torque ASTON MARTIN V8 VANTAGE 2010 Manual PDF

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 283 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-9

6. Fill tank with approximately amount of displaced oil and replace cap.

7. Use handbook procedure to check oil level.

Oil Cooler Tank Assembly - Renew

Removal

1. Disconnect breather pipe qu ickfits (x2) from air cleaner

duct.

2. Remove throttle body du ct for access (clips x3).

3. Remove cap.

4. Disconnect top hose from engine (clip x1) tie aside

(catch coolant).

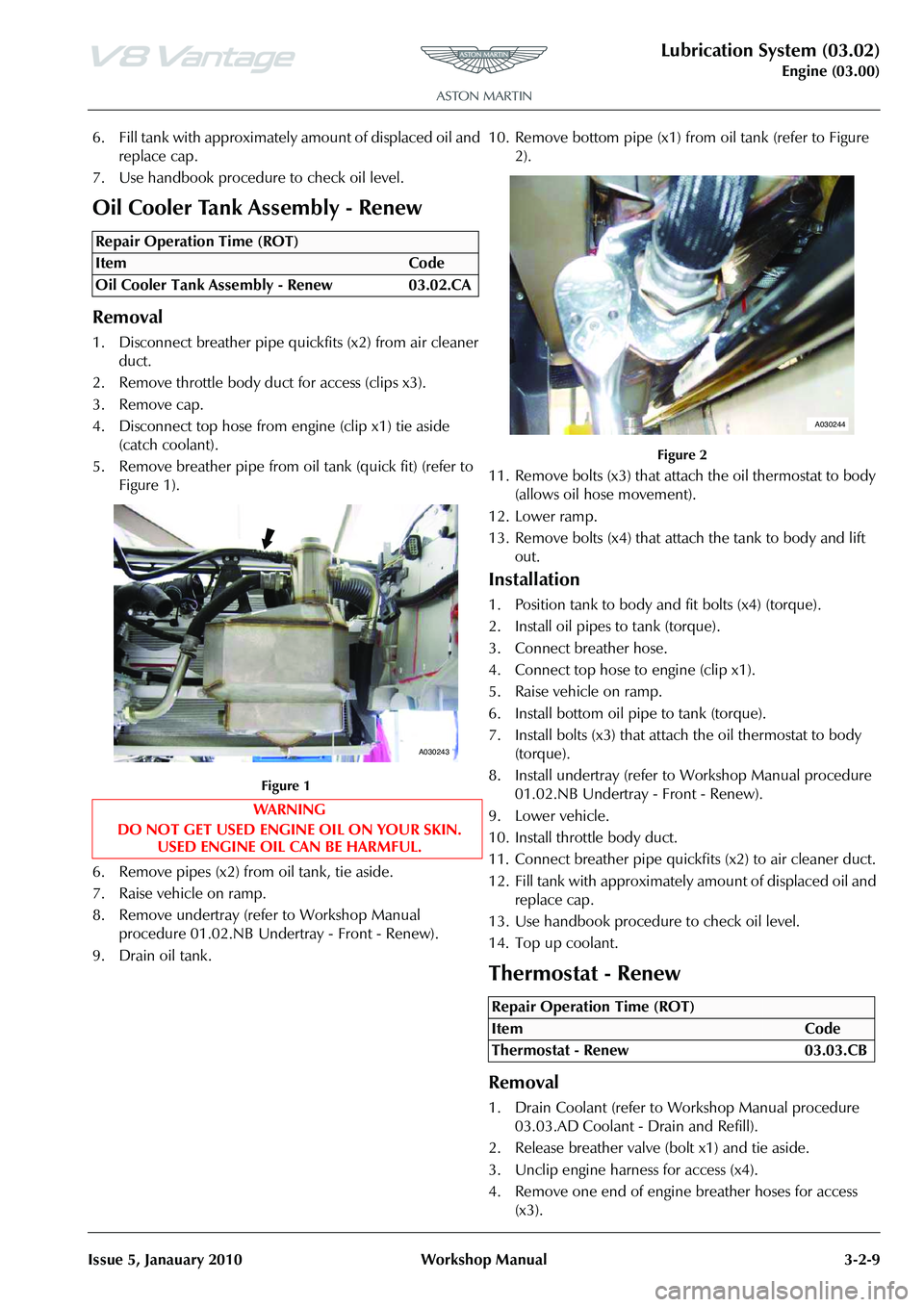

5. Remove breather pipe from oil tank (quick fit) (refer to Figure 1).

Figure 1

6. Remove pipes (x2) fr om oil tank, tie aside.

7. Raise vehicle on ramp.

8. Remove undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

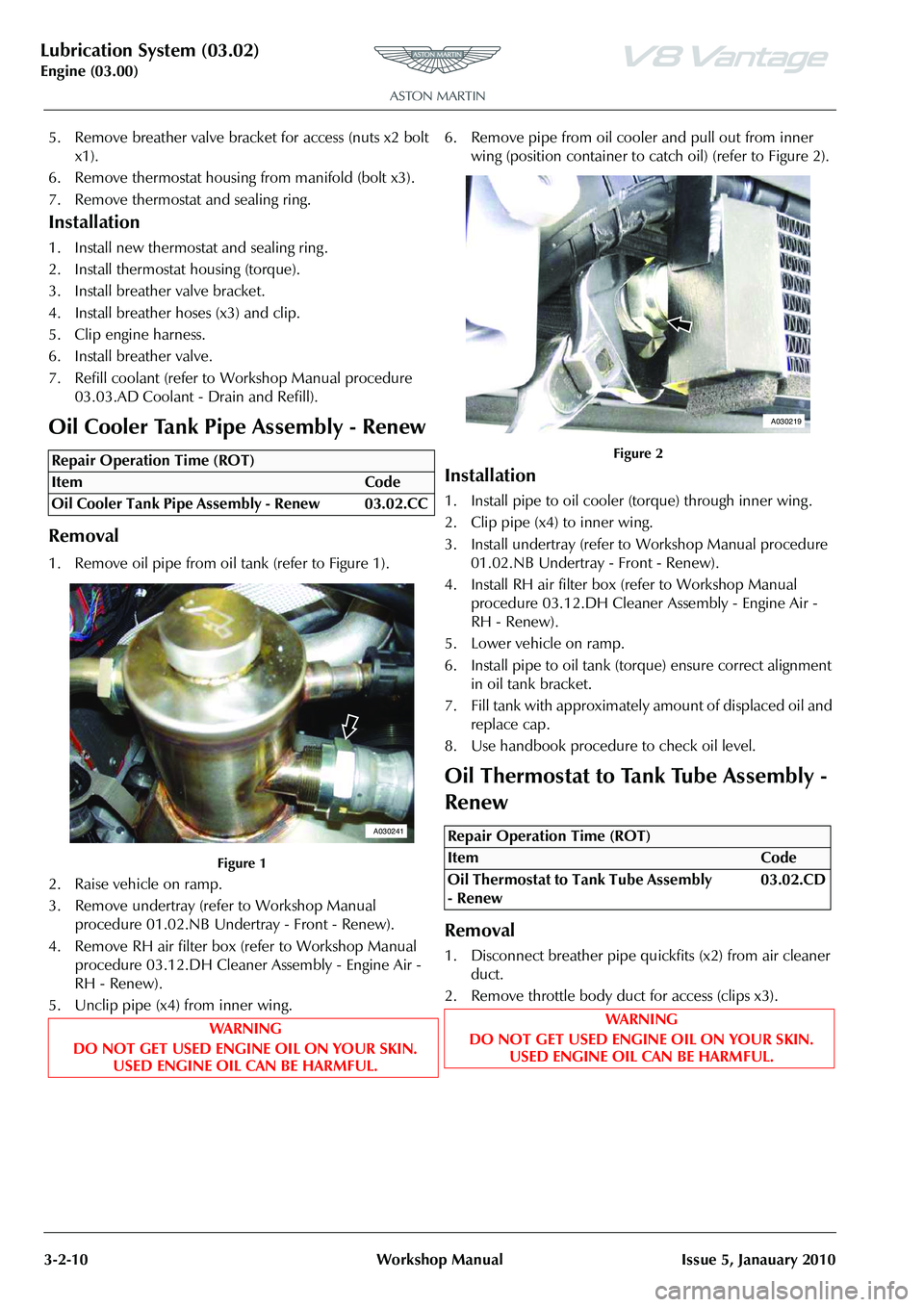

9. Drain oil tank. 10. Remove bottom pipe (x1) from oil tank (refer to Figure

2).

Figure 2

11. Remove bolts (x3) that attach the oil thermostat to body (allows oil hose movement).

12. Lower ramp.

13. Remove bolts (x4) that attach the tank to body and lift out.

Installation

1. Position tank to body and fit bolts (x4) (torque).

2. Install oil pipes to tank (torque).

3. Connect breather hose.

4. Connect top hose to engine (clip x1).

5. Raise vehicle on ramp.

6. Install bottom oil pipe to tank (torque).

7. Install bolts (x3) that attach the oil thermostat to body (torque).

8. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

9. Lower vehicle.

10. Install throttle body duct.

11. Connect breather pipe quickf its (x2) to air cleaner duct.

12. Fill tank with approximately amount of displaced oil and replace cap.

13. Use handbook procedure to check oil level.

14. Top up coolant.

Thermostat - Renew

Removal

1. Drain Coolant (refer to Workshop Manual procedure 03.03.AD Coolant - Drain and Refill).

2. Release breather valve (bolt x1) and tie aside.

3. Unclip engine harness for access (x4).

4. Remove one end of engine breather hoses for access (x3).

Repair Operation Time (ROT)

A030243

Repair Operation Time (ROT)

A030244

Page 284 of 947

Lubrication System (03.02)

Engine (03.00)3-2-10 Workshop Manual Issue 5, Janauary 2010

5. Remove breather valve bracket for access (nuts x2 bolt x1).

6. Remove thermostat housing from manifold (bolt x3).

7. Remove thermostat and sealing ring.

Installation

1. Install new thermostat and sealing ring .

2. Install thermostat housing (torque).

3. Install breather valve bracket.

4. Install breather hoses (x3) and clip.

5. Clip engine harness.

6. Install breather valve.

7. Refill coolant (refer to Workshop Manual procedure 03.03.AD Coolant - Drain and Refill).

Oil Cooler Tank Pipe Assembly - Renew

Removal

1. Remove oil pipe from oil tank (refer to Figure 1).

Figure 1

2. Raise vehicle on ramp.

3. Remove undertray (refer to Workshop Manual

procedure 01.02.NB Undertray - Front - Renew).

4. Remove RH air filter box (refer to Workshop Manual

procedure 03.12.DH Cleaner Assembly - Engine Air -

RH - Renew).

5. Unclip pipe (x4) from inner wing. 6. Remove pipe from oil cool

er and pull out from inner

wing (position container to catch oil) (refer to Figure 2).

Figure 2

Installation

1. Install pipe to oil cooler (torque) through inner wing .

2. Clip pipe (x4) to inner wing.

3. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

4. Install RH air filter box (refer to Workshop Manual

procedure 03.12.DH Cleaner Assembly - Engine Air -

RH - Renew).

5. Lower vehicle on ramp.

6. Install pipe to oil tank (torque) ensure correct alignment in oil tank bracket.

7. Fill tank with approximatel y amount of displaced oil and

replace cap.

8. Use handbook procedure to check oil level.

Oil Thermostat to Tank Tube Assembly -

Renew

Removal

1. Disconnect breather pipe qu ickfits (x2) from air cleaner

duct.

2. Remove throttle body duct for access (clips x3).

Repair Operation Time (ROT)

A030241Repair Operation Time (ROT)

ItemCode

Oil Thermostat to Tank Tube Assembly

- Renew 03.02.CD

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

A030219

Page 285 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-11

3. Remove pipes from oil tank (refer to Figure 1).

Figure 1

4. Raise vehicle on ramp.

5. Remove undertray (refer to Workshop Manual procedure. 01.02.NB Undertray - Front - Renew).

6. Remove pipe from oil thermostat (position container to catch oil) (refer to Figure 2).

Figure 2

Installation

1. Install pipe to oil thermostat (torque) ensure correct alignment in oil tank bracket.

2. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Lower vehicle on ramp.

4. Install oil pipe to tank.

5. Install throttle body duct.

6. Connect breather pipe quickf its (x2) to air cleaner duct.

7. Fill tank with approximately amount of displaced oil and replace cap.

8. Use handbook procedure to check oil level.

Oil Pump Inlet Tube Assembly - Renew

Removal

1. Remove the PAS pump (refer to Workshop Manual procedure 03.05.AA Pump - Power Steering - Renew).

2. Remove pipe from oil contro ller (position container to

catch oil).

3. Remove bolt, pipes to bracket (refer to Figure 1).

Figure 1

4. Remove LH exhaust manifo ld (refer to Workshop

Manual procedure 09.00.CD Gasket - Exhaust Manifold

- LH - Renew).

5 . R e m o v e h a r n e s s t o p i p e c l i p ( r e f e r t o F i g u r e 2 ) .

Figure 2

6. Remove bolts that attach the oil pipes to block.

7. Release both pipes from bl ock and remove inlet pipe.

Installation

1. Renew O-ring on remaining oil pipe.

2. Install inlet pipe and position both pipes into block.

A030244

A030246

Repair Operation Time (ROT)

A030248

A030247

Page 286 of 947

Lubrication System (03.02)

Engine (03.00)3-2-12 Workshop Manual Issue 5, Janauary 2010

3. Install bolts that attach th e oil pipes to block (torque).

4. Install LH exhaust manifold (refer to Workshop Manual

procedure 09.00.CD Gasket - Exhaust Manifold - LH -

Renew).

5. Install bolt, pipes to bracket.

6. Install harness clip to pipe.

7. Install pipe to oil controller (torque).

8. Install P.A.S pump (refer to Workshop Manual procedure 03.05.AA Pump - Power Steering - Renew).

9. Fill tank with approximately amount of displaced oil and replace cap.

10. Use handbook procedure to check oil level.

Oil Pump Inlet Tube Assembly - Renew

Removal

1. Remove the PAS pump (refer to Workshop Manual procedure 03.05.AA Pump - Power Steering - Renew).

2. Remove pipe from oil controller (position container to catch oil).

3. Remove bolt, pipes to bracket (refer to Figure 1).

Figure 1

4. Remove LH exhaust manifold (refer to Workshop Manual procedure 09.00.CD Gasket - Exhaust Manifold

- LH - Renew). 5 . R e m o v e h a r n e s s t o p i p e c l i p ( r e f e r t o F i g u r e 2 ) .

Figure 2

6. Remove bolts that attach the oil pipes to block.

7. Release both pipes from bl

ock and remove inlet pipe.

Installation

1. Renew O-ring on remaining oil pipe.

2. Install inlet pipe and position both pipes into block.

3. Install bolts that attach the oil pipes to block (torque).

4. Install LH exhaust manifold (refer to Workshop Manual

procedure 09.00.CD Gasket - Exhaust Manifold - LH -

Renew).

5. Install bolt, pipes to bracket.

6. Install harness clip to pipe.

7. Install pipe to oil controller (torque).

8. Install P.A.S pump (refer to Workshop Manual procedure 03.05.AA Pump - Power Steering - Renew).

9. Fill tank with approximatel y amount of displaced oil and

replace cap.

10. Use handbook procedure to check oil level.

Oil Pump Outlet Tube Assembly - Renew

Removal

1. Remove PAS pump (refer to Workshop Manual procedure 03.05.AA Pump - Power Steering - Renew).

Repair Operation Time (ROT)

A030248

Repair Operation Time (ROT)

ItemCode

Oil Pump Outlet Tube Assembly -

Renew 03.02.CF

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

A030247

Page 287 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-13

2. Remove pipe from oil tank (position container to catch oil) (refer to Figure 1).

Figure 1

3. Remove bolt, pipes to bracket (refer to Figure 2).

Figure 2

4. Remove LH exhaust manifold (refer to Workshop Manual procedure 09.00.CD Gasket - Exhaust Manifold

- LH - Renew).

5. Remove harness to pipe clip (refer to Figure 3).

Figure 3

6. Remove bolts that attach the oil pipes to block.

7. Release both pipes from block and remove outlet pipe.

Installation

1. Renew O-ring on remaining oil pipe.

2. Install outlet pipe and position both pipes into block.

3. Install bolts that attach the oil pipes to block (torque).

4. Install bolt, pipes to bracket.

5. Install harness clip to pipe.

6. Install pipe to oil tank (torque).

7. Install LH exhaust manifold (refer to Workshop Manual

procedure 09.00.CD Gasket - Exhaust Manifold - LH -

Renew).

8. Install P.A.S pump (refer to Workshop Manual procedure 03.05.AA Pump - Power Steering - Renew).

9. Fill tank with approximately amount of displaced oil and replace cap.

10. Use handbook procedure to check oil level.

Oil Thermostat Cooler Pipe Assembly -

Renew

Removal

1. Raise vehicle on ramp.

2. Remove undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Remove LH air filter box (refer to Workshop Manual

procedure 03.12.AB Air Filter Box LH Renew).

4. Remove pipe from oil thermo stat (position container to

catch oil) (refer to Figure 1).

Figure 1

5. Unclip pipe (x4) from inner wing.

A030244

A030248

A030247

Repair Operation Time (ROT)

A030240

Page 288 of 947

Lubrication System (03.02)

Engine (03.00)3-2-14 Workshop Manual Issue 5, Janauary 2010

6. Remove pipe from oil cooler and pull out from inner wing (position container to catch oil) (refer to Figure 2).

Figure 2

Installation

1. Install pipe to oil cooler (torque) through inner wing .

2. Clip pipe (x4) to inner wing.

3. Install pipe to oil thermostat and ensure correct alignment in oil tank bracket.

4. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

5. Lower vehicle on ramp.

6. Install LH air filter box (refer to Workshop Manual procedure 03.12.AB Air Filter Box LH Renew).

7. Fill tank with approximately amount of displaced oil and replace cap.

8. Use handbook procedure to check oil level.

Oil Temperature Controller - Renew

Remove

1. Raise vehicle on ramp.

2. Remove undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew). 3. Remove pipes from oil thermostat (position container to

catch oil) (refer to Figure 1).

Figure 1

4. Remove controller fr om body (bolts x2).

Install

1. Install controller to body (bolts x2) (torque).

2. Install pipes to oil thermost at (torque) ensure correct

alignment in oil tank bracket.

3. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

4. Fill tank with approximatel y amount of displaced oil and

replace cap.

5. Use handbook procedure to check oil level.

6. Lower vehicle on ramp.

Oil Sump Pan - Renew (with Engine

Removed

)

Removal

1. Remove oil sump (refer to Workshop Manual procedure 03.02.CN Pan - Oil Sump - Remove and Reseal With

Engine Removed).

Repair Operation Time (ROT)

A030220

Repair Operation Time (ROT)

ItemCode

Oil Sump Pan-Renew (with Engine

Removed) 03.02.CM

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

A030242

Page 290 of 947

Lubrication System (03.02)

Engine (03.00)3-2-16 Workshop Manual Issue 5, Janauary 2010

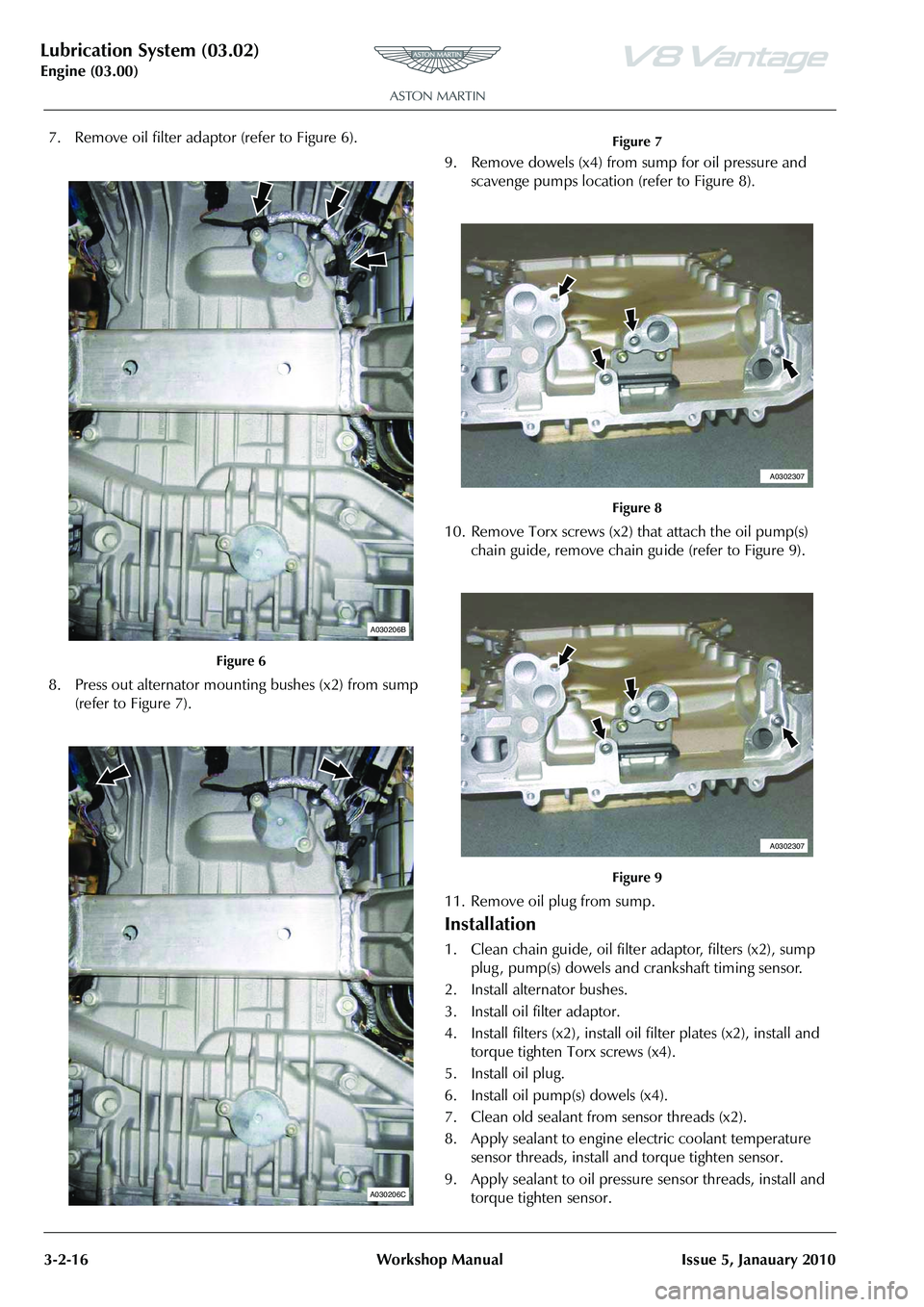

7. Remove oil filter adaptor (refer to Figure 6).

8. Press out alternator mounting bushes (x2) from sump (refer to Figure 7). 9. Remove dowels (x4) from

sump for oil pressure and

scavenge pumps location (refer to Figure 8).

10. Remove Torx screws (x2) that attach the oil pump(s)

chain guide, remove chain gu ide (refer to Figure 9).

11. Remove oil plug from sump.

Installation

1. Clean chain guide, oil filter adaptor, filters (x2), sump plug , pump(s) dowels and crankshaft timing sensor.

2. Install alternator bushes.

3. Install oil filter adaptor.

4. Install filters (x2), install oil filter plates (x2), install and

torque tighten Torx screws (x4).

5. Install oil plug.

6. Install oil pump(s) dowels (x4).

7. Clean old sealant from sensor threads (x2).

8. Apply sealant to engine electric coolant temperature sensor threads, install and torque tighten sensor.

9. Apply sealant to oil pressure sensor threads, install and torque tighten sensor.

Figure 6

A030206B

A030206C

Figure 7

Figure 8

Figure 9

A0302307

A0302307

Page 291 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-17

10. Install oil pump(s) chain guid e, Install and torque tighten

Torx screws (x2).

11. Install crankshaft timing sensor, install and torque

tighten bolt.

12. Install oil sump (refer to Workshop Manual procedure

03.02.CN Pan - Oil Sump - Remove and Reseal With

Engine Removed).

Oil Sump Pan - Remove and Reseal (with

Engine Removed

)

Removal

1. Remove oil pump(s) drive chain (refer to Workshop Manual procedure 03.02.BJ Chain - Oil Pump - Renew

With Engine Removed).

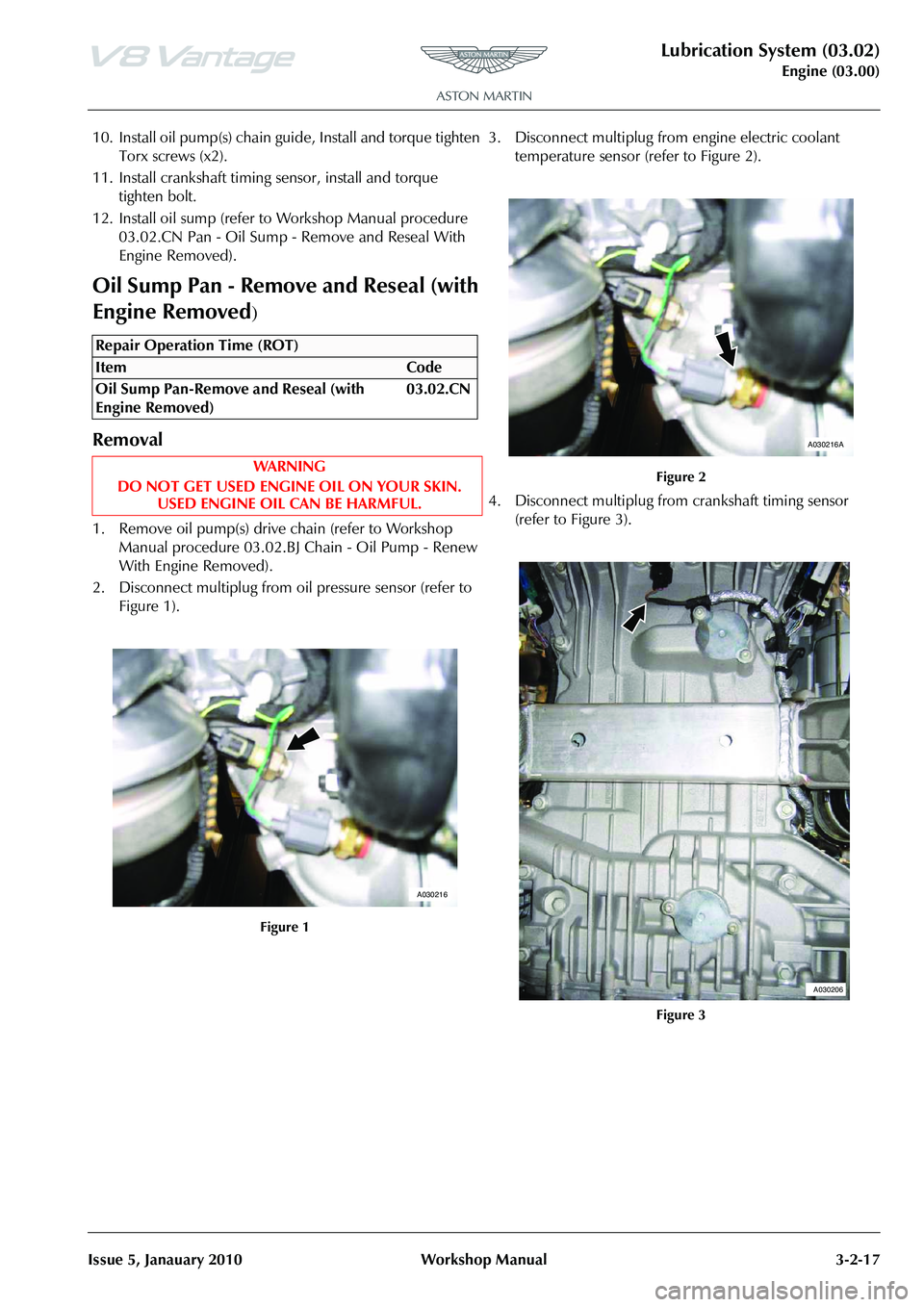

2. Disconnect multiplug from oi l pressure sensor (refer to

Figure 1). 3. Disconnect multiplug from

engine electric coolant

temperature sensor (refer to Figure 2).

4. Disconnect multiplug from crankshaft timing sensor

(refer to Figure 3).

Repair Operation Time (ROT)

A030216

Figure 2

Figure 3

A030216A

A030206

Page 293 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-19

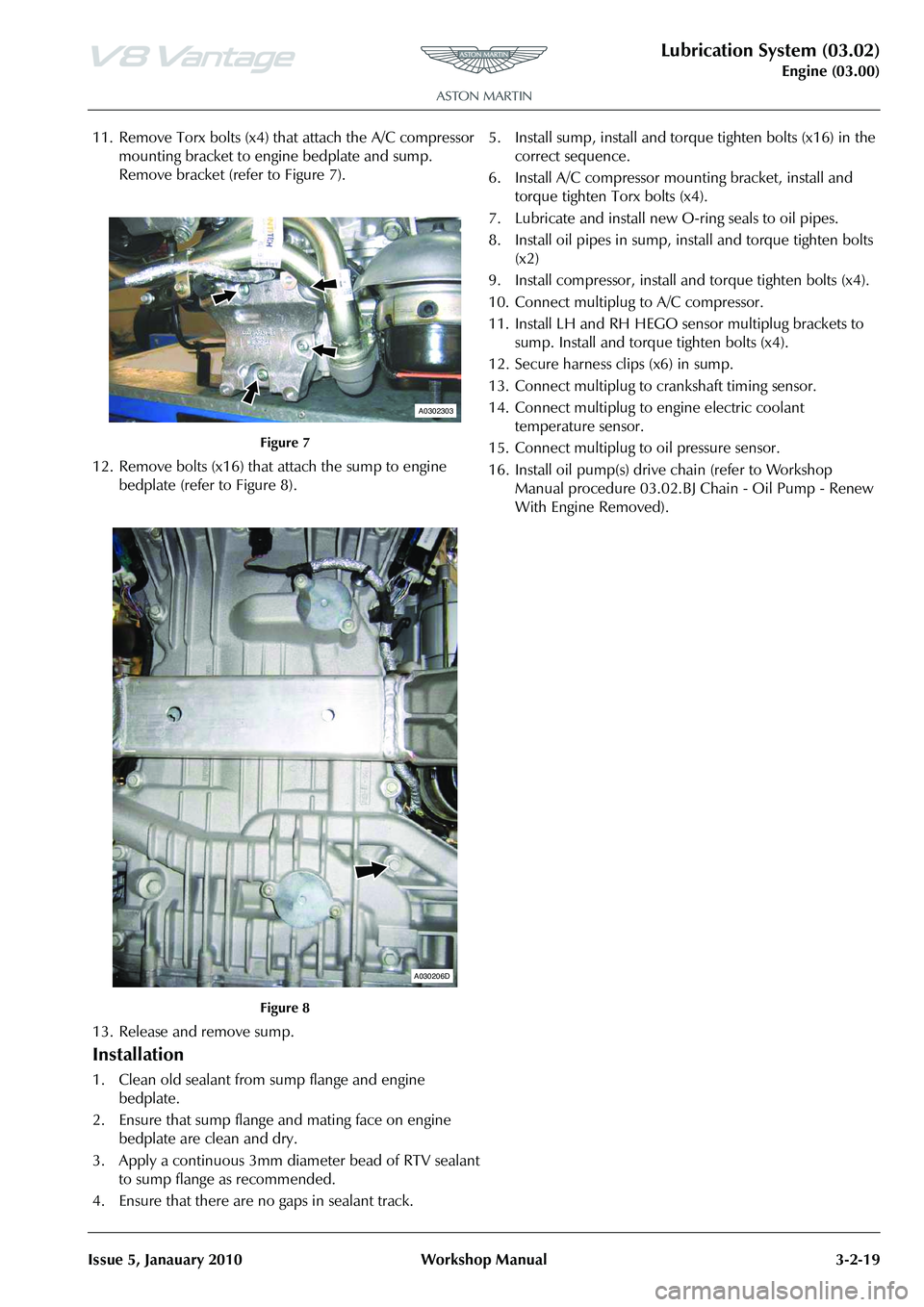

11. Remove Torx bolts (x4) that attach the A/C compressor mounting bracket to engine bedplate and sump.

Remove bracket (refer to Figure 7).

12. Remove bolts (x16) that attach the sump to engine bedplate (refer to Figure 8).

13. Release and remove sump.

Installation

1. Clean old sealant from sump flange and engine bedplate.

2. Ensure that sump flange and mating face on engine bedplate are clean and dry.

3. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

4. Ensure that there are no gaps in sealant track. 5. Install sump, install and torque tighten bolts (x16) in the

correct sequence.

6. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

7. Lubricate and install new O-ring seals to oil pipes.

8. Install oil pipes in sump, install and torque tighten bolts (x2)

9. Install compressor, install and torque tighten bolts (x4).

10. Connect multiplug to A/C compressor.

11. Install LH and RH HEGO se nsor multiplug brackets to

sump. Install and torque tighten bolts (x4).

12. Secure harness clips (x6) in sump.

13. Connect multiplug to crankshaft timing sensor.

14. Connect multiplug to engine electric coolant temperature sensor.

15. Connect multiplug to oil pressure sensor.

16. Install oil pump(s) drive chain (refer to Workshop Manual procedure 03.02.BJ Chain - Oil Pump - Renew

With Engine Removed).

Figure 7

Figure 8

A0302303

A030206D

Page 296 of 947

Cooling System (03.03)

Engine (03.00)3-3-2 Workshop Manual Issue 5, Janauary 2010

cooling system. No manual bleed points are provided on the

system.

The coolant reservoir should be full when the coolant system

is cold.

Engine Oil Cooler

The oil temperature is contro lled by an air/oil cooler

mounted at the front of the car. Engine oil is removed from

the dry sump, with the scavenge pump. The oil is routed to

a temperature controlled thermostat which controls the

directional flow of the oil. With the thermostat closed the oil

is routed directly to the oil tank. When the thermostat starts

to open (at 105°C) the oil is routed via the air/oil cooler

before entering the tank.

Specifications

Torque Figures

Maintenance

Coolant-Drain/Fill

1. Raise vehicle on ramp.

2. Remove front undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Position suitable container to collect coolant.

4. Remove pressure cap from coolant reservoir.

5. Remove drain plug from radiator, allow coolant to drain.

6. Installation

7. Clean radiator drain plug.

8. Install and tighten drain plug.

9. Remove drain container.

10. Install front undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

11. Lower vehicle on ramp.

12. Fill cooling system with specified coolant mix to maximum level in coolant reservoir.

Antifreeze Mix

50% OAT coolant/50% water

Pressure Cap 150kpa

Leakage Rates 30cm/min. 150-180kpa

60xcm/min. 10kpa

Up to 75kpa @ 150cm/h

Water Pump Pumps 4ltr/min. @ 1000rpm

Pumps 240ltr/min. @ 7000rpm

Thermostat Opens between 86°C - 90°C (186.8°F -

194°F)

Fully open at 102°C

The anti-freeze is un ique and cannot be mixed with other

anti-freeze solutions. The OAT coolant/water mixture has a

life of 150,000 miles or 5 years (which ever comes first).

Description Nm. Ib/ft

Condenser A/C pipes 8-10 6-8

Thermostat Housing 8-12 6-9

Thermostat housing support bracket 23-27 17-20

Water pump 23-27 17-20

Water pump pulley 23-27 17-20

Oil Cooler 50 36

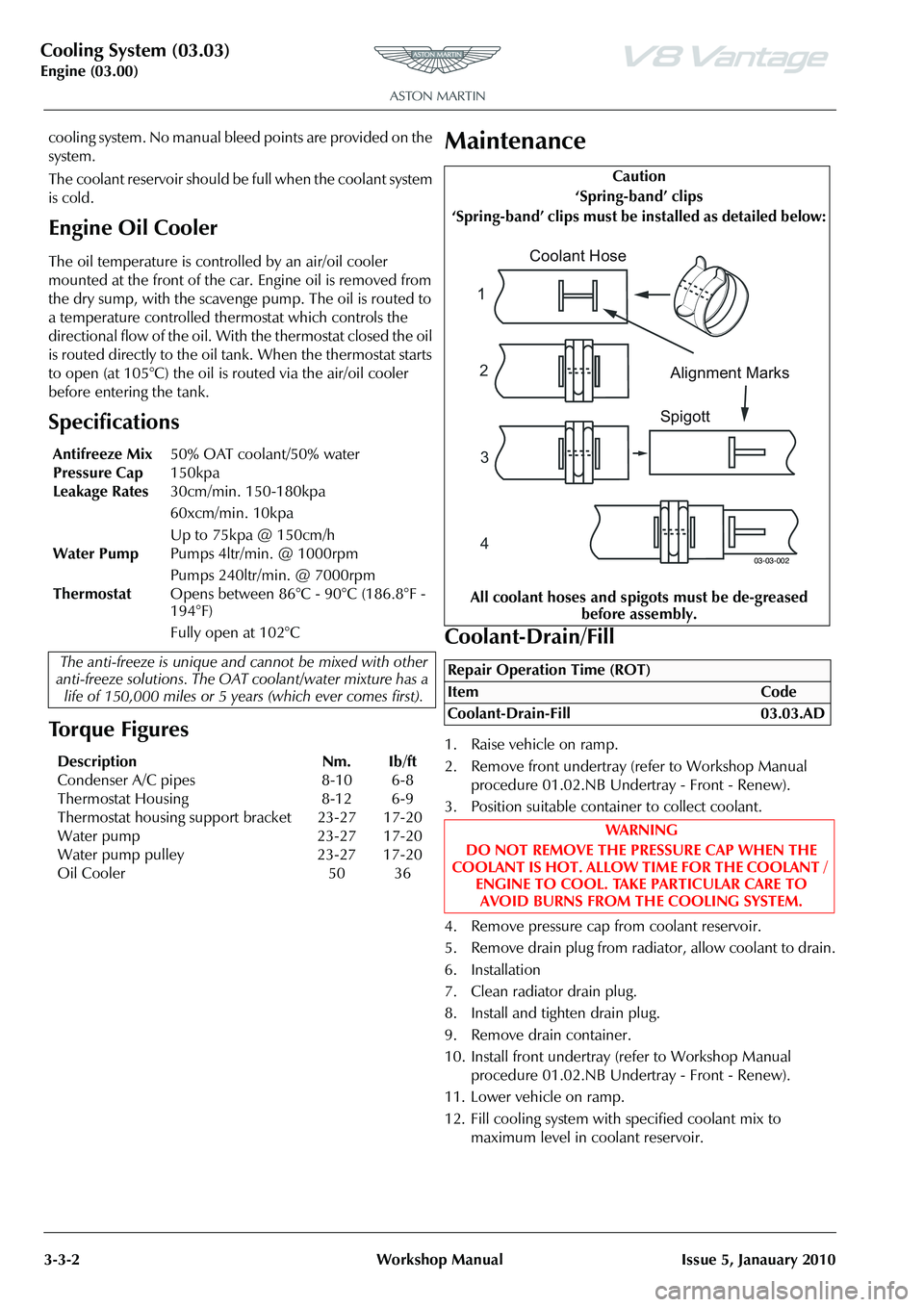

Caution

‘Spring-band’ clips

‘Spring-band’ clips must be installed as detailed below:

All coolant hoses and spigots must be de-greased before assembly.

Repair Operation Time (ROT)

ItemCode

Coolant-Drain-Fill 03.03.AD

WAR NI NG

DO NOT REMOVE THE PRESSURE CAP WHEN THE

COOLANT IS HOT. ALLOW TIME FOR THE COOLANT /

ENGINE TO COOL. TAKE PARTICULAR CARE TO AVOID BURNS FROM THE COOLING SYSTEM.

03-03-002

3

2

4

Coolant Hose SpigottAlignment Marks