service CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1210 of 1903

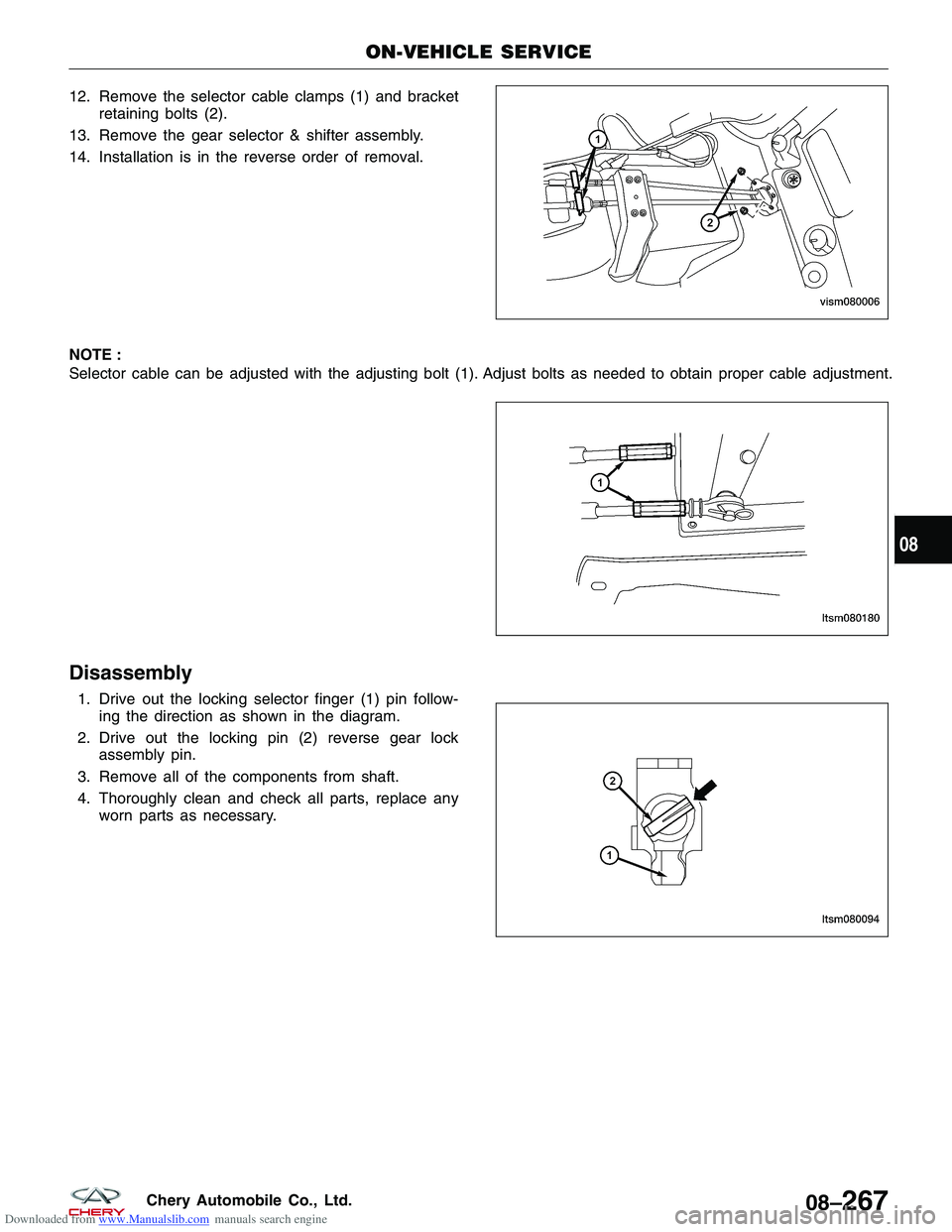

Downloaded from www.Manualslib.com manuals search engine 12. Remove the selector cable clamps (1) and bracketretaining bolts (2).

13. Remove the gear selector & shifter assembly.

14. Installation is in the reverse order of removal.

NOTE :

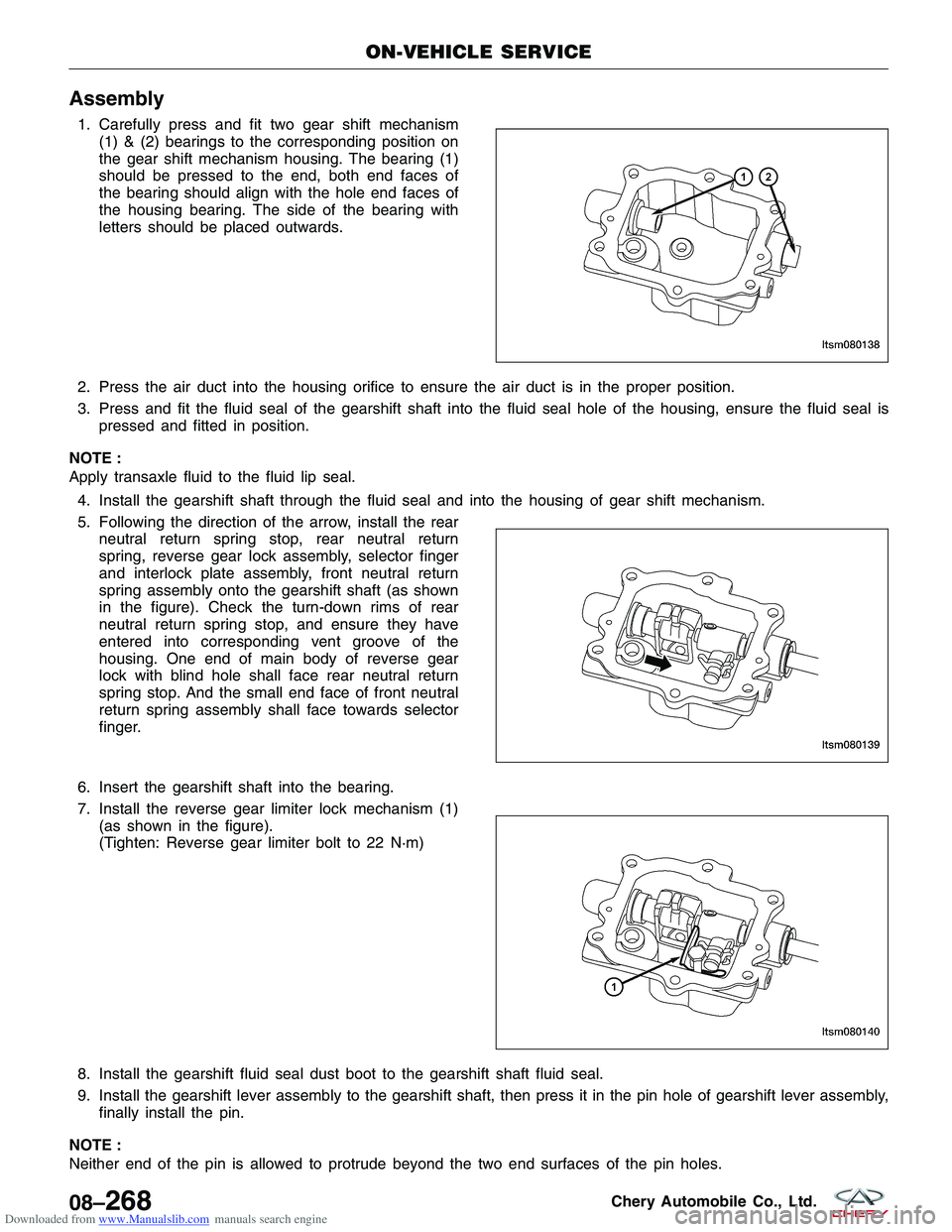

Selector cable can be adjusted with the adjusting bolt (1). Adjust bolts as needed to obtain proper cable adjustment.

Disassembly

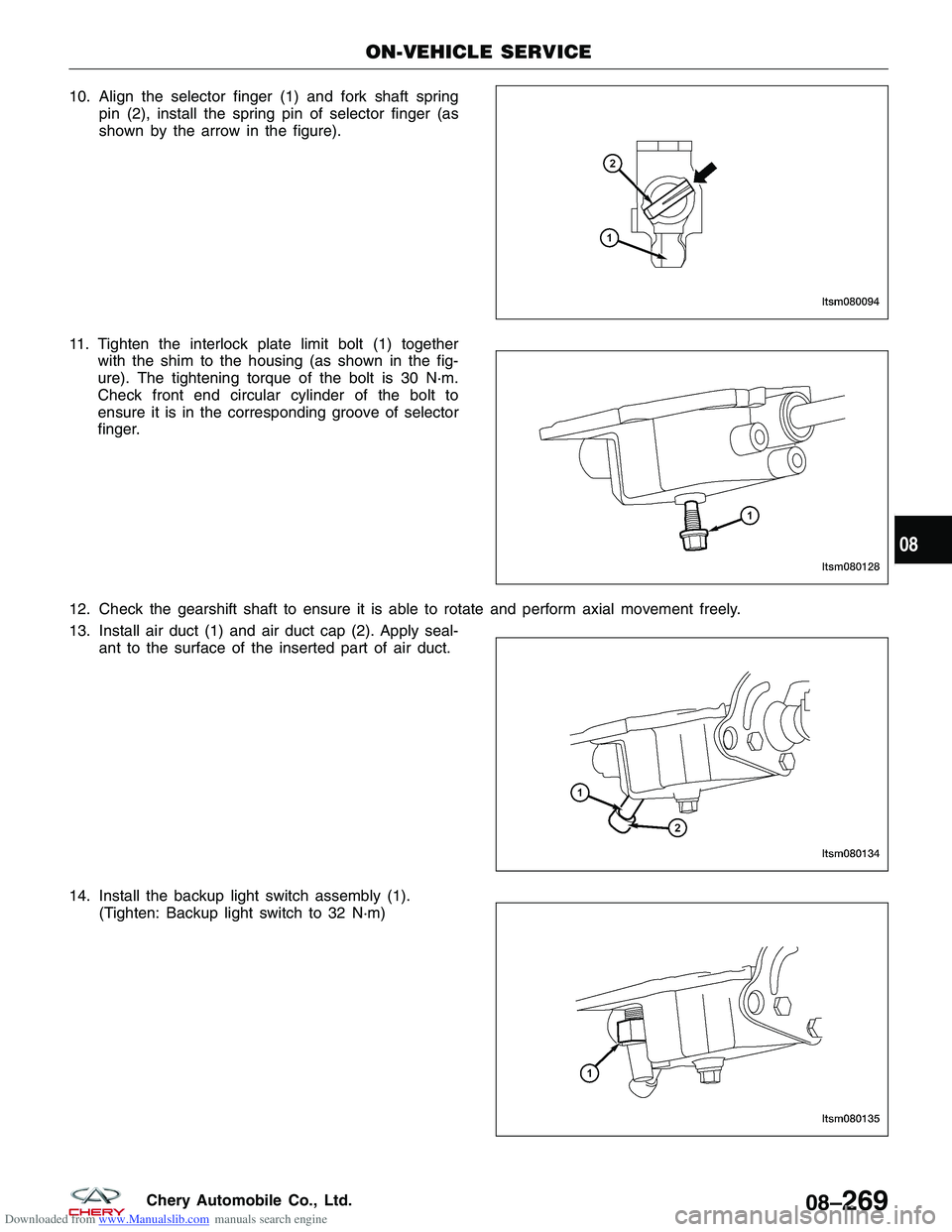

1. Drive out the locking selector finger (1) pin follow- ing the direction as shown in the diagram.

2. Drive out the locking pin (2) reverse gear lock assembly pin.

3. Remove all of the components from shaft.

4. Thoroughly clean and check all parts, replace any worn parts as necessary.

ON-VEHICLE SERVICE

VISM080006

LTSM080180

LTSM080094

08

08–267Chery Automobile Co., Ltd.

Page 1211 of 1903

Downloaded from www.Manualslib.com manuals search engine Assembly

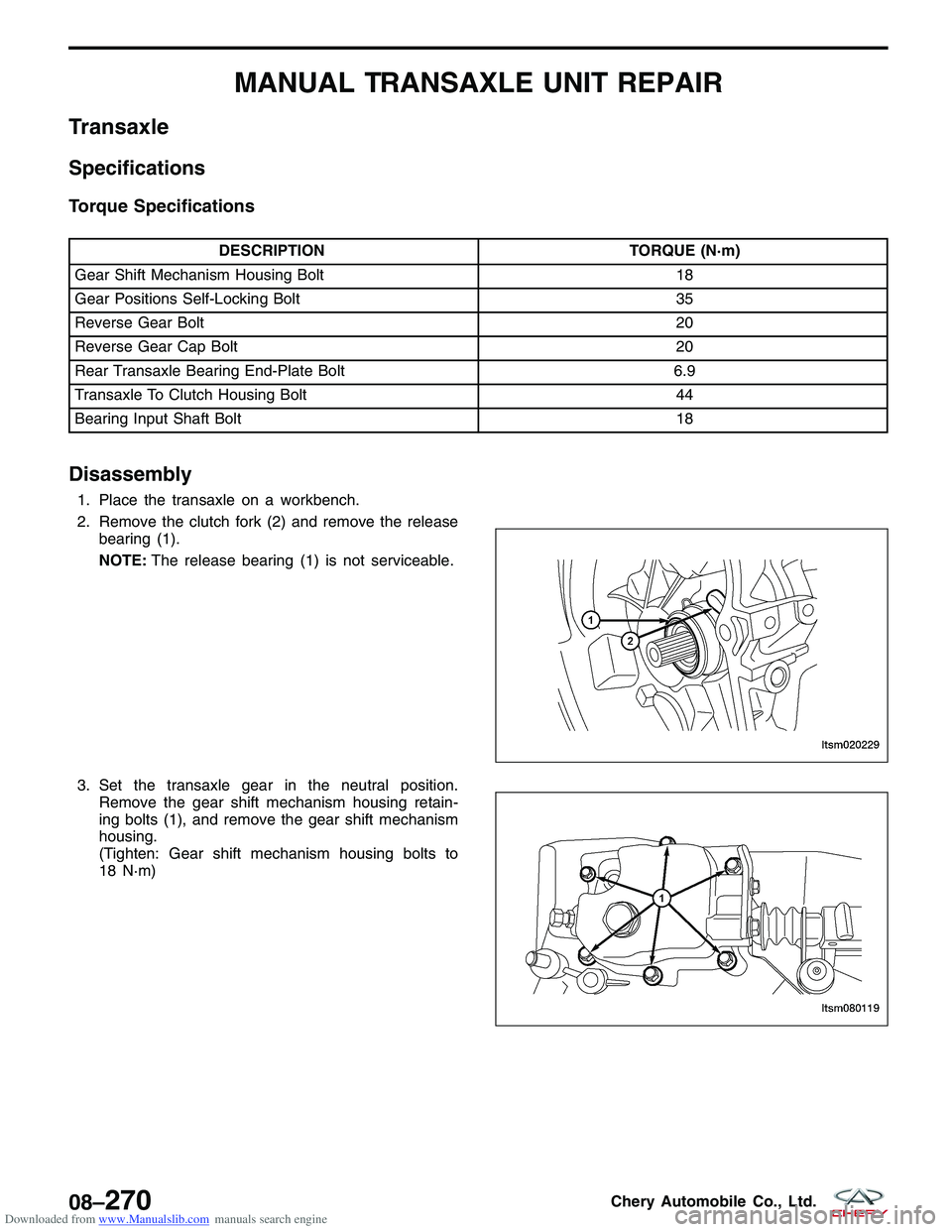

1. Carefully press and fit two gear shift mechanism(1) & (2) bearings to the corresponding position on

the gear shift mechanism housing. The bearing (1)

should be pressed to the end, both end faces of

the bearing should align with the hole end faces of

the housing bearing. The side of the bearing with

letters should be placed outwards.

2. Press the air duct into the housing orifice to ensure the air duct is in the proper position.

3. Press and fit the fluid seal of the gearshift shaft into the fluid seal hole of the housing, ensure the fluid seal is pressed and fitted in position.

NOTE :

Apply transaxle fluid to the fluid lip seal. 4. Install the gearshift shaft through the fluid seal and into the housing of gear shift mechanism.

5. Following the direction of the arrow, install the rear neutral return spring stop, rear neutral return

spring, reverse gear lock assembly, selector finger

and interlock plate assembly, front neutral return

spring assembly onto the gearshift shaft (as shown

in the figure). Check the turn-down rims of rear

neutral return spring stop, and ensure they have

entered into corresponding vent groove of the

housing. One end of main body of reverse gear

lock with blind hole shall face rear neutral return

spring stop. And the small end face of front neutral

return spring assembly shall face towards selector

finger.

6. Insert the gearshift shaft into the bearing.

7. Install the reverse gear limiter lock mechanism (1) (as shown in the figure).

(Tighten: Reverse gear limiter bolt to 22 N·m)

8. Install the gearshift fluid seal dust boot to the gearshift shaft fluid seal.

9. Install the gearshift lever assembly to the gearshift shaft, then press it in the pin hole of gearshift lever assembly, finally install the pin.

NOTE :

Neither end of the pin is allowed to protrude beyond the two end surfaces of the pin holes.

ON-VEHICLE SERVICE

LTSM080138

LTSM080139

LTSM080140

08–268Chery Automobile Co., Ltd.

Page 1212 of 1903

Downloaded from www.Manualslib.com manuals search engine 10. Align the selector finger (1) and fork shaft springpin (2), install the spring pin of selector finger (as

shown by the arrow in the figure).

11. Tighten the interlock plate limit bolt (1) together with the shim to the housing (as shown in the fig-

ure). The tightening torque of the bolt is 30 N·m.

Check front end circular cylinder of the bolt to

ensure it is in the corresponding groove of selector

finger.

12. Check the gearshift shaft to ensure it is able to rotate and perform axial movement freely.

13. Install air duct (1) and air duct cap (2). Apply seal- ant to the surface of the inserted part of air duct.

14. Install the backup light switch assembly (1). (Tighten: Backup light switch to 32 N·m)

ON-VEHICLE SERVICE

LTSM080094

LTSM080128

LTSM080134

LTSM080135

08

08–269Chery Automobile Co., Ltd.

Page 1213 of 1903

Downloaded from www.Manualslib.com manuals search engine MANUAL TRANSAXLE UNIT REPAIR

Transaxle

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Gear Shift Mechanism Housing Bolt 18

Gear Positions Self-Locking Bolt 35

Reverse Gear Bolt 20

Reverse Gear Cap Bolt 20

Rear Transaxle Bearing End-Plate Bolt 6.9

Transaxle To Clutch Housing Bolt 44

Bearing Input Shaft Bolt 18

Disassembly

1. Place the transaxle on a workbench.

2. Remove the clutch fork (2) and remove the release

bearing (1).

NOTE: The release bearing (1) is not serviceable.

3. Set the transaxle gear in the neutral position. Remove the gear shift mechanism housing retain-

ing bolts (1), and remove the gear shift mechanism

housing.

(Tighten: Gear shift mechanism housing bolts to

18 N·m)

LTSM020229

LTSM080119

08–270Chery Automobile Co., Ltd.

Page 1229 of 1903

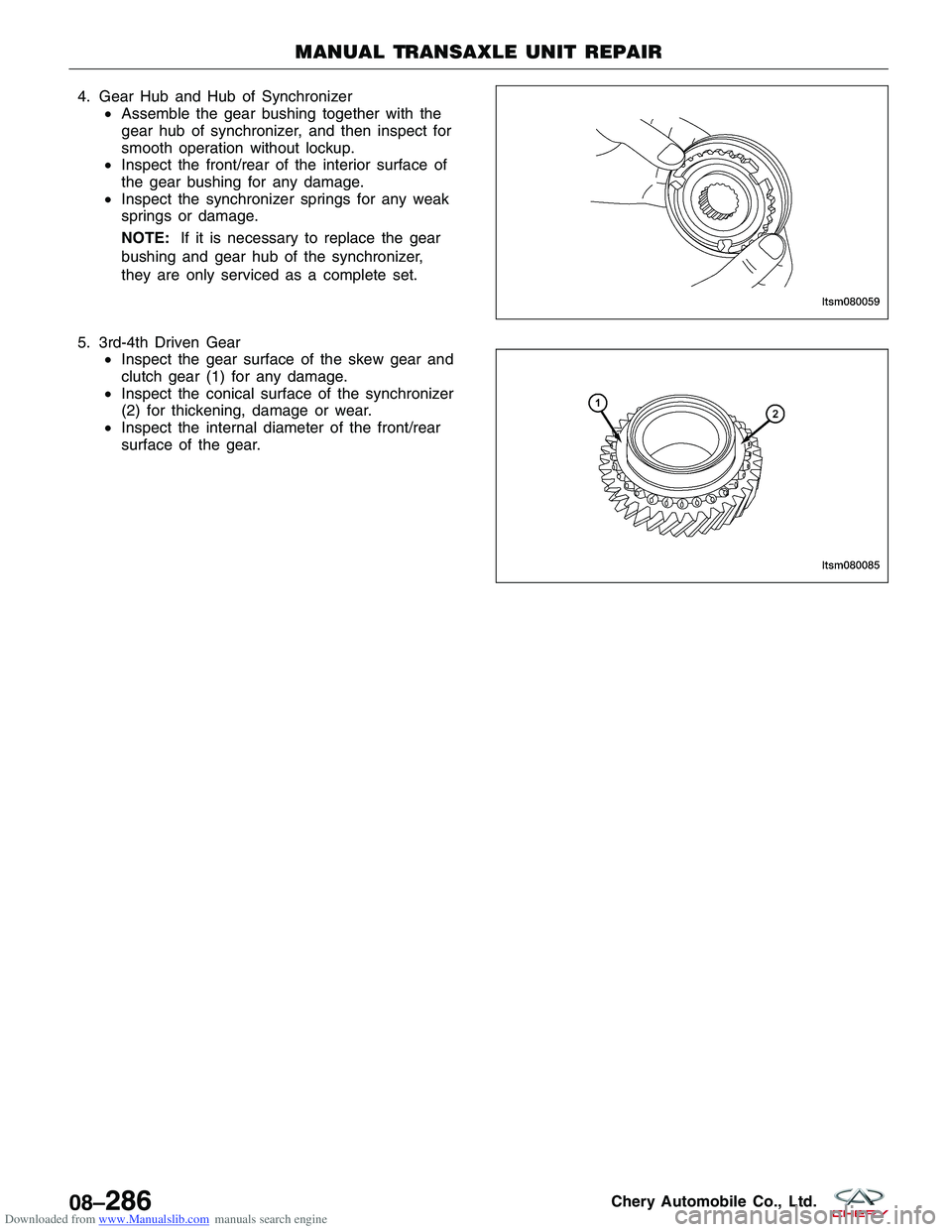

Downloaded from www.Manualslib.com manuals search engine 4. Gear Hub and Hub of Synchronizer•Assemble the gear bushing together with the

gear hub of synchronizer, and then inspect for

smooth operation without lockup.

• Inspect the front/rear of the interior surface of

the gear bushing for any damage.

• Inspect the synchronizer springs for any weak

springs or damage.

NOTE: If it is necessary to replace the gear

bushing and gear hub of the synchronizer,

they are only serviced as a complete set.

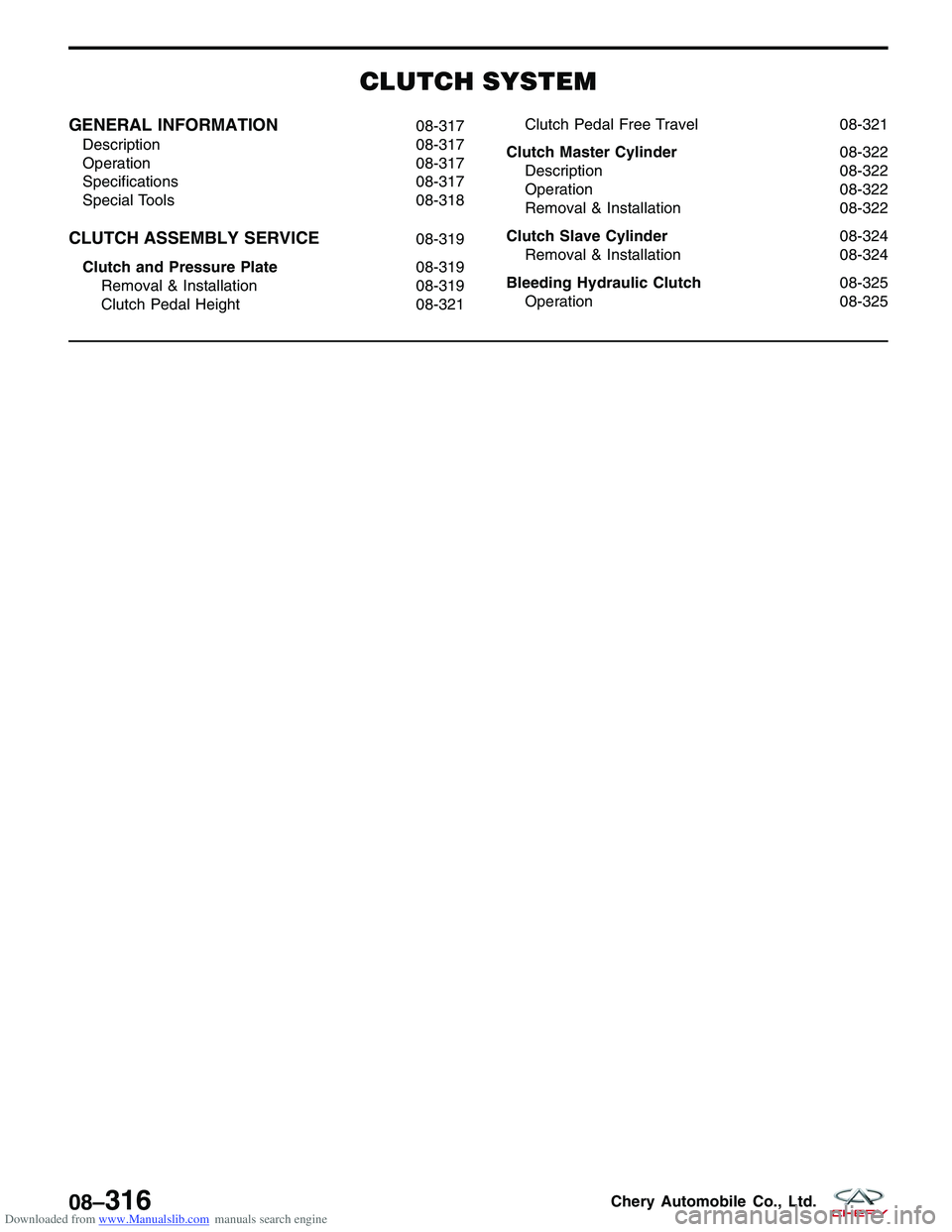

5. 3rd-4th Driven Gear •Inspect the gear surface of the skew gear and

clutch gear (1) for any damage.

• Inspect the conical surface of the synchronizer

(2) for thickening, damage or wear.

• Inspect the internal diameter of the front/rear

surface of the gear.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080059

LTSM080085

08–286Chery Automobile Co., Ltd.

Page 1259 of 1903

Downloaded from www.Manualslib.com manuals search engine CLUTCH SYSTEM

GENERAL INFORMATION08-317

Description 08-317

Operation 08-317

Specifications 08-317

Special Tools 08-318

CLUTCH ASSEMBLY SERVICE08-319

Clutch and Pressure Plate 08-319

Removal & Installation 08-319

Clutch Pedal Height 08-321Clutch Pedal Free Travel

08-321

Clutch Master Cylinder 08-322

Description 08-322

Operation 08-322

Removal & Installation 08-322

Clutch Slave Cylinder 08-324

Removal & Installation 08-324

Bleeding Hydraulic Clutch 08-325

Operation 08-325

08–316Chery Automobile Co., Ltd.

Page 1262 of 1903

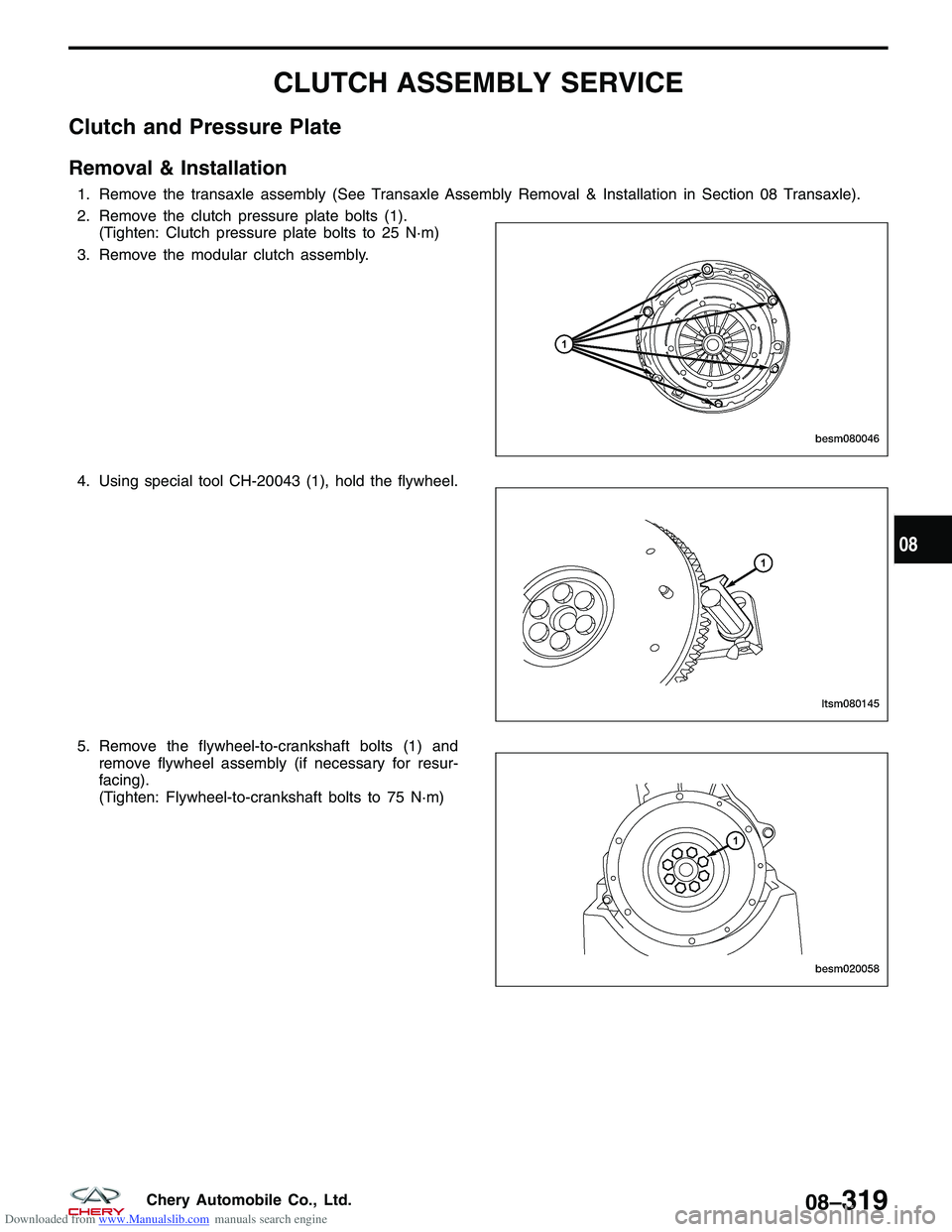

Downloaded from www.Manualslib.com manuals search engine CLUTCH ASSEMBLY SERVICE

Clutch and Pressure Plate

Removal & Installation

1. Remove the transaxle assembly (See Transaxle Assembly Removal & Installation in Section 08 Transaxle).

2. Remove the clutch pressure plate bolts (1).(Tighten: Clutch pressure plate bolts to 25 N·m)

3. Remove the modular clutch assembly.

4. Using special tool CH-20043 (1), hold the flywheel.

5. Remove the flywheel-to-crankshaft bolts (1) and remove flywheel assembly (if necessary for resur-

facing).

(Tighten: Flywheel-to-crankshaft bolts to 75 N·m)

BESM080046

LTSM080145

BESM020058

08

08–319Chery Automobile Co., Ltd.

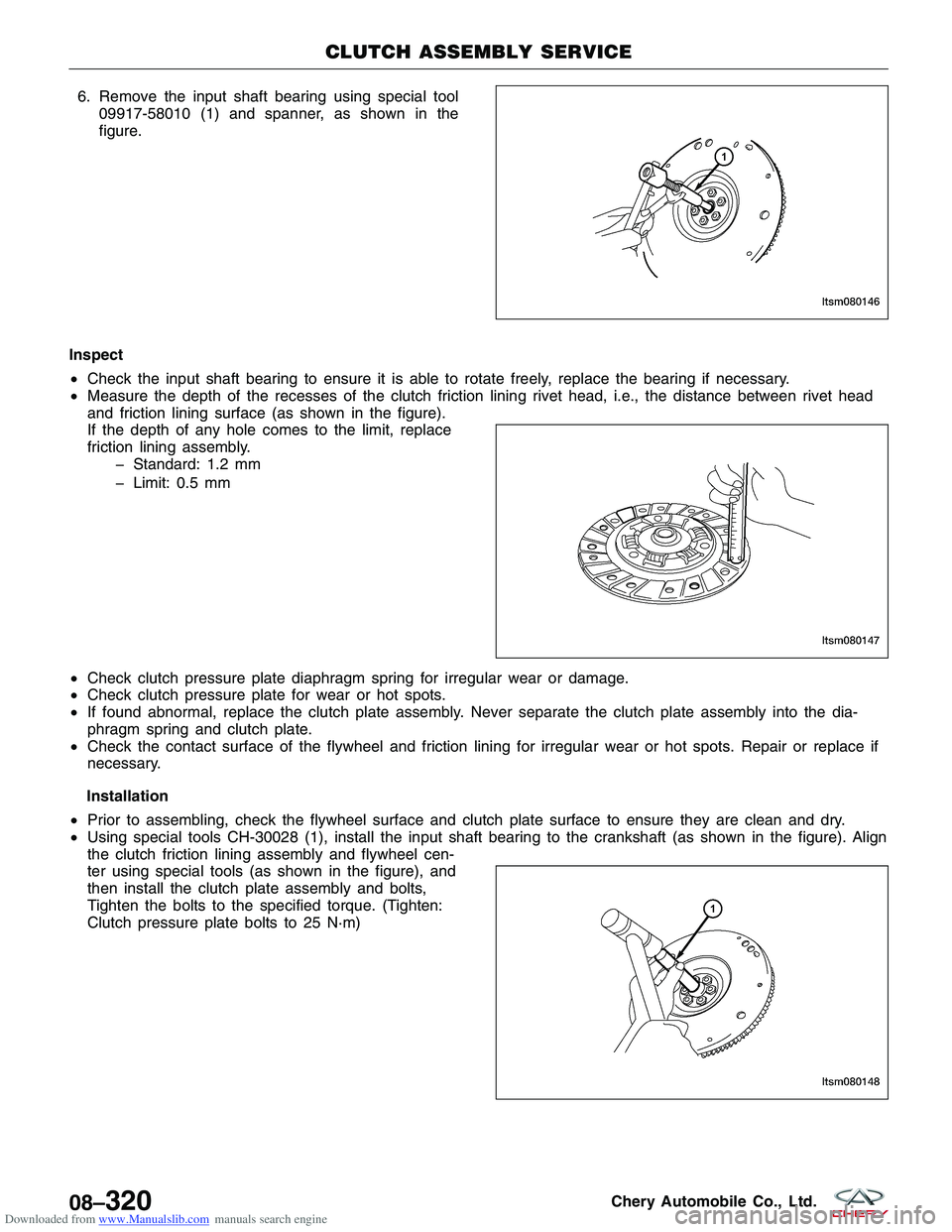

Page 1263 of 1903

Downloaded from www.Manualslib.com manuals search engine 6. Remove the input shaft bearing using special tool09917-58010 (1) and spanner, as shown in the

figure.

Inspect

• Check the input shaft bearing to ensure it is able to rotate freely, replace the bearing if necessary.

• Measure the depth of the recesses of the clutch friction lining rivet head, i.e., the distance between rivet head

and friction lining surface (as shown in the figure).

If the depth of any hole comes to the limit, replace

friction lining assembly.

� Standard: 1.2 mm

� Limit: 0.5 mm

• Check clutch pressure plate diaphragm spring for irregular wear or damage.

• Check clutch pressure plate for wear or hot spots.

• If found abnormal, replace the clutch plate assembly. Never separate the clutch plate assembly into the dia-

phragm spring and clutch plate.

• Check the contact surface of the flywheel and friction lining for irregular wear or hot spots. Repair or replace if

necessary.

Installation

• Prior to assembling, check the flywheel surface and clutch plate surface to ensure they are clean and dry.

• Using special tools CH-30028 (1), install the input shaft bearing to the crankshaft (as shown in the figure). Align

the clutch friction lining assembly and flywheel cen-

ter using special tools (as shown in the figure), and

then install the clutch plate assembly and bolts,

Tighten the bolts to the specified torque. (Tighten:

Clutch pressure plate bolts to 25 N·m)

CLUTCH ASSEMBLY SERVICE

LTSM080146

LTSM080147

LTSM080148

08–320Chery Automobile Co., Ltd.

Page 1264 of 1903

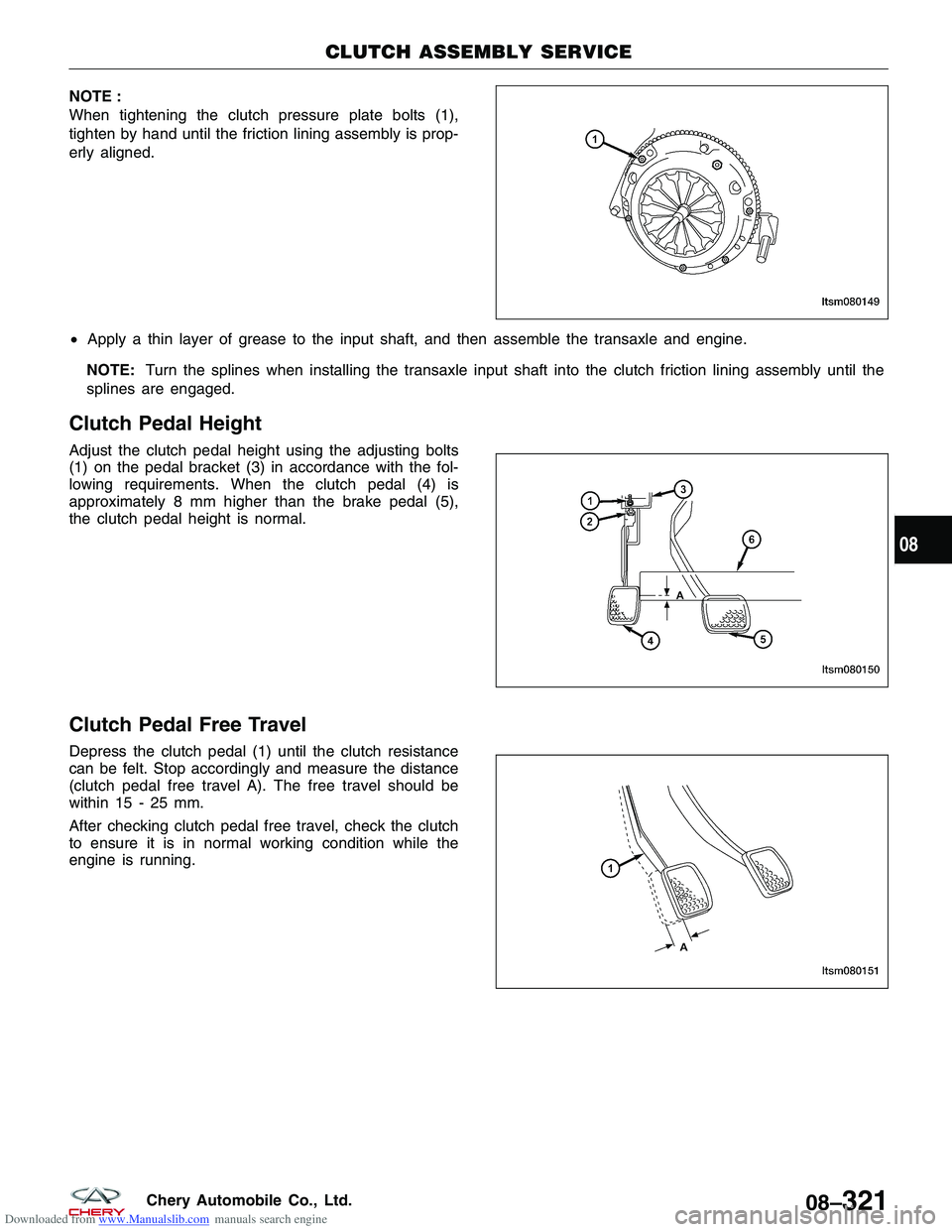

Downloaded from www.Manualslib.com manuals search engine NOTE :

When tightening the clutch pressure plate bolts (1),

tighten by hand until the friction lining assembly is prop-

erly aligned.

•Apply a thin layer of grease to the input shaft, and then assemble the transaxle and engine.

NOTE: Turn the splines when installing the transaxle input shaft into the clutch friction lining assembly until the

splines are engaged.

Clutch Pedal Height

Adjust the clutch pedal height using the adjusting bolts

(1) on the pedal bracket (3) in accordance with the fol-

lowing requirements. When the clutch pedal (4) is

approximately 8 mm higher than the brake pedal (5),

the clutch pedal height is normal.

Clutch Pedal Free Travel

Depress the clutch pedal (1) until the clutch resistance

can be felt. Stop accordingly and measure the distance

(clutch pedal free travel A). The free travel should be

within 15 - 25 mm.

After checking clutch pedal free travel, check the clutch

to ensure it is in normal working condition while the

engine is running.

CLUTCH ASSEMBLY SERVICE

LTSM080149

LTSM080150

LTSM080151

08

08–321Chery Automobile Co., Ltd.

Page 1265 of 1903

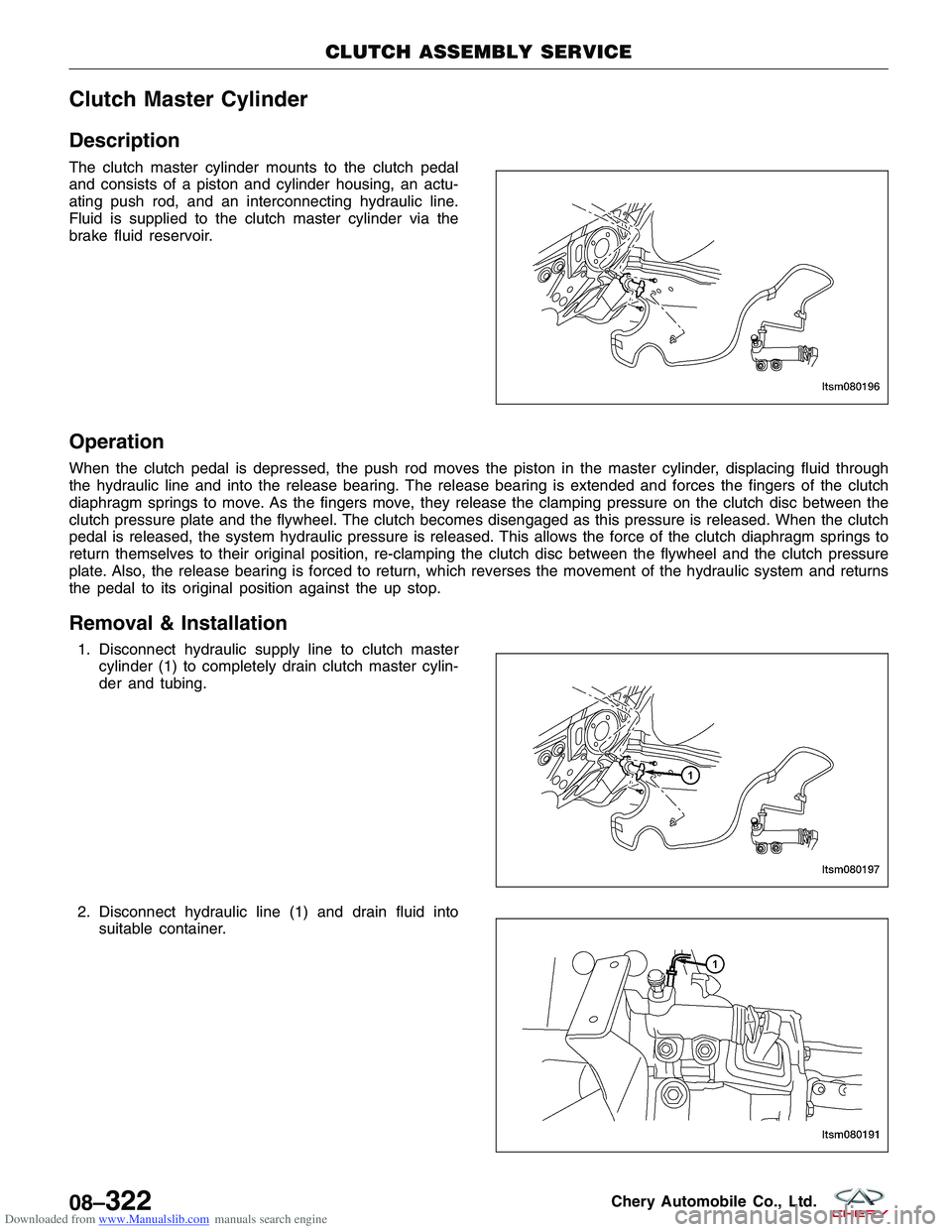

Downloaded from www.Manualslib.com manuals search engine Clutch Master Cylinder

Description

The clutch master cylinder mounts to the clutch pedal

and consists of a piston and cylinder housing, an actu-

ating push rod, and an interconnecting hydraulic line.

Fluid is supplied to the clutch master cylinder via the

brake fluid reservoir.

Operation

When the clutch pedal is depressed, the push rod moves the piston in the master cylinder, displacing fluid through

the hydraulic line and into the release bearing. The release bearing is extended and forces the fingers of the clutch

diaphragm springs to move. As the fingers move, they release the clamping pressure on the clutch disc between the

clutch pressure plate and the flywheel. The clutch becomes disengaged as this pressure is released. When the clutch

pedal is released, the system hydraulic pressure is released. This allows the force of the clutch diaphragm springs to

return themselves to their original position, re-clamping the clutch disc between the flywheel and the clutch pressure

plate. Also, the release bearing is forced to return, which reverses the movement of the hydraulic system and returns

the pedal to its original position against the up stop.

Removal & Installation

1. Disconnect hydraulic supply line to clutch mastercylinder (1) to completely drain clutch master cylin-

der and tubing.

2. Disconnect hydraulic line (1) and drain fluid into suitable container.

CLUTCH ASSEMBLY SERVICE

LTSM080196

LTSM080197

LTSM080191

08–322Chery Automobile Co., Ltd.