torque ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 441 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-1

Suspension (04.00)

Shock Absorber System (04.03)

Description

Movement of each road spring is independently damped by

a telescopic, hydraulically-controlled shock absorber. Each

shock absorber is installed coax ially within the road spring.

Front spring and damper assemblies are located between

the upper suspension arm and attach to the lower

suspension arm and the body structure.

Rear spring and damper assemblies attach to the lower

suspension arm and the rear subframe, via a mounting

bracket, laying to the rear of the upper suspension arm.

Specifications

Maintenance

Front Spring and Damper Assembly-Pair-

Renew

Removal

1. Raise vehicle on ramp.

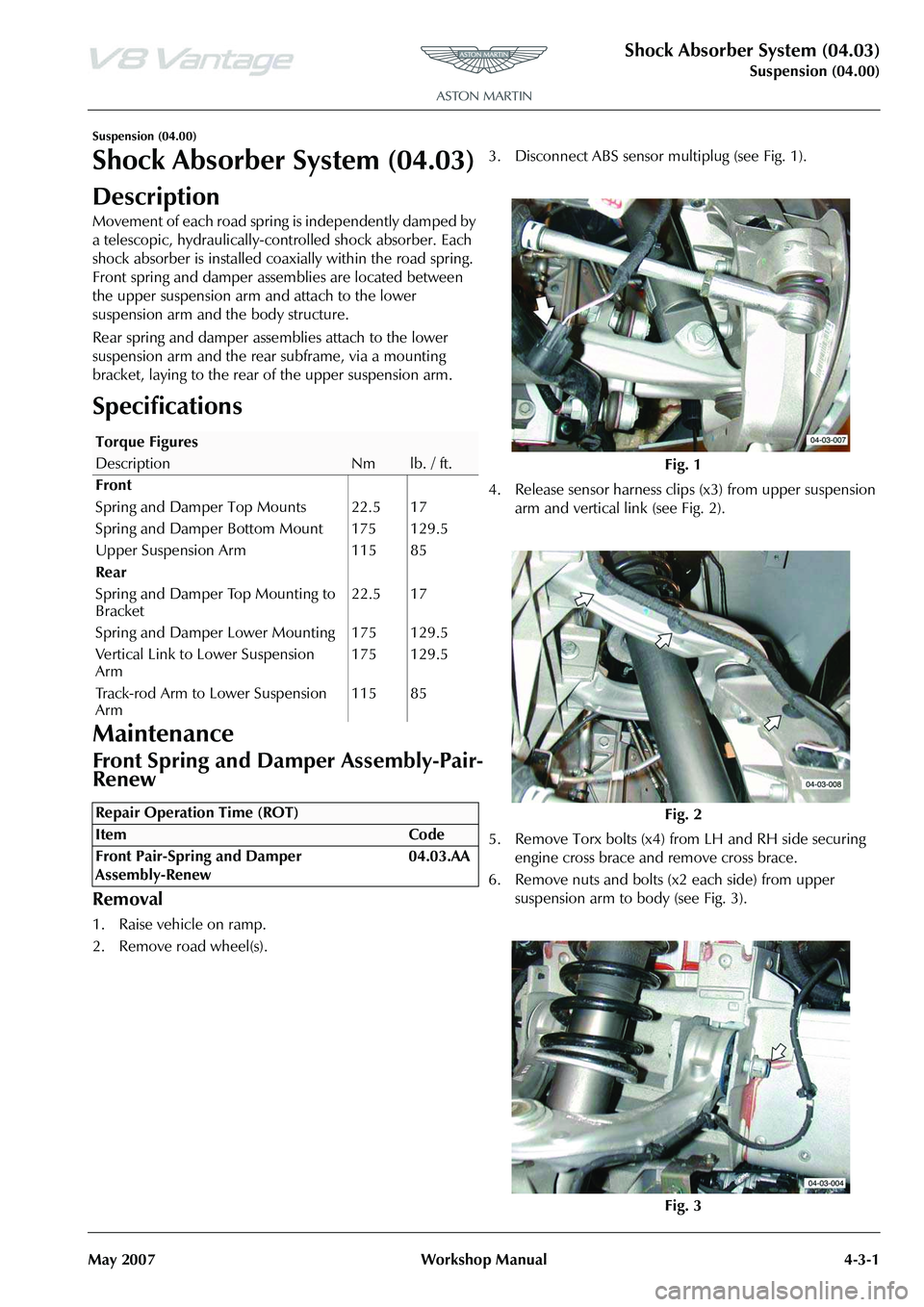

2. Remove road wheel(s). 3. Disconnect ABS sensor

multiplug (see Fig. 1).

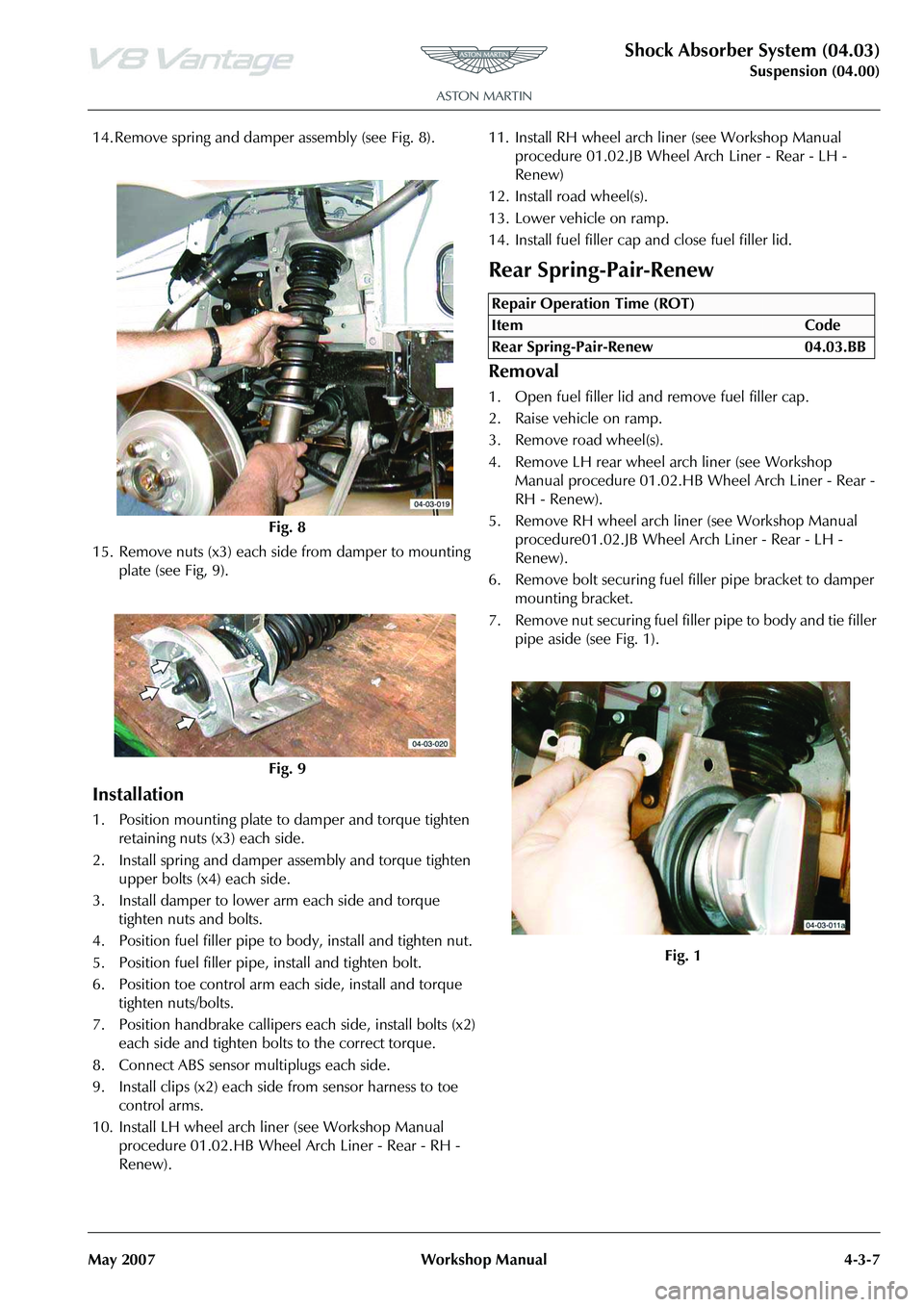

4. Release sensor harness clips (x3) from upper suspension arm and vertical li nk (see Fig. 2).

5. Remove Torx bolts (x4) fr om LH and RH side securing

engine cross brace and remove cross brace.

6. Remove nuts and bolts (x2 each side) from upper suspension arm to body (see Fig. 3).

Torque Figures

DescriptionNmlb. / ft.

Front

Spring and Damper Top Mounts 22.5 17

Spring and Damper Bottom Mount 175 129.5

Upper Suspension Arm 115 85

Rear

Spring and Damper Top Mounting to

Bracket 22.5 17

Spring and Damper Lower Mounting 175 129.5

Vertical Link to Lower Suspension

Arm 175 129.5

Track-rod Arm to Lower Suspension

Arm 115 85

Repair Operation Time (ROT)

Fig. 1

Fig. 2

Fig. 3

Page 442 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-2 Workshop Manual May 2007

7. Position suspension arm aside (see Fig. 4).

8. Remove nuts (x3 each side) from damper top mounting. and remove engine cross br ace support (see Fig. 5). 9. Remove nuts and bolts each side from damper lower

mountings (see Fig, 6).

10. Remove spring and damper assembly.

Installation

1. Install spring and damper assembly and engine cross brace support.

2. Install top mounting nuts (x3) each side (do not torque tighten).

3. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

4. Position upper suspension arm to body and install bolts and nuts (x2) each side (do not torque tighten).

5. Connect ABS sensor multiplug and install harness clips in upper suspension ar m and vertical link.

6. Install road wheel(s).

7. Lower vehicle on ramp.

8. Tighten upper arm nuts and bolts.

9. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

10. Install engine cross brace and install and torque tighten

Torx bolts (x4).

Allow the upper suspension ar

m and vertical link to fall

back, giving access to remo ve the spring and damper

assembly.

Caution

Make sure that the brake flex hose is not over stretched.

Fig. 4

Fig. 5

If removing both spring and damper units - the engine bay

cross brace will be released.

Fig. 6

If removed, place the engine ba y cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum

upward travel.

Page 444 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-4 Workshop Manual May 2007

8. Remove nuts (x3 each side) from damper top mounting and remove engine cross br ace support (see Fig. 5).

9. Remove nuts and bolts (each side) from damper lower mountings (see Fig. 6).

10. Remove spring and damper assembly.

11. Position spring compressor to spring and compress spring.

12. Hold damper shaft and remove top mounting retaining nut.

13. Remove top mounting and spring assembly.

14. Remove spring compressor from spring.

Installation

1. Clean spring and top mounting.

2. Position spring compressor to new spring and compress spring.

3. Install spring and top mounting and install and torque tighten retaining nut.

4. Remove spring compressor. 5. Install spring and damper assembly and install engine

cross brace support.

6. Install top mounting nuts (x3) each side (do not torque tighten).

7. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

8. Position upper suspension arm and install bolts and nuts (x2) each side (do not torque tighten).

9. Connect ABS sensor multiplug and install harness clips in upper suspension ar m and vertical link.

10. Install road wheel(s).

11. Lower vehicle on ramp.

12. Torque tighten upper arm nuts and bolts.

13. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

14. Align engine cross brace and install Torx bolts (x2).

15. Tighten Torx bolts (x4) to correct torque.

Front Damper-Pair-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Disconnect ABS sensor multiplug.

4. Release sensor harness clips (x3) from upper suspension arm and vertical link.

5. Remove Torx bolts (x4) from LH and RH side securing

engine cross brace and remove cross brace.

6. Remove nuts and bolts (x2 each side) from upper suspension arm to body and position suspension arm

aside.

Fig. 5

Fig. 6

If removed, place the engine ba

y cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum

upward travel.

Repair Operation Time (ROT)

ItemCode

Front Damper-Pair-Renew 04.03.AC

If removing both spring and damper units - the engine bay

cross brace will be released.

Allow the upper suspension arm and vertical link to fall back, giving access to remo ve the spring and damper

assembly.

Caution

Ensure that the brake flex hose is not over stretched.

Page 445 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-5

7. Remove nuts (x3 each side) from damper top mounting and remove engine cross brace support.

8. Remove nuts and bolts each side from damper lower mountings.

9. Remove spring and damper assembly.

10. Position spring compresso r to spring and compress

spring.

11. Hold damper shaft, and remove top mounting retaining nut.

12. Remove top mounting and spring assembly.

13. Remove dust shield from rebound bumper and spring seat flange.

Installation

1. Clean spring , spring seat flange, bumper, dust shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and install and tighten retaining nut.

4. Remove spring compressor.

5. Install spring and damper assembly and install engine cross brace support.

6. Install top mounting nuts (x3) each side (do not torque tighten).

7. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

8. Position upper suspension arm and install bolts and nuts (x2) each side (do not torque tighten).

9. Connect ABS sensor multiplug and install harness clips in upper suspension arm and vertical link.

10. Install road wheel(s).

11. Lower vehicle on ramp.

12. Tighten upper arm nuts an d bolts to correct torque.

13. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

14. Align engine cross brace, install Torx bolts (x2) and

tighten Torx bolts (x4) to correct torque.

Rear Spring and Damper Assembly-Pair-

Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to shock

absorber mounting bracket.

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

8. Disconnect ABS sensor multiplug (see Fig. 2).

If removed, place the engine

bay cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspension components must be

carried out with the suspensi on arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum upward travel.

Repair Operation Time (ROT)

Page 447 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-7

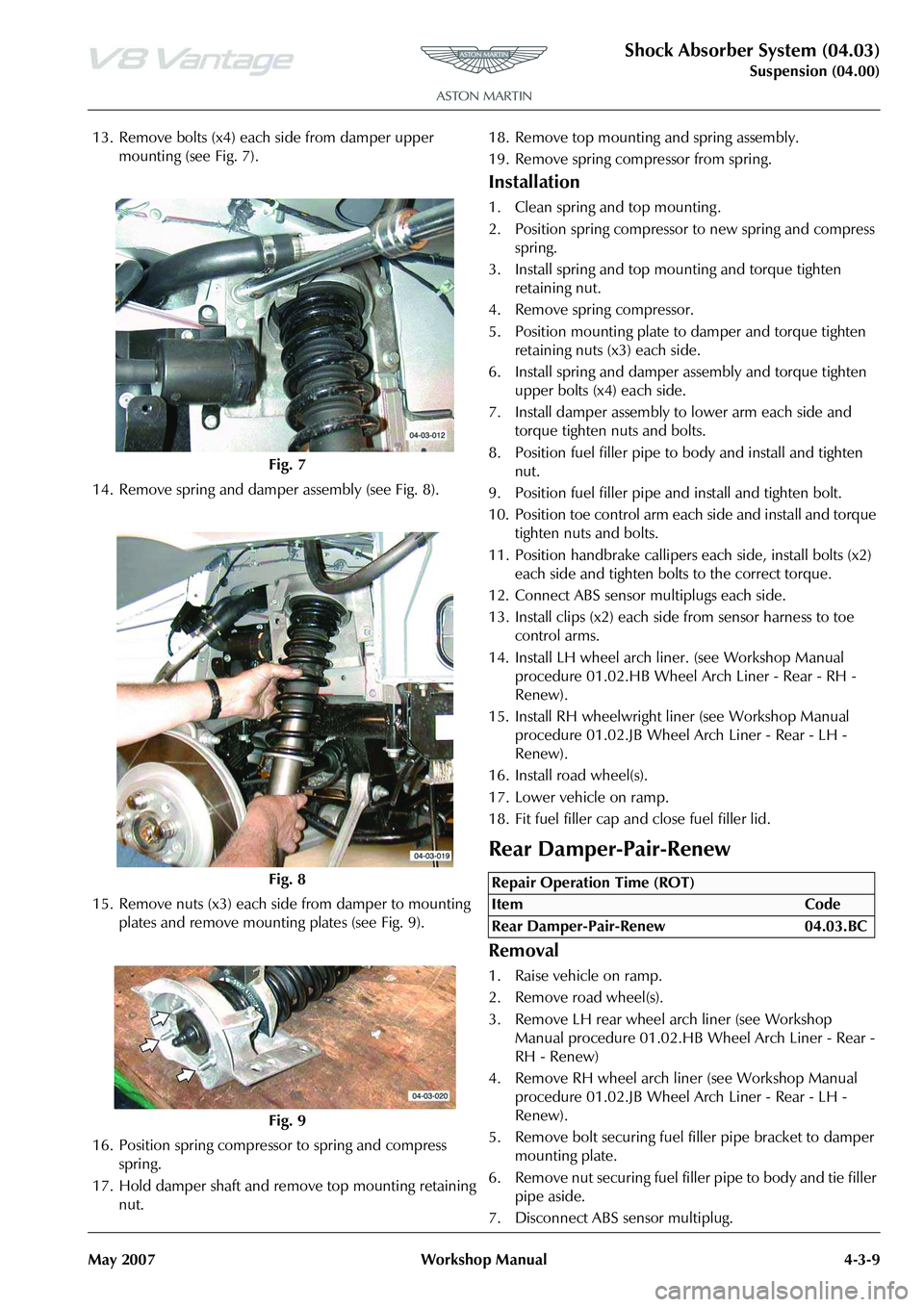

14. Remove spring and damper assembly (see Fig. 8).

15. Remove nuts (x3) each side from damper to mounting plate (see Fig, 9).

Installation

1. Position mounting plate to damper and torque tighten retaining nuts (x3) each side.

2. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

3. Install damper to lower arm each side and torque tighten nuts and bolts.

4. Position fuel filler pipe to body, install and tighten nut.

5. Position fuel filler pipe, install and tighten bolt.

6. Position toe control arm each side, install and torque tighten nuts/bolts.

7. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

8. Connect ABS sensor multiplugs each side.

9. Install clips (x2) each side from sensor harness to toe control arms.

10. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew). 11. Install RH wheel arch li

ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

12. Install road wheel(s).

13. Lower vehicle on ramp.

14. Install fuel filler cap and close fuel filler lid.

Rear Spring-Pair-Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to damper

mounting bracket.

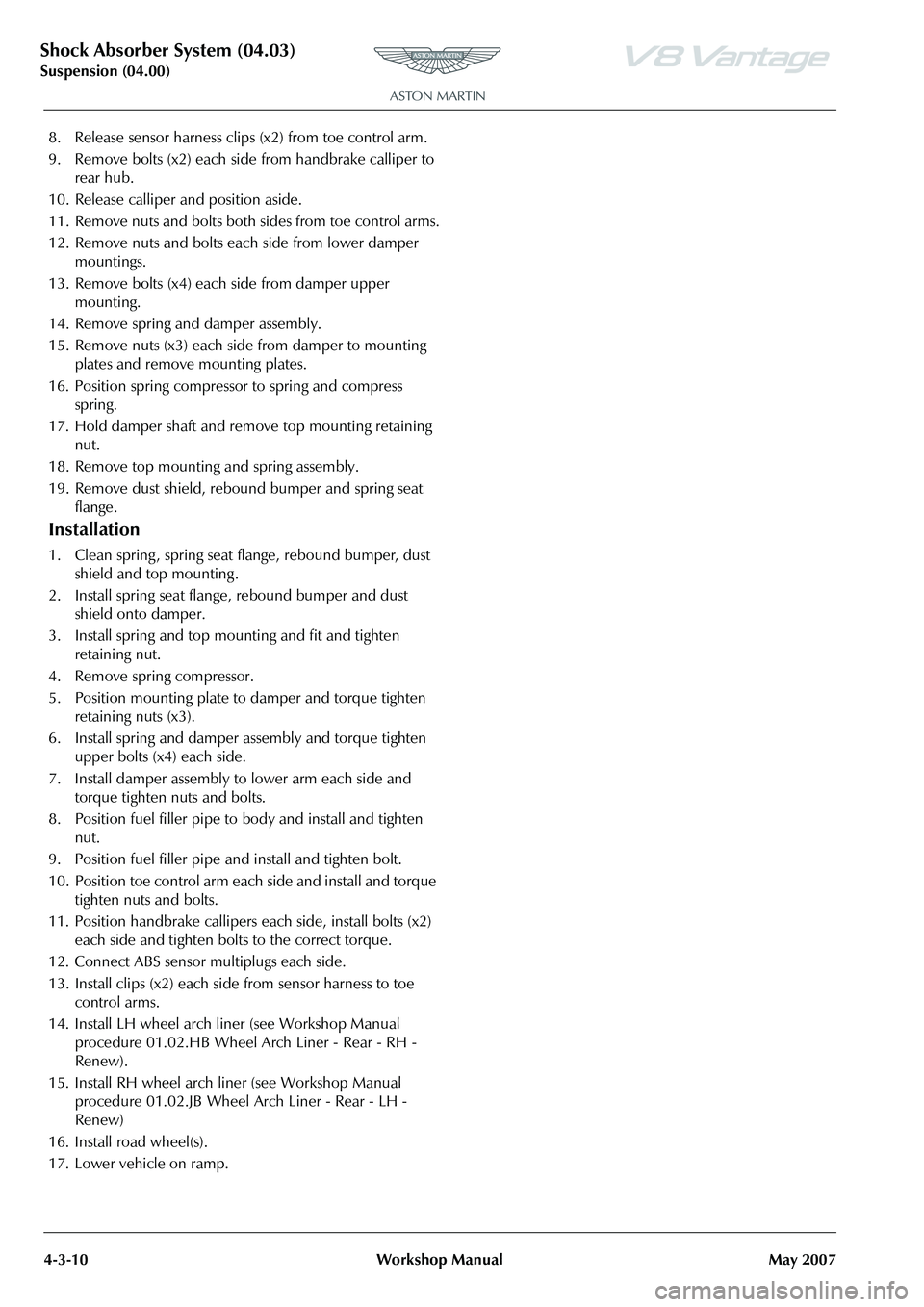

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 449 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-9

13. Remove bolts (x4) each side from damper upper mounting (see Fig. 7).

14. Remove spring and damper assembly (see Fig. 8).

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates (see Fig. 9).

16. Position spring compresso r to spring and compress

spring.

17. Hold damper shaft and remove top mounting retaining nut. 18. Remove top mounting and spring assembly.

19. Remove spring compressor from spring.

Installation

1. Clean spring and top mounting .

2. Position spring compressor to new spring and compress

spring.

3. Install spring and top mounting and torque tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten

retaining nuts (x3) each side.

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch li ner. (see Workshop Manual

procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheelwright li ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

16. Install road wheel(s).

17. Lower vehicle on ramp.

18. Fit fuel filler cap and close fuel filler lid.

Rear Damper-Pair-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew)

4. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

5. Remove bolt securing fuel filler pipe bracket to damper

mounting plate.

6. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside.

7. Disconnect ABS sensor multiplug.

Fig. 7

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 450 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-10 Workshop Manual May 2007

8. Release sensor harness clips (x2) from toe control arm.

9. Remove bolts (x2) each side from handbrake calliper to rear hub.

10. Release calliper and position aside.

11. Remove nuts and bolts both sides from toe control arms.

12. Remove nuts and bolts each side from lower damper mountings.

13. Remove bolts (x4) each side from damper upper mounting.

14. Remove spring and damper assembly.

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates.

16. Position spring compressor to spring and compress spring.

17. Hold damper shaft and remove top mounting retaining nut.

18. Remove top mounting and spring assembly.

19. Remove dust shield, rebound bumper and spring seat flange.

Installation

1. Clean spring, spring seat flange, rebound bumper, dust

shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and fit and tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten retaining nuts (x3).

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

16. Install road wheel(s).

17. Lower vehicle on ramp.

Page 452 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)4-4-2 Workshop Manual May 2007

USA Tyre Gradings

The following information relates to the tyre grading system

developed by the National Highway Traffic Safety

Administration which grades tyres by tread wear, traction

and temperature performance.

Tr e a d W e a r

Tread wear grade is a comparat ive rating based on the wear

rate of the tyre when tested under controlled conditions

(specified government test course). For example, a tyre

graded 150 would wear one and a half times less on the

government course than a tyre graded 100. Relative

performance of the tyres depends upon actual conditions of

use and may depart significantly from normal due to

variations in driving habits, service practices and differences

in road characteristics and climate.

Tr a c t i o n

Traction grades, A (highest), B and C represent a tyre’s ability

to stop in wet conditions measured on specified government

test surfaces of asphalt and concrete.

Te m p e r a t u r e

Temperature grades, A (highest), B and C, represent a tyre’s

resistance to the generation of wear and its ability to

dissipate heat when tested under controlled conditions

(specified indoor laboratory test road wheel). Sustained high

temperature can cause the material of a tyre to degenerate

and reduce tyre life; excessive temperatures can lead to

sudden tyre failure. Grade ‘C’ corresponds to a level of

performance which all passenger vehicle tyres must meet

under Federal Motor Vehicle Safety Standard No. 109.

Grades ‘B’ and ‘A’ represent higher levels of performance

than the minimum required by law. Aston Martin grade as follows:

Torque Figures

DescriptionNmlb/ft

Road wheel nuts:

Step 1 for all Wheel Nuts 80 60

Step 2 for 22 mm Wheel Nuts 135 100

Step 2 for Titanium Wheel Nuts 150 111

Step 2 for 21 mm Wheel Nuts 180 133

WAR NI NG

PDI INSPECTION.

TRACTION GRADE IS BASED ON BRAKING (STRAIGHT AHEAD) TRACTION TESTS AND DOES NOT INCLUDE

CORNERING (TURNING) TRACTION.

WAR NI NG

TEMPERATURE GRADE IS ESTABLISHED FOR A TYRE THAT IS PROPERLY INFLATED AND NOT

OVERLOADED. EXCESSIVE SPEED, UNDER INFLATION

OR EXCESSIVE LOADING, WHETHER SEPARATELY OR

IN COMBINATION, CAN CAUSE HEAT BUILD-UP AND POSSIBLE TYRE FAILURE.

Tyre Grade Level Achieved

Tread Wear 140 Traction A

Temperature A

Page 455 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)

May 2007 Workshop Manual 4-4-5

Road Test

A tyre vibration diagnostic proc edure always begins with a road test. The road test and customer interview (if available)

will provide much of the information neede d to find the source of a vibration.

During the road test, drive the vehicle on a road that is smoot h and free of undulations. If vibration is apparent, note and

record the following:

• The speed at which the vibration occurs

• What type of vibration occurs in each speed range

• How the vibration is affected by changes in the following types of vibration-sensitivity:

Torque Sensitive - This means that the condition may be improved or made worse by accelerating, decelerating, coasting,

maintaining a steady vehicle speed or applying engine torque.

Vehicle Speed Sensitive - This means that the vibration always occurs at the same vehicle speed and is not affected by

engine torque, engine speed or the transmission gear selected.

Engine Speed Sensitive - This means that the vibration occurs at varyin g vehicle speeds when a different transmission

gear is selected. It may sometimes be isolated by increasing or decreasing engine speed with the transmission in NEUTRAL

or by stall testing with the transmission in gear. If the condition is engine speed sensitive, the cause is probably not relate d

to the tyres.

If the road test indicates that there is tyre whine, but no sh ake or vibration, the noise originates with the contact between

the tyre and the road surface.

A thumping noise usually means that the tyre has a flat or soft spot making a noise as they slap the roadway. Tyre whine

may be distinguished from axle noise. Tyre whine remains the same over a range of speeds.

Symptoms

SymptomPossible Source(s):Action(s)

Tyres show excess wear on

edge of treads Tyres under-inflated Correct pressure to specification.

Vehicle overloaded Correct as required.

Tyres show excess wear on

edge of treads (having the

correct tyre pressures) Incorrect toe setting Set to specification.

Tyres show excess wear in

center of tread Tyres over-inflated Correct pressure to specification.

Other excessive tyre wear

problems Incorrect tyre pressure Correct pressure to specification.

Incorrect tyre and wheel usage Install correct tyre and wheel combination.

Geometry out of alignm

ent Check and adjust.

Loose, worn or damaged suspension

components Inspect, repair or install new suspension

components as necessary.

Wheel and tyre assembly out of

balance Balance wheel and tyre assembly.

Excessive lateral or radial runout of

wheel or tyre Check, repair or install a new wheel or tyre as

necessary.

Wheel mounting is difficult Incorrect application or mismatched

parts, including wheel studs and wheel

nuts. Corroded, worn or damaged parts Clean or install new parts.

Wobble or shimmy affecting

wheel runout Damaged wheel (eventually damaging

wheel bearings and causing uneven

tyre wear) Inspect wheel rims for damage and runout.

Install a new wheel rim as necessary.

Excessive vibration, rough

steering or severe tyre wear Loose or incorrect attaching parts Tighten or install new parts.

Page 463 of 947

May 2007 Workshop Manual 5-1-1

Driveline (05.00)

Contents

Driveshaft (05.01) .................................................. 5-1-2Description ............................................................. 1-2

Specifications.......................................................... 1-2

Maintenance ........................................................... 1-2 Propeller Shaft-Renew ........................................... 1-2

Propshaft Cam Sensor-Sportshift-Renew

-Sportshift Only...................................................... 1-2

Torque Tube-Renew .............................................. 1-3

Torque Tube & Prop Shaft Assembly-

Renew-Manual Vehicles Only ................................ 1-4

Torque Tube & Prop Shaft Assembly-

Renew-Sportshift Vehicles Only ............................. 1-4

Torque Tube-Remove for Access/Refit .................... 1-5

RH/LH Drive Shaft Assembly-Renew ...................... 1-7

Halfshafts (05.05) .................................................. 5-2-1 Specifications.......................................................... 2-1