AUDI TT COUPE 2009 Owners Manual

Manufacturer: AUDI, Model Year: 2009, Model line: TT COUPE, Model: AUDI TT COUPE 2009Pages: 316, PDF Size: 71.16 MB

Page 271 of 316

_______________________________________________ W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? _ __.ffllll

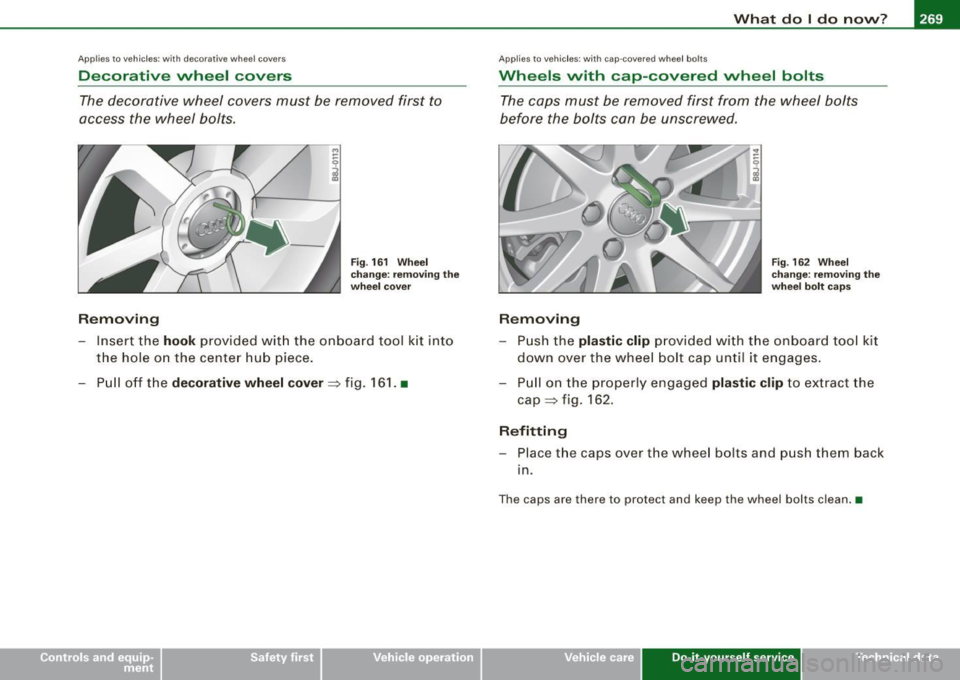

Ap plies to vehic les: with decorative wheel covers

Decorative wheel covers

The decorative wheel covers must be removed first to

access the wheel bolts.

Removing

Fig . 161 Wheel

change : removing the

wheel cover

- Insert the hook provided with the on board tool kit into

the hole on the center hub piece.

- Pull off the

decorative wheel cover=> fig. 161. •

Applies to vehicles: with cap-covered wheel bolts

Wheels with cap-covered wheel bo lts

The caps must be removed first from the wheel bolts

before the bolts can be unscrewed.

Removing

Fig . 162 Wheel

change : removing the

wheel bolt caps

-Push the plastic clip provided with the on board tool kit

down over the wheel bolt cap until it engages.

- Pull on the properly engaged

plastic clip to extract the

cap=> fig. 162.

Refitting

-Place the caps over the wheel bo lts and push them back

1n.

The caps are there to protect and keep the wheel bolts clean.•

Vehicle care Do-it-yourself service irechnical data

Page 272 of 316

1111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

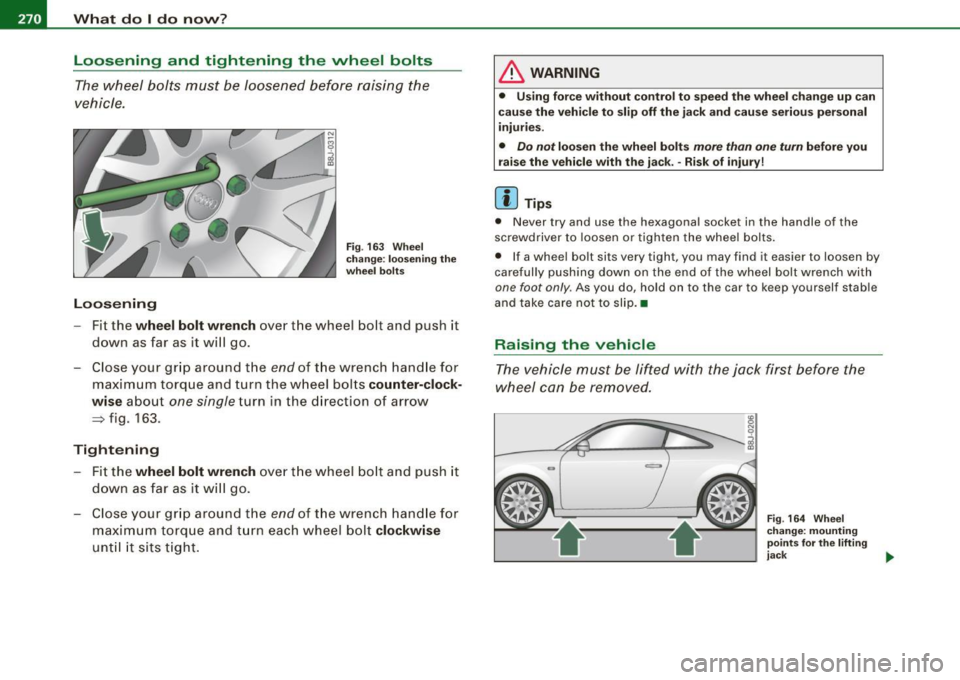

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the

vehicle.

Loosening

Fig . 163 Wheel

change: loosening the

wheel bolts

- Fit the wheel bolt wrench over the wheel bolt and push it

down as far as it will go .

- Close your grip around the

end of the wrench handle for

maximum torque and turn the wheel bolts

counter-clock

wise

about one single turn in the direction of arrow

~ fig. 163.

Tightening

Fit the wheel bolt wrench over the wheel bolt and push it

down as far as it will go.

- Close your grip around the

end of the wrench handle for

maximum torque and turn each wheel bolt

clockwise

until it sits tight.

& WARNING

• Using force without control to speed the wheel change up can

cause the vehicle to slip off the jack and cause serious personal

injuries.

• Do not loosen the wheel bolts more than one turn before you

raise the vehicle with the jack. -Risk of injury!

[ i] Tips

• Never try and use the hexagonal socket in the handle of the

screwdriver to loosen or tighten the wheel bolts.

• If a wheel bolt sits very tight, you may find it easier to loosen by

carefully pushing down on the end of the wheel bolt wrench with

one foot only . As you do, hold on to the car to keep yourself stable

and take care not to slip.•

Raising the vehicle

The vehicle must be lifted with the jack first before the

wheel can be removed.

Fig. 164 Wheel

change: mounting

points

for the lifting

jack ..

Page 273 of 316

What do I do now? -

------------------

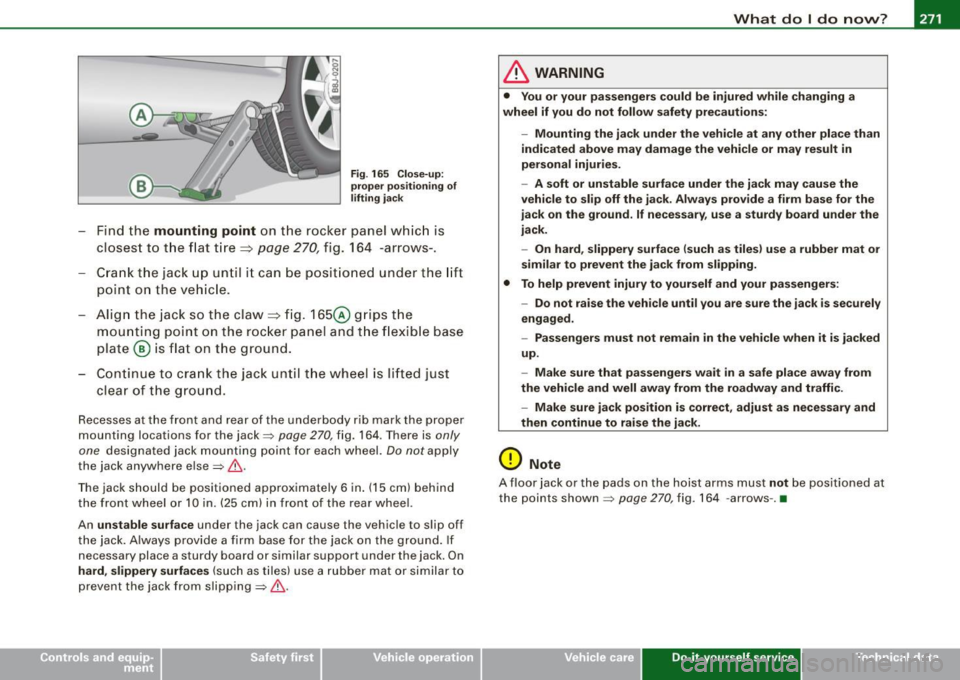

Fig. 165 Close-up:

proper positioning of

lifting jack

- Find the mounting point on the rocker panel which is

closest to the flat tire =>

page 270, fig. 164 -arrows-.

- Crank the jack up until it can be positioned under the lift

point on the vehicle.

- Align the jack so the claw=> fig. 165@ grips the

mounting point on the rocker panel and the flexible base

plate ® is flat on the ground.

- Continue to crank the jack until the wheel is lifted just

clear of the ground.

Recesses at the front and rear of the underbody rib mark the proper

mounting locations for the jack=>

page 270 , fig. 164. There is only

one

designated jack mounting point for each wheel. Do not apply

the jack anywhere else=>&.

The jack should be positioned approximately 6 in. (15 cm) behind

the front wheel or 10 in. (25 cm) in front of the rear wheel.

An

unstable surface under the jack can cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary place a sturdy board or similar support under the jack. On

hard, slippery surfaces (such as tiles) use a rubber mat or similar to

prevent the jack from slipping=> &.

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow safety precautions:

-Mounting the jack under the vehicle at any other place than

indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack. Always provide a firm base for the

jack on the ground. If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers:

-Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait

in a safe place away from

the vehicle and well away from the roadway and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack.

0 Note

A floor jack or the pads on the hoist arms must not be positioned at

the points shown

=> page 270 , fig. 164 -arrows -. •

Vehicle care Do-it-yourself service irechnical data

Page 274 of 316

-What d o I do novv ? P'cV:IL--.....:...:..:....:....:.:...:..::......;..;____ ___________ _

Taking the vvheel off

Follow these instructions step-by-step for changing the

wheel.

Fig. 166 Wheel

c han ge: usi ng th e

screwdriver handl e

!w ith t he b lade

re move d) to tu rn th e

bolts

F ig . 16 7 W hee l

c h a ng e: a lig nm ent p in

in side th e top ho le

After you have lo ose ned all wheel bolts and raised the

vehicle off the gro und , pe rform the following steps to

remove and replace the wheel :

Removing th e vvh eel

- Use t he

he xagonal sock et in th e sc rewdriver handle to

completely turn out the topmost wheel bo lt and set it

aside on a

clean surface => fig. 166. -

Screw the t hreaded en d of the

alignm ent pin from the

tool kit hand -tight into t he now vacant bo lt hole

=> fig . 167.

- Then comple tely unscrew the other wheel bolts as

described above .

- Take off the whee l leaving the alignment pin in the bolt

hole .

Putting on the vvhe el

- Lift the spare wheel and carefully s lide it over the align

ment p in to gu ide it in place.

- Use t he he xag onal socket in the sc rewdriver hand le t o

screw in and tig hten all whee l bolts

slightly.

Unscrew the alignment p in and insert and tighten t he

remai ning wheel bol t slightly like the rest.

- Tu rn the jack handle counter -c lockw ise to lower the

ve hicle until the jack is fully released.

- Use the whee l bolt w rench to tighten all wheel bolts

firmly =>

page 270. Tighten them crosswise , from one

bolt to the (approximately) opposite one, to keep the

wheel centered .

[ i ] Tip s

Never use the hexagonal socket in the handle of the screwdriver to

loosen or tighten the wheel bolts .

• Pull the reversible blade from the screwdriver before you use the

hexagonal socket in the handle to turn the wheel bolts.

• When mounting tires with

unid ire cti on al t re ad de sign make sure

the tread pattern is pointed the right way=>

page 273. ~

Page 275 of 316

What do I do now? -

----------------

•

• The whe el bo lts should be cl ean and easy to turn . C heck for dirt

an d corro sion on the mati ng s urfaces o f both th e wheel a nd the

hub. Remove a ll dirt fro m these surfaces before remountin g the

whee l.•

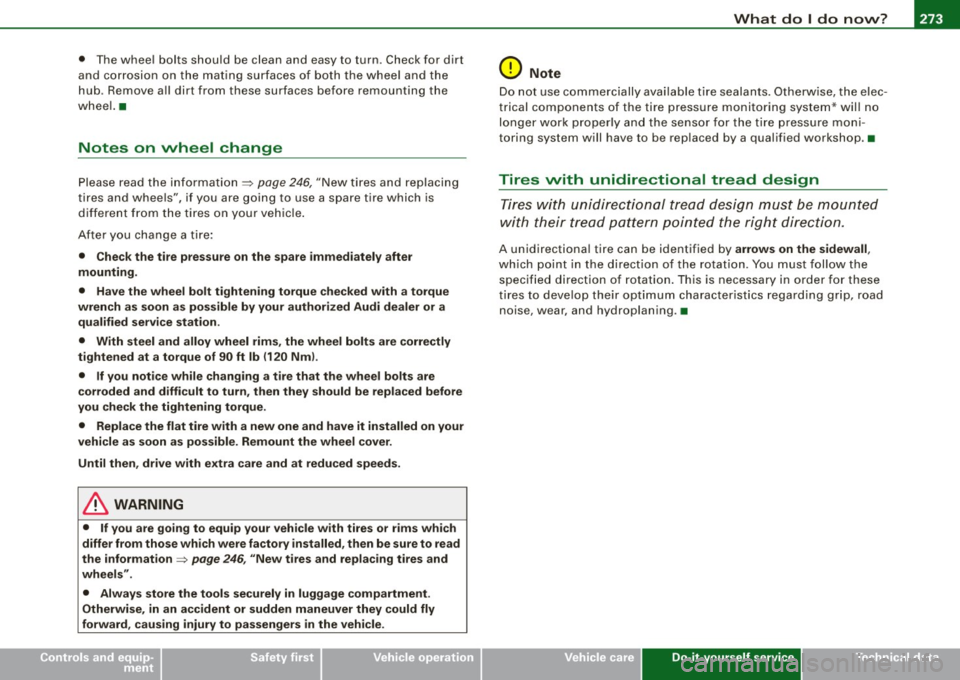

Notes on wheel change

Ple as e rea d th e informati on => pag e 246 , "New tir es an d r ep laci ng

tir es and whee ls", if you ar e goin g to us e a spar e tire which is

d ifferent from th e tir es on y our v ehic le .

After you ch ange a tire :

• Check the tire pressure on the spare immediately after

mounting.

• Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a qualified service station .

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 90 ft lb (120 Nm l.

• If you notice while changing a tire that the wheel bolts are

corroded and difficult to turn , then they should be replaced before

you check the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible . Remount the wheel cover.

Until then , drive with extra care and at reduced speeds .

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed , then be sure to read

the information

=> page 246, "New tires and replacing tires and

wheels ".

• Always store the tools securely in luggage compartment .

Otherwise, in an accident or sudden maneuver they could fly

forward, causing injury to passengers in the vehicle.

0 Note

D o not us e comme rc ia lly av ai labl e tire sea lants. Otherw ise, t he elec

trical components of the ti re pressure monitor ing system* will no

l o nger wor k properly a nd the se ns or fo r the tire pr essure moni

to ring system will have to be rep laced b y a qualified workshop. •

Tires with unidirectional tread design

T ires w ith unid ire ction al tread design must be m ounted

w ith their tread patte rn po inted t he r ight dire ction.

A un id irectiona l tir e ca n be iden tified by arrows on the sidewall ,

w hi ch point in th e dir ec tion of the r otation. You mus t follow th e

specified direction of rotati on. T his is necessa ry in o rder fo r these

t ire s to de ve lop their optimum ch arac ter ist ics rega rdin g grip, r oad

noise, wear, and h ydroplaning .•

Do-it -yourself service

Page 276 of 316

llffl.,___F_ u_ s_ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

Fuses and bulbs

Fuses

Replacing a fuse

A problem in the electrical system may be caused by a

blown fuse.

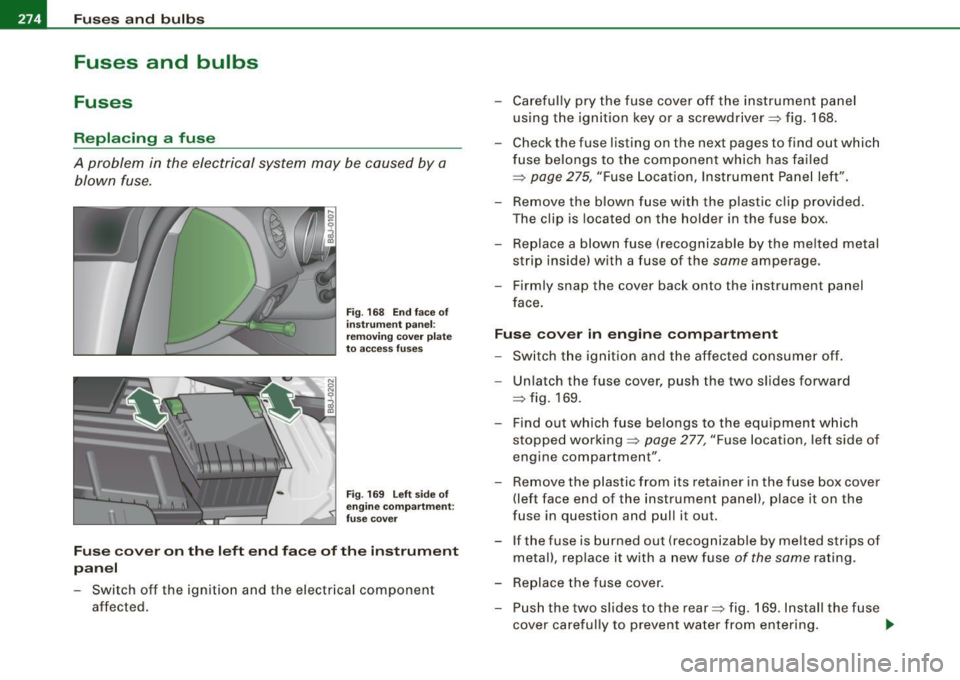

Fig . 168 End face of

instrument panel:

removing cover plate

to access fuses

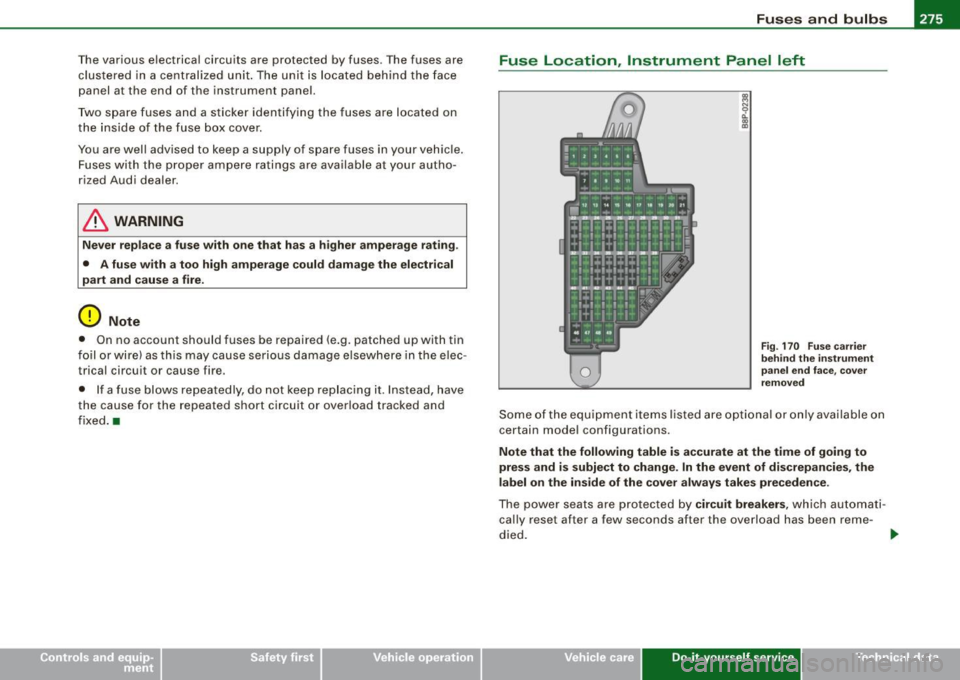

Fig .

169 Left side of

engine compartment :

fuse cover

Fuse cover on the left end face of the instrument

panel

- Switch off the ignition and the electrical component

affected. - Carefully pry the fuse cover off the instrument panel

using the ignition key or a screwdriver~ fig. 168.

- Check the fuse listing on the next pages to find out which

fuse belongs to the component which has failed

~ page 275, "Fuse Locatio n, Instrume nt Panel left".

- Remove the blown fuse with the plastic clip provided.

The clip is located on the holder in the fuse box.

- Replace a blown fuse (recognizable by the melted metal

strip inside) w ith a fuse of the same amperage .

- Firmly snap the cover back onto the instrument panel

face.

Fuse cover in engine compartment

- Switch the ignition and the affected consumer off.

- Unlatch the fuse cover, push the two slides forward

~ fig. 169.

- Find out which fuse belongs to the equipment which

stopped working~ page 277, "Fuse location, left side of

engine compartment".

- Remove the plastic from its reta iner in the fuse box cover

(left face end of the instrument panel), place it on the

fuse in question and pull it out.

- If the fuse is burned out (recognizable by melted strips of

metal), replace it with a new fuse of the same rating.

- Replace the fuse cover.

- Push the two slides to the rear~ fig. 169. Install the fuse

cover carefully to prevent water from entering.

~

Page 277 of 316

Fuses and bulbs -

------------------

The various electrical circuits are protected by fuses. The fuses are

clustered in a centralized unit. The unit is located behind the face

panel at the end of the instrument panel.

Two spare fuses and a sticker identifying the fuses are located on

the inside of the fuse box cover.

You are well advised to keep a supply of spare fuses in your vehicle.

Fuses with the proper ampere ratings are available at your autho

rized Audi dealer.

& WARNING

Never replace a fuse with one that has a higher amperage rating .

• A fuse with a too high amperage could damage the electrical

part and cause a fire.

0 Note

• On no account should fuses be repaired (e.g. patched up with tin

foil or wire) as this may cause serious damage elsewhere in the elec

trical circuit or cause fire.

• If a fuse blows repeatedly, do not keep replacing it. Instead, have

the cause for the repeated short circuit or overload tracked and

fixed. •

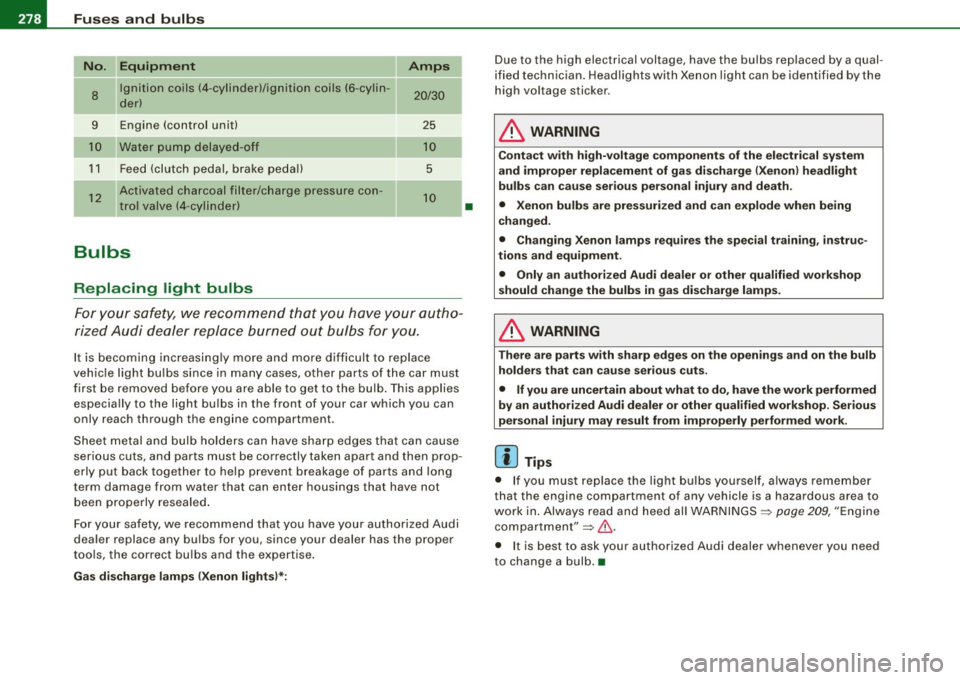

Fuse Location , Instrument Panel left

Fig . 170 Fuse carrier

behind the instrument

panelendface,cover

removed

Some of the equipment items listed are optional or only available on

certain model configurations.

Note that the following table is accurate at the time of going to

press and is subject to change. In the event of discrepancies, the

label on the inside of the cover always takes precedence.

The power seats are protected by circuit breakers, which automati

cally reset after a few seconds after the overload has been reme-

died. .,_

Vehicle care Do-it-yourself service irechnical data

Page 278 of 316

ffl.___F_ u_ s _ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

Equipment No.

II Equipment

Amps I

Engine relay, fuel tank control unit, Airbag Off 16 A/C system (control unit) 10

1 light, light switch (switch illumination), diagnos-10

tic connector

17 Tire pressure monitoring system (control unit) 5

18 Not used

2 ABS, ASR, ESP, brake light switch 5

19

Not used

3 AFS headlight (left) 5 20

Not used

Oil level sensor (extended maintenance interval)

(WIVl, tire pressure monitoring system, switch

21 Fuel injectors (gasoline engine) 10

4 for Electronic Stability Program (ESP), AFS head-5 22 Wind deflector (Roadster) 30

lights (control unit), A/C system (pressure sen-23 Horn 20 llsorl, backup light switch

Automatic headlight range control, AFS head -

24 Transmission (control unit) 15

5

light (right)/ manual headlight range control, 5/10 25 Heater rear window Coupe/heated rear window 30/20

halogen headlights Roadster

Control unit for CAN data transfer (gateway),

26 Driver's side power window 30

6 electromechanical steering, automatic transmis-5 27 Passenger's side power window 30

sion shift gate

28 Not used

Acoustic Park Assist, automatic dipping interior

rear view mirror, garage door opener, heatable

29 Washer pump 15

7

windshield washer nozzles, washer pump, wind 5

30 Cigarette lighter 20

deflector relay (Roadster)

31 Starter 40

8

Haldex clutch 5 32 Steering column module 5

9

Control unit Audi magnetic ride 5 33

Instrument cluster 5

Airbag control unit 5 34 Radio navigation system, radio 15

1 1 Mass airflow sensor, crankcase heating 5/10

35

Audio amplifier 30

Door control unit (central locking driver/passen-12 10

36 Engine (control unit) 10 gerl

13 Diagnostic connector 10 37 CAN (Gateway) 5

Rain sensor, automatic transmission shift gate 5 38 Not used

15 Roof light (interior lighting) 5 39 Not

used

Page 279 of 316

_______________________________________________ F_ u_ s_ e_s _ a_ n_d _ b_u_ l_ b _s_--J _

No. Equipm ent Amps

40 Not used

41 Not used

42 Not used

43 Not us ed

44 Not use d

45 Not used

Not used

47 SDARS tuner, cell phone package, TV tune r 5

48 VDA interface

5

49 Not us ed

Fuse location , left side of engine

compartment

"' ~ M 9 -, ., m

F ig . 17 1 Illus tration o f

fu se h old er on l eft s ide

of engin e compart-

m en t: fuses (wi thout

fu se cov er)

Some of the equipment items listed a re optiona l or on ly avai lable on

ce rtain model co nfigurations .

Not e th at the foll owing t able is acc urate at th e tim e of goin g to

pr es s and i s subject to chang e. In the even t of di scr epanc ies, the

lab el on the insi de of th e cove r alwa ys takes pre ced en ce .

•

No . Equipm ent

Fuse h old er (bl ack)

1 Not used

2 Not used

3 Not used

4 Not used

5

II Anti-theft warning system (sensor), anti-theft

warning system (ho rn)

6 Headlamp washer system

7 Electric fue

l pumps (supplyl/volume control

valve

8 Windshield wipers

9 Heated seats (driver and passenger)

10 Lumbar support (driver and passenger

)

1 1 Not used

12 Ventilation b

lower

Fus e holder (brown )

1

2

3

4

5

6

7 Fuel pump (6-cylinderl

02 sensors (6-cylinderl Mass airflow sensor (6 -cy linder)

02 sensors (6-cylin derl

Relay coil relay volum e con tro l valve 14-cylin-

der)

Secondary air pump valve (6 -cylinderl , 02 sen

so rs ( 4-cylinderl

Positioning valves pre-wired engine harness

Vehicle care Do-it-yourself service

Amps

5

30

15/10 30

25 1 0

40 15

10

5

10

5

1 0

10

-

irechnical data

Page 280 of 316

.,,___F_ u_ s _ e_s _ a_n _ d_ b_ u_lb _ s _______________________________________________ _

No. Equipment Amps

8 Ignition coils (4

-cylinderl/ignition coils (6-cylin -

20/30

der)

9 Engine (control unitl 25

Water pump delayed-off 10

1 1 Feed (clutch pedal, brake pedal) 5

12

Activated charcoal filter/charge pressure con-10 trol valve (4-cylinder)

-' -

Bulbs

Replacing light bulbs

For your safety, we recommend that you have your autho

rized Audi dealer replace burned out bulbs for you.

It is becoming increasingly more and more difficult to replace

vehicle light bulbs since in many cases , other parts of the car must

first be removed before you are able to get to the bulb. This applies

especially to the light bulbs in the front of your car which you can

only reach through the engine compartment.

Sheet metal and bulb holders can have sharp edges that can cause

serious cuts, and parts must be correctly taken apart and then prop

erly put back together to help prevent breakage of parts and long

term damage from water that can enter housings that have not been properly resealed.

For your safety , we recommend that you have your authorized Audi

dealer replace any bulbs for you, since your dealer has the proper

tools, the correct bulbs and the expertise.

Gas discharge lamps (Xenon lights)*:

•

Due to the high electrical voltage, have the bulbs replaced by a qual

ified technician. Headlights with Xenon light can be identified by the

high voltage sticker .

& WARNING

Contact with high-voltage components of the electrical system

and improper replacement of gas discharge (Xenon) headlight

bulbs can cause serious personal injury and death .

• Xenon bulbs are pressurized and can explode when being

changed.

• Changing Xenon lamps requires the special training, instruc

tions and equipment .

• Only an authorized Audi dealer or other qualified workshop

should change the bulbs in gas discharge lamps.

& WARNING

There are parts with sharp edges on the openings and on the bulb holders that can cause serious cuts .

• If you are uncertain about what to do, have the work performed

by an authorized Audi dealer or other qualified workshop. Serious

personal injury may result from improperly performed work.

[ i] Tips

• If you must replace the light bulbs yourself, always remember

that the engine compartment of any vehicle is a hazardous area to

work in. Always read and heed all WARNINGS=>

page 209, "Engine

compartment"=>

/A .

• It is best to ask your authorized Audi dealer whenever you need

to change a bulb .•