BMW M4 2016 Owners Manual

Manufacturer: BMW, Model Year: 2016, Model line: M4, Model: BMW M4 2016Pages: 228, PDF Size: 4.88 MB

Page 171 of 228

Mobility

To assist you in preserving your car’s mobility, this section contains important information on

operating fluids, wheels and tyres, maintenance and breakdown assistance.Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 172 of 228

RefuellingVehicle equipmentThis chapter describes all standard, national

and special equipment provided in the model

series. Equipment not available in the vehicle is

therefore also described, for example the se‐

lected special equipment or national version.

This also applies to safety-relevant functions

and systems. Comply with the relevant na‐

tional regulations when using the correspond‐

ing functions and systems.

Notes Before refuelling, observe notes on fuel quality,

see page 174.

ATTENTION

If the range drops below 50 km, approx.

30 miles, the engine could not be supplied

anymore with sufficient fuel. Engine functions

are not ensured anymore. Danger of damage

to property. Refuel in good time.◀

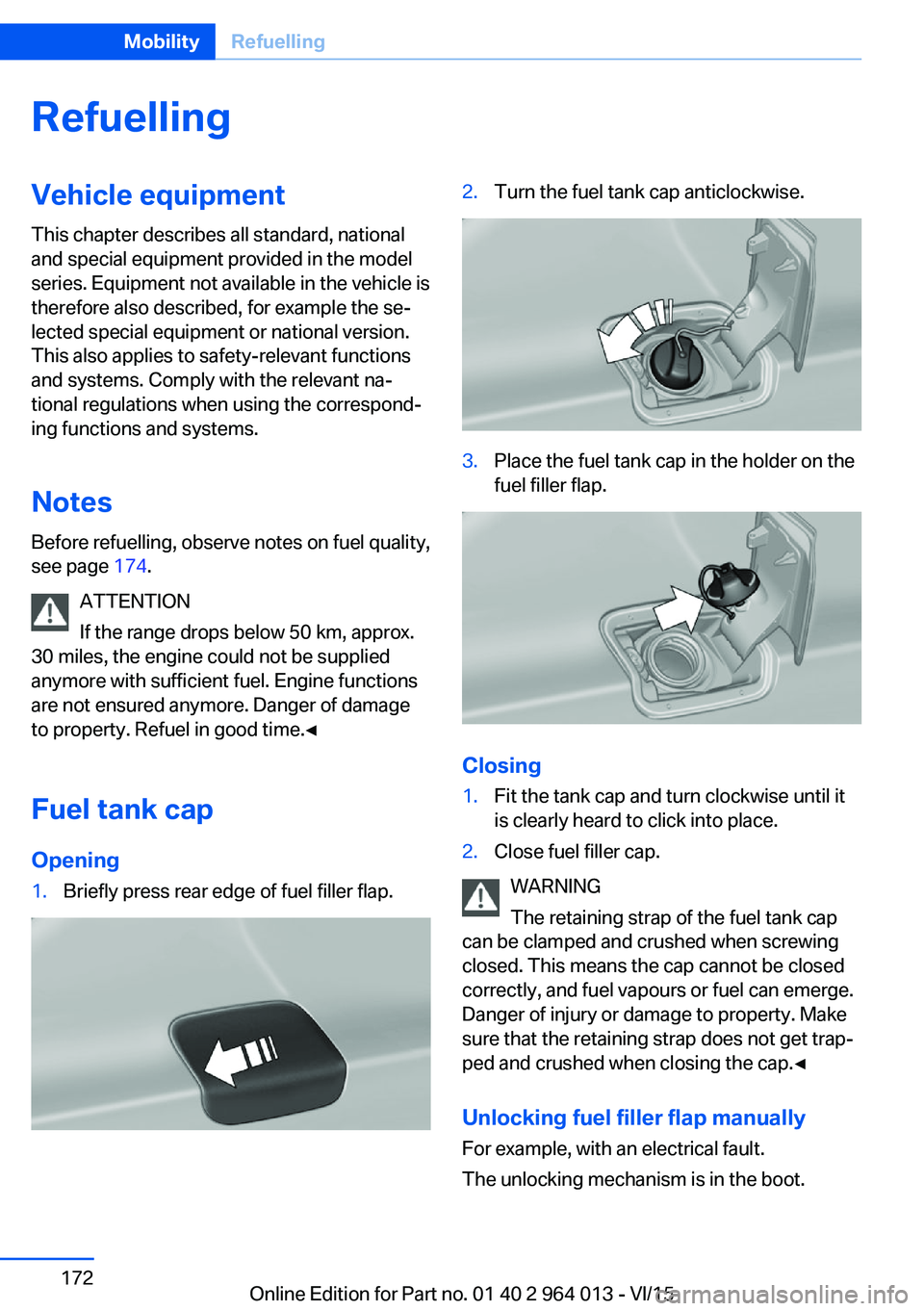

Fuel tank cap Opening1.Briefly press rear edge of fuel filler flap.2.Turn the fuel tank cap anticlockwise.3.Place the fuel tank cap in the holder on the

fuel filler flap.

Closing

1.Fit the tank cap and turn clockwise until it

is clearly heard to click into place.2.Close fuel filler cap.

WARNING

The retaining strap of the fuel tank cap

can be clamped and crushed when screwing

closed. This means the cap cannot be closed

correctly, and fuel vapours or fuel can emerge.

Danger of injury or damage to property. Make

sure that the retaining strap does not get trap‐

ped and crushed when closing the cap.◀

Unlocking fuel filler flap manually

For example, with an electrical fault.

The unlocking mechanism is in the boot.

Seite 172MobilityRefuelling172

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 173 of 228

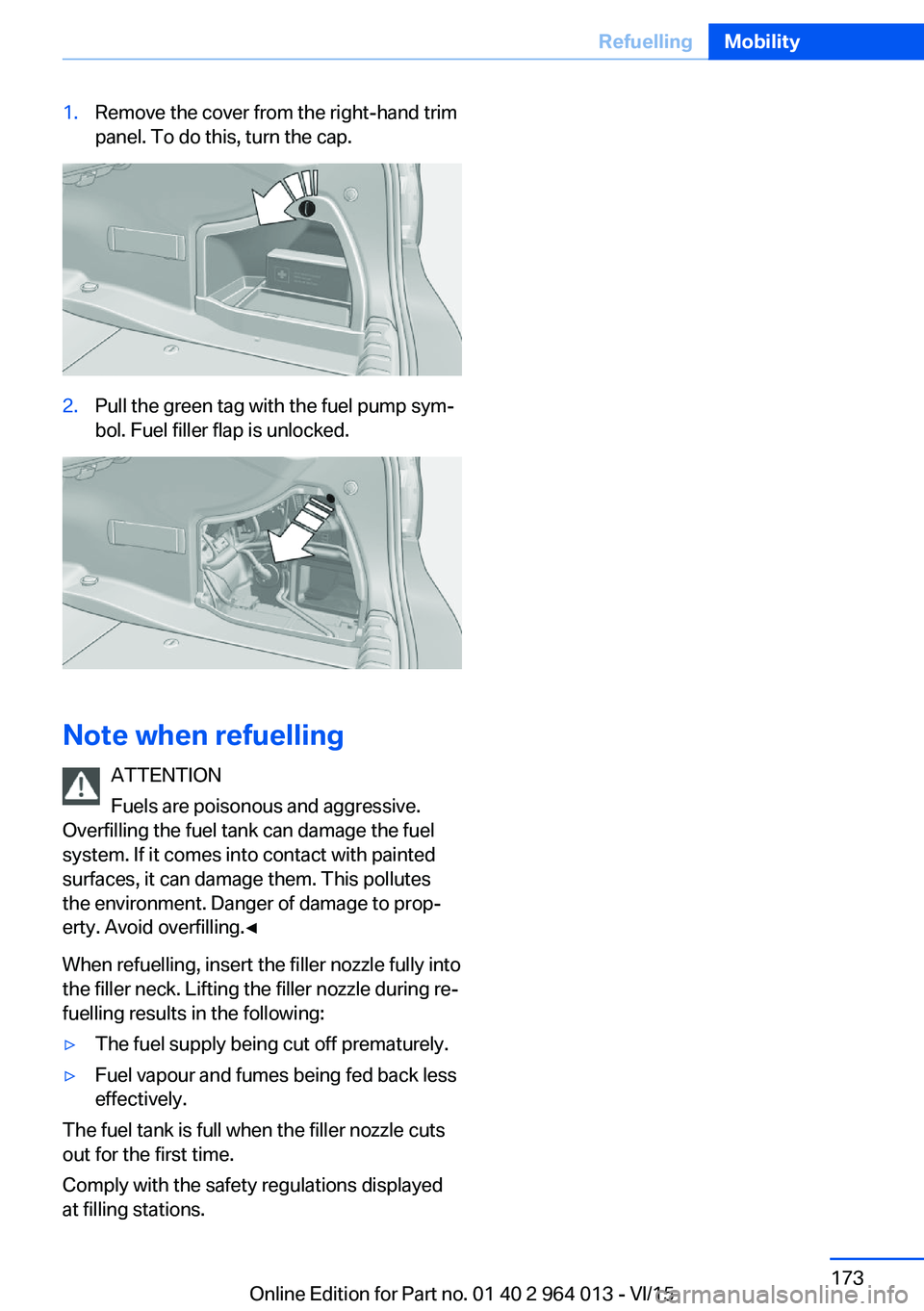

1.Remove the cover from the right-hand trim

panel. To do this, turn the cap.2.Pull the green tag with the fuel pump sym‐

bol. Fuel filler flap is unlocked.

Note when refuelling

ATTENTION

Fuels are poisonous and aggressive.

Overfilling the fuel tank can damage the fuel

system. If it comes into contact with painted

surfaces, it can damage them. This pollutes

the environment. Danger of damage to prop‐

erty. Avoid overfilling.◀

When refuelling, insert the filler nozzle fully into

the filler neck. Lifting the filler nozzle during re‐

fuelling results in the following:

▷The fuel supply being cut off prematurely.▷Fuel vapour and fumes being fed back less

effectively.

The fuel tank is full when the filler nozzle cuts

out for the first time.

Comply with the safety regulations displayed

at filling stations.

Seite 173RefuellingMobility173

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 174 of 228

FuelVehicle equipmentThis chapter describes all standard, national

and special equipment provided in the model

series. Equipment not available in the vehicle is

therefore also described, for example the se‐

lected special equipment or national version.

This also applies to safety-relevant functions

and systems. Comply with the relevant na‐

tional regulations when using the correspond‐

ing functions and systems.

Fuel quality

General Depending on the region, many filling stations

sell fuel that is adapted to the conditions in

winter or summer. Fuel that is sold in winter fa‐

cilitates cold starting, for example.

Note ATTENTION

Even fuels corresponding to the specifi‐

cations may be of low quality. Engine problems

can arise, for example poor engine starting, im‐

paired driving properties or reduced perform‐

ance. Danger of damage to property. In the

case of engine problems, use a different filling

station or refuel with a higher octane fuel from

a brand maufacturer.◀

Petrol

For optimal fuel consumption, the petrol

should be sulphur-free or as low in sulphur

content as possible.

Fuels labelled on the pump as containing metal

must not be used.ATTENTION

Even small quantities of the wrong fuel or

wrong fuel additives can damage the fuel sys‐

tem and engine. In addition, the catalytic con‐

verter will be permanently damaged. Danger of

damage to property. Do not use the following

fuel or additives with petrol engines:▷Leaded petrol.▷Metallic additives, for example manganese

or iron.

After filling the wrong fuel, do not press the

start/stop button. Contact a Service Partner or

a qualified specialist workshop.◀

You can fill up with fuels with a maximum pro‐

portion of ethanol of 10 %, in other words E10.

ATTENTION

Incorrect fuels can damage the fuel sys‐

tem and engine. Danger of damage to prop‐

erty. Do not fill with any fuels that either have a

higher ethanol content than recommended or

that contain methanol, for example M5 to

M100.◀

The engine has anti-knock control. This means

that different petrol grades can be used.

Petrol grade Super Plus, with RON 98.

Fill up this fuel so that the nominal perform‐

ance data values and consumption is achieved.

Minimum grade Super with RON 95.

ATTENTION

Fuel below the specified minimum qual‐

ity can impact the engine function or lead to

engine damage. Danger of damage to prop‐

erty. Do not refuel petrol below the specified

minimum quality.◀

Seite 174MobilityFuel174

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 175 of 228

Wheels and tyresVehicle equipment

This chapter describes all standard, national

and special equipment provided in the model

series. Equipment not available in the vehicle is

therefore also described, for example the se‐

lected special equipment or national version.

This also applies to safety-relevant functions

and systems. Comply with the relevant na‐

tional regulations when using the correspond‐

ing functions and systems.

Tyre pressures Information for your safety

A tyre’s condition and pressure influence the

following:▷Operating life of the tyre.▷Driving safety.▷Driving comfort.

Checking tyre pressures

WARNING

A tyre with inadequate or missing tyre in‐

flation pressure impairs driving properties, for example steering and braking. Danger of acci‐

dents. Check tyre inflation pressure regularly

and adjust as necessary, for example twice a

month or before any long journey.◀

Tyres have a natural, uniform tyre pressure

loss.

Tyres heat up when driving and with the tem‐

perature of the tyre, the tyre filling pressure in‐

creases. The tyre filling pressure data relate to

cold tyres or tyres at ambient temperature.

Only check the tyre pressure when the tyres

are cold. In other words, after driving for a max‐

imum of 2 km or if the vehicle has been parked

for at least 2 hours.

Inflating devices can display a pressure as

much as 0.1 bar too low.

With runflat indicator: reinitialise the runflat in‐

dicator after adjusting tyre pressures.

With tyre pressure monitor: reset the tyre pres‐

sure monitor after adjusting the tyre pressure

to a new value.

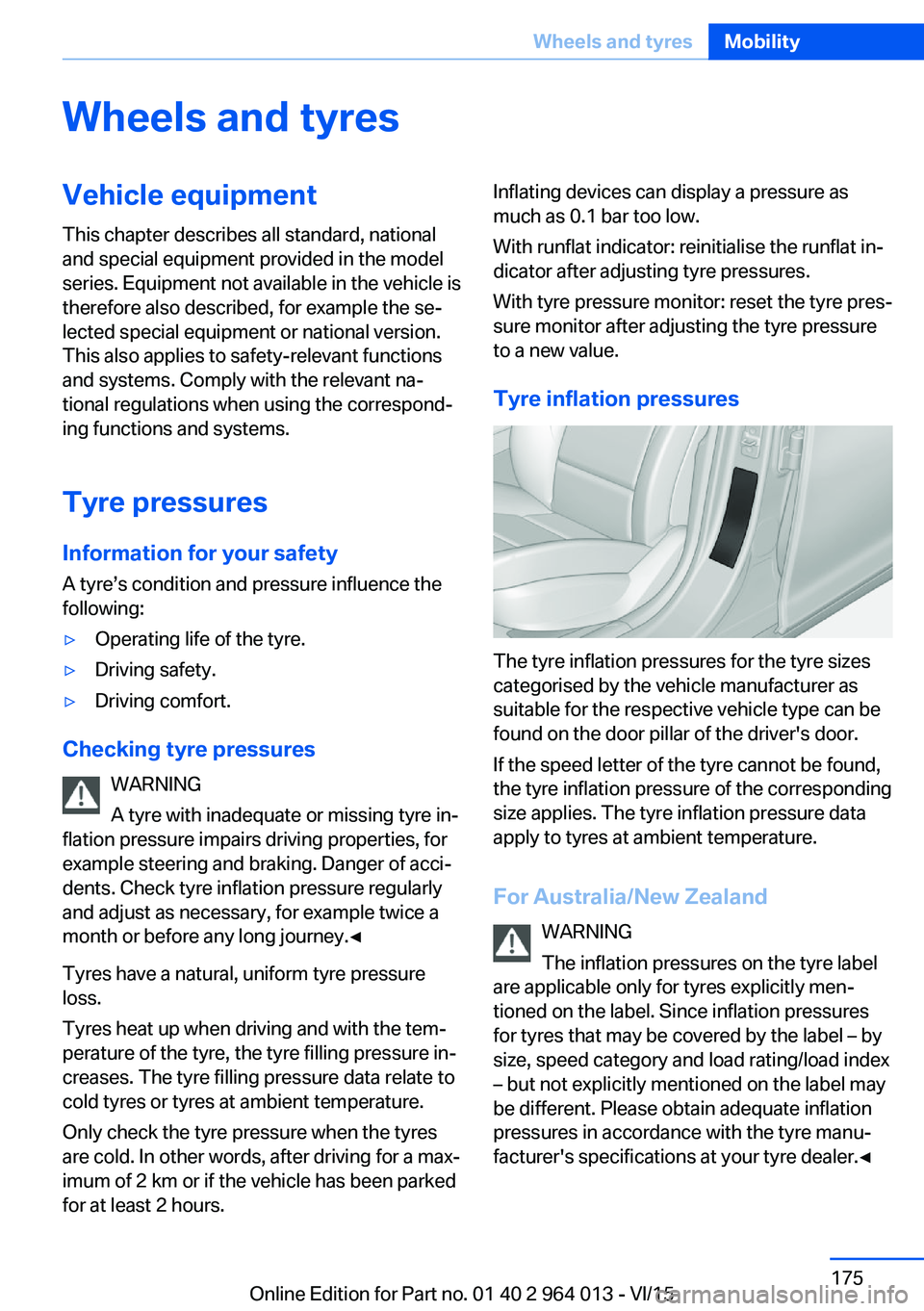

Tyre inflation pressures

The tyre inflation pressures for the tyre sizes

categorised by the vehicle manufacturer as

suitable for the respective vehicle type can be

found on the door pillar of the driver's door.

If the speed letter of the tyre cannot be found,

the tyre inflation pressure of the corresponding

size applies. The tyre inflation pressure data

apply to tyres at ambient temperature.

For Australia/New Zealand WARNING

The inflation pressures on the tyre label

are applicable only for tyres explicitly men‐

tioned on the label. Since inflation pressures

for tyres that may be covered by the label – by

size, speed category and load rating/load index

– but not explicitly mentioned on the label may

be different. Please obtain adequate inflation

pressures in accordance with the tyre manu‐

facturer's specifications at your tyre dealer.◀

Seite 175Wheels and tyresMobility175

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 176 of 228

Tyre sizes

The pressure values apply for the tyre sizes

categorised by the vehicle manufacturer as

suitable and the tyre makes recommended for

the respective vehicle type.

More information regarding wheels and tyres

can be enquired with a Service Partner or a

qualified specialist workshop.

Tyre tread

Summer tyres

The tyre tread depth should not be less than

3 mm, 0.12 in.

Below a tread depth of 3 mm, approximately

0.12 in, there is a high risk of aquaplaning.

Winter tyres The tyre tread depth should not be less than4 mm, approximately 0.16 in.

Below a tread depth of 4 mm, approximately

0.16 in, suitability for vehicle operation in win‐

ter is restricted.

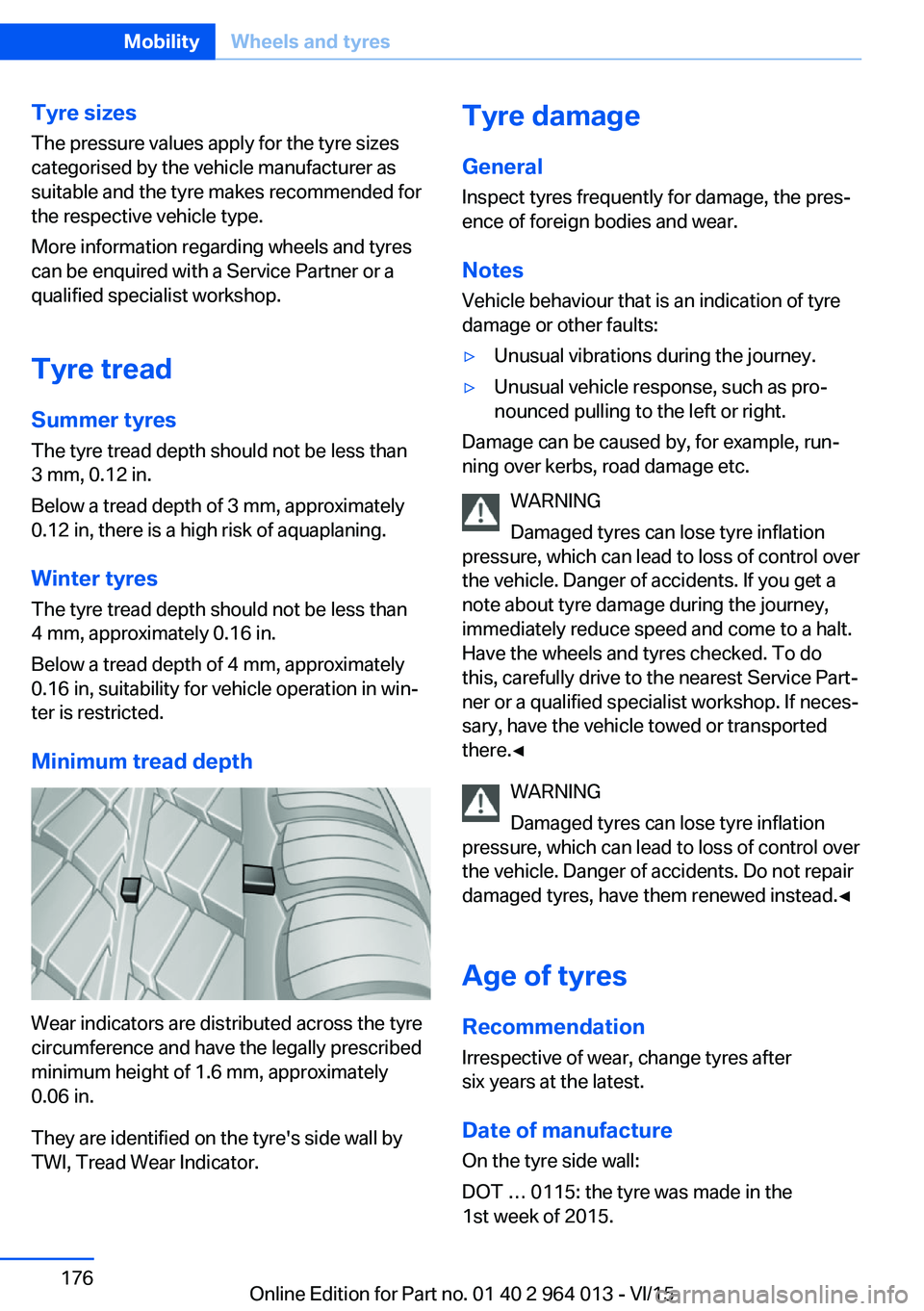

Minimum tread depth

Wear indicators are distributed across the tyre

circumference and have the legally prescribed

minimum height of 1.6 mm, approximately

0.06 in.

They are identified on the tyre's side wall by

TWI, Tread Wear Indicator.

Tyre damage

General Inspect tyres frequently for damage, the pres‐

ence of foreign bodies and wear.

Notes

Vehicle behaviour that is an indication of tyre

damage or other faults:▷Unusual vibrations during the journey.▷Unusual vehicle response, such as pro‐

nounced pulling to the left or right.

Damage can be caused by, for example, run‐

ning over kerbs, road damage etc.

WARNING

Damaged tyres can lose tyre inflation

pressure, which can lead to loss of control over

the vehicle. Danger of accidents. If you get a

note about tyre damage during the journey,

immediately reduce speed and come to a halt.

Have the wheels and tyres checked. To do

this, carefully drive to the nearest Service Part‐

ner or a qualified specialist workshop. If neces‐

sary, have the vehicle towed or transported

there.◀

WARNING

Damaged tyres can lose tyre inflation

pressure, which can lead to loss of control over

the vehicle. Danger of accidents. Do not repair

damaged tyres, have them renewed instead.◀

Age of tyres

Recommendation

Irrespective of wear, change tyres after

six years at the latest.

Date of manufacture

On the tyre side wall:

DOT … 0115: the tyre was made in the

1st week of 2015.

Seite 176MobilityWheels and tyres176

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 177 of 228

Replacement of wheels and

tyres

Fitting Have fitting and balancing performed by a

Service Partner or a qualified specialist work‐

shop.

Wheel and tyre combination The correct wheel and tyre combination and

rim designs for the vehicle can be consulted at

a Service Partner or a qualified specialist work‐

shop.

Incorrect wheel and tyre combinations will in‐

terfere with the proper functioning of various

systems, such as ABS and DSC.

To maintain good vehicle handling, always fit

tyres of the same make and tread pattern to all

wheels.

After a tyre has been damaged, fit the original

wheel and tyre combination again.

WARNING

Wheels and tyres that are categorised as

unsuitable by the vehicle manufacturer can

damage parts of the vehicle, for example by

touching the bodywork as a result of toleran‐

ces, in spite of having the same nominal size.

Danger of accidents. Use wheels and tyres that

have been categorised as suitable for the re‐

spective vehicle type by the vehicle manufac‐

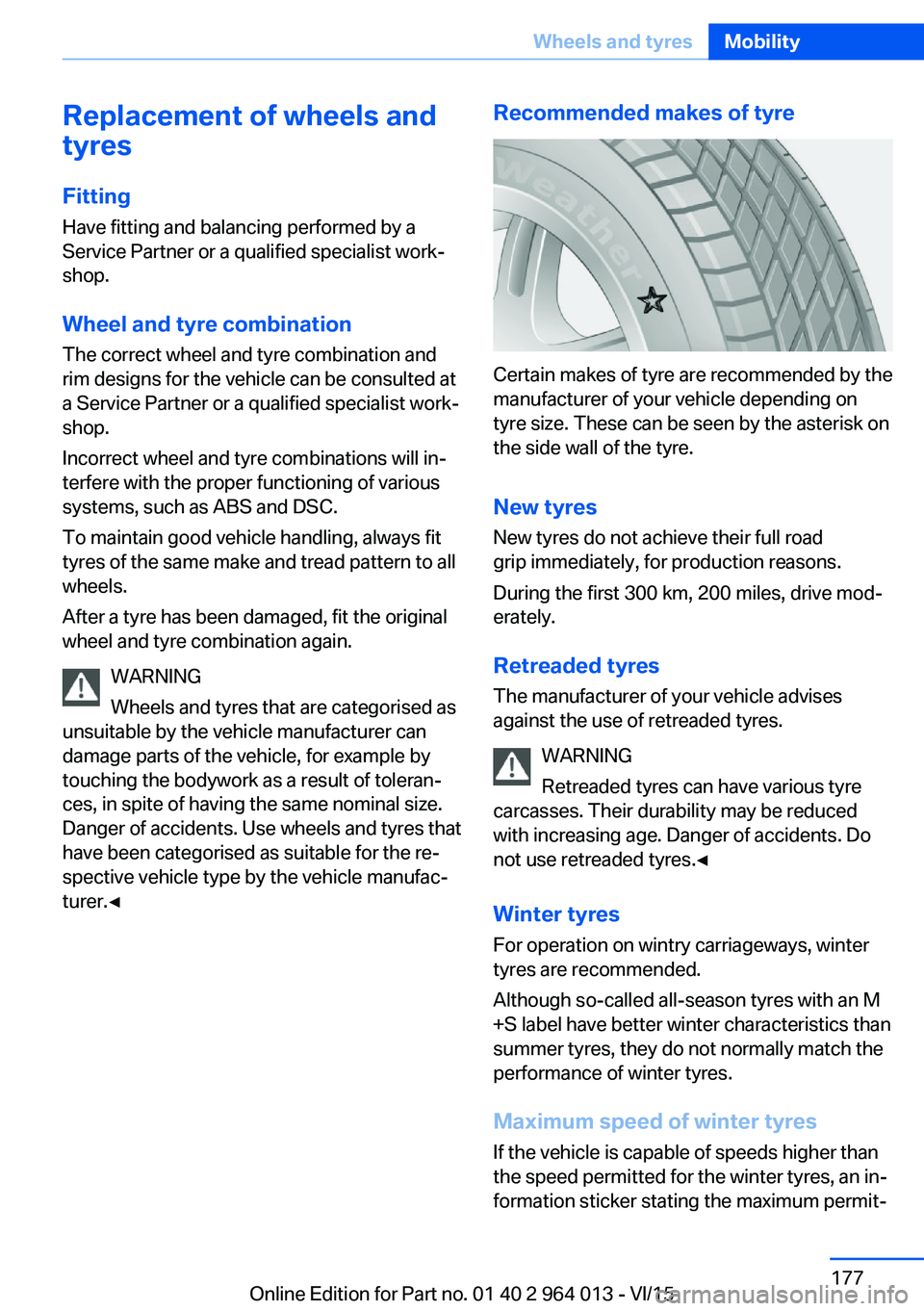

turer.◀Recommended makes of tyre

Certain makes of tyre are recommended by the

manufacturer of your vehicle depending on

tyre size. These can be seen by the asterisk on

the side wall of the tyre.

New tyres New tyres do not achieve their full road

grip immediately, for production reasons.

During the first 300 km, 200 miles, drive mod‐

erately.

Retreaded tyres The manufacturer of your vehicle advises

against the use of retreaded tyres.

WARNING

Retreaded tyres can have various tyre

carcasses. Their durability may be reduced

with increasing age. Danger of accidents. Do

not use retreaded tyres.◀

Winter tyres For operation on wintry carriageways, winter

tyres are recommended.

Although so-called all-season tyres with an M

+S label have better winter characteristics than

summer tyres, they do not normally match the

performance of winter tyres.

Maximum speed of winter tyres

If the vehicle is capable of speeds higher than

the speed permitted for the winter tyres, an in‐

formation sticker stating the maximum permit‐

Seite 177Wheels and tyresMobility177

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 178 of 228

ted speed for the tyres fitted must be dis‐

played in the driver's field of view. The sticker

is available from a Service Partner or a qualified

specialist workshop.

If winter tyres are fitted, observe and comply

with the respectively permitted maximum

speed.

Interchanging front and rear wheels

The manufacturer of your vehicle advises

against interchanging the front and rear

wheels. This could impair vehicle handling

Such a change is not permitted in vehicles with

different tyre or rim dimensions on the front

and rear axles.

Tyre storage

Store wheels and tyres in a cool, dry and pref‐

erably dark place when not in use.

Protect tyres against contamination from oil,

grease and fuel.

Do not exceed the maximum tyre pressure in‐

dicated on the tyre's side wall.

Remedying flat tyres Safety measures▷Park the vehicle on a solid surface and as

far away from moving traffic as possible.▷Switch on hazard warning lights.▷Protect the vehicle against rolling, by ap‐

plying the parking brake.▷Engage the steering wheel lock in the

straight ahead position of the wheels.▷Allow all vehicle occupants get out of the

vehicle and guide them out of the danger

area, for example behind the crash barrier.▷Set up warning triangle an appropriate dis‐

tance away.Mobility system

Principle With the mobility system, minor tyre damage

can be quickly sealed, to allow you to drive on.

To do that, liquid sealant is pumped into the

tyres which encloses the damage from the in‐ side when it hardens.

The compressor can be used to check the tyre

inflation pressure.

Notes▷Please observe the notes on the applica‐

tion of the Mobility system which are on

the compressor and the sealant container.▷Applying the Mobility system can be inef‐

fective for tyre damage as from a size of

approximately 4 mm.▷Contact a Service Partner or a qualified

specialist workshop if you are unable to put

the tyre back in operation.▷If possible, foreign matter that has penetra‐

ted the tyre should remain inside the tyre.▷Remove the speed limit sticker from the

sealant container and attach to the steer‐

ing wheel.▷Using sealants can damage the TPM wheel

electronics. If sealant is used, check the

electronics as soon as you get an opportu‐

nity and have them replaced if necessary.

DANGER

A blocked exhaust pipe or inadequate

ventilation can allow harmful exhaust fumes to

penetrate the vehicle. The exhaust gas con‐

tains carbon monoxide, which is colourless and

odourless, but highly toxic. In enclosed spaces,

the exhaust fumes can also build up outside

the vehicle. Danger of fatal injury. Keep the ex‐

haust pipe clear and ensure sufficient ventila‐

tion.◀

Storage

Mobility system is located under boot floor.

Seite 178MobilityWheels and tyres178

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 179 of 228

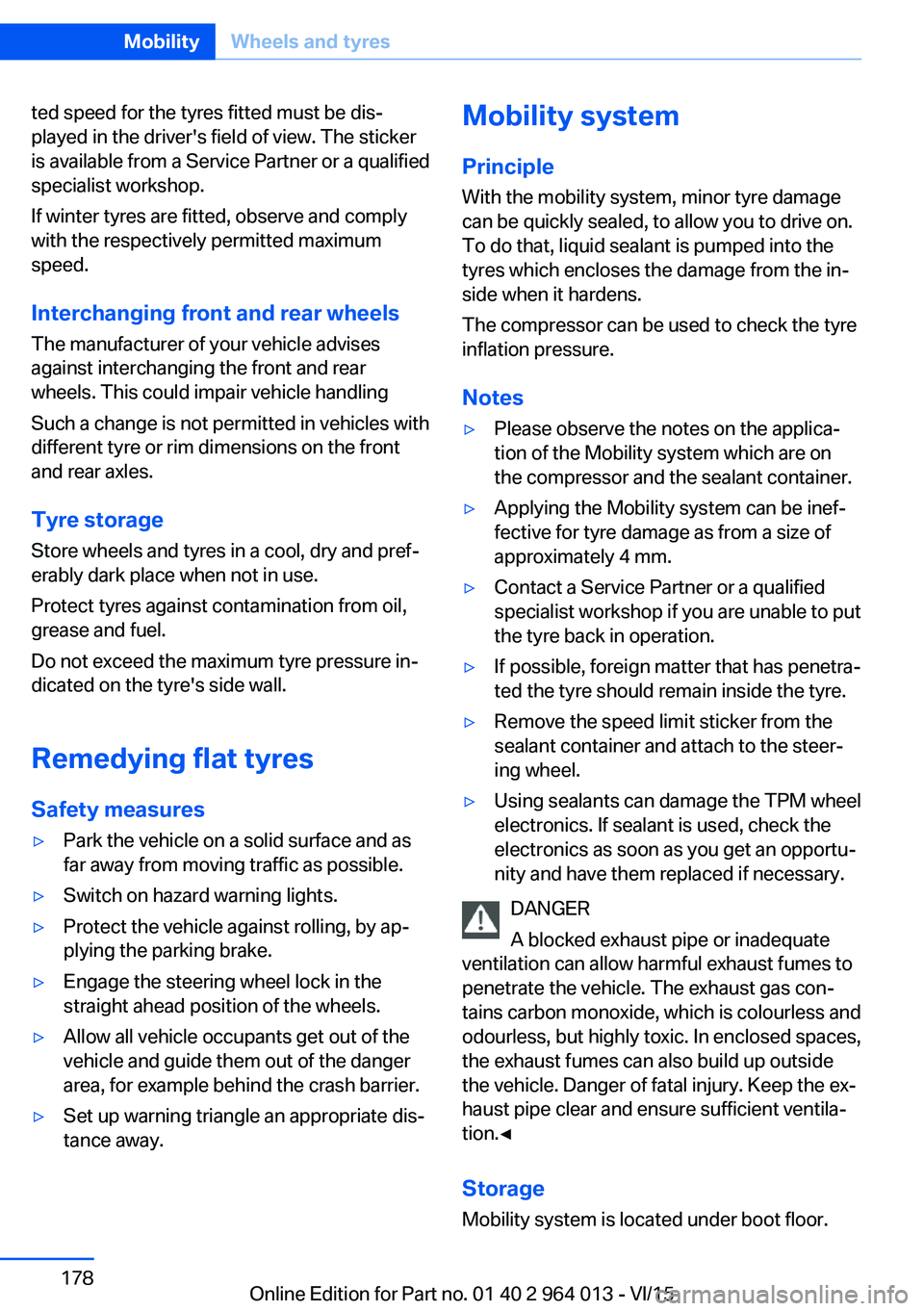

Sealant container▷Sealant container, arrow 1.▷Filler hose, arrow 2.

Note the use-by date on the sealant container.

Compressor

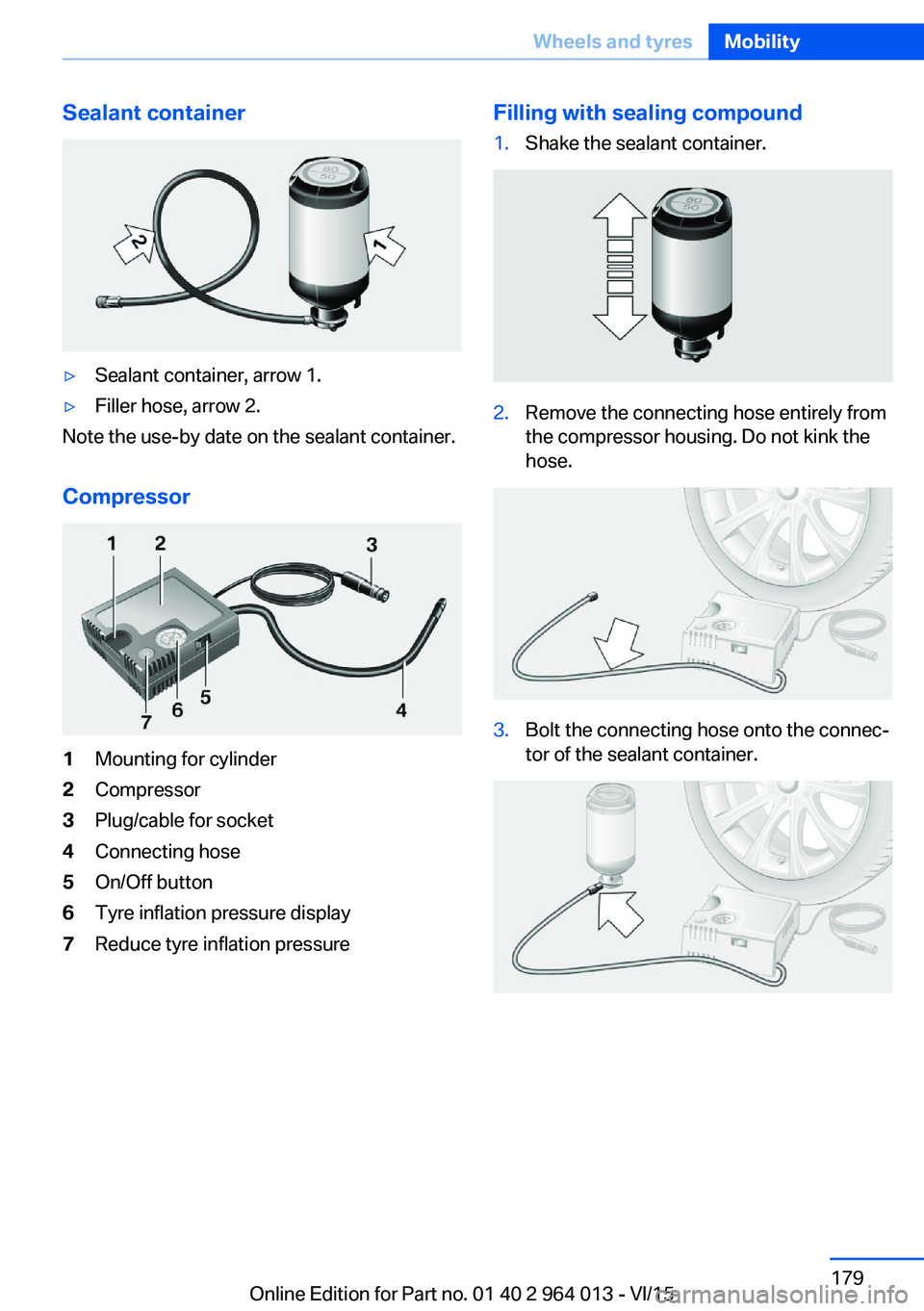

1Mounting for cylinder2Compressor3Plug/cable for socket4Connecting hose5On/Off button6Tyre inflation pressure display7Reduce tyre inflation pressureFilling with sealing compound1.Shake the sealant container.2.Remove the connecting hose entirely from

the compressor housing. Do not kink the

hose.3.Bolt the connecting hose onto the connec‐

tor of the sealant container.Seite 179Wheels and tyresMobility179

Online Edition for Part no. 01 40 2 964 013 - VI/15

Page 180 of 228

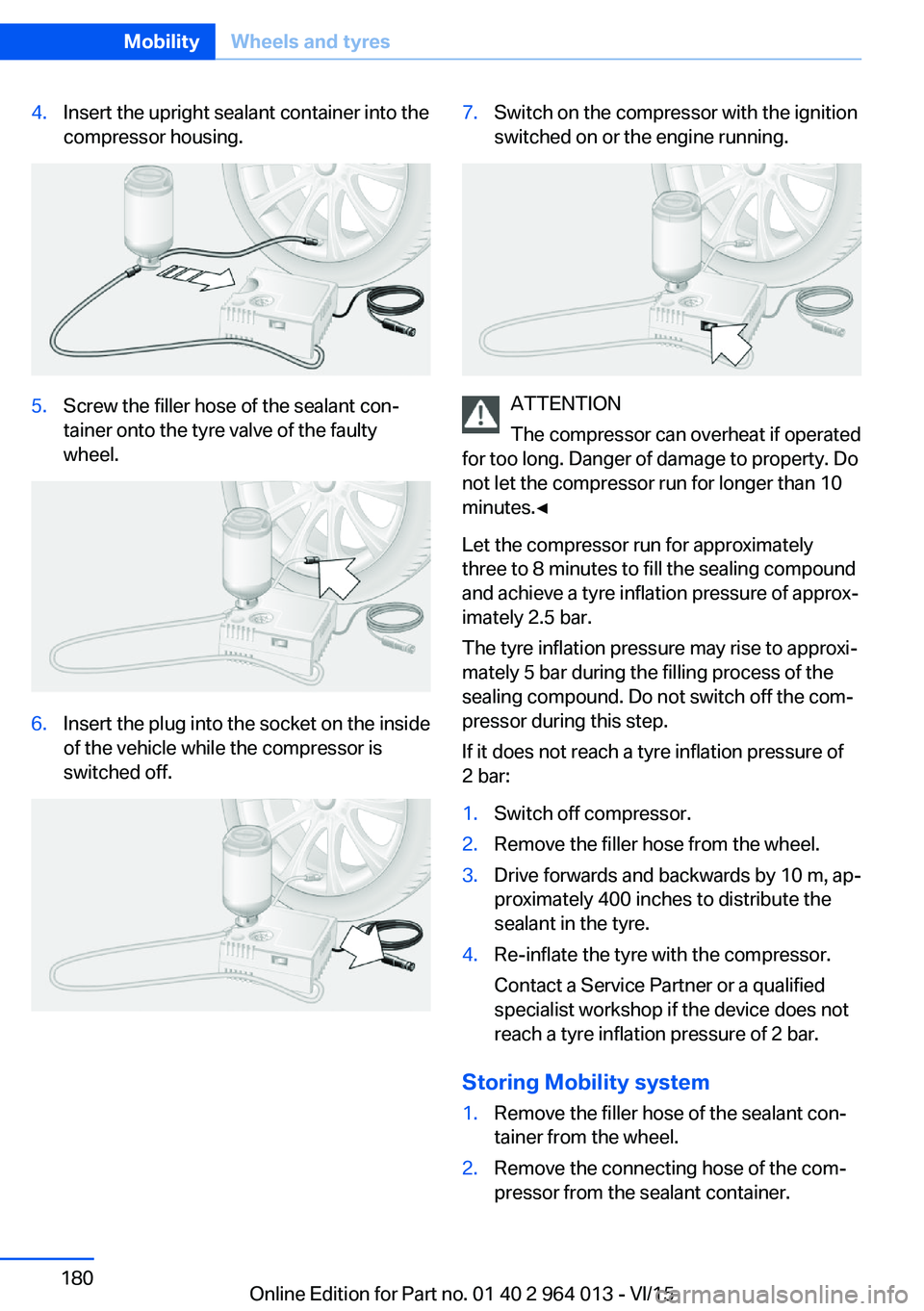

4.Insert the upright sealant container into the

compressor housing.5.Screw the filler hose of the sealant con‐

tainer onto the tyre valve of the faulty

wheel.6.Insert the plug into the socket on the inside

of the vehicle while the compressor is

switched off.7.Switch on the compressor with the ignition

switched on or the engine running.

ATTENTION

The compressor can overheat if operated

for too long. Danger of damage to property. Do

not let the compressor run for longer than 10

minutes.◀

Let the compressor run for approximately

three to 8 minutes to fill the sealing compound

and achieve a tyre inflation pressure of approx‐

imately 2.5 bar.

The tyre inflation pressure may rise to approxi‐

mately 5 bar during the filling process of the

sealing compound. Do not switch off the com‐

pressor during this step.

If it does not reach a tyre inflation pressure of

2 bar:

1.Switch off compressor.2.Remove the filler hose from the wheel.3.Drive forwards and backwards by 10 m, ap‐

proximately 400 inches to distribute the

sealant in the tyre.4.Re-inflate the tyre with the compressor.

Contact a Service Partner or a qualified

specialist workshop if the device does not

reach a tyre inflation pressure of 2 bar.

Storing Mobility system

1.Remove the filler hose of the sealant con‐

tainer from the wheel.2.Remove the connecting hose of the com‐

pressor from the sealant container.Seite 180MobilityWheels and tyres180

Online Edition for Part no. 01 40 2 964 013 - VI/15