torque ASTON MARTIN V8 VANTAGE 2010 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 257 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-9

Removal Manifold

37. Disconnect manifold heating hoses (x2).

38. Disconnect throttle body multiplug and harness clip.

39. Disconnect breather pipe qu ickfits (x2) from air cleaner

duct.

40. Disconnect air clea ner duct (clip x1).

41. Disconnect EGR vacuum hose.

42. Disconnect EGR pipe union and tie aside.

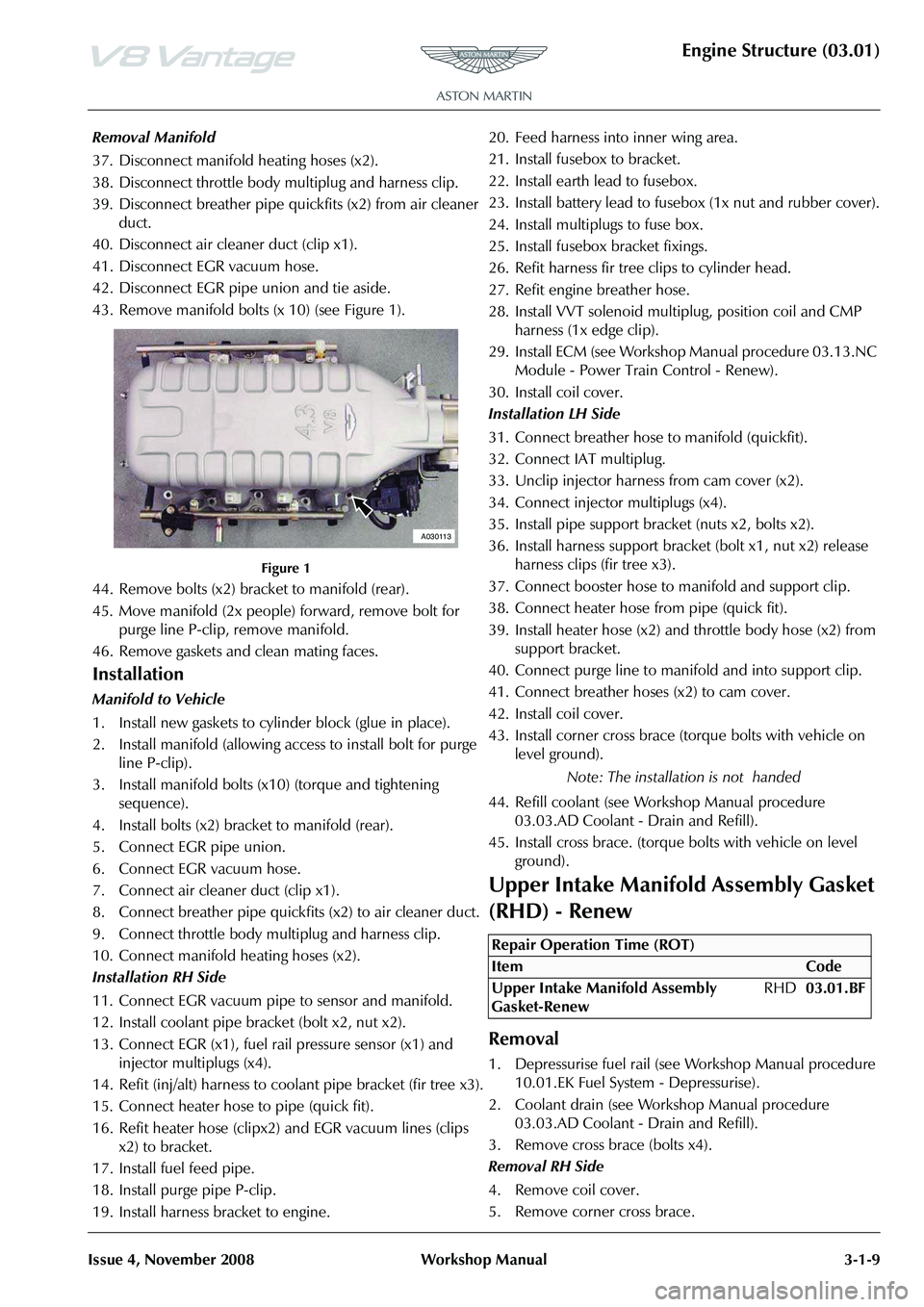

43. Remove manifold bolts (x 10) (see Figure 1).

Figure 1

44. Remove bolts (x2) bracket to manifold (rear).

45. Move manifold (2x people) forward, remove bolt for purge line P-clip, remove manifold.

46. Remove gaskets and clean mating faces.

Installation

Manifold to Vehicle

1. Install new gaskets to cylinder block (glue in place).

2. Install manifold (allowing access to install bolt for purge line P-clip).

3. Install manifold bolts (x10) (torque and tightening sequence).

4. Install bolts (x2) bracket to manifold (rear).

5. Connect EGR pipe union.

6. Connect EGR vacuum hose.

7. Connect air cleaner duct (clip x1).

8. Connect breather pipe quickf its (x2) to air cleaner duct.

9. Connect throttle body multiplug and harness clip.

10. Connect manifold heating hoses (x2).

Installation RH Side

11. Connect EGR vacuum pipe to sensor and manifold.

12. Install coolant pipe bracket (bolt x2, nut x2).

13. Connect EGR (x1), fuel rail pressure sensor (x1) and

injector multiplugs (x4).

14. Refit (inj/alt) harness to coolant pipe bracket (fir tree x3).

15. Connect heater hose to pipe (quick fit).

16. Refit heater hose (clipx2) and EGR vacuum lines (clips x2) to bracket.

17. Install fuel feed pipe.

18. Install purge pipe P-clip.

19. Install harness bracket to engine. 20. Feed harness into inner wing area.

21. Install fusebox to bracket.

22. Install earth lead to fusebox.

23. Install battery lead to fusebox (1x nut and rubber cover).

24. Install multiplugs to fuse box.

25. Install fusebox bracket fixings.

26. Refit harness fir tree clips to cylinder head.

27. Refit engine breather hose.

28. Install VVT solenoid multip

lug, position coil and CMP

harness (1x edge clip).

29. Install ECM (see Workshop Manual procedure 03.13.NC Module - Power Train Control - Renew).

30. Install coil cover.

Installation LH Side

31. Connect breather hose to manifold (quickfit).

32. Connect IAT multiplug.

33. Unclip injector harness from cam cover (x2).

34. Connect injector multiplugs (x4).

35. Install pipe support bracket (nuts x2, bolts x2).

36. Install harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3).

37. Connect booster hose to manifold and support clip.

38. Connect heater hose from pipe (quick fit).

39. Install heater hose (x2) and throttle body hose (x2) from support bracket.

40. Connect purge line to manifold and into support clip.

41. Connect breather hoses (x2) to cam cover.

42. Install coil cover.

43. Install corner cross brace (t orque bolts with vehicle on

level ground).

44. Refill coolant (see Workshop Manual procedure 03.03.AD Coolant - Drain and Refill).

45. Install cross brace. (torque bolts with vehicle on level

ground).

Upper Intake Manifold Assembly Gasket

(RHD) - Renew

Removal

1. Depressurise fuel rail (see Workshop Manual procedure 10.01.EK Fuel System - Depressurise).

2. Coolant drain (see Workshop Manual procedure 03.03.AD Coolant - Drain and Refill).

3. Remove cross brace (bolts x4).

Removal RH Side

4. Remove coil cover.

5. Remove corner cross brace.

A030113

Note: The installation is not handed

Repair Operation Time (ROT)

Page 258 of 947

Engine Structure (03.01)

3-1-10Workshop ManualIssue 4, November 2008

6. Disconnect breather hose (quick fit) move aside.

7. Remove purge pipe P-clip (bolt x1) and move pipe

aside.

8. Remove harness bracket from engine (bolts x2, nut x1).

9. Release fuel feed hose from rail (clip x1) and move aside.

10. Disconnect heater hose from pipe (quick fit).

11. Release heater hose (clips x2) and EGR vacuum line (clips x2) from bracket.

12. Release harness from coolant pipe bracket (fir tree x3).

13. Disconnect EGR (x1), fuel rail pressure sensor (x1) and injector (x4) multiplugs, move harness aside.

14. Remove coolant pipe bracket (nuts x2 and bolts x2).

15. Disconnect EGR vacuum pipe from sensor and manifold, move aside.

Removal LH Side

16. Remove coil cover.

17. Disconnect breather hoses from cam cover (x2) for access.

18. Release harness fir tree clips (x3) from cylinder head and move aside.

19. Remove fuse box bracket fixings (bolt and nut) (allows movement).

20. Remove ECM (see Workshop Manual procedure 03.13.ND Module - Power Train Control - RHD -

Renew).

21. Remove battery lead (1x nu t and rubber cover) from

fuse box (2x leads).

22. Remove multiplugs (x10) from fusebox.

23. Disconnect purge line from manifold (quickfit) and support clip for access.

24. Remove earth terminal (1x nut and rubber cover) from fusebox.

25. Remove fuse box from bracket (bolt x2).

26. Release harness fir tree clips (x3) from engine bracket.

27. Feed harness from inner wing and over engine.

28. Disconnect heater hose from pipe (quick fit).

29. Release heater hose (x2) and throttle body hose (x2) from support bracket.

30. Remove booster hose from manifold and support clip.

31. Remove harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3).

32. Release pipe support brack et (nuts x2, bolts x2) move

aside.

33. Disconnect injector multiplugs (x4).

34. Unclip injector harness from cam cover (x2).

35. Disconnect IAT multiplug.

36. Disconnect breather hose from manifold (quickfit).

Removal Manifold from Vehicle

37. Remove booster hose from support bracket.

38. Disconnect manifold heating hoses (x2).

39. Disconnect throttle body multiplug and harness clip. 40. Disconnect breather pipe qu

ickfits (x2) from air cleaner

duct.

41. Disconnect air cleaner duct (clip x1).

42. Disconnect EGR vacuum hose.

43. Disconnect EGR pipe union and tie aside.

44. Remove manifold bolts (x 10) (see Figure 1)

Figure 1

45. Remove bolts (x2) bracket to manifold (rear).

46. Move manifold (2x people) forward, remove bolt for purge line P-clip, remove manifold.

47. Remove gaskets and clean mating faces.

Installation

1. Install new gaskets to cylinder block (glue in place).

2. Install manifold (allowing access to install bolt for purge line P-clip).

3. Install manifold bolts (x 10) (torque and tightening

sequence).

4. Install bolts (x2) bracket to manifold (rear).

5. Connect EGR pipe union.

6. Connect EGR vacuum hose.

7. Connect air cleaner duct (clip x1).

8. Connect breather pipe quickfits (x2) to air cleaner duct.

9. Connect throttle body multiplug and harness clip.

10. Connect manifold heating hoses (x2).

11. Install booster hose to support bracket.

Installation RH Side

12. Connect EGR vacuum pipe to sensor and manifold.

13. Install coolant pipe bracket (bolt x2, nut x2).

14. Connect EGR (x1), fuel rail pressure sensor (x1) and injector multiplugs (x4).

15. Refit harness to coolant pipe bracket (fir tree x3).

16. Connect heater hose to pipe (quick fit).

17. Refit heater hose (clipx2) and EGR vacuum lines (clips

x2) to bracket.

18. Install fuel feed pipe.

19. Install purge pipe P-clip.

20. Install harness bracket to engine.

21. Refit harness fir tree clips to cylinder head.

22. Refit engine breather hose.

A030113

Page 259 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-11

23. Install VVT solenoid multiplug, position coil and CMP

harness (1x edge clip).

24. Install corner cross brace (t orque bolts with vehicle on

level ground).

25. Install coil cover.

Installation LH Side

26. Connect breather hose to manifold (quickfit).

27. Connect IAT multiplug.

28. Install injector harness to cam cover (x2).

29. Connect injector multiplugs (x4).

30. Install pipe support bracket (nuts x2, bolts x2).

31. Install harness support bracket (bolt x1, nut x2) release harness clips (fir tree x3).

32. Connect booster hose to manifold and support clip.

33. Connect heater hose from pipe (quick fit).

34. Install heater hose (x2) and throttle body hose (x2) from support bracket.

35. Connect purge line to mani fold and into support clip.

36. Connect breather hoses (x2) to cam cover.

37. Feed harness into inner wing area.

38. Install fusebox to bracket.

39. Install earth lead to fusebox.

40. Install battery lead to fusebox (1x nut and rubber cover).

41. Install multiplugs to fuse box.

42. Install fusebox bracket fixings.

43. Install ECM (see Workshop Manual procedure 03.13.ND Module - Powe r Train Control - RHD -

Renew)

44. Install coil cover.

45. Refill coolant (see Workshop Manual procedure 03.03.AD Coolant - Drain and Refill).

46. Install cross brace. (torque bolts with vehicle on level

ground).

Intake Manifold Assembly - Remove for

Access and Refit (With Engine Removed

)

Removal

1. Remove RH coil cover.

2. Disconnect breather hose (quick fit).

3. Release alternator and injector harness fir tree clips (x3) from cylinder head.

4. Remove nut and bolts (x2) securing harness bracket to

engine, remove bracket.

5. Release heater hose (clips x2) and EGR vacuum line (clips x2) from bracket.

6. Release alternator and injector harness fir tree clips (x3) from coolant pipe bracket. 7. Disconnect multiplugs from EGR valve, fuel rail pressure

sensor and injectors (x4).

8. Remove nuts (x2) and bolts (x2) securing coolant pipe

bracket, remove bracket.

9. Disconnect EGR vacuum pipe from sensor and manifold.

10. Remove LH coil cover.

11. Disconnect breather hoses (x2) from LH engine cover.

12. Disconnect purge line from manifold (quickfit) and

support clip for access.

13. Disconnect heater hose from pipe (quick fit).

14. Release heater hose (x2) and throttle body hose (x2) from support bracket.

15. Remove bolt and nuts (x2) securing harness support bracket, release harness clips (fir tree x3). Remove

bracket.

16. Remove nuts (x2) and bolts (x2) pipe support bracket.

17. Disconnect injector multiplugs (x4).

18. Release injector harness clip s (x2) from LH engine cover.

19. Disconnect IAT multiplug.

20. Disconnect breather hose from manifold (quickfit).

21. Disconnect manifold heating hoses (x2).

22. Disconnect throttle body multiplug and harness clip.

23. Disconnect EGR vacuum hose.

24. Loosen and disconnect EGR pipe union from EGR valve.

25. Remove bolts (x2) securing EGR pipe to RH exhaust

manifold, remove pi pe, discard gasket.

26. Progressively loosen and remove bolts (x 10) securing intake manifold to cylinder heads (see Figure 1).

Figure 1

27. Carefully remove intake ma nifold from cylinder heads.

28. Remove and discard gaskets (x2).

Installation

1. Clean intake manifold and mating faces on cylinder heads.

2. Install new gaskets to cyli nder block (glue in place).

3. Install intake manifold (allowing access to install bolt for purge line P-clip).

4. Install and torque tighten in take manifold bolts (x10) in

the correct sequence.

5. Clean EGR pipe and mating face on exhaust manifold.

Repair Operation Time (ROT)

A030113

Page 260 of 947

Engine Structure (03.01)

3-1-12Workshop ManualIssue 4, November 2008

6. Install new gasket on exhaust manifold.

7. Install EGR pipe to exhaust manifold and EGR valve.,

8. Install EGR pipe to EGR valve, install pipe union. Do not

torque tighten at this stage.

9. Install and torque tighten bolts (x2), EGR pipe to exhaust manifold. Torque tighten pipe union.

10. Connect EGR vacuum hose.

11. Connect throttle body multiplug and harness clip.

12. Connect manifold heating hoses (x2).

13. Connect EGR vacuum pipe to sensor and manifold.

14. Install coolant pipe bracket, install and torque tighten bolts (x2) and nuts (x2).

15. Connect multiplugs to EGR valve, fuel rail pressure

sensor and injectors.

16. Install alternator and injector harness fir tree clips (x3) to coolant pipe bracket.

17. Install heater hose clips (x2) and EGR vacuum lines clips (x2) to bracket.

18. Install harness bracket to engine.

19. Refit harness fir tree clips to cylinder head.

20. Refit engine breather hose.

21. Install VVT solenoid multiplug, position coil and CMP harness (1x edge clip).

22. Install coil cover.

23. Connect breather hose to manifold (quickfit).

24. Connect IAT multiplug.

25. Secure injector harness clips (x2) to LH engine cover.

26. Connect injector multiplugs (x4).

27. Install pipe support bracket, install and tighten nuts (x2

and bolts(x2).

28. Install harness support bracket, install and tighten bolt (x1) and, nut (x1).

29. Install heater hoses (x2) an d throttle body hoses (x2) in

support bracket.

30. Connect breather hoses (x2) to engine cover.

31. Install coil cover.

RH/LH Cylinder Head Gasket - Renew

Removal

1. Re-install front subframe to body, install and tighten bolts (x6), remove support trolley.

2. Install and tighten engine mounting nuts (x2).

3. With assistance, remove engine lifting beam (SPX M553D). 4. Remove SAI pump and bracket assembly (see Workshop

Manual procedure 03.08.DB/03.08.DJ Pump and

Bracket Assembly - Secondary Air Injection - Renew).

5. Disconnect multiplugs (x2) from knock sensors.

6. Disconnect multiplug from camshaft timing sensor.

7. Remove RH/LH exhaust manifold (see Workshop Manual procedure 09.00.CC/09.00.CD Gasket -

Exhaust Manifold - RH/LH - Renew).

8. Remove RH/LH intake camshaft (see Workshop Manual procedure 03.09.AT/03.09.AV Camshaft - Intake - RH/

LH - Renew).

9. Remove RH exhaust camshaft bearing cap retaining bolts (x10) evenly and in stages (see Figure 1).

Figure 1

10. Note their orientation and markings and remove the RH

exhaust camshaft bearing caps.

11. Remove RH exhaust camshaft (see Figure 2).

12. Remove bolts (x2) securing front end of RH cylinder

head to cylinder block.

Repair Operation Time (ROT)

Figure 2

A0309258

A0309260

Page 261 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-13

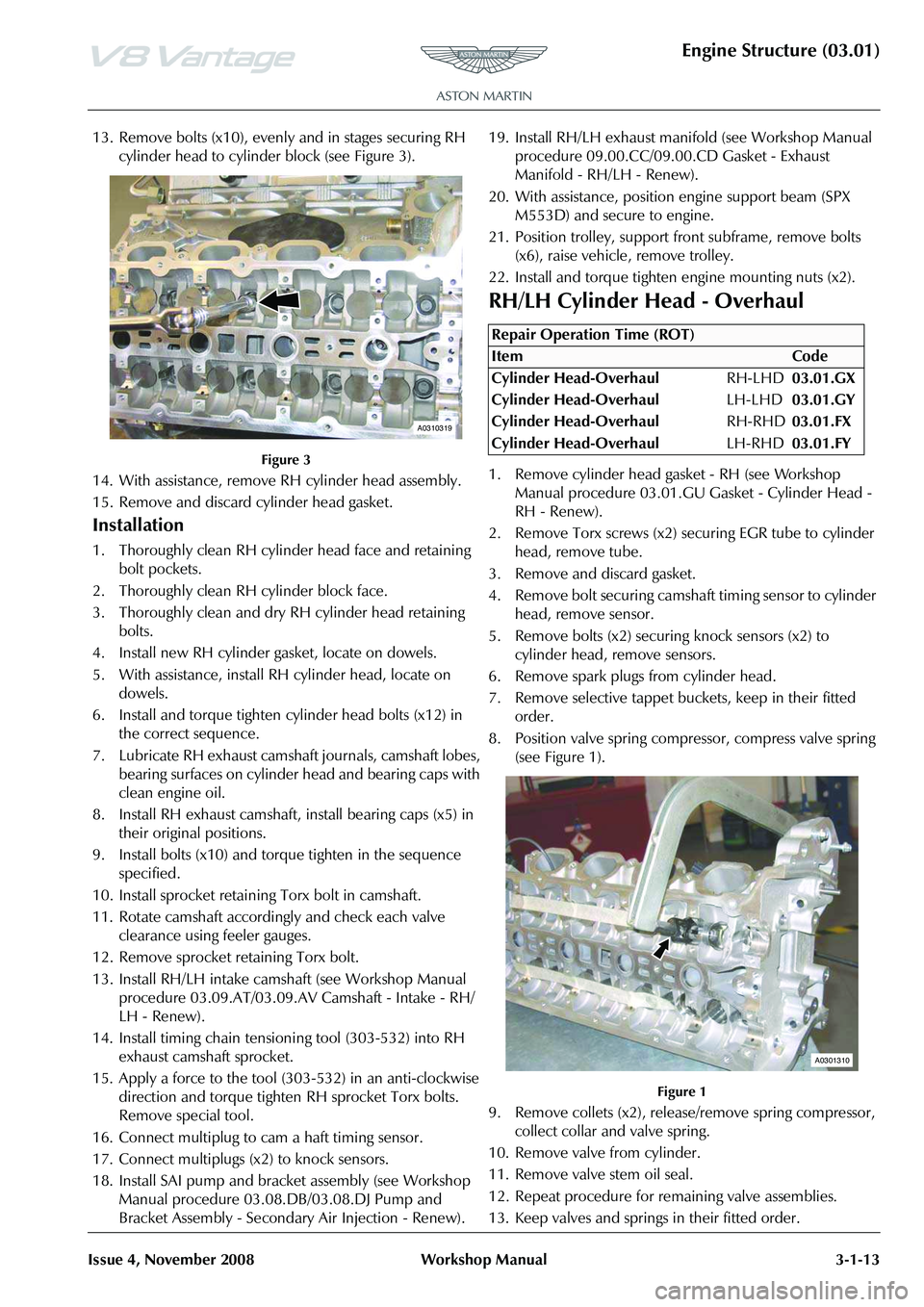

13. Remove bolts (x10), evenly and in stages securing RH

cylinder head to cylinder block (see Figure 3).

Figure 3

14. With assistance, remove RH cylinder head assembly.

15. Remove and discard cylinder head gasket.

Installation

1. Thoroughly clean RH cylind er head face and retaining

bolt pockets.

2. Thoroughly clean RH cylinder block face.

3. Thoroughly clean and dry RH cylinder head retaining

bolts.

4. Install new RH cylinder gasket, locate on dowels.

5. With assistance, install RH cylinder head, locate on dowels.

6. Install and torque tighten cylinder head bolts (x12) in the correct sequence.

7. Lubricate RH exhaust camsha ft journals, camshaft lobes,

bearing surfaces on cylinder head and bearing caps with

clean engine oil.

8. Install RH exhaust camshaft, install bearing caps (x5) in their original positions.

9. Install bolts (x10) and torque tighten in the sequence specified.

10. Install sprocket retaining Torx bolt in camshaft.

11. Rotate camshaft accordingly and check each valve clearance using feeler gauges.

12. Remove sprocket retaining Torx bolt.

13. Install RH/LH intake cams haft (see Workshop Manual

procedure 03.09.AT/03.09.AV Camshaft - Intake - RH/

LH - Renew).

14. Install timing chain tensioni ng tool (303-532) into RH

exhaust camshaft sprocket.

15. Apply a force to the tool (303-532) in an anti-clockwise direction and torque tighten RH sprocket Torx bolts.

Remove special tool.

16. Connect multiplug to cam a haft timing sensor.

17. Connect multiplugs (x2) to knock sensors.

18. Install SAI pump and bracket assembly (see Workshop Manual procedure 03.08.DB/03.08.DJ Pump and

Bracket Assembly - Secondary Air Injection - Renew). 19. Install RH/LH exhaust manifold (see Workshop Manual

procedure 09.00.CC/09.00.CD Gasket - Exhaust

Manifold - RH/LH - Renew).

20. With assistance, position engine support beam (SPX M553D) and secure to engine.

21. Position trolley, support front subframe, remove bolts (x6), raise vehicle, remove trolley.

22. Install and torque tighten engine mounting nuts (x2).

RH/LH Cylinder Head - Overhaul

1. Remove cylinder head gasket - RH (see Workshop Manual procedure 03.01.GU Gasket - Cylinder Head -

RH - Renew).

2. Remove Torx screws (x2) se curing EGR tube to cylinder

head, remove tube.

3. Remove and discard gasket.

4. Remove bolt securing camshaf t timing sensor to cylinder

head, remove sensor.

5. Remove bolts (x2) securing knock sensors (x2) to cylinder head, remove sensors.

6. Remove spark plugs from cylinder head.

7. Remove selective tappet buckets, keep in their fitted order.

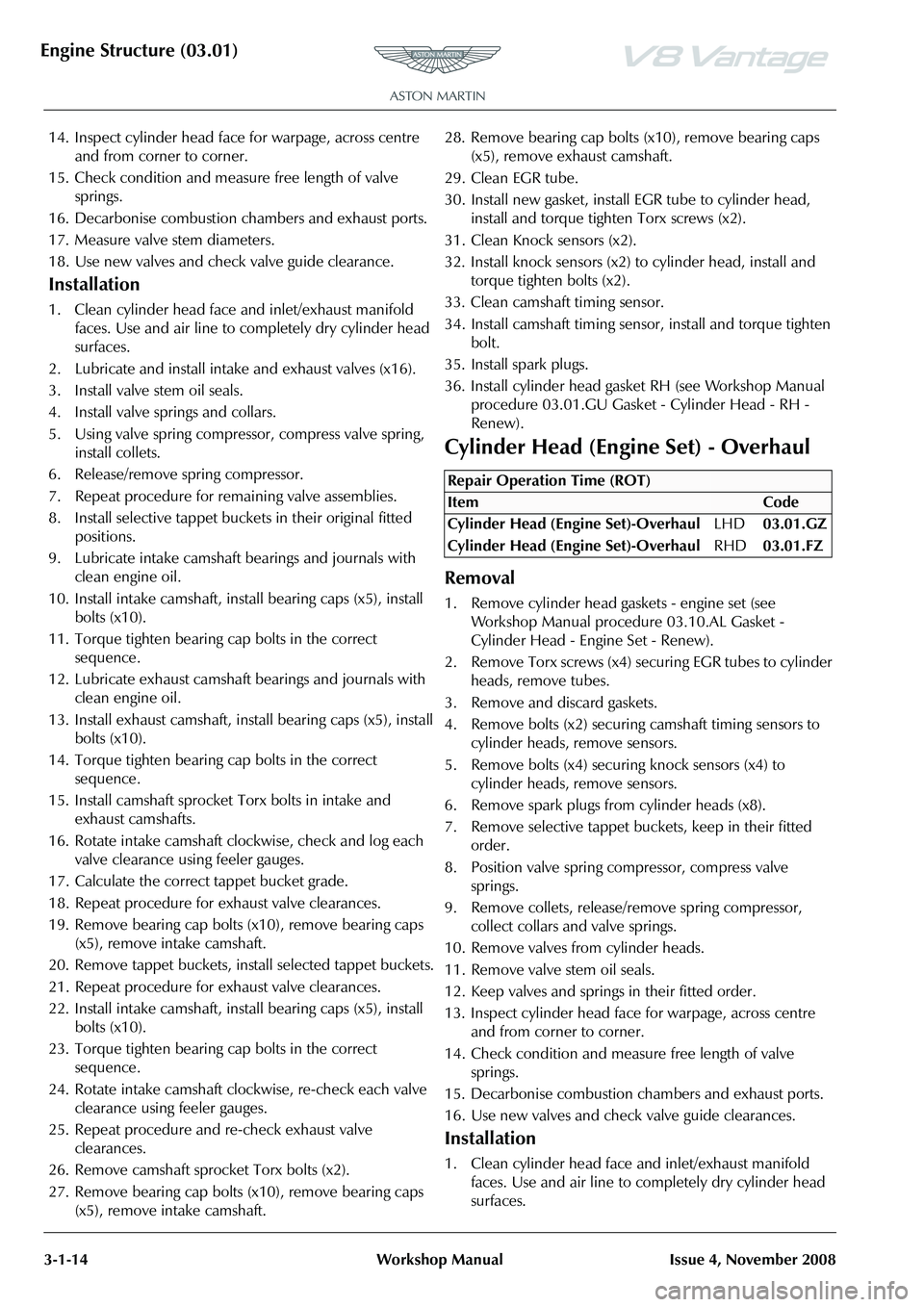

8. Position valve spring compressor, compress valve spring (see Figure 1).

Figure 1

9. Remove collets (x2), releas e/remove spring compressor,

collect collar and valve spring.

10. Remove valve from cylinder.

11. Remove valve stem oil seal.

12. Repeat procedure for remaining valve assemblies.

13. Keep valves and springs in their fitted order.

A0310319

Repair Operation Time (ROT)

A0301310

Page 262 of 947

Engine Structure (03.01)

3-1-14Workshop ManualIssue 4, November 2008

14. Inspect cylinder head face for warpage, across centre

and from corner to corner.

15. Check condition and measure free length of valve springs.

16. Decarbonise combustion chambers and exhaust ports.

17. Measure valve stem diameters.

18. Use new valves and check valve guide clearance.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Lubricate and install intake and exhaust valves (x16).

3. Install valve stem oil seals.

4. Install valve springs and collars.

5. Using valve spring compressor, compress valve spring, install collets.

6. Release/remove spring compressor.

7. Repeat procedure for remaining valve assemblies.

8. Install selective tappet buckets in their original fitted positions.

9. Lubricate intake camshaft bearings and journals with clean engine oil.

10. Install intake camshaft, install bearing caps (x5), install bolts (x10).

11. Torque tighten bearing cap bolts in the correct sequence.

12. Lubricate exhaust camshaft be arings and journals with

clean engine oil.

13. Install exhaust camshaft, install bearing caps (x5), install bolts (x10).

14. Torque tighten bearing cap bolts in the correct sequence.

15. Install camshaft sprocket Torx bolts in intake and exhaust camshafts.

16. Rotate intake camshaft clockwise, check and log each valve clearance using feeler gauges.

17. Calculate the correct tappet bucket grade.

18. Repeat procedure for exhaust valve clearances.

19. Remove bearing cap bolts (x10), remove bearing caps (x5), remove intake camshaft.

20. Remove tappet buckets, install selected tappet buckets.

21. Repeat procedure for exhaust valve clearances.

22. Install intake camshaft, install bearing caps (x5), install bolts (x10).

23. Torque tighten bearing cap bolts in the correct sequence.

24. Rotate intake camshaft clockwise, re-check each valve clearance using feeler gauges.

25. Repeat procedure and re-check exhaust valve clearances.

26. Remove camshaft sprocket Torx bolts (x2).

27. Remove bearing cap bolts (x10), remove bearing caps (x5), remove intake camshaft. 28. Remove bearing cap bolts (x10), remove bearing caps

(x5), remove exhaust camshaft.

29. Clean EGR tube.

30. Install new gasket, install EGR tube to cylinder head, install and torque tighten Torx screws (x2).

31. Clean Knock sensors (x2).

32. Install knock sensors (x2) to cylinder head, install and torque tighten bolts (x2).

33. Clean camshaft timing sensor.

34. Install camshaft timing sensor, install and torque tighten bolt.

35. Install spark plugs.

36. Install cylinder head gasket RH (see Workshop Manual procedure 03.01.GU Gasket - Cylinder Head - RH -

Renew).

Cylinder Head (Engine Set) - Overhaul

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove Torx screws (x4) securing EGR tubes to cylinder heads, remove tubes.

3. Remove and discard gaskets.

4. Remove bolts (x2) securing camshaft timing sensors to cylinder heads, remove sensors.

5. Remove bolts (x4) securing knock sensors (x4) to cylinder heads, remove sensors.

6. Remove spark plugs from cylinder heads (x8).

7. Remove selective tappet buckets, keep in their fitted order.

8. Position valve spring compressor, compress valve springs.

9. Remove collets, release/remove spring compressor, collect collars and valve springs.

10. Remove valves from cylinder heads.

11. Remove valve stem oil seals.

12. Keep valves and springs in their fitted order.

13. Inspect cylinder head face for warpage, across centre and from corner to corner.

14. Check condition and measure free length of valve springs.

15. Decarbonise combustion chambers and exhaust ports.

16. Use new valves and check valve guide clearances.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

Repair Operation Time (ROT)

ItemCode

Cylinder Head (Engine Set)-Overhaul LHD03.01.GZ

Cylinder Head (Engine Set)-Overhaul RHD03.01.FZ

Page 263 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-15

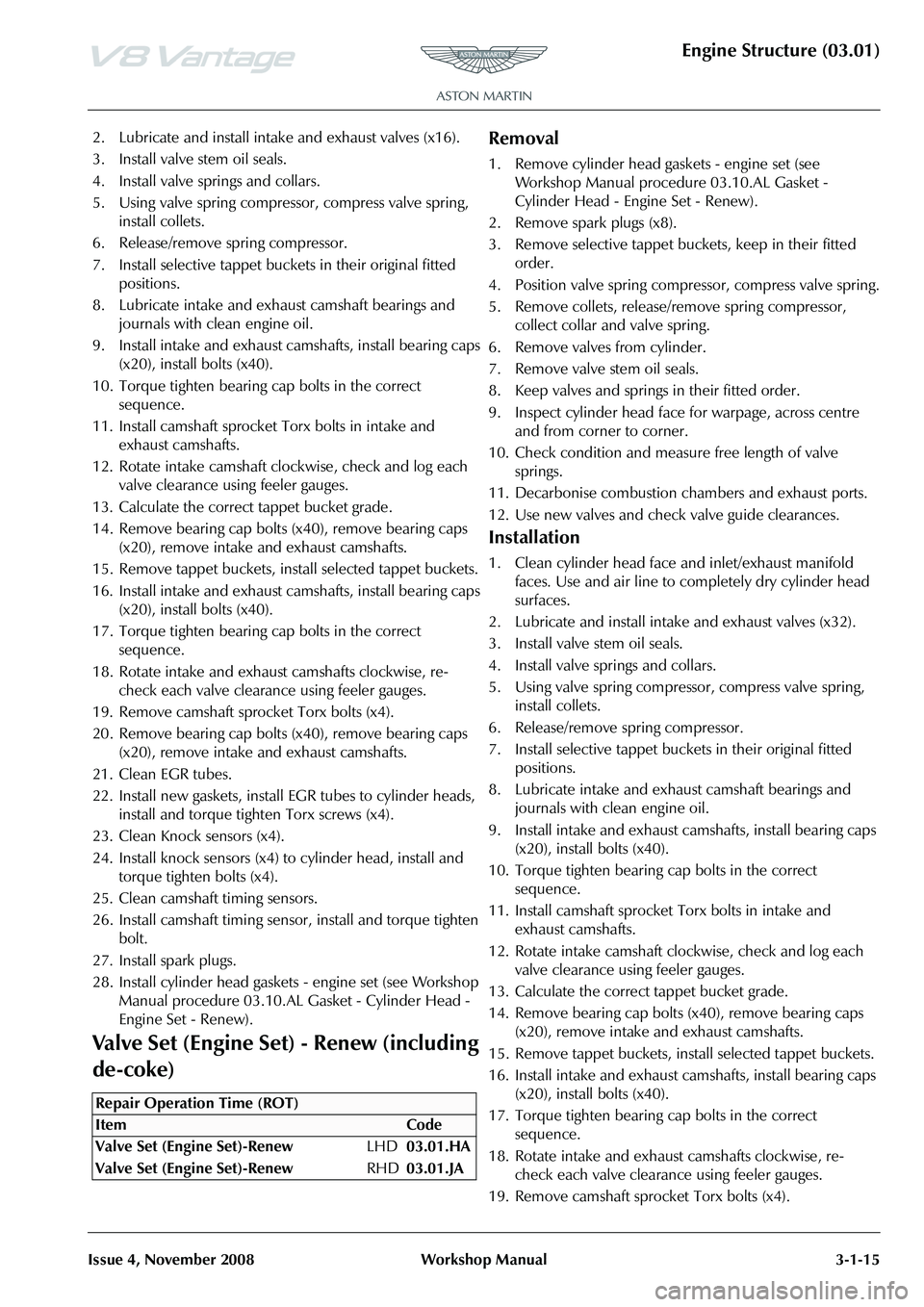

2. Lubricate and install intake and exhaust valves (x16).

3. Install valve stem oil seals.

4. Install valve springs and collars.

5. Using valve spring compressor, compress valve spring,

install collets.

6. Release/remove spring compressor.

7. Install selective tappet buckets in their original fitted positions.

8. Lubricate intake and exha ust camshaft bearings and

journals with clean engine oil.

9. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

10. Torque tighten bearing cap bolts in the correct sequence.

11. Install camshaft sprocket Torx bolts in intake and exhaust camshafts.

12. Rotate intake camshaft cl ockwise, check and log each

valve clearance using feeler gauges.

13. Calculate the correct tappet bucket grade.

14. Remove bearing cap bolts (x40), remove bearing caps

(x20), remove intake and exhaust camshafts.

15. Remove tappet buckets, install selected tappet buckets.

16. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

17. Torque tighten bearing cap bolts in the correct sequence.

18. Rotate intake and exhaus t camshafts clockwise, re-

check each valve clearance using feeler gauges.

19. Remove camshaft sprocket Torx bolts (x4).

20. Remove bearing cap bolts (x40), remove bearing caps

(x20), remove intake and exhaust camshafts.

21. Clean EGR tubes.

22. Install new gaskets, install EGR tubes to cylinder heads, install and torque tighten Torx screws (x4).

23. Clean Knock sensors (x4).

24. Install knock sensors (x4) to cylinder head, install and torque tighten bolts (x4).

25. Clean camshaft timing sensors.

26. Install camshaft timing sensor, install and torque tighten bolt.

27. Install spark plugs.

28. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

Valve Set (Engine Set) - Renew (including

de-coke)

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs (x8).

3. Remove selective tappet buckets, keep in their fitted order.

4. Position valve spring compressor, compress valve spring.

5. Remove collets, release/remove spring compressor, collect collar and valve spring.

6. Remove valves from cylinder.

7. Remove valve stem oil seals.

8. Keep valves and springs in their fitted order.

9. Inspect cylinder head face for warpage, across centre and from corner to corner.

10. Check condition and measure free length of valve springs.

11. Decarbonise combustion chambers and exhaust ports.

12. Use new valves and check valve guide clearances.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Lubricate and install intake and exhaust valves (x32).

3. Install valve stem oil seals.

4. Install valve springs and collars.

5. Using valve spring compressor, compress valve spring, install collets.

6. Release/remove spring compressor.

7. Install selective tappet buckets in their original fitted positions.

8. Lubricate intake and exhaust camshaft bearings and journals with clean engine oil.

9. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

10. Torque tighten bearing cap bolts in the correct sequence.

11. Install camshaft sprocket Torx bolts in intake and exhaust camshafts.

12. Rotate intake camshaft clockwise, check and log each valve clearance using feeler gauges.

13. Calculate the correct tappet bucket grade.

14. Remove bearing cap bolts (x40), remove bearing caps (x20), remove intake and exhaust camshafts.

15. Remove tappet buckets, install selected tappet buckets.

16. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

17. Torque tighten bearing cap bolts in the correct sequence.

18. Rotate intake and exhaust camshafts clockwise, re- check each valve clearance using feeler gauges.

19. Remove camshaft sprock et Torx bolts (x4).

Repair Operation Time (ROT)

Page 264 of 947

Engine Structure (03.01)

3-1-16Workshop ManualIssue 4, November 2008

20. Remove bearing cap bolts (x40), remove bearing caps

(x20), remove intake and exhaust camshafts.

21. Install spark plugs.

22. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

Inlet Valve (Set) - Renew

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs from cylinder head.

3. Remove intake selective tappet buckets from cylinder heads, keep in their fitted order.

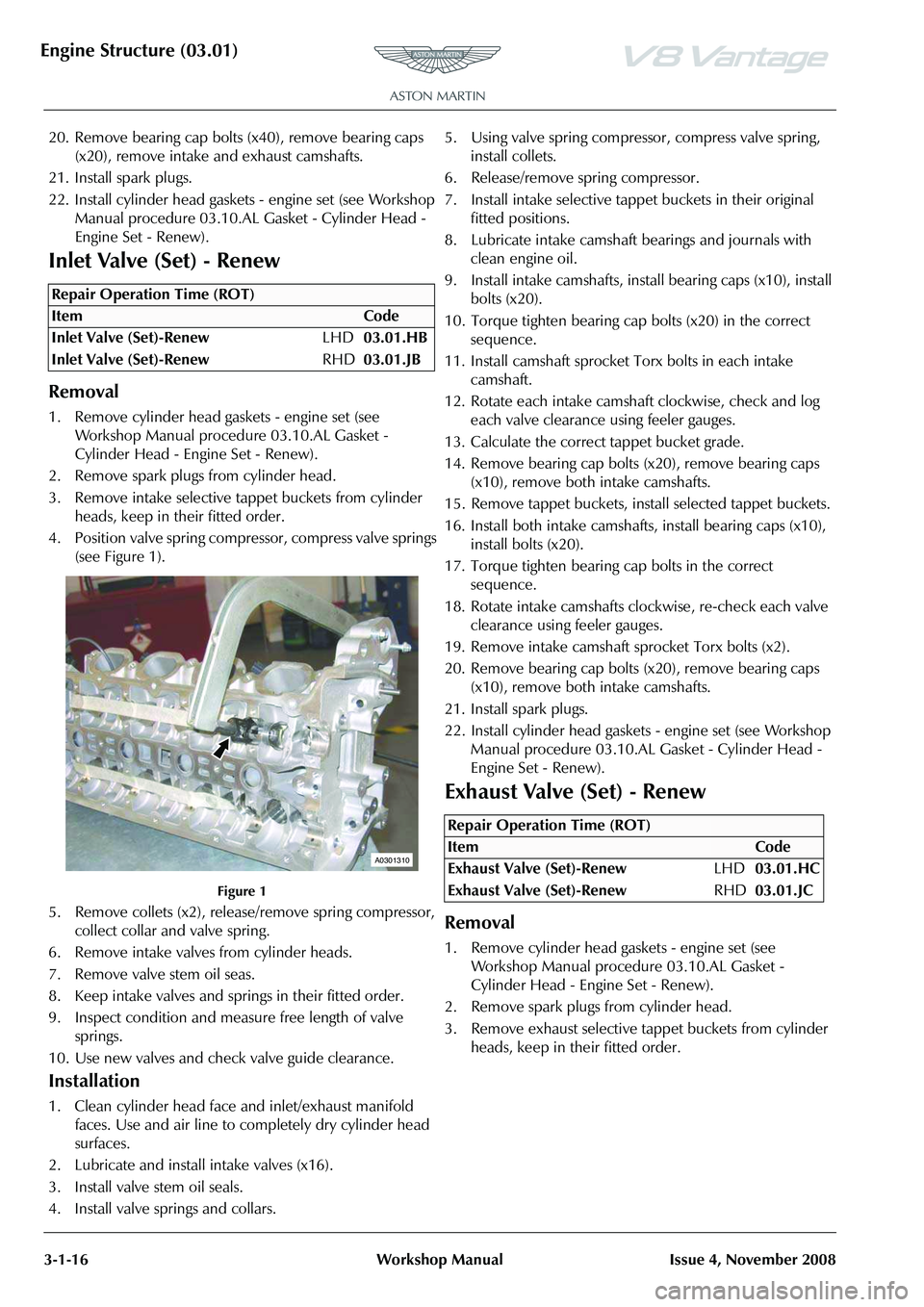

4. Position valve spring compressor, compress valve springs (see Figure 1).

Figure 1

5. Remove collets (x2), releas e/remove spring compressor,

collect collar and valve spring.

6. Remove intake valves from cylinder heads.

7. Remove valve stem oil seas.

8. Keep intake valves and springs in their fitted order.

9. Inspect condition and measure free length of valve springs.

10. Use new valves and check valve guide clearance.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Lubricate and install intake valves (x16).

3. Install valve stem oil seals.

4. Install valve springs and collars. 5. Using valve spring compressor, compress valve spring,

install collets.

6. Release/remove spring compressor.

7. Install intake selective tappet buckets in their original fitted positions.

8. Lubricate intake camshaft bearings and journals with clean engine oil.

9. Install intake camshafts, inst all bearing caps (x10), install

bolts (x20).

10. Torque tighten bearing cap bolts (x20) in the correct sequence.

11. Install camshaft sprocket Torx bolts in each intake

camshaft.

12. Rotate each intake camshaft clockwise, check and log each valve clearance using feeler gauges.

13. Calculate the correct tappet bucket grade.

14. Remove bearing cap bolts (x20), remove bearing caps (x10), remove both intake camshafts.

15. Remove tappet buckets, install selected tappet buckets.

16. Install both intake camshaf ts, install bearing caps (x10),

install bolts (x20).

17. Torque tighten bearing cap bolts in the correct sequence.

18. Rotate intake camshafts clockwise, re-check each valve clearance using feeler gauges.

19. Remove intake camshaft sp rocket Torx bolts (x2).

20. Remove bearing cap bolts (x20), remove bearing caps (x10), remove both intake camshafts.

21. Install spark plugs.

22. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

Exhaust Valve (Set) - Renew

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs from cylinder head.

3. Remove exhaust selective tappet buckets from cylinder heads, keep in their fitted order.

Repair Operation Time (ROT)

A0301310

Repair Operation Time (ROT)

ItemCode

Exhaust Valve (Set)-Renew LHD03.01.HC

Exhaust Valve (Set)-Renew RHD03.01.JC

Page 265 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-17

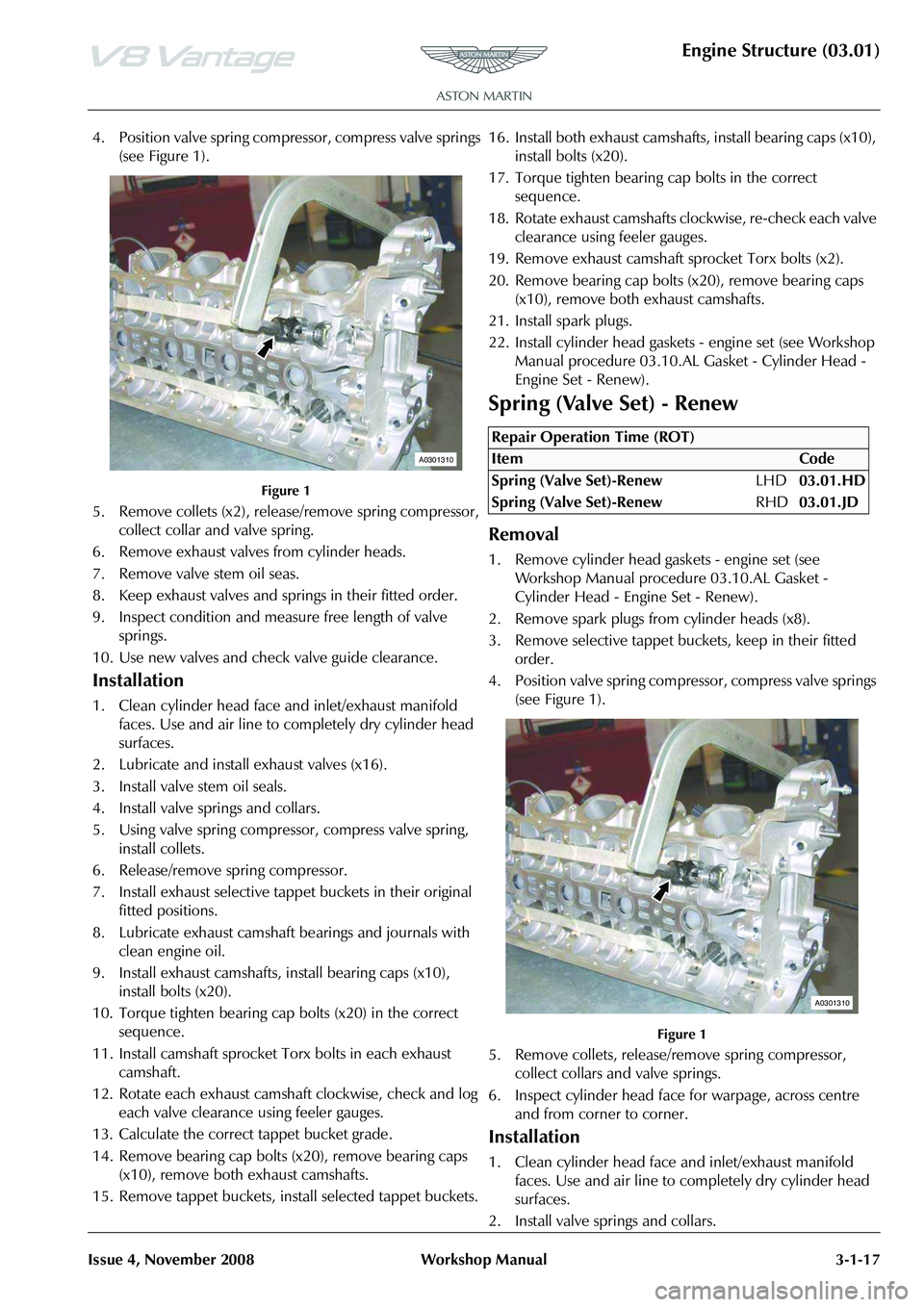

4. Position valve spring compressor, compress valve springs

(see Figure 1).

Figure 1

5. Remove collets (x2), release/remove spring compressor, collect collar and valve spring.

6. Remove exhaust valves from cylinder heads.

7. Remove valve stem oil seas.

8. Keep exhaust valves and springs in their fitted order.

9. Inspect condition and measure free length of valve springs.

10. Use new valves and check valve guide clearance.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Lubricate and install exhaust valves (x16).

3. Install valve stem oil seals.

4. Install valve springs and collars.

5. Using valve spring compressor, compress valve spring, install collets.

6. Release/remove spring compressor.

7. Install exhaust selective tappet buckets in their original fitted positions.

8. Lubricate exhaust camshaft be arings and journals with

clean engine oil.

9. Install exhaust camshafts, install bearing caps (x10), install bolts (x20).

10. Torque tighten bearing cap bolts (x20) in the correct

sequence.

11. Install camshaft sprocket Torx bolts in each exhaust camshaft.

12. Rotate each exhaust camshaf t clockwise, check and log

each valve clearance using feeler gauges.

13. Calculate the correct tappet bucket grade.

14. Remove bearing cap bolts (x20), remove bearing caps

(x10), remove both exhaust camshafts.

15. Remove tappet buckets, install selected tappet buckets. 16. Install both exhaust camshaft

s, install bearing caps (x10),

install bolts (x20).

17. Torque tighten bearing cap bolts in the correct sequence.

18. Rotate exhaust camshafts clockwise, re-check each valve clearance using feeler gauges.

19. Remove exhaust camshaft sprocket Torx bolts (x2).

20. Remove bearing cap bolts (x20), remove bearing caps (x10), remove both exhaust camshafts.

21. Install spark plugs.

22. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

Spring (Valve Set) - Renew

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs from cylinder heads (x8).

3. Remove selective tappet buckets, keep in their fitted order.

4. Position valve spring compressor, compress valve springs (see Figure 1).

Figure 1

5. Remove collets, release/remove spring compressor, collect collars and valve springs.

6. Inspect cylinder head face for warpage, across centre and from corner to corner.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Install valve springs and collars.

A0301310

Repair Operation Time (ROT)

A0301310

Page 266 of 947

Engine Structure (03.01)

3-1-18Workshop ManualIssue 4, November 2008

3. Using valve spring compressor, compress valve spring,

install collets.

4. Release/remove spring compressor.

5. Install selective tappet buckets in their original fitted positions.

6. Lubricate intake and exhaust camshaft bearings and journals with clean engine oil.

7. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

8. Torque tighten bearing cap bolts in the correct sequence.

9. Install camshaft sprocket Torx bolts in intake and exhaust camshafts.

10. Rotate intake camshaft clockwise, check and log each valve clearance using feeler gauges.

11. Calculate the correct tappet bucket grade.

12. Remove bearing cap bolts (x40), remove bearing caps (x20), remove intake and exhaust camshafts.

13. Remove tappet buckets, install selected tappet buckets.

14. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

15. Torque tighten bearing cap bolts in the correct sequence.

16. Rotate intake and exhaust camshafts clockwise, re- check each valve clearance using feeler gauges.

17. Remove camshaft sprocket Torx bolts (x4).

18. Remove bearing cap bolts (x40), remove bearing caps (x20), remove intake and exhaust camshafts.

19. Install spark plugs.

20. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

Spring (Inlet Valve Set) - Renew

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs from cylinder heads (x8).

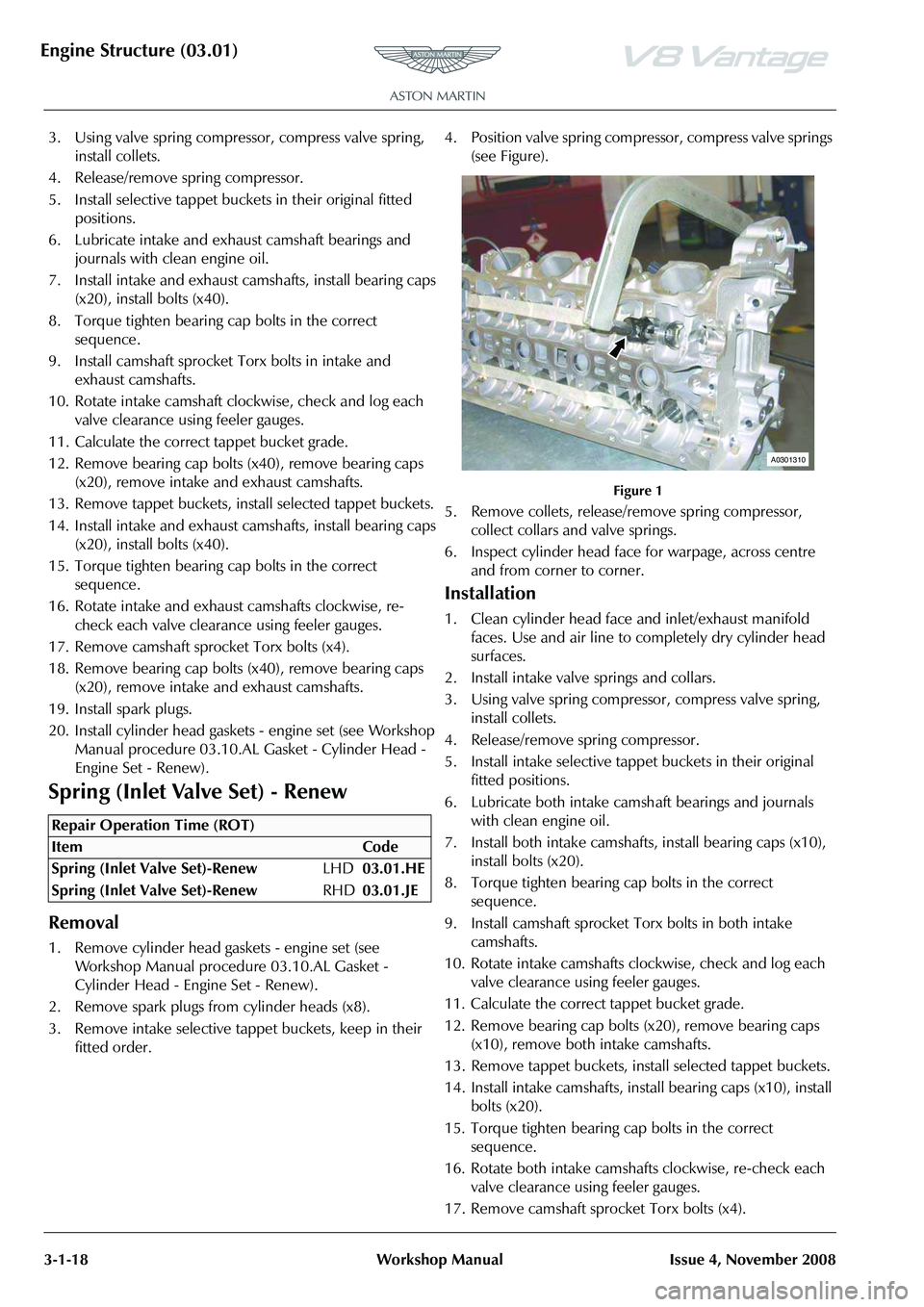

3. Remove intake selective tappet buckets, keep in their fitted order. 4. Position valve spring compressor, compress valve springs

(see Figure).

Figure 1

5. Remove collets, release/remove spring compressor, collect collars and valve springs.

6. Inspect cylinder head face for warpage, across centre and from corner to corner.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Install intake valve springs and collars.

3. Using valve spring compressor, compress valve spring, install collets.

4. Release/remove spring compressor.

5. Install intake selective tappet buckets in their original fitted positions.

6. Lubricate both intake camsh aft bearings and journals

with clean engine oil.

7. Install both intake camshafts, install bearing caps (x10), install bolts (x20).

8. Torque tighten bearing cap bolts in the correct sequence.

9. Install camshaft sprocket Torx bolts in both intake camshafts.

10. Rotate intake camshafts clockwise, check and log each valve clearance using feeler gauges.

11. Calculate the correct tappet bucket grade.

12. Remove bearing cap bolts (x20), remove bearing caps (x10), remove both intake camshafts.

13. Remove tappet buckets, install selected tappet buckets.

14. Install intake camshafts, inst all bearing caps (x10), install

bolts (x20).

15. Torque tighten bearing cap bolts in the correct sequence.

16. Rotate both intake camshafts clockwise, re-check each valve clearance using feeler gauges.

17. Remove camshaft sprocket Torx bolts (x4).

Repair Operation Time (ROT)

A0301310