CADILLAC DEVILLE 1994 7.G Owners Manual

Manufacturer: CADILLAC, Model Year: 1994, Model line: DEVILLE, Model: CADILLAC DEVILLE 1994 7.GPages: 399, PDF Size: 20.97 MB

Page 331 of 399

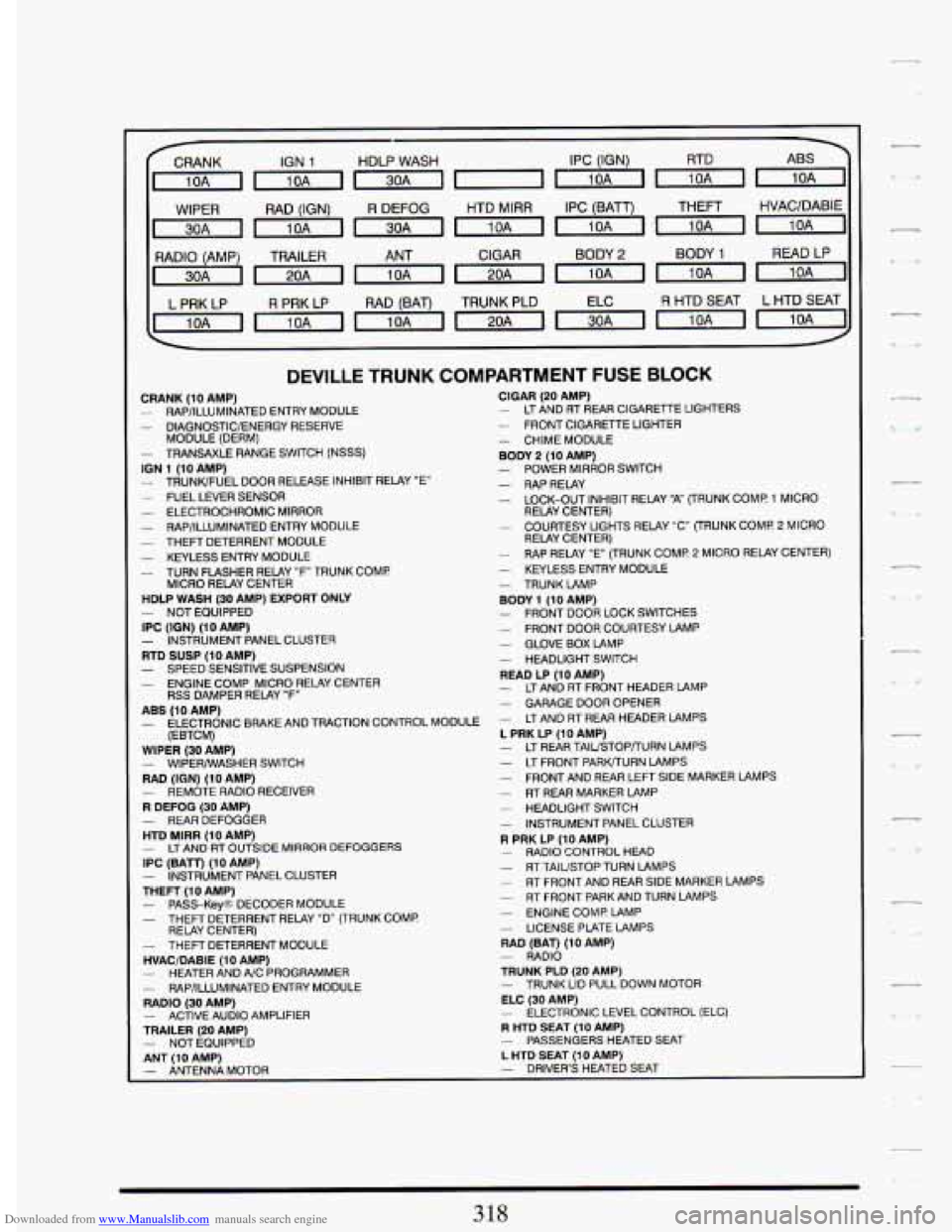

Downloaded from www.Manualslib.com manuals search engine IGN 1 HDLP WASH IPC (IGN) RTD

~~l~~~mm

WIPER RAD (IGN) R DEFOG HTD MlRR IPC (BATT) THEFT HVAC/DABIE

CIGAR BODY

2 BODY 1 READ LP

L PRK LP

R PRK LP RAD (BAT) TRUNK PLD R HTD SEAT L HTD SEAT

DEVILLE TRUNK COMPARTMENT FUSE BLOCK

CRANK (10 AMP)

- DlAGNOSTlClENERGY RESERVE

- TRANSAXLE RANGE SWITCH (NSSS)

- RAP/ILLUMINATED ENTRY MODULE

MODULE (DERM)

ION 1 (10 AMP) - TRUNWFUEL DOOR RELEASE INHIBIT RELAY "E" - FUEL LEVER SENSOR - ELECTROCHROMIC MIRROR - RAP/ILLUMINATED ENTRY MODULE - THEFT DETERRENT MODULE - KEYLESS ENTRY MODULE - TURN FLASHER RELAY "F TRUNK COMP.

HDLP WASH (30 AMP) EXPORT ONLY

IPC

(ION) (10 AMP) - INSTRUMENT PANEL CLUSTER RTD SUSP (10 AMP)

- ENGINE COMP MICRO REL4Y CENTER

ABS (IO AMP) - ELECTRONIC BRAKE AND TRACTION CONTROL MODULE

(EBTCM)

WIPER (30 AMP) - WIPERMASHER SWITCH RAD (IGN) (10 AMP)

R DEFOG (30 AMP) - REAR DEFOGGER HTD MlRR (10 AMP) - LTAND RT OUTSIDE MIRROR DEFOGGERS IPC (BATr) (10 AMP)

THEFT

(10 AMP) - PASS-Key@ DECODER MODULE - THEFT DETERRENT RELAY "D" (TRUNK COMP.

- THEFT DETERRENT MODULE HVAC/DABIE (10 AMP) - HEATER AND A/C PROGRAMMER

RADIO (30 AMP) - ACTIVE AUDIO AMPLIFIER TRAILER (20 AMP)

ANT

I10 AMP)

MICRO RELAY CENTER

- NOT EQUIPPED

- SPEED SENSITIVE SUSPENSION

RSS DAMPER RELAY "F"

- REMOTE RADIO RECEIVER

- INSTRUMENT PANEL CLUSTER

RELAY CENTER)

- RAP/ILLUMINATED ENTRY MODULE

- NOT EQUIPPED

CIGAR (20 AMP) - LT AND RT REAR CIGARETTE LIGHTERS - FRONT CIGARETTE LIGHTER - CHIME MODULE BODY 2 (10 AMP) - POWER MIRROR SWITCH - RAPRELAY - LOCK-OUT INHIBIT RELAY "A" (TRUNK COMP 1 MICRO

- COURTESY LIGHTS RELAY "C" (TRUNK COME 2 MICRO

RELAY CENTER)

RELAY CENTER)

- RAP RELAY "E (TRUNK COMP. 2 MICRO

RELAY CENTER) - KEYLESS ENTRY MODULE - TRUNKLAMP

- FRONT DOOR LOCK SWITCHES BODY 1 (10 AMP)

- FRONT DOOR COURTESY LAMP - GLOVE BOX LAMP - HEADLIGHT SWITCH READ LP (10 AMP) - LTAND AT FRONT HEADER LAMP - GARAGE DOOR OPENER - LT AND RT REAR HEADER LAMPS L PRK LP (10 AMP) - LT REAR TAlUSTOPrURN LAMPS

- FRONT AND REAR LEFT SIDE MARKER LAMPS - RT REAR MARKER LAMP - HEADLIGHT SWITCH - INSTRUMENT PANEL CLUSTER R PRK LP (10 AMP) - RADIO CONTROL HEAD - RT TAIUSTOP TURN LAMPS - RT FRONT AND REAR SIDE MARKER LAMPS - RT FRONT PARK AND TURN LAMPS - ENGINE COME LAMP - LICENSE PLATE LAMPS RAD (BAT) (10 AMP) - RADIO TRUNK PLD (20 AMP) - TRUNK LID PULL DOWN MOTOR ELC (30 AMP) - ELECTRONIC LEVEL CONTROL (ELC) R HTD SEAT (10 AMP) - PASSENGERS HEATED SEAT

- LT FRONT PARWURN LAMPS

L HTD SEAT (10 AMP) - ANTENNA MOTOR - DRIVER'S HEATED SEAT

318

,

Page 332 of 399

Downloaded from www.Manualslib.com manuals search engine - Headlights

The headlight wiring is protected by a circuit breaker in the light switch.

An electrical overload will cause the lights to go on and off, or in some

cases to remain off.

If this happens, have your headlight wiring checked

right away.

Windshield Wipers

The windshield wiper motor is protected by a circuit breaker and a fuse.

If the motor overheats due to heavy snow, etc., the wiper will stop until

the motor cools. If the overload is caused by some electrical problem and

not snow, etc., be sure to get it fixed.

Power Windows and Other Power Options

Circuit breakers in the fuse panel protect the power windows and other

opens and closes, protecting the circuit until the problem is fixed or goes

away.

__ power accessories. When the current load is too heavy, the circuit breaker

--

BULB CH4RT

DESCRIPTION BULB NO.

Backup Lights ......................................... 2057

Cornering Light ..................................... 3156 52

Ash Tray Illumination .................................. 1445

Courtesy Reading Light

................................. 168

Glove Compartment Light

............................... 194

-Inner High Beam

................................. 9005 HB3

Headlights Composite

-Outer Low Beam

................................. 9006 HB4

License Plate Light

..................................... 194

Park and Turn Signal

................................ 3157 K2

Side Marker Lights ..................................... 194

Stop/Tail/Turn Signal

................................ 2057 NA

Trunk Light

........................................... 1003

Vanity Mirror Illumination

............................... 124

319

Page 333 of 399

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS

4.9 Liter Engine

The 4.9 Liter transverse engine is an overhead valve 90 degree V-8

design. The cylinder bore diameter and the piston stroke provide a piston

displacement of

300 cubic inches (4.9Liter).

This engine utilizes an aluminum crankcase with a separate aluminum

lifter carrier and removable cast iron cylinder liners. The cylinder heads

ar,e made

of cast iron and feature intergral valve seats and guides. The

cast nodular iron crankshaft is supported at five main bearing journals by

cast iron main bearing caps and shell type steel-backed aluminum inserts.

The center main bearing

is the thrust bearing.

B

D

t3

320

Page 334 of 399

Downloaded from www.Manualslib.com manuals search engine The cast aluminum pistons use two compression rings and one oil control

ring. The pistons are tin plated to provide a non-scuffing surface when

the engine is new.

c_ A steel camshaft is supported by five steel backed babbit bearings. It is

driven by the crankshaft through a chain at

the front of the engine. The

give gear is keyed to the crankshaft and the driven sprocket is bolted to

the camshaft. Both the crankshaft gear and camshaft sprocket have

locating marks to provide the correct valve timing and timing chain

installation.

The valve lifters are roller hydraulic type and are positioned

in the aluminum lifter carrier.

-1_

-

4T60E Transaxle

The Hydra-Matic 4T60E 4-speed overdrive, electronic transaxle consists

primarily of a five element torque converter,

two planetary gear sets,

-- various clutches, final drive assembly, and a control valve body.

321

~. .

Page 335 of 399

Downloaded from www.Manualslib.com manuals search engine c-

The torque converter houses a pump, turbine, pressure plate which is

splined to the turbine, and a stator assembly, serving as a fluid coupling, it

smoothly transmits power from the engine to the transaxle. It also

hydraulically provides a additional torque when required. When applied,

the pressure plate provides a mechanical torque when required. When

applied, the pressure plate provides a mechanical direct drive coupling of

the engine to the transaxle.

-

n

The two planetary gear sets provide the four forward gear ratios and

reverse. Changing of the gear ratios is fully automatic and is

accomplished through the use of various electronic and mechanical

requirements. Four multiple disc clutches, two roller clutches, a sprag

clutch, and three bands provide the friction elements required to obtain

the various ratios with the planetary gear sets.

A hydraulic system (the control valve body) pressurized by a vein type

pump provides the working pressure needed to operate the friction

elements and automatic controls.

Front Suspension

Your fully independent front suspension is a combination strut and spring

design. The frame is isolated from the body with six rubber mounts.

r

Page 336 of 399

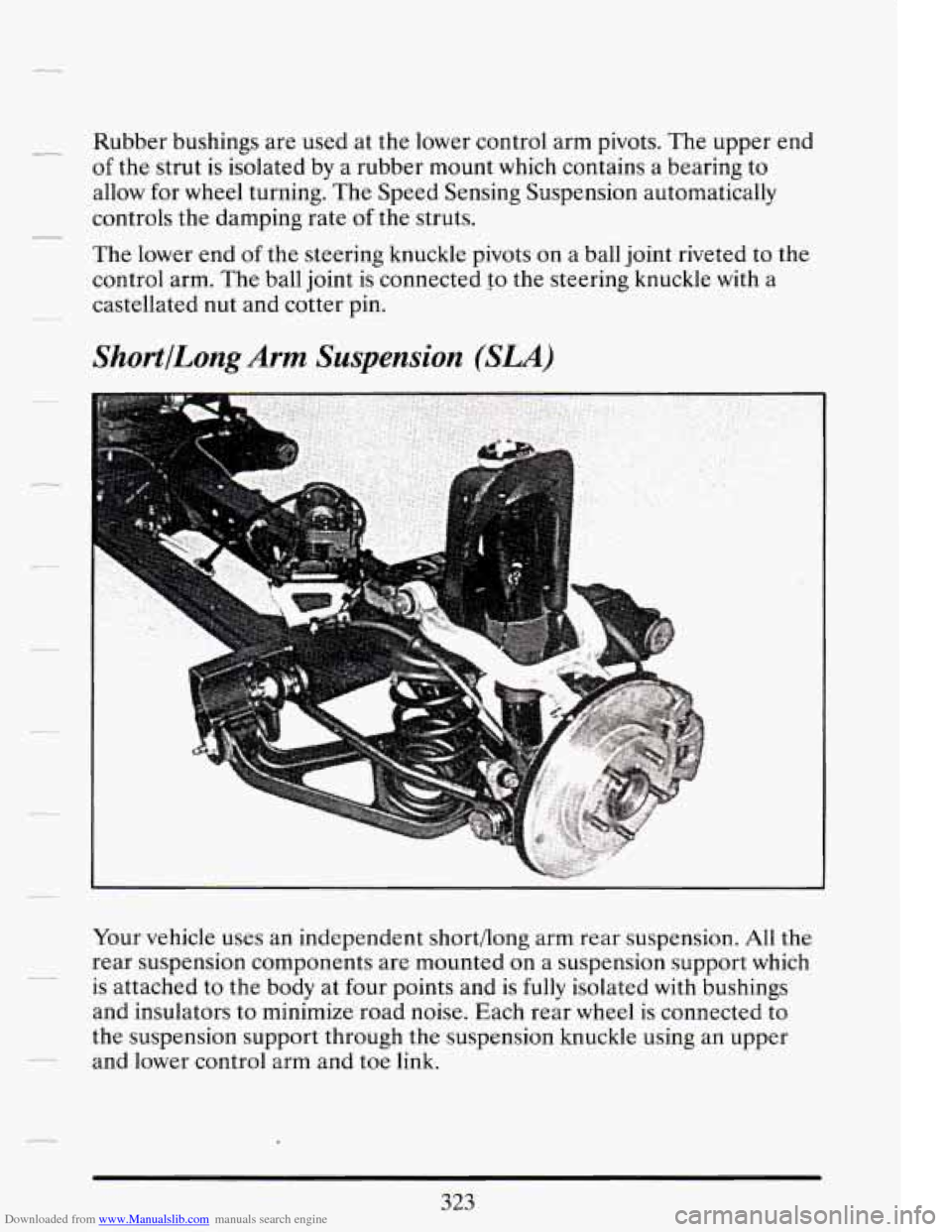

Downloaded from www.Manualslib.com manuals search engine Rubber bushings are used at the lower control arm pivots. The upper end

of the strut is isolated by a rubber mount which contains a bearing to

allow for wheel turning. The Speed Sensing Suspension automatically

controls the damping rate

of the struts.

The lower end

of the steering knuckle pivots on a ball joint riveted to the

control arm. The ball joint

is connected ,to the steering knuckle with a

castellated nut and cotter pin.

ShortlLong Arm Suspension (SLA)

Your vehicle uses an independent short/long arm rear suspension. All the

rear suspension components are mounted

on a suspension support which

is attached to the body at four points and is

fully isolated with bushings

and insulators to minimize road noise. Each rear wheel is connected to

the suspension support through the suspension knuckle using

an upper

and lower control arm and

toe link. --

Page 337 of 399

Downloaded from www.Manualslib.com manuals search engine The control arms and toe link are attached to the suspension support on

the inboard side, and to a suspension knuckle on the outboard side. The

hub and bearing assembly is mounted to the knuckle and

is a single,

non-serviceable unit which eliminates the need for wheel bearing

adjustment. The load leveling

(ELC) shock absorbers are attached to the

lower control arm, with

the upper end of the shock attached to the

suspension support. The springs are held in position between the lower

control arms and a pocket in the suspension support.

The suspension system also incorporates a

new damping system known as

Speed Sensing Suspension. This system controls the damping forces

in

the shock absorbers and struts, in response to various road and driving

conditions. The systems are capable of making these damping changes

extremely fast.

A computer receives inputs from vertical acceleration sensors, wheel to

body position sensors, vehicle speed sensor,

lift and dive signals. This

computer evaluates the input from these sensors, to control the damping

of each

of the struts and shocks independently to provide varied levels of

suspension control.

The system also has

the capability of providing Speed Sensitive Steering

control. This system changes your steering effort based on your vehicle

speed.

c-

Page 338 of 399

Downloaded from www.Manualslib.com manuals search engine Speed Sensitive Steering

This system varies the amount of steering effort proportionate to your

vehicle speed. Steering is easier at a lower speed for increased

maneuverability and parking ease.

As your vehicle speed increases, the

steering effort is also increased to provide a manual

like steering feel for

maximum control and enhanced vehicle stability.

The power rack and pinion steering system has a rotary spool valve which

directs hydraulic fluid coming from the power steering pump to one side

or the other side

of the rack piston. The integral rack piston is attached to

the rack. The rack piston converts hydraulic pressure to a linear force

which moves the rack left or right. The force is

then transmitted through

the inner and outer tie rods to the steering knuckles, which turn the

wheels

If hydraulic assist is not available, manual control is maintained. However

under these conditions more steering effort

is required.

Page 339 of 399

Downloaded from www.Manualslib.com manuals search engine 4.9 LITER ENGINE

Displacement ............................... 4.9L (300 cu. in.)

No. of Cylinders .............................. 8 - 90 Degree V

Power (Acc. to

SAE 51349) ............... 200 (bhp) @ 4100 rpm

Torque

(Acc. to SAE 51349) ............ 275 (lbs. ft.) @ 3000 rpm

Bore

....................................... 92mm (3.623 in.)

Stroke

..................................... 92mm (3.623 in.)

Compression Ratio

.................................... 9.5:l

Cylinder Block

...... Die Cast Alumbum with Iron Cylinder Bores

Cylinder Heads Cast Iron

Intake Manifold

.............................. Cast Aluminum

Lifter Trpe

................................. Roller Hydraulic

Intake Valve Head Diameter

.................. 45mm (1.772 in.)

Exhaust Valve Head Diameter

................. 38mm (1.496 in.)

Pistons

...................................... Cast Aluminum

Firing Order

.................................. 1-8-4-3-6-5-7-2

Left Bank

.......................................... 1-3-5-7

Right Bank

......................................... 2-4-6-8

Camshaft

............................................. Steel

Camshaft Drive

...................................... Chain

Crankshaft Material

..................... Pearlitic Nodular Iron

Main Bearings

......................................... Five

...................................... 250 (kW) @ 4100 rpm

...................................... 375(N.m) @ 3000 rpm

.. - .- :.,-< ...................................

ENGINE LUBRICATION SYSTEM

Type of Intake ..................................... Stationary

Filter System

...................................... Full-Flow

Oil Pump

........................................... Geroto

326

Page 340 of 399

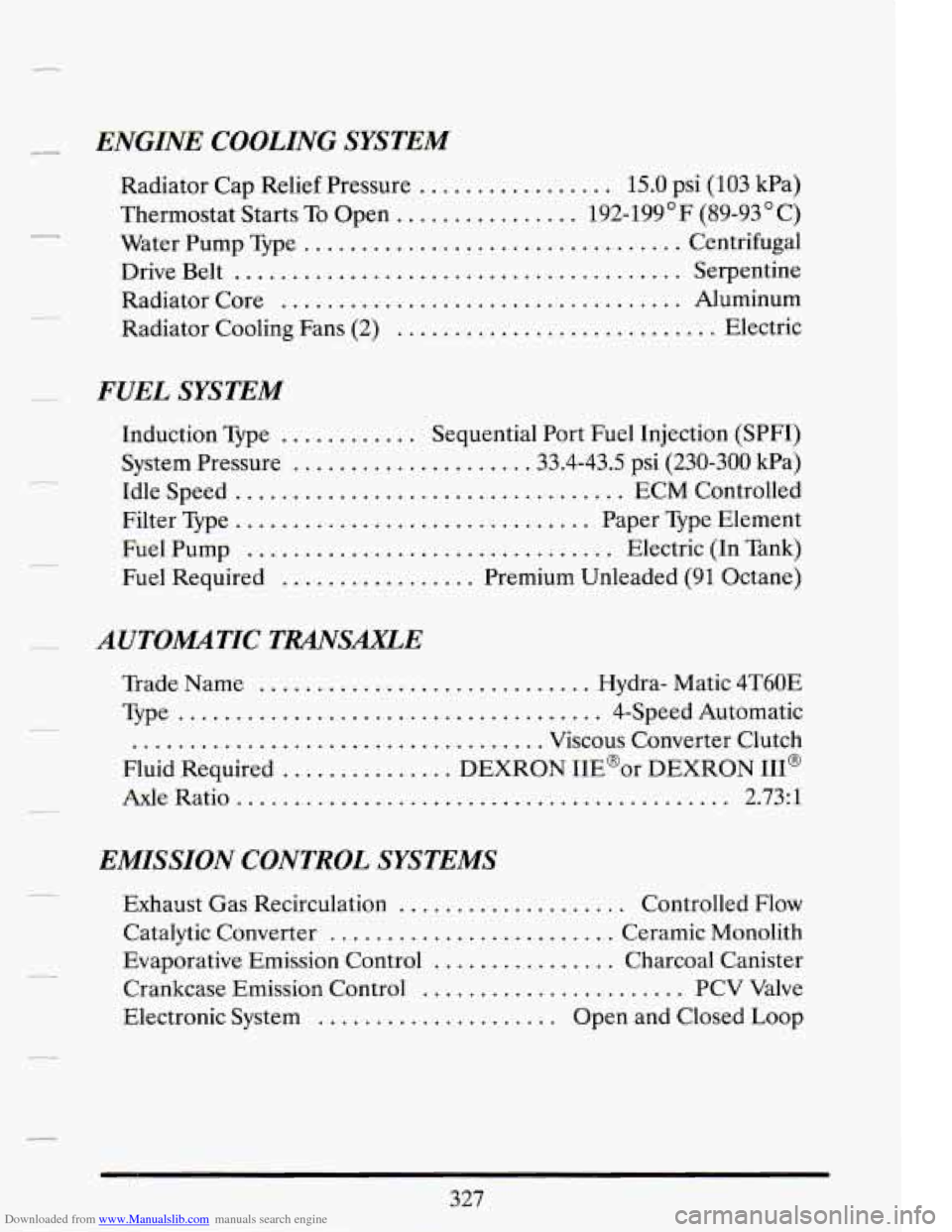

Downloaded from www.Manualslib.com manuals search engine Ly ENGINE COOLING SYSTEM

Radiator Cap Relief Pressure ................. 15.0 psi (103 kPa)

Thermostat Starts To Open

................ 192-199'F (89-93OC)

Water Pump Type

................................. Centrifugal

Drive Belt

....................................... Serpentine

Radiator Core

................................... Aluminum

Radiator Cooling Fans (2)

............................ Electric

FUEL SYSTEM

Induction Type ............ Sequential Port Fuel Injection (SPFI)

System Pressure

.................... .33.4-43.5 psi (230-300 kPa)

Idle Speed

.................................. ECM Controlled

Filter Type

............................... Paper Type Element

Fuel Pump

................................ Electric (In Tank)

Fuel Required ................. Premium Unleaded (91 Octane)

AUTOMATIC TRANSAXLE

Trade Name ............................. Hydra- Matic 4T60E

Type ..................................... 4-Speed Automatic

.................................... Viscous Converter Clutch

Fluid Required

............... DEXRON IIE@or DEXRON HI@

Axle Ratio

........................................... 2.73:l

EMISSION CONTROL SYSTEMS

Exhaust Gas Recirculation .................... Controlled Flow

Catalytic Converter

......................... Ceramic Monolith

Evaporative Emission Control

................ Charcoal Canister

Crankcase Emission Control

....................... PCV Valve

Electronic System

..................... Open and Closed Loop

327

-