fuel ASTON MARTIN V8 VANTAGE 2010 Owner's Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 312 of 947

Fuel Charging System (03.04)

Engine (03.00)3-4-6 Workshop Manual May 2007

Installation

1. Install new O-rings to remaining injectors (lube O-ringP-

clips).

2. Install clip to new injector then injector into rail.

3. Install rail (with injectors) to manifold (bolt x2) (torque)

(taking care each injector is aligned correctly).

4. Connect EGR vac pipe to sensor and manifold.

5. Install coolant pipe bracket (bolt x2, nut x2).

6. Connect EGR (x1), fuel rail pressure sensor (x1) and injector multiplugs (x4).

7. Refit harness to coolant pipe bracket (fir tree x3).

8. Connect heater hose to pipe (quick fit).

9. Refit heater hose (clipx2) and EGR vacuum lines (clips

x2) to bracket.

10. Install fuel feed pipe.

11. Install purge pipe P-clip.

12. Install harness bracket to engine.

13. Feed harness into inner wing area.

14. Install fusebox to bracket.

15. Install earth lead to fusebox.

16. Install battery lead to fusebox (1x nut and rubber cover).

17. Install multiplugs to fuse box.

18. Install fusebox bracket fixings.

19. Refit harness fir tree clips to cylinder head.

20. Refit engine breather hose.

21. Install VVT solenoid multiplug, position coil and CMP harness (1x edge clip).

22. Install ECM (see Workshop Manual procedure 03.14.BB Engine Control Module - RH Renew).

Engine Set - Fuel Injector - LH Bank -

Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise).

2. Remove corner cross brace.

3. Disconnect breather hoses from cam cover (x2) for access.

4. Disconnect purge line from manifold (quickfit) and

support clip for access.

5. Disconnect heater hose from pipe (quick fit).

6. Release heater hose (x2) and throttle body hose (x2)

from support bracket.

7. Remove booster hose from manifold and support clip.

8. Remove harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3). 9. Release pipe support bracket

(nuts x2, bolts x2) move

aside.

10. Disconnect IAT multiplug.

11. Disconnect injector multiplugs (x4).

12. Unclip injector harness from cam cover (x2).

13. Disconnect breather hose from manifold (quickfit).

14. Remove Injector to rail clips.

15. Remove fuel rail bolts (x2) and lift rail (tie aside).

16. Remove injectors from manifold.

Installation

1. Install clips on to new injectors then fit injectors into manifold.

2. Install rail onto injectors (taking care each injector is aligned correctly and the clip seats properly) and fit bolts

(x2) (torque).

3. Connect breather hose to manifold (quickfit).

4. Connect IAT multiplug.

5. Unclip injector harness from cam cover (x2).

6. Connect injector multiplugs (x4).

7. Install pipe support bracket (nuts x2, bolts x2).

8. Install harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3).

9. Connect booster hose to manifold and support clip.

10. Connect heater hose from pipe (quick fit).

11. Install heater hose (x2) and throttle body hose (x2) from support bracket.

12. Connect purge line to manifold and into support clip.

13. Connect breather hoses (x2) to cam cover.

14. Install corner cross brace (torque bolts with vehicle on level ground).

Engine Set - Fuel Injector - RH Bank -

Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise

2. Disconnect breather hose (quick fit) move aside.

3. Release harness fir tree clips (x3) from cylinder head and move aside.

4. Remove fuse box bracket fixings (bolt and nut) (allows movement).

5. Remove ECM (see Workshop Manual procedure 03.14.BB Engine Contro l Module - RH Renew).

6. Remove battery lead (1x nut and rubber cover) from fuse box (2x leads).

7. Remove multiplugs (x10) from fusebox.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Engine Set-Fuel Injector-RH Bank-

Renew LHD

03.04.GK

Engine Set-Fuel Injector-RH Bank-

Renew RHD

03.04.GP

Page 313 of 947

Fuel Charging System (03.04)

Engine (03.00)

May 2007 Workshop Manual 3-4-7

8. Remove earth terminal (1x nut and rubber cover) from

fusebox.

9. Remove fuse box from bracket (bolt x2).

10. Release harness fir tree clips (x3) from engine bracket.

11. Feed harness from inner wing and over engine to gain access to cam cover.

12. Remove purge pipe P-clip (bolt x1) and move pipe aside.

13. Remove harness bracket from engine (bolts x2, nut x1).

14. Release fuel feed hose from rail (clip x1) and move aside.

15. Disconnect heater hose from pipe (quick fit).

16. Release heater hose (clips x2) and EGR vacuum line (clips x2) from bracket.

17. Release harness from coolant pipe bracket (fir tree x3).

18. Disconnect EGR (x1), fuel ra il pressure sensor (x1) and

injector multiplugs (x 4), move harness aside.

19. Remove coolant pipe bracket (nuts x2 and bolts x2).

20. Disconnect EGR vac pipe from sensor and manifold,

move aside.

21. Remove Injector to rail clips.

22. Remove fuel rail bolts (x2) and lift rail (tie aside).

23. Remove injectors from manifold.

Installation

1. Install clips on to new injectors then fit injectors into manifold.

2. Install rail onto injectors (taking care each injector is aligned correctly and the clip seats properly) and fit bolts

(x2) (torque).

3. Connect EGR vac pipe to sensor and manifold.

4. Install coolant pipe bracket (bolt x2, nut x2).

5. Connect EGR (x1), fuel rail pressure sensor (x1) and

injector multiplugs (x4).

6. Refit harness to coolant pipe bracket (fir tree x3).

7. Connect heater hose to pipe (quick fit).

8. Refit heater hose (clipx2) and EGR vac lines (clips x2) to bracket.

9. Install fuel feed pipe.

10. Install purge pipe P-clip.

11. Install harness bracket to engine.

12. Feed harness into inner wing area.

13. Install fusebox to bracket.

14. Install earth lead to fusebox.

15. Install battery lead to fusebox (1x nut and rubber cover).

16. Install multiplugs to fuse box.

17. Install fusebox bracket fixings.

18. Refit harness fir tree clips to cylinder head.

19. Refit engine breather hose.

20. Install VVT solenoid multip lug, position coil and CMP

harness (1x edge clip).

21. Install ECM (see Workshop Manual procedure 03.14.BB Engine Control Module - RH Renew).

Page 314 of 947

Fuel Charging System (03.04)

Engine (03.00)3-4-8 Workshop Manual May 2007

Page 415 of 947

Evaporative Emissions (03.13)

Engine (03.00)

May 2007 Workshop Manual 3-13-1

Engine (03.00)

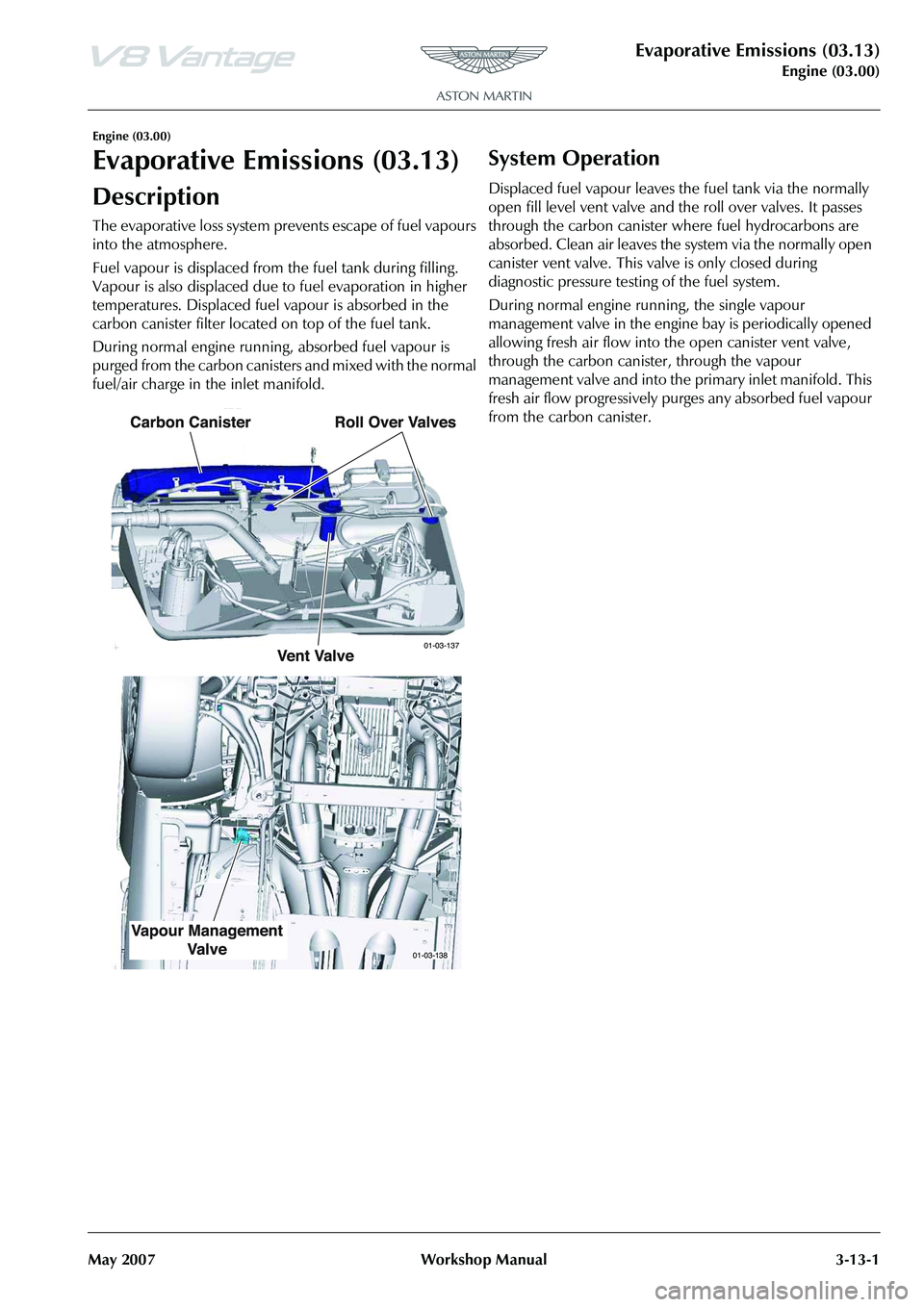

Evaporative Emissions (03.13)

Description

The evaporative loss system prevents escape of fuel vapours

into the atmosphere.

Fuel vapour is displaced from the fuel tank during filling.

Vapour is also displaced due to fuel evaporation in higher

temperatures. Displaced fuel vapour is absorbed in the

carbon canister filter located on top of the fuel tank.

During normal engine running, absorbed fuel vapour is

purged from the carbon canisters and mixed with the normal

fuel/air charge in the inlet manifold.

System Operation

Displaced fuel vapour leaves the fuel tank via the normally

open fill level vent valve and the roll over valves. It passes

through the carbon canister where fuel hydrocarbons are

absorbed. Clean air leaves the system via the normally open

canister vent valve. This valve is only closed during

diagnostic pressure testing of the fuel system.

During normal engine ru nning, the single vapour

management valve in the engine bay is periodically opened

allowing fresh air flow into th e open canister vent valve,

through the carbon canister, through the vapour

management valve and into the primary inlet manifold. This

fresh air flow progressively purg es any absorbed fuel vapour

from the carbon canister.

Page 426 of 947

Road Wheel Alignment (04.00)

Suspension (04.00)1-1-2 Workshop Manual Issue 6, May 2010

Suspension (04.00)

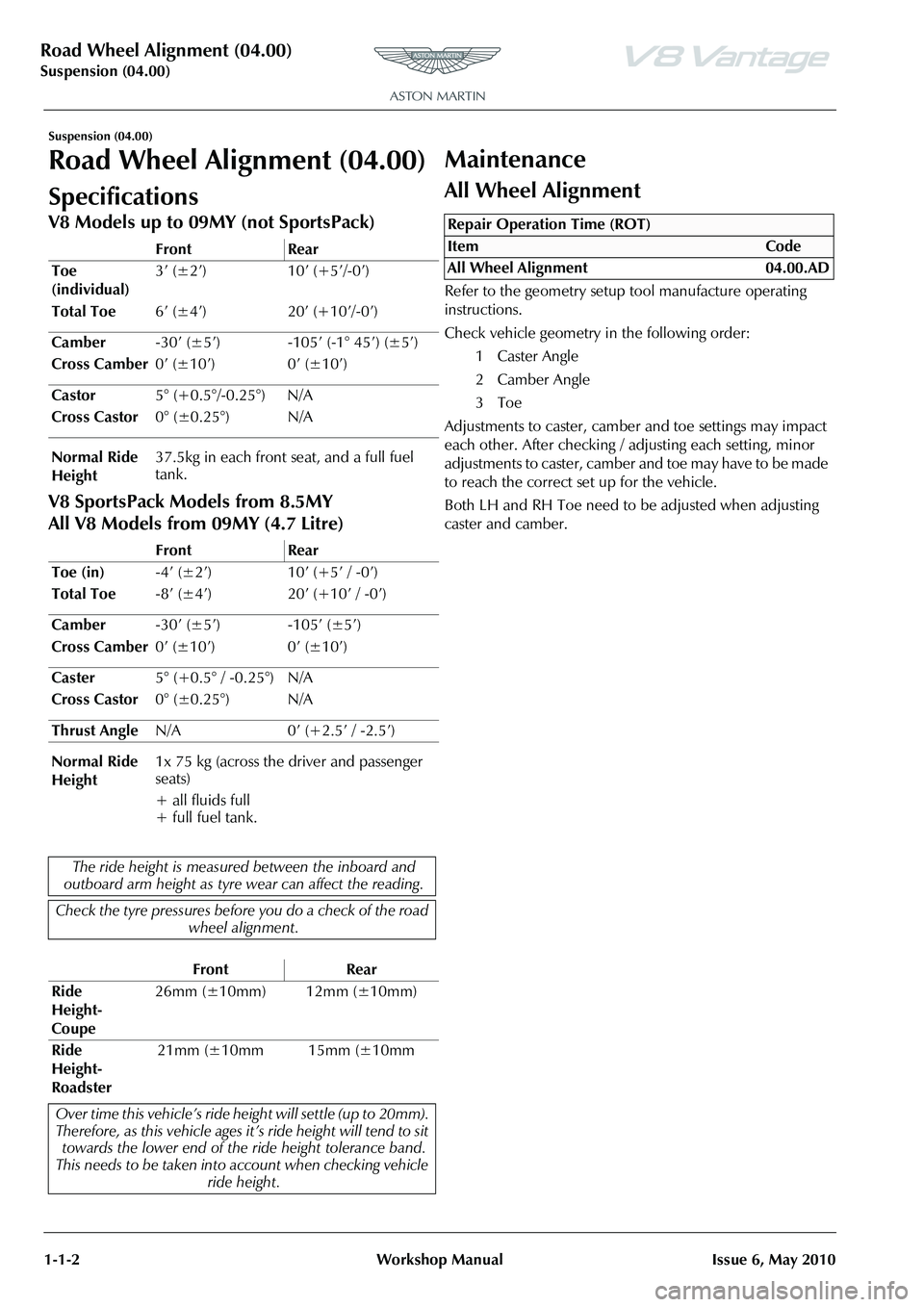

Road Wheel Alignment (04.00)

Specifications

V8 Models up to 09MY (not SportsPack)

V8 SportsPack Models from 8.5MY

All V8 Models from 09MY (4.7 Litre)

Maintenance

All Wheel Alignment

Refer to the geometry setup tool manufacture operating

instructions.

Check vehicle geometry in the following order:

1 Caster Angle

2 Camber Angle

3Toe

Adjustments to caster, camber and toe settings may impact

each other. After checking / adjusting each setting, minor

adjustments to caster, camber and toe may have to be made

to reach the correct set up for the vehicle.

Both LH and RH Toe need to be adjusted when adjusting

caster and camber.

Front Rear

Toe

(individual) 3’ (±2’) 10’ (+5’/-0’)

Total Toe 6’ (±4’) 20’ (+10’/-0’)

Camber -30’ (±5’) -105’ (-1° 45’) (±5’)

Cross Camber 0’ (±10’) 0’ (±10’)

Castor 5° (+0.5°/-0.25°) N/A

Cross Castor 0° (±0.25°) N/A

Normal Ride

Height 37.5kg in each front seat, and a full fuel

tank.

Front Rear

Toe (in) -4

Page 427 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-1

Suspension (04.00)

Front Suspension (04.01)

Description

Suspension Arms

The upper suspension arm is attached to the body structure.

The lower suspension arm is attached to the front subframe.

Each upper suspension arm has a press-fit ball-joint, and two

interleaved rubber bushes. Two bolts attach the upper

suspension arm to the body structure.

Each lower suspension arm has a press fit ball-joint and

metal-to-rubber bonded bushes which are attached to the

front subframe by two eccentric cam bolts (Camber and

castor settings).

Anti-roll Bar

The anti-roll bar, is attached to the subframe in two positions

by rubber bushes and clamps. The outer ends of the anti-roll

bar are attached to the lower suspension arms by drop links.

The anti-roll bar provides the required stiffness to control

body roll.

Vertical link

The Vertical link (Knuckle Joint) swivels on the upper and

lower suspension arms via ball-joints, and carries the hub, a

unit 3 wheel bearing (including the ABS encoder ring), the

wheel speed sensor, the brake caliper, and the brake disc

and shield. The position of the Vertical link is determined by

the movement of the steering rack, which is connected to

the Vertical link by the steering track rod.

Specifications

Upper Arm Ball Joint

and Bushes

Ball Joint

and Bushes Verticle

Link

Bolts to Body

Lower Arm

Anti-roll Bar Drop Links

Eccentric

Cam Bolts

04-01-003

Torque Figures

DescriptionNmlb. / ft.

Brake dust shield. 9 7

Bearing Assembly to the Vertical

link. 55 41

Vertical Link to the Lower

Suspension Arm. 90 66.5

Vertical Link to the Upper

Suspension Arm. 90 66.5

Track-rod End Lock Nut. 70 52

Vehicle Ride Height Sensor. M8 M522.5

9 17

7

Anti-roll Bar Link Nuts 110 81.5

Anti-roll Bar Mounting Bolts

Torque bolt 1, then bolt 2, then

bolt 1 again (to allow for rubber

compression) 22.5 17

Torque the following suspensi on fixings with the vehicle

at normal ride height

Lower Suspension Arm front

bush to the Subframe M14 185 137

Lower Suspension Arm rear

bush to the Subframe. M12 115 85

Upper Suspension Arm to the

Front Structure 115 85

Spring and Damper Bolts Top Lower22.5

175 17

129.5

Normal ride height 2 x 37.5kg in front seats (37.5kg in

each seat) plus a full fuel tank.

Page 436 of 947

Rear Suspension (04.02)

Suspension (04.00)4-2-2 Workshop Manual May 2007

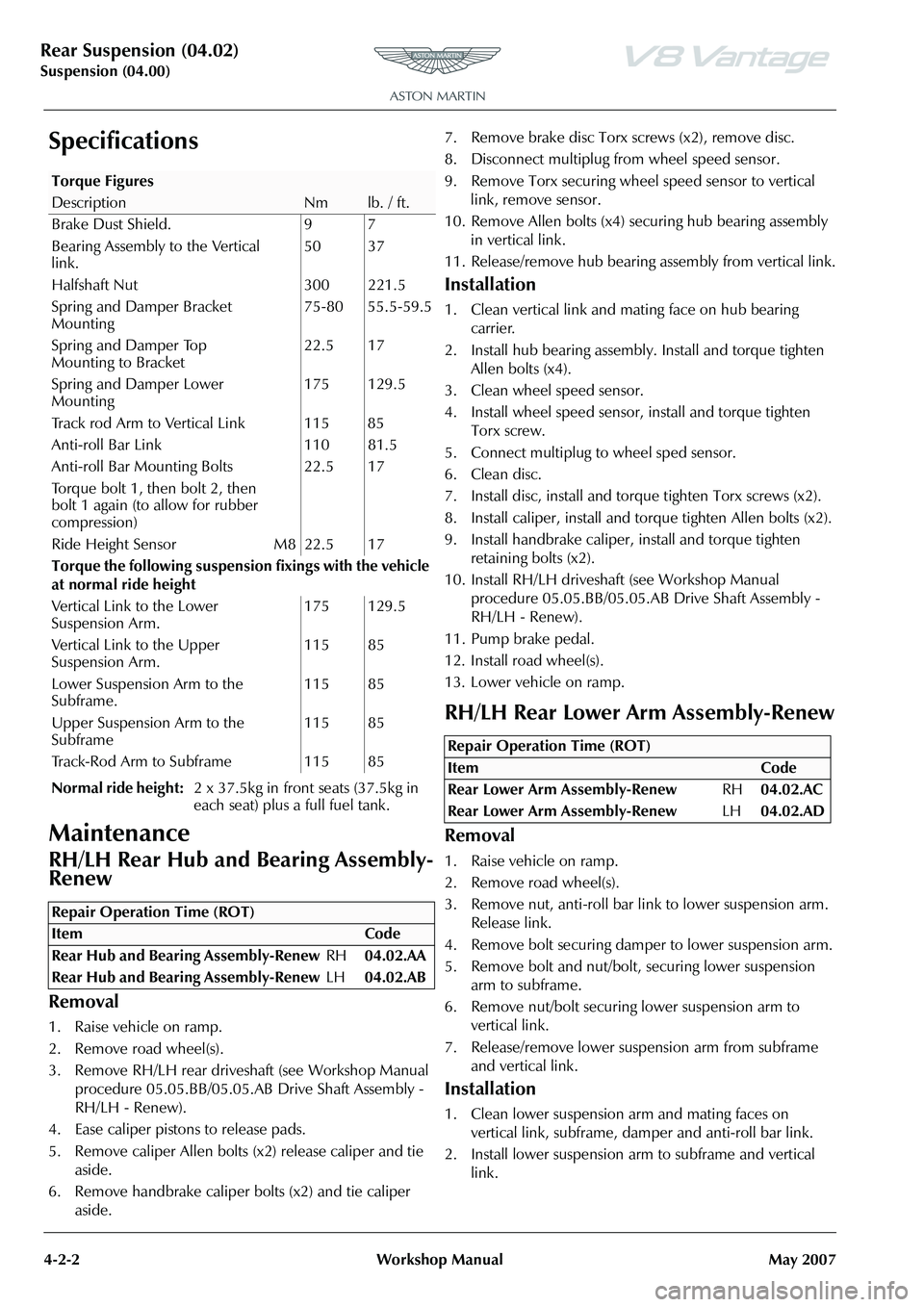

Specifications

Maintenance

RH/LH Rear Hub and Bearing Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove RH/LH rear drivesha ft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

4. Ease caliper pistons to release pads.

5. Remove caliper Allen bolts (x2) release caliper and tie aside.

6. Remove handbrake caliper bolts (x2) and tie caliper aside. 7. Remove brake disc Torx screws (x2), remove disc.

8. Disconnect multiplug fr

om wheel speed sensor.

9. Remove Torx securing wheel speed sensor to vertical link, remove sensor.

10. Remove Allen bolts (x4) se curing hub bearing assembly

in vertical link.

11. Release/remove hub bearing a ssembly from vertical link.

Installation

1. Clean vertical link and mating face on hub bearing

carrier.

2. Install hub bearing assembly. Install and torque tighten Allen bolts (x4).

3. Clean wheel speed sensor.

4. Install wheel speed sensor, install and torque tighten Torx screw.

5. Connect multiplug to wheel sped sensor.

6. Clean disc.

7. Install disc, install and torq ue tighten Torx screws (x2).

8. Install caliper, install and torque tighten Allen bolts (x2).

9. Install handbrake caliper, install and torque tighten

retaining bolts (x2).

10. Install RH/LH driveshaft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

11. Pump brake pedal.

12. Install road wheel(s).

13. Lower vehicle on ramp.

RH/LH Rear Lower Arm Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut, anti-roll bar li nk to lower suspension arm.

Release link.

4. Remove bolt securing damper to lower suspension arm.

5. Remove bolt and nut/bolt, securing lower suspension arm to subframe.

6. Remove nut/bolt securing lower suspension arm to

vertical link.

7. Release/remove lower suspension arm from subframe and vertical link.

Installation

1. Clean lower suspension arm and mating faces on vertical link, subframe, damper and anti-roll bar link.

2. Install lower suspension ar m to subframe and vertical

link.

Torque Figures

DescriptionNmlb. / ft.

Brake Dust Shield. 9 7

Bearing Assembly to the Vertical

link. 50 37

Halfshaft Nut 300 221.5

Spring and Damper Bracket

Mounting 75-80 55.5-59.5

Spring and Damper Top

Mounting to Bracket 22.5 17

Spring and Damper Lower

Mounting 175 129.5

Track rod Arm to Vertical Link 115 85

Anti-roll Bar Link 110 81.5

Anti-roll Bar Mounting Bolts

Torque bolt 1, then bolt 2, then

bolt 1 again (to allow for rubber

compression) 22.5 17

Ride Height Sensor M8 22.5 17

Torque the following suspensi on fixings with the vehicle

at normal ride height

Vertical Link to the Lower

Suspension Arm. 175 129.5

Vertical Link to the Upper

Suspension Arm. 115 85

Lower Suspension Arm to the

Subframe. 115 85

Upper Suspension Arm to the

Subframe 115 85

Track-Rod Arm to Subframe 115 85

Normal ride height: 2 x 37.5kg in front seats (37.5kg in

each seat) plus a full fuel tank.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Rear Lower Arm Assembly-Renew RH04.02.AC

Rear Lower Arm Assembly-Renew LH04.02.AD

Page 445 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-5

7. Remove nuts (x3 each side) from damper top mounting and remove engine cross brace support.

8. Remove nuts and bolts each side from damper lower mountings.

9. Remove spring and damper assembly.

10. Position spring compresso r to spring and compress

spring.

11. Hold damper shaft, and remove top mounting retaining nut.

12. Remove top mounting and spring assembly.

13. Remove dust shield from rebound bumper and spring seat flange.

Installation

1. Clean spring , spring seat flange, bumper, dust shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and install and tighten retaining nut.

4. Remove spring compressor.

5. Install spring and damper assembly and install engine cross brace support.

6. Install top mounting nuts (x3) each side (do not torque tighten).

7. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

8. Position upper suspension arm and install bolts and nuts (x2) each side (do not torque tighten).

9. Connect ABS sensor multiplug and install harness clips in upper suspension arm and vertical link.

10. Install road wheel(s).

11. Lower vehicle on ramp.

12. Tighten upper arm nuts an d bolts to correct torque.

13. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

14. Align engine cross brace, install Torx bolts (x2) and

tighten Torx bolts (x4) to correct torque.

Rear Spring and Damper Assembly-Pair-

Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to shock

absorber mounting bracket.

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

8. Disconnect ABS sensor multiplug (see Fig. 2).

If removed, place the engine

bay cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspension components must be

carried out with the suspensi on arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum upward travel.

Repair Operation Time (ROT)

Page 447 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-7

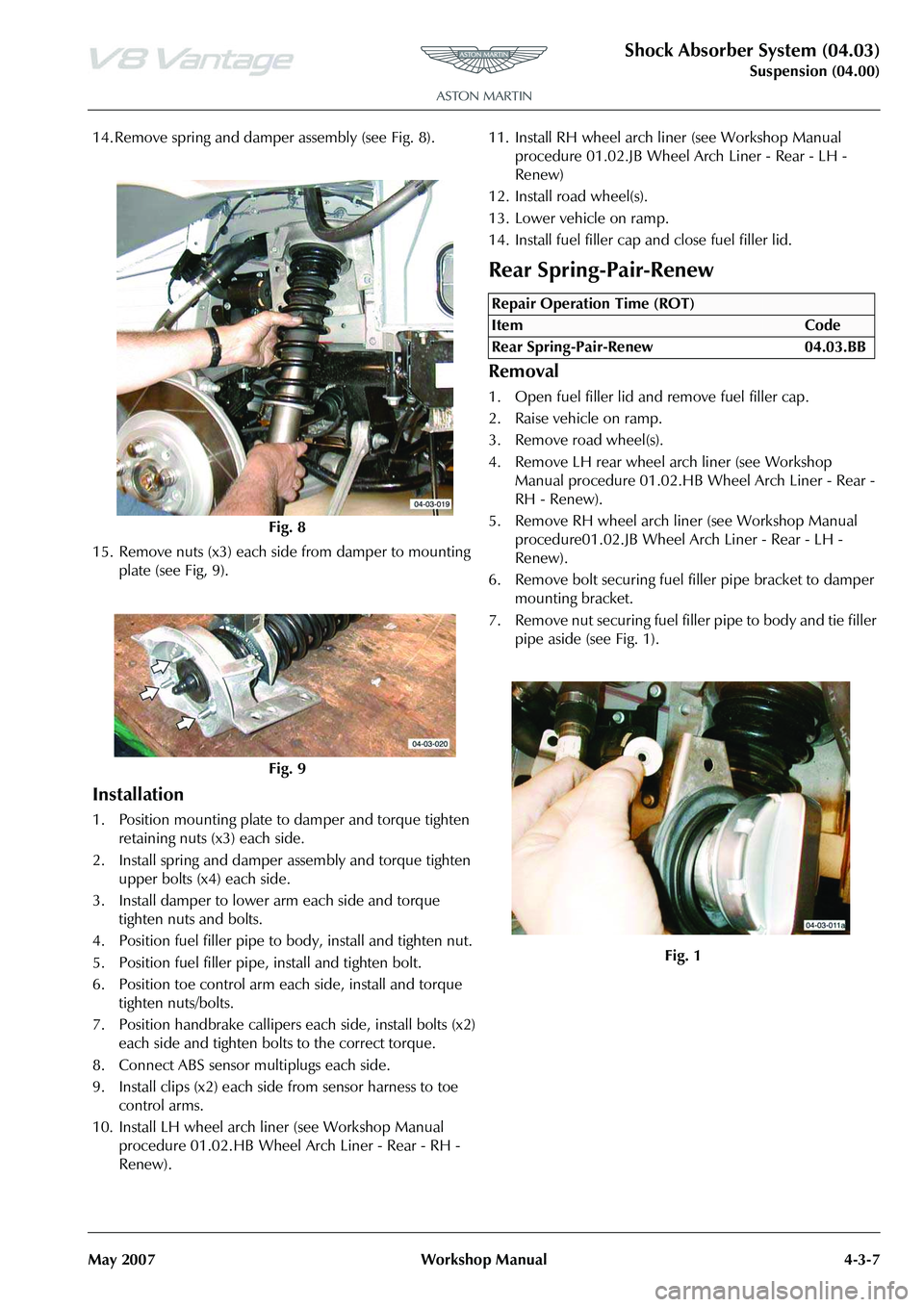

14. Remove spring and damper assembly (see Fig. 8).

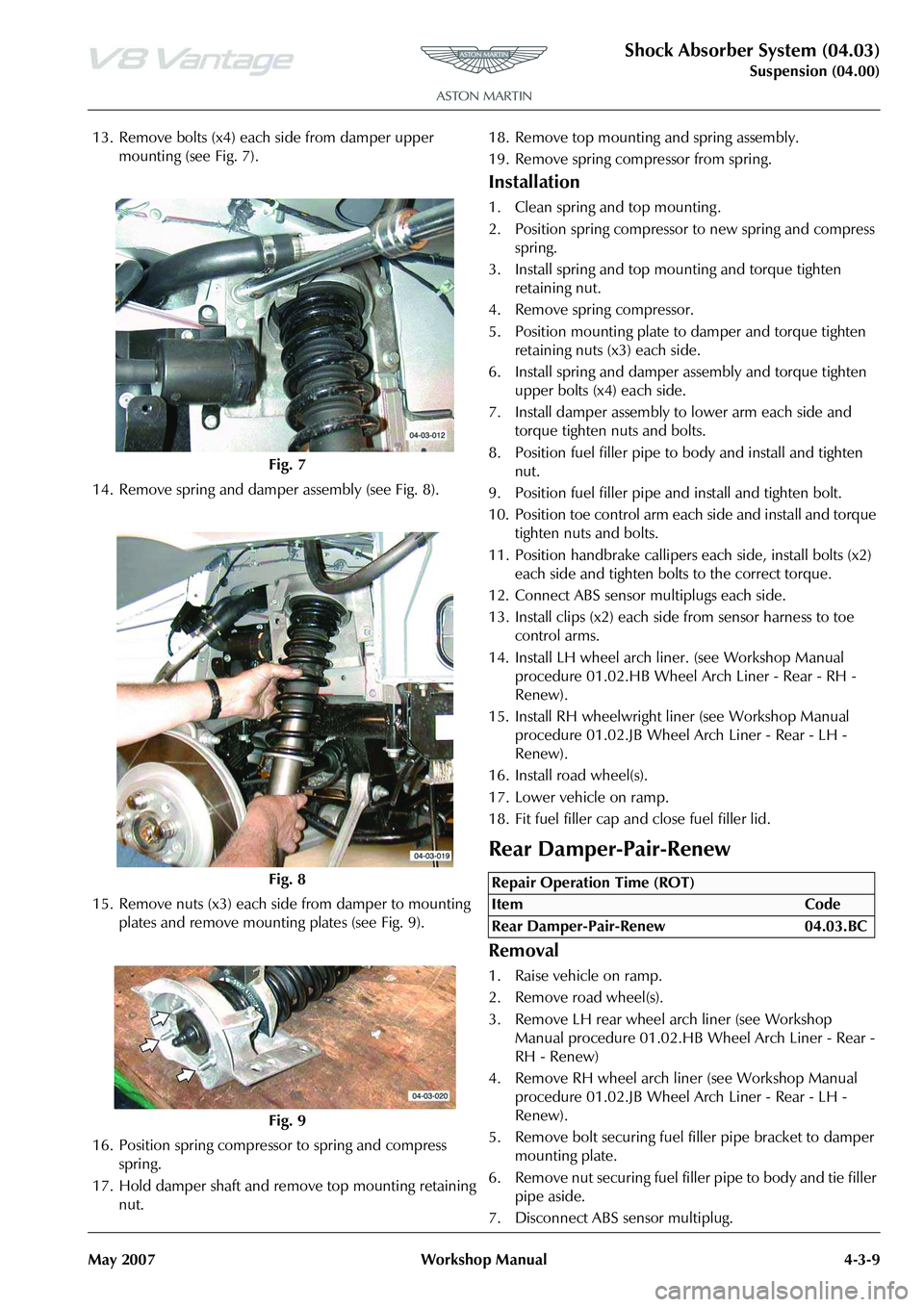

15. Remove nuts (x3) each side from damper to mounting plate (see Fig, 9).

Installation

1. Position mounting plate to damper and torque tighten retaining nuts (x3) each side.

2. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

3. Install damper to lower arm each side and torque tighten nuts and bolts.

4. Position fuel filler pipe to body, install and tighten nut.

5. Position fuel filler pipe, install and tighten bolt.

6. Position toe control arm each side, install and torque tighten nuts/bolts.

7. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

8. Connect ABS sensor multiplugs each side.

9. Install clips (x2) each side from sensor harness to toe control arms.

10. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew). 11. Install RH wheel arch li

ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

12. Install road wheel(s).

13. Lower vehicle on ramp.

14. Install fuel filler cap and close fuel filler lid.

Rear Spring-Pair-Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to damper

mounting bracket.

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 449 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-9

13. Remove bolts (x4) each side from damper upper mounting (see Fig. 7).

14. Remove spring and damper assembly (see Fig. 8).

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates (see Fig. 9).

16. Position spring compresso r to spring and compress

spring.

17. Hold damper shaft and remove top mounting retaining nut. 18. Remove top mounting and spring assembly.

19. Remove spring compressor from spring.

Installation

1. Clean spring and top mounting .

2. Position spring compressor to new spring and compress

spring.

3. Install spring and top mounting and torque tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten

retaining nuts (x3) each side.

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch li ner. (see Workshop Manual

procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheelwright li ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

16. Install road wheel(s).

17. Lower vehicle on ramp.

18. Fit fuel filler cap and close fuel filler lid.

Rear Damper-Pair-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew)

4. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

5. Remove bolt securing fuel filler pipe bracket to damper

mounting plate.

6. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside.

7. Disconnect ABS sensor multiplug.

Fig. 7

Fig. 8

Fig. 9

Repair Operation Time (ROT)