AUDI RS7 SPORTBACK 2016 Owners Manual

Manufacturer: AUDI, Model Year: 2016, Model line: RS7 SPORTBACK, Model: AUDI RS7 SPORTBACK 2016Pages: 282, PDF Size: 70.78 MB

Page 241 of 282

Emergency assistance

Equipment

Warning triangle

Applies to: ve hicles with warning triangle

D

Fig. 196 Luggage co mpa rtment lid : w arnin g tria ngle

The warning triangle placed in the vehicle at the

factory is located in the luggage compartment.

• Turn the twist lock ¢

fig. 196 and pull the cover

downward to open the cover .

• Remove the warning triangle from its holder.

The luggage compartment lid is only designed to hold the warning triang le offered by the original

accessories program.

Vehicle tool kit

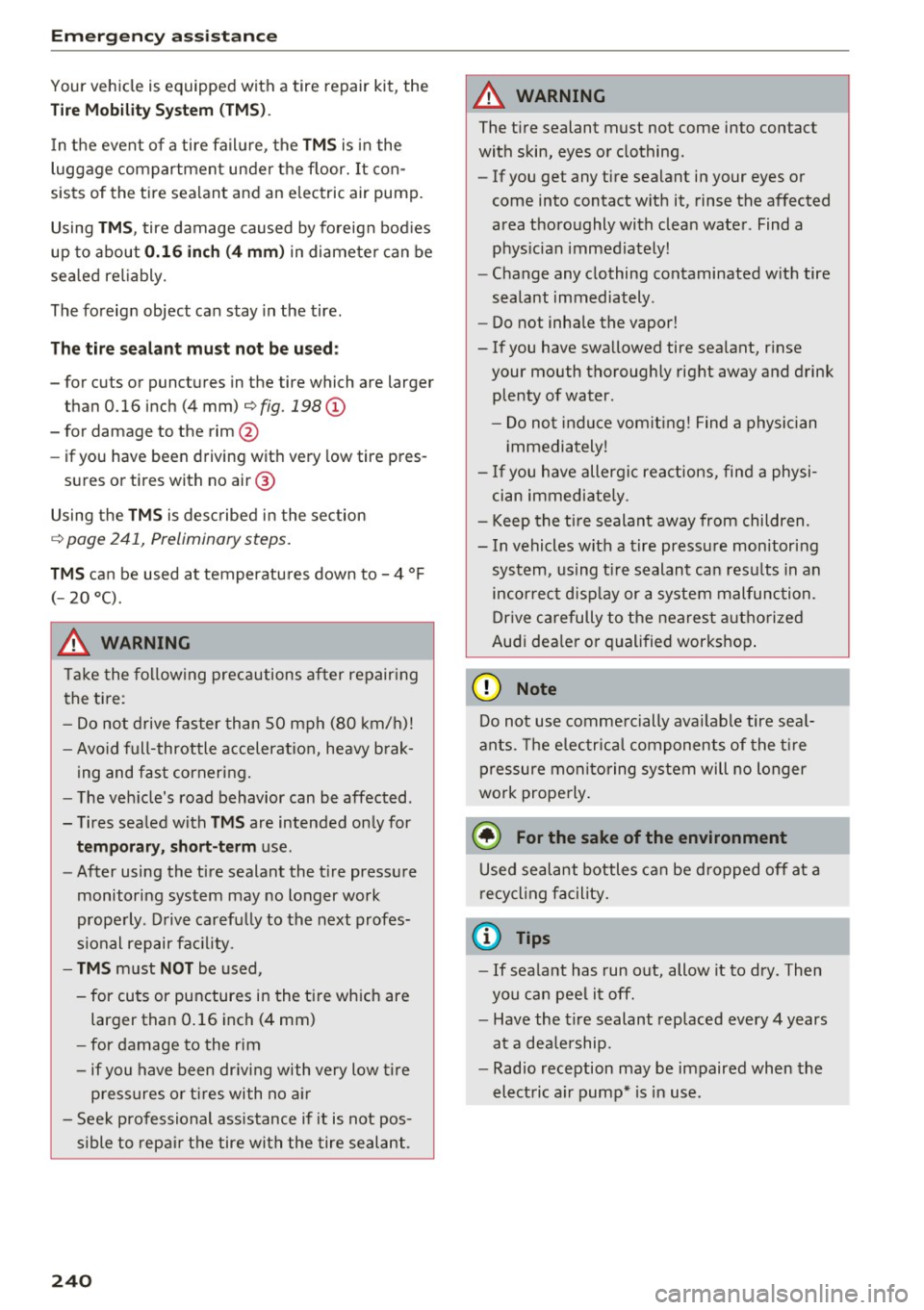

F ig. 197 Luggage co mpa rtment : veh icle tool kit

The vehicle tool kit , vehicle jack*, tire mobi lity kit

and compressor are stored in the luggage com

partment under the cargo floor cover .

• Lift the cargo floor by the plastic handle.

• Turn the handle counter-clockwise and remove

the cover .

Emergen cy a ssis tanc e

A WARNING

-Improper use of the veh icle jack can cause se-

rious pe rsonal injuries.

- Never use the screw driver hex head to

tighten wheel bolts, since the bolts cannot

attain the necessary tightening torque if you

use the hex head, potentially causing an ac

cident.

- The factory-supplied jack is intended only

for your veh icle model. Under no circum

stances s hou ld it be used to lift heavy

veh icles o r othe r loads; you risk in juring

yourse lf .

- Neve r start the engine when the ve hicle is

raised, which co uld cause an acciden t.

- Support the vehicle securely with appropri

ate stands if work is to be pe rformed under

neath the vehicle; otherwise, there is a po

t ential risk for injury .

- Neve r use the ja ck supplied w ith your Aud i

on anot her vehicle, particularly on a heavier

one. The jack is only s uitable for use on the

vehicle it came with.

(D Tips

The vehicle jack* in your vehicle is m ainte

nance -free .

Tire repair set

General and safety pointers

Tire repair is intended only for temporary, short

term use.

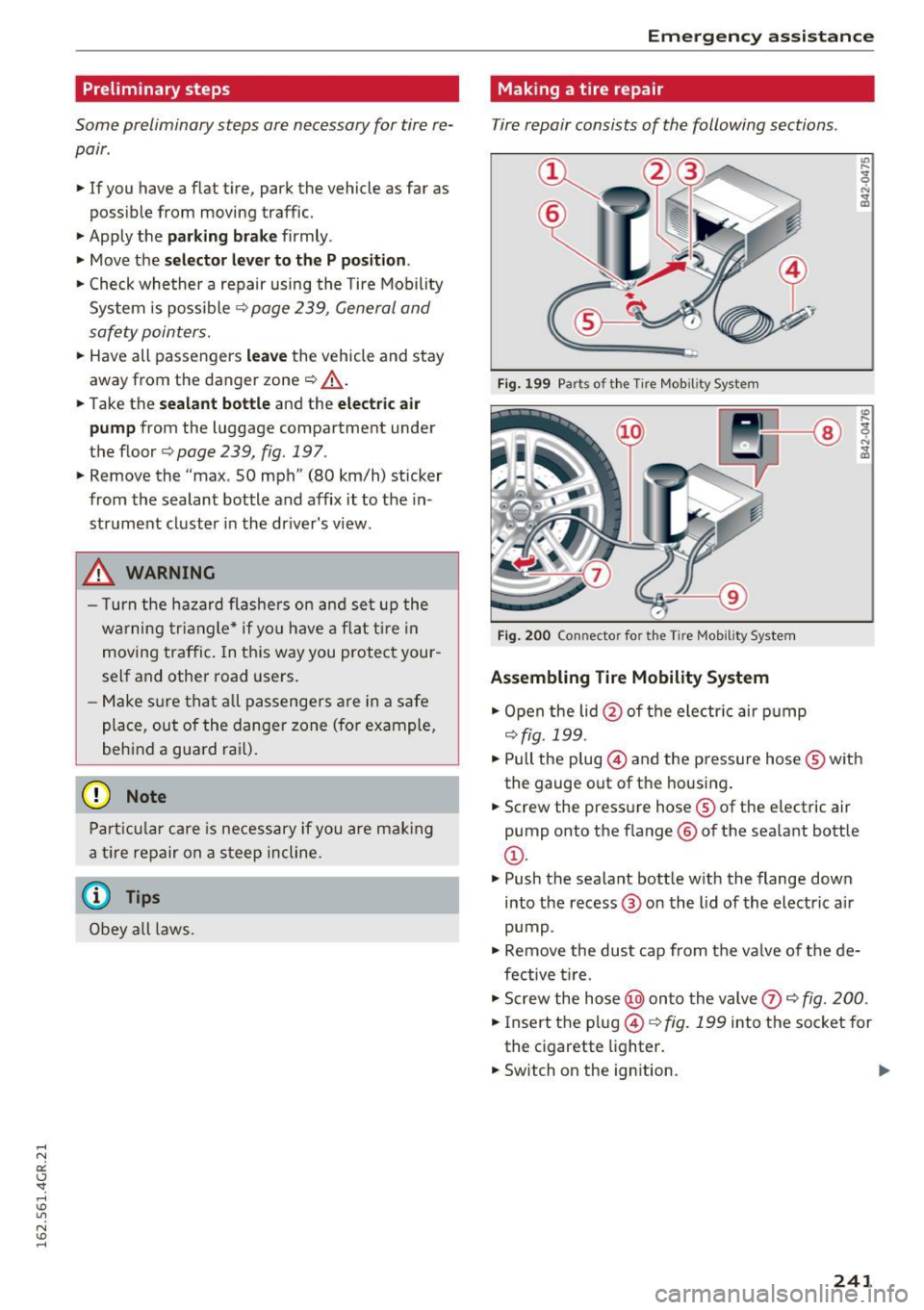

F ig. 198 Tire damage for wh ich the Tire Mob ility Sys tem is

not s uited

IIJI,

239

Page 242 of 282

Emerg enc y assis ta nc e

Your vehicle is equipped with a tire repair kit, the

Tire M obil ity Syste m (TMS ).

In the event of a tire fa il u re, the TMS is in the

luggage compartment under the floor.

It con

sists of the tire sealant and an electric air pump.

Using

TMS , tire damage caused by foreign bod ies

up to about

0 .1 6 inch (4 mm ) in diameter can be

sealed re liably.

The foreign object can stay in the tire.

The tire se a lant must not be used :

- for cuts or punctures in the tire which are larger

th an 0.16 inch (4 mm)

c> fig. 198 (i)

- for damage to the rim@

- if you have been driving with very low tire pres-

sures or tires with no air @

Using the

TMS is described i n the section

c> page 241, Preliminary steps.

TMS can be used at temperatu res down to -4 ° F

(- 20 °().

/i\, WARNING

Take the following precautions after repair ing

the tire :

- Do not drive faster than SO mph (80 km/ h)!

- Avoid full-throttle accelerat ion, heavy b rak-

i ng and fast cornering.

- The veh icle's road behavior can be affected .

- Tires sealed with

TM S are intended only for

te mpor ary , s hort-term use .

- After using the tire sealant the t ire pressure

monitoring system may no longer work

properly . Drive carefully to the next profes

sional repair fac ility.

- TMS must NOT be used,

- for cu ts or punctures in the tire wh ich are

larger than 0 .16 inch (4 mm)

- for damage to the rim

- if you have been dr iving with very low t ire

p ressures or t ires with no a ir

- Seek professional assistance if it is not pos

sible to repa ir the tire with the tire sealant.

240

A WARNING ,_

The tire sealant must not come into contact

with skin, eyes or clothing .

- lfyou get any tire sealant in your eyes or

come into contact w ith it, rinse the affected

area thoroughly with clean water . Find a

phys ician immediately!

- Change any clothing contaminated w it h tire

sealant immediately .

- Do not inhale the vapor!

- If you have swallowed tire sea lant, r inse

your mouth thoroughly right away and drink plenty of water .

- Do not induce vom it in g! Find a physician

i mmediately !

- I f you have allergic rea ctions, find a physi

cian immediate ly .

- Keep the ti re sealant away from children.

- In vehicles with a tire pressure monitoring

system, using t ire sealant can resu lts in an

incor rect d isp lay or a system malfunction.

Dr ive carefully to the nearest a utho rized

Audi dea ler o r qualified workshop .

(D Note

Do not use commercially ava ilable tire sea l

ants. The e lectrical components of the t ire

pressure monitoring system will no longer

work prope rly .

@ For the sake of the environment

Used sealant bottles ca n be dropped off at a

recycl ing facility.

(D Tips

- If sea lant has run out, allow it to dry. Then

you can pee l it off.

- Have the tire sealant rep laced every 4 years

at a dea le rship.

- Radio reception may be impaired when the

electric a ir pump* is in use .

Page 243 of 282

Preliminary steps

Some preliminary steps are necessary for tire re

pair.

• If you have a flat tire, park the vehicle as far as

poss ible from moving traffic.

• Apply the

parking brake firmly .

• Move the

selector lever to the P position .

• Check whether a repair using the Tire Mobility

System is possible ¢

page 239, General and

safety pointers.

• Have all passengers leave the vehicle and stay

away from the danger zone

~ _& .

• Take the sealant bottle and the electric air

pump from the luggage compartment under

the floor

¢page 239, fig. 197 .

• Remove the "max . SO mph" (80 km/h) sticker

from the sealant bottle and affix it to the in

strument cluster in the dr iver's view .

..&, WARNING

- Turn the hazard flashers on and set up the

warning triangle* if you have a flat tire in

moving traffic. In this way you protect your

self and other road users.

- Make sure that all passengers are in a safe

place, out of the danger zone (for example,

behind a guard rail).

(D Note

Particular care is necessary if you are making

a tire repair on a steep incline.

{i) Tips

Obey all laws .

Emergency assistance

Making a tire repair

Tire repair consists of the following sections .

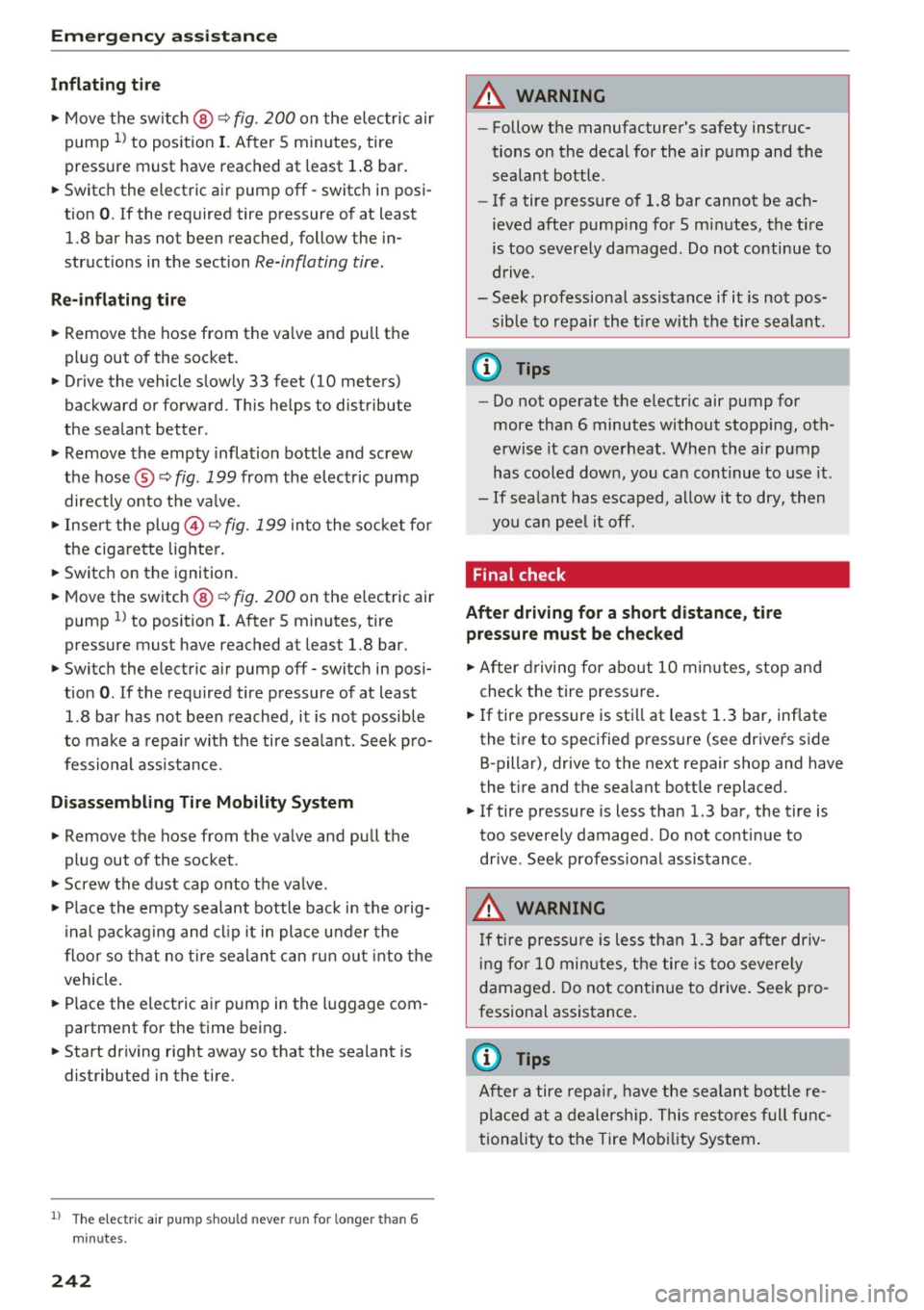

Fig. 199 Parts of th e Tire Mobility System

Fig. 200 Con necto r fo r t he Tire Mobi lity System

Assembling Tire Mobility System

• Open the lid@ of the electr ic air pump

¢fig. 199 .

• Pull the p lug @ and the pressure hose® with

the gauge out of the housing.

• Screw the pressure hose® of the electric air

pump onto the f lange ® of the sealant bottle

@.

• Push the sealant bottle w ith the flange down

into the recess @ on the lid of the electric a ir

pump .

• Remove the dust cap from the va lve of the de

fective ti re.

• Screw the hose@) onto the valve

(J) ~ fig. 200.

• Ins ert the plug @¢ fig. 199 into the socket for

the cigarette lighter.

• Switch on the ign ition.

241

Page 244 of 282

Emergency assistance

Inflating tire

.,. Move the switch@¢ fig. 200 on the e lectric air

pump

ll to position I. After S minutes, tire

pressure must have reached at least 1.8 bar.

.,. Switch the electric air pump off- switch in posi

tion

0. If the required tire pressure of at least

1.8 bar has not been reached, follow the in

structions in the section

Re-inflating tire.

Re-inflating tire

.,. Remove the hose from the va lve and pu ll the

plug out of the socket.

.,. Drive the vehicle slowly 33 feet (10 meters)

backward or forward . This helps to distribute

the sealant better .

.,. Remove the empty inflation bottle and screw

the hose ®~

fig. 199 from the electric pump

directly onto the

valve.

.,. Inse rt the plug ©~ fig. 199 into the socket for

the cigarette lighter.

.,. Switch on the ignition .

.,. Move the switch @¢

fig. 200 on the electric air

pump

ll to posit ion I. After S minutes, tire

pressure must have reached at least 1.8 bar.

.,. Switch the electric air pump off- switch in posi

tion

0. If the required tire pressure of at least

1.8 bar has not been reached, it is not possible

to make a repair with the tire sea lant . Seek p ro

fessional assistance.

Disassembling Tire Mobility System

.,. Remove the hose from the valve and pull the

plug out of the socket .

.,. Screw the dust cap onto the

valve.

.,. Place the empty sealant bottle back in the orig

inal packaging and clip it in place under the

floor so that no tire sealant can ru n out into the

vehicle.

.,. Place the electric air pump in the luggage com

partment for the time being.

.,. Start driving right away so that the sealant is

distributed in the tire.

l ) The electric air pu m p sho uld never r un for lo ng er than 6

m in ute s.

242

A WARNING ,_ -

- Follow the manufacturer's safety instruc

tions on the decal for the air pump and the

sealant bottle .

- If a tire pressure of 1.8 bar cannot beach

ieved after pumping for S minutes, the tire

is too severely damaged . Do not continue to

drive .

- Seek professional assistance if it is not pos

sible to repair the tire with the tire sealant .

(D Tips

-Do not operate the e lectr ic air pump for

more than 6 minutes without stopping, oth

erwise it can overheat . When the air pump

has cooled down, you can continue to use it.

- If sealant has escaped, allow it to dry, then

you can peel it off .

· Final check

After driving for a short distance , tire

pressure must be checked

.,. After driving for about 10 minutes, stop and

check the tire pressure.

.,. If tire pressure is sti ll at least 1.3 bar, inflate

the t ire to specified pressure (see drivers side

B-pillar), drive to the next repair shop and have

the tire and the sealant bottle replaced.

.,. If tire pressure is less than 1.3 bar, the tire is

too severely damaged . Do not continue to

drive . Seek profess ional assistance .

A WARNING

If tir e pressure is less than 1.3 bar after driv

in g for 10 minutes, the tire is too severely

damaged. Do not continue to drive. Seek pro

fessional assistance.

(D Tips

After a tire repair , have the sealant bottle re

placed at a dealership. This restores full func

tionality to the Tire Mobility System.

Page 245 of 282

Replacing wheels

Before changing a wheel

Observe the following precautions for your own

and your passenger's safety when changing a

wheel.

.,. After you experience a tire failure, pull the car

well away from moving traffic and try to reach

level ground before you stop¢.,&..

.. All passengers should

leave the car and move

to a safe location (for instance, beh ind the

guardrail)¢ .,&. .

.,. Engage the

parking brake to prevent your vehi

cle from rolling unintentionally¢ .,&..

.. Move

selector lever to position P ¢ .,&. .

.. Take the

jack out of the luggage compartment

c:>page 239.

A WARNING

You or your passengers could be injured while

chang ing a wheel if you do not follow these

safety precautions:

- If you have a flat tire, move a safe distance

off the road. Turn off the engine, turn the

eme rgency flashers on and use other warn

ing devices to alert other motorists.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

- To help prevent the vehicle from moving

sudden ly and possibly slipping off the jack,

always fully set the parking brake and block

the wheel diagonally opposite the wheel be

ing changed . When one front wheel is lifted

off the ground, placing the Automatic

Transmission in P (Park) will

not prevent the

vehicle from moving.

- Before you change a wheel, be sure the

ground is level and firm. If necessary, use a

sturdy board under the jack.

- Always store the veh icle tool k it, the jack

and the replaced tire in the luggage com

partment

c> page 124.

(D Note

If you are changing the whee l on a steep in

cline, use a rock or similar object to b lock the

Emergency assistance

opposite wheel to prevent the vehicle from

moving.

(D Tips

- Before changing the wheel, you must acti

vate the jacking mode, so that the automat

ic controls for the Adaptive Air Suspension*

do not make it more difficu lt to lift the vehi

cle with the jack

c> page 245.

- Obey all laws .

Changing a wheel

When you change a wheel, follow the sequence

described below step-by-step and in exactly thot

order .

1. Activate the vehicle jack mode* c> page 245.

2. Remove the

wheel bolt caps*. For more de

tails see also

¢ page 244, Wheels with

wheel bolt caps.

3. Loosen the wheel bolts c:> page 244.

4. Locate the proper mounting point for the

jack and align the jack below that point

~page 245.

5. Raise the car with the jack c:> page 245.

6. Remove the

wheel with the flat tire and then

install the other whee l¢

page 246.

7. Tighten all whee l bolts lightly.

8.

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly tighten

all wheel bolts

c> page 244.

10. Replace the

wheel bolt caps*.

11. Deact ivate the vehicle jack mode* in the

MMI:

I CARI funct ion button> (C ar )* systems

contro l butto n > Servicing & checks > Air

susp.: jack mode >

Off.

The vehicle jack mode* switches off automat ical

ly at speeds above 6 mph (10 km/h) .

A WARNING

-

Always read and follow all WARNINGS and in-

formation

¢ .&. in Raising the vehicle on

page

245 and ¢ page 247.

243

Page 246 of 282

Emerg ency assis ta nce

After changing a wheel

A wheel change is not complete without the do

ing the following.

• Always store the vehicle tool kit, the jack* and

the replaced tire in the luggage compartment

<=>page 124.

• As soon as possible, have the tightenin g tor

qu es

on all whee l bolts checked with a torque

wrench. The correct tightening torque is 90 ft lb (120 Nm).

• Have the flat tire

replac ed as soon as possible.

(D Tips

- If yo u notice that the whee l bolts are cor

roded and difficu lt to turn wh ile changing a

tire, they should be replaced before you

check the tightening torque.

- Drive at reduced speed until you have the

tightening torques checked .

- After changing a w heel, the tire pressure in

a ll four tires must be checked/corrected and

the tire pressure monitoring indicator must be stored in the MMI

c> page 23 7.

Wheels with wheel bolt caps

A ppl ies to: ve hicles w ith whee l bolts w it h ea ps

The caps must be removed first from the wheel

bolts before the bolts can be unscrewed .

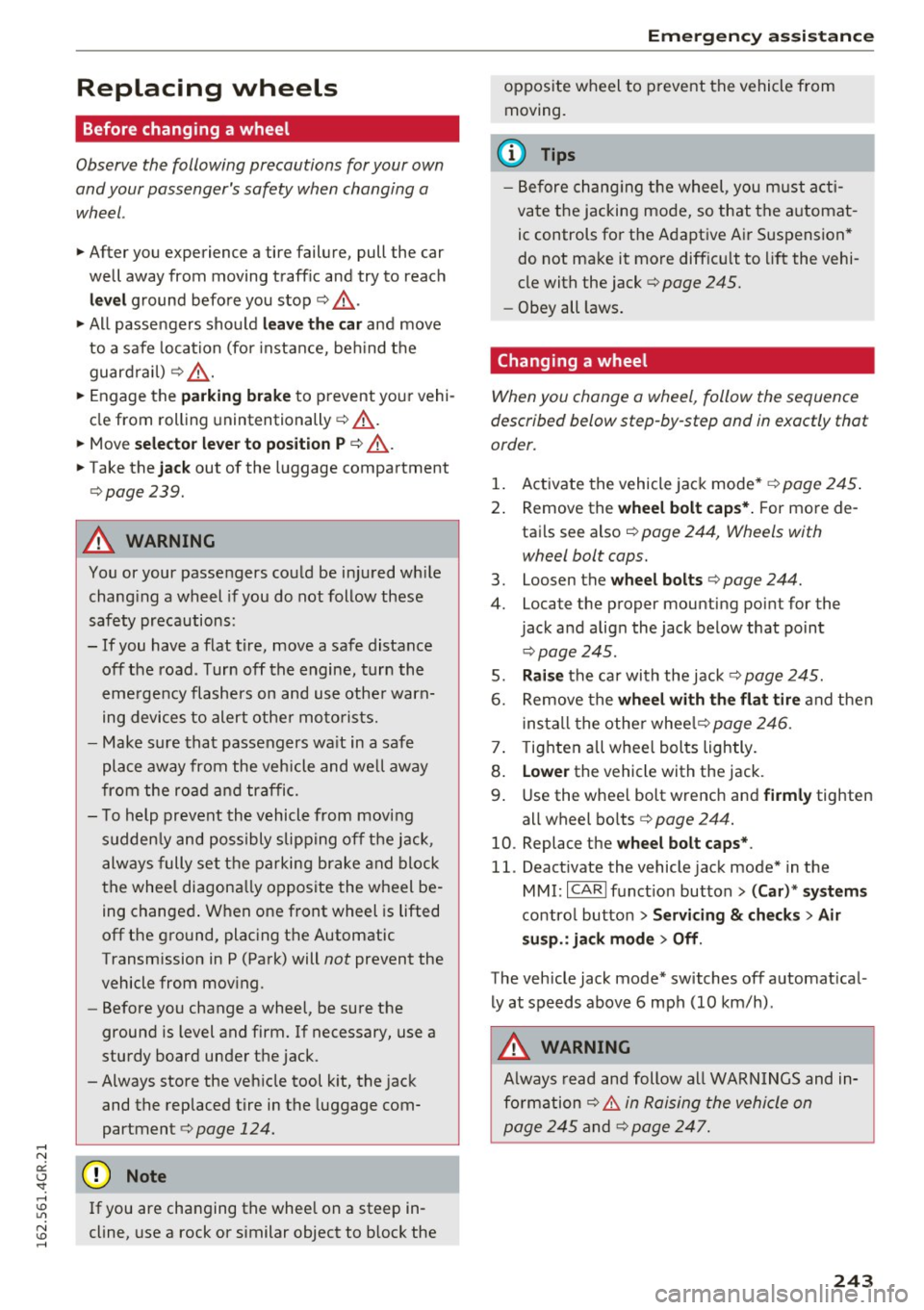

Fig. 201 Chang ing a wheel : removing the whee l bo lt caps

Removing

• Push the

pla stic clip (provided with the veh icle

tool kit) over the wheel bolt cap unt il the inner

retainers on the clip align wit h the edge of the

cover.

244

• Remove the cap with t he pla stic clip (vehicle

tool kit)

c> fig. 201.

Refitt ing

• Place t he caps over the wheel bolts and push

them back on.

The caps are to protect and keep the wheel bo lts

clean.

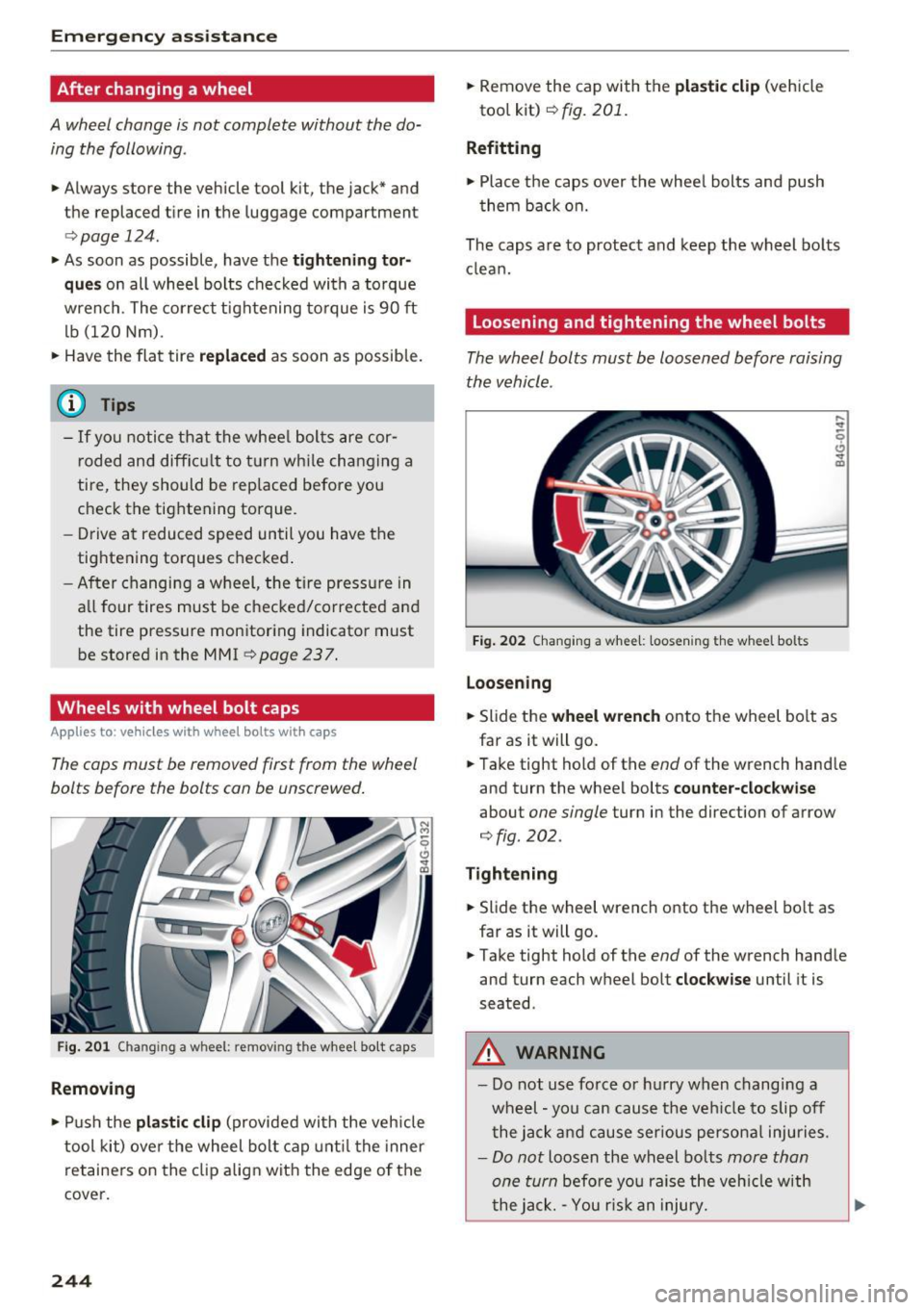

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising

the vehicle .

Fig. 202 Chang ing a whee l: loosening the wheel bolts

Lo ose ning

• Slide the

w hee l w ren ch onto the wheel bo lt as

far as it will go.

• Take tight hold of the

end of the wrench hand le

and turn the wheel bolts

count er-clo ckwis e

about one single turn in the direction of arrow

¢fig. 202.

Tightening

• Slide the wheel wrench onto the wheel bo lt as

far as it will go.

• Take tight hold of the

end of the wrench handle

and turn each wheel bolt

clockwis e until it is

seated .

_&. WARNING

- Do not use force or hurry when changing a

wheel -you can cause the veh icle to slip off

the jack and cause serious persona l injuries.

- Do not loosen the wheel bo lts more than

one turn

before you raise the veh icle w ith

the jack. -You r is k an injury.

Page 247 of 282

@ Tips

-Never use the hexagonal socket in the han

dle of the screwdriver to loosen or tighten

the wheel bo lts .

- If a whee l bolt is very tight, you may find it

easier to loosen by carefully pushing down

on the end of the wheel bolt wrench with

one foot only . As you do so, hold on to the

car to keep your balance and take care not

to s lip.

Raising the vehicle

The vehicle must be li~ed with the jack first be

fore the wheel can be removed .

Fig. 203 S ill pane ls: markin gs

a,

"' ~ 9

---~,.----~ a,

Fig . 204 S ill : posit io ning th e vehi cle ja ck

.. Activate the vehicle jack mode* in the MMI:

I CAR ! function button > (C ar)* sys tems contro l

button

> Serv icing & checks> Air s usp. : jac k

mod e> On.

.. Engage the par king br ake to preven t your vehi

cle from roll ing unintentionally .

.. Move the

selector lever t o position P .

.... N .,. Find the cover on the si ll that is nearest the a::

~ wheel that will be changed¢ fig. 203. Under

~ the cover, there is a liftin g point on the sill for U"I

~ the vehicle jack .

......

Em ergen cy a ssis tanc e

.. Remove the cover from the sill before lift ing

the vehicle with a vehicle jack¢

page 246 .

.. Turn the vehicle ja ck located under the lifting

point on the sill to raise the jack unt il its arm ®

¢

fig. 204 is located under the designated plas

tic mount ¢

.&,¢(D .

.. Alig n the jack so that its arm@¢ fig. 204 en

gages in the designated lifting point in the door

sill and the movable base @ lies flat o n the

gro und . The base @ must be

vertical unde r the

lifting point @ .

.. Wind the jack up further until the f lat tire

comes off the ground¢_&. .

Pos ition the vehicle jack

only under the des igna t

ed lift ing points on the sill

¢ fig. 203. There is ex

actly

one l ocation for each whee l. The jack must

not be posit ioned at any other location¢ & ¢0 .

An

un stable surfa ce under the jack can cause the

vehicle to slip off the jack . Always provide a f irm

base for the jack on the ground. If necessary

place a sturdy board o r similar support under the

jack. On

ha rd, slipper y surfa ce s (such as tiles)

use a rubbe r mat or similar to prevent the jack

from slipping ¢& .

A WARNING

-You o r your passengers could be inj ured

while changing a wheel if you do not fo llow

these safety precautions :

- Position the vehicle jack only at the des ig

nated lift ing po ints and align the jack.

Otherwise, the vehicle jack could slip and

cause an injury if it does not have suffi

c ient hold on the vehicle .

- A soft or unstable surface under the jack

may cause the veh icle to slip off the jack .

Always provide a firm base for the jack on

the g round . If necessary, use a sturdy

boa rd unde r the jack.

- On hard, slippery surface (s uch as t iles)

u se a rubber mat or sim ilar to prevent the

ja ck from s lipping.

- To help prevent injury to yourse lf and your

passengers:

- Do not raise the vehicle until you are sure

the jack is securely engaged.

245

Page 248 of 282

Emergency assistance

-Passengers must not remain in the vehicle

when it is jacked up.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

- Make sure jack posit ion is correct, adjust

as necessary and then continue to raise

the jack.

- Changes in temperature or load can affect

the height of the vehicle.

(D Note

Do not lift the vehicle by the sill. Position the

vehicle jack only at the designated lifting

points on the sill. Otherwise, your vehicle will

be damaged.

@ Tips

The vehicle jack mode* switches off automati

cally at speeds

above 6 mph (10 km/h).

Removing and installing the sill extension

cover

Applies to: vehicles w ith sil l extension

Fig. 205 Sill: removing the cover

.,. Pull the cover down to remove it. c:> fig. 205

.,. To install the cover, insert i t in the mount and

press it upward until it clicks into place. The

cover must be flush with the surface of the sill

extension .

1

> A pp lies to vehicles wit h c eramic brake ro tor s*: Use a sec

on d alig nment pin* (sto re d in th e spare w hee l w ell mold

in g) fo r the lower hole, foll ow in g t he descrip tion for the

firs t alig nm ent pin.

246

@ Tips

Some models may also have a cover for the

rear vehicle lift point.

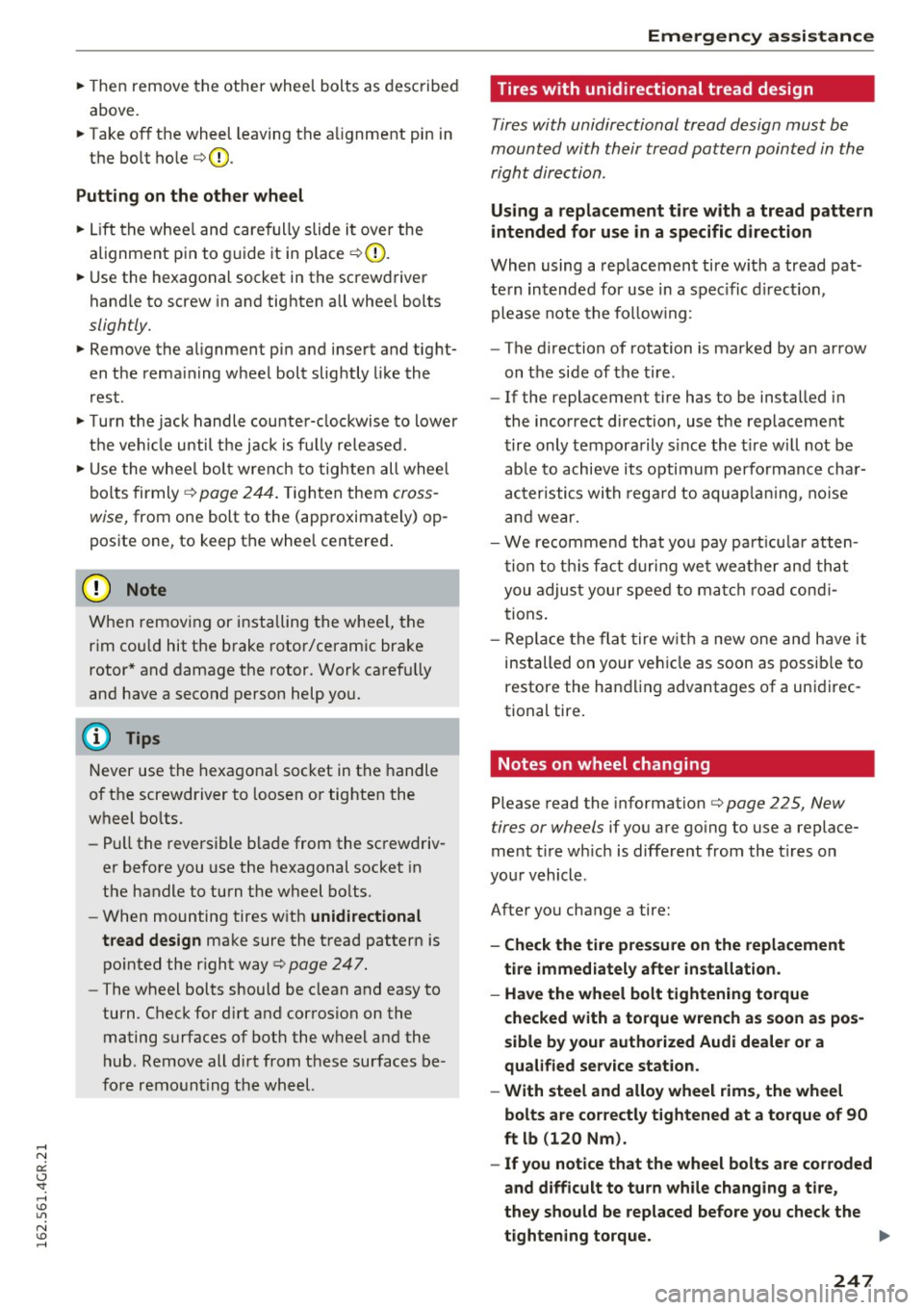

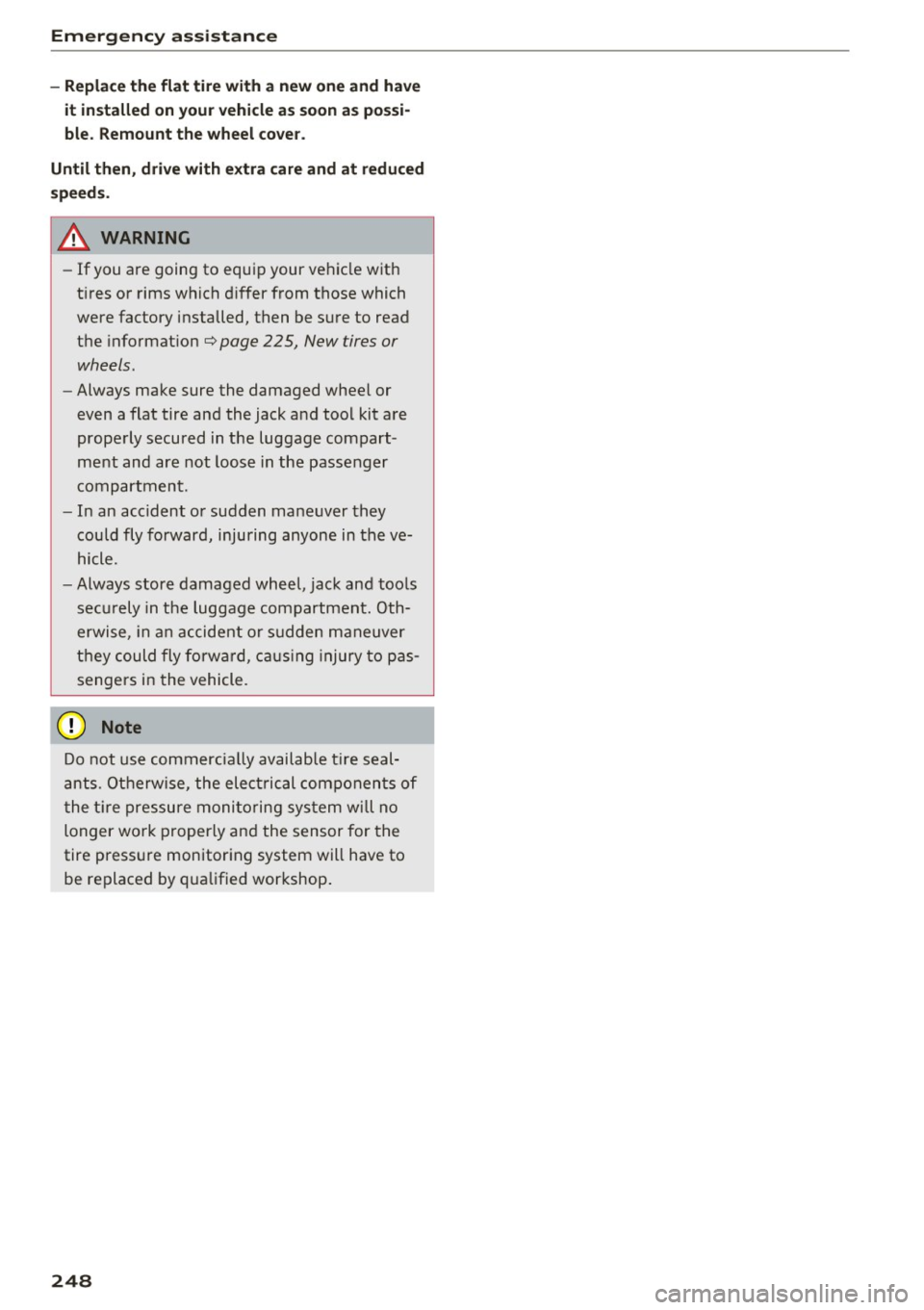

Taking the wheel off/installing a wheel

Follow these instructions step -by-step for chang

ing the wheel.

Fig. 206 Changing a wheel : using the sc rewdr iver han d le

(wi th t he blade re m oved) to turn the bol ts

Fig. 207 Changing a wh eel: alignment pin in side the t op

ho le

After you have loosened all wheel bolts and

raised the vehicle off the ground,

remove and re

place the wheel as follows:

Removing the wheel

.,. Use the hexagonal socket in the screwdriver

handle

to completely remove the topmost

wheel bolt and set it aside on a

clean surface

c::> fig. 206.

.,. Sc rew the threaded end of the alignment pin

from the tool kit hand-t ight into the empty bolt

hole

¢ fig . 2011>. .,.

Page 249 of 282

~ Then remove the other wheel bolts as described above.

~ Takeoff the wheel leaving the a lignment pin in

the bolt ho le ¢ (D.

Putting on th e oth er w heel

~ Lift the whee l and carefully slide it over the

alignment pin to guide it in place ¢(D.

~ Use the hexagonal socket in the screwdriver

handle to screw in and tighten all whee l bolts

sligh tly.

~ Remove the alignment pin and insert and tight

en the remaining wheel bolt slightly like the

rest .

~ Turn the jack handle counter-clockwise to lower

the vehicle until the jack is fu lly re leased.

~ Use the wheel bolt wrench to tighten all wheel

bolts firmly ¢

page 244 . Tighten them cross

wise,

from one bolt to the (approximately) op

posite one, to keep the whee l centered .

When removing or installing the whee l, the

rim could hit the brake rotor/ceramic brake

rotor* and damage the rotor. Work carefully

and have a second person help you.

(D Tips

Never use the hexagonal socket in the handle

of the screwdriver to loosen or tighten the

wheel bo lts.

- Pu ll the reversible blade from the screwdriv

er before you use the hexagonal socket in

the handle to turn the wheel bo lts.

- When mounting tires w ith

u nidirectio nal

tre ad design

make sure the tread pattern is

po inted the r ight way ¢

page 247.

-The wheel bolts should be clean and easy to

turn . Check for d irt and corrosion on the

mating surfaces of both the wheel and the

hub . Remove all dirt from these surfaces be

fo re remo unt ing the wheel.

Em ergenc y ass is tanc e

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in the

right direction .

Using a repl acement t ire w ith a tread pattern

intend ed for use in a sp ecific direction

When using a rep lacement tire with a tread pat

tern intended for use in a spec ific d irection ,

please note the follow ing:

- The direction of rotation is marked by an arrow

on the side of the tire .

- If the replacement tire has to be installed in

the incorrect direction, use the replacement tire only temporarily s ince the t ire w ill not be

ab le to achieve its optimum perfo rmance char

acter istics with rega rd to aquap lan ing, no ise

and wear.

- We recommend that you pay pa rt icu lar atten

tion to th is fact d uring wet weather and that

you adjust your speed to match road cond i

tions .

- Rep lace the flat tire w ith a new one and have it

installed on your veh icle as soon as possib le to

restore the hand ling advantages of a unidirec

tional tire.

Notes on wheel changing

Please read the information ¢ page 225, New

tires or wheels

if you a re go ing to u se a replace

ment t ire wh ich is different from the t ires on

you r vehicle .

After you change a tire:

- Check the tire pre ssure on the r epl acement

tire immed iatel y afte r in st a llat ion .

- Have th e whe el bolt tight ening torqu e

c hecked with a torque w rench as s oon as pos

s ible b y your authorized Audi de aler o r a

qualified ser vice st ation.

- With steel and allo y wheel rim s, the wheel

bolt s are co rr ectl y ti ghtened at a torque of 90

ft lb

( 1 20 Nm) .

-If you notice that the wheel bolts are corroded

and diffi cult to turn while changing a ti re ,

the y should be r eplaced before you chec k the

tightening torque. ..,.

247

Page 250 of 282

Emerg enc y assis ta nc e

-Repl ace th e flat tire with a ne w one and have

it in st a lled on you r vehicl e as s oon as poss i

ble . R emount the wheel co ve r.

Until th en, driv e with extr a care and at r educe d

s peeds .

A WARNING

-If you are going to equip your vehicle w ith

t ires or rims which differ from those which

were factory installed, then be sure to read

the informat ion¢

page 225, New tires or

wheels.

- Always make sure the damaged wheel or

even a flat tire and the jack and tool kit are

properly secured in the luggage compart

ment and are not loose in the passenger

compartment.

- In an accident or sudden ma neuver they

could fly forward, injuring anyone in the ve

hicle.

- Always store damaged wheel, jack and too ls

sec urely in the luggage compartment. Oth

erwise, in an accident or s udden maneuver

they could fly forward, causing injury to pas

sengers in the vehicle.

(D Note

Do not use commercia lly available t ire seal

ants . Otherwise , the electrical components of

the t ire pressure monito ring sys tem wi ll no

longer work properly and the sensor for the

tire press ure monitoring system will have to

be replaced by qualified workshop .

248

-