service CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1081 of 1903

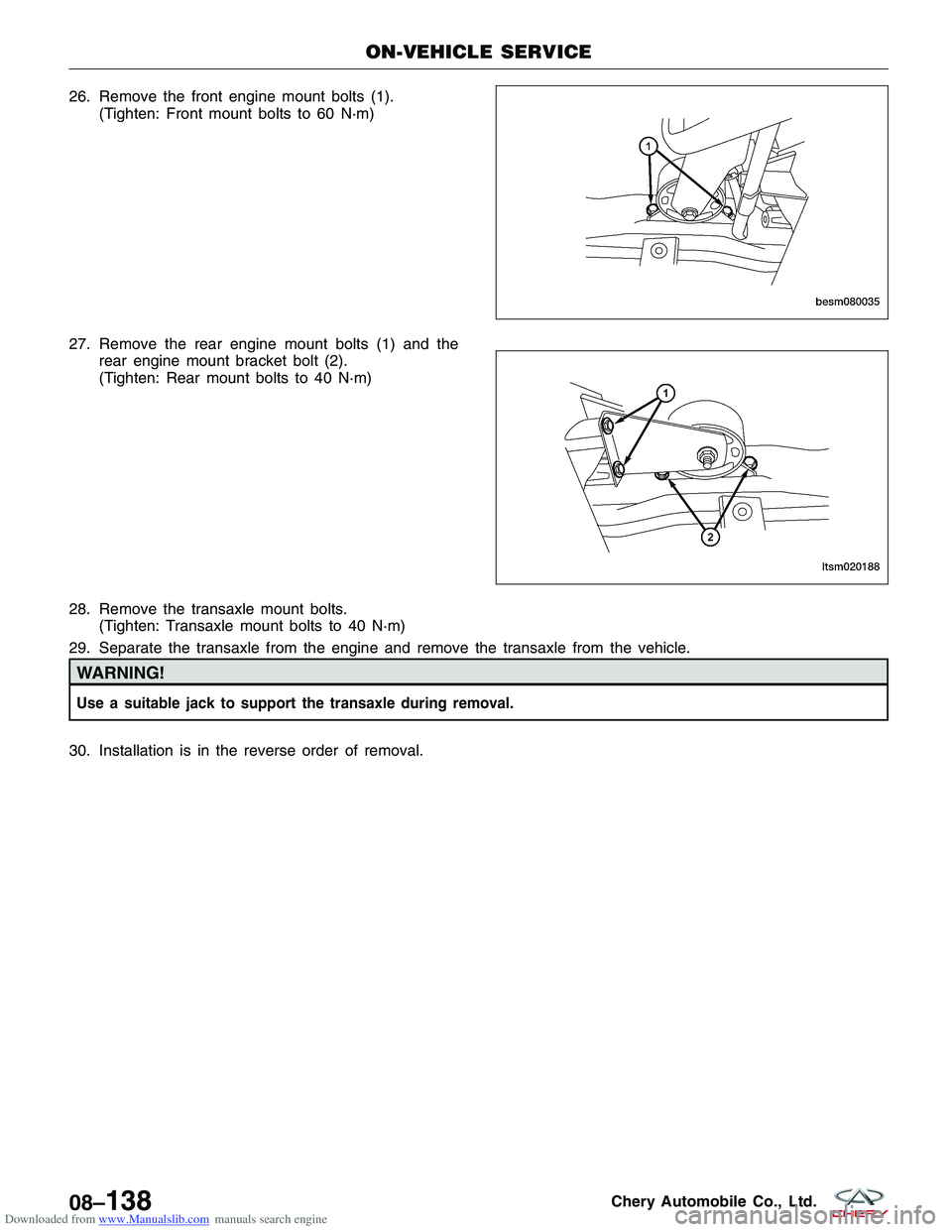

Downloaded from www.Manualslib.com manuals search engine 26. Remove the front engine mount bolts (1).(Tighten: Front mount bolts to 60 N·m)

27. Remove the rear engine mount bolts (1) and the rear engine mount bracket bolt (2).

(Tighten: Rear mount bolts to 40 N·m)

28. Remove the transaxle mount bolts. (Tighten: Transaxle mount bolts to 40 N·m)

29. Separate the transaxle from the engine and remove the transaxle from the vehicle.

WARNING!

Use a suitable jack to support the transaxle during removal.

30. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

BESM080035

LTSM020188

08–138Chery Automobile Co., Ltd.

Page 1082 of 1903

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

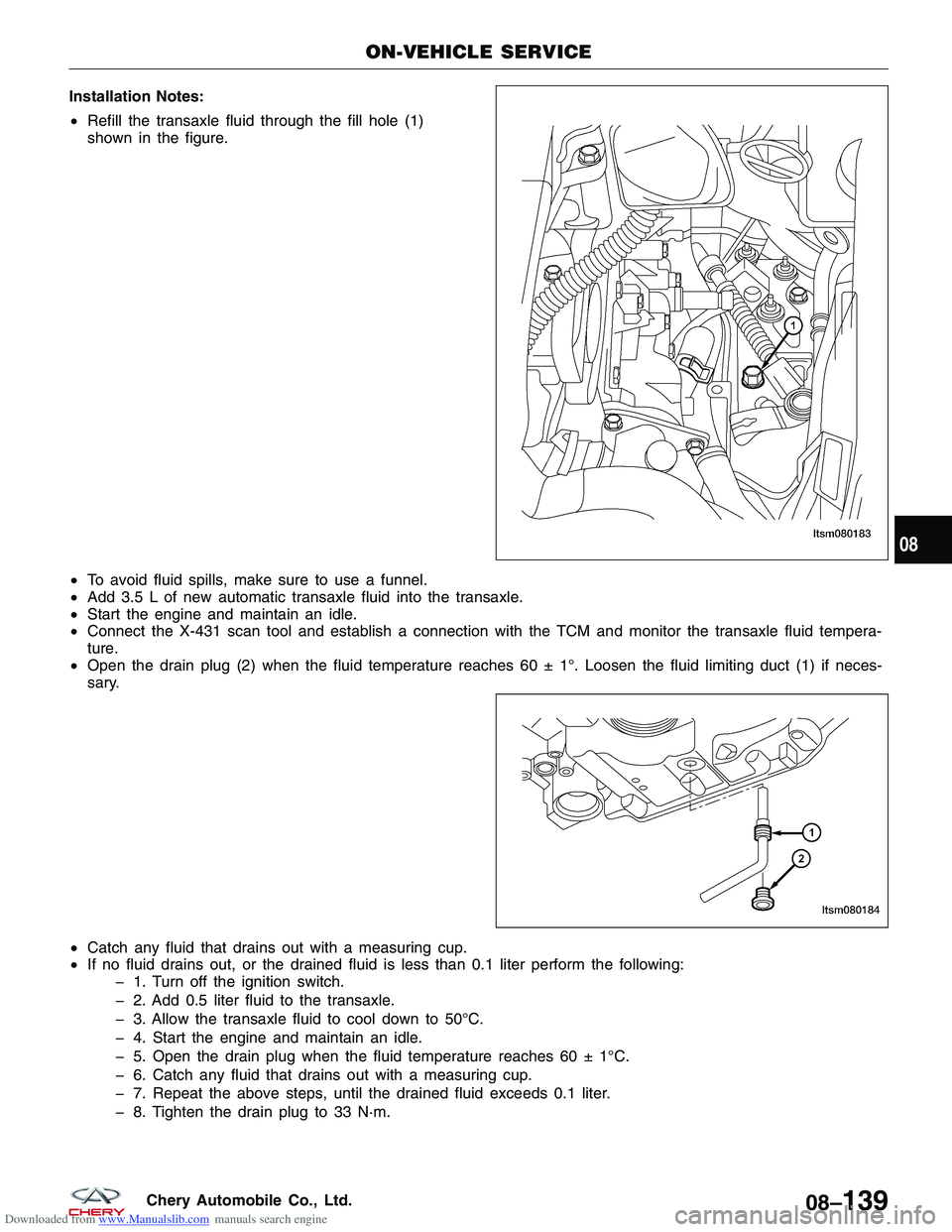

•Refill the transaxle fluid through the fill hole (1)

shown in the figure.

• To avoid fluid spills, make sure to use a funnel.

• Add 3.5 L of new automatic transaxle fluid into the transaxle.

• Start the engine and maintain an idle.

• Connect the X-431 scan tool and establish a connection with the TCM and monitor the transaxle fluid tempera-

ture.

• Open the drain plug (2) when the fluid temperature reaches 60 ± 1°. Loosen the fluid limiting duct (1) if neces-

sary.

• Catch any fluid that drains out with a measuring cup.

• If no fluid drains out, or the drained fluid is less than 0.1 liter perform the following:

� 1. Turn off the ignition switch.

� 2. Add 0.5 liter fluid to the transaxle.

� 3. Allow the transaxle fluid to cool down to 50°C.

� 4. Start the engine and maintain an idle.

� 5. Open the drain plug when the fluid temperature reaches 60 ± 1°C.

� 6. Catch any fluid that drains out with a measuring cup.

� 7. Repeat the above steps, until the drained fluid exceeds 0.1 liter.

� 8. Tighten the drain plug to 33 N·m.

ON-VEHICLE SERVICE

LTSM080183

LTSM080184

08

08–139Chery Automobile Co., Ltd.

Page 1083 of 1903

Downloaded from www.Manualslib.com manuals search engine WARNING!

The gearshift lever must be shifted to gear P while adding transaxle fluid.

Automatic Shifter Selector

Removal & Installation

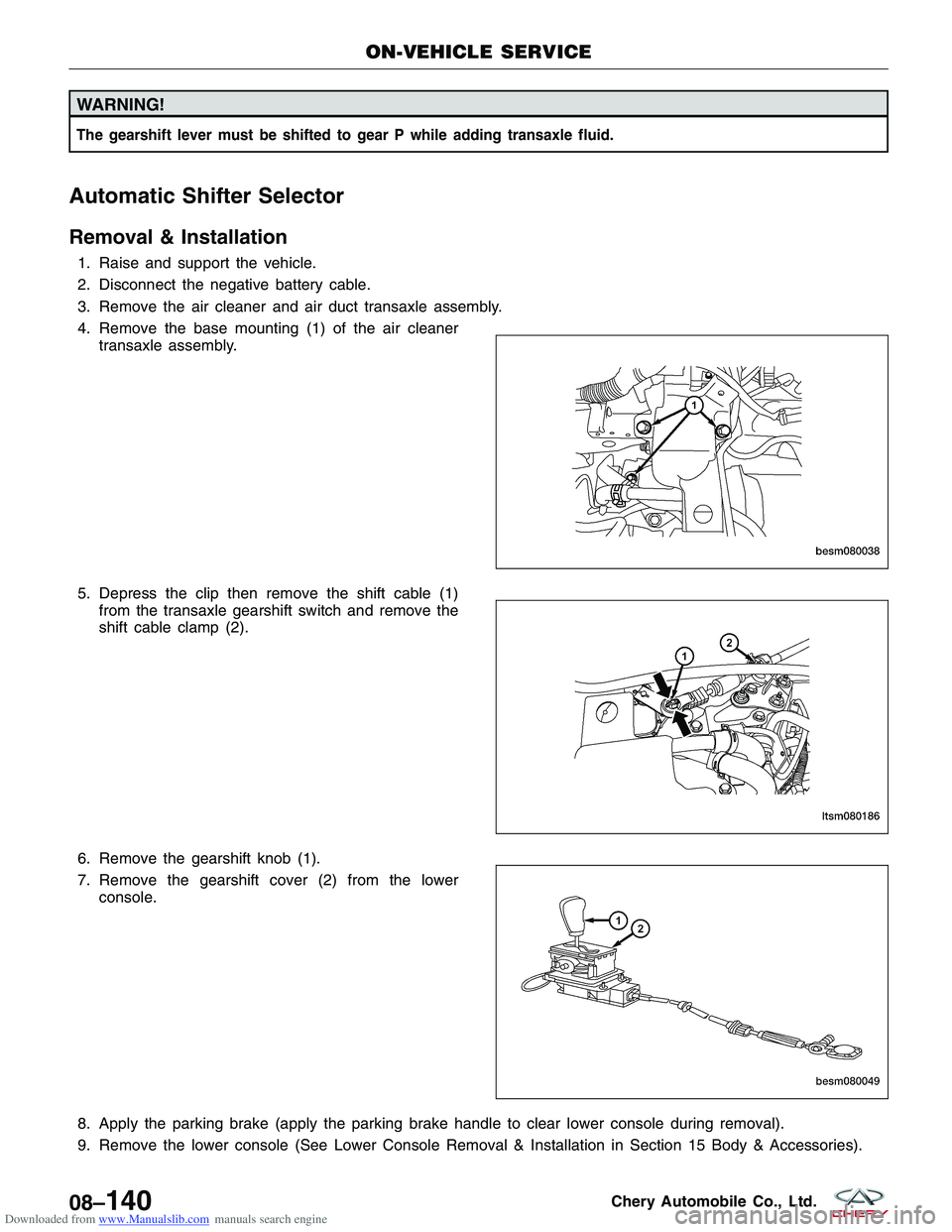

1. Raise and support the vehicle.

2. Disconnect the negative battery cable.

3. Remove the air cleaner and air duct transaxle assembly.

4. Remove the base mounting (1) of the air cleanertransaxle assembly.

5. Depress the clip then remove the shift cable (1) from the transaxle gearshift switch and remove the

shift cable clamp (2).

6. Remove the gearshift knob (1).

7. Remove the gearshift cover (2) from the lower console.

8. Apply the parking brake (apply the parking brake handle to clear lower console during removal).

9. Remove the lower console (See Lower Console Removal & Installation in Section 15 Body & Accessories).

ON-VEHICLE SERVICE

BESM080038

LTSM080186

BESM080049

08–140Chery Automobile Co., Ltd.

Page 1084 of 1903

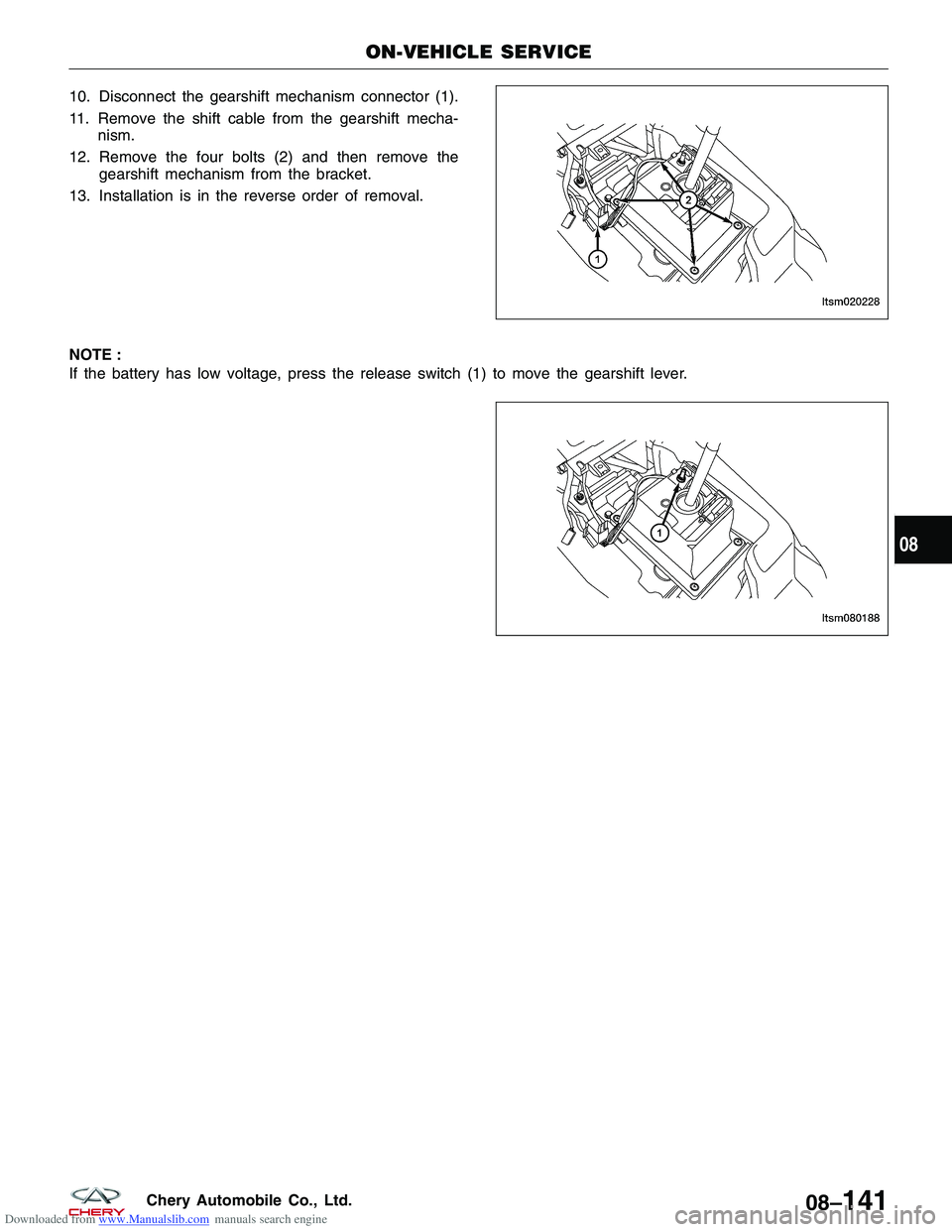

Downloaded from www.Manualslib.com manuals search engine 10. Disconnect the gearshift mechanism connector (1).

11. Remove the shift cable from the gearshift mecha-nism.

12. Remove the four bolts (2) and then remove the gearshift mechanism from the bracket.

13. Installation is in the reverse order of removal.

NOTE :

If the battery has low voltage, press the release switch (1) to move the gearshift lever.

ON-VEHICLE SERVICE

LTSM020228

LTSM080188

08

08–141Chery Automobile Co., Ltd.

Page 1085 of 1903

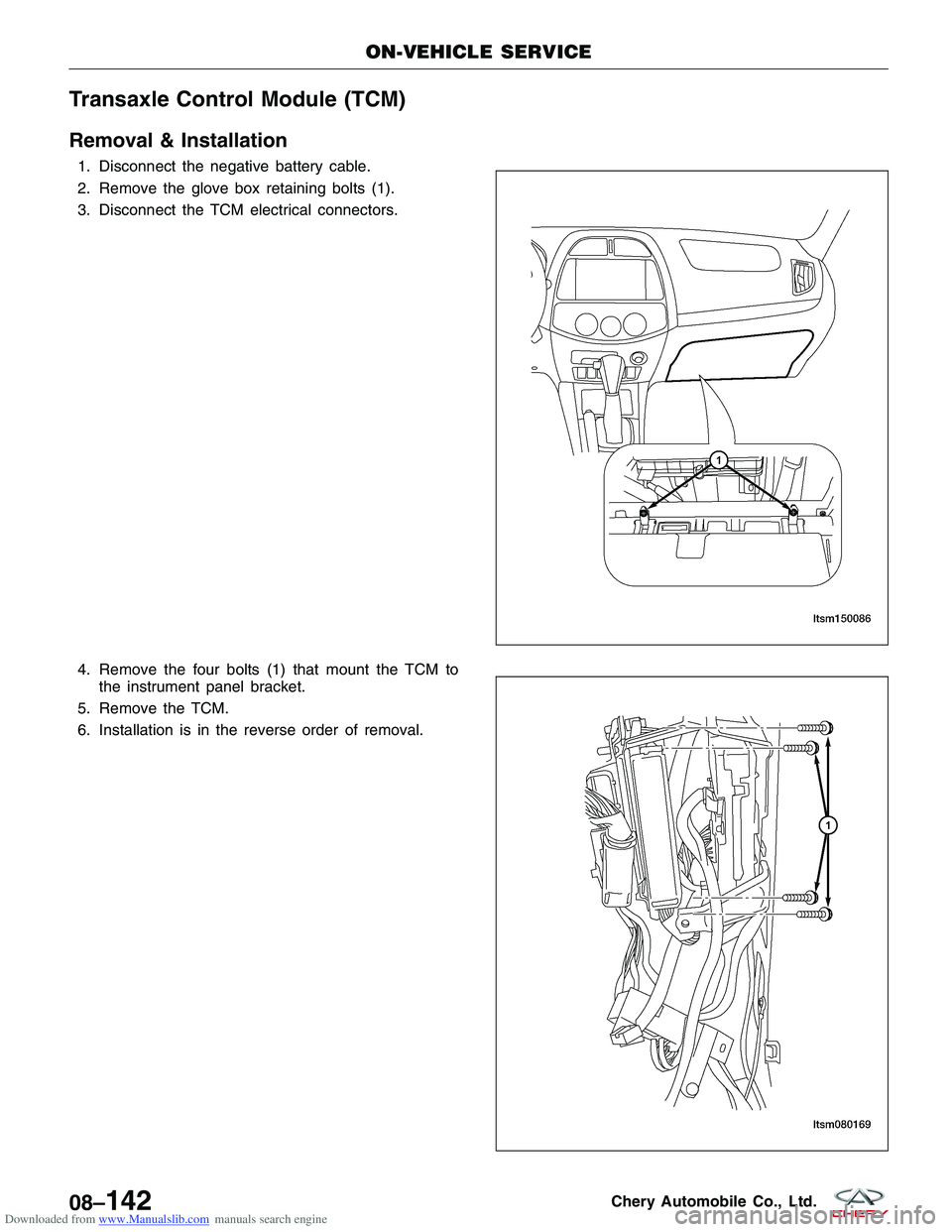

Downloaded from www.Manualslib.com manuals search engine Transaxle Control Module (TCM)

Removal & Installation

1. Disconnect the negative battery cable.

2. Remove the glove box retaining bolts (1).

3. Disconnect the TCM electrical connectors.

4. Remove the four bolts (1) that mount the TCM tothe instrument panel bracket.

5. Remove the TCM.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM150086

LTSM080169

08–142Chery Automobile Co., Ltd.

Page 1086 of 1903

Downloaded from www.Manualslib.com manuals search engine F4A4 AUTOMATIC TRANSAXLE

GENERAL INFORMATION08-144

Description 08-144

Operation 08-145

Specifications 08-147

Special Tools 08-148

Electrical Schematics 08-152

Transaxle Control Module (TCM)

Connector Pin-Out Table 08-157

DIAGNOSIS & TESTING08-158

Diagnostic Help 08-158

Diagnostic Tools 08-158

Diagnostic Trouble Code (DTC) List 08-159

F4A4 Automatic Transaxle DTC List 08-159

Diagnostic Trouble Code (DTC) Tests 08-160

15 - TFT Sensor Open Circuit 08-160

22 - Input Speed Sensor 08-163

23 - Output Speed Sensor Fault 08-168

26 - Brake Pedal Position Switch Circuit

Malfunction 08-17431 - Reverse/Low Solenoid Malfunction 08-177

32 - Low Speed Solenoid Malfunction 08-182

33 - 2nd Gear Solenoid Open Circuit 08-188

34 - Overdrive Solenoid Circuit

Malfunction

08-194

36 - Damper Clutch System Control

Solenoid Malfunction 08-200

41 - First Gear, Ratio Out Of Limits 08-206

42 - Second Gear, Ratio Out Of Limits 08-212

43 - Third Gear, Ratio Out Of Limits 08-218

44 - Fourth Gear, Ratio Out Of Limits 08-224

46 - Reverse Gear, Ratio Out Of Limits 08-230

54 - Electrical Relay Open Circuit 08-236

ON-VEHICLE SERVICE08-240

F4A4 Automatic Transaxle Assembly 08-240

Removal & Installation 08-240

Automatic Shifter Selector 08-243

Removal & Installation 08-243

08

08–143Chery Automobile Co., Ltd.

Page 1183 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

F4A4 Automatic Transaxle Assembly

Removal & Installation

1. Raise and support the vehicle.

2. Disconnect the negative battery cable.

3. Remove the battery and battery tray (See Battery Removal & Installation in Section 05 Starting & Charging).

4. Remove the air cleaner and air duct assembly.

5. Drain the cooling system (See Cooling System Draining Procedure in Section 06 Cooling System).

6. Remove the base mounting bolts (1) of the aircleaner housing assembly.

7. Disconnect and remove the electrical connectors for the following components:• Output shaft sensor (1)

• Input shaft sensor (2)

• Electromagnetic valve switch connector (3)

• Gear switch connector (5)

8. Disconnect the transaxle fluid lines (6) using a suit- able tool.

9. Remove the shift cable (4) from the transaxle assembly.

10. Remove the starter motor (See Starter Removal & Installation in Section 05 Starting & Charging).

BESM080038

LTSM080153

08–240Chery Automobile Co., Ltd.

Page 1184 of 1903

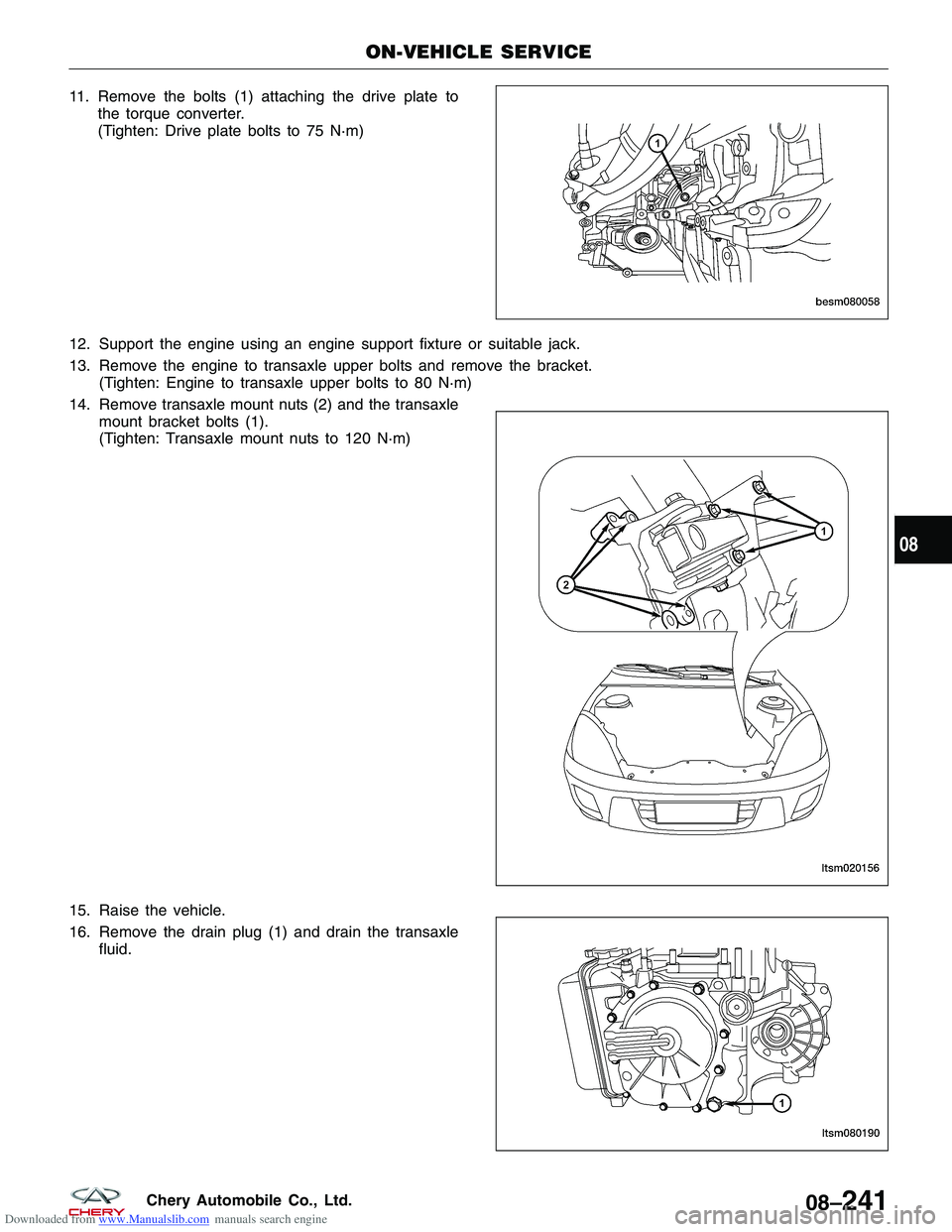

Downloaded from www.Manualslib.com manuals search engine 11. Remove the bolts (1) attaching the drive plate tothe torque converter.

(Tighten: Drive plate bolts to 75 N·m)

12. Support the engine using an engine support fixture or suitable jack.

13. Remove the engine to transaxle upper bolts and remove the bracket. (Tighten: Engine to transaxle upper bolts to 80 N·m)

14. Remove transaxle mount nuts (2) and the transaxle mount bracket bolts (1).

(Tighten: Transaxle mount nuts to 120 N·m)

15. Raise the vehicle.

16. Remove the drain plug (1) and drain the transaxle fluid.

ON-VEHICLE SERVICE

BESM080058

LTSM020156

LTSM080190

08

08–241Chery Automobile Co., Ltd.

Page 1185 of 1903

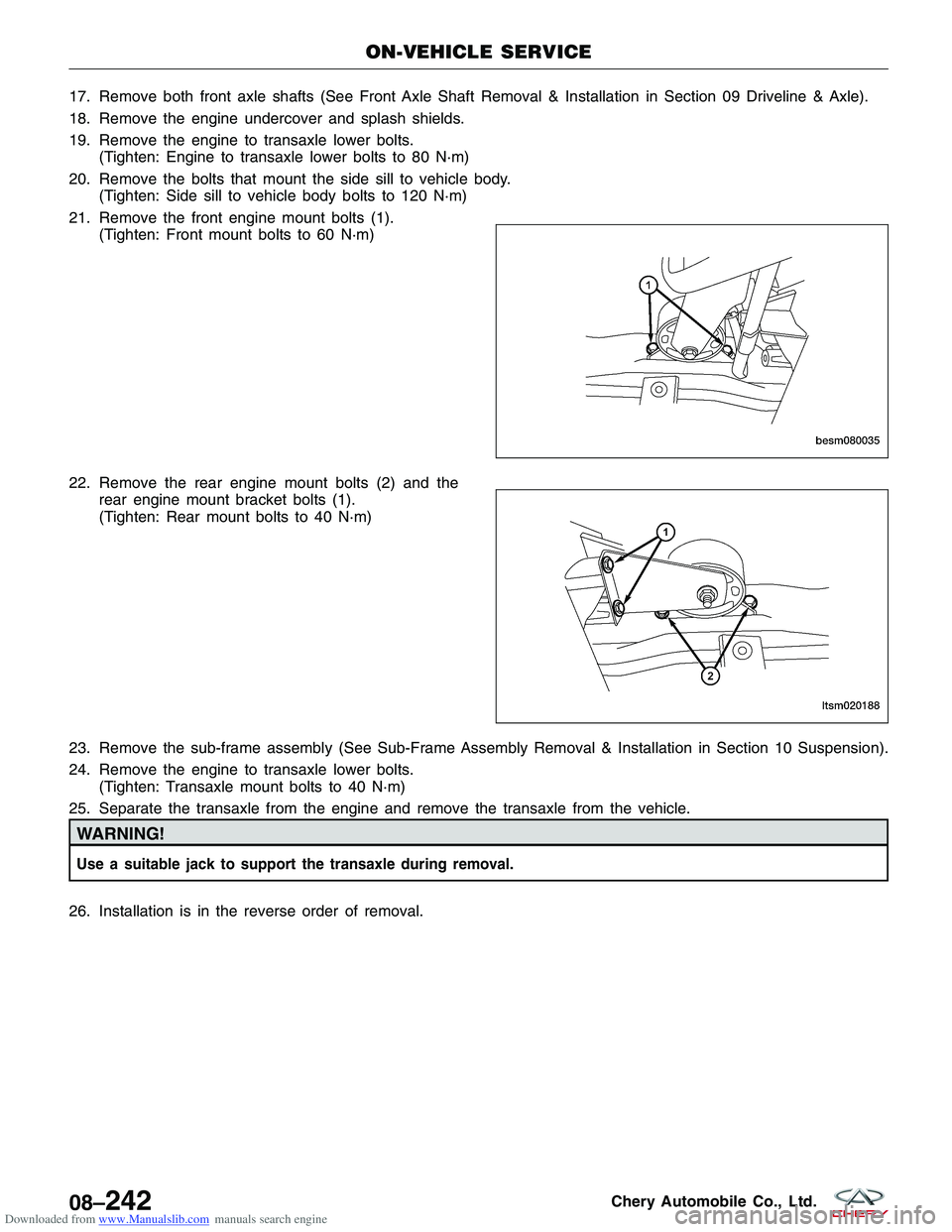

Downloaded from www.Manualslib.com manuals search engine 17. Remove both front axle shafts (See Front Axle Shaft Removal & Installation in Section 09 Driveline & Axle).

18. Remove the engine undercover and splash shields.

19. Remove the engine to transaxle lower bolts.(Tighten: Engine to transaxle lower bolts to 80 N·m)

20. Remove the bolts that mount the side sill to vehicle body. (Tighten: Side sill to vehicle body bolts to 120 N·m)

21. Remove the front engine mount bolts (1). (Tighten: Front mount bolts to 60 N·m)

22. Remove the rear engine mount bolts (2) and the rear engine mount bracket bolts (1).

(Tighten: Rear mount bolts to 40 N·m)

23. Remove the sub-frame assembly (See Sub-Frame Assembly Removal & Installation in Section 10 Suspension).

24. Remove the engine to transaxle lower bolts. (Tighten: Transaxle mount bolts to 40 N·m)

25. Separate the transaxle from the engine and remove the transaxle from the vehicle.

WARNING!

Use a suitable jack to support the transaxle during removal.

26. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

BESM080035

LTSM020188

08–242Chery Automobile Co., Ltd.

Page 1186 of 1903

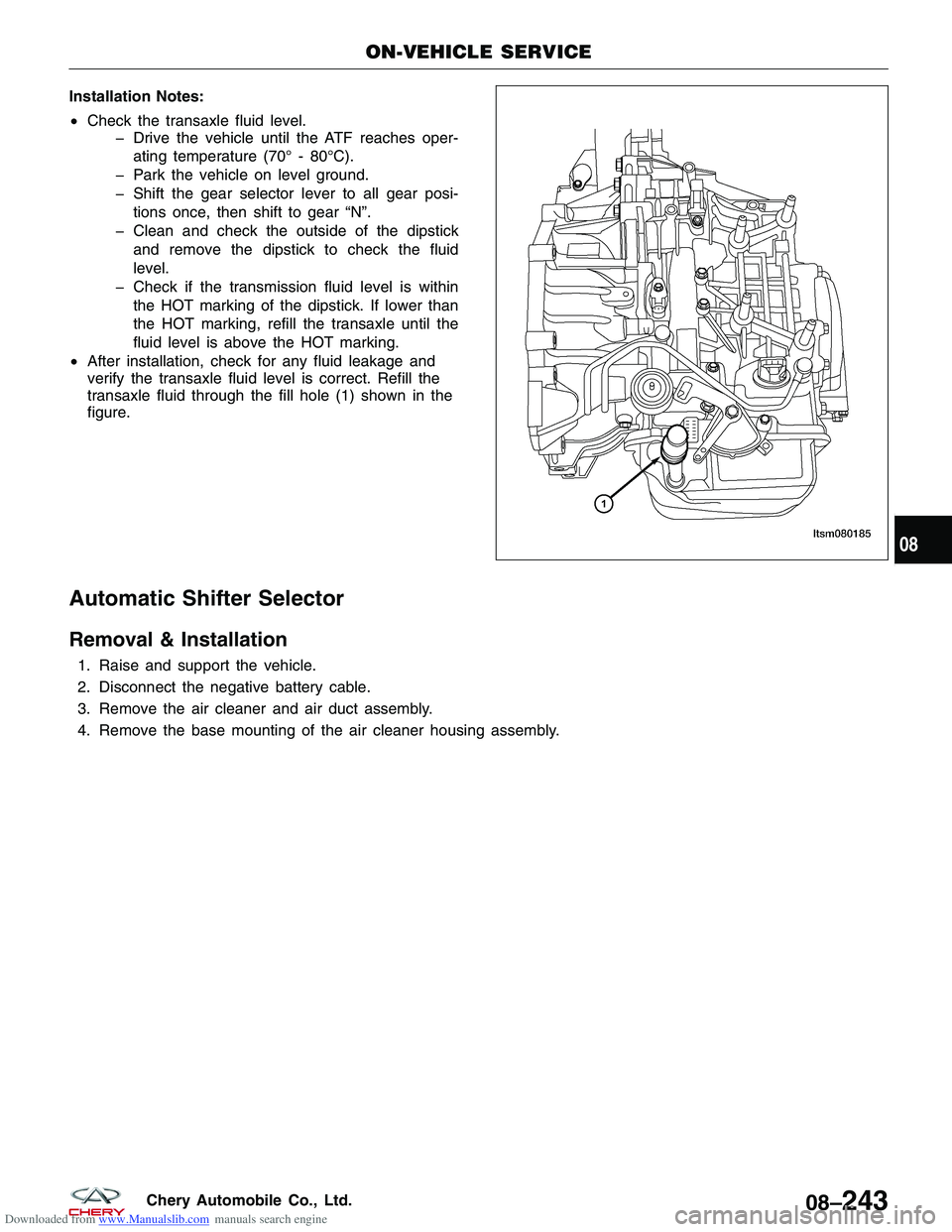

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

•Check the transaxle fluid level.

� Drive the vehicle until the ATF reaches oper-

ating temperature (70° - 80°C).

� Park the vehicle on level ground.

� Shift the gear selector lever to all gear posi- tions once, then shift to gear “N”.

� Clean and check the outside of the dipstick and remove the dipstick to check the fluid

level.

� Check if the transmission fluid level is within the HOT marking of the dipstick. If lower than

the HOT marking, refill the transaxle until the

fluid level is above the HOT marking.

• After installation, check for any fluid leakage and

verify the transaxle fluid level is correct. Refill the

transaxle fluid through the fill hole (1) shown in the

figure.

Automatic Shifter Selector

Removal & Installation

1. Raise and support the vehicle.

2. Disconnect the negative battery cable.

3. Remove the air cleaner and air duct assembly.

4. Remove the base mounting of the air cleaner housing assembly.

ON-VEHICLE SERVICE

LTSM080185

08

08–243Chery Automobile Co., Ltd.