ECU ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 228 of 421

Electrics

Seat Control Module Removal/Replacement 97.5 MY 'O "3^2?

Switch on the ignition and checi< that the airbag

warning lamp comes on when the ignition is

switched on and extinguishes after approximately

six seconds indicating satisfactory completion of

the pretensioner and airbag system self

tests.

Fit

the front

seat

retaining screws ensuring

a

1.2mm

gap between the screw heads

and

the

slides.

Power

the seat forward and refit the rear screws.

Caution:

Centralise the

rear

fixing holes

with the

body weld

nuts

prior to

inserting the

bolts.

Torque the rear screws to 25 Nm. Power the seat

backwards. Torque the front screws to 25 Nm.

Motor the seat through its full range of movement

to ensure correct

operation.

6.6.08

Seat Control Module 97.5 MY

Removal

WARNING -

Seat

belt

Pretensioners

(if

fitted):

To avoid the possibility

of

personal injury caused

by accidental deployment of the seat belt

pretensioner,

disconnect

the

vehicle battery and

wait at

least

10

minutes

for all

voltages

to fully

discharge

before

working

near the

pretensioner

system.

This covers

the

possibility

of

the

normal

capacitor

discharge circuits

being

inoperative and

failing to discharge the detonator capacitor when

instructed

to

do

so.

1.

Lower the door window and open the relevant

door. Disconnect

the

battery ground cableand wait

for 10 minutes if

a

pretensioner

is

fitted.

Otherwise,

proceed immediately to step 2.

(ei-SMiECu

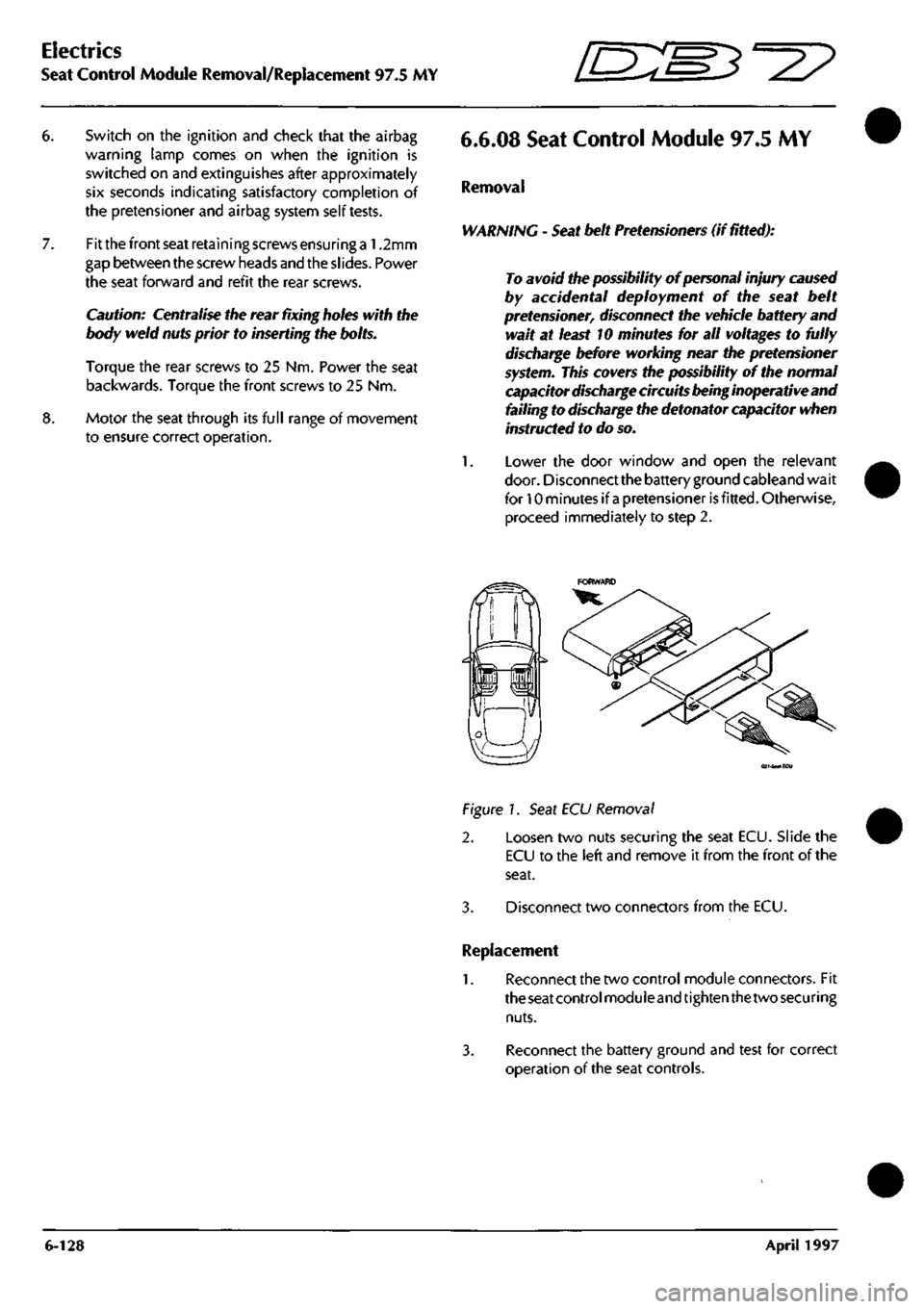

Figure!.

Seat ECU Removal

2. Loosen two nuts securing the seat ECU. Slide the

ECU to the left and remove it from the front of the

seat.

3. Disconnect two connectors from the ECU.

Replacement

1.

Reconnect the two control module connectors. Fit

the seat control

moduleand

tighten

thetwo securing

nuts.

3. Reconnect the battery ground and test for correct

operation of the seat controls.

6-128 April 1997

Page 229 of 421

O" D^?

Body and Trim

Contents

Contents

Body and Trim

Body Repair

Potential Risks

Precautions

General Repair Notes

Steel Body Parts - Repair, Remove and Replace

RTM Body Parts

Body Panel and Trim Removal

Front Apron

Front Undertray

Wheel Arch Liners

Side Sills (top fixings)

Side Sills (bottom fixings)

Rear Bumper

Doors

Door Liners

Door Liner (components)

Steering Wheel

Column Switches

Instrument Panel (surround)

Instrument Panel

Facia Underscuttles

Glove Box

Facia Mountings (1)

Facia Mountings (2)

Console Instruments

Radio

Front Seats

Ashtray

Centre Console

Seat ECU Covers

Rear Console

Rear Seats and C Post Trim

Quarter Panels, B Post Panels, Parcel Shelf

Headlining

Roof System Description and Repair Procedures

Vol ante Roof

Roof and Rear Quarter Light Control

Roof Component Location

Roof Control System

9.0.02.1

Roof Removal/Replacement

9.0.02.3

Roof Hydrailic Control System

9.0.02.5

Bleeding the Roof Hydraulic System

9.1.01.1

Rear Quarter Window Renewal

9.1.01.2

Rear Quarter Glass Adjustment

9.1.01.4

Rear Quarter Window Lift Motor - LH

9.1.01.5

Rear Quarter Window Lift Motor - RH

Roof Sealing and Wind Noise

9.2.01.5

'A' Post/Header Sealing and Lock Adj

9.2.01.6

Roof Seals - Adjustment

9.2.01.7

Cheater Plate Seals - Adjust/Renew

9.2.01.8

Door Glass Adjustment

Alcantara Cleaning

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-6

Sheet 1

Sheet 2

Sheet 3

Sheet 4

Sheet 5

Sheet 6

Sheet 7

Sheet 8

Sheet 9

Sheet 10

Sheet 11

Sheet 12

Sheet 13

Sheet 14

Sheet 15

Sheet 16

Sheet 17

Sheet 18

Sheet 19

Sheet 20

Sheet 21

Sheet 22

Sheet 23

Sheet 24

Sheet 25

Sheet 26

Sheet 27

7-7

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-17

7-18

7-19

7-20

7-21

May 1996 7-1

Page 233 of 421

'^?

Body and Trim

Body Repair - RTM Body Panels

RTM Body Parts

Certain exterior panels of the vehicle are

manufactured from RTM as shown as shaded areas

in Figure 1. The Front and rear bumpers are made

from

R-RIM

Repair Procedures

Cosmetic Damage

Repair the paintwork using standard procedures.

Substrate surface

Where the defect does not affect the physical

strength of the panel, fill and repaint using standard

techniques.

Substrate Penetration

No reliable repair procedures are possible to correct

major physical damage to RTM panels. Any small

defect which do not affect the intgrity or security of

the panel may be filled and repainted at the owners

risk.

Uote: Becauseof the inherent flexibility of plastic panels,

hard filler may

crack.

Such repairs cannot

therefore

be

guaranteed.

Where the damage affects the security and or the

integrity of the panel, it must be replaced.

Precautions during Paint Operations

When any repair operation is being completed on

the DB7 paintwork, take particular care to protect

the leather upholstery and trim from paint

contamination.

Figure 1.

Damage Recognition

Before any remedial action is carried out the

damaged should be

assessed.

If the cover has been

holed or torn it must be replaced. Repair should be

attempted only if the damage falls into one of the

following three categories.

Cosmetic

Substrate surface

Substrate

penetration

Abrasion to the surface paint

finish

Deep scratches, gouges or

localised radial stress cracks.

Splits not exceeding 100 mm.

Splits radiating from a gouge

and accompanied by localised

stress cracks.

May 1996 7-5

Page 234 of 421

Body and Trim

Body Panel and Trim Removal 5^7

Body Panel and Trim Removal

The following diagrams show the fixings for all

removeable body and trim panels.

Sheet 1. Front Apron

Sheet 2. Front Undertray

Sheet 3. Wheel Arch Liners

Sheet 4. Side Sills (top fixings)

Sheets. Side Sills (bottom fixings)

Sheet 6. Rear Bumper

Sheet 7. Doors

Sheet 8. Door Liners

Sheet 9. Door Liner (components)

Sheet 10. Steering Wheel

Sheet 11. Column Switches

Sheet 12. Instrument Panel (surround)

Sheet 13. Instrument Panel

Sheet 14. Facia Underscuttles

Sheet 15. Glove Box

Sheet 16. Facia Mountings (1)

Sheet

1

7. Facia Mountings (2)

Sheet 18. Console Instruments

Sheet 19. Radio

Sheet 20. Front Seats

Sheet

21.

Ashtray

Sheet 22. Centre Console

Sheet 23. Seat ECU Covers

Sheet 24. Rear Console

Sheet 25. Rear Seats and C Post Trim

Sheet 26. Quarter Panels, B Post Panels, Parcel Shelf

Sheet 27. Headlining

7-6 May 1996

Page 265 of 421

Body and Trim

Roof Removal/Replacement [D::M^=2?

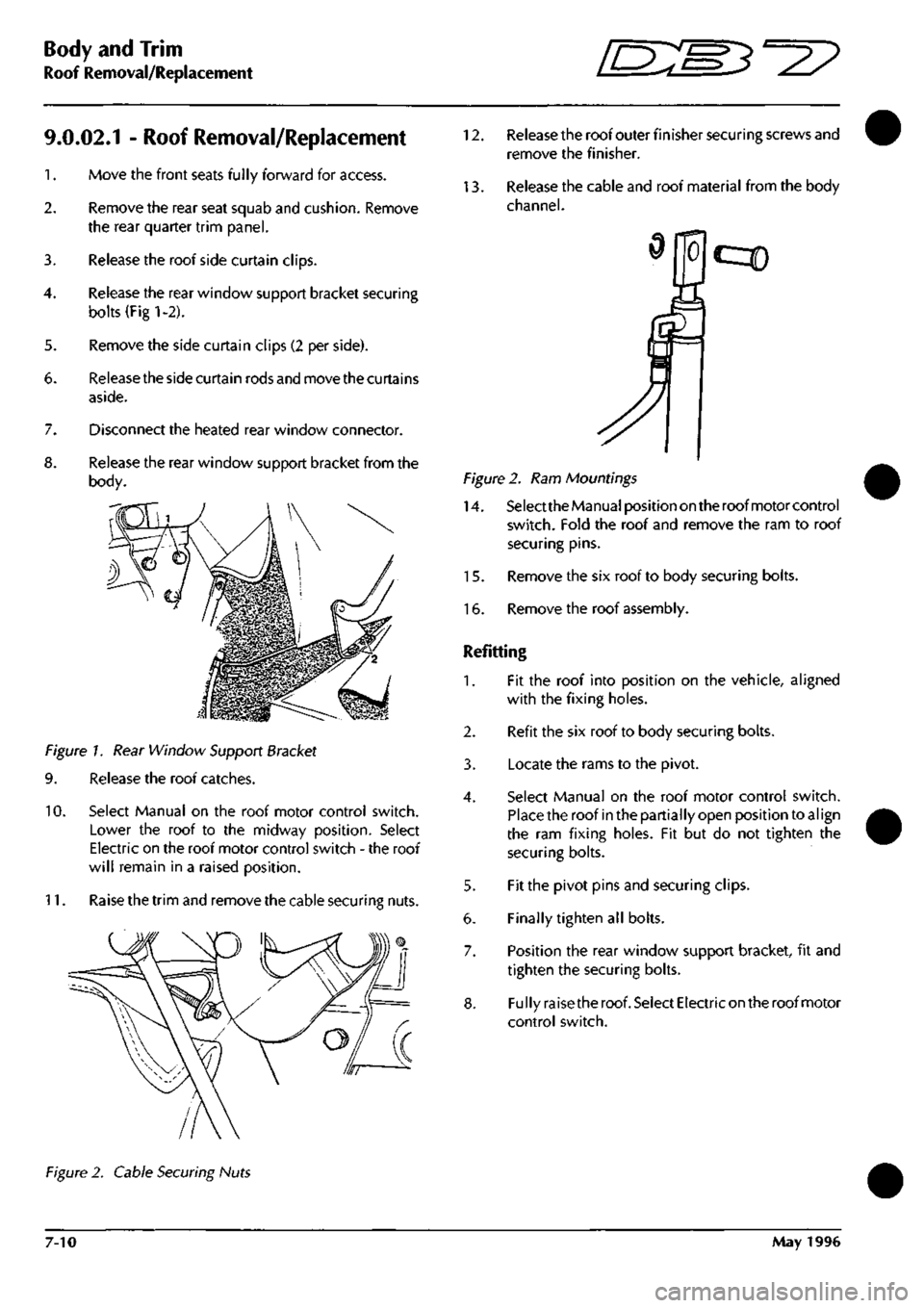

9.0.02.1 - Roof Removal/Replacement

1.

2.

3.

4.

5.

6.

7.

8.

Move the front seats fully forward for access.

Remove the rear seat squab and cushion. Remove

the rear quarter trim panel.

Release the roof side curtain clips.

Release the rear window support bracket securing

bolts (Fig 1-2).

Remove the side curtain clips (2 per side).

Release the side curtain rods and move the curtains

aside.

Disconnect the heated rear window connector.

Release the rear window support bracket from the

body.

Figure 1. Rear Window Support Bracket

9. Release the roof catches.

10.

Select Manual on the roof motor control switch.

Lower the roof to the midway position. Select

Electric on the roof motor control switch - the roof

will remain in a raised position.

11.

Raise the trim and remove the cable securing nuts.

12.

Release the roof outer finisher securing screws and

remove the finisher.

13.

Release the cable and roof material from the body

channel.

cqD

Figure 2. Ram Mountings

14.

Select the Manual position on the roof motor control

switch.

Fold the roof and remove the ram to roof

securing pins.

15.

Remove the six roof to body securing bolts.

16.

Remove the roof assembly.

Refitting

1.

Fit the roof into position on the vehicle, aligned

with the fixing holes.

2.

Refit the six roof to body securing bolts.

3. Locate the rams to the pivot.

4.

Select Manual on the roof motor control switch.

Place the roof in the partially open position to

al

ign

the ram fixing holes. Fit but do not tighten the

securing bolts.

5. Fit the pivot pins and securing clips.

6. Finally tighten all bolts.

7. Position the rear window support bracket, fit and

tighten the securing bolts.

8. Fully raise the roof. Select Electric on the roof motor

control switch.

Figure 2. Cable Securing Nuts

7-10 May 1996

Page 266 of 421

^=2?

Body and Trim

Roof Hydraulic Control System

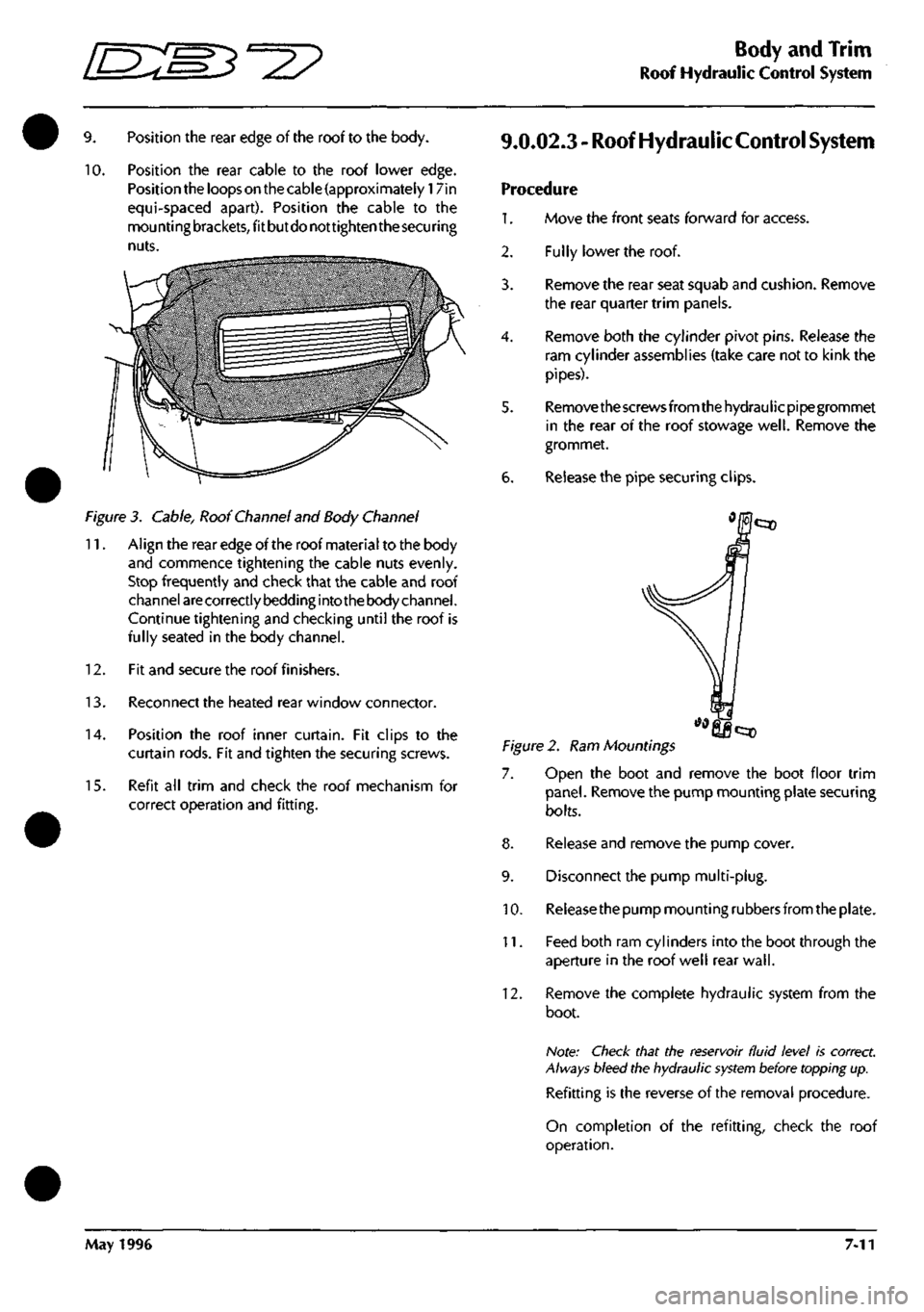

9. Position the rear edge of the roof to the body.

10.

Position the rear cable to the roof lower edge.

Position the loops on the cable (approximately 17in

equi-spaced apart). Position the cable to the

mou nti ng

brackets,

fit but do not tighten the

secu

ring

nuts.

Figure 3. Cable, Roof Channel and Body Channel

11.

Align the rear edge of the roof material to the body

and commence tightening the cable nuts evenly.

Stop frequently and check that the cable and roof

channel

are

correctly bedding into the body channel.

Continue tightening and checking until the roof is

fully seated in the body channel.

12.

Fit and secure the roof finishers.

13.

Reconnect the heated rear window connector.

14.

Position the roof inner curtain. Fit clips to the

curtain rods. Fit and tighten the securing screws.

15.

Refit all trim and check the roof mechanism for

correct operation and fitting.

9.0.02.3 - Roof Hydraulic

Control

System

Procedure

1.

Move the front seats forward for access.

Fully lower the roof.

2.

3.

4.

6.

Remove the rear seat squab and cushion. Remove

the rear quarter trim panels.

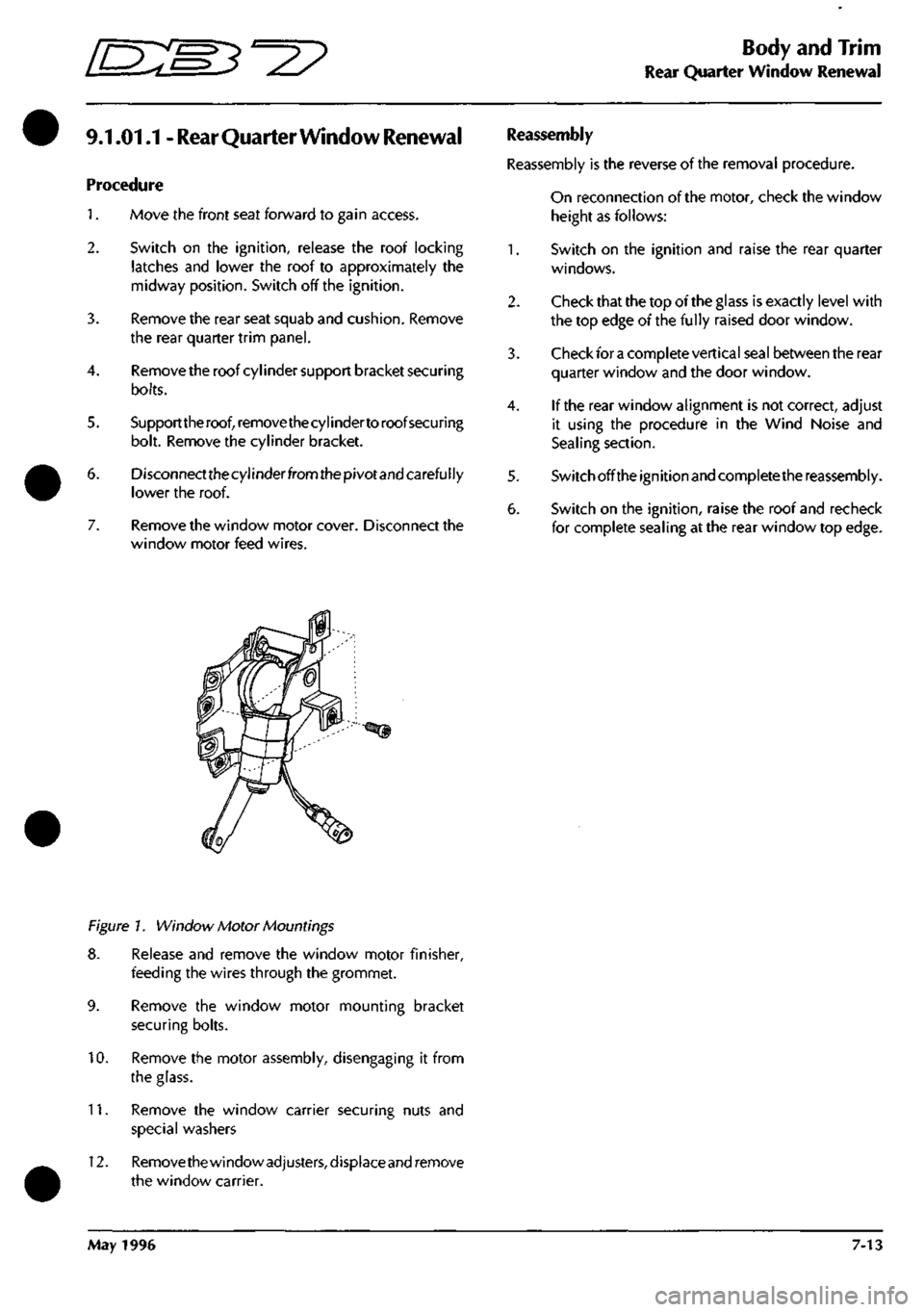

Remove both the cylinder pivot pins. Release the

ram cylinder assemblies (take care not to kink the

pipes).

Remove the screws from the hydraulicpipegrommet

in the rear of the roof stowage

well.

Remove the

grommet.

Release the pipe securing clips.

Figure 2. Ram Mountings

7. Open the boot and remove the boot floor trim

panel.

Remove the pump mounting plate securing

bolts.

8. Release and remove the pump cover.

9. Disconnect the pump multi-plug.

10.

Releasethe pump mounting rubbers from the plate.

11.

Feed both ram cylinders into the boot through the

aperture in the roof well rear

wall.

12.

Remove the complete hydraulic system from the

boot.

Note: Check that the reservoir fluid level is correct.

Always bleed the hydraulic

system

before topping up.

Refitting is the reverse of the removal procedure.

On completion of the refitting, check the roof

operation.

May 1996 7-11

Page 268 of 421

•=2?

Body and Trim

Rear Quarter Window Renewal

9.1.01.1 -

Rear

Quarter Window Renewal

Procedure

1.

Move the front seat forward to gain access.

2.

Switch on the ignition, release the roof locking

latches and lower the roof to approximately the

midway position. Switch off the ignition.

3. Remove the rear seat squab and cushion. Remove

the rear quarter trim panel.

4.

Remove the roof cylinder support bracket securing

bolts.

5. Support the roof, removethecylindertoroofsecuring

bolt. Remove the cylinder bracket.

6. Disconnectthecylinderfromthepivotand carefully

lower the roof.

7. Remove the window motor cover. Disconnect the

window motor feed wires.

Reassembly

Reassembly is the reverse of the removal procedure.

On reconnection of the motor, check the window

height as follows:

1.

Switch on the ignition and raise the rear quarter

windows.

2.

Check that the top of the glass is exactly level with

the top edge of the fully raised door window.

3. Check for

a

complete vertical seal between the rear

quarter window and the door window.

4.

If the rear window alignment is not correct, adjust

it using the procedure in the Wind Noise and

Sealing section.

5. Switch off the ignition and complete the reassembly.

6. Switch on the ignition, raise the roof and recheck

for complete sealing at the rear window top edge.

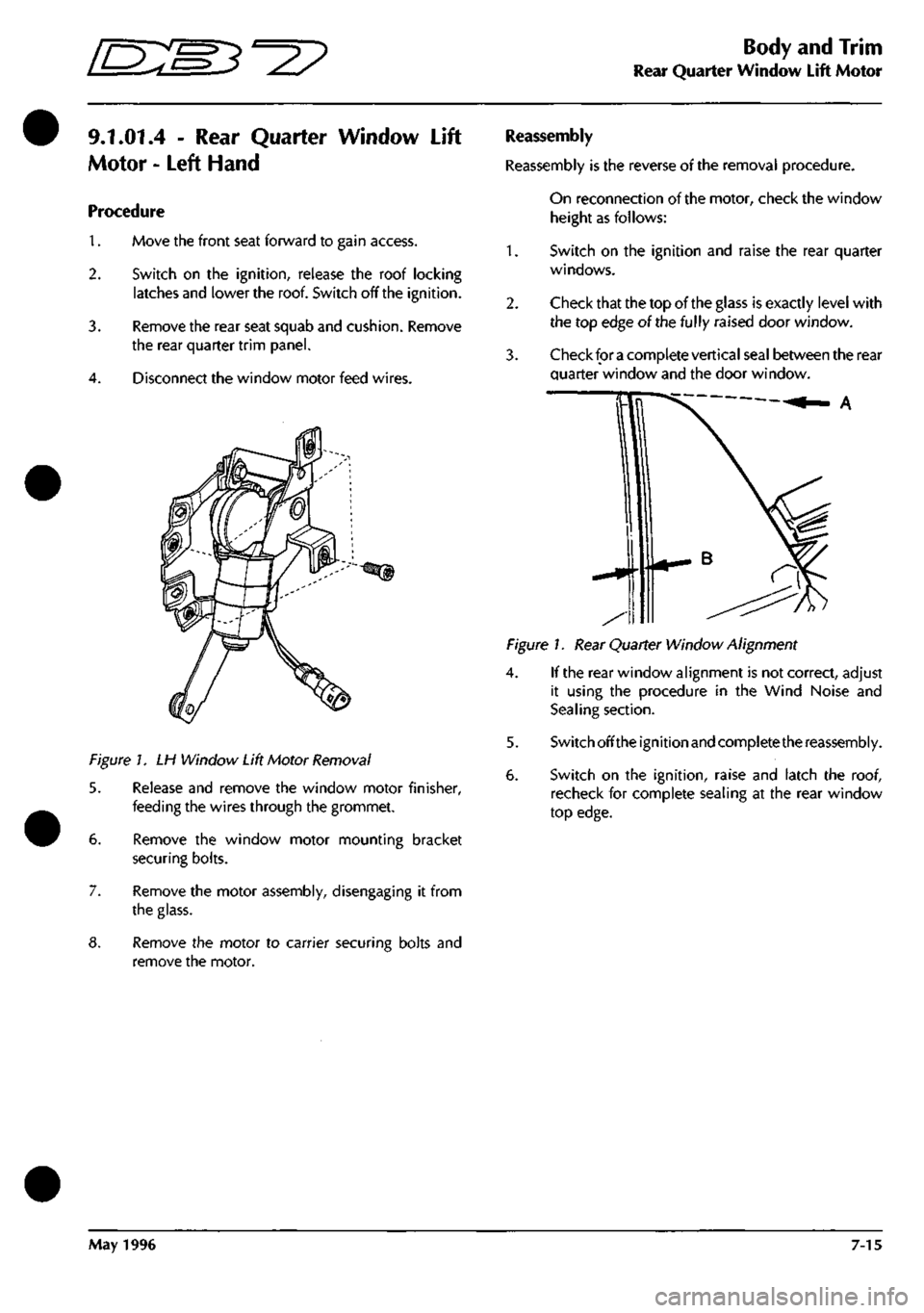

Figure 1. Window Motor Mountings

8. Release and remove the window motor finisher,

feeding the wires through the grommet.

9. Remove the window motor mounting bracket

securing bolts.

10.

Remove the motor assembly, disengaging it from

the glass.

11.

Remove the window carrier securing nuts and

special washers

12.

Remove the window

adjusters,

d isplace and remove

the window carrier.

May 1996 7-13

Page 270 of 421

^^7

Body and Trim

Rear Quarter Window Lift Motor

9.1.01.4 - Rear Quarter Window Lift

Motor - Left Hand

Procedure

1.

Move the front seat forward to gain access.

2.

Switch on the ignition, release the roof locking

latches and lower the roof. Switch off the ignition.

Remove the rear seat squab and cushion. Remove

the rear quarter trim panel.

Disconnect the window motor feed wires.

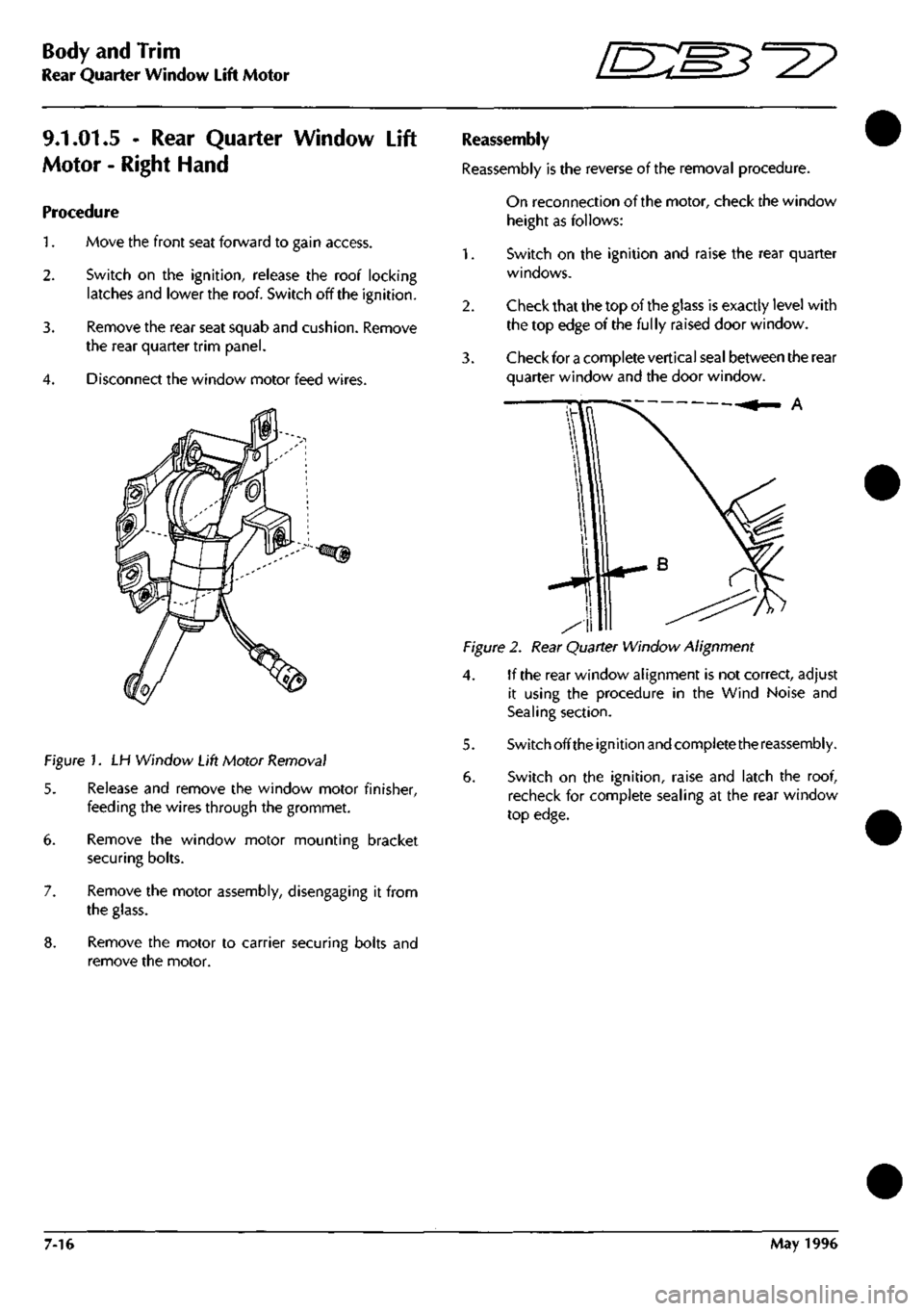

Figure 1. LH Window Lift Motor Removal

5. Release and remove the window motor finisher,

feeding the wires through the grommet.

6. Remove the window motor mounting bracket

securing bolts.

7. Remove the motor assembly, disengaging it from

the glass.

8. Remove the motor to carrier securing bolts and

remove the motor.

Reassembly

Reassembly is the reverse of the removal procedure.

On reconnection of the motor, check the window

height as follows:

1.

2.

Switch on the ignition and raise the rear quarter

windows.

Check that the top of the glass is exactly level with

the top edge of the fully raised door window.

Check for

a

complete vertical seal between the rear

quarter window and the door window.

Figure 1. Rear Quarter Window Alignment

4.

If the rear window alignment is not correct, adjust

it using the procedure in the Wind Noise and

Sealing section.

5. Switch off the ignition and complete the reassembly.

6. Switch on the ignition, raise and latch the roof,

recheck for complete sealing at the rear window

top edge.

May 1996 7-15

Page 271 of 421

Body and Trim

Rear Quarter Window Lift Motor '^^

9.1.01.5 - Rear Quarter Window Lift

Motor - Right Hand

Procedure

1.

Move the front seat forward to gain access.

2.

Switch on the ignition, release the roof locking

latches and lower the roof. Switch off the ignition.

3. Remove the rear seat squab and cushion. Remove

the rear quarter trim panel.

4.

Disconnect the window motor feed wires.

Figure 1. LH Window Lift Motor Removal

5. Release and remove the window motor finisher,

feeding the wires through the grommet.

6. Remove the window motor mounting bracket

securing bolts.

7. Remove the motor assembly, disengaging it from

the glass.

8. Remove the motor to carrier securing bolts and

remove the motor.

Reassembly

Reassembly is the reverse of the removal procedure.

On reconnection of the motor, check the window

height as follows:

1.

Switch on the ignition and raise the rear quarter

windows.

2.

Check that the top of the glass is exactly level with

the top edge of the fully raised door window.

3. Check for a complete vertical seal between the rear

quarter window and the door window.

A

Figure 2. Rear Quarter Window Alignment

4. If the rear window alignment is not correct, adjust

it using the procedure in the Wind Noise and

Sealing section.

5. Switch offthe ignition and complete the reassembly.

6. Switch on the ignition, raise and latch the roof,

recheck for complete sealing at the rear window

top edge.

7-16 May 1996

Page 273 of 421

Body and Trim

Roof Seals - Adjustment

9.2.01.6 - Roof

Seals

- Adjustment

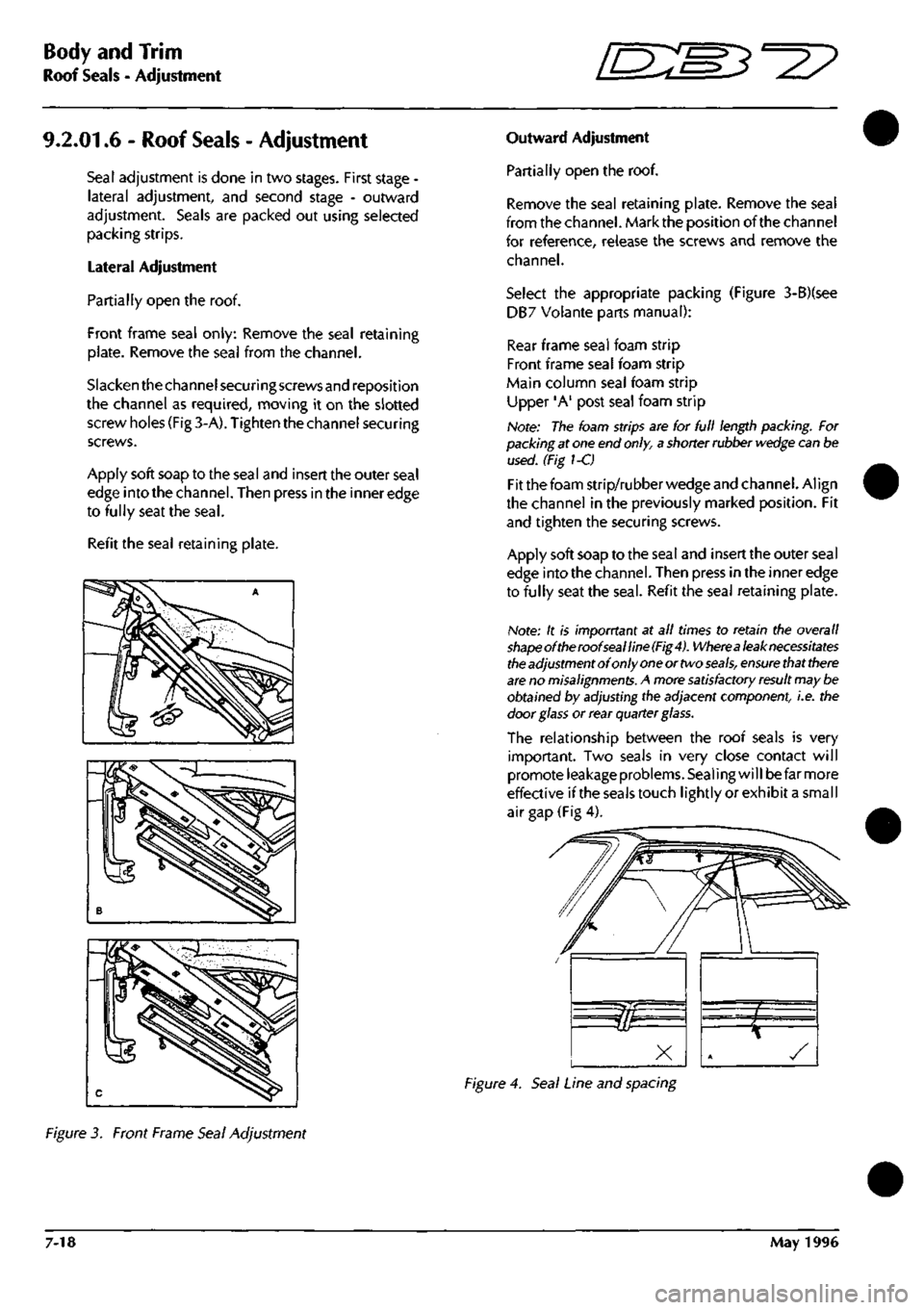

Seal adjustment is done in two stages. First stage -

lateral adjustment, and second stage - outward

adjustment. Seals are packed out using selected

packing strips.

Lateral Adjustment

Partially open the roof.

Front frame seal only: Remove the seal retaining

plate.

Remove the seal from the channel.

Slacken the channel securing screws and reposition

the channel as required, moving it on the slotted

screw holes (Fig 3-A). Tighten the channel securing

screws.

Apply soft soap to the seal and insert the outer seal

edge into the channel. Then press in the inner edge

to fully seat the

seal.

Refit the seal retaining plate.

Outward Adjustment

Partially open the roof.

Remove the seal retaining plate. Remove the seal

from the channel. Mark the position of the channel

for reference, release the screws and remove the

channel.

Select the appropriate packing (Figure 3-B)(see

DB7 Volante parts manual):

Rear frame seal foam strip

Front frame seal foam strip

Main column seal foam strip

Upper 'A' post seal foam strip

Note: The foam strips are for full length packing. For

packing at one end

only,

a shorter rubber

wedge

can be

used. (Fig 1-C)

Fit the foam strip/rubber wedge and channel. Align

the channel in the previously marked position. Fit

and tighten the securing screws.

Apply soft soap to the seal and insert the outer seal

edge into the channel. Then press in the inner edge

to fully seat the

seal.

Refit the seal retaining plate.

Note: It is imporrtant at all times to retain the overall

shapeoftheroofsealline(Fig4).

Wherea

leak necessitates

the

adjustment of only

one

or two

seals,

ensure

that

there

are

no

misalignments.

A more

satisfactory result

may be

obtained by adjusting the adjacent component, i.e. the

door

glass

or rear quarter glass.

The relationship between the roof seals is very

important. Two seals in very close contact will

promote leakage problems. Sealing will be far more

effective ifthe seals touch lightly or exhibit a small

air gap (Fig 4).

Figure 4. Seal Line and spacing

Figure 3. Front Frame Seal Adjustment

7-18 May 1996