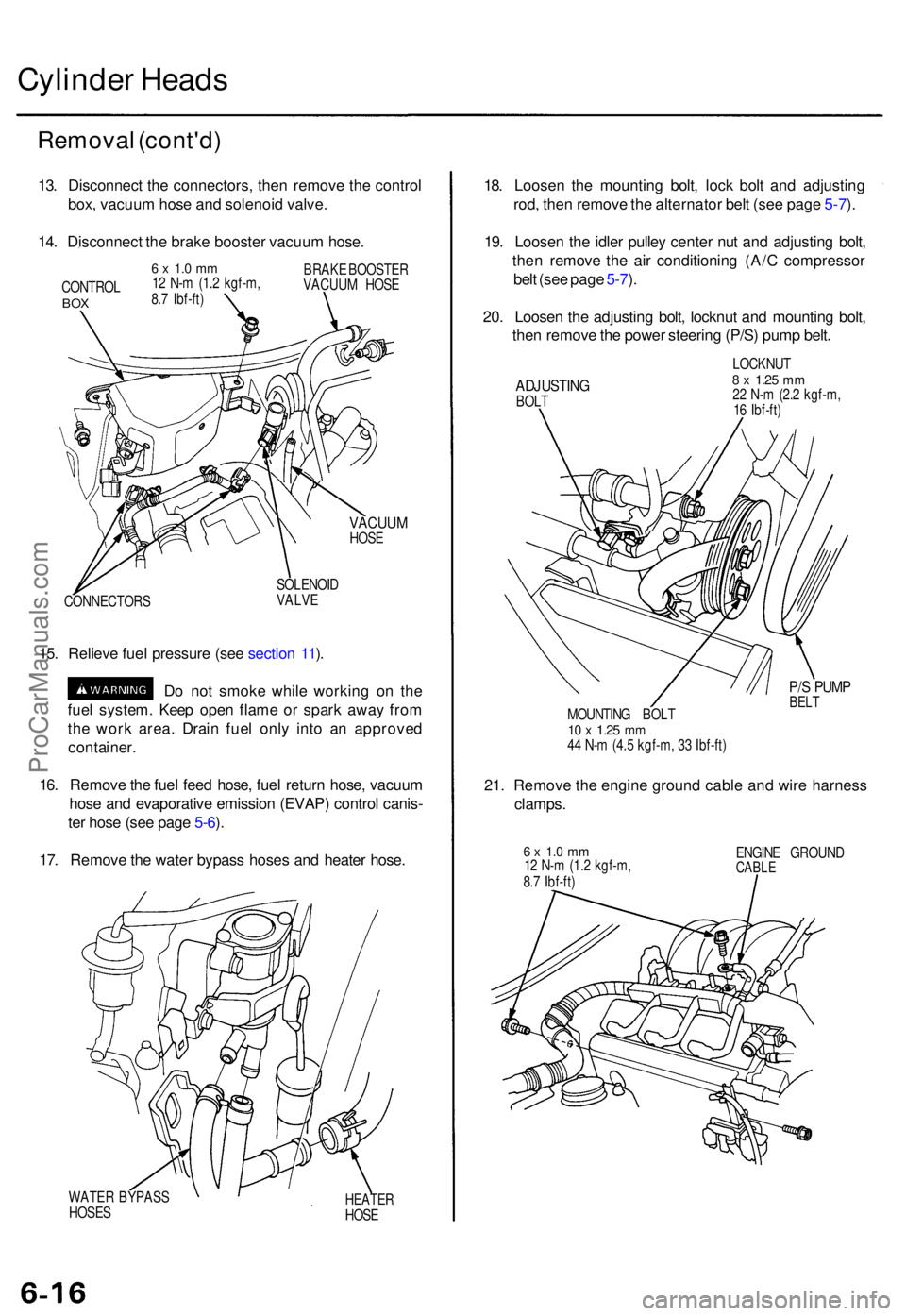

13. Disconnec t th e connectors , the n remov e th e contro l

box , vacuu m hos e an d solenoi d valve .

14 . Disconnec t th e brak e booste r vacuu m hose .

CONTRO LBOX

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) BRAK

E BOOSTE R

VACUU M HOS E

VACUU MHOSE

CONNECTOR S SOLENOI

D

VALVE

15. Reliev e fue l pressur e (se e sectio n 11 ).

D o no t smok e whil e workin g o n th e

fue l system . Kee p ope n flam e o r spar k awa y fro m

th e wor k area . Drai n fue l onl y int o a n approve d

container .

16 . Remov e th e fue l fee d hose , fue l retur n hose , vacuu m

hos e an d evaporativ e emissio n (EVAP ) contro l canis -

te r hos e (se e pag e 5-6 ).

17 . Remov e th e wate r bypas s hose s an d heate r hose .

WATE R BYPAS S

HOSE SHEATE RHOSE

18. Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

19 . Loose n th e idle r pulle y cente r nu t an d adjustin g bolt ,

the n remov e th e ai r conditionin g (A/ C compresso r

bel t (se e pag e 5-7 ).

20 . Loose n th e adjustin g bolt , locknu t an d mountin g bolt ,

the n remov e th e powe r steerin g (P/S ) pum p belt .

ADJUSTIN GBOLT LOCKNU

T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

P/S PUM PBELTMOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

21. Remov e th e engine ground cabl e an d wir e harnes s

clamps.

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) ENGIN

E GROUN DCABLE

ProCarManuals.com