ECU ASTON MARTIN DB7 1997 Service Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 208 of 421

Electrics

Airbag System ^^2?

Airbag DM Fault Code 33

Passengers airbag circuit high resistance or open

circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-2 and 2-3 every time the ignition is

switched on. The resistance should be 0.9 to 1.1Q.

If the total resistance in the passengers airbag

circuit exceeds 4.0Q, fault code 33 will be declared

and the airbag lamp will be illuminated.

Note:

The

nominal

resistance

of the airbag simulator

is

2.5£2,

therefore

expect

a

total circuitresistancereadingof

2.4 - 2.6Q with the simulator

fitted.

Caution: The passenger airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE THE AIRBAG SHORTING

BAR

UNDER ANY CIRCUMSTANCES.

The harness shorting bar may be temporarily

removed during the following resistance checks.

Possible Causes

• Open circuit or high resistance in the wiring

harness

• Open circuit or high resistance in the passenger

airbag module.

• Defective diagnostic module

WARNING: Do not attempt a direct resistance

check on the airbag module. Accidental

deployment can occur due to the induced voltage

from the measuring equipment.

Fault Analysis

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnectthediagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-2 and 2-3. The

resistance should be 2.4 - 2.6Q.

if the resistance is 2.4 - 2.6Q, go to step 3.

Ifthe resistance is not in the range 2.4-2.6S2, isolate

the continuity problem noting the following:

a) In the diagnostic module connector, pin 2-2 is

shorted to pin 2-3 by a shorting link when plug

2 of the diagnostic connector is removed.

Removal of the plastic wedge from the plug wi

11

remove this short circuit.

b) At the airbag module harness connector, pin 1

is shorted to pin 3 when the airbag is

disconnected. Removal of the plastic wedge

from the plug will remove this short circuit.

c) The shorting link fitted in the airbag module

connector will short pin 1 to pin 3 when the

airbag is disconnected. Do not attempt to

remove

this

shorting link or the plastic wedge.

Do not attempt

to

measure the resistance of the

airbag module.

c) Carefully replace all plastic wedges on

completion of the circuit checks.

3. The fault is therefore in either the airbag module or

in the airbag diagnostic module.

Substitute a known good diagnostic module. If

code 33 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

Ifthe fault code 33 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 33 recurs with the airbag module fitted,

the airbag module is faulty. Replace the passengers

airbag module (7.8.02.6).

6-92 September 1996

Page 209 of 421

in:m3'^?

Electrics

Airbag System

Airbag DM Fault Code 34

Drivers airbag circuit low resistance or short circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-5 and 2-4 every time the ignition is

switched on. The resistance should be 1.6 to 1.8Q.

This value is made up of the airbag

1

.OQ and the

cable reel cassette windings 0.3-0.4£2 per winding.

If the total resistance in the passengers airbag

circuit falls below 0.7Q, fault code 34 will be

declared and the airbag lamp will be illuminated.

Note: The nominal

resistance

of the airbag simulator is

2.5Q, therefore expect

a

total circuit resistance readingof

3.1 -

3.3£2

with the simulator

fitted.

Caution: The drivers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE THE AIRBAC CONNECTOR

SHORTING BAR UNDER ANY CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated cable reel cassette connector. If

the connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-4 and 2-

5 together.

• Short circuit in the cable reel cassette windings.

• A short across the airbag terminals in the airbag

module.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-5 and 2-4. The

resistance should be 3.1 - 3.3Q.

If the resistance is 3.1 to 3.3Q, go to step 4.

If the resistance is below 3.1 - 3.3Q, go to step 3.

Disconnect the cable reel cassette connector at the

steering column and remove the plastic wedge.

Measure the resistance from pins 2-4 and 2-5 at the

diagnostic module connector.

If the resistance is infinity, check the cable reel

cassette for short circuits. Replace the column

switchgear assembly if necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 34. Rearm the airbags (6.4.21.4).

If the resistance is less than infinity, replace the

main airbag harness. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

34.

Rearm the airbags (6.4.21.4).

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 34 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 34 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 34 recurs with the airbag modulefitted,

the airbag module is faulty. Replace the drivers

airbag module (4.5.01.3).

September 1996 6-93

Page 210 of 421

Electrics

Airbag System ^^?

Airbag DM Fault Code 35

Passengers airbag circuit low resistance or short

circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-2 and 2-3 every time the ignition is

switched on. The resistance should be 0.9 to

1.1Q..

If the total resistance in the passengers airbag

circuit falls below 0.7S2, fault code 35 will be

declared and the airbag lamp will be illuminated.

f^ote:

The

nominal

resistance

of the airbag simulator

is

2.5£2,

therefore expect

a

total circuit

resistance

reading of

2.4 - 2.6Q with the simulator fitted.

Caution: The passengers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE OR DISABLE THE AIRBAG

CONNECTOR SHORTING BAR UNDER ANY

CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated airbag harness connector. If the

connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-2 and 2-

3 together.

• A short across the airbag terminals in the

passengers airbag module.

Fault Analysis

1.

Disarm the airbag system and check the security of

the passengers airbag module connector before

disconnecting.

If the connector is secure, complete the disarming

procedure, fit the airbag simulators (6.4.21.4). Go

to step 2

If the connector is insecure, service as necessary,

clear the code 35, rearm the airbags. Check that

code 35 does not recur.

2.

Disconnectthediagnostic module and removethe

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-2 and 2-3. The

resistance should be 2.4 - 2.6Q.

If the resistance is 2.4 - 2.6Q, go to step 4.

If the resistance is below 2.4 - 2.6fl, go to step 3.

3. Disconnect the airbag simulator at the passengers

airbag module and remove the plastic wedge from

the harness connector. Measure the resistance

between pins 2-2 and 2-3 at the diagnostic module

connector.

If the resistance is infinity, the airbag harness is

good at this time. Swap the airbag simulators at the

drivers and passengers airbag connectors. Repeat

the resistance check. If the resistance is less than

infinity, there is a fault in the passengers airbag

harness connector. Service the connector or replace

the harness as necessary. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

35.

Rearm the airbags.

If the resistance is less than infinity, service the

bulkhead harness as necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 35. Rearm the airbags (6.4.21.4).

4.

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 35 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 35 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 35 recurs with the airbag module fitted,

the airbag module is faulty. Replace the passengers

airbag module (7.8.02.6).

6-94 September 1996

Page 211 of 421

Electrics

Airbag System

Airbag DM Fault Code 41

Right hand crash sensor feed or return open circuit.

Airbag DM Fault Code 42

Left hand crash sensor feed or return open circuit.

Normal Operation

The diagnostic module constantly measures the

voltage at pins

1

-2 and

1-11.

The voltage should be

10±1 volt. The two wires are connected together

within the right hand crash sensor. If the voltage at

1-2 falls below that at 1-11, an open circuit has

occurred.

Fault code 41 will be declared and the

airbag lamp will be illuminated.

Normal Operation

The diagnostic module constantly measures the

voltage at pins

1

-6 and

1

-12.

The voltage should be

10±1 volt. The two wires are connected together

within the left hand crash sensor. If the voltage at

1

-

5 falls below that at 1-12, an open circuit has

occurred.

Fault code 42 will be declared and the

airbag lamp will be illuminated.

Possible Causes

• Open circuit in the wires from diagnostic module

pins

1

-2 or

1 -11

to the right hand crash sensor.

• An open circuit within the right hand crash

sensor across pins 1 and 2 of the sensor

connector.

Fault Analysis

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnect the diagnostic module and check

continuity between pins 1-2 and 1-11.

If the resistance is significantly greater than OQ, go

to step 3.

If the circu it resistance

is

OQ.,

the

fau It

is intermittent.

Manipulate the harness, particularly in the area of

the sensor connector and the crash sensor harness

to bulkhead harness connector, to identify the

location of the open circuit. Service the circuit as

necessary.

3. Check the right hand crash sensor connector for

security and service the connector if necessary.

If the connector is secure, disconnect and check

continuity from pin 1 to pin 2 of the sensor.

If the resistance is

h igh

or

an

open circuit

is

detected,

replace the crash sensor.

If the sensor continuity is good (0^2), service the

crash sensor loom or bu Ikhead harness

as

necessary

to remove the high resistance or open circuit.

4.

With the airbag simulators in circuit and all

connectors in place, clear the code

41.

Switch off

and then on again to check that the airbag warning

lamp comes on at 'ignition on' and extinguishes

after approximately six seconds.

5. Switch off and rearm the airbags (6.4.21.4)

3.

Possible Causes

• Opencircuitinthewiresfromdiagnosticmodule

pins

1

-6 or

1

-12 to the left hand crash sensor.

• An open circuit within the left hand crash sensor

across pins 1 and 2 of the sensor connector.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and check

continuity between pins 1-6 and 1-12.

If the resistance is significantly greater than OQ, go

to step 3.

If the circu it resistance

isO£2,

the fault is intermittent.

Manipulate the harness, particularly in the area of

the sensor connector and the crash sensor harness

to bulkhead harness connector, to identify the

location of the open circuit. Service the circuit as

necessary.

Check the left hand crash sensor connector for

security and service the connector if necessary.

If the connector is secure, disconnect and check

continuity from pin 1 to pin 2 of the sensor.

If the resistance is high or

an

open circuit is

detected,

replace the crash sensor.

If the sensor continuity is good (OQ), service the

crash sensor harness or bulkhead harness as

necessary to remove the high resistance or open

circuit.

With the airbag simulators in circuit and all

connectors in place, clear the code 42. Switch off

and then on again to check that the airbag warning

lamp comes on at 'ignition on' and extinguishes

after approximately six seconds.

Switch off and rearm the airbags (6.4.21.4).

September 1996 6-95

Page 212 of 421

Electrics

Airbag System o

--i.

D^?

Airbag DM Fault Code 44

Right hand crash sensor incorrectly mounted.

Normal Operation

The diagnostic module constantly measures the

resistance between pins 2-8 (RH crash sensor

ground) and

1

-3 (airbag DM system ground). If the

resistance rises above 2Q, fault code 44 is declared

and the airbag warning lamp is illuminated.

Possible Causes

• Loose sensor mounting or an accumulation of

dirt or corrosion at the sensor mountings.

• An open circuit or loose wire from DM pin 2-8

to the sensor.

• An open circuit wire or loose rivet within the

sensor.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and check

continuity between pins 1-3 and 2-8.

If the resistance is significantly greater than

OQ,,

go

to step 3.

Ifthe circuit resistance

is

OQ,thefault is intermittent.

Manipulate the harness, particularly in the area of

the sensor connector and the crash sensor harness

to bulkhead harness connector, to identify the

location of the open circuit. Service the circuit as

necessary.

Check the right hand crash sensor mounting for

security and corrosion.

If neither problem is evident, go to step 4.

If either problem is evident, remove, clean and

resecure the sensor. Reconnect the diagnostic

module. Switch on and clear the code 44. Switch

off and then on again to check that the airbag

warning lamp comes on at 'ignition on' and

extinguishes after approximately six seconds.

4.

Check the right hand crash sensor connector for

security and service the connector if necessary.

If the connector is secure, disconnect and check

continuity from pin 1 to pin 2 of the sensor.

Ifthe resistance is high or

an

open circuit isdetected,

replace the crash sensor. Go to step 5

If the sensor continuity is good (OQ), service the

crash sensor harness or bulkhead harness as

necessary to remove the high resistance or open

circuit. Go to step 5.

5. With the airbag simulators in circuit and all

connectors in place, clear the code 44. Switch off

and then on again to check that the airbag warning

lamp comes on at 'ignition on' and extinguishes

after approximately six seconds.

6. Switch off and rearm the airbags (6.4.21.4)

6-96 September 1996

Page 213 of 421

"3^=2?

Electrics

Airbag System

Airbag DM Fault Code 45

Left hand crash sensor incorrectly mounted.

Normal Operation

The diagnostic module constantly measures the

resistance between pins2-9 (LH crash sensor ground)

and

1

-3 (airbag DM system ground). If the resistance

rises above 2£2, fault code 45 is declared and the

airbag warning lamp is illuminated.

Possible Causes

• Loose sensor mounting or an accumulation of

dirt or corrosion at the sensor mountings.

• An open circuit or loose wire from DM pin 2-9

to the sensor.

• An open circuit wire or loose rivet within the

sensor.

Fault Analysis

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnect the diagnostic module and check

continuity between pins 1-3 and 2-9.

If the resistance is significantly greater than OQ, go

to step 3.

If thecircuit resistance

is

OQ,

the fault is intermittent.

Manipulate the harness, particularly in the area of

the sensor connector and the crash sensor harness

to bulkhead harness connector, to identify the

location of the open circuit. Service the circuit as

necessary.

3. Check the left hand crash sensor mounting for

security and corrosion.

If neither problem is evident, go to step 4.

If either problem is evident, remove, clean and

resecure the sensor. Reconnect the diagnostic

module. Switch on and clear the code 45. Switch

off and then on again to check that the airbag

warning lamp comes on at 'ignition on' and

extinguishes after approximately six seconds.

4.

Check the left hand crash sensor connector for

security and service the connector if necessary.

If the connector is secure, disconnect and check

continuity from pin 1 to pin 2 of the sensor.

If the resistance is high or

an

open circuit isdetected,

replace the crash sensor. Go to step 5

If the sensor continuity is good (OQ), service the

crash sensor harness or bulkhead harness as

necessary to remove the high resistance or open

circuit. Goto step 5.

5. With the airbag simulators in circuit and all

connectors in place, clear the code 45. Switch off

and then on again to check that the airbag warning

lamp comes on at 'ignition on' and extinguishes

after approximately six seconds.

6. Switch off and rearm the airbags (6.4.21.4)

September 1996 6-97

Page 217 of 421

5^^?

Electrics

Seat Belt Pretensioner

The Seat Belt Pretensioner System (where fitted)

Description

The DB7 seat belt pretensioner system operates the drivers seat belt pretensioner in conjunction with the Airbag

system.

The seat belt pretensioner control module is located under the right hand seat, beside the right hand seat

control module.

The pretensioner control module calculates changes in vehicle speed using an input signal from an accelerometer.

When a collision is detected (Rapid reduction in vehicle speed) and the safing sensor in the airbag system is also

activated,

the pretensioner charge

is

fi red usingelectrical energy stored in a capacitor within the pretensioner control

module. Firing of the pretensioner charge applies additional tension to the drivers seat belt.

The airbag and seat belt pretensioner systems share the SRS (Airbag) warning lamp. Any fault detected by the

pretensioner control module is indicated by constant illumination ofthe

SRS

(Airbag) warning lamp. Flashing of the

SRS warning lamp indicates a fault in the airbag system.

Should both systems develop faults, the pretensioner system will permanently illuminate the warning lamp. This

would mask the airbag system warning indication. Therefore, rectify the pretensioner fault and then retest for faults

in the airbag system

The pretensioner control module can log up to 10 diagnostic trouble codes together with a time since each fault was

alerted to the driver. Each

fau It

wi

11

be identified as 'Permanent' or 'Intermittent' on the PDU diagnostic trouble codes

screen.

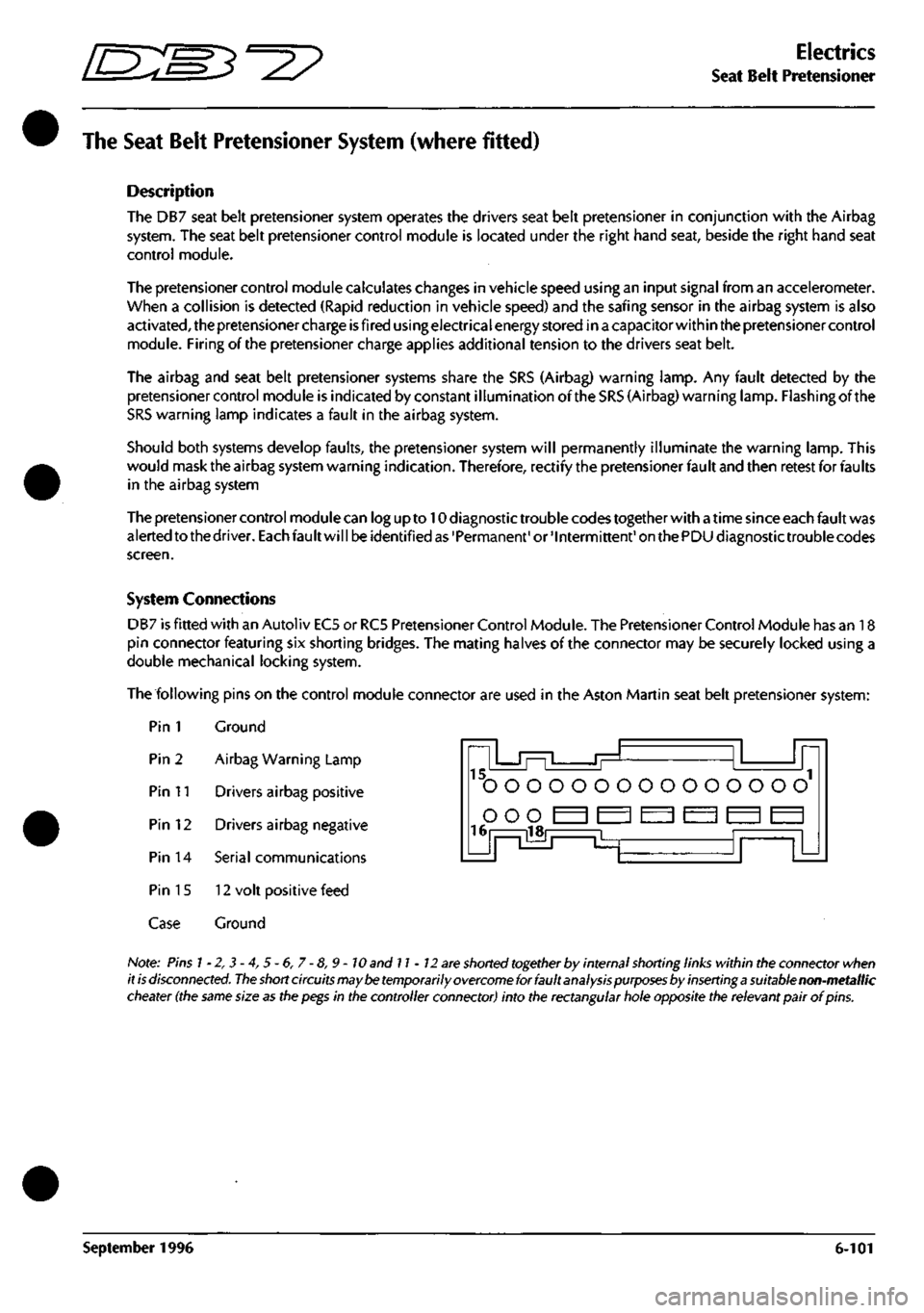

System Connections

DB7 is fitted with an Autoliv ECS or RC5 Pretensioner Control Module. The Pretensioner Control Module has an 18

pin connector featuring six shorting bridges. The mating halves of the connector may be securely locked using a

double mechanical locking system.

The following pins on the control module connector are used in the Aston Martin seat belt pretensioner system:

Pin 1 Ground

' ' "L Pin 2 Airbag Warning Lamp

Pin 11 Drivers airbag positive

Pin 12 Drivers airbag negative

Pin 14 Serial communications

Pin 15 12 volt positive feed

Case Ground

15.

rrj ^

ooooooooooooooo

16 illn

^

Note: Pins

1

-2, 3 -4, 5 -6, 7 -8,9 -

10

and 11-12

are

shorted

together

by internal shorting links within the connector when

it

is

disconnected.

The

short circuits may

be

temporarily

overcome

for fault analysis

purposes

by inserting

a

suitable non-metallic

cheater

(the

sBfTiG

size

3s

the

p€gs

in the controller connector) into the rectsngul^r hole opposite the relevsnt p3ir of pins.

September 1996 6-101

Page 219 of 421

'^^

Electrics

Seat Belt Pretensioner

6.6.26.1

Pretensioner Control Module -

Renew

Read the warnings given in system fault strategy

and service instructions on the previous page before

starting the following procedure.

Procedure

1.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note:

The

vehicle battery must

be

disconnected within

12

seconds

of switching off

the

ignition to avoid the alarm

siren sounding.

2. Motor the right front seat to its rearmost position.

3. Remove the floor carpet and the ECU cover.

4.

Disconnect the pretensioner control module

connector (orange connector with black safety

clip).

5. Remove 3 flange screws securing the module,

noting the position of the earth strap.

6. Fit the new pretensioner control module with the

connector facing to the rear and secure with 3

flange screwsensuringthatthe earth strap is secured

with the outboard rear screw.

7. Connect the orange connector to the control

module.

8. RefitandsecuretheECU cover and the floor carpet.

9. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and the window control unit will

need

resetting

after completion of this procedure.

10.

Switch on the ignition and check that the airbag

warni ng I ight comes on when the ign ition

is

switched

on and extinguishesafterapproximately sixseconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

6.6.24.1

Pretensioner Assembly Renew

Read the warnings given in system fault strategy

and service i nstruaions on the previous page before

starting the following procedure.

1.

2.

4.

Procedure

Motor the drivers seat to its rearmost position.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note: Disconnect the battery within 12 seconds of

switchingoffthe ignition to avoid the alarm siren sounding.

Remove the pretensioner trim cover. Unbolt the

drivers seat. Tip the seat rearwards and disconnect

the seat and pretensioner squib connectors.

Release one bolt at the

base

of the seat belt

stal k

and

remove the pretensioner assembly.

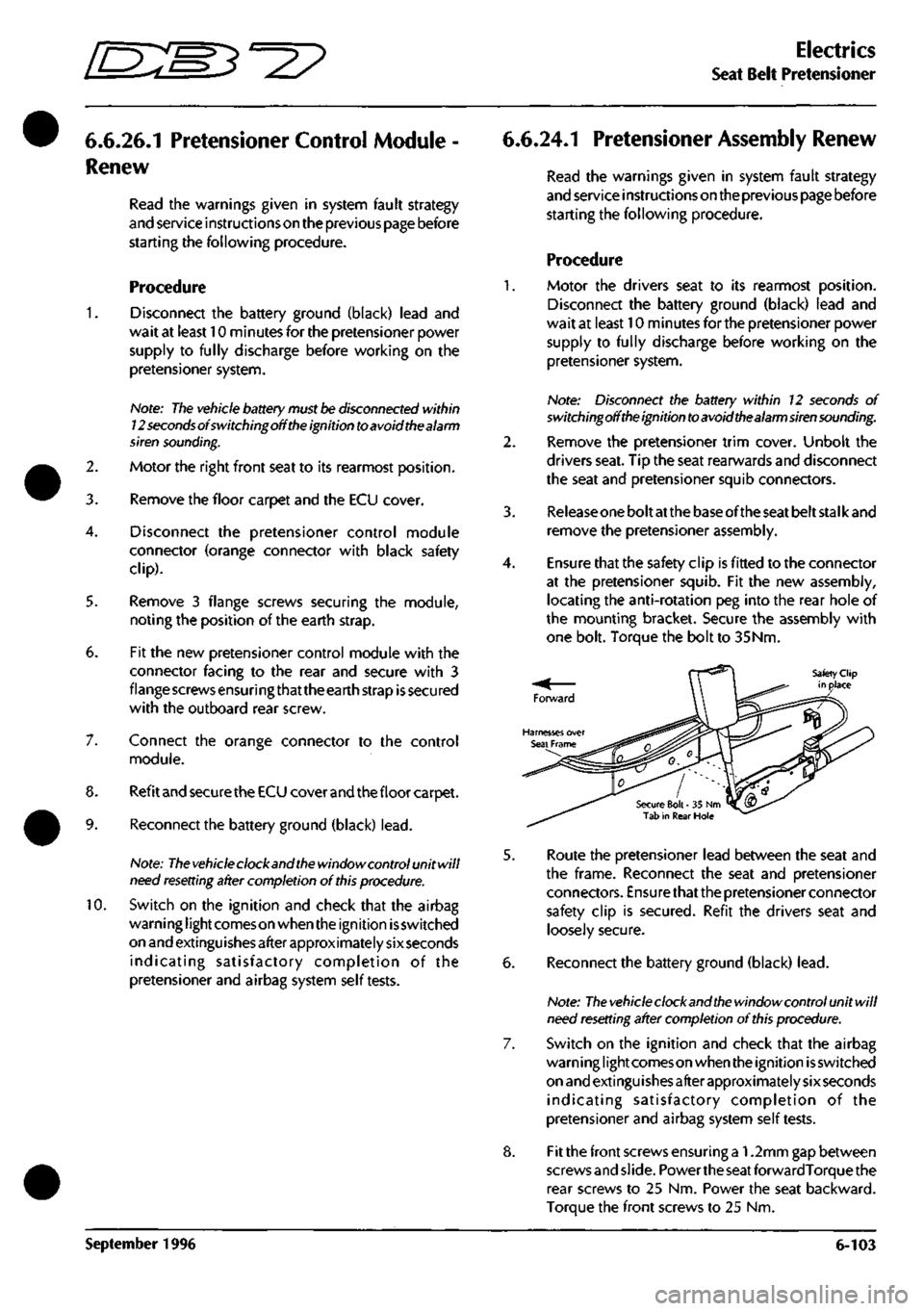

Ensure that the safety clip is fitted to the connector

at the pretensioner squib. Fit the new assembly,

locating the anti-rotation peg into the rear hole of

the mounting bracket. Secure the assembly with

one bolt. Torque the bolt to 35Nm.

Safety Clip in place

5. Route the pretensioner lead between the seat and

the frame. Reconnect the seat and pretensioner

connectors. Ensure that the pretensioner connector

safety clip is secured. Refit the drivers seat and

loosely secure.

6. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of this procedure.

7. Switch on the ignition and check that the airbag

warn i ng I ight comes on when the ignition

is

switched

on and extingu

ishes

after approximately six seconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

8. Fit the front screws ensuring a 1.2mm gap between

screws and slide. Power the seat forwardTorque the

rear screws to 25 Nm. Power the seat backward.

Torque the front screws to 25 Nm.

September 1996 6-103

Page 224 of 421

Electrics

Seat Belt Pretensioner ^?

060C Warning Lamp Short Circuit

060C will be logged if the nnonitor current flow

through the SRS/Airbag warning lamp is excessive.

The warning lamp circuit is normally at 12 volts and

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

If either control module connector is displaced and

the ignition is switched on, the warning lamp will

be illuminated via the ground shorting link between

pins!

and 2 ofthe pretensioner controller connector

or pins 4 and 5 of the airbag controller connector,

both control modules must be checked for the

appropriate DTC to isolate which circuit is at fault.

Procedure

1.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060C code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

If fault code 060C is not logged, go to the diagnostics

section of the airbag system.

2.

Check the security of the pretensioner control

module connector.

If the connector is secure, go to step 3.

If the connector isdisplaced,resecu re theconnector.

Clear all logged DTCs and retest the vehicle to

ensure that the problem is resolved.

3. Access the SRS/Airbag warning lamp and check the

lamp resistance.

If the resistance is approximately

120£2,

the lamp is

good.

Refit the lamp and go to step 4.

If the resistance of the lamp is significantly less than

approximately 120^, fit a new lamp and refit the

instrument panel. Clear the logged DTCs from the

pretensioner control module and retest the vehicle

to ensure that the problem is resolved.

4.

If the checks in step 3 are good, the low circuit

resistance must be in the instrument pack or in the

control module. Replace the pretensioner control

module and reconnect all components.

6. Switch on the ignition and then test the vehicle.

If the 060C code is logged again, replace the

instrument pack.

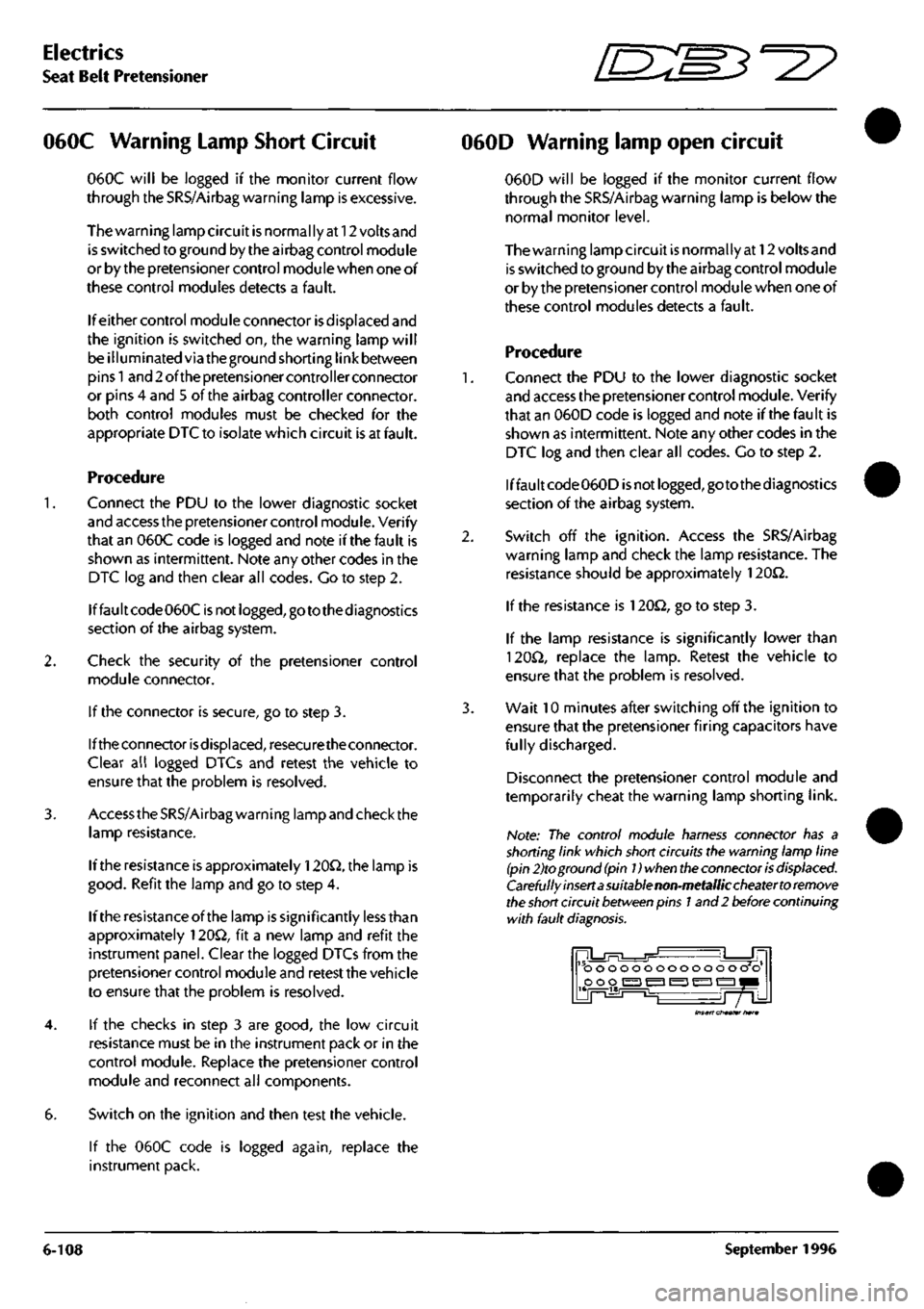

060D Warning lamp open circuit

060D will be logged if the monitor current flow

through the SRS/Airbag warning lamp is below the

normal monitor level.

The warning lampcircuit is normally at 12 voltsand

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

Procedure

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

lffaultcode060D is not

logged,

gotothediagnostics

section of the airbag system.

Switch off the ignition. Access the SRS/Airbag

warning lamp and check the lamp resistance. The

resistance should be approximately 120Q.

If the resistance is 120i2, go to step 3.

If the lamp resistance is significantly lower than

120^2,

replace the lamp. Retest the vehicle to

ensure that the problem is resolved.

Wait 10 minutes after switching off the ignition to

ensure that the pretensioner firing capacitors have

fully discharged.

Disconnect the pretensioner control module and

temporarily cheat the warning lamp shorting link.

Note: The control module harness connector has a

shorting link which short circuits the warning lamp line

(pin 2)to ground

(pin

Dwhen

the

connector

is

displaced.

Carefully insert a suitable non-metallic cheater to remove

the

short

circuit

between

pins

1

and 2 before continuing

with fault

diagnosis.

ooooooooooooo o o poo

i^i

^ ^ ^ 1^1

Insert cheater hare

6-108

September

1996

Page 227 of 421

3-^?

Electrics

Seat Removal/Replacement 97.5 MY

6.6.03

Seat Removal 97.5 MY

Description

The 97.5 MY front seats are common to the DB7

Coupe

and

Volante

models.

Seat

switch

assembi ies

are located on the outboard side of both driver and

passenger

seats.

The front switch controls fore and

aft movement and the seat height adjustment. The

centre switch controls the recline adjustment. The

rear switch

controls

the

lumbar support adjustment.

The seat

heater switches are mounted on the centre

console, forward of the gear selector

lever.

Only one of

the

slide,

recline or height motors can

be driven under manual control at any one time.

Each seat switch pack is hard wired to the relevant

Seat Control

Module

beneath each

seat.

The

module

outputs are hard wired to the seat motors.

Removal

WARNING -

Seat

belt

Pretensioners

(if fitted):

To avoid the possibility

of

personal

injury

caused

by accidental deployment of the seat belt

pretensioner,

disconnect

the

vehicle battery and

wait at

least

10

minutes

for all

voltages

to fully

discharge

before working on the

pretensioner

system.

This covers the possibility

of

the normal

capacitor

discharge

circuits being inoperative and

failing to discharge the detonator capacitor when

instructed

to

do

so.

Procedure

1.

Motortheseatto

its

maximum forward position and

remove the fixings at the rear of the slides.

2.

Motor the seat to its maximum rearward position

and remove the front seat slide fixings.

3. Disconnect the battery

ground

(black)

lead.

Wait at

least 10 minutes for the pretensioner power supply

to fully discharge before working on the seat if a

pretensioner is fitted.

Note: Disconnect the battery within 12 seconds of

switching off the ignition to avoid the alarm siren sounding.

4.

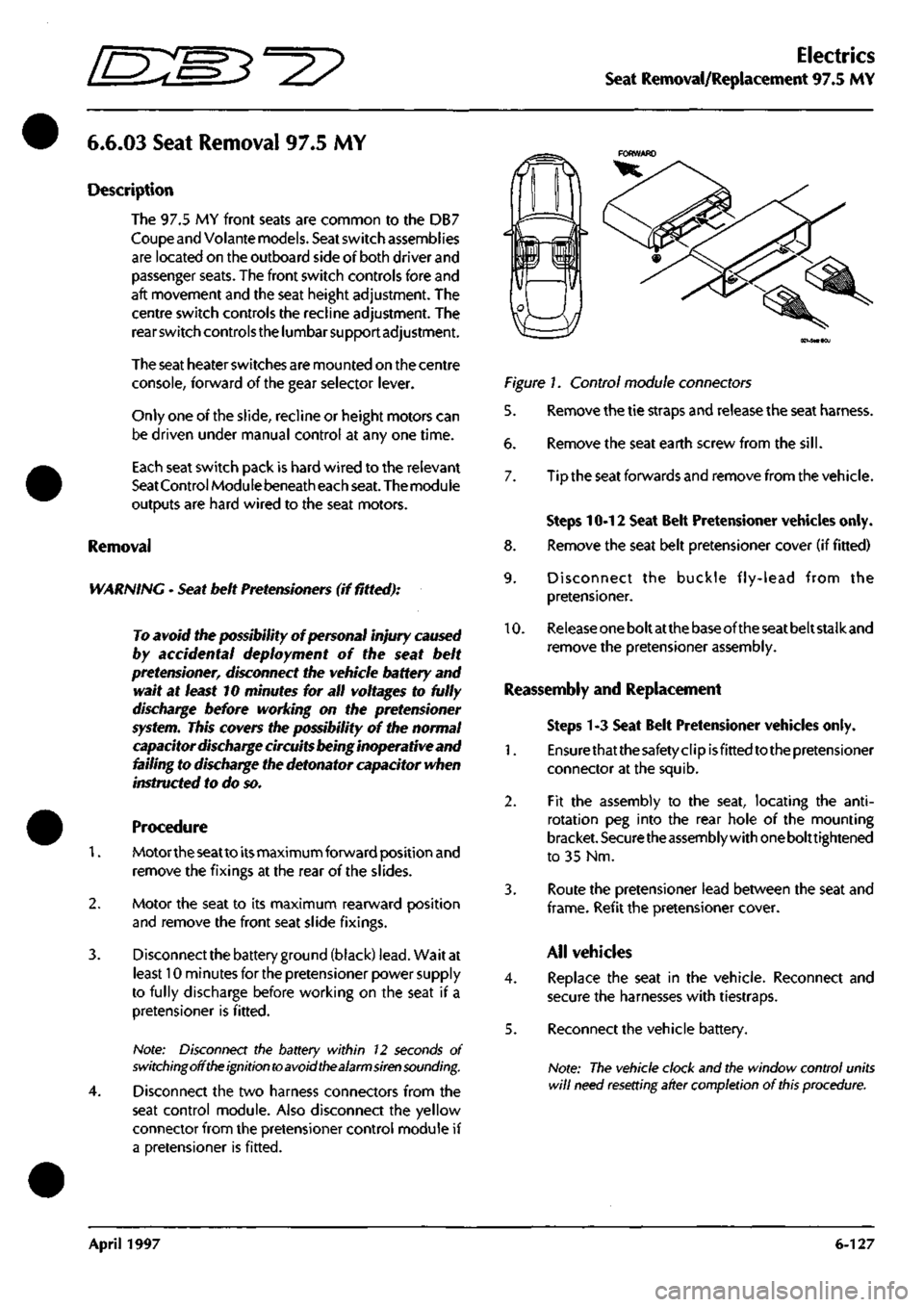

Disconnect the two harness connectors from the

seat control module. Also disconnect the yellow

connector from the pretensioner control module if

a pretensioner is fitted.

Figure 1. Control module connectors

5. Remove the tie straps and release the seat harness.

6. Remove the seat earth screw from the

sill.

7. Tip the seat forwards and remove from the vehicle.

Steps 10-12 Seat Belt Pretensioner vehicles only.

8. Remove the seat belt pretensioner cover (if fitted)

9. Disconnect the buckle fly-lead from the

pretensioner.

10.

Release

one

bolt at

the

base of the

seat

belt stalk and

remove the pretensioner assembly.

Reassembly and Replacement

Steps 1-3 Seat Belt Pretensioner vehicles only.

1.

Ensurethatthesafetyclipisfittedtothepretensioner

connector at the squib.

2.

Fit the assembly to the seat, locating the

anti-

rotation peg into the rear hole of the mounting

bracket.

Securethe

assembly with

one

bolttightened

to 35 Nm.

3. Route the pretensioner lead between the seat and

frame.

Refit the pretensioner

cover.

All vehicles

4.

Replace the seat in the vehicle. Reconnect and

secure the harnesses with tiestraps.

5. Reconnect the vehicle battery.

Note:

The vehicle clock and the window control units

will

need resetting after completion

of

this

procedure.

April 1997 6-127