transmission fluid ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 28 of 1771

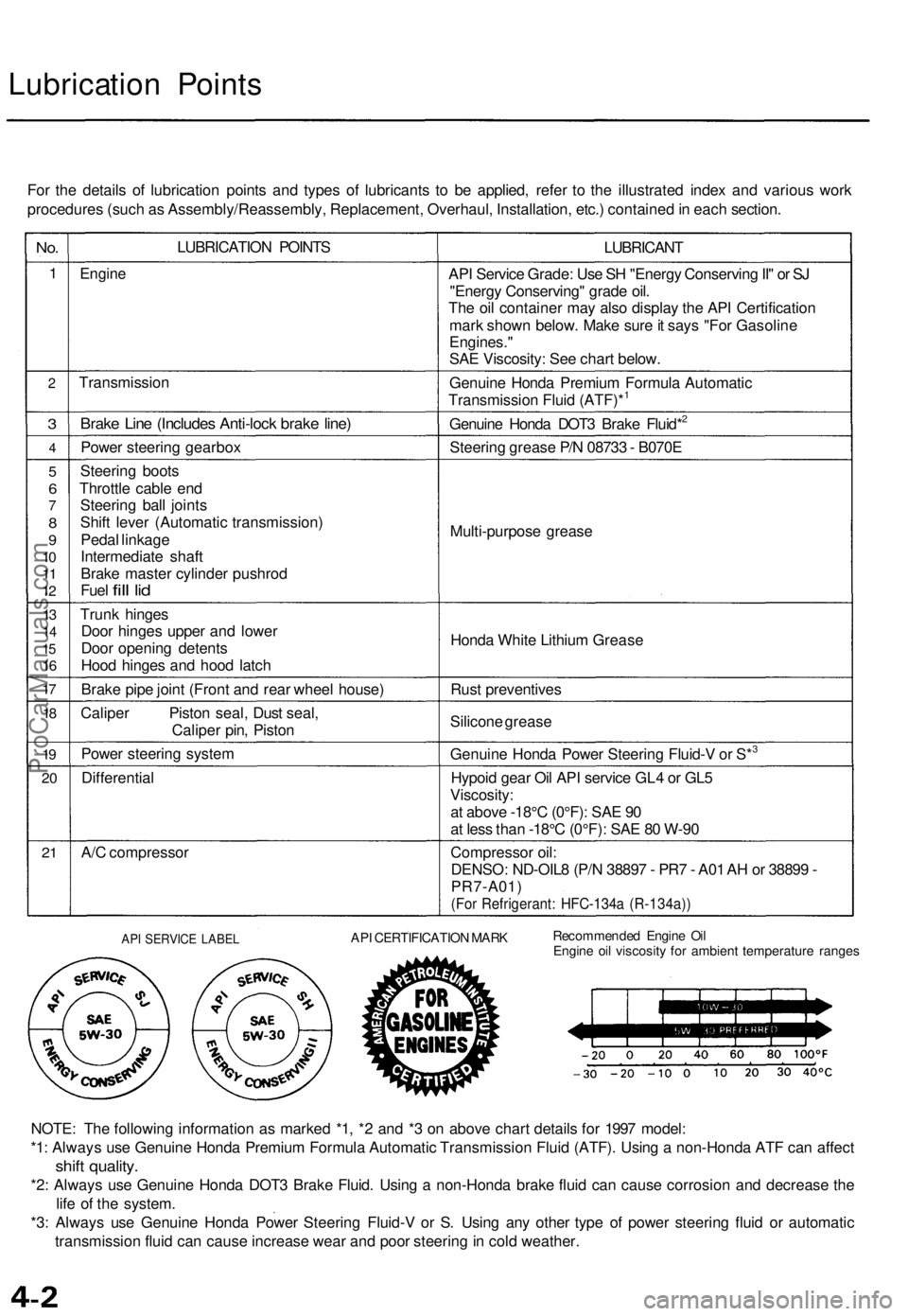

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

LUBRICATION POINTS

Engine

Transmission

Brake Line (Includes Anti-lock brake line)

Power steering gearbox

Steering boots

Throttle cable end

Steering ball joints

Shift lever (Automatic transmission)

Pedal linkage

Intermediate shaft

Brake master cylinder pushrod

Fuel

fill

lid

Trunk hinges

Door hinges upper and lower

Door opening detents

Hood hinges and hood latch

Brake pipe joint (Front and rear wheel house)

Caliper Piston seal, Dust seal,

Caliper pin, Piston

Power steering system

Differential

A/C compressor

LUBRICANT

API Service Grade: Use SH "Energy Conserving II" or SJ

"Energy Conserving" grade oil.

The oil container may also display the API Certification

mark shown below. Make sure it says "For Gasoline

Engines."

SAE Viscosity: See chart below.

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF)*1

Genuine Honda DOT3 Brake Fluid*2

Steering grease P/N 08733 - B070E

Multi-purpose grease

Honda White Lithium Grease

Rust preventives

Silicone grease

Genuine Honda Power Steering Fluid-V or S*3

Hypoid gear Oil API service GL4 or GL5

Viscosity:

at above -18°C (0°F): SAE 90

at less than -18°C (0°F): SAE 80 W-90

Compressor oil:

DENSO: ND-OIL8 (P/N 38897 - PR7 - A01 AH or 38899 -

PR7-A01)

(For Refrigerant: HFC-134a (R-134a))

API SERVICE LABEL

API CERTIFICATION MARK

Recommended Engine Oil

Engine oil viscosity for ambient temperature ranges

NOTE: The following information as marked *1, *2 and *3 on above chart details for 1997 model:

*1: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift quality.

*2: Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

*3: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatic

transmission fluid can cause increase wear and poor steering in cold weather.ProCarManuals.com

Page 257 of 1771

Description

The automatic transmission is a combination of a 3-element torque converter and a dual-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 reverse. The entire unit is positioned in line with the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the drive plate is a ring gear which

meshes with the starter pinion when the engine is being started.

The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in line with the engine

crankshaft. The mainshaft includes the 1st, 4th and 2nd clutches and gears for 4th, 1st, 2nd and reverse (3rd gear is integral

with the mainshaft). The countershaft includes the 3rd, 1st-hold and reverse clutches, and gears for 3rd, 4th, 1st, 2nd,

reverse and parking. The secondary drive gear is integrated with the countershaft. The gears on the mainshaft are in con-

stant mesh with those on the countershaft. When certain combinations of gears in the transmission are engaged by clutch-

positions.

and

es, power is transmitted from the mainshaft to the countershaft to provide

Electronic Control

The electronic control system consists of a Powertrain Control Module (PCM), sensors, a linear solenoid and four solenoid

valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The PCM is located below the dashboard, under the front lower panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the secondary valve body, the throttle valve body, the lin-

ear solenoid, the shift control solenoid valves and the ATF passage body. They are bolted on the lower part of the trans-

mission housing. The regulator valve body, the ATF pump body, and the accumulator body are bolted to the torque con-

verter housing.

The main valve body on '96 model contains the manual valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the

4-3 kick-down valve and the Clutch Pressure Control (CPC) valve. The main valve body on '97 model contains the manual

valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the 4-3 kick-down valve and the main orifice control valve.

The secondary valve body on '96 model contains the 3-4 orifice control valve, the 4-3 shift timing valve, the modulator valve

and the accumulator pistons.The secondary valve body on '97 model contains the 3-4 orifice control valve, the 4-3 shift tim-

ing valve, the line pressure control valve, the modulator valve and the accumulator pistons. The throttle valve body

includes the throttle valve which is bolted onto the secondary valve body. The linear solenoid is joined to the throttle valve

body. The regulator valve body contains the regulator valve, the lock-up shift valve and the cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves. The ATF pump body contains the lock-up tim-

ing valve, the lock-up control valve and the relief valve. The torque converter check valve is located in the torque converter

housing under the ATF pump body. The accumulator body contains the accumulator pistons. The reverse accumulator and

the 1st-hold accumulator pistons are assembled in the rear cover.

The 1st, 1st-hold, 2nd and reverse clutches receive fluid from their respective feed pipes, and the 3rd and 4th clutches

receive fluid from the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the PCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a

line to one of the clutches, engaging the clutch and its corresponding gear.

er through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the PCM optimizes the tim-

ing of the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves

A and B, and throttle valve. When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-

up control solenoid valves A and B are mounted on the torque converter housing, and are controlled by the PCM.

(cont'd)

Lock-up Mechanism

In

position, in 2nd, 3rd, and 4th, and

position in 3rd, pressurized fluid is drained from the back of the torque convert-ProCarManuals.com

Page 278 of 1771

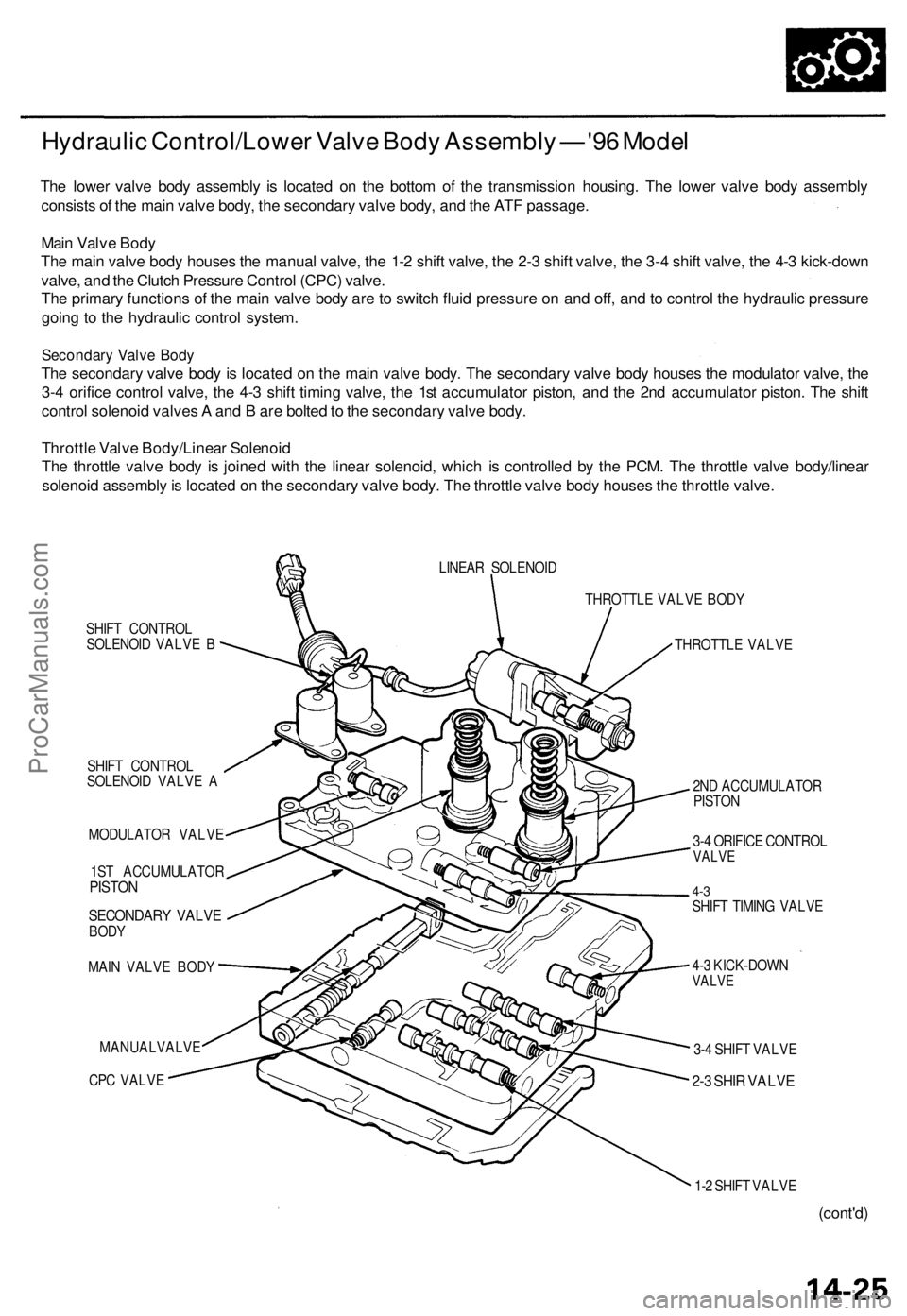

Hydraulic Control/Lower Valve Body Assembly — '96 Model

The lower valve body assembly is located on the bottom of the transmission housing. The lower valve body assembly

consists of the main valve body, the secondary valve body, and the ATF passage.

Main Valve Body

The main valve body houses the manual valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the 4-3 kick-down

valve, and the Clutch Pressure Control (CPC) valve.

The primary functions of the main valve body are to switch fluid pressure on and off, and to control the hydraulic pressure

going to the hydraulic control system.

Secondary Valve Body

The secondary valve body is located on the main valve body. The secondary valve body houses the modulator valve, the

3-4 orifice control valve, the 4-3 shift timing valve, the 1st accumulator piston, and the 2nd accumulator piston. The shift

control solenoid valves A and B are bolted to the secondary valve body.

Throttle Valve Body/Linear Solenoid

The throttle valve body is joined with the linear solenoid, which is controlled by the PCM. The throttle valve body/linear

solenoid assembly is located on the secondary valve body. The throttle valve body houses the throttle valve.

SHIFT CONTROL

SOLENOID VALVE B

SHIFT CONTROL

SOLENOID VALVE A

MODULATOR VALVE

1ST ACCUMULATOR

PISTON

SECONDARY VALVE

BODY

MAIN VALVE BODY

MANUALVALVE

CPC VALVE

LINEAR SOLENOID

THROTTLE VALVE BODY

THROTTLE VALVE

2ND ACCUMULATOR

PISTON

3-4 ORIFICE CONTROL

VALVE

4-3

SHIFT TIMING VALVE

4-3 KICK-DOWN

VALVE

3-4 SHIFT VALVE

2-3 SHIR VALVE

1-2 SHIFT VALVE

(cont'd)ProCarManuals.com

Page 279 of 1771

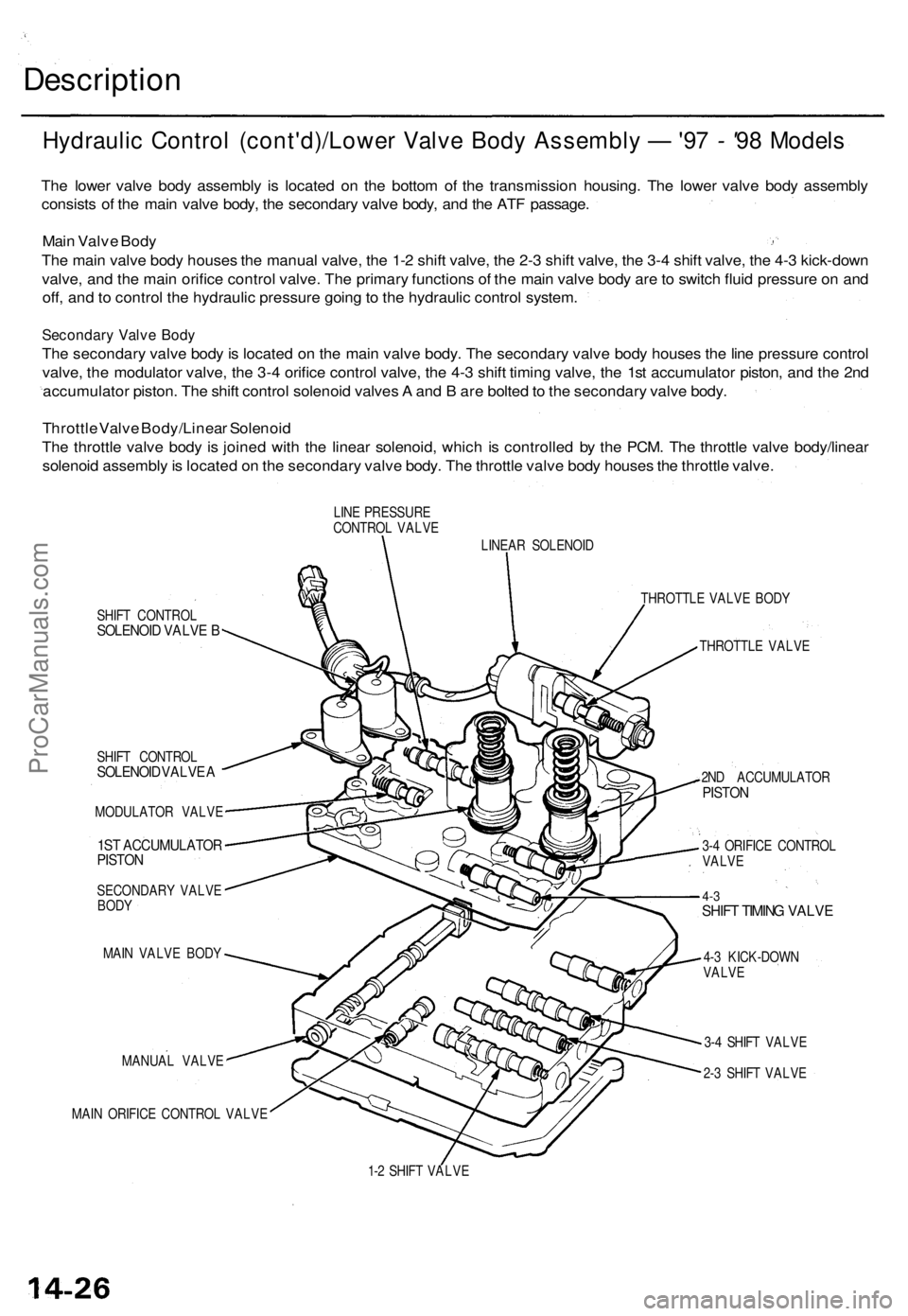

Hydraulic Control (cont'd)/Lower Valve Body Assembly — '97 - '98 Models

The lower valve body assembly is located on the bottom of the transmission housing. The lower valve body assembly

consists of the main valve body, the secondary valve body, and the ATF passage.

Main Valve Body

The main valve body houses the manual valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the 4-3 kick-down

valve, and the main orifice control valve. The primary functions of the main valve body are to switch fluid pressure on and

off, and to control the hydraulic pressure going to the hydraulic control system.

Secondary Valve Body

The secondary valve body is located on the main valve body. The secondary valve body houses the line pressure control

valve, the modulator valve, the 3-4 orifice control valve, the 4-3 shift timing valve, the 1st accumulator piston, and the 2nd

accumulator piston. The shift control solenoid valves A and B are bolted to the secondary valve body.

Throttle Valve Body/Linear Solenoid

The throttle valve body is joined with the linear solenoid, which is controlled by the PCM. The throttle valve body/linear

solenoid assembly is located on the secondary valve body. The throttle valve body houses the throttle valve.

LINE PRESSURE

CONTROL VALVE

LINEAR SOLENOID

SHIFT CONTROL

SOLENOID VALVE B

SHIFT CONTROL

SOLENOID VALVE A

MODULATOR VALVE

1ST ACCUMULATOR

PISTON

SECONDARY VALVE

BODY

MAIN VALVE BODY

MANUAL VALVE

MAIN ORIFICE CONTROL VALVE

THROTTLE VALVE BODY

THROTTLE VALVE

2ND ACCUMULATOR

PISTON

3-4 ORIFICE CONTROL

VALVE

4-3

SHIFT TIMING VALVE

4-3 KICK-DOWN

VALVE

3-4 SHIFT VALVE

2-3 SHIFT VALVE

1-2 SHIFT VALVE

DescriptionProCarManuals.com

Page 284 of 1771

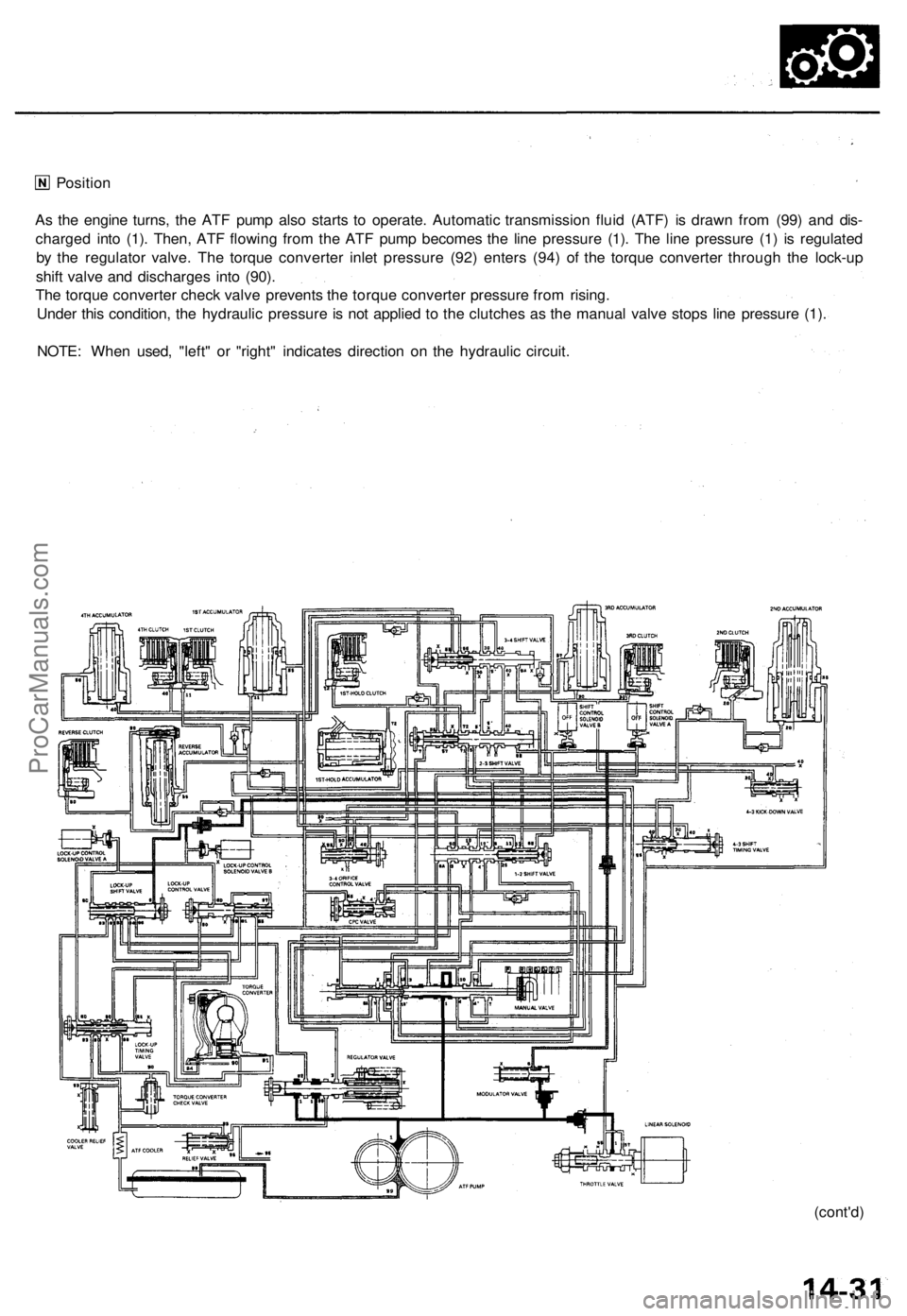

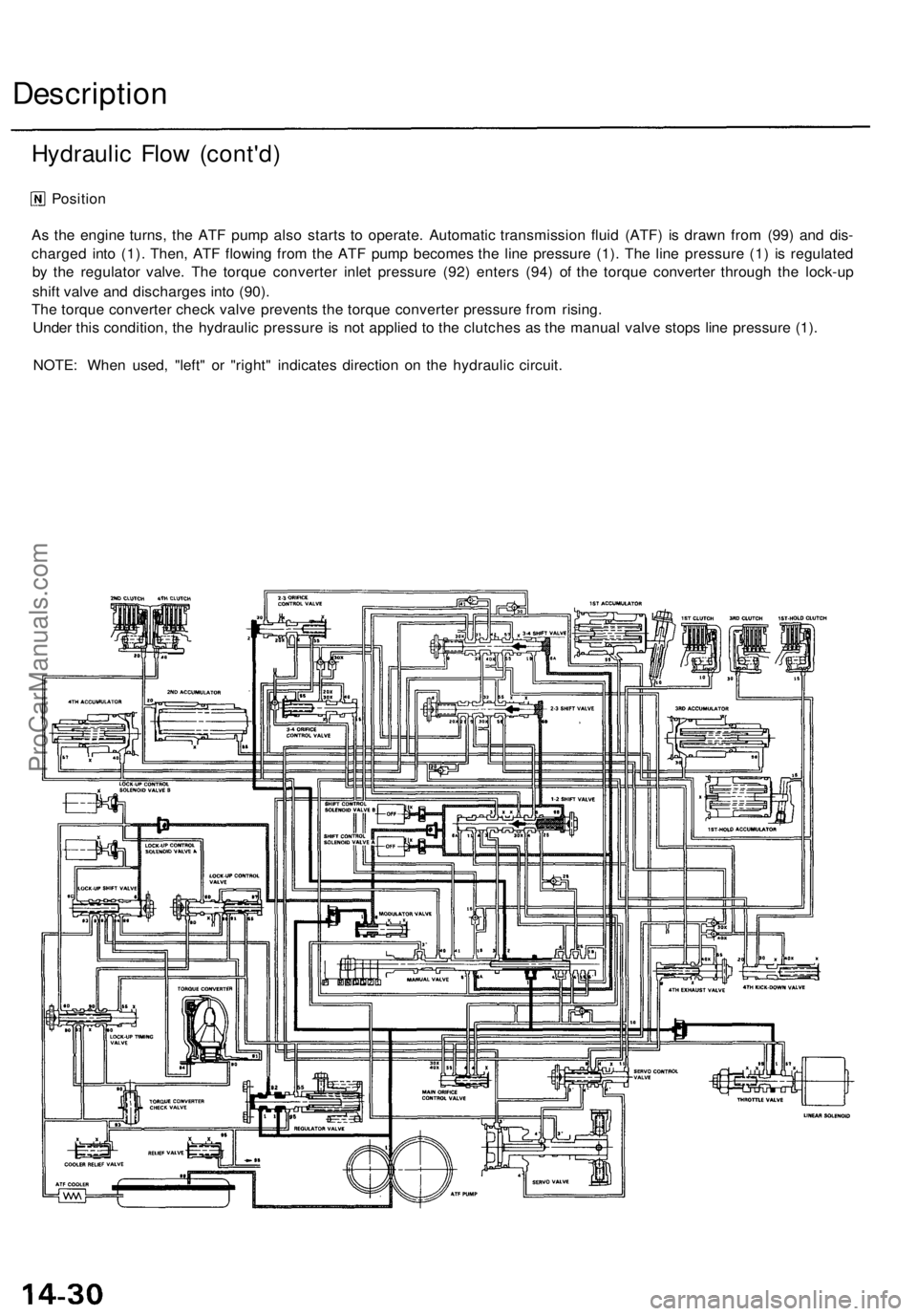

Position

(cont'd)

As the engine turns, the ATF pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-

charged into (1). Then, ATF flowing from the ATF pump becomes the line pressure (1). The line pressure (1) is regulated

by the regulator valve. The torque converter inlet pressure (92) enters (94) of the torque converter through the lock-up

shift valve and discharges into (90).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches as the manual valve stops line pressure (1).

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.ProCarManuals.com

Page 328 of 1771

Fluid Level

Checking/Changing

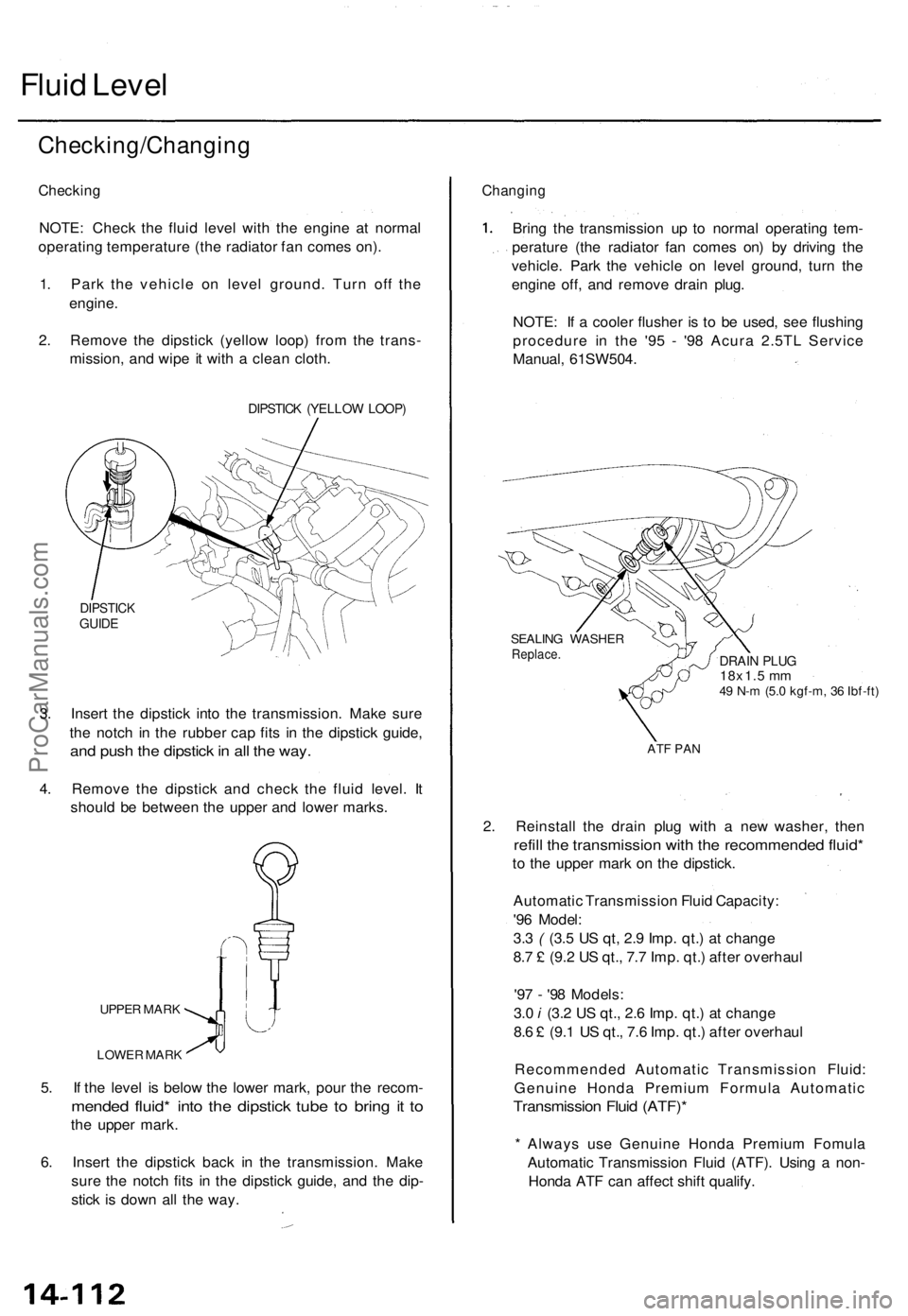

Checking

NOTE: Check the fluid level with the engine at normal

operating temperature (the radiator fan comes on).

1. Park the vehicle on level ground. Turn off the

engine.

2. Remove the dipstick (yellow loop) from the trans-

mission, and wipe it with a clean cloth.

DIPSTICK (YELLOW LOOP)

DIPSTICK

GUIDE

3. Insert the dipstick into the transmission. Make sure

the notch in the rubber cap fits in the dipstick guide,

and push the dipstick in all the way.

4. Remove the dipstick and check the fluid level. It

should be between the upper and lower marks.

UPPER MARK

LOWER MARK

5. If the level is below the lower mark, pour the recom-

mended fluid* into the dipstick tube to bring it to

the upper mark.

6. Insert the dipstick back in the transmission. Make

sure the notch fits in the dipstick guide, and the dip-

stick is down all the way.

Changing

Bring the transmission up to normal operating tem-

perature (the radiator fan comes on) by driving the

vehicle. Park the vehicle on level ground, turn the

engine off, and remove drain plug.

NOTE: If a cooler flusher is to be used, see flushing

procedure in the '95 - '98 Acura 2.5TL Service

Manual, 61SW504.

SEALING WASHER

Replace.

DRAIN PLUG

18x1.5 mm

49 N-m (5.0 kgf-m, 36 Ibf-ft)

ATF PAN

2. Reinstall the drain plug with a new washer, then

refill the transmission with the recommended fluid*

to the upper mark on the dipstick.

Automatic Transmission Fluid Capacity:

'96 Model:

3.3 ( (3.5 US qt, 2.9 Imp. qt.) at change

8.7 £ (9.2 US qt., 7.7 Imp. qt.) after overhaul

'97 - '98 Models:

3.0 i (3.2 US qt., 2.6 Imp. qt.) at change

8.6 £ (9.1 US qt., 7.6 Imp. qt.) after overhaul

Recommended Automatic Transmission Fluid:

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF)*

* Always use Genuine Honda Premium Fomula

Automatic Transmission Fluid (ATF). Using a non-

Honda ATF can affect shift qualify.ProCarManuals.com

Page 332 of 1771

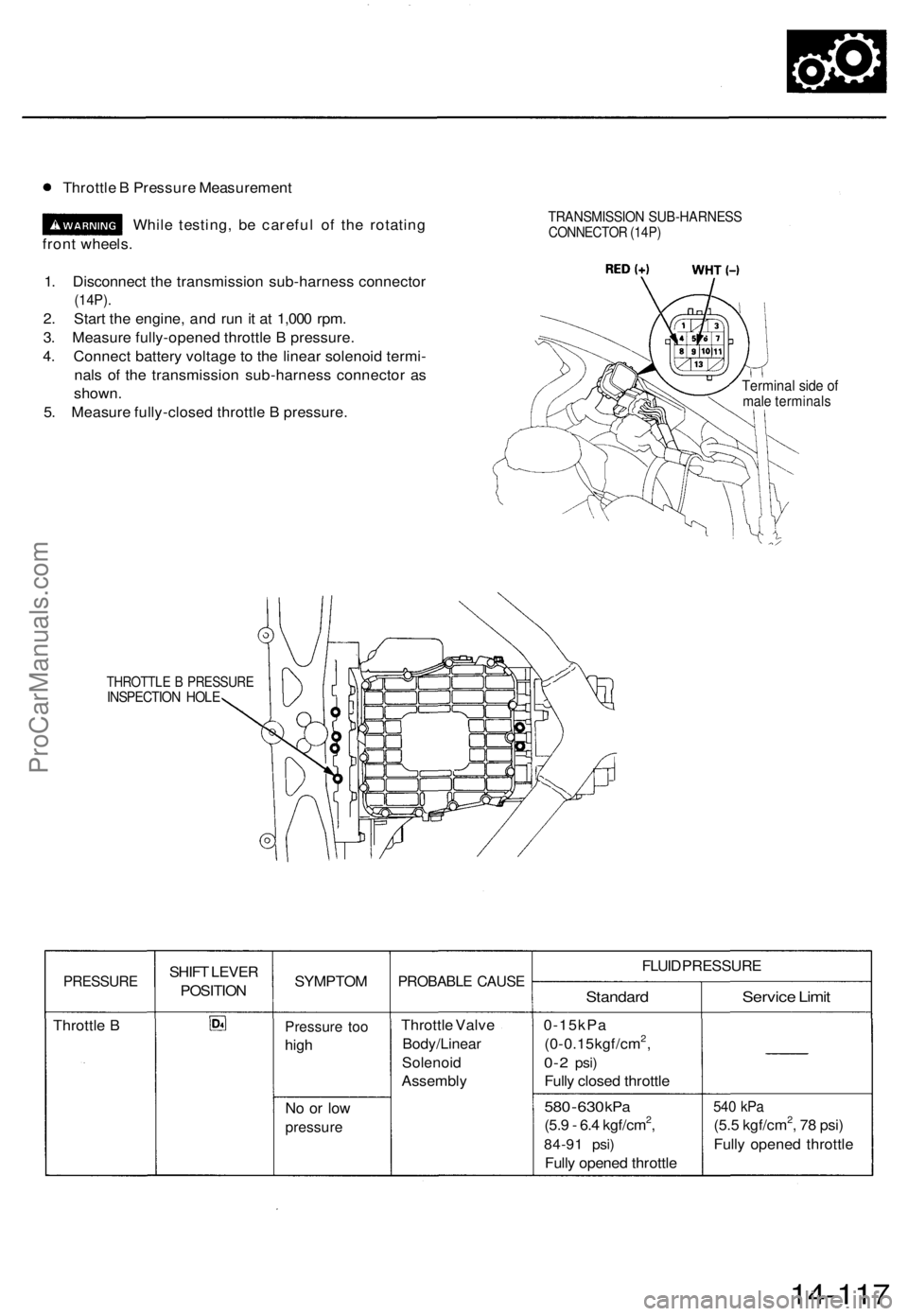

Throttle B Pressure Measurement

While testing, be careful of the rotating

front wheels.

1. Disconnect the transmission sub-harness connector

(14P).

2. Start the engine, and run it at 1,000 rpm.

3. Measure fully-opened throttle B pressure.

4. Connect battery voltage to the linear solenoid termi-

nals of the transmission sub-harness connector as

shown.

5. Measure fully-closed throttle B pressure.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

Terminal side of

male terminals

THROTTLE B PRESSURE

INSPECTION HOLE

PRESSURE

Throttle B

SHIFT LEVER

POSITION

SYMPTOM

Pressure too

high

No or low

pressure

PROBABLE CAUSE

Throttle Valve

Body/Linear

Solenoid

Assembly

FLUID PRESSURE

Standard

0-15kPa

(0-0.15kgf/cm2,

0-2

psi)

Fully closed throttle

580

-

630

kPa

(5.9 - 6.4 kgf/cm2,

84-91 psi)

Fully opened throttle

Service Limit

540 kPa

(5.5 kgf/cm2, 78 psi)

Fully opened throttle

14-117ProCarManuals.com

Page 334 of 1771

![ACURA TL 1995 Service Repair Manual

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

8. Shift to the [HI or [P] position, and measure ACURA TL 1995 Service Repair Manual

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

8. Shift to the [HI or [P] position, and measure](/img/32/56993/w960_56993-333.png)

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

8. Shift to the [HI or [P] position, and measure line pressure at fully-opened throttle.

9. Connect battery voltage to the linear solenoid terminals of the transmission sub-harness connector as shown.

10. Measure line pressure at fully-closed throttle.

If line pressure is out of specification, check and repair the probable cause in the table below.

PRESSURE

Line

SHIFT LEVER

POSITION

or

SYMPTOM

No (or

low)

line pressure

PROBABLE CAUSE

Torque converter,

ATF pump, pres-

sure regulator.

torque converter

check valve

FLUID PRESSURE

Standard

520 kPa

(5.3 kgf/cm2, 75 psi)

Fully closed throttle

|

910 kPa

(9.3 kgf/cm2, 130 psi)

Fully opened throttle

Service Limit

500 kPa

(5.1 kgf/cm2, 73 psi)

Fully closed throttle

790 kPa

(8.1 kgf/cm2, 120 psi)

Fully opened throttle

11. Stop the engine, and connect the transmission sub-harness connector (14P).

12. Disconnect the special tool from line pressure inspection hole, and connect the special tool to each inspection hole.

13. Start the engine, and run it at 2,000 rpm.

(cont'd)ProCarManuals.com

Page 936 of 1771

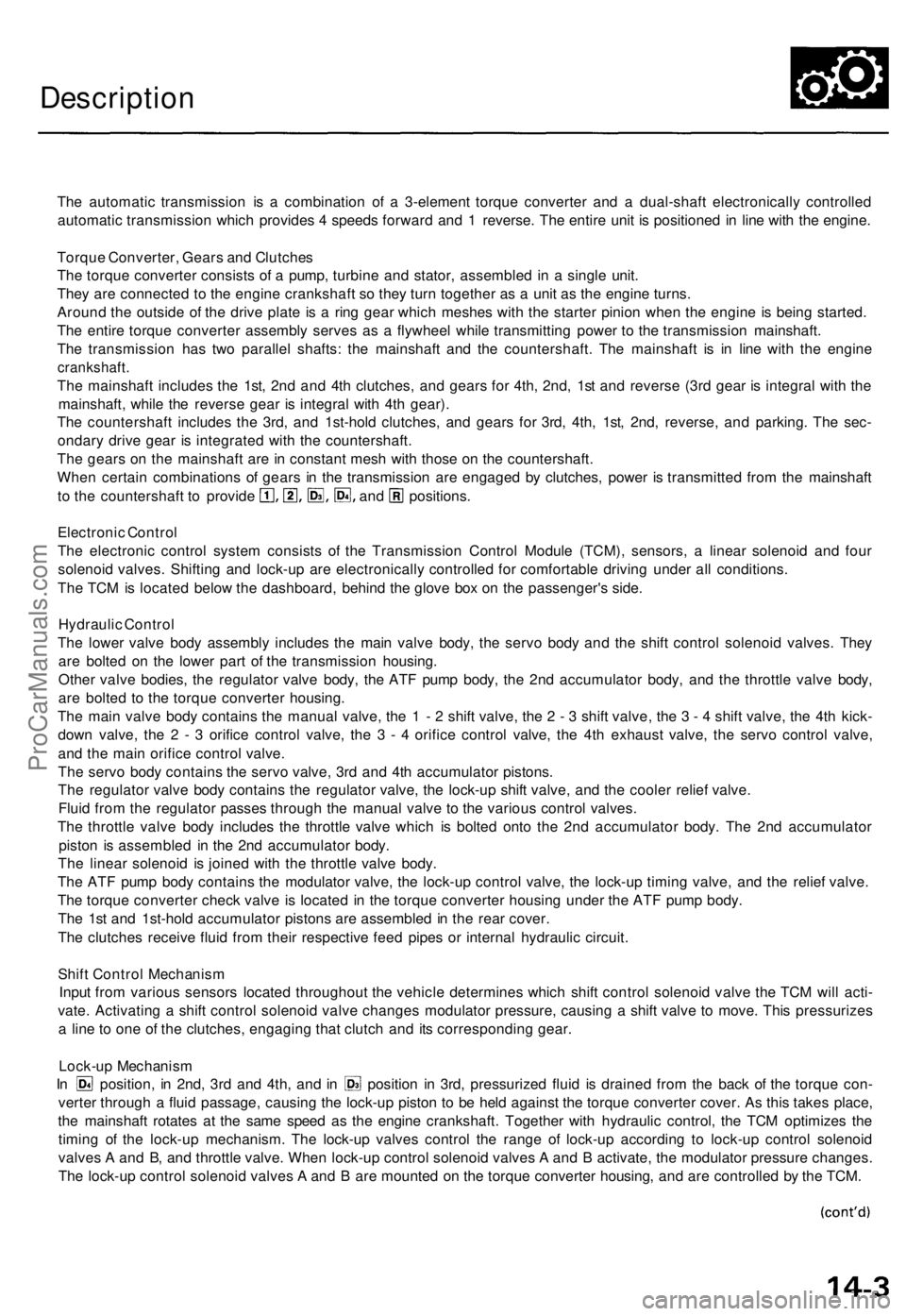

Description

The automatic transmission is a combination of a 3-element torque converter and a dual-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 reverse. The entire unit is positioned in line with the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the drive plate is a ring gear which meshes with the starter pinion when the engine is being started.

The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in line with the engine

crankshaft.

The mainshaft includes the 1st, 2nd and 4th clutches, and gears for 4th, 2nd, 1st and reverse (3rd gear is integral with the

mainshaft, while the reverse gear is integral with 4th gear).

The countershaft includes the 3rd, and 1st-hold clutches, and gears for 3rd, 4th, 1st, 2nd, reverse, and parking. The sec-

ondary drive gear is integrated with the countershaft.

The gears on the mainshaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide and positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid and four

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the glove box on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the servo body and the shift control solenoid valves. They

are bolted on the lower part of the transmission housing.

Other valve bodies, the regulator valve body, the ATF pump body, the 2nd accumulator body, and the throttle valve body,

are bolted to the torque converter housing.

The main valve body contains the manual valve, the 1 - 2 shift valve, the 2 - 3 shift valve, the 3 - 4 shift valve, the 4th kick-

down valve, the 2 - 3 orifice control valve, the 3 - 4 orifice control valve, the 4th exhaust valve, the servo control valve,

and the main orifice control valve.

The servo body contains the servo valve, 3rd and 4th accumulator pistons.

The regulator valve body contains the regulator valve, the lock-up shift valve, and the cooler relief valve.

Fluid from the regulator passes through the manual valve to the various control valves.

The throttle valve body includes the throttle valve which is bolted onto the 2nd accumulator body. The 2nd accumulator

piston is assembled in the 2nd accumulator body.

The linear solenoid is joined with the throttle valve body.

The ATF pump body contains the modulator valve, the lock-up control valve, the lock-up timing valve, and the relief valve.

The torque converter check valve is located in the torque converter housing under the ATF pump body.

The 1st and 1st-hold accumulator pistons are assembled in the rear cover.

The clutches receive fluid from their respective feed pipes or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position, in 2nd, 3rd and 4th, and in position in 3rd, pressurized fluid is drained from the back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place,

the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the

timing of the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid

valves A and B, and throttle valve. When lock-up control solenoid valves A and B activate, the modulator pressure changes.

The lock-up control solenoid valves A and B are mounted on the torque converter housing, and are controlled by the TCM.ProCarManuals.com

Page 962 of 1771

Description

Position

As the engine turns, the ATF pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-

charged into (1). Then, ATF flowing from the ATF pump becomes the line pressure (1). The line pressure (1) is regulated

by the regulator valve. The torque converter inlet pressure (92) enters (94) of the torque converter through the lock-up

shift valve and discharges into (90).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches as the manual valve stops line pressure (1).

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.

Hydraulic Flow (cont'd)ProCarManuals.com