service CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 934 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The radiator cooling fan operation is controlled by the Engine Control Module (ECM) and the fan relays, with inputs

from the following:

•Engine coolant temperature

• Automatic transaxle fluid temperature (with DP0 transaxle)

• A/C signal

Inspect the cooling fan for proper low speed and high speed operation:

• The low speed fan should be switched on at 98°C and switched off at 94°C.

• The high speed fan should be switched on at 105°C and switched off at 101°C.

• If the water temperature is greater than 101°C after the fan is switched off, the fan will continue to operate for

1 minute.

• If the water temperature is greater than 94°C after the fan is switched off, the fan will continue to operate for

0.5 minute.

• If the water temperature is less than 85°C after the fan is switched off, the fan will stop operating.

Removal & Installation

WARNING!

Always allow the engine to cool before opening the cooling system. Do not remove the coolant pressure relief

cap when the engine is operating or the cooling system is hot. The cooling system is under pressure; steam and

hot liquid can come out forcefully when the cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

1. Disconnect the negative battery cable.

2. Drain the cooling system (See Cooling System Draining Procedure in Section 06 Cooling System).

3. Disconnect the upper radiator hose from the radiator.

4. Disconnect the cooling fan electrical connector and the cooling fan ground cable connected to the body.

5. Remove the cooling fan mounting bolts (1) to the

radiator.

(Tighten: Cooling fan mounting bolts to 5 N·m)

6. Remove the radiator fan from the engine compartment.

7. Remove the cooling fan from its support, if necessary.

8. Installation is in the reverse order of removal.

Installation Notes:

• Verify the cooling system is filled to proper specifications.

Cooling Fan Inspection

1. Using the following table, apply battery voltage to the specified connector terminals.

2. Verify that the fan motor operates smoothly when voltage is applied.

3. If the test results are not as specified, replace the fan motor.

ON-VEHICLE SERVICE

LTSM060008

06

06–19Chery Automobile Co., Ltd.

Page 935 of 1903

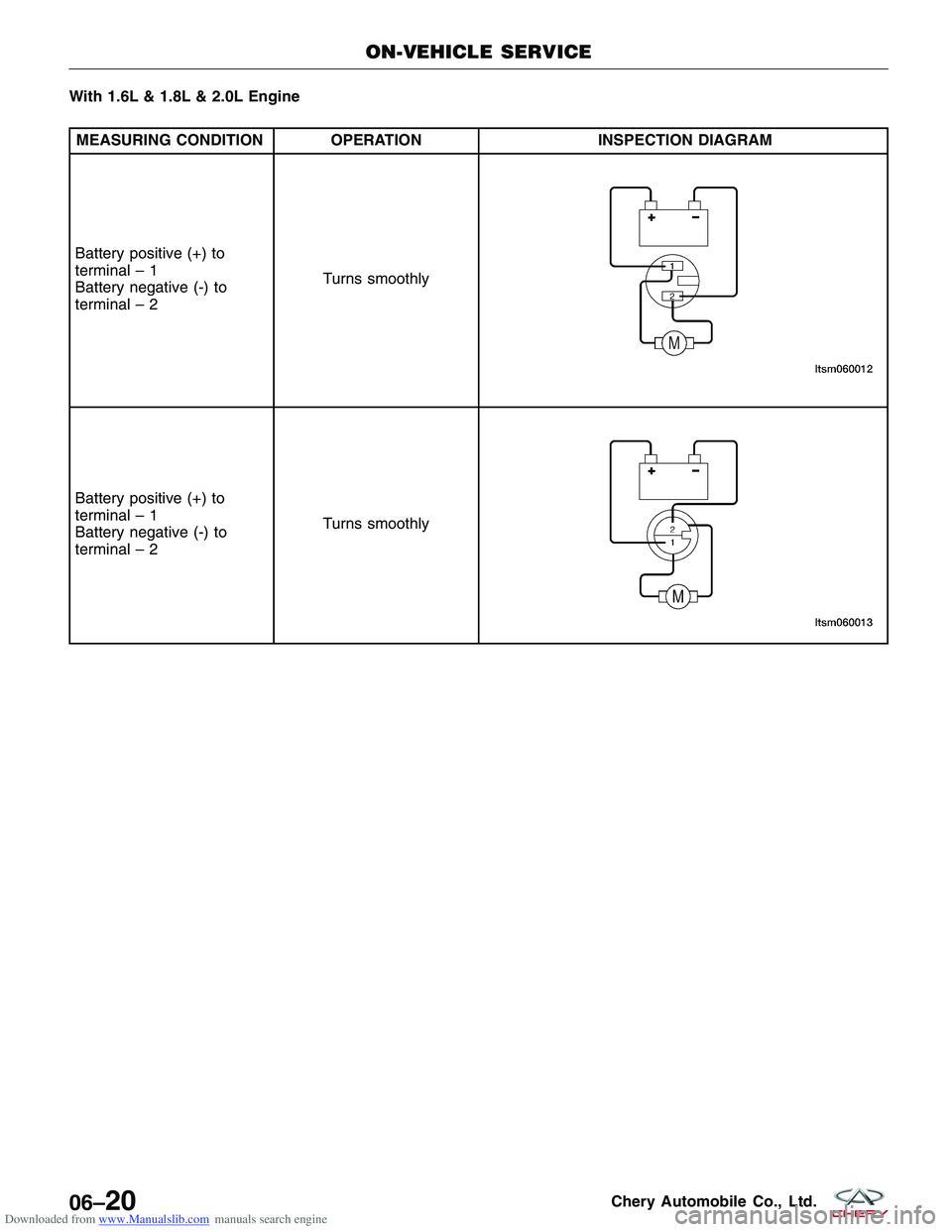

Downloaded from www.Manualslib.com manuals search engine With 1.6L & 1.8L & 2.0L Engine

MEASURING CONDITION OPERATIONINSPECTION DIAGRAM

Battery positive (+) to

terminal – 1

Battery negative (-) to

terminal – 2 Turns smoothly

Battery positive (+) to

terminal – 1

Battery negative (-) to

terminal – 2Turns smoothly

ON-VEHICLE SERVICE

06–20Chery Automobile Co., Ltd.

Page 936 of 1903

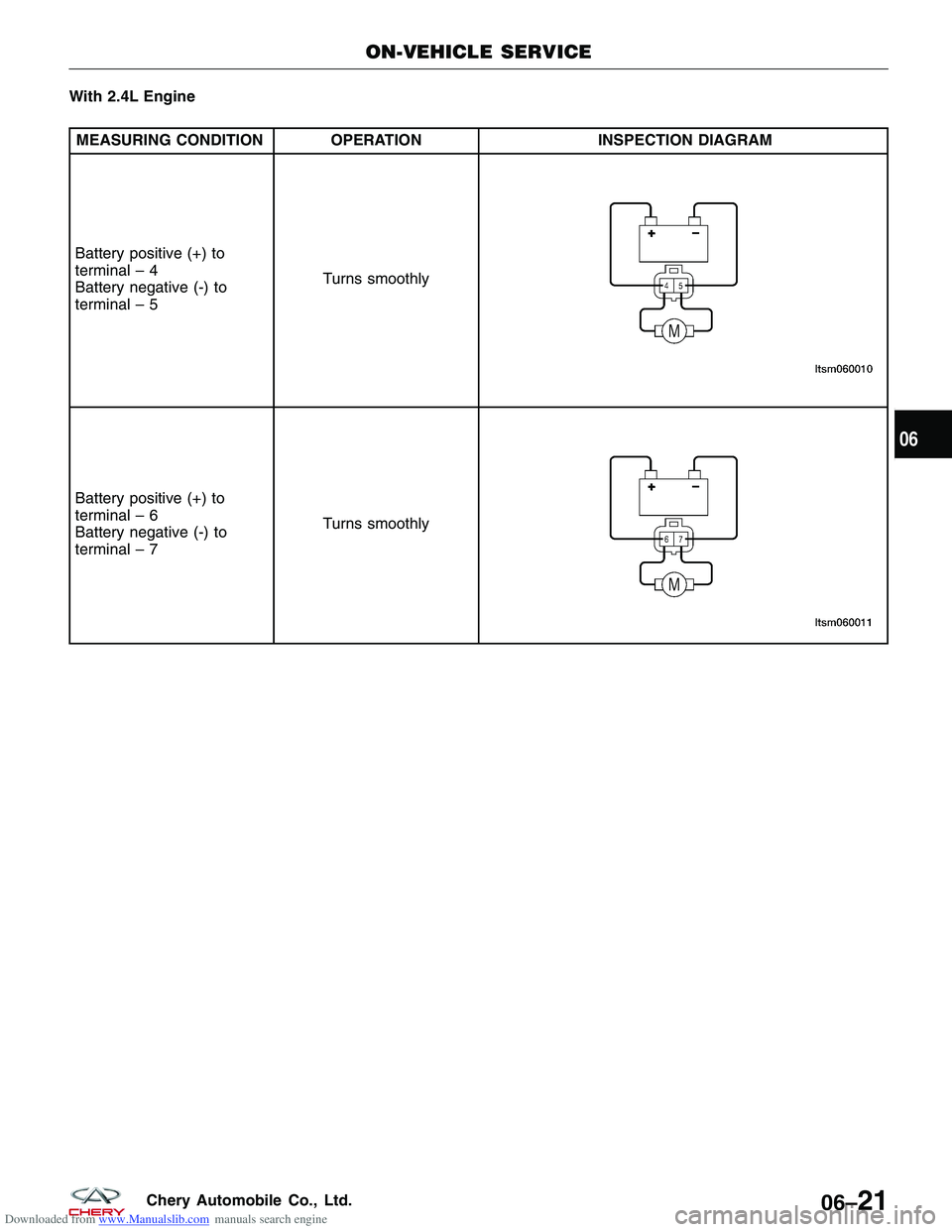

Downloaded from www.Manualslib.com manuals search engine With 2.4L Engine

MEASURING CONDITION OPERATIONINSPECTION DIAGRAM

Battery positive (+) to

terminal – 4

Battery negative (-) to

terminal – 5 Turns smoothly

Battery positive (+) to

terminal – 6

Battery negative (-) to

terminal – 7Turns smoothly

ON-VEHICLE SERVICE

06

06–21Chery Automobile Co., Ltd.

Page 937 of 1903

Downloaded from www.Manualslib.com manuals search engine EXHAUST

07

CONTENTSpage

Exhaust System ...................................................................... 07-1

EXHAUST SYSTEM

GENERAL INFORMATION07-2

Description 07-2

Operation 07-3

Specifications 07-3

DIAGNOSIS AND TESTING07-4

Exhaust System Diagnostic Chart 07-4

ON-VEHICLE SERVICE07-5

Exhaust Pipe Assembly 07-5

Removal & Installation - 1.6L & 1.8L &

2.0L 07-5 Removal & Installation - 2.4L 07-5

Muffler 07-6

Removal & Installation 07-6

Catalytic Converter 07-6

Description 07-6

Operation 07-6

Removal & Installation 07-7

07

07–1Chery Automobile Co., Ltd.

Page 941 of 1903

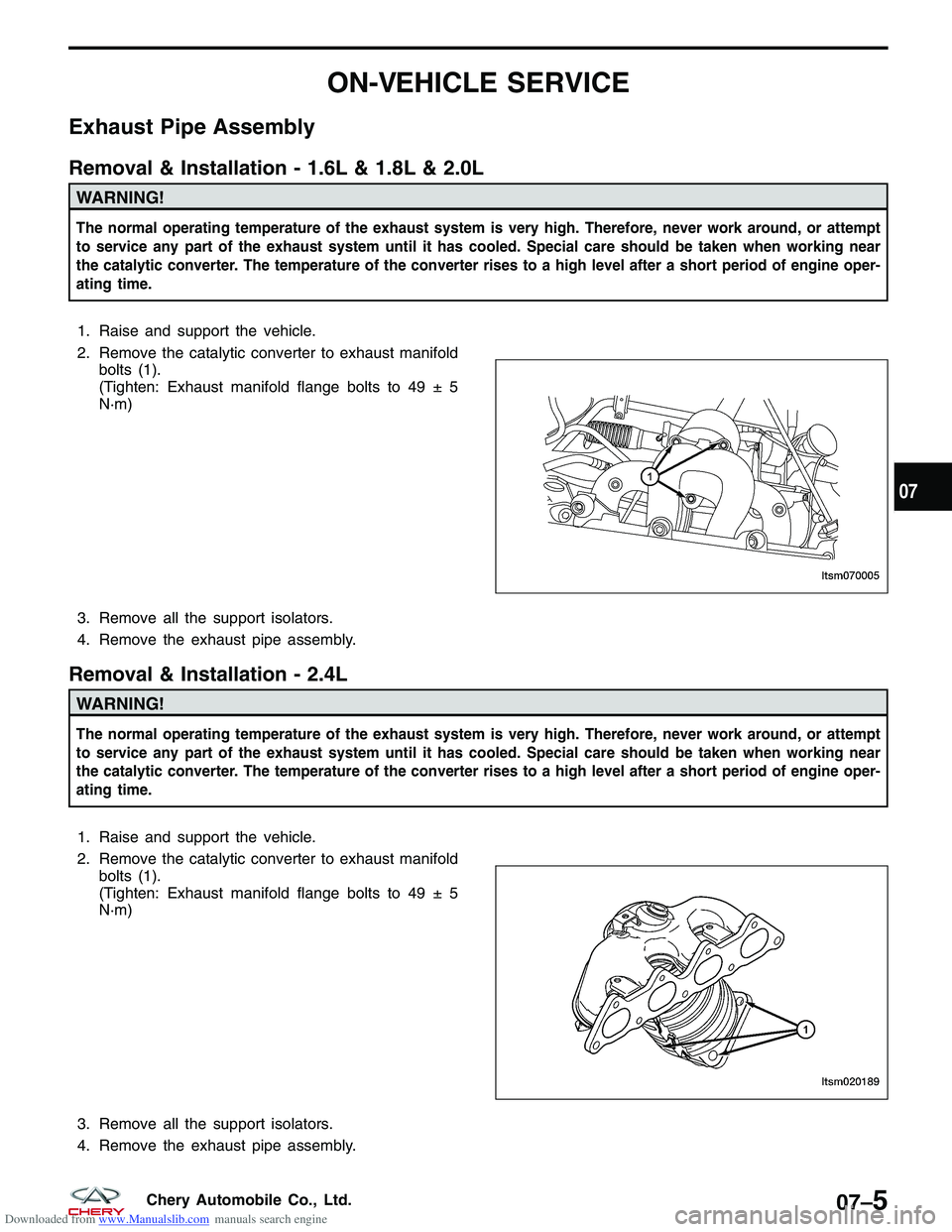

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Exhaust Pipe Assembly

Removal & Installation - 1.6L & 1.8L & 2.0L

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the catalytic converter to exhaust manifoldbolts (1).

(Tighten: Exhaust manifold flange bolts to 49 ± 5

N·m)

3. Remove all the support isolators.

4. Remove the exhaust pipe assembly.

Removal & Installation - 2.4L

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the catalytic converter to exhaust manifold bolts (1).

(Tighten: Exhaust manifold flange bolts to 49 ± 5

N·m)

3. Remove all the support isolators.

4. Remove the exhaust pipe assembly.

LTSM070005

LTSM020189

07

07–5Chery Automobile Co., Ltd.

Page 942 of 1903

Downloaded from www.Manualslib.com manuals search engine Muffler

Removal & Installation

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

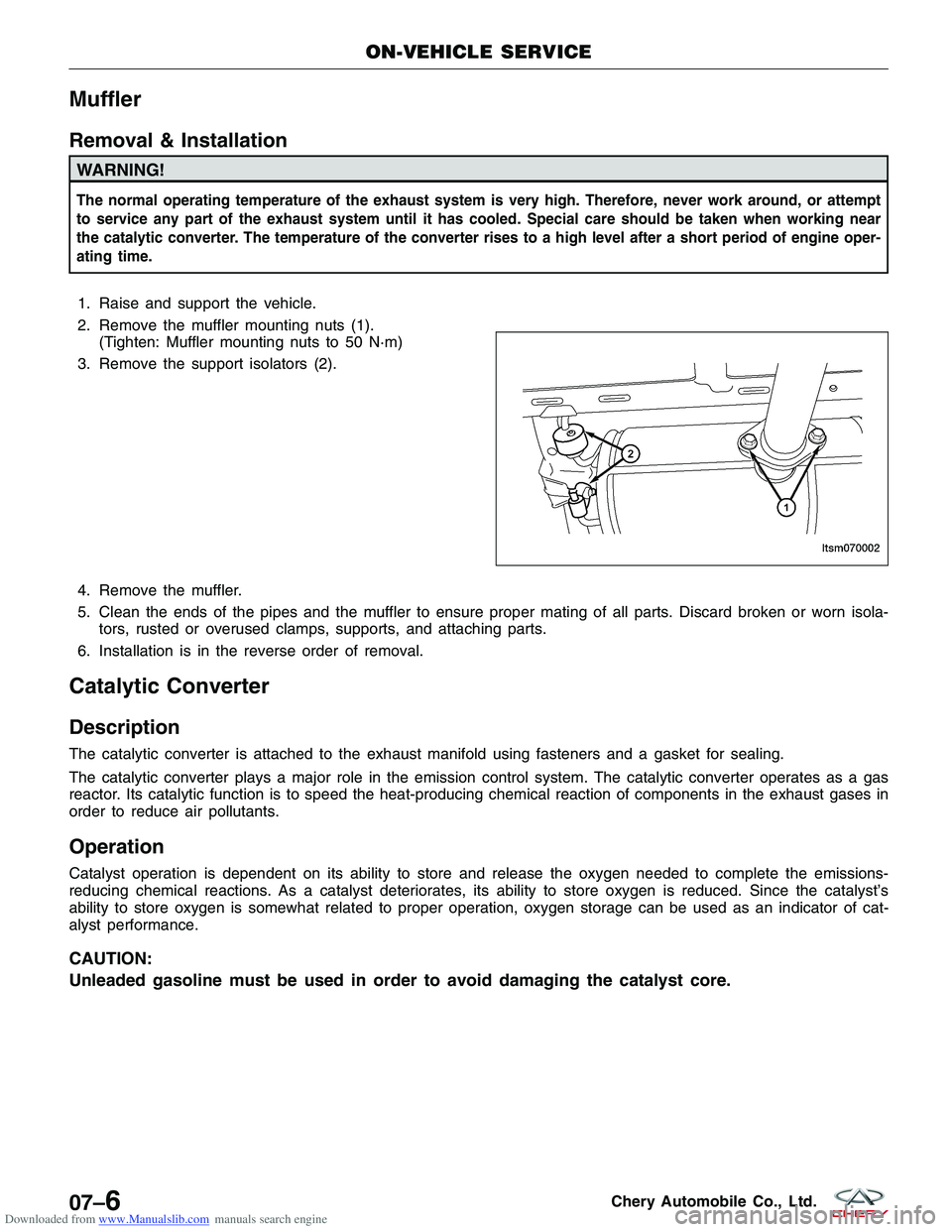

1. Raise and support the vehicle.

2. Remove the muffler mounting nuts (1).(Tighten: Muffler mounting nuts to 50 N·m)

3. Remove the support isolators (2).

4. Remove the muffler.

5. Clean the ends of the pipes and the muffler to ensure proper mating of all parts. Discard broken or worn isola- tors, rusted or overused clamps, supports, and attaching parts.

6. Installation is in the reverse order of removal.

Catalytic Converter

Description

The catalytic converter is attached to the exhaust manifold using fasteners and a gasket for sealing.

The catalytic converter plays a major role in the emission control system. The catalytic converter operates as a gas

reactor. Its catalytic function is to speed the heat-producing chemical reaction of components in the exhaust gases in

order to reduce air pollutants.

Operation

Catalyst operation is dependent on its ability to store and release the oxygen needed to complete the emissions-

reducing chemical reactions. As a catalyst deteriorates, its ability to store oxygen is reduced. Since the catalyst’s

ability to store oxygen is somewhat related to proper operation, oxygen storage can be used as an indicator of cat-

alyst performance.

CAUTION:

Unleaded gasoline must be used in order to avoid damaging the catalyst core.

ON-VEHICLE SERVICE

LTSM070002

07–6Chery Automobile Co., Ltd.

Page 943 of 1903

Downloaded from www.Manualslib.com manuals search engine Removal & Installation

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

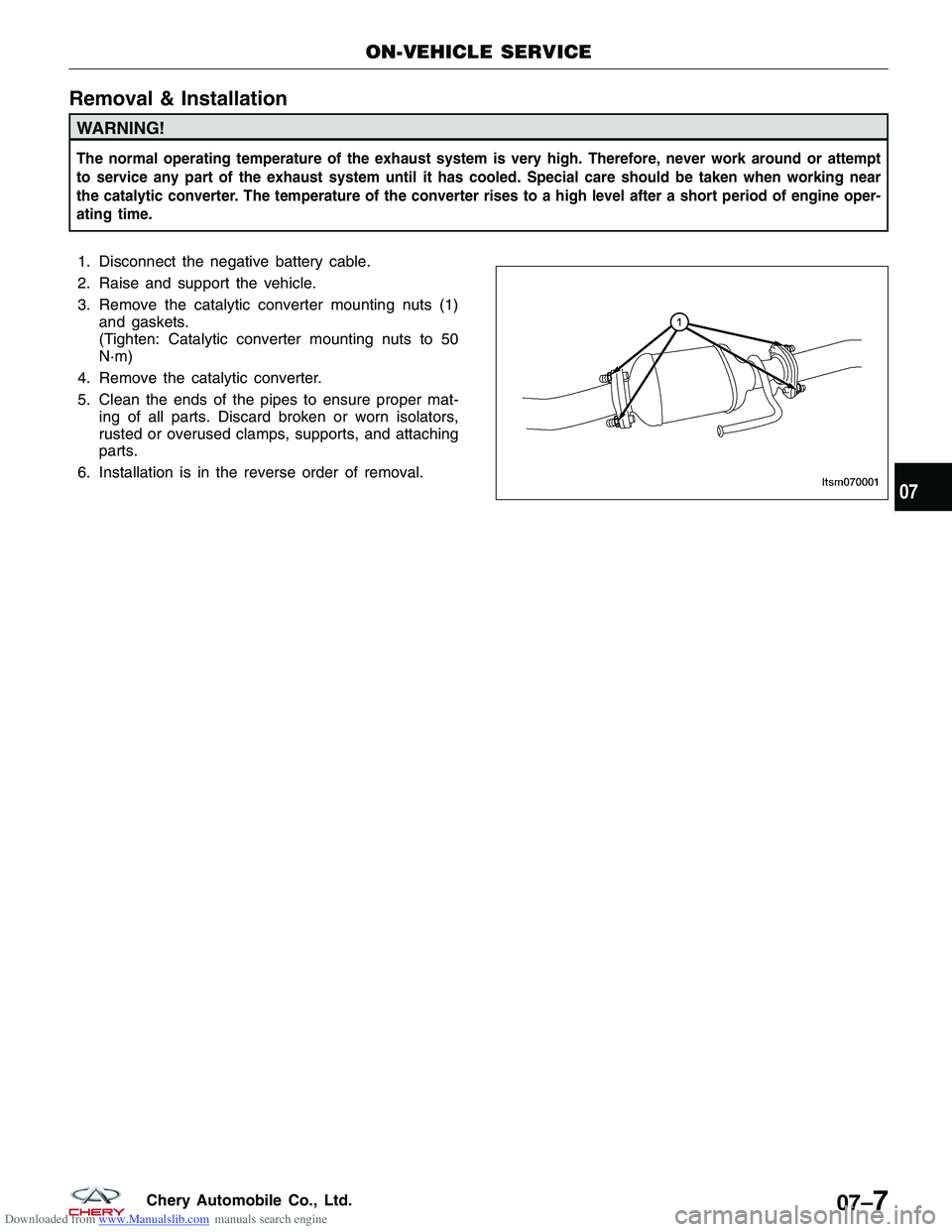

1. Disconnect the negative battery cable.

2. Raise and support the vehicle.

3. Remove the catalytic converter mounting nuts (1)and gaskets.

(Tighten: Catalytic converter mounting nuts to 50

N·m)

4. Remove the catalytic converter.

5. Clean the ends of the pipes to ensure proper mat- ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM07000107

07–7Chery Automobile Co., Ltd.

Page 945 of 1903

Downloaded from www.Manualslib.com manuals search engine P2753 - EPDE Circuit Or Short To

Power Supply, P2753 - EPDE Open

Circuit Or Short To Ground 08-125

U0001 - CAN Communication Error 08-130ON-VEHICLE SERVICE08-136

DPO Automatic Transaxle Assembly 08-136

Removal & Installation 08-136

Automatic Shifter Selector 08-140

Removal & Installation 08-140

Transaxle Control Module (TCM) 08-142

Removal & Installation 08-142

08–2Chery Automobile Co., Ltd.

Page 1079 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

DPO Automatic Transaxle Assembly

Removal & Installation

1. Raise and support the vehicle.

2. Remove the engine cover.

3. Remove the battery and battery tray (See Battery Removal & Installation in Section 05 Starting & Charging).

4. Remove the air cleaner and air duct assembly.

5. Drain the cooling system (See Cooling System Draining Procedure in Section 06 Cooling System).

6. Remove the base mounting (1) of the air cleanerhousing assembly.

7. Remove the transaxle ground cable.

8. Disconnect and remove the electrical connectors for the following components:• Vehicle speed sensor (2)

• Crankshaft position sensor

• Automatic transaxle assembly (3)

9. Disconnect the transaxle fluid coolant lines (4) using a suitable tool.

10. Remove the shift cable (1) from the transaxle assembly.

11. Raise the vehicle.

12. Remove the drain plug (2) with an inner square socket wrench.

13. Remove the fluid limiting duct (1) with an 8 mm inner hex socket wrench.

14. Drain the transaxle fluid.

LTSM050002

BESM080057 LTSM080184

08–136Chery Automobile Co., Ltd.

Page 1080 of 1903

Downloaded from www.Manualslib.com manuals search engine 15. Remove the bolts attaching the transaxle cooling lines to the transaxle.

16. Remove the starter motor (See Starter Removal & Installation in Section 05 Starting & Charging).

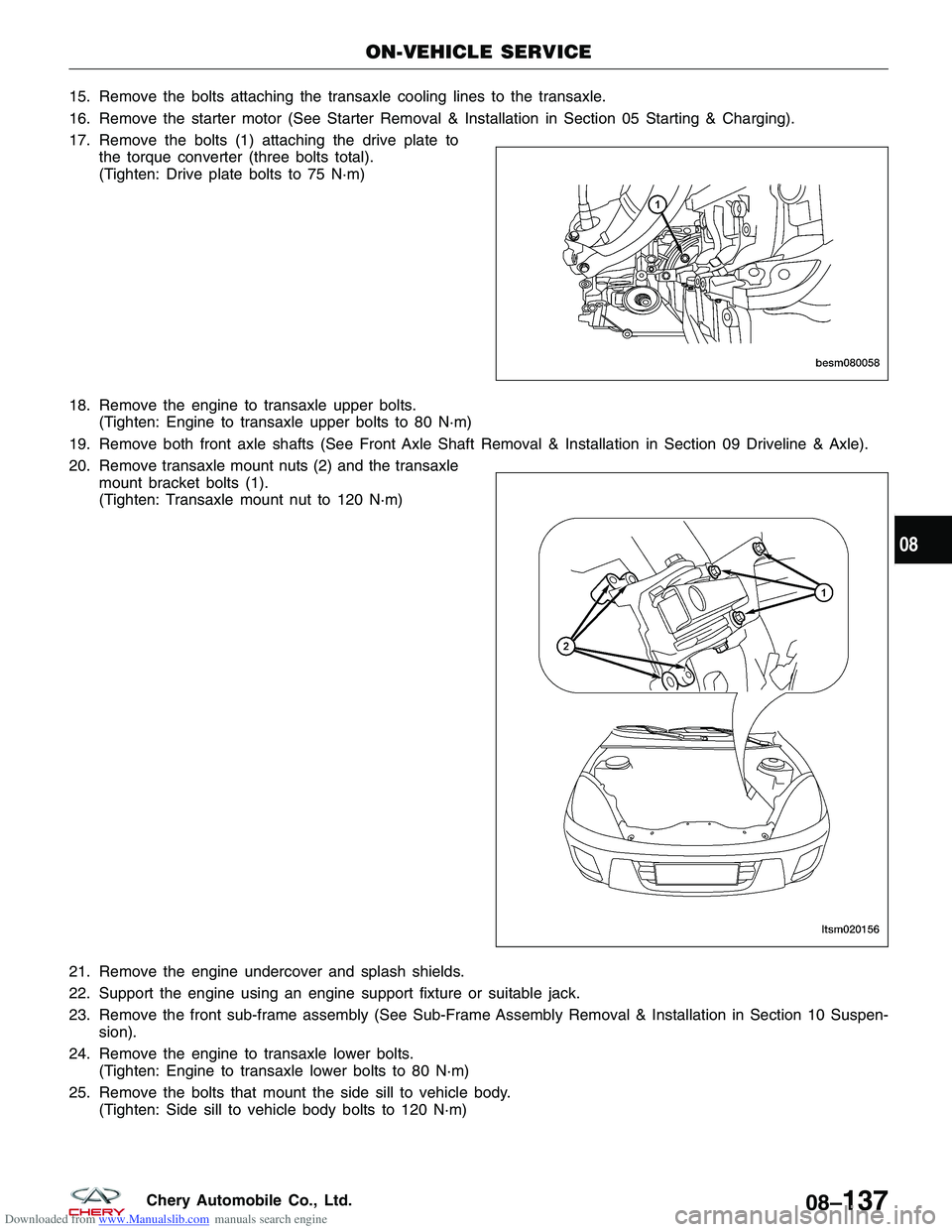

17. Remove the bolts (1) attaching the drive plate tothe torque converter (three bolts total).

(Tighten: Drive plate bolts to 75 N·m)

18. Remove the engine to transaxle upper bolts. (Tighten: Engine to transaxle upper bolts to 80 N·m)

19. Remove both front axle shafts (See Front Axle Shaft Removal & Installation in Section 09 Driveline & Axle).

20. Remove transaxle mount nuts (2) and the transaxle mount bracket bolts (1).

(Tighten: Transaxle mount nut to 120 N·m)

21. Remove the engine undercover and splash shields.

22. Support the engine using an engine support fixture or suitable jack.

23. Remove the front sub-frame assembly (See Sub-Frame Assembly Removal & Installation in Section 10 Suspen- sion).

24. Remove the engine to transaxle lower bolts. (Tighten: Engine to transaxle lower bolts to 80 N·m)

25. Remove the bolts that mount the side sill to vehicle body. (Tighten: Side sill to vehicle body bolts to 120 N·m)

ON-VEHICLE SERVICE

BESM080058

LTSM020156

08

08–137Chery Automobile Co., Ltd.