AUDI S6 2008 Owners Manual

Manufacturer: AUDI, Model Year: 2008, Model line: S6, Model: AUDI S6 2008Pages: 390, PDF Size: 88.42 MB

Page 341 of 390

-------------------------------------------~W~h~a~t~d~o~l ~d~o~n~o~w~ ?::__fflll

•

& WARNING (continued)

front wheel is lifted off the ground, placing the Automatic Trans

mission in "P" {Park) will

not prevent the vehicle from moving.

• Before you change a wheel, be sure the ground is level and firm.

If necessary, use a sturdy board under the jack.

• After installing the spare wheel, make sure that you replace the

flat tire/wheel in its storage area properly and tighten the knurled

retaining screw securely. •

Changing a wheel

When you change a wheel, follow the sequence described

below step-by-step and in exactly that order.

1. Activate the vehicle jack mode (only vehicles with Adap

tive Air Suspension)~

page 184.

2. Remove the decorative wheel cover*. For more details

see also ~

page 340, "Decorative wheel covers" or

~ page 340, "Wheels with wheel bolt caps".

3. Loosen the

wheel bolts~ page 341.

4. Locate the proper mounting point for the jack and align

the jack below that point~

page 341.

5. Lift the car with the jack ~ page 341.

6. Remove the wheel with the flat tire and then install the

spare

~ page 343.

7. Tighten all wheel bolts lightly.

8.

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly tighten all wheel

bolts~

page 341 .

10. Replace the decorative wheel cover*.

11. Deactivate the vehicle jack mode (only vehicles with

Adaptive Air Suspension)~

page 184.

& WARNING

Always read and follow all WARNINGS and information => & in

uRaising the vehicle" on

page 341 and=> page 344. •

After changing a wheel

A wheel change is not complete without the doing the

following.

- Store and secure the wheel you replaced in the spare

wheel well.

- Replace the tools and the jack in their proper location.

- Check the tire pressure on the spare wheel immediately

after mounting it.

- As soon as possible, have the

tightening torques on all

wheel bolts checked with a torque wrench. The correct

tightening torque is 90 ft lb (120 Nm).

- Have the flat tire

replaced as soon as possible.

[ i] Tips

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Drive at reduced speed until you have the tightening torques

checked .•

Do-it -yourself service

Page 342 of 390

11111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

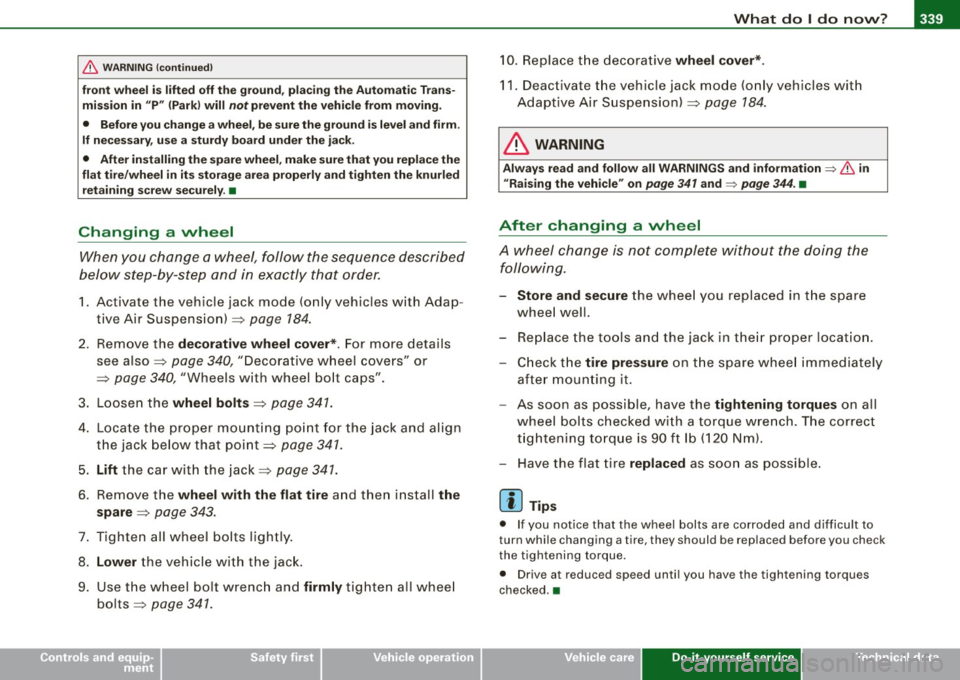

App lies to veh ic les : w ith deco rative whee l covers

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts.

Removing

Fig . 249 Changing a

wheel: Removing the

wheel cover

- Insert the hook provided with the vehicle tool kit in the

hole in t he hub.

- Pull off the

decorative wheel cover=> fig. 249. •

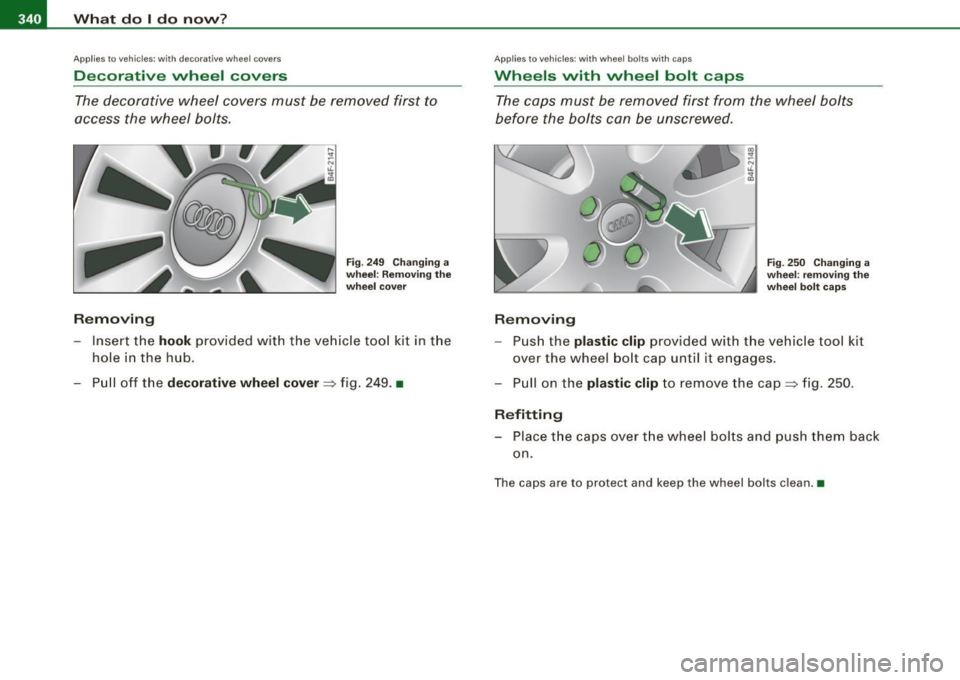

Applies to veh ic les: w ith whee l bolts w ith ca ps

Whee ls vvith wheel bolt caps

The caps must be removed first from the wheel bolts

before the bolts can be unscrewed .

Removing

Fig. 250 Changing a

wheel: removing the

wheel bolt caps

-Push the plastic clip prov ided w ith the vehicle tool kit

ov er the wheel bolt cap unt il it engages .

- Pull on t he

plastic clip to remove the cap=> fig. 250 .

Refitting

-Place the caps over the wheel bolts and push them back

on .

The caps are to pro tect and keep the wheel bolts clean. •

Page 343 of 390

_______________________________________________ W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? _ __._

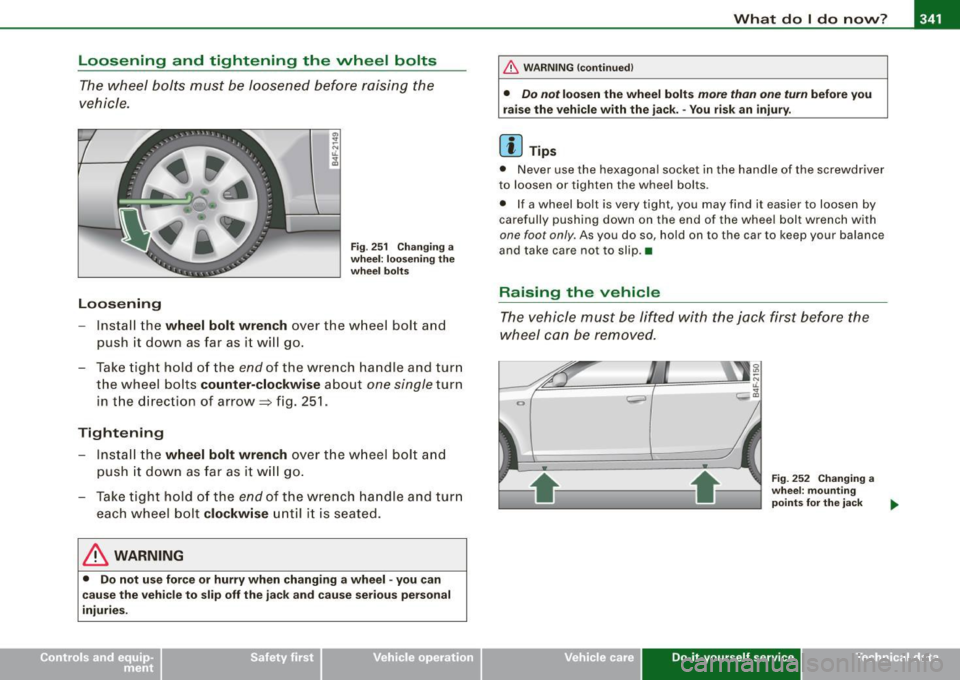

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle .

Loosening

Fig . 25 1 Chan ging a

w he el: lo os en ing th e

whe el bolt s

- Install the wheel bolt wrench over the wheel bolt and

push it down as far as it will go.

- Take tight hold of the

end o f the wrench handle and turn

the wheel bolts counter-clockwise about

one single turn

in the direction of arrow =} fig. 251 .

Tightening

-Insta ll the wheel bolt wren ch ov er the w heel bolt a nd

push it down as far as it wi ll go.

- Take tight hold o f the

end of the wrench ha ndle and tur n

each wheel bolt clockwise until i t is sea ted.

& WARNING

• Do not u se for ce or hu rry w hen changing a wheel -you c an

ca use the vehi cle to slip off the j ack a nd cause se rio us perso nal

injurie s.

& W ARNING (continued )

• Do n ot loo sen the wh eel bolt s more than one turn before y ou

rais e the vehicle with the jack . - You ri sk an injur y.

[ i ] Tip s

• Never use the hexagona l socke t in the handle of the screwdriver

to loosen or tighten the wheel bolts .

• If a wheel bolt is

very tight, you may find it easier to loosen by

carefully pushing down on the end of the whee l bolt wrench with

one foot only . As you do so , hold on to the car to keep your balance

and take care not to slip .•

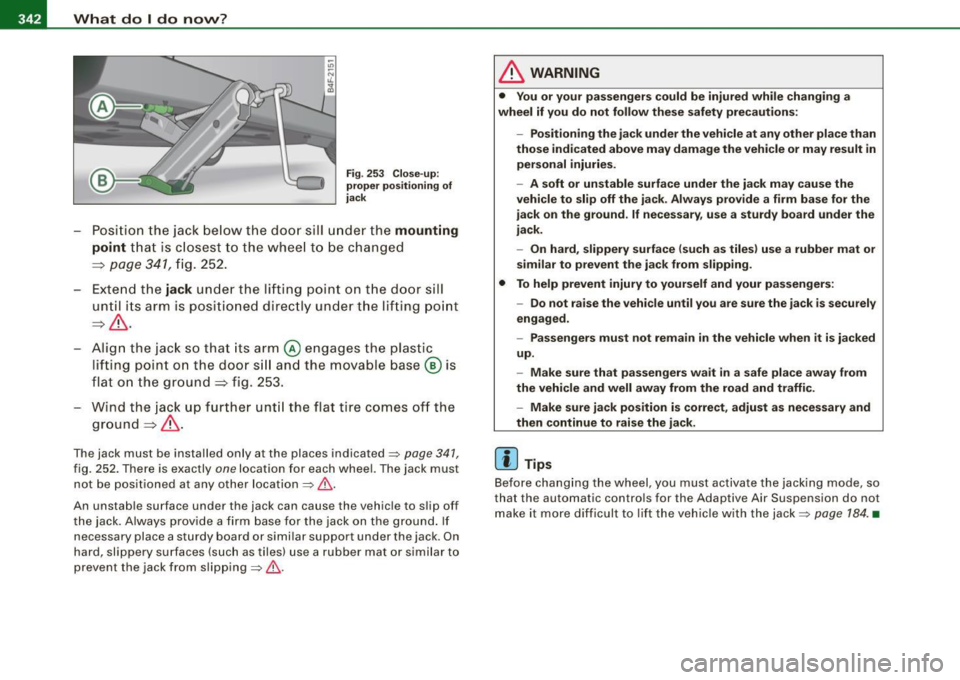

Raising the veh ic le

The vehicle must be lifted with the jack first before the

wheel can be removed .

Vehicle care

Fig. 252 Cha nging a

w he el: m oun ting

poi nts for the jack ..

Do-it-yourself service irechnical data

Page 344 of 390

lllftl.,___W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

Fig. 253 Close-up:

proper positioning of

jack

- Position the jack below the door sill under the mounting

point

that is closest to the wheel to be changed

:::::, page 341 , fig. 252.

Extend the

jack under the lifting point on the door sill

until its arm is pos itioned d irectly under the lifting point

:::::,& .

- Align the jack so that its arm @ engages the plastic

l ifting point on the door sill and the movable base@ is

flat on the ground :::::, fig. 253.

Wind the jack up further until the flat tire comes off the

ground :::::,& .

The jack must be installed only at the places indicated~ page 341,

fig. 252. There is exactly one location for each wheel. The jack must

not be positioned at any other location~&.

An unstable surface under the jack can cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary place a sturdy board or similar support under the jack . On

hard, slippery surfaces (such as tiles) use a rubber mat or similar to

prevent the jack from slipping~&.

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow these safety precautions:

-Positioning the jack under the vehicle at any other place than

those indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack . Always provide a firm base for the

jack on the ground. If necessary, use a sturdy board under the

jack.

- On hard, slippery surface {such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers:

-Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait in a safe place away from

the vehicle and well away from the road and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack.

[ i ] Tips

Before changing the wheel, you must activate the jacking mode, so

that the automatic controls for the Adaptive Air Suspension do not

make it more difficult to lift the vehicle with the jack ~

page 184. •

Page 345 of 390

_____________________________________________ W_ h_ a_t _d_ o_l _ d_o _ n_o_ w_ ?_--J IIIII

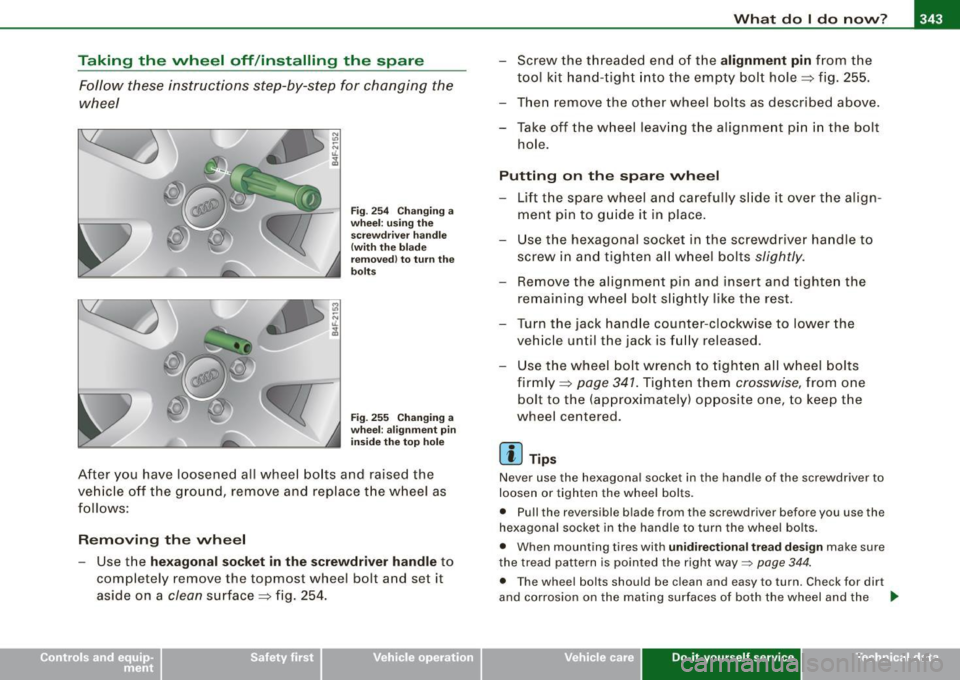

Taking the wheel off /installing the spare

Follow these instructions step-by-step for changing the

wheel

N

"' ;; u.

al

Fig . 254 Changing a

wheel: using the screwdriver handle

!with the blade

removed) to turn the

bolts

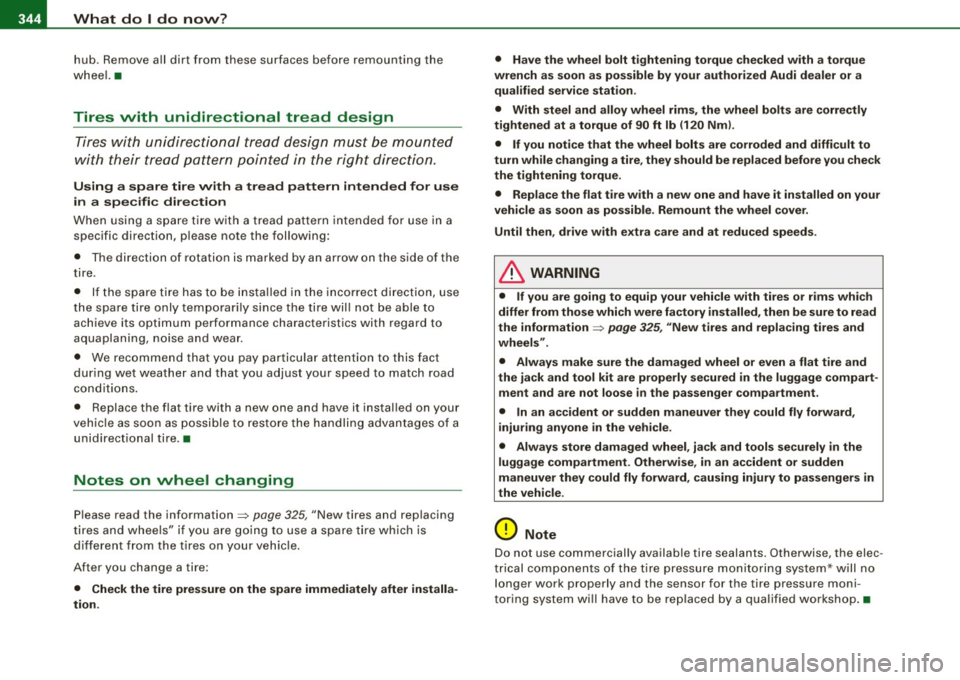

Fig . 255 Changing a

wheel: alignment pin

inside the top hole

After you have loosened all wheel bolts and raised the

vehicle off the ground, remove and replace the wheel as

follows:

Removing the wheel

- Use the hexagonal socket in the screwdriver handle to

completely remove the topmost wheel bolt and set it

aside on a clean surface => fig. 254. - Screw the threaded end of the

alignment pin from the

tool kit hand-tight into the empty bolt hole=> fig. 255.

- Then remove the other wheel bolts as described above.

- Take off the wheel leaving the alignment pin in the bolt

hole.

Putting on the spare wheel

- Lift the spare wheel and carefully slide it over the align

ment pin to guide it in place.

- Use the hexagonal socket in the screwdriver handle to

screw in and tighten all wheel bolts slightly.

- Remove the alignment pin and insert and tighten the

remaining wheel bolt slightly like the rest.

- Turn the jack handle counter-clockwise to lower the

vehicle until the jack is fully released .

- Use the wheel bolt wrench to tighten all wheel bolts

firmly => page 341. Tighten them crosswise, from one

bolt to the (approximately) opposite one, to keep the

wheel centered .

[ i] Tips

Never use the hexagonal socket in the handle of the screwdriver to

loosen or tighten the wheel bolts.

• Pull the reversible blade from the screwdriver before you use the

hexagonal socket in the handle to turn the wheel bolts.

• When mounting tires with

unidirectional tread design make sure

the tread pattern is pointed the right way~

page 344.

• The wheel bolts should be clean and easy to turn. Check for dirt

and corrosion on the mating surfaces of both the wheel and the ..

Vehicle care Do-it-yourself service irechnical data

Page 346 of 390

-L___:W:..:..:. h.:.: a::.. t:...:: d:.:o:::....:. l..: d::. O ::::....: n:..:.:: O:..:W :.:..:. ? ____________________________________________ _

hub. Remove all dirt from these surfaces before remounting the

wheel. •

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern intended for use

in a specific direction

When using a spare tire with a tread pattern intended for use in a

specific direction, please note the following:

• The direction of rotation is marked by an arrow on the side of the

tire .

• If the spare tire has to be installed in the incorrect direction, use

the spare tire only temporarily since the tire will not be able to

achieve its optimum performance characteristics with regard to

aquaplaning, noise and wear.

• We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

conditions.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirectional tire. •

Notes on wheel changing

Please read the information~ page 325, "New tires and replacing

tires and wheels " if you are going to use a spare tire which is

different from the tires on your vehicle.

After you change a tire:

• Check the tire pressure on the spare immediately after installa

tion . •

Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a qualified service station .

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 90 ft lb (120 Nml.

• If you notice that the wheel bolts are corroded and difficult to

turn while changing a tire, they should be replaced before you check

the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds .

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to read

the information

~ page 325, "New tires and replacing tires and

wheels".

• Always make sure the damaged wheel or even a flat tire and

the jack and tool kit are properly secured in the luggage compart ment and are not loose in the passenger compartment.

• In an accident or sudden maneuver they could fly forward,

injuring anyone in the vehicle .

• Always store damaged wheel, jack and tools securely in the

luggage compartment . Otherwise, in an accident or sudden

maneuver they could fly forward, causing injury to passengers in

the vehicle .

0 Note

Do not use commercially available tire sealants. Otherwise, the elec

trical components of the tire pressure monitoring system* will no

longe r work properly and the sensor for the tire pressure moni

toring system will have to be replaced by a qualified workshop. •

Page 347 of 390

_________________________________________________ F_ u_ s_ e_s _ a_n _d_ b_ u _ lb_ s _ __.1111

Fuses and bulbs

Fuses

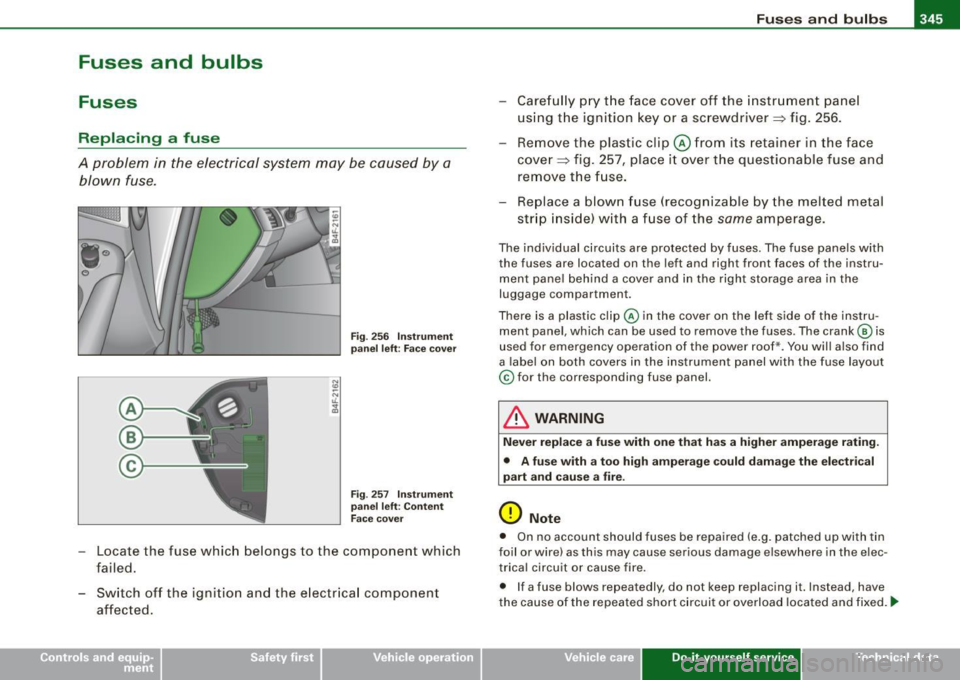

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

Fig . 256 Ins trumen t

pa nel left: Face c over

F ig . 257 I nst rume nt

pa nel left: Co ntent

F ac e cover

- Locate the fuse which belongs to the component which

failed.

- Switch off the ignition and the e lectr ica l component

affected. - Carefully p

ry t he face cover off the instr umen t pane l

using the ignition key or a screwdriver~ fig. 256.

- Rem ove the plastic clip @ from i ts retainer in the face

cove r~ fig. 257, p lace i t over the questionable fuse and

remove the fuse.

- Replace a blown fuse (recognizable by the melted metal

str ip inside) wi th a f use of the

same amperage.

The individual circuits are protected by fuses. T he fuse panels with

the fuses are located on the left and right front faces of the instru

ment pane l behind a cover and in the right storage area in the

luggage compartment.

There is a plastic clip @ in the cover on the lef t side of the instru

ment pane l, which can be used to remove the fuses . The crank © is

used for emergency operation of the power roof*. You will also find

a label on both covers in the instrument panel with the fuse layout

© for the corresponding fuse panel.

& WARNING

Nev er r eplac e a fuse with one that ha s a high er amperag e rati ng.

• A fu se w ith a to o high ampe rage co uld d amag e the ele ctr ical

pa rt a nd cau se a fire .

0 Note

• On no account should fuses be repaired (e .g. patched up wi th tin

foil or wire) as this may cause serious damage elsewhere in the e lec

trica l circuit o r cause fire.

• If a fuse blows repeatedly, do not keep replacing it. Instead , have

the cause of the repea ted short circuit or overload located and fixed.

ti>

Vehicle care Do-it-yourself service Technical data

Page 348 of 390

llft!I Fuses and bulbs ..._ __________________________________________ _

[ i J Tip s

You are wel l advised to keep a supply of spare fuses in your vehicle .

Fuses with the proper ampere ratings are availab le at your Audi

dea ler. •

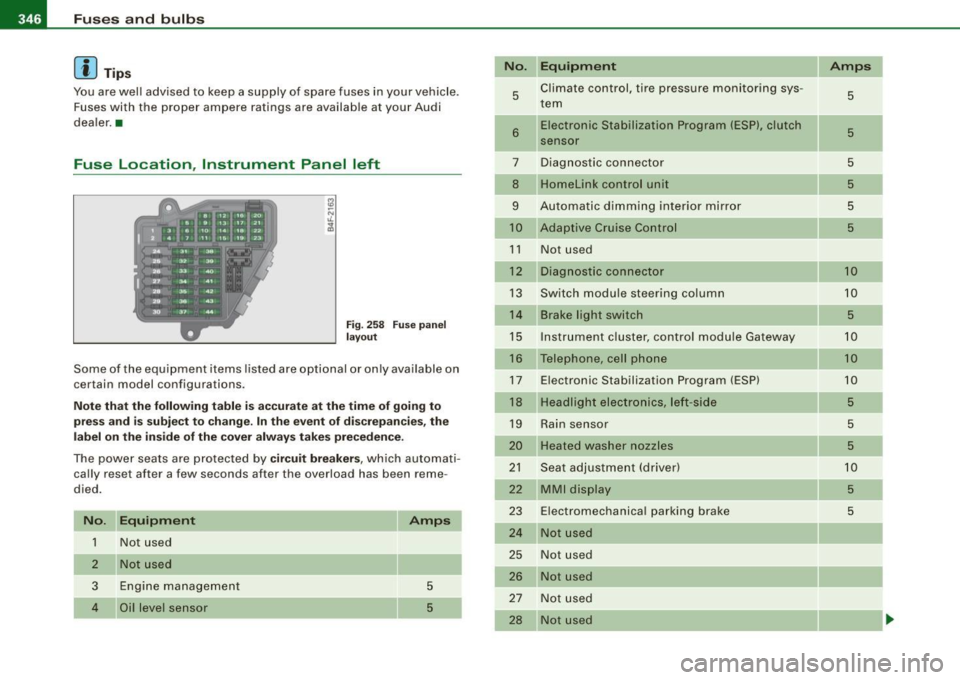

Fuse Location , Instrument Panel left

Fig . 258 Fuse pa nel

l ayo ut

Some of the equipment items listed are optional or only ava ilable on

certain model configurations .

Note th at t he fo llo wi ng t able i s acc urat e at th e time of goin g to

pr ess and is subject t o ch ang e. In th e eve nt of d iscrep ancie s, th e

labe l on th e in side of th e cover always ta kes prece de nce .

The power seats are protected by cir cuit br eaker s, which automati

cally reset after a few seconds after the overload has been reme

died.

N o. Equipm ent

1 Not used

2

3

4

Not used

Engine management

Oil level sensor Amps

5

5

No

.

5

6

..

7

8

9

10

1 1

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Equipm ent

Climate cont rol , tire pressure monitoring sys

tem

Electronic Stabilization Program (ESP), clutch

sensor

Diagnostic connector

Homelink control unit

Automa tic dimming interior mirror

Adaptive Cruise Control

Not used

Diagnostic connector

Switch modu le steering column

Brake light switch

I nstrument c luster, control module Ga teway

Telephone, cell phone E lectronic Stabilization Program (ESP)

Headlight electronics, left -side

Rain sensor

Heated washer nozzles

Seat adjustment (driver)

MMI display

E lectromechanica l parking brake

Not used

Not used

Not used

N ot used

Not used Amps

5

5

5

5

5

5

10

10

5

10

10

10

5

5

5

10

5

5

-

Page 349 of 390

_______________________________________________ F_ u_ s...:....... e...;.s _ a_ n_d :.:.....:.: b:...: u:...: l:.:.: b :...:s:...___,J

No . Equipm ent

29 Not used

30 Not used

31 Back-up light swi

tch, transmission , engine

components

Intelligent power mo dule driver (footwell l ight

32 and front headlights , horn, wiper system, elec

tr ically adjusta ble steering wheel)

33 I

ntelligent power modu le driver

(lights left -side)

---,--

34

35

36

37

38

39 I

nte lligent power modu le driver

(lights right -side)

Not used

Headlight washer system

E lectronic Stabilization Program (ESP)

Wip er system

Door control module left -side

Horn

41 Heater fan

42 Control module electronic ignition lock/electri

cally adjustable steering wheel

43 Rear windsh iel d wiper (Avant)

4 4 Power window opener (left-side)

Amps

15

30

25

25

30 25

30

15

25

40

30

15

35

-

•

Fuse Location , Instrument Panel right

Fig . 2 59 F use p an el

la yo ut

Some of the equipm ent items lis ted are op tional or on ly available on

certain m ode l configu rations.

Note that the following table is ac curate at the time of g oing to

press and is subject t o change . In the ev ent of d iscrepan cies , th e

l a b el on t he in side of the cover alw ay s take s prec eden ce.

Th e power seats are pr otected by circuit breaker s, which automa ti

ca lly reset after a few seconds a fter the ove rload has been reme

died .

No. Equipment Amps

Fu se holder (bla ck )

1 Control module Advanced Key 15

2 Cigarette

lighter front

20

3 Tire pressure moni tor ing system

5

4 E lectrica l outlet front (center conso le) 20

5 Intellige

nt power module passenger

15

(glove box lock)

6 Door control module right -side 15

Sunroof 20

Vehicle care Do-it-yourself service irechnical data

Page 350 of 390

111!1 Fuses and bulbs ..._ ____ .;__...;_;,;_ _______________________________ _

No. Equipm ent Amps

8 A/C controls 10

9 Heated seats, front 30

10

MMI , Antenna amplifier 10

11

Seat adjustment (passenger) 10

12

Communication 5

Fu se holder (b rown )

1 Electric fuel pump 20/30

2

Adaptive Air Suspension 15

3

Lane assist 10

4 Not used

5 Adaptive Air Suspension 5

6 Shift gate automatic transmission/clutch 5 switch

-

7 Acoustic Park ing System 5

8 Control module Gateway 5

9 Automatic headlight range contro l (auxiliary 5 driving lights), head light electronics, right -side

10 Airbag 5

11

Heated rear seats 5

12

Telephone 5 •

Fuse Location, Luggage Compartment r ight

No . Equipm ent

Fuse hold er (bl ack)

1 Digital Signal Processing (DSP)/

BOSE ampl ifier

2 Communication , Antenna amplifier

3 Electromechanical parking brake, l eft

4 Electromechanical parking brake, right

5 Luggage compartment powe r outlet

6 Bat tery energy management

7 Intelligent power module rear

(lights right -si de)

8 Intelligent power module (comfort)

9 Intelligent power module rear

(lights le ft-side)

10 Powe r window opener (right-side)

11 Acoustic Parking System

12 Cigarette lighter rear

Fig . 260 F use pa nel

l ay ou t

Amps

30

5

30

30

20

5

2 0

5

30

35 5

20

-