torque ASTON MARTIN V8 VANTAGE 2010 Owners Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 311 of 947

Fuel Charging System (03.04)

Engine (03.00)

May 2007 Workshop Manual 3-4-5

17. Install fusebox bracket fixings.

18. Refit harness fir tree clips to cylinder head.

19. Refit engine breather hose.

20. Install VVT solenoid multiplug, position coil and CMP

harness (1x edge clip).

21. Install LH injectors (see Workshop Manual procedure

03.04.GH Injector - Fuel - LH Bank - Each - Renew).

22. Install ECM (see Workshop Manual procedure 03.14.BB Engine Control Module - RH Renew).

1. Install coils (see Workshop Manual procedure 03.07.HC

Coil Assembly - Engine Set - RH - Renew).

Fuel Injector - Each - LH Bank - Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise).

2. Remove corner cross brace.

3. Disconnect breather hoses from cam cover (x2) for access.

4. Disconnect purge line from manifold (quickfit) and support clip for access.

5. Disconnect heater hose from pipe (quick fit).

6. Release heater hose (x2) and throttle body hose (x2) from support bracket.

7. Remove booster hose from manifold and support clip.

8. Remove harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3).

9. Release pipe support bracket (nuts x2, bolts x2) move aside.

10. Disconnect IAT multiplug.

11. Disconnect injector multiplugs (x4).

12. Unclip injector harness from cam cover (x2).

13. Disconnect breather hose from manifold (quickfit).

14. Remove Injector to rail clip (for injector to be changed).

15. Remove fuel rail bolts (x2) and lift rail with remaining injectors (tie aside).

16. Remove injector from manifold.

Installation

1. Install new O-rings to remaining injectors (lube O-rings).

2. Install clip to new injector then injector into rail.

3. Install rail (with injectors) to manifold (bolt x2) (torque) (taking care each injector is aligned correctly).

4. Connect breather hose to manifold (quickfit).

5. Connect IAT multiplug.

6. Unclip injector harness from cam cover (x2).

7. Connect injector multiplugs (x4).

8. Install pipe support br acket (nuts x2, bolts x2). 9. Install harness support bracket (bolt x1, nut x2) release

harness clips (fir tree x3).

10. Connect booster hose to manifold and support clip.

11. Connect heater hose from pipe (quick fit).

12. Install heater hose (x2) and throttle body hose (x2) from support bracket.

13. Connect purge line to manifold and into support clip.

14. Connect breather hoses (x2) to cam cover.

15. Install corner cross brace (t orque bolts with vehicle on

level ground).

Fuel Injector - Each - RH Bank - Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise).

2. Disconnect breather hose (quick fit) move aside.

3. Release harness fir tree clips (x3) from cylinder head and move aside.

4. Remove fuse box bracket fi xings (bolt and nut) (allows

movement).

5. Remove ECM (see Workshop Manual procedure 03.14.BB Engine Control Module - RH Renew).

6. Remove battery lead (1x nut and rubber cover) from fuse box (2x leads).

7. Remove multiplugs (x10) from fusebox.

8. Remove earth terminal (1x nut and rubber cover) from fusebox.

9. Remove fuse box from bracket (bolt x2).

10. Release harness fir tree clips (x3) from engine bracket.

11. Feed harness from inner wing and over engine to gain access to cam cover.

12. Remove purge pipe P-clip (bolt x1) and move pipe aside.

13. Remove harness bracket from engine (bolts x2, nut x1).

14. Release fuel feed hose from rail (clip x1) and move aside.

15. Disconnect heater hose from pipe (quick fit).

16. Release heater hose (clips x2) and EGR vacuum line

(clips x2) from bracket.

17. Release harness from coolan t pipe bracket (fir tree x3).

18. Disconnect EGR (x1), fuel rail pressure sensor (x1) and injector multiplugs (x4), move harness aside.

19. Remove coolant pipe bracket (nuts x2 and bolts x2).

20. Disconnect EGR vac pipe from sensor and manifold, move aside.

21. Remove Injector to rail clip (for injector to be changed).

22. Remove fuel rail bolts (x2) and lift rail with remaining injectors (tie aside).

23. Remove injector from manifold.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 312 of 947

Fuel Charging System (03.04)

Engine (03.00)3-4-6 Workshop Manual May 2007

Installation

1. Install new O-rings to remaining injectors (lube O-ringP-

clips).

2. Install clip to new injector then injector into rail.

3. Install rail (with injectors) to manifold (bolt x2) (torque)

(taking care each injector is aligned correctly).

4. Connect EGR vac pipe to sensor and manifold.

5. Install coolant pipe bracket (bolt x2, nut x2).

6. Connect EGR (x1), fuel rail pressure sensor (x1) and injector multiplugs (x4).

7. Refit harness to coolant pipe bracket (fir tree x3).

8. Connect heater hose to pipe (quick fit).

9. Refit heater hose (clipx2) and EGR vacuum lines (clips

x2) to bracket.

10. Install fuel feed pipe.

11. Install purge pipe P-clip.

12. Install harness bracket to engine.

13. Feed harness into inner wing area.

14. Install fusebox to bracket.

15. Install earth lead to fusebox.

16. Install battery lead to fusebox (1x nut and rubber cover).

17. Install multiplugs to fuse box.

18. Install fusebox bracket fixings.

19. Refit harness fir tree clips to cylinder head.

20. Refit engine breather hose.

21. Install VVT solenoid multiplug, position coil and CMP harness (1x edge clip).

22. Install ECM (see Workshop Manual procedure 03.14.BB Engine Control Module - RH Renew).

Engine Set - Fuel Injector - LH Bank -

Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise).

2. Remove corner cross brace.

3. Disconnect breather hoses from cam cover (x2) for access.

4. Disconnect purge line from manifold (quickfit) and

support clip for access.

5. Disconnect heater hose from pipe (quick fit).

6. Release heater hose (x2) and throttle body hose (x2)

from support bracket.

7. Remove booster hose from manifold and support clip.

8. Remove harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3). 9. Release pipe support bracket

(nuts x2, bolts x2) move

aside.

10. Disconnect IAT multiplug.

11. Disconnect injector multiplugs (x4).

12. Unclip injector harness from cam cover (x2).

13. Disconnect breather hose from manifold (quickfit).

14. Remove Injector to rail clips.

15. Remove fuel rail bolts (x2) and lift rail (tie aside).

16. Remove injectors from manifold.

Installation

1. Install clips on to new injectors then fit injectors into manifold.

2. Install rail onto injectors (taking care each injector is aligned correctly and the clip seats properly) and fit bolts

(x2) (torque).

3. Connect breather hose to manifold (quickfit).

4. Connect IAT multiplug.

5. Unclip injector harness from cam cover (x2).

6. Connect injector multiplugs (x4).

7. Install pipe support bracket (nuts x2, bolts x2).

8. Install harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3).

9. Connect booster hose to manifold and support clip.

10. Connect heater hose from pipe (quick fit).

11. Install heater hose (x2) and throttle body hose (x2) from support bracket.

12. Connect purge line to manifold and into support clip.

13. Connect breather hoses (x2) to cam cover.

14. Install corner cross brace (torque bolts with vehicle on level ground).

Engine Set - Fuel Injector - RH Bank -

Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise

2. Disconnect breather hose (quick fit) move aside.

3. Release harness fir tree clips (x3) from cylinder head and move aside.

4. Remove fuse box bracket fixings (bolt and nut) (allows movement).

5. Remove ECM (see Workshop Manual procedure 03.14.BB Engine Contro l Module - RH Renew).

6. Remove battery lead (1x nut and rubber cover) from fuse box (2x leads).

7. Remove multiplugs (x10) from fusebox.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Engine Set-Fuel Injector-RH Bank-

Renew LHD

03.04.GK

Engine Set-Fuel Injector-RH Bank-

Renew RHD

03.04.GP

Page 313 of 947

Fuel Charging System (03.04)

Engine (03.00)

May 2007 Workshop Manual 3-4-7

8. Remove earth terminal (1x nut and rubber cover) from

fusebox.

9. Remove fuse box from bracket (bolt x2).

10. Release harness fir tree clips (x3) from engine bracket.

11. Feed harness from inner wing and over engine to gain access to cam cover.

12. Remove purge pipe P-clip (bolt x1) and move pipe aside.

13. Remove harness bracket from engine (bolts x2, nut x1).

14. Release fuel feed hose from rail (clip x1) and move aside.

15. Disconnect heater hose from pipe (quick fit).

16. Release heater hose (clips x2) and EGR vacuum line (clips x2) from bracket.

17. Release harness from coolant pipe bracket (fir tree x3).

18. Disconnect EGR (x1), fuel ra il pressure sensor (x1) and

injector multiplugs (x 4), move harness aside.

19. Remove coolant pipe bracket (nuts x2 and bolts x2).

20. Disconnect EGR vac pipe from sensor and manifold,

move aside.

21. Remove Injector to rail clips.

22. Remove fuel rail bolts (x2) and lift rail (tie aside).

23. Remove injectors from manifold.

Installation

1. Install clips on to new injectors then fit injectors into manifold.

2. Install rail onto injectors (taking care each injector is aligned correctly and the clip seats properly) and fit bolts

(x2) (torque).

3. Connect EGR vac pipe to sensor and manifold.

4. Install coolant pipe bracket (bolt x2, nut x2).

5. Connect EGR (x1), fuel rail pressure sensor (x1) and

injector multiplugs (x4).

6. Refit harness to coolant pipe bracket (fir tree x3).

7. Connect heater hose to pipe (quick fit).

8. Refit heater hose (clipx2) and EGR vac lines (clips x2) to bracket.

9. Install fuel feed pipe.

10. Install purge pipe P-clip.

11. Install harness bracket to engine.

12. Feed harness into inner wing area.

13. Install fusebox to bracket.

14. Install earth lead to fusebox.

15. Install battery lead to fusebox (1x nut and rubber cover).

16. Install multiplugs to fuse box.

17. Install fusebox bracket fixings.

18. Refit harness fir tree clips to cylinder head.

19. Refit engine breather hose.

20. Install VVT solenoid multip lug, position coil and CMP

harness (1x edge clip).

21. Install ECM (see Workshop Manual procedure 03.14.BB Engine Control Module - RH Renew).

Page 315 of 947

Accessory Drive System (03.05)

Issue 4, November 2008Workshop Manual 3-5-1

Engine (03.00)

Accessory Drive System (03.05)

Description

Remove

1. Set the battery isolation switch to ‘OFF’.

2. Release the three clips and remove the throttle body

duct for access..

3. Disconnect the two ‘quickfit’ breather pipe connections from the air cleaner duct.

Torque Figures

DescriptionNmlb/ft

Belt Tensioner 34-46 25.1-

34

Idler Pulleys 34-46 25.1-

34

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 316 of 947

Accessory Drive System (03.05)

3-5-2Workshop ManualIssue 4, November 2008

4. Release the tensioner and remove the belt from the idler

(see Figure 1).

Figure 1

5. Remove the bolt that attaches the tensioner to the engine and remove.

Install

1. Install tensioner to engine (bolt x1) (torque).

2. Release tensioner and slip belt on idler.

3. Install throttle body duct.

4. Connect breather pipe quickf its (x2) to air cleaner duct.

5. Battery isolation switch ‘ON’.

Idler Pulley-Renew

Removal

1. Set the battery isolation switch to ‘OFF’.

2. Release the three clips and remove the throttle body duct for access.

3. Disconnect the two ‘quick-fit’ breather pipe connectors from the air cleaner duct.

4. Release the tensioner and remove the belt from the idler. 5. Remove the bolt (2) that attaches the idler (1) to the

engine (refer to Figure 1)..

Figure 1

6. Remove the idler.

Install

1. Install idler to engine (bolt x1) (torque).

2. Release tensioner and slip belt on idler.

3. Install throttle body duct.

4. Connect breather pipe quickfits (x2) to air cleaner duct.

5. Battery isolation switch ‘ON’.

Engine Drive Belt Idler Assembly-Renew

Removal

1. Set the battery isolation switch to ‘OFF’.

2. Release the three clips and remove the throttle body duct for access.

3. Disconnect the two ‘quick-fit’ breather pipe connectors from the air cleaner duct.

Repair Operation Time (ROT)

A030553

Repair Operation Time (ROT)

ItemCode

Engine Drive Belt Idler Assembly-

Renew 03.05.BG

Page 317 of 947

Accessory Drive System (03.05)

Issue 4, November 2008Workshop Manual 3-5-3

4. Release the tensioner and remove the belt from the idler

(see Figure 1).

Figure 1

5. Remove the bolt that attaches the idler to the engine.

6. Remove the idler.

Installation

1. Put the idler in position on the engine.

2. Install and torque the bolt that attaches the idler.

3. Release the tensioner and put the belt on the idler.

4. Install the duct for the throttle body.

5. Connect the two ‘quick-fit’ connectors for the breather pipes to the air cleaner duct.

6. Set the battery isolation switch to ‘ON’.

Page 324 of 947

Emission Control (03.08)

Engine (03.00)3-8-2 Workshop Manual October 2005

6. Disconnect hose from engine (quickfit) and remove

hose.

Installation

1. Connect hose to engine (quickfit).

2. Clip hose to bracket.

3. Remove drain container.

4. Lower vehicle on ramp.

5. Install hose to oil separator (quickfit).

6. Install throttle body to air cleaner duct (clip x1).

7. Fill tank with approximately amount of displaced oil and replace cap.

8. Use handbook procedure to check oil level.

Oil Separator Assembly-Renew

Removal

1. Release clip and disconnect air cleaner duct from throttle body.

2. Disconnect hoses from oil separator (clips x2).

3. Remove separator (bolt x1) (place cloth to catch oil)

Installation

1. Install separator (bolt x1) (torque).

2. Install hoses to oil separator (clips x2).

3. Install throttle body to air cleaner duct (clip x1).

4. Use handbook procedure to check oil level.

Emissions Separator Hose-Renew

Removal

1. Move throttle body to air cleaner duct for access (clip x1).

2. Disconnect hose from oil separator (clips x1).

3. Disconnect hose from engi ne and remove (clips x1).

Installation

1. Connect hose to engine (clips x1).

2. Install hose to oil separator (clips x1).

3. Install throttle body to air cleaner duct (clip x1).

4. Use handbook procedure to check oil level.

Secondary Air Injection Pump and

Bracket Assembly-Renew

Removal

1. Disconnect vehicle battery. 2. Remove inlet manifold assembly (see Workshop Manual

procedure 03.01.BA Manifold Assembly - Intake Upper

- Renew).

3. Disconnect breather tube to secondary air pump (quickfit).

4. Disconnect vacuum tube from solenoid valve.

5. Disconnect vacuum tubes (x2) from actuator valves.

6. Loosen unions and disconnect secondary air injection tubes (x2).

7. Disconnect multiplug, air injection pump. Release multiplug from mounting bracket.

8. Release harness and vacuum tube fir tree clips (x6) from mounting bracket.

9. Remove bolts (x3), securing secondary air injection pump assembly to engine.

10. Remove secondary air injection pump assembly.

Installation

1. Position secondary air injection pump assembly, install and torque tighten bolts (x3).

2. Secure harness and vacuum tube fir tree clips (x6) in

mounting bracket.

3. Secure multiplug in bracket, connect multiplug.

4. Connect and torque tighten secondary air tube unions (x2).

5. Connect vacuum tubes to solenoid and actuator valves (x3).

6. Connect breather tube to secondary air injection pump.

7. Install inlet manifold assembly (see Workshop Manual procedure 03.01.BA Manifold Assembly - Intake Upper

- Renew).

8. Connect vehicle battery.

PCV Valve Assembly-Renew

Removal

1. Disconnect breather tube from PCV valve.

2. Remove bolts (x2) securing PCV valve, remove PCV valve.

Installation

1. Clean PCV valve and mating face.

2. Install PCV valve, install and torque tighten bolts (x2).

3. Connect breather tube to PCV valve.

Crank Vent Hose-Renew

Removal

1. Disconnect hose from cam cover (quickfit).

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

PCV Valve Assembly-Renew 03.08.DC

Repair Operation Time (ROT)

ItemCode

Crank Vent Hose-Renew 03.08.DD

Page 325 of 947

Emission Control (03.08)

Engine (03.00)

October 2005 Workshop Manual 3-8-3

2. Disconnect hose from oil separator (quickfit) and

remove.

Installation

1. Install hose to oil separator (quickfit).

2. Connect hose to cam cover (quickfit).

Exhaust Valve to Exhaust Manifold Tube

Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove flange nuts (x2) on RH exhaust manifold. Remove and discard gasket.

3. Lower vehicle.

4. Undo tube union connection (x1) at exhaust valve, remove tube.

Installation

1. Clean flange and pipe connections.

2. Align tube and loosely connect at the valve.

3. Raise vehicle.

4. Fit new gasket to manifold flange.

5. Install tube assembly. install and torque tighten nuts (x2).

6. Lower vehicle on ramp.

7. Torque tighten valve union connection.

Oil Separator to Inlet Manifold Hose-

Renew

Removal

1. Disconnect hose from throttle body adaptor assembly (quickfit).

2. Disconnect hose from PCV valve (quickfit), remove hose.

Installation

1. Install hose to PCV valve (quickfit).

2. Connect hose to throttle body adapter assembly (quickfit).

EGR Module-Renew

Removal

1. Disconnect vacuum tube and multiplug from EGR module. 2. Loosen and disconnect pipe union, EGR module to

exhaust manifold.

3. Remove bolts (x2) securi ng EGR module to inlet

manifold, remove EGR module, discard gasket.

Installation

1. Clean EGR module and mating face on inlet manifold.

2. Install EGR module with new gasket, install and torque tighten bolts (x2).

3. Clean EGR module pipe and union connection.

4. Install and torque tighten pipe union.

5. Connect multiplug and vacuum tube to EGR module.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 327 of 947

Valve Train (03.09)

Engine (03.00)

Issue 5, January 2010 Workshop Manual 3-9-1

Engine (03.00)

Valve Train (03.09)

Specifications

Maintenance

Left Side Timing Chain Arm Assembly -

Remove and Install

Remove

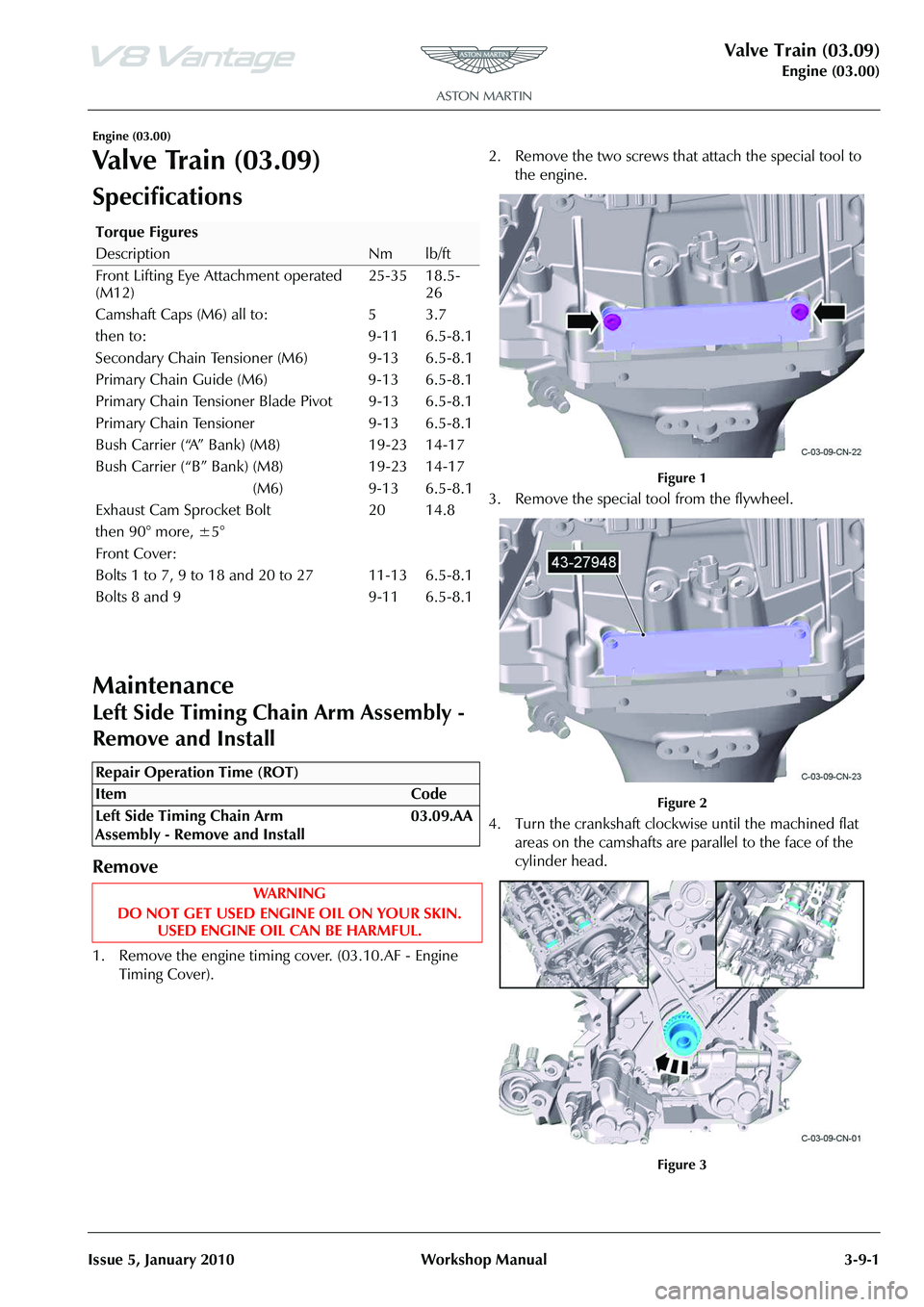

1. Remove the engine timing cover. (03.10.AF - Engine Timing Cover). 2. Remove the two screws that attach the special tool to

the engine.

Figure 1

3. Remove the special tool from the flywheel.

Figure 2

4. Turn the crankshaft clockwise until the machined flat areas on the camshafts are parallel to the face of the

cylinder head.

Figure 3

Torque Figures

DescriptionNmlb/ft

Front Lifting Eye Attachment operated

(M12) 25-35 18.5-

26

Camshaft Caps (M6) all to: 5 3.7

then to: 9-11 6.5-8.1

Secondary Chain Tensioner (M6) 9-13 6.5-8.1

Primary Chain Guide (M6) 9-13 6.5-8.1

Primary Chain Tensioner Blade Pivot 9-13 6.5-8.1

Primary Chain Tensioner 9-13 6.5-8.1

Bush Carrier (“A” Bank) (M8) 19-23 14-17

Bush Carrier (“B” Bank) (M8) 19-23 14-17

(M6) 9-13 6.5-8.1

Exhaust Cam Sprocket Bolt

then 90° more, ±5° 20 14.8

Front Cover:

Bolts 1 to 7, 9 to 18 and 20 to 27

Bolts 8 and 9 11-13

9-116.5-8.1

6.5-8.1

Repair Operation Time (ROT)

Page 331 of 947

Valve Train (03.09)

Engine (03.00)

Issue 5, January 2010 Workshop Manual 3-9-5

25. Loosen the two Torx bolts that attach the camshaft sprockets to the camshafts.

Figure 22

Install

1. Install the tensioner arm (refer to Figure 21).

2. Install the special bolt that attaches the tensioner arm to the engine and torque the bolt to 11 Nm (refer to

Figure 20).

3. Install the timing chain tens ioner (refer to Figure 19).

4. Install the two bolts that attach the timing chain tensioner to the engine and torque the bolts to 11 Nm

(refer to Figure 18).

5. Install the special tool on the exhaust camshaft sprocket.

Figure 23

6. Use the special tool to turn the exhaust sprocket counterclockwise until there is tension in the chain.

Figure 24

7. Release the pin from the ti ming chain tensioner and let

the tension piston gradually apply tension to the timing

chain.

Figure 25

Note: You must use the special tool to hold the timing chain

in the correct position during the subsequent two steps of

the procedure.

Note: Make sure that the tensio ner is fully operated but do

not use too much force.