torque ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 367 of 947

Engine Sealing (03.10)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-10-9

8. Install the right exhaust camshaft.

9. Install the five bearing caps in their correct positions.

10. Install the ten bolts and torque tighten them in the sequence specified.

11. Install the Torx bolt that attaches the sprocket to the camshaft.

12. Rotate the camshaft and use feeler gauges to do a check of each valve clearance .

13. Do the procedure again an d install the right intake

camshaft.

14. Remove the Torx bolt that attaches the sprocket.

15. Rotate the right intake and exhaust camshafts until the timing flats on each camshaft face up.

16. Install tool (303-530) onto the right cylinder head to hold the camshafts. Install and tighten the three bolts.

17. Install a new left cylinder he ad gasket. Make sure that it

is correctly engaged on the dowels.

18. With the aid of one more person, install the left cylinder head. Make sure that it is correctly engaged on the

dowels.

19. Install and torque the 12 cylinder head bolts in the correct sequence.

20. Lubricate the left exhaust camshaft journals, camshaft lobes, bearing surfaces on the cylinder head and the

bearing caps with clean engine oil.

21. Install left exhaust camshaft.

22. Install the five bearing caps in their correct positions.

23. Install the ten bolts and torque in the sequence specified.

24. Install the Torx bolt that attaches the sprocket to the left exhaust camshaft.

25. Rotate the left exhaust cam shaft as necessary and use

feeler guages to do a check of each valve clearance.

26. Remove the Torx bolt that attaches the sprocket.

27. Install the left intake camshaft (refer to Workshop Manual procedure 03.09.AV Camshaft - Intake - LH -

Renew).

28. Install the timing chain tensioning tool (303-532) into the right exhaust camshaft sprocket.

29. Apply a force to the tool (303-532) in a counterclockwise direction to hold the sprocket and

torque the right sprocket Torx bolts.

30. Remove the special tool.

31. Connect the electrical conne ctors to the left and right

camshaft timing sensors.

32. Connect the electrical connector to each of the two left and two right knock sensors. 33. Install SAI pump and bracket assembly (refer to

Workshop Manual procedure 03.08.DB Pump and

Bracket Assembly - Secondary Air Injection - Renew).

34. Clean the left exhaust manifold.

35. Install a new gasket for the left exhaust manifold .

36. Install the left exhaust manifold.

37. Install and torque tighten the eight nuts.

38. Install the left front wheel arch liner (refer to Workshop

Manual procedure 01.02.FB Wheel Arch Liner - Front -

LH - Renew).

39. Install the right exhaust manifold (refer to Workshop Manual procedure 09.00.CC Gasket - Exhaust Manifold

- right - Renew).

Right Side Cam Cover - Remove and

Install

Removal

1. Disconnect the battery earth cable.

2. Remove the front crush brace. (Refer to procedure

01.01.LC - Front Crush Brace)

3. Remove the right side fr ont crush bar for the body

reinforcement. (Refer to procedure 01.01.AB - Right

Side Front Crush Bar for the Body Reinforcement)

4. Remove the breather pipe from the cam cover.

5. Install applicable caps to seal the open ports.

6. Remove the ignition coil cover.

7. Disconnect the electrical connector from each of the four ignition coils.

8. Disconnect the electrical connector from the Variable Valve Timing (VVT) solenoid.

9. Release the fir tree clip that attaches the wiring harness for the ignition coils.

10. Move the wiring harness for the ignition coils away.

11. Release the wiring harness for the injectors from the mounts.

12. Cut and remove the three cable ties that attach the rear of the wiring harness for the injectors.

13. Remove the screw that attaches the purge pipe P-clip to the cam cover.

14. Move the purge-pipe P-clip away.

15. Release the purge pipe and heater pipe from the two clips on the wiring harness bracket.

16. Remove the two nuts and two screws that attach the front bracket for the wiring harness.

17. Remove the three screws that attach the rear bracket for

the wiring harness.

18. Remove the rear bracket for the wiring harness.

19. Remove the front bracket for the wiring harness.

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Gradually tighten one bolt and then the next to correctly

install the camshaft bearing ca ps in the step that follows.

Repair Operation Time (ROT)

Page 368 of 947

Engine Sealing (03.10)

Engine (03.00)3-10-10 Workshop Manual Issue 5, Janauary 2010

20. Remove the four screws that attach each ignition coil.

21. Remove the four ignition coils.

22. Remove the 14 screws that attach the cam cover to the engine.

23. Remove and discard the seals for the 14 cam cover screws.

24. Remove the cam cover.

25. Remove and discard the O-ring seal for the VVT solenoid.

26. Remove and discard the cam cover gasket.

27. Remove and discard the four O-ring seals from the spark plug wells.

28. Clean the component mating faces.

Install

1. Install four new O-ring seals in the spark plug wells.

2. Install a new O-ring seal for the VVT solenoid.

3. Install a new cam cover gasket.

4. Apply a 12 mm by 3 mm bead of sealant to the tri-joints shown.

Figure C03-10-101

5. Install the cam cover.

6. Install new seals for the 14 cam cover screws. 7. Install and torque the 14 screws that attach the cam

cover to the engine in the sequence shown to 10 Nm.

8. Install the four ignition coils.

9. Install and torque the screw that attaches each of the four ignition coils to 5 Nm.

10. Install the front bracket for the wiring harness.

11. Install the rear bracket for the wiring harness.

12. Install and torque the three screws that attach the rear bracket for the wiring harness to 11 Nm.

13. Install and tighten the two nuts and three screws that attach the front bracket for the wiring harness.

14. Install the purge pipe and he ater pipe into the two clips

on the wiring harness bracket.

15. Put the purge pipe P-clip into the correct position.

16. Install and tighten the screw that attaches the purge pipe P-clip to the cam cover.

17. Use three applicable cable ties to attach the rear of the wiring harness to the front bracket.

18. Install the wiring harness for the injectors into the mounts.

19. Install the fir tree clip that attaches the wiring harness for the ignition coils.

20. Connect the electrical conne ctors to each of the four

ignition coils.

21. Connect the electrical connector to the VVT solenoid.

22. Install the ignition coil cover.

23. Remove and discard the caps from the breather pipes.

24. Install the breather pipes to the cam cover.

25. Install the right side front crush bar for the body reinforcement. (0101AB - Righ t Side Front Crush Bar for

the Body Reinforcement)

26. Install the front crush brace. (0101LC - Front Crush Brace)

Note: When you remo ve the cam cover

attachment screws in th e step that follows,

record their installed positions in the cam

cover.

CAUTION

Tighten the screws gradually and equally in the step

that follows. If you do not, the cam cover gasket can be

damaged.

C03-10-101

Repair Operation Time (ROT)

ItemCode

Cam Cover - Vehicle Set - Remove

and Install 03.10.AW

Page 371 of 947

Engine Sealing (03.10)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-10-13

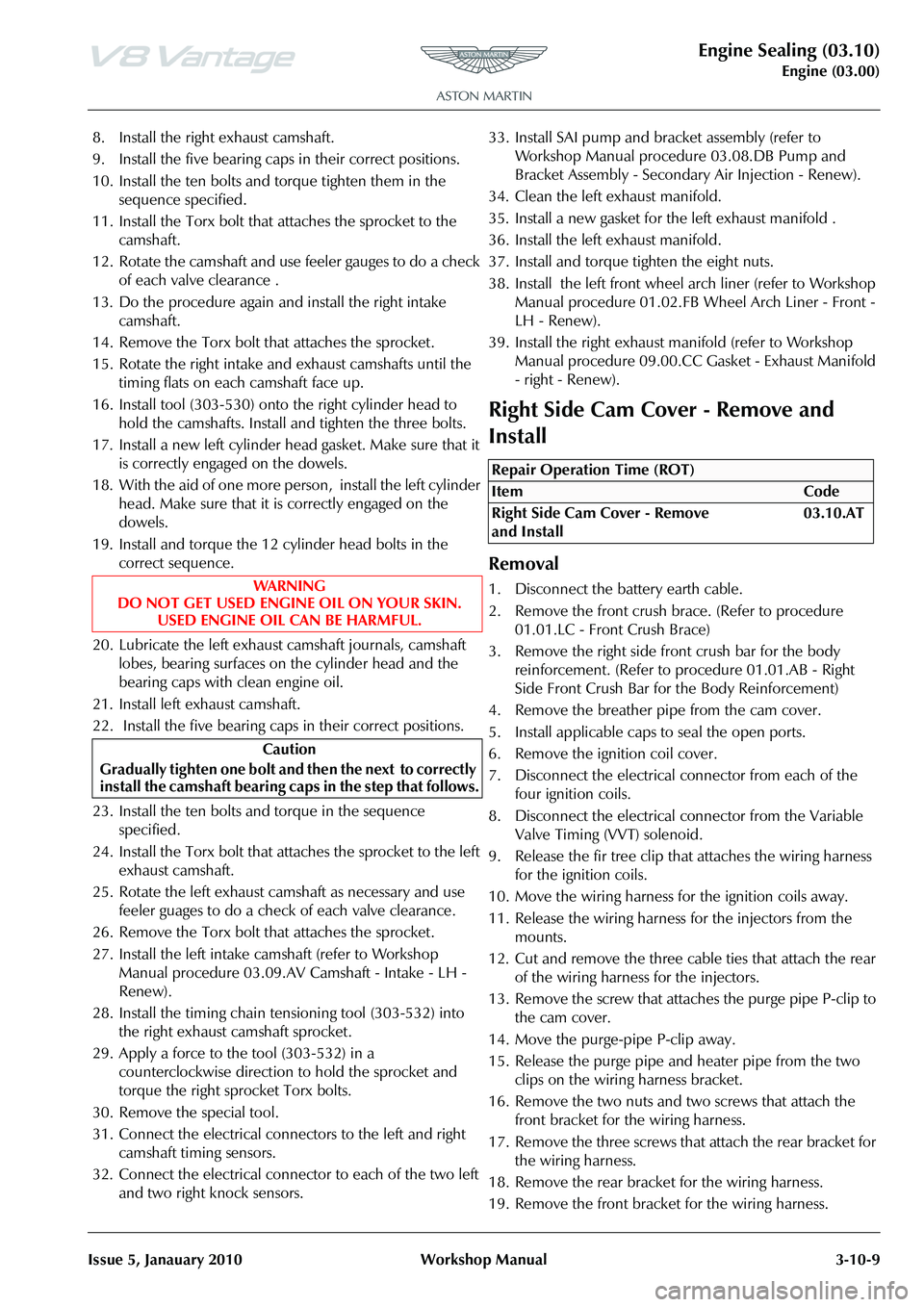

38. Remove the four Torx bolts that attach the PAS pump mounting bracket to the cylinder block. Remove the

bracket (refer to Figure 9).

Figure 9

39. Remove the 27 bolts that attach the timing cover to the engine. Collect the bracet for the oil separator drain

tube. Remove the timing cover.

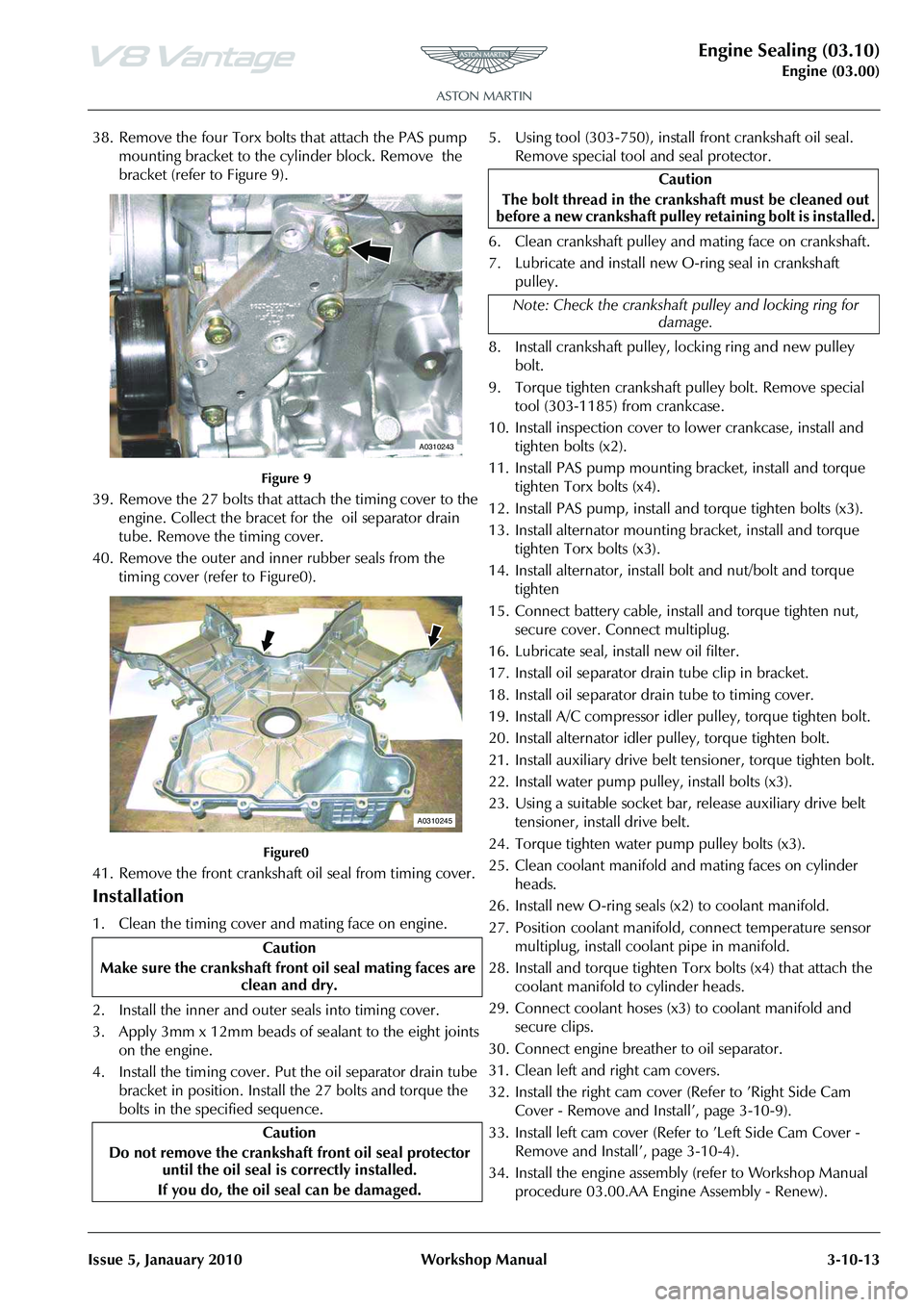

40. Remove the outer and inner rubber seals from the timing cover (refer to Figure0).

Figure0

41. Remove the front crankshaft oil seal from timing cover.

Installation

1. Clean the timing cover and mating face on engine.

2. Install the inner and outer seals into timing cover.

3. Apply 3mm x 12mm beads of sealant to the eight joints

on the engine.

4. Install the timing cover. Put the oil separator drain tube bracket in position. Install the 27 bolts and torque the

bolts in the specified sequence. 5. Using tool (303-750), instal

l front crankshaft oil seal.

Remove special tool and seal protector.

6. Clean crankshaft pulley and mating face on crankshaft.

7. Lubricate and install new O-ring seal in crankshaft pulley.

8. Install crankshaft pulley, locking ring and new pulley bolt.

9. Torque tighten crankshaft pulley bolt. Remove special tool (303-1185) from crankcase.

10. Install inspection cover to lower crankcase, install and tighten bolts (x2).

11. Install PAS pump mounting bracket, install and torque tighten Torx bolts (x4).

12. Install PAS pump, install and torque tighten bolts (x3).

13. Install alternator mounting bracket, install and torque tighten Torx bolts (x3).

14. Install alternator, install bolt and nut/bolt and torque tighten

15. Connect battery cable, install and torque tighten nut, secure cover. Connect multiplug.

16. Lubricate seal, install new oil filter.

17. Install oil separator drai n tube clip in bracket.

18. Install oil separator drain tube to timing cover.

19. Install A/C compressor idler pulley, torque tighten bolt.

20. Install alternator idler pulley, torque tighten bolt.

21. Install auxiliary drive belt te nsioner, torque tighten bolt.

22. Install water pump pulley, install bolts (x3).

23. Using a suitable socket ba r, release auxiliary drive belt

tensioner, install drive belt.

24. Torque tighten water pump pulley bolts (x3).

25. Clean coolant manifold and mating faces on cylinder heads.

26. Install new O-ring seals (x2) to coolant manifold.

27. Position coolant manifold, connect temperature sensor

multiplug, install coolant pipe in manifold.

28. Install and torque tighten Torx bolts (x4) that attach the coolant manifold to cylinder heads.

29. Connect coolant hoses (x3) to coolant manifold and

secure clips.

30. Connect engine breather to oil separator.

31. Clean left and right cam covers.

32. Install the right cam cover (Refer to ’Right Side Cam Cover - Remove and Install’, page 3-10-9).

33. Install left cam cover (Refer to ’Left Side Cam Cover -

Remove and Install’, page 3-10-4).

34. Install the engine assembly (refer to Workshop Manual procedure 03.00.AA Engine Assembly - Renew).

Caution

Make sure the cranks haft front oil seal mating faces are

clean and dry.

Caution

Do not remove the crankshaft front oil seal protector

until the oil seal is correctly installed.

If you do, the oil seal can be damaged.

A0310243

A0310245

Caution

The bolt thread in the cran kshaft must be cleaned out

before a new crankshaft pulley retaining bolt is installed.

Note: Check the crankshaft pulley and locking ring for damage.

Page 373 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-1

Engine (03.00)

Power Conversion (03.11)

Maintenance

Connecting Rod Bearing-Renew (Engine

Set)

Removal

1. Remove engine oil sump (see Workshop Manual

procedure 03.02.BN Pan - Oil Sump - Remove and Re-

seal).

2. Remove spark plugs (see Workshop Manual procedure 03.07.DB Spark Plugs - Engine Set - Renew).

3. Remove bolts (x8) securing windage tray to engine bedplate, remove windage tray.

4. Mark bearing caps and connecting rods for correct installation.

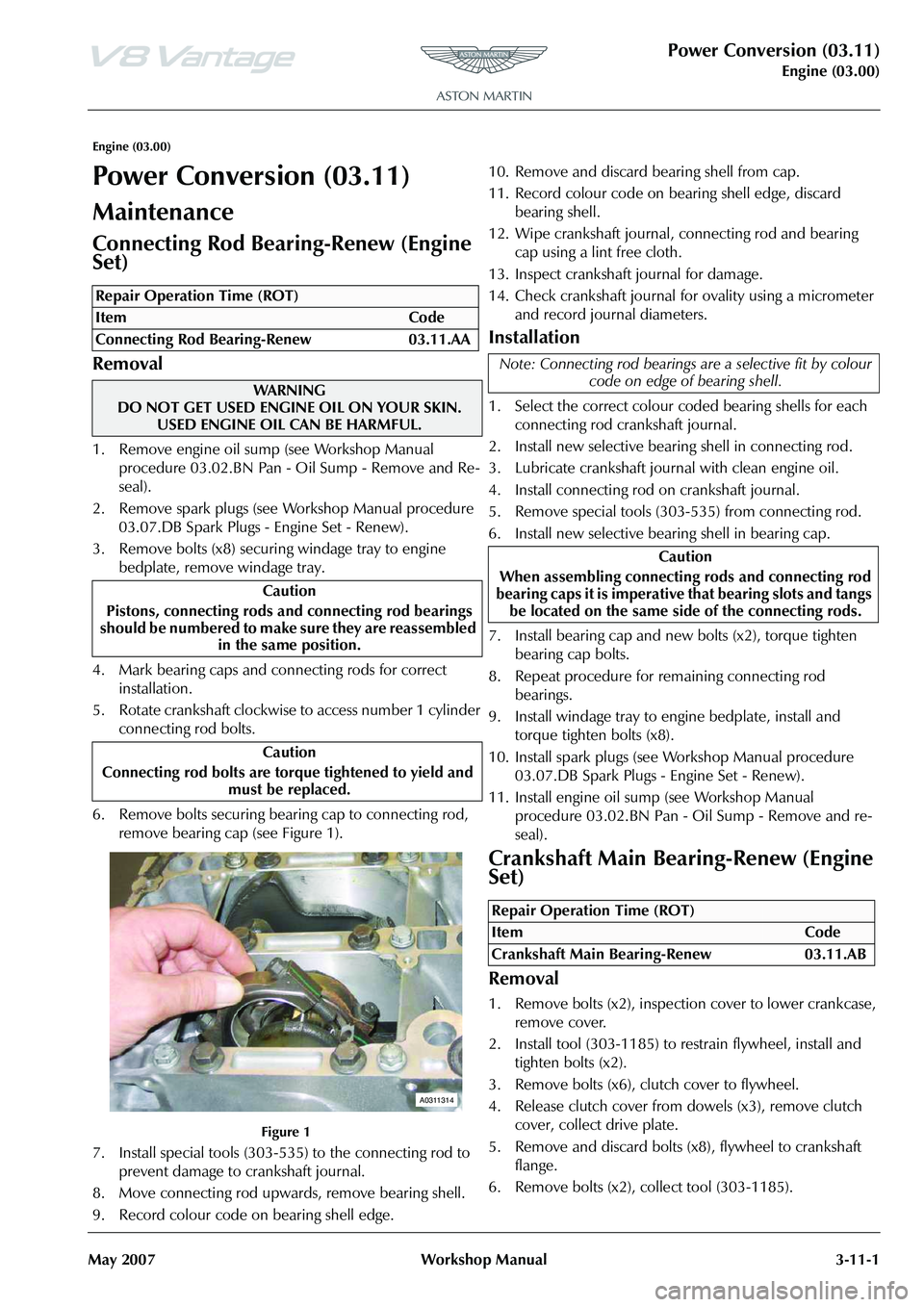

5. Rotate crankshaft clockwise to access number 1 cylinder connecting rod bolts.

6. Remove bolts securing bearing cap to connecting rod, remove bearing cap (see Figure 1).

Figure 1

7. Install special tools (303-535) to the connecting rod to prevent damage to crankshaft journal.

8. Move connecting rod upwards, remove bearing shell.

9. Record colour code on bearing shell edge. 10. Remove and discard bearing shell from cap.

11. Record colour code on bearing shell edge, discard

bearing shell.

12. Wipe crankshaft journal, connecting rod and bearing cap using a lint free cloth.

13. Inspect crankshaft journal for damage.

14. Check crankshaft journal for ovality using a micrometer and record journal diameters.

Installation

1. Select the correct colour coded bearing shells for each connecting rod crankshaft journal.

2. Install new selective bearing shell in connecting rod.

3. Lubricate crankshaft journal with clean engine oil.

4. Install connecting rod on crankshaft journal.

5. Remove special tools (303-535) from connecting rod.

6. Install new selective bearing shell in bearing cap.

7. Install bearing cap and new bolts (x2), torque tighten bearing cap bolts.

8. Repeat procedure for remaining connecting rod bearings.

9. Install windage tray to engine bedplate, install and torque tighten bolts (x8).

10. Install spark plugs (see Workshop Manual procedure 03.07.DB Spark Plugs - Engine Set - Renew).

11. Install engine oil sump (see Workshop Manual

procedure 03.02.BN Pan - Oil Sump - Remove and re-

seal).

Crankshaft Main Bearing-Renew (Engine

Set)

Removal

1. Remove bolts (x2), inspection cover to lower crankcase, remove cover.

2. Install tool (303-1185) to restrain flywheel, install and tighten bolts (x2).

3. Remove bolts (x6), clutch cover to flywheel.

4. Release clutch cover from dowels (x3), remove clutch cover, collect drive plate.

5. Remove and discard bolts (x8), flywheel to crankshaft flange.

6. Remove bolts (x2), collect tool (303-1185).

Repair Operation Time (ROT)

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Pistons, connecting rods an d connecting rod bearings

should be numbered to make sure they are reassembled

in the same position.

Caution

Connecting rod bolts are tor qu

e tightened to yield and

mu st be replaced.

A0311314

Note: Connecting rod bearings ar e a selective fit by colour

code on edge of bearing shell.

Caution

When assembling connecting rods and connecting rod

bearing caps it is imperative that bearing slots and tangs

be located on the same side of the connecting rods.

Repair Operation Time (ROT)

Page 376 of 947

Power Conversion (03.11)

Engine (03.00)3-11-4 Workshop Manual May 2007

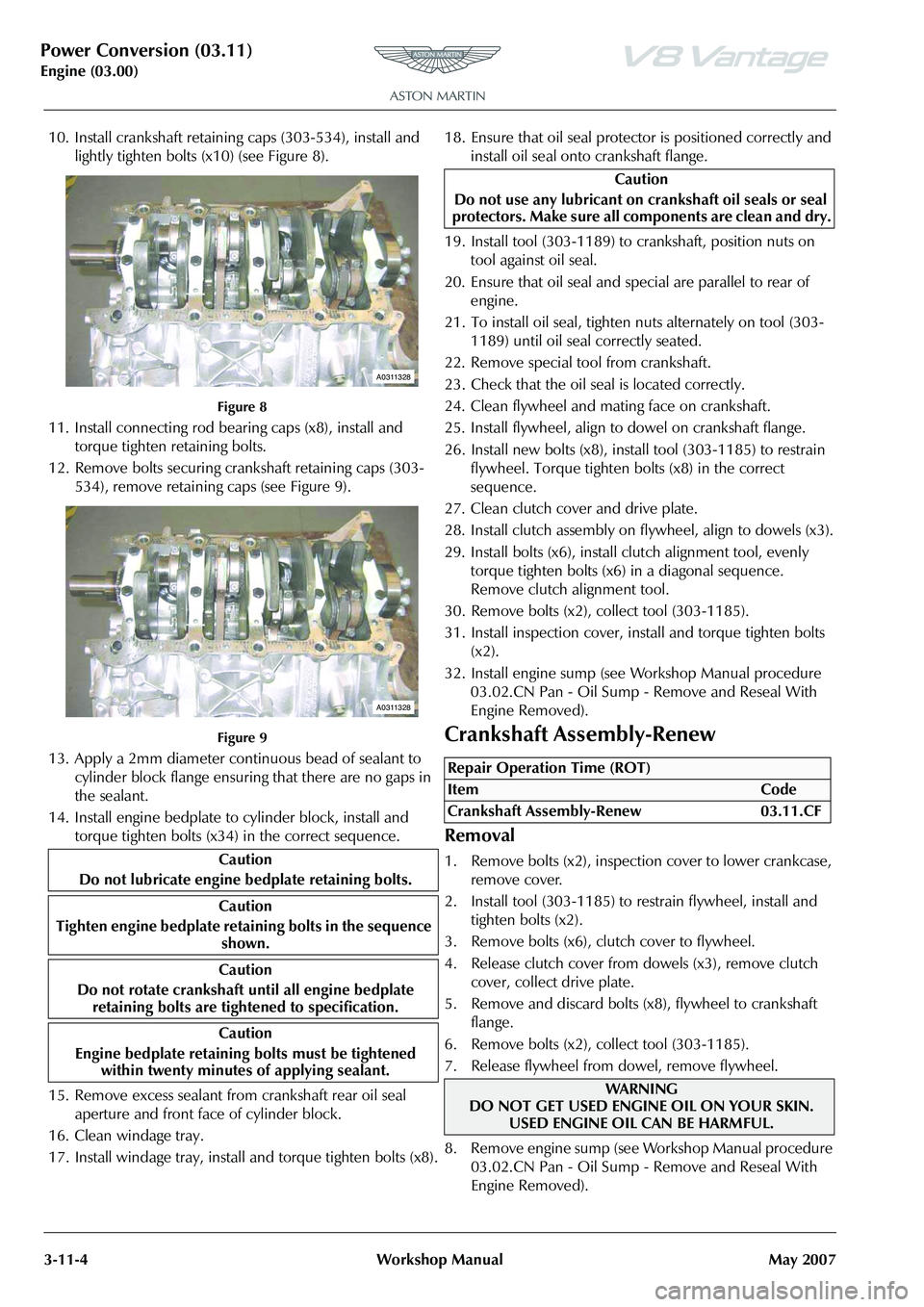

10. Install crankshaft retaining caps (303-534), install and

lightly tighten bolts (x10) (see Figure 8).

Figure 8

11. Install connecting rod bearing caps (x8), install and torque tighten retaining bolts.

12. Remove bolts securing crankshaft retaining caps (303- 534), remove retaining caps (see Figure 9).

Figure 9

13. Apply a 2mm diameter continuous bead of sealant to cylinder block flange ensuring that there are no gaps in

the sealant.

14. Install engine bedplate to cylinder block, install and torque tighten bolts (x34) in the correct sequence.

15. Remove excess sealant from crankshaft rear oil seal

aperture and front face of cylinder block.

16. Clean windage tray.

17. Install windage tray, install and torque tighten bolts (x8). 18. Ensure that oil seal protector is positioned correctly and

install oil seal onto crankshaft flange.

19. Install tool (303-1189) to crankshaft, position nuts on tool against oil seal.

20. Ensure that oil seal and special are parallel to rear of engine.

21. To install oil seal, tighten nuts alternately on tool (303- 1189) until oil seal correctly seated.

22. Remove special tool from crankshaft.

23. Check that the oil se al is located correctly.

24. Clean flywheel and mating face on crankshaft.

25. Install flywheel, align to dowel on crankshaft flange.

26. Install new bolts (x8), install tool (303-1185) to restrain flywheel. Torque tighten bolts (x8) in the correct

sequence.

27. Clean clutch cover and drive plate.

28. Install clutch assembly on flywheel, align to dowels (x3).

29. Install bolts (x6), install clutch alignment tool, evenly torque tighten bolts (x6) in a diagonal sequence.

Remove clutch alignment tool.

30. Remove bolts (x2), collect tool (303-1185).

31. Install inspection cover, install and torque tighten bolts (x2).

32. Install engine sump (see Workshop Manual procedure 03.02.CN Pan - Oil Sump - Remove and Reseal With

Engine Removed).

Crankshaft Assembly-Renew

Removal

1. Remove bolts (x2), inspection cover to lower crankcase, remove cover.

2. Install tool (303-1185) to restrain flywheel, install and tighten bolts (x2).

3. Remove bolts (x6), clutch cover to flywheel.

4. Release clutch cover from dowels (x3), remove clutch cover, collect drive plate.

5. Remove and discard bolts (x8), flywheel to crankshaft flange.

6. Remove bolts (x2), collect tool (303-1185).

7. Release flywheel from dowel, remove flywheel.

8 . R e m o v e e n g i n e s u mp ( s e e Wo r k s h o p M a n u a l p ro c e d u re 03.02.CN Pan - Oil Sump - Remove and Reseal With

Engine Removed).

Caution

Do not lubricate engine bedplate retaining bolts.

Caution

Tighten engine bedplate retaining bolts in the sequence shown.

Caution

Do not rotate crankshaft until all engine bedplate

retaining bolts are tightened to specification.

Caution

Engine bedplate retaining bolts must be tightened

within twenty minutes of applying sealant.

A0311328

A0311328

Caution

Do not use any lubricant on cr ankshaft oil seals or seal

protectors. Make sure all co mponents are clean and dry.

Repair Operation Time (ROT)

ItemCode

Crankshaft Assembly-Renew 03.11.CF

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN.

USED ENGINE OIL CAN BE HARMFUL.

Page 378 of 947

Power Conversion (03.11)

Engine (03.00)3-11-6 Workshop Manual May 2007

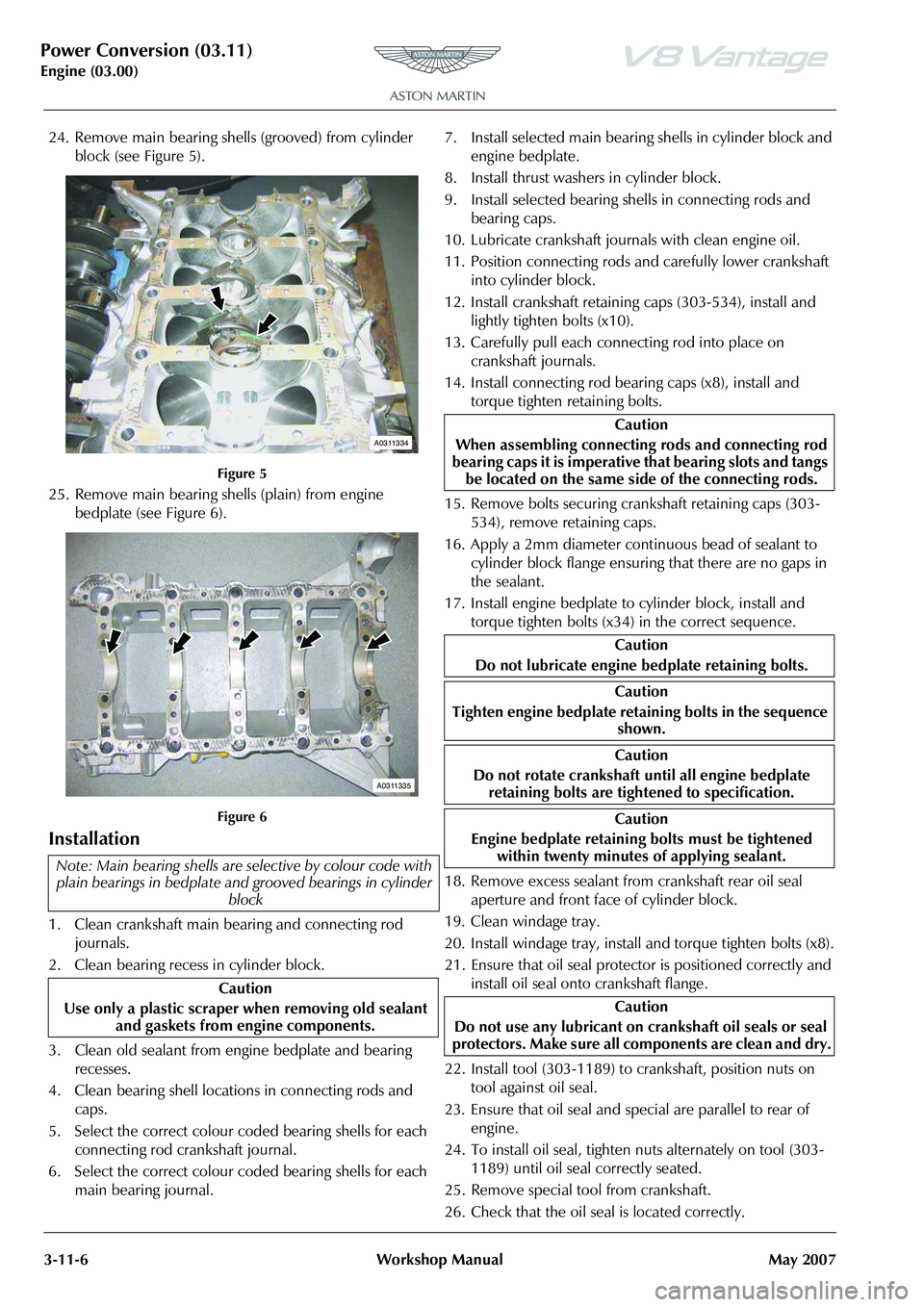

24. Remove main bearing shells (grooved) from cylinder

block (see Figure 5).

Figure 5

25. Remove main bearing shells (plain) from engine bedplate (see Figure 6).

Figure 6

Installation

1. Clean crankshaft main bearing and connecting rod journals.

2. Clean bearing recess in cylinder block.

3. Clean old sealant from engine bedplate and bearing recesses.

4. Clean bearing shell locations in connecting rods and caps.

5. Select the correct colour coded bearing shells for each connecting rod crankshaft journal.

6. Select the correct colour coded bearing shells for each main bearing journal. 7. Install selected main bearing

shells in cylinder block and

engine bedplate.

8. Install thrust washers in cylinder block.

9. Install selected bearing shells in connecting rods and bearing caps.

10. Lubricate crankshaft journa ls with clean engine oil.

11. Position connecting rods and carefully lower crankshaft into cylinder block.

12. Install crankshaft retaining caps (303-534), install and lightly tighten bolts (x10).

13. Carefully pull each connecting rod into place on crankshaft journals.

14. Install connecting rod bearing caps (x8), install and torque tighten retaining bolts.

15. Remove bolts securing cran kshaft retaining caps (303-

534), remove retaining caps.

16. Apply a 2mm diameter continuous bead of sealant to cylinder block flange ensuring that there are no gaps in

the sealant.

17. Install engine bedplate to cylinder block, install and torque tighten bolts (x34) in the correct sequence.

18. Remove excess sealant from crankshaft rear oil seal aperture and front face of cylinder block.

19. Clean windage tray.

20. Install windage tray, install and torque tighten bolts (x8).

21. Ensure that oil seal protector is positioned correctly and install oil seal onto crankshaft flange.

22. Install tool (303-1189) to crankshaft, position nuts on tool against oil seal.

23. Ensure that oil seal and special are parallel to rear of engine.

24. To install oil seal, tighten nuts alternately on tool (303- 1189) until oil seal correctly seated.

25. Remove special tool from crankshaft.

26. Check that the oil se al is located correctly.

Note: Main bearing shells are

selective by colour code with

plain bearings in bedplate and grooved bearings in cylinder

block

Caution

Use only a plastic scraper when removing old sealant and gaskets from engine components.

A0311334

A0311335

Caution

When assembling connecting rods and connecting rod

bearing caps it is imperative that bearing slots and tangs

be located on the same side of the connecting rods.

Caution

Do not lubricate engine bedplate retaining bolts.

Caution

Tighten engine bedplate retaining bolts in the sequence shown.

Caution

Do not rotate crankshaft until all engine bedplate

retaining bolts are tightened to specification.

Caution

Engine bedplate retaining bolts must be tightened within twenty minutes of applying sealant.

Caution

Do not use any lubricant on cr ankshaft oil seals or seal

protectors. Make sure all co mponents are clean and dry.

Page 379 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-7

27. Clean flywheel and mating face on crankshaft.

28. Install flywheel, align to dowel on crankshaft flange.

29. Install new bolts (x8), install tool (303-1185) to restrain

flywheel. Torque tighten bolts (x8) in the correct

sequence.

30. Clean clutch cover and drive plate.

31. Install clutch assembly on fl ywheel, align to dowels (x3).

32. Install bolts (x6), install clutch alignment tool, evenly torque tighten bolts (x6) in a diagonal sequence.

Remove clutch alignment tool.

33. Remove bolts (x2), collect tool (303-1185).

34. Install inspection cover, install and torque tighten bolts (x2).

35. Install engine sump (see Workshop Manual procedure 03.02.CN Pan - Oil Sump - Remove and Reseal With

Engine Removed).

Piston-Renew (Engine Set)

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.01.HW Gasket -

Cylinder Head - Engine Set - Renew With Engine

Removed).

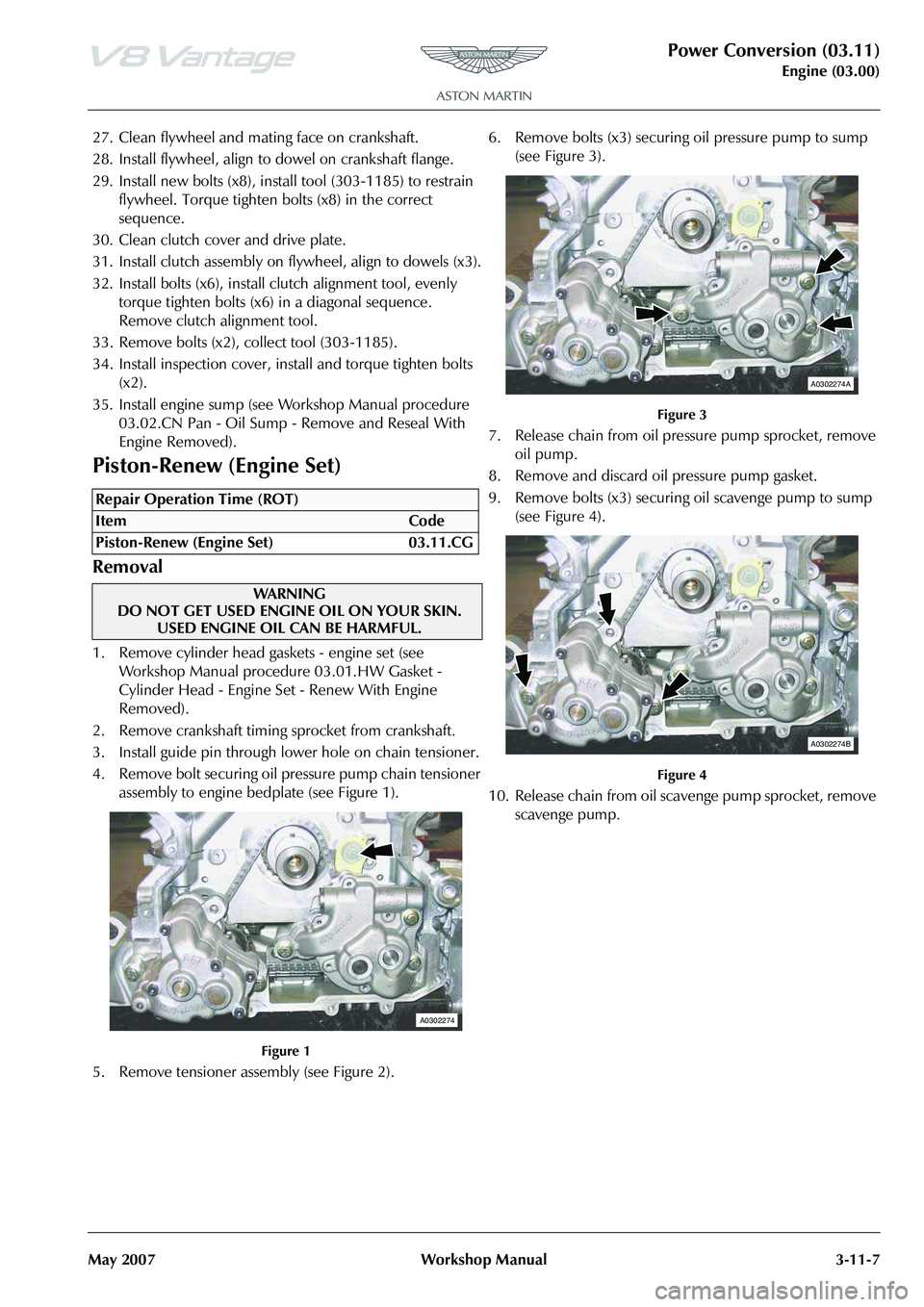

2. Remove crankshaft timing sprocket from crankshaft.

3. Install guide pin through lower hole on chain tensioner.

4. Remove bolt securing oil pr essure pump chain tensioner

assembly to engine bedplate (see Figure 1).

Figure 1

5. Remove tensioner assembly (see Figure 2). 6. Remove bolts (x3) securing oil pressure pump to sump

(see Figure 3).

Figure 3

7. Release chain from oil pressure pump sprocket, remove oil pump.

8. Remove and discard oil pressure pump gasket.

9. Remove bolts (x3) securing oil scavenge pump to sump

(see Figure 4).

Figure 4

10. Release chain from oil scavenge pump sprocket, remove scavenge pump.

Repair Operation Time (ROT)

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN.

USED ENGINE OIL CAN BE HARMFUL.

A0302274

A0302274A

A0302274B

Page 384 of 947

Power Conversion (03.11)

Engine (03.00)3-11-12 Workshop Manual May 2007

12. Install piston ring clamp to each piston in turn and install

in its respective cylinder bore. Remove piston ring

clamp (see Figure 19).

Figure 19

13. Lubricate crankshaft journa ls with clean engine oil.

14. Carefully pull each connecting rod into place on each crankshaft journal.

15. Install bearing caps to their relevant connecting rods. Install and torque tighten retaining bolts (x16).

16. Clean windage tray.

17. Install windage tray, install and torque tighten bolts (x8).

18. Clean old sealant from sump flange and engine bedplate.

19. Ensure that sump flange and mating face on engine bedplate are clean and dry.

20. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

21. Ensure that there are no gaps in sealant track.

22. Install sump, install and torque tighten bolts (x16) in the correct sequence.

23. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

24. Lubricate and install new O-ring seals to oil pipes.

25. Install oil pipes in sump, install and torque tighten bolts (x2)

26. Install compressor, install and torque tighten bolts (x4).

27. Connect multiplug to A/C compressor.

28. Install LH and RH HEGO sensor multiplug brackets to sump. Install and torque tighten bolts (x4).

29. Secure harness clips (x6) in sump.

30. Connect multiplug to crankshaft timing sensor.

31. Connect multiplug to engine electric coolant temperature sensor.

32. Connect multiplug to oil pressure sensor.

33. Clean oil scavenge pump and mating face on sump.

34. Install oil pump(s) drive sprocket. 35. Install new oil scavenge pump gasket, align on dowels

(x2).

36. Install chain onto oil scavenge pump sprocket.

37. Install oil scavenge pump, align to dowels (x2), Install

and torque tighten bolts (x3).

38. Install chain onto oil pump drive sprocket.

39. Clean oil pressure pump and mating face on sump.

40. Install new gasket to sump, align to dowels (x2).

41. Position oil pressure pu mp, install chain on pump

sprocket.

42. Install oil pressure pump, align to dowels (x2), Install and

torque tighten bolts (x3).

43. Install chain tensioner, install and torque tighten bolt, remove guide pin.

44. Install crankshaft timing sprocket.

45. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.01.HW Gasket - Cylinder Head -

Engine Set - Renew Wi th Engine Removed).

Piston-Renew

Removal

1. Remove cylinder head gaskets - engine set (see

Workshop Manual procedure 03.01.HW Gasket -

Cylinder Head - Engine Set - Renew With Engine

Removed).

2. Remove crankshaft timing sprocket from crankshaft.

3. Install guide pin through lower hole on chain tensioner.

4. Remove bolt securing oil pressure pump chain tensioner assembly to engine bedplate (see Figure 1).

Figure 1

Caution

When assembling connecting rods and connecting rod

bearing caps it is imperative that bearing slots and tangs

be located on the same side of the connecting rods.

A0311337

Repair Operation Time (ROT)

ItemCode

Piston-Renew 03.11.CH

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN.

USED ENGINE OIL CAN BE HARMFUL.

A0302274

Page 389 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-17

12. Install piston ring clamp to piston, install piston assembly

in its cylinder bore. Remo ve piston ring clamp (see

Figure 19).

Figure 19

13. Lubricate crankshaft journal with clean engine oil.

14. Carefully pull connecting ro d into place on crankshaft

journal.

15. Install bearing cap to connecting rod. Install and torque tighten retaining bolts (x2).

16. Clean windage tray.

17. Install windage tray, install and torque tighten bolts (x8).

18. Clean old sealant from sump flange and engine bedplate.

19. Ensure that sump flange and mating face on engine bedplate are clean and dry.

20. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

21. Ensure that there are no gaps in sealant track.

22. Install sump, install and torque tighten bolts (x16) in the correct sequence.

23. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

24. Lubricate and install new 'O' ring seals to oil pipes.

25. Install oil pipes in sump, install and torque tighten bolts (x2)

26. Install compressor, install and torque tighten bolts (x4).

27. Connect multiplug to A/C compressor.

28. Install LH and RH HEGO sensor multiplug brackets to sump. Install and torque tighten bolts (x4).

29. Secure harness clips (x6) in sump.

30. Connect multiplug to crankshaft timing sensor.

31. Connect multiplug to engine electric coolant temperature sensor.

32. Connect multiplug to oil pressure sensor.

33. Clean oil scavenge pump and mating face on sump.

34. Install oil pump(s) drive sprocket.

35. Install new oil scavenge pu mp gasket, align on dowels

(x2). 36. Install chain onto oil scavenge pump sprocket.

37. Install oil scavenge pump, align to dowels (x2), Install

and torque tighten bolts (x3).

38. Install chain onto oil pump drive sprocket.

39. Clean oil pressure pump and mating face on sump.

40. Install new gasket to sump, align to dowels (x2).

41. Position oil pressure pump, install chain on pump sprocket.

42. Install oil pressure pump, align to dowels (x2), Install and torque tighten bolts (x3).

43. Install chain tensioner, install and torque tighten bolt, remove guide pin.

44. Install crankshaft timing sprocket.

45. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.01.HW Gasket - Cylinder Head -

Engine Set - Renew With Engine Removed).

Additional Piston-Renew (Each)

Removal

1. Mark bearing caps and connecting rods for correct installation.

2. Remove bolts (x2) securing bearing cap to connecting rod, remove bearing cap.

3. Install special tools (303-535) to the connecting rod to prevent damage to crankshaft journal.

4. Carefully push connecting rod/piston assembly upwards and remove from cylinder bore.

5. Remove special tools from connecting rod.

6. Install bearing cap on connecting rod, install and lightly tighten retaining bolts.

7. Remove circlip (x2) securing gudgeon pin in piston and

connecting rod. Remove piston.

Installation

1. Clean cylinder bore.

2. Install piston rings in cylinder bore to a pre-determined depth and measure ring gaps.

3. Remove piston ring set from cylinder bore and install on piston.

4. Clean connecting rod.

5. Install piston on connecting rod in its correct orientation, install circlip(s).

Caution

Install pistons into cylinder block with the ‘arrow’ on the

piston crown facing to the front of the engine.

A0311337

Repair Operation Time (ROT)

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Connecting rod bolts are tor que

tightened to yield and

mu st

be replaced.

Page 390 of 947

Power Conversion (03.11)

Engine (03.00)3-11-18 Workshop Manual May 2007

6. Correctly position ring gaps on piston prior to

installation.

7. Remove connecting rod bearing cap.

8. Install bearings in connecting rod and bearing cap.

9. Lubricate cylinder bore, pi ston and rings with clean

engine oil.

10. Install special tools (303-535) to the connecting rod to prevent damage to crankshaft journal.

11. Install piston ring clamp to piston, install piston assembly in its cylinder bore. Remove piston ring clamp.

12. Lubricate crankshaft journal with clean engine oil.

13. Carefully pull connecting rod into place on crankshaft journal.

14. Install bearing cap to connecting rod. Install and torque tighten retaining bolts (x2).

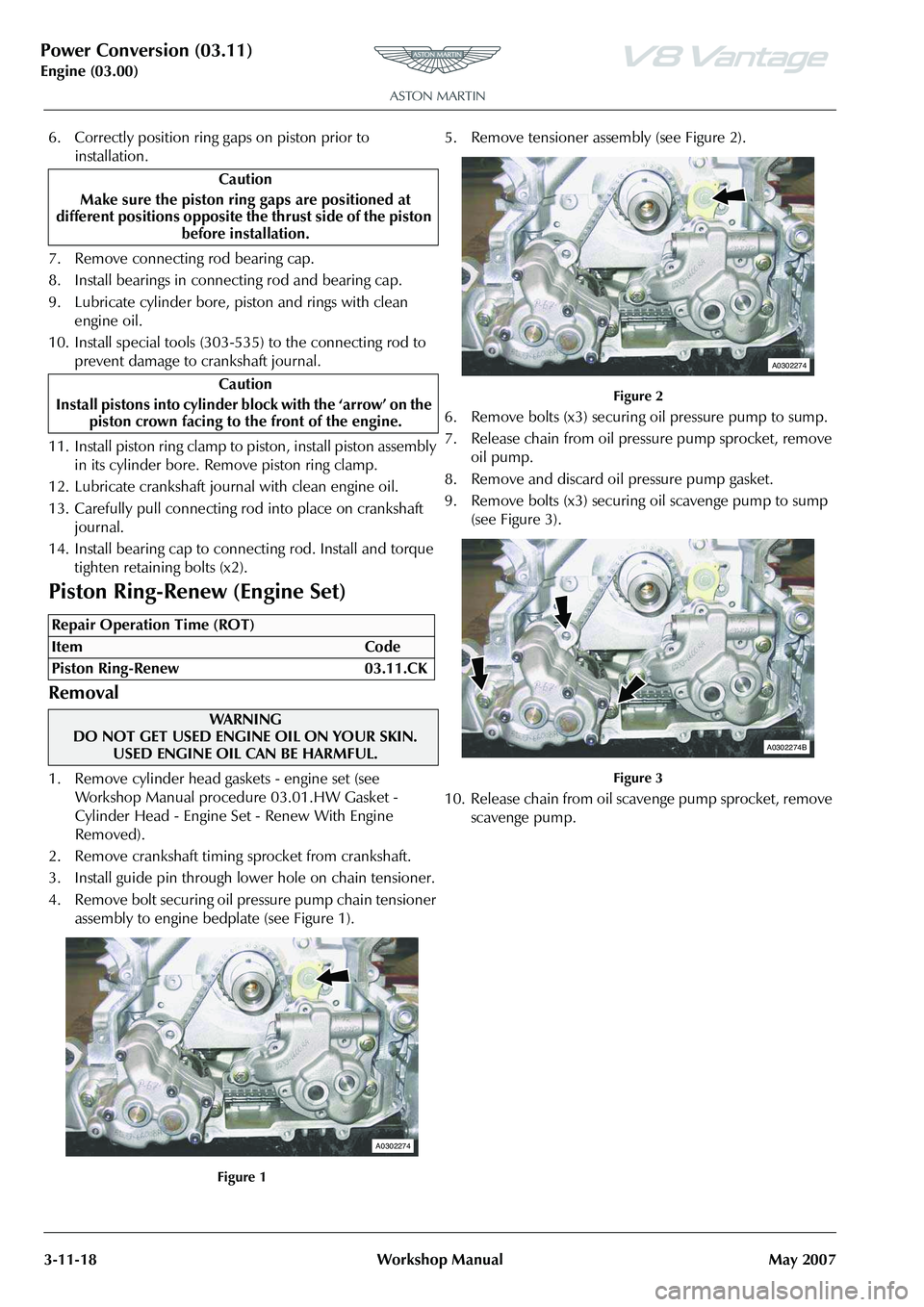

Piston Ring-Renew (Engine Set)

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.01.HW Gasket -

Cylinder Head - Engine Set - Renew With Engine

Removed).

2. Remove crankshaft timing sprocket from crankshaft.

3. Install guide pin through lower hole on chain tensioner.

4. Remove bolt securing oil pressure pump chain tensioner assembly to engine bedplate (see Figure 1).

Figure 1

5. Remove tensioner assembly (see Figure 2).

Figure 2

6. Remove bolts (x3) securing oil pressure pump to sump.

7. Release chain from oil pres sure pump sprocket, remove

oil pump.

8. Remove and discard oil pressure pump gasket.

9. Remove bolts (x3) securing oil scavenge pump to sump (see Figure 3).

Figure 3

10. Release chain from oil scavenge pump sprocket, remove scavenge pump.

Caution

Make sure the piston ring gaps are positioned at

different positions opposite th e thrust side of the piston

before installation.

Caution

Install pistons into cylinder block with the ‘arrow’ on the

piston crown facing to the front of the engine.

Repair Operation Time (ROT)

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

A0302274

A0302274

A0302274B