service CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1286 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

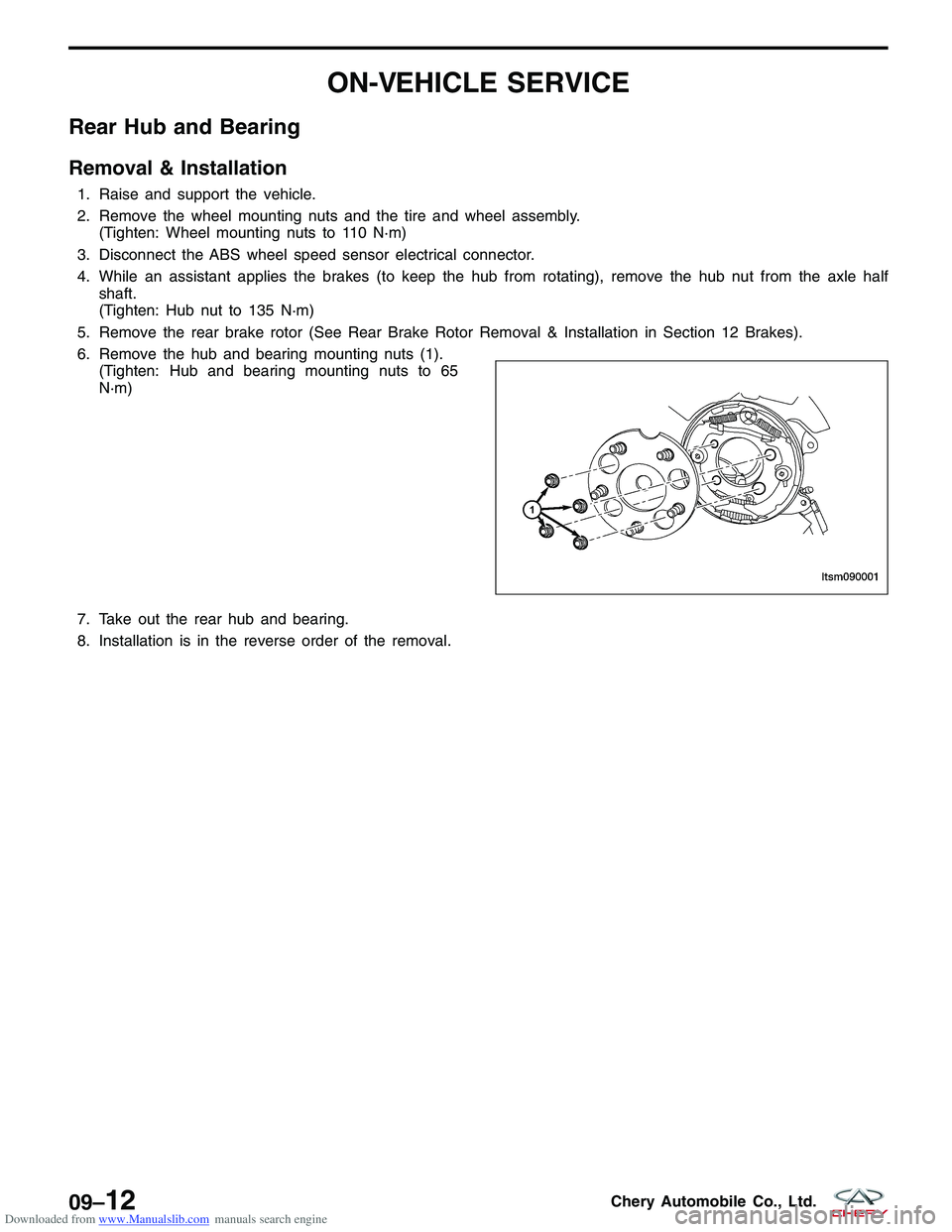

Rear Hub and Bearing

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Disconnect the ABS wheel speed sensor electrical connector.

4. While an assistant applies the brakes (to keep the hub from rotating), remove the hub nut from the axle half shaft.

(Tighten: Hub nut to 135 N·m)

5. Remove the rear brake rotor (See Rear Brake Rotor Removal & Installation in Section 12 Brakes).

6. Remove the hub and bearing mounting nuts (1). (Tighten: Hub and bearing mounting nuts to 65

N·m)

7. Take out the rear hub and bearing.

8. Installation is in the reverse order of the removal.

LTSM090001

09–12Chery Automobile Co., Ltd.

Page 1287 of 1903

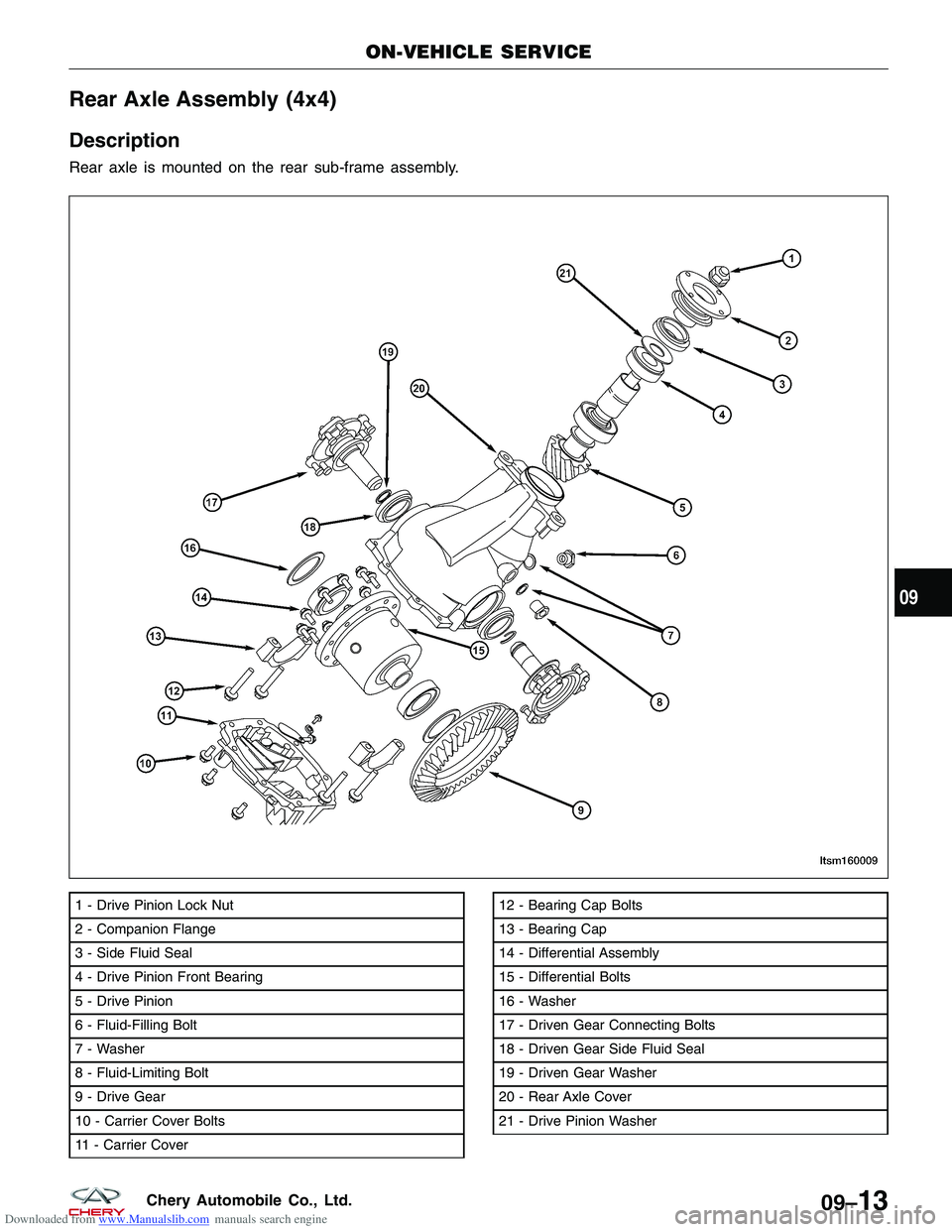

Downloaded from www.Manualslib.com manuals search engine Rear Axle Assembly (4x4)

Description

Rear axle is mounted on the rear sub-frame assembly.

1 - Drive Pinion Lock Nut

2 - Companion Flange

3 - Side Fluid Seal

4 - Drive Pinion Front Bearing

5 - Drive Pinion

6 - Fluid-Filling Bolt

7 - Washer

8 - Fluid-Limiting Bolt

9 - Drive Gear

10 - Carrier Cover Bolts

11 - Carrier Cover12 - Bearing Cap Bolts

13 - Bearing Cap

14 - Differential Assembly

15 - Differential Bolts

16 - Washer

17 - Driven Gear Connecting Bolts

18 - Driven Gear Side Fluid Seal

19 - Driven Gear Washer

20 - Rear Axle Cover

21 - Drive Pinion Washer

ON-VEHICLE SERVICE

LTSM160009

09

09–13Chery Automobile Co., Ltd.

Page 1288 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The axle receives power from the transaxle through the rear intermediate drive shaft. The drive shaft is connected to

the pinion gear which rotates the differential through the gear mesh with the ring gear bolted to the differential case.

The engine power is transmitted to the axle shafts through the pinion mate and side gears.

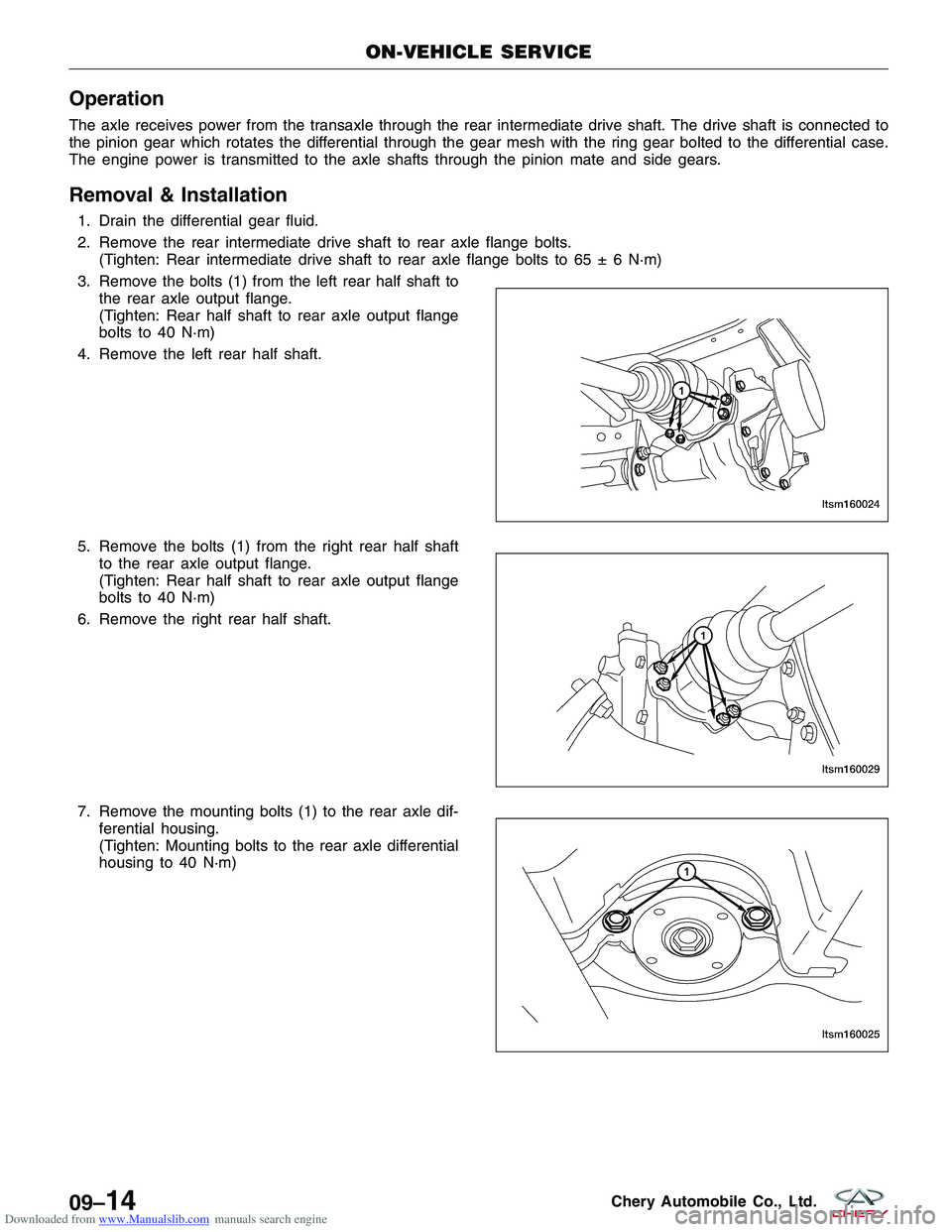

Removal & Installation

1. Drain the differential gear fluid.

2. Remove the rear intermediate drive shaft to rear axle flange bolts.(Tighten: Rear intermediate drive shaft to rear axle flange bolts to 65 ± 6 N·m)

3. Remove the bolts (1) from the left rear half shaft to the rear axle output flange.

(Tighten: Rear half shaft to rear axle output flange

bolts to 40 N·m)

4. Remove the left rear half shaft.

5. Remove the bolts (1) from the right rear half shaft to the rear axle output flange.

(Tighten: Rear half shaft to rear axle output flange

bolts to 40 N·m)

6. Remove the right rear half shaft.

7. Remove the mounting bolts (1) to the rear axle dif- ferential housing.

(Tighten: Mounting bolts to the rear axle differential

housing to 40 N·m)

ON-VEHICLE SERVICE

LTSM160024

LTSM160029

LTSM160025

09–14Chery Automobile Co., Ltd.

Page 1289 of 1903

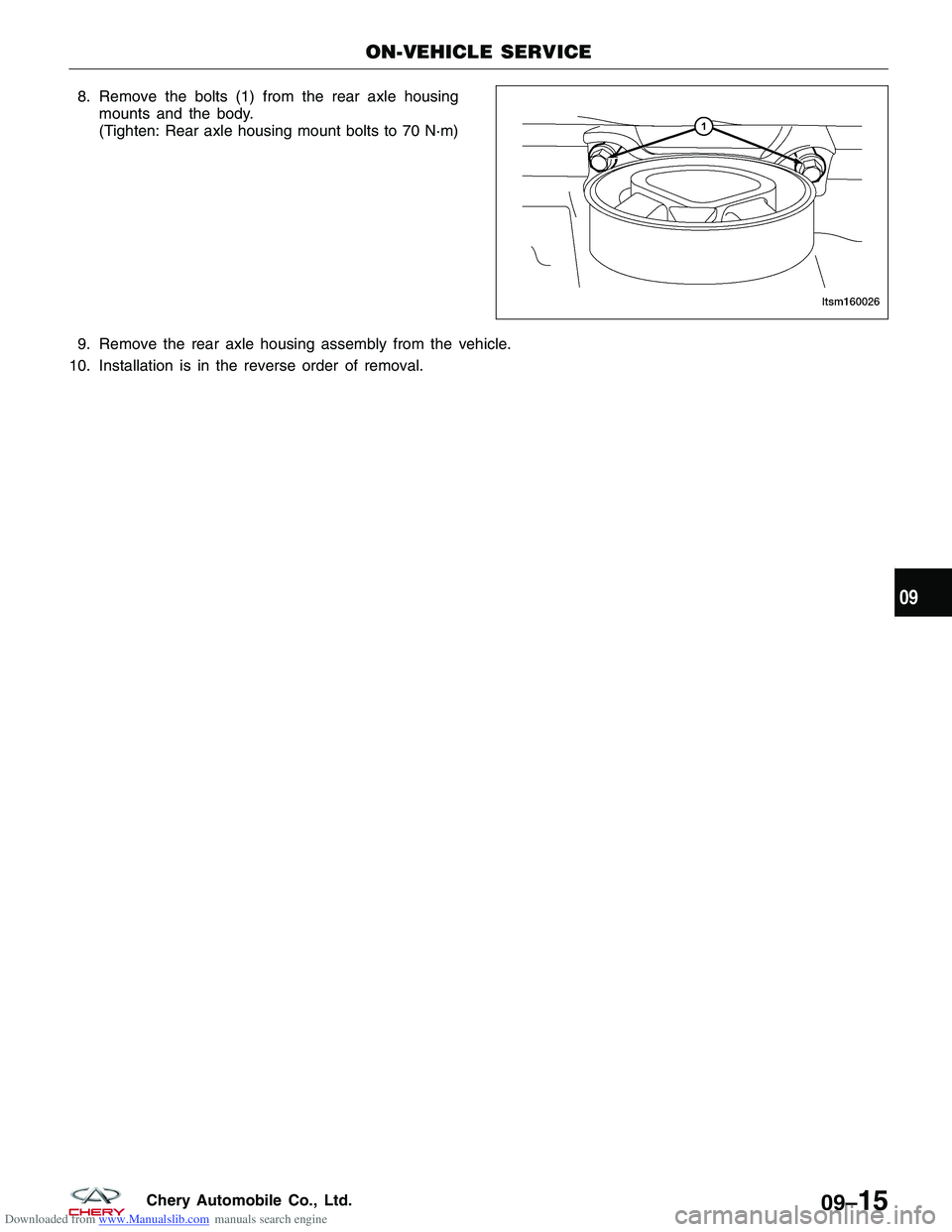

Downloaded from www.Manualslib.com manuals search engine 8. Remove the bolts (1) from the rear axle housingmounts and the body.

(Tighten: Rear axle housing mount bolts to 70 N·m)

9. Remove the rear axle housing assembly from the vehicle.

10. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM160026

09

09–15Chery Automobile Co., Ltd.

Page 1290 of 1903

Downloaded from www.Manualslib.com manuals search engine INTERACTIVE TORQUE MANAGEMENT (ITM) SYSTEM (4X4)

GENERAL INFORMATION09-17

Description 09-17

Operation 09-18

Specification 09-18

Special Tools 09-20

ON-VEHICLE SERVICE09-21

Interactive Torque Management (ITM)

Controller 09-21

Description 09-21 Operation 09-21

Removal & Installation 09-22

Interactive Torque Management (ITM)

Control Module 09-23

Description 09-23

Operation 09-23

Removal & Installation 09-23

09–16Chery Automobile Co., Ltd.

Page 1295 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

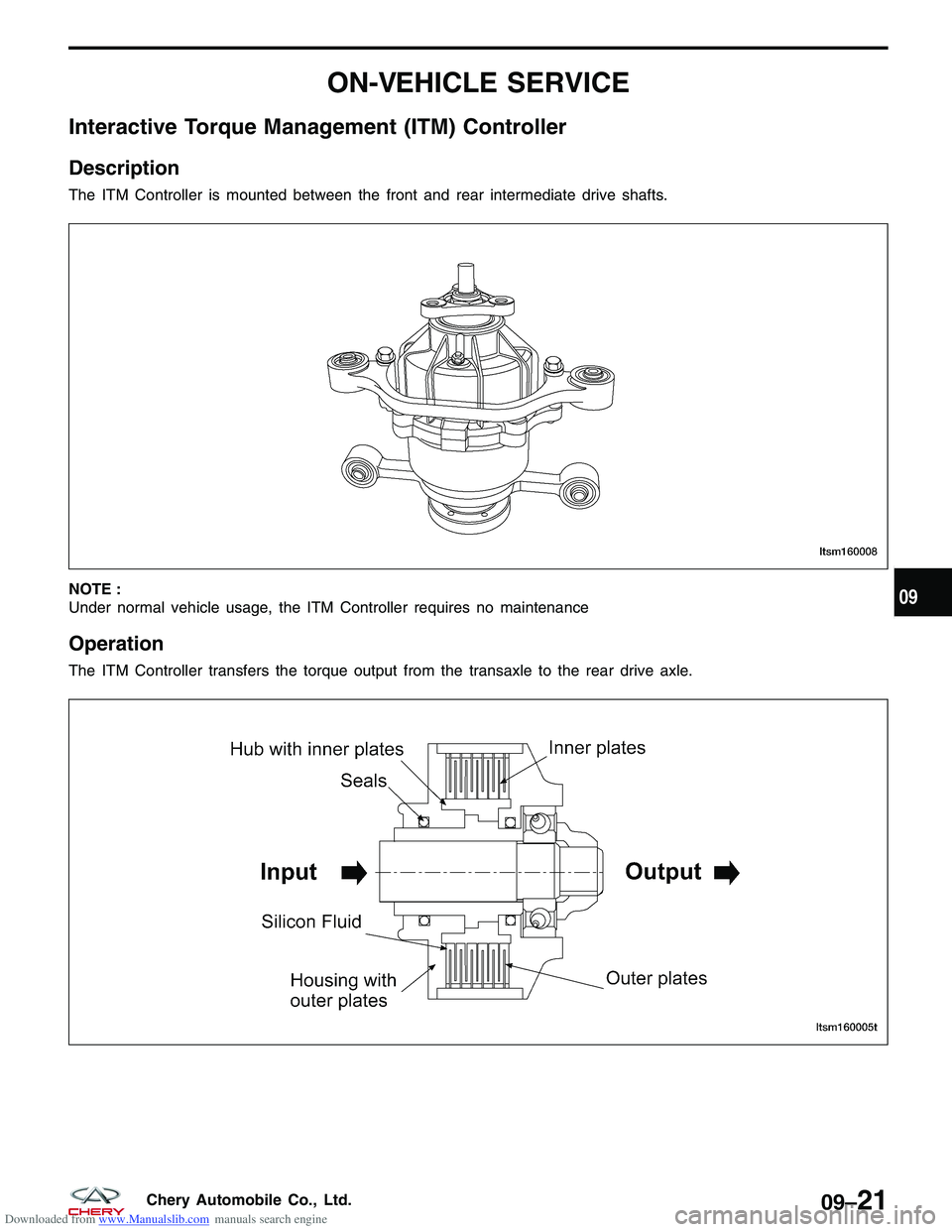

Interactive Torque Management (ITM) Controller

Description

The ITM Controller is mounted between the front and rear intermediate drive shafts.

NOTE :

Under normal vehicle usage, the ITM Controller requires no maintenance

Operation

The ITM Controller transfers the torque output from the transaxle to the rear drive axle.

LTSM160008

LTSM160005T

09

09–21Chery Automobile Co., Ltd.

Page 1296 of 1903

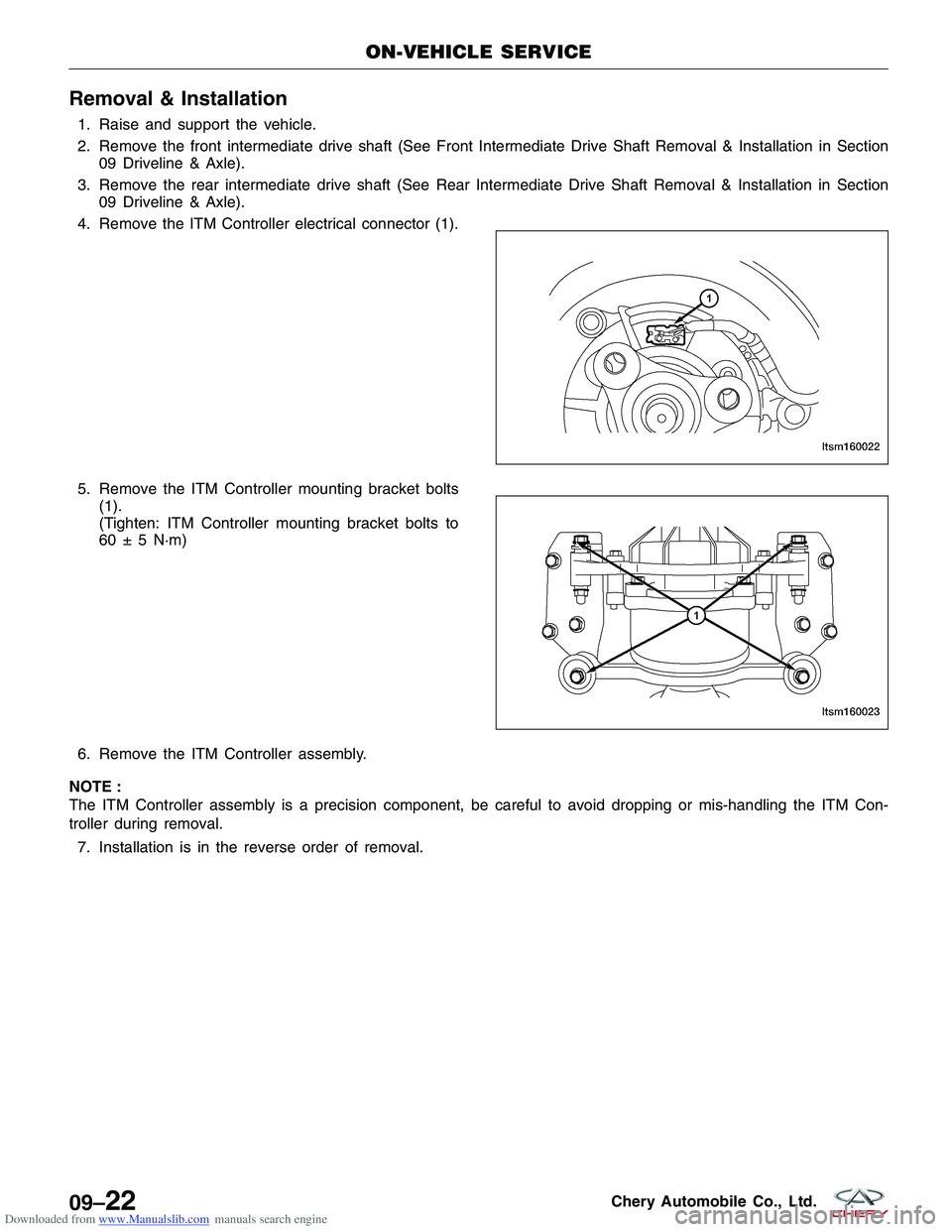

Downloaded from www.Manualslib.com manuals search engine Removal & Installation

1. Raise and support the vehicle.

2. Remove the front intermediate drive shaft (See Front Intermediate Drive Shaft Removal & Installation in Section09 Driveline & Axle).

3. Remove the rear intermediate drive shaft (See Rear Intermediate Drive Shaft Removal & Installation in Section 09 Driveline & Axle).

4. Remove the ITM Controller electrical connector (1).

5. Remove the ITM Controller mounting bracket bolts (1).

(Tighten: ITM Controller mounting bracket bolts to

60 ± 5 N·m)

6. Remove the ITM Controller assembly.

NOTE :

The ITM Controller assembly is a precision component, be careful to avoid dropping or mis-handling the ITM Con-

troller during removal. 7. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM160022

LTSM160023

09–22Chery Automobile Co., Ltd.

Page 1297 of 1903

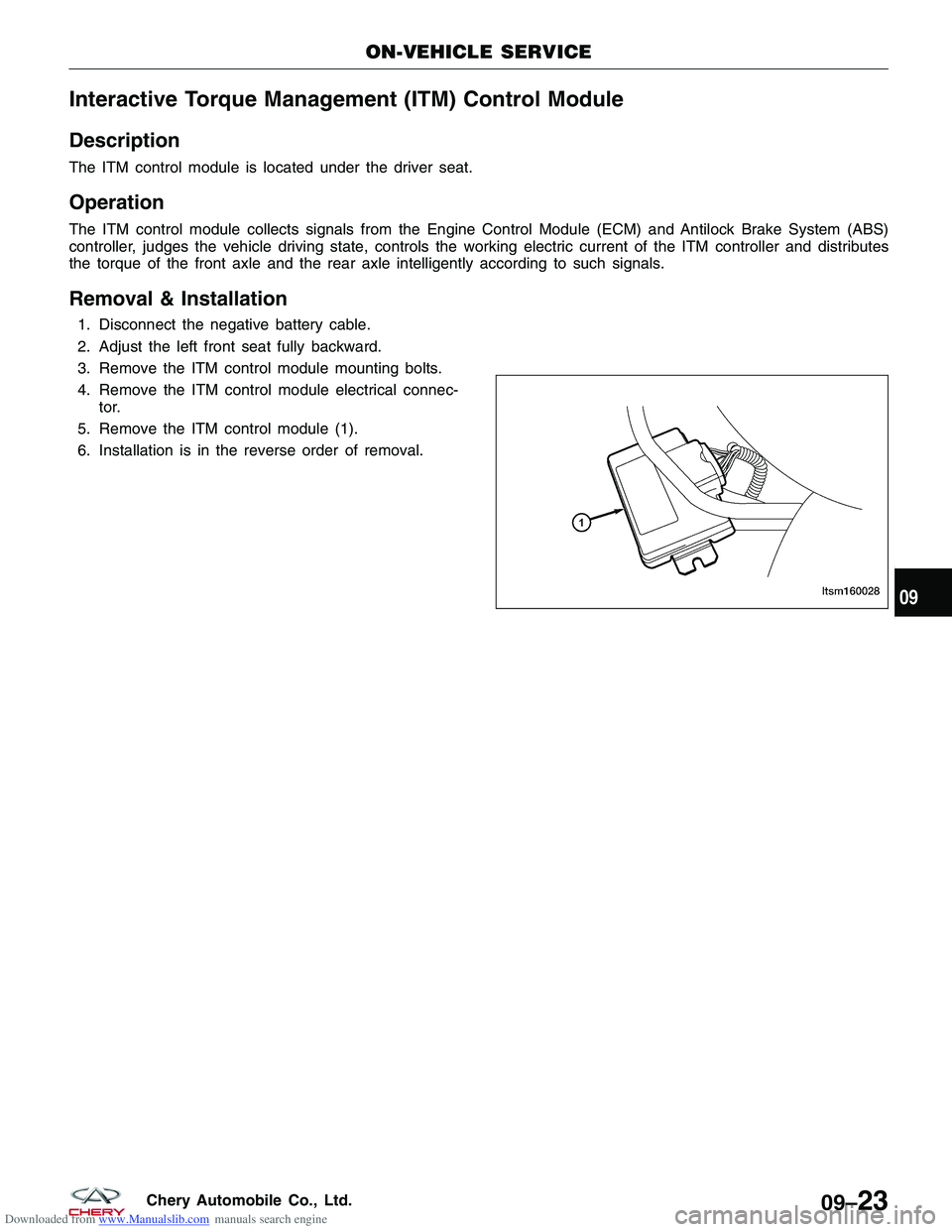

Downloaded from www.Manualslib.com manuals search engine Interactive Torque Management (ITM) Control Module

Description

The ITM control module is located under the driver seat.

Operation

The ITM control module collects signals from the Engine Control Module (ECM) and Antilock Brake System (ABS)

controller, judges the vehicle driving state, controls the working electric current of the ITM controller and distributes

the torque of the front axle and the rear axle intelligently according to such signals.

Removal & Installation

1. Disconnect the negative battery cable.

2. Adjust the left front seat fully backward.

3. Remove the ITM control module mounting bolts.

4. Remove the ITM control module electrical connec-tor.

5. Remove the ITM control module (1).

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM16002809

09–23Chery Automobile Co., Ltd.

Page 1298 of 1903

Downloaded from www.Manualslib.com manuals search engine DRIVE SHAFT (4X4)

GENERAL INFORMATION09-25

Description 09-25

Operation 09-25

Specifications 09-25

DIAGNOSIS & TESTING09-26

Vehicle Inspection 09-26

Shudder Or Vibration During Acceleration 09-26

Clunking Noise During Acceleration 09-26 Shudder Or Vibration During Acceleration 09-26

Vibration At High Speeds 09-26

ON-VEHICLE SERVICE09-27

Front Intermediate Drive Shaft 09-27

Removal & Installation 09-27

Rear Intermediate Drive Shaft 09-27

Removal & Installation 09-27

09–24Chery Automobile Co., Ltd.

Page 1301 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Front Intermediate Drive Shaft

Removal & Installation

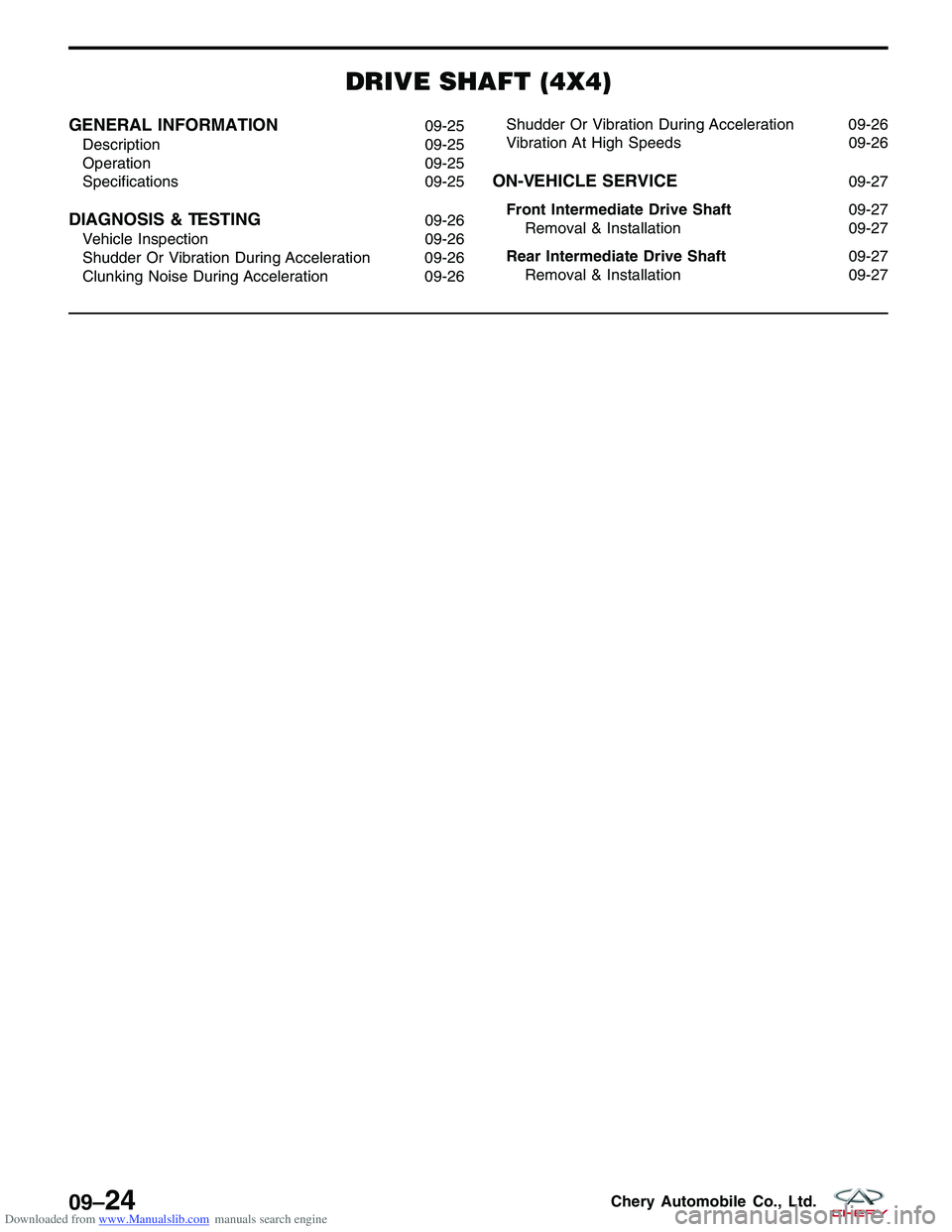

1. Remove the bolts (1) between the front intermedi-ate drive shaft and the ITM Controller input shaft.

(Tighten: Front intermediate drive shaft and ITM

controller bolts to 70 ± 7 N·m)

2. Installation is in the reverse order of removal.

Rear Intermediate Drive Shaft

Removal & Installation

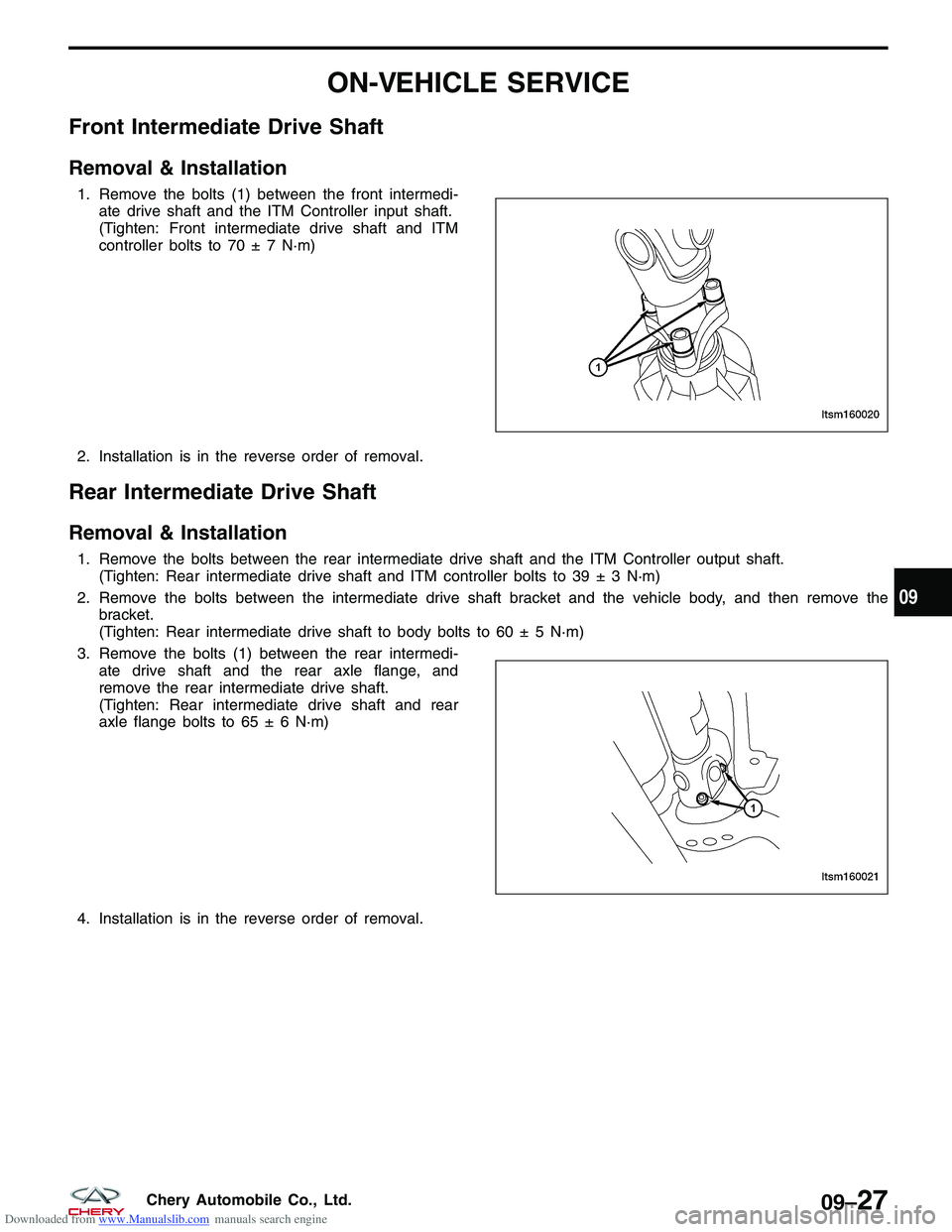

1. Remove the bolts between the rear intermediate drive shaft and the ITM Controller output shaft. (Tighten: Rear intermediate drive shaft and ITM controller bolts to 39 ± 3 N·m)

2. Remove the bolts between the intermediate drive shaft bracket and the vehicle body, and then remove the bracket.

(Tighten: Rear intermediate drive shaft to body bolts to 60 ± 5 N·m)

3. Remove the bolts (1) between the rear intermedi- ate drive shaft and the rear axle flange, and

remove the rear intermediate drive shaft.

(Tighten: Rear intermediate drive shaft and rear

axle flange bolts to 65 ± 6 N·m)

4. Installation is in the reverse order of removal.

LTSM160020

LTSM160021

09

09–27Chery Automobile Co., Ltd.