torque ASTON MARTIN V8 VANTAGE 2010 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 267 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-19

18. Remove bearing cap bolts (x20), remove bearing caps

(x10), remove both intake camshafts.

19. Install spark plugs.

20. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

Inlet and Exhaust Valve Seal (Engine Set)

- Renew

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs (x8).

3. Remove selective tappet buckets, keep in their fitted order.

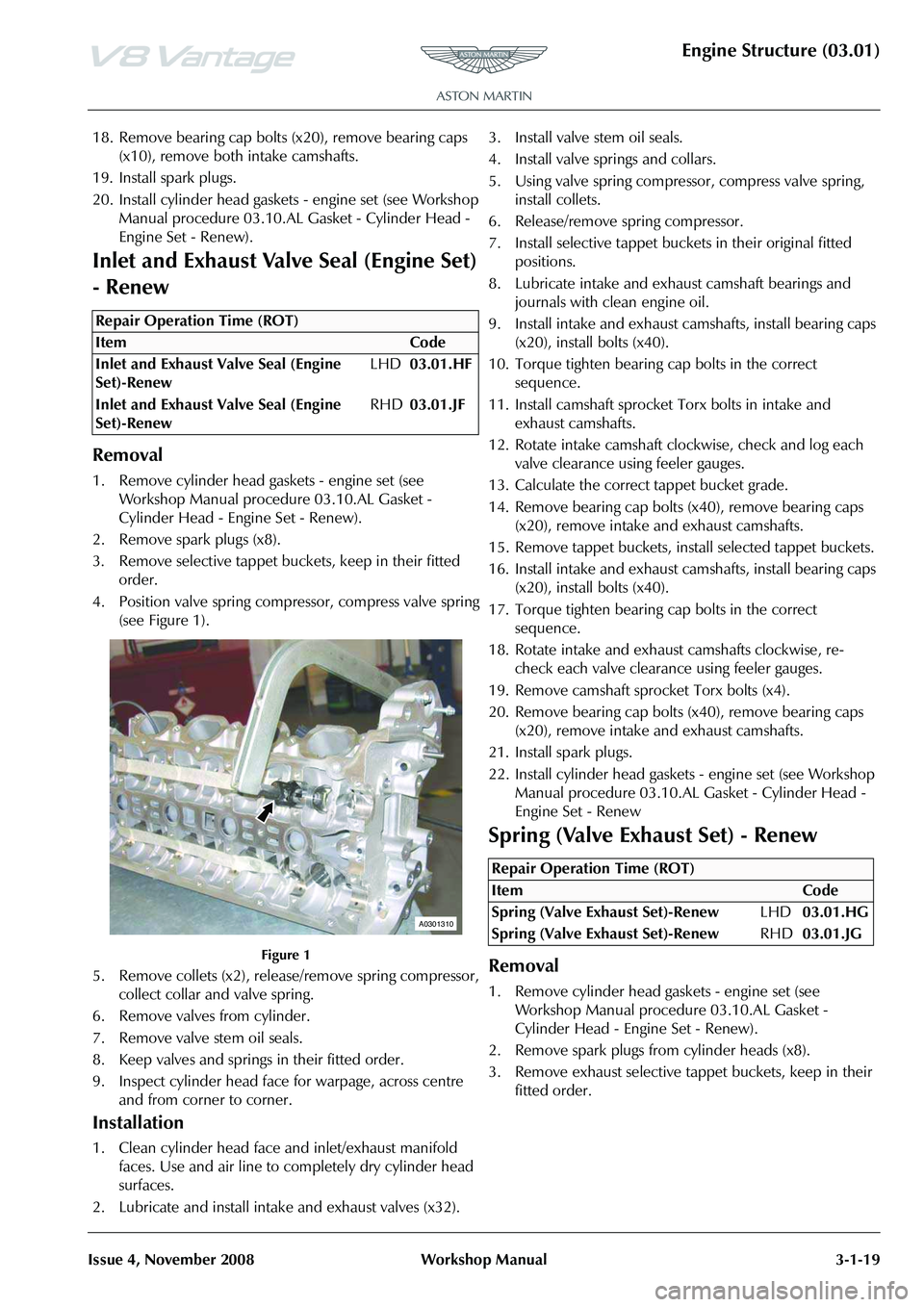

4. Position valve spring compressor, compress valve spring (see Figure 1).

Figure 1

5. Remove collets (x2), release/remove spring compressor, collect collar and valve spring.

6. Remove valves from cylinder.

7. Remove valve stem oil seals.

8. Keep valves and springs in their fitted order.

9. Inspect cylinder head face for warpage, across centre and from corner to corner.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Lubricate and install intake and exhaust valves (x32). 3. Install valve stem oil seals.

4. Install valve springs and collars.

5. Using valve spring compressor, compress valve spring,

install collets.

6. Release/remove spring compressor.

7. Install selective tappet buckets in their original fitted positions.

8. Lubricate intake and exhaust camshaft bearings and journals with clean engine oil.

9. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

10. Torque tighten bearing cap bolts in the correct sequence.

11. Install camshaft sprocket Torx bolts in intake and exhaust camshafts.

12. Rotate intake camshaft clockwise, check and log each valve clearance using feeler gauges.

13. Calculate the correct tappet bucket grade.

14. Remove bearing cap bolts (x40), remove bearing caps (x20), remove intake and exhaust camshafts.

15. Remove tappet buckets, install selected tappet buckets.

16. Install intake and exhaust camshafts, install bearing caps (x20), install bolts (x40).

17. Torque tighten bearing cap bolts in the correct sequence.

18. Rotate intake and exhaust camshafts clockwise, re- check each valve clearance using feeler gauges.

19. Remove camshaft sprock et Torx bolts (x4).

20. Remove bearing cap bolts (x40), remove bearing caps (x20), remove intake and exhaust camshafts.

21. Install spark plugs.

22. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew

Spring (Valve Exhaust Set) - Renew

Removal

1. Remove cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket -

Cylinder Head - Engine Set - Renew).

2. Remove spark plugs from cylinder heads (x8).

3. Remove exhaust selective tappet buckets, keep in their fitted order.

Repair Operation Time (ROT)

A0301310

Repair Operation Time (ROT)

Page 268 of 947

Engine Structure (03.01)

3-1-20Workshop ManualIssue 4, November 2008

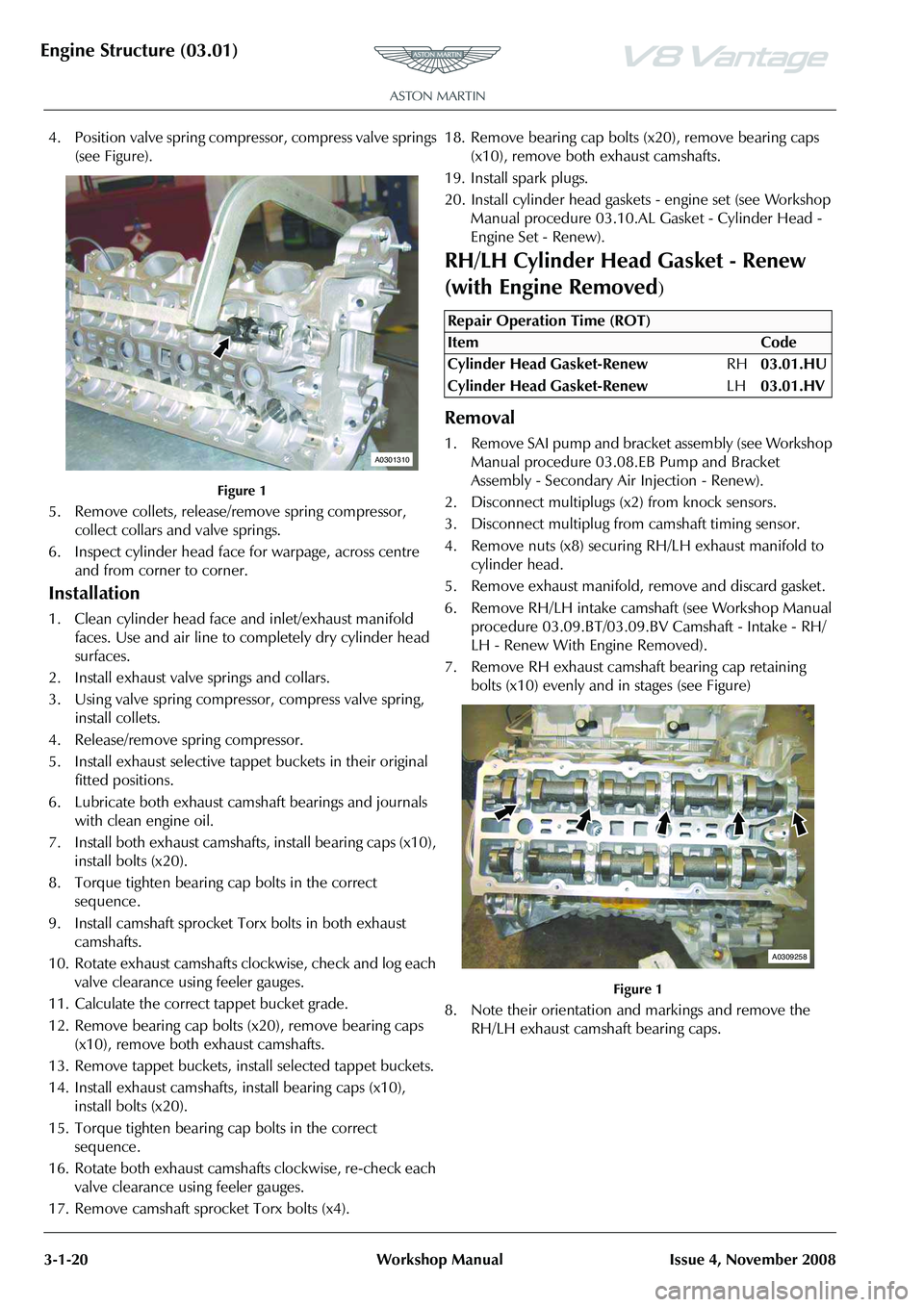

4. Position valve spring compressor, compress valve springs

(see Figure).

Figure 1

5. Remove collets, release/re move spring compressor,

collect collars and valve springs.

6. Inspect cylinder head face for warpage, across centre and from corner to corner.

Installation

1. Clean cylinder head face and inlet/exhaust manifold faces. Use and air line to completely dry cylinder head

surfaces.

2. Install exhaust valve springs and collars.

3. Using valve spring compressor, compress valve spring, install collets.

4. Release/remove spring compressor.

5. Install exhaust selective tappet buckets in their original fitted positions.

6. Lubricate both exhaust camshaft bearings and journals with clean engine oil.

7. Install both exhaust camshafts , install bearing caps (x10),

install bolts (x20).

8. Torque tighten bearing cap bolts in the correct sequence.

9. Install camshaft sprocket Torx bolts in both exhaust camshafts.

10. Rotate exhaust camshafts clockwise, check and log each valve clearance using feeler gauges.

11. Calculate the correct tappet bucket grade.

12. Remove bearing cap bolts (x20), remove bearing caps (x10), remove both exhaust camshafts.

13. Remove tappet buckets, install selected tappet buckets.

14. Install exhaust camshafts, install bearing caps (x10), install bolts (x20).

15. Torque tighten bearing cap bolts in the correct sequence.

16. Rotate both exhaust camshafts clockwise, re-check each valve clearance using feeler gauges.

17. Remove camshaft sprocket Torx bolts (x4). 18. Remove bearing cap bolts (x20), remove bearing caps

(x10), remove both exhaust camshafts.

19. Install spark plugs.

20. Install cylinder head gaskets - engine set (see Workshop Manual procedure 03.10.AL Gasket - Cylinder Head -

Engine Set - Renew).

RH/LH Cylinder Head Gasket - Renew

(with Engine Removed

)

Removal

1. Remove SAI pump and bracket assembly (see Workshop Manual procedure 03.08. EB Pump and Bracket

Assembly - Secondary Ai r Injection - Renew).

2. Disconnect multiplugs (x2) from knock sensors.

3. Disconnect multiplug from camshaft timing sensor.

4. Remove nuts (x8) securing RH/LH exhaust manifold to

cylinder head.

5. Remove exhaust manifold, remove and discard gasket.

6. Remove RH/LH intake camshaft (see Workshop Manual procedure 03.09.BT/03.09.BV Camshaft - Intake - RH/

LH - Renew With Engine Removed).

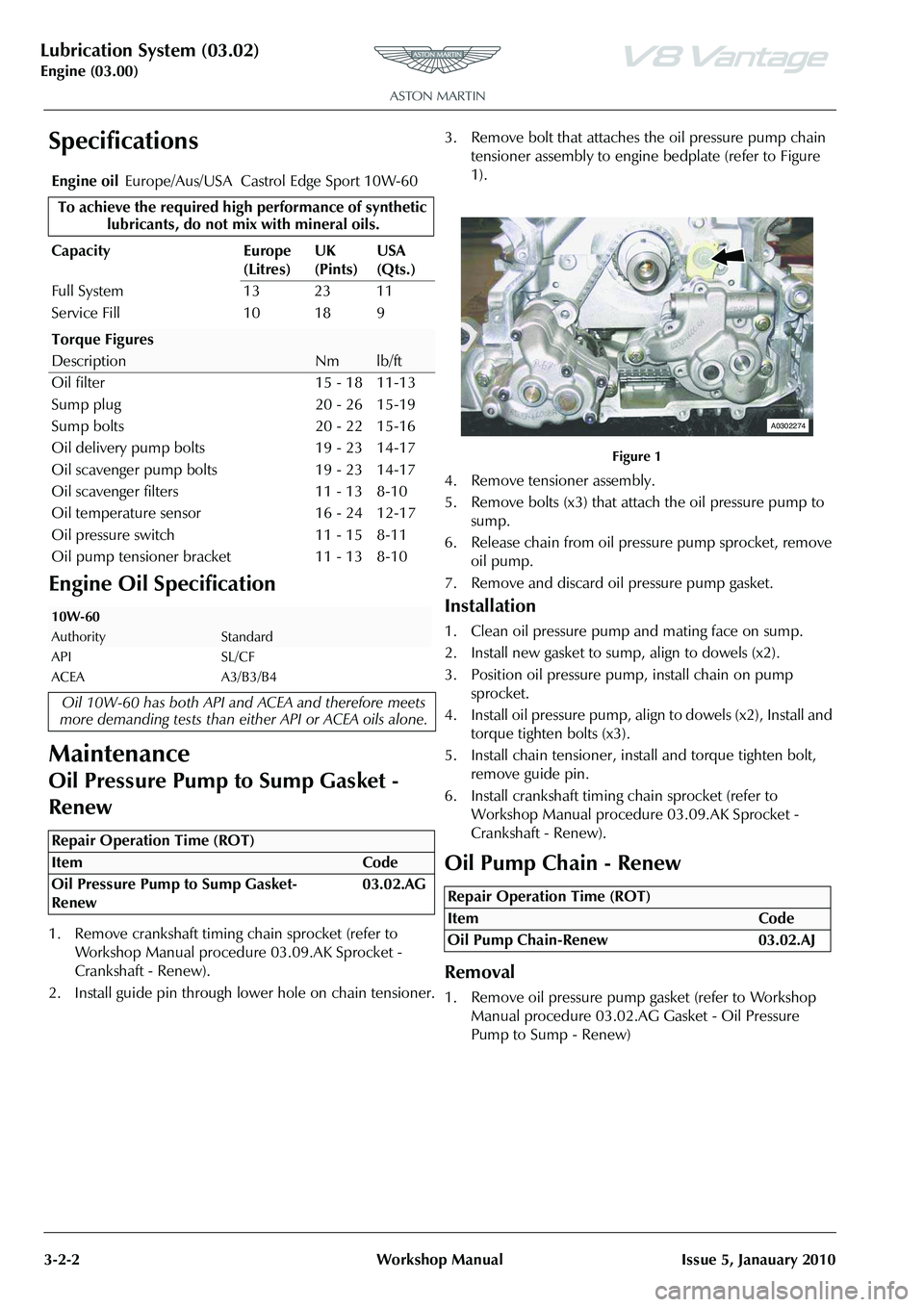

7. Remove RH exhaust camshaft bearing cap retaining bolts (x10) evenly and in stages (see Figure)

Figure 1

8. Note their orientation and markings and remove the RH/LH exhaust camshaft bearing caps.

A0301310

Repair Operation Time (ROT)

ItemCode

Cylinder Head Gasket-Renew RH03.01.HU

Cylinder Head Gasket-Renew LH03.01.HV

A0309258

Page 269 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-21

9. Remove RH/LH exhaust camshaft (see Figure 2).

Figure 2

10. Remove bolts (x2) securing front end of RH/LH cylinder

head to cylinder block.

11. Remove bolts (x10), evenly and in stages securing RH/ LH cylinder head to cylinder block (see Figure 3).

Figure 3

12. With assistance, remove RH /LH cylinder head assembly.

13. Remove and discard cylinder head gasket.

Installation

1. Thoroughly clean RH/LH cylinder head face and retaining bolt pockets.

2. Thoroughly clean RH/LH cylinder block face.

3. Thoroughly clean and dry RH cylinder head retaining

bolts.

4. Install new RH/LH cylinder gasket, locate on dowels.

5. With assistance, install RH/LH cylinder head, locate on dowels.

6. Install and torque tighten cylinder head bolts (x12) in the correct sequence.

7. Lubricate RH exhaust camsha ft journals, camshaft lobes,

bearing surfaces on cylinder head and bearing caps with

clean engine oil.

8. Install RH exhaust camshaft, install bearing caps (x5) in their original positions.

9. Install bolts (x10) and torque tighten in the sequence specified.

10. Install sprocket retaining Torx bolt in camshaft. 11. Rotate camshaft accordingly and check each valve

clearance using feeler gauges.

12. Remove sprocket retaining Torx bolt.

13. Install RH intake camsha ft (see Workshop Manual

procedure (03.09.BT/03.09.BV) Camshaft - Intake - RH/

LH - Renew With Engine Removed).

14. Install timing chain tensioni ng tool (303-532) into RH/

LH exhaust camshaft sprocket.

15. Apply a force to the tool (3 03-532) in an anti-clockwise

direction and torque tighten RH/LH sprocket Torx bolts.

Remove special tool.

16. Connect multiplug to camshaft timing sensor.

17. Connect multiplugs (x2) to knock sensors.

18. Clean RH/LH exhaust manifold.

19. Install new RH/LH exhaust manifold gasket, install exhaust manifold.

20. Install and torque tighten RH/LH exhaust manifold nuts (x8).

21. Install SAI pump and bracket assembly (see Workshop Manual procedure 03.08. EB Pump and Bracket

Assembly - Secondary Air Injection - Renew).

Cylinder Head Gasket (Engine Set) -

Renew (with Engine Removed)

Removal

1. Remove SAI pump and bracke t assembly (see Workshop

Manual procedure 03.08.EB Pump and Bracket

Assembly - Secondary Air Injection - Renew).

2. Disconnect multiplugs (x4) from LH and RH knock sensors.

3. Disconnect multiplugs (x2) from LH and RH camshaft

timing sensors.

4. Remove nuts (x8) securing LH exhaust manifold to cylinder head.

5. Remove LH exhaust manifold, remove and discard gasket.

6. Remove LH intake camshaft (see Workshop Manual procedure 03.09.BV Camshaft - Intake - LH - Renew

With Engine Removed).

A0309260

A0310319

Repair Operation Time (ROT)

Page 272 of 947

Engine Structure (03.01)

3-1-24Workshop ManualIssue 4, November 2008

23. Remove RH exhaust camshaft bearing cap retaining

bolts (x10) evenly and in stages (see Figure 10).

Figure 10

24. Note their orientation and markings and remove the RH exhaust camshaft bearing caps.

25. Remove RH exhaust camshaft (see Figure 11).

Figure 11

26. Remove bolts (x2) securing front end of RH cylinder head to cylinder block.

27. Remove bolts (x10), evenly and in stages securing RH cylinder head to cylinder block (see Figure 12).

Figure 12

28. With assistance, remove RH cylinder head assembly.

29. Remove and discard cylinder head gasket.

Installation

1. Thoroughly clean LH and RH cylinder head faces and retaining bolt pockets.

2. Thoroughly clean LH and RH cylinder block faces.

3. Thoroughly clean and dry LH and RH cylinder head retaining bolts.

4. Install new RH cylinder gasket, locate on dowels.

5. With assistance, install RH cylinder head, locate on dowels.

6. Install and torque tighten cylinder head bolts (x12) in the correct sequence.

7. Lubricate camshaft journals , camshaft lobes, bearing

surfaces on cylinder head and bearing caps with clean

engine oil.

8. Install RH exhaust camshaft, install bearing caps (x5) in their original positions.

9. Install bolts (x10) and torque tighten in the sequence specified.

10. Install sprocket retaining Torx bolt in camshaft.

11. Rotate camshaft accordingly and check each valve clearance using feeler gauges.

12. Repeat procedure and install RH intake camshaft.

13. Remove sprocket retaining Torx bolt.

14. Rotate RH intake and exhaust camshafts until timing flats on each camshaft face uppermost.

15. Install tool (303-530) to RH cylinder head to secure camshafts, install and tighten bolts (x3).

16. Install new LH cylinder gasket, locate on dowels.

17. With assistance, install LH cylinder head, locate on dowels.

18. Install and torque tighten cylinder head bolts (x12) in the correct sequence.

19. Lubricate LH exhaust camshaf t journals, camshaft lobes,

bearing surfaces on cylinder head and bearing caps with

clean engine oil.

20. Install LH exhaust camshaft, install bearing caps (x5) in their original positions.

21. Install bolts (x10) and torque tighten in the sequence specified.

22. Install sprocket retaining Torx bolt in LH exhaust camshaft.

23. Rotate LH exhaust camshaft accordingly and check each valve clearance using feeler gauges.

24. Remove sprocket retaining Torx bolt.

25. Install LH intake camshaft (see Workshop Manual procedure 03.09.BV Camshaft - Intake - LH - Renew

With Engine Removed).

26. Install timing chain tensio ning tool (303-532) into RH

exhaust camshaft sprocket.

27. Apply a force to the tool (303-532) in an anti-clockwise direction and torque tighten RH sprocket Torx bolts.

Remove special tool.

28. Connect multiplugs to LH and RH camshaft timing sensors.

A0309258

A0309260

A0310319

Page 273 of 947

Engine Structure (03.01)

Issue 4, November 2008Workshop Manual 3-1-25

29. Connect multiplugs (x4) to LH and RH knock sensors.

30. Install SAI pump and bracket assembly (see Workshop

Manual procedure 03.08.EB Pump and Bracket

Assembly - Secondary Air Injection - Renew).

31. Clean LH and RH exhaust manifolds.

32. Install new LH and RH exhaust manifold gaskets.

33. Install LH and RH exhaust ma nifolds, install and torque

tighten nuts (x16).

Page 276 of 947

Lubrication System (03.02)

Engine (03.00)3-2-2 Workshop Manual Issue 5, Janauary 2010

Specifications

Engine Oil Specification

Maintenance

Oil Pressure Pump to Sump Gasket -

Renew

1. Remove crankshaft timing chain sprocket (refer to Workshop Manual procedure 03.09.AK Sprocket -

Crankshaft - Renew).

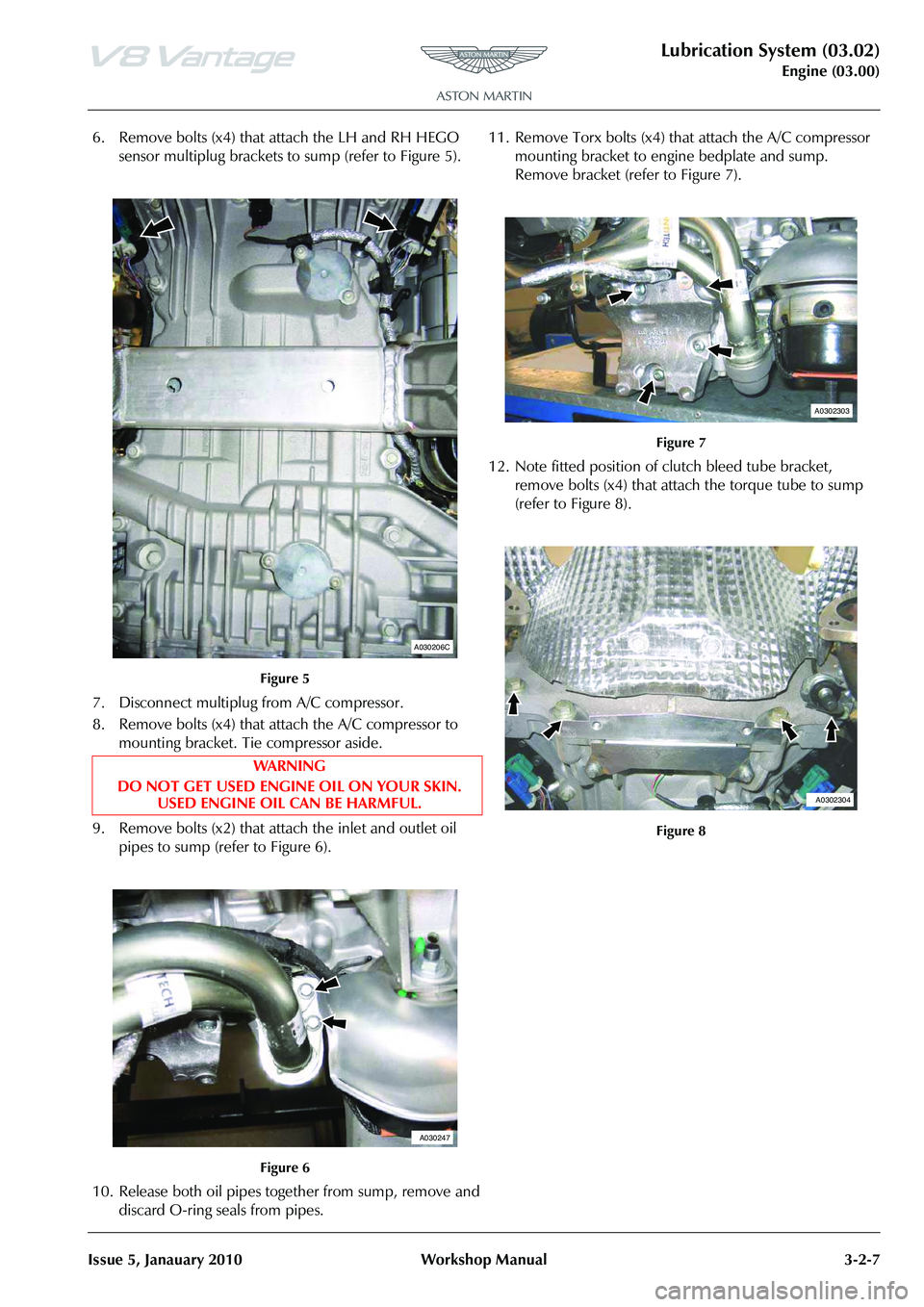

2. Install guide pin through lower hole on chain tensioner. 3. Remove bolt that attaches

the oil pressure pump chain

tensioner assembly to engine bedplate (refer to Figure

1).

4. Remove tensioner assembly.

5. Remove bolts (x3) that attach the oil pressure pump to sump.

6. Release chain from oil pres sure pump sprocket, remove

oil pump.

7. Remove and discard oil pressure pump gasket.

Installation

1. Clean oil pressure pump and mating face on sump.

2. Install new gasket to sump, align to dowels (x2).

3. Position oil pressure pump, install chain on pump sprocket.

4. Install oil pressure pump, align to dowels (x2), Install and torque tighten bolts (x3).

5. Install chain tensioner, install and torque tighten bolt, remove guide pin.

6. Install crankshaft timing chain sprocket (refer to Workshop Manual procedure 03.09.AK Sprocket -

Crankshaft - Renew).

Oil Pump Chain - Renew

Removal

1. Remove oil pressure pump gasket (refer to Workshop Manual procedure 03.02.AG Gasket - Oil Pressure

Pump to Sump - Renew)

Engine oil

Europe/Aus/USA Castrol Edge Sport 10W-60

To achieve the required high performance of synthetic

lubricants, do not mi x with mineral oils.

Capacity Europe (Litres)UK

(Pints)USA

(Qts.)

Full System 13 23 11

Service Fill 10 18 9

Torque Figures

DescriptionNmlb/ft

Oil filter 15 - 18 11-13

Sump plug 20 - 26 15-19

Sump bolts 20 - 22 15-16

Oil delivery pump bolts 19 - 23 14-17

Oil scavenger pump bolts 19 - 23 14-17

Oil scavenger filters 11 - 13 8-10

Oil temperature sensor 16 - 24 12-17

Oil pressure switch 11 - 15 8-11

Oil pump tensioner bracket 11 - 13 8-10

10W-60

AuthorityStandard

API SL/CF

ACEA A3/B3/B4

Oil 10W-60 has both API and ACEA and therefore meets

more demanding tests than eith er API or ACEA oils alone.

Repair Operation Time (ROT)

Figure 1

Repair Operation Time (ROT)

ItemCode

Oil Pump Chain-Renew 03.02.AJ

A0302274

Page 277 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-3

2. Remove bolts (x3) that attach the oil scavenge pump to sump (refer to Figure 1).

3. Remove oil scavenge pump, remove and discard gasket (refer to Figure 2).

4. Release chain from oil pu mp drive sprocket, remove

chain (refer to Figure 3).Installation

1. Clean oil scavenge pump and mating face on sump.

2. Install new oil scavenge pump gasket, align on dowels (x2).

3. Install chain onto oil scavenge pump sprocket.

4. Install oil scavenge pump, align to dowels (x2), Install and torque tighten bolts (x3).

5. Install chain onto oil pump drive sprocket.

6. Install oil pressure pump gasket (refer to Workshop

Manual procedure 03.02.AG Gasket - Oil Pressure

Pump to Sump - Renew).

Oil Sump Pan - Renew

Removal

1. Remove oil sump (refer to Workshop Manual procedure

03.02.BN Pan - Oil Sump - Remove and Reseal).

2. Remove bolt that attach the crankshaft timing sensor, remove sensor (refer to Figure 1).

Figure 1

Figure 2

Figure 3

A0302274

A0302276

Repair Operation Time (ROT)

A0302305

Page 279 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-5

8. Press out alternator mounting bushes (x2) from sump (refer to Figure 7).

9. Remove dowels (x4) from sump for oil pressure and scavenge pumps location (refer to Figure 8). 10. Remove Torx screws (x2) that attach the oil pump(s)

chain guide, remove chain gu ide (refer to Figure 9).

11. Remove oil plug from sump.

Installation

1. Clean chain guide, oil filter adaptor, filters (x2), sump plug , pump(s) dowels and crankshaft timing sensor.

2. Install alternator bushes.

3. Install oil filter adaptor.

4. Install filters (x2), install oil filter plates (x2), install and

torque tighten Torx screws (x4).

5. Install oil plug.

6. Install oil pump(s) dowels (x4).

7. Clean old sealant from sensor threads (x2).

8. Apply sealant to engine electric coolant temperature sensor threads, install and torque tighten sensor.

9. Apply sealant to oil pressure sensor threads, install and torque tighten sensor.

10. Install oil pump(s) chain guid e, Install and torque tighten

Torx screws (x2).

11. Install crankshaft timing sensor, install and torque tighten bolt.

12. Install oil sump (refer to Workshop Manual procedure 03.02.BN Pan - Oil Sump - Remove and Reseal).

Oil Sump Pan - Remove and Reseal

Removal

1. Remove oil pump(s) drive chain (refer to Workshop Manual procedure 03.02.AJ Chain - Oil Pump - Renew).

Figure 7

Figure 8

A030206C

A0302307

Figure 9

Repair Operation Time (ROT)

A0302307A

Page 281 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-7

6. Remove bolts (x4) that attach the LH and RH HEGO sensor multiplug brackets to sump (refer to Figure 5).

7. Disconnect multiplug from A/C compressor.

8. Remove bolts (x4) that attach the A/C compressor to mounting bracket. Tie compressor aside.

9. Remove bolts (x2) that attach the inlet and outlet oil pipes to sump (refer to Figure 6).

10. Release both oil pipes toge ther from sump, remove and

discard O-ring seals from pipes. 11. Remove Torx bolts (x4) that attach the A/C compressor

mounting bracket to engine bedplate and sump.

Remove bracket (refer to Figure 7).

12. Note fitted position of clutch bleed tube bracket, remove bolts (x4) that attach the torque tube to sump

(refer to Figure 8).

Figure 5

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Figure 6

A030206C

A030247

Figure 7

Figure 8

A0302303

A0302304

Page 282 of 947

Lubrication System (03.02)

Engine (03.00)3-2-8 Workshop Manual Issue 5, Janauary 2010

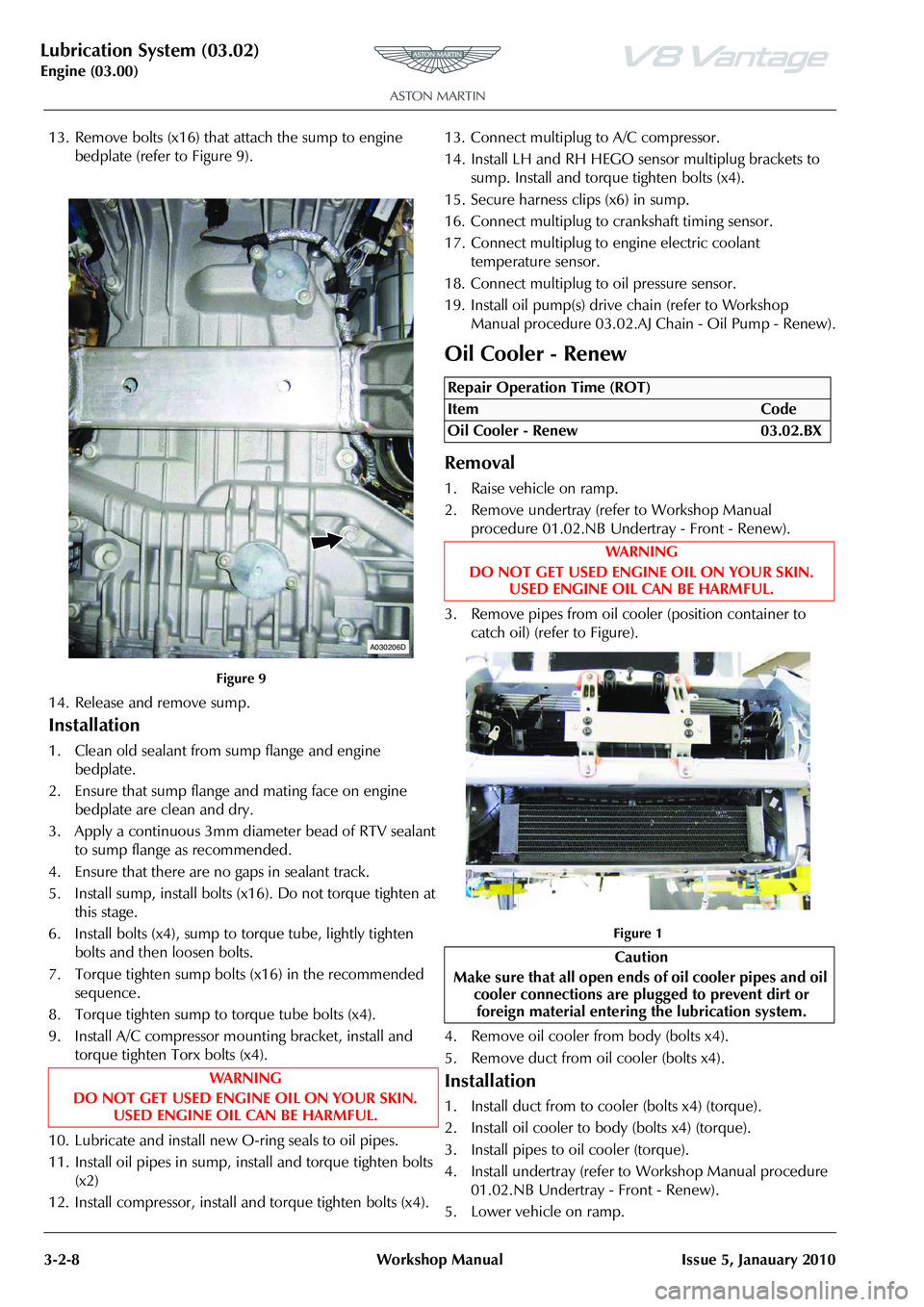

13. Remove bolts (x16) that attach the sump to engine bedplate (refer to Figure 9).

14. Release and remove sump.

Installation

1. Clean old sealant from sump flange and engine bedplate.

2. Ensure that sump flange and mating face on engine bedplate are clean and dry.

3. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

4. Ensure that there are no gaps in sealant track.

5. Install sump, install bolts (x16). Do not torque tighten at this stage.

6. Install bolts (x4), sump to torque tube, lightly tighten bolts and then loosen bolts.

7. Torque tighten sump bolts (x16) in the recommended sequence.

8. Torque tighten sump to torque tube bolts (x4).

9. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

10. Lubricate and install new O-ring seals to oil pipes.

11. Install oil pipes in sump, install and torque tighten bolts (x2)

12. Install compressor, install and torque tighten bolts (x4). 13. Connect multiplug to A/C compressor.

14. Install LH and RH HEGO

sensor multiplug brackets to

sump. Install and torque tighten bolts (x4).

15. Secure harness clips (x6) in sump.

16. Connect multiplug to crankshaft timing sensor.

17. Connect multiplug to engine electric coolant temperature sensor.

18. Connect multiplug to oil pressure sensor.

19. Install oil pump(s) drive chain (refer to Workshop

Manual procedure 03.02.AJ Chain - Oil Pump - Renew).

Oil Cooler - Renew

Removal

1. Raise vehicle on ramp.

2. Remove undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Remove pipes from oil cooler (position container to catch oil) (refer to Figure).

Figure 1

4. Remove oil cooler from body (bolts x4).

5. Remove duct from oil cooler (bolts x4).

Installation

1. Install duct from to cooler (bolts x4) (torque).

2. Install oil cooler to body (bolts x4) (torque).

3. Install pipes to oil cooler (torque).

4. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

5. Lower vehicle on ramp.

Figure 9

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

A030206D

Repair Operation Time (ROT)

ItemCode

Oil Cooler - Renew 03.02.BX

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Make sure that all open ends of oil cooler pipes and oil cooler connections are plugged to prevent dirt or

foreign material entering the lubrication system.