lock CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 347 of 659

ENGINE-ELECTRICAL 6Y-22

ADJUST DWELL

ANGLE SETTING OR

POINT OPENING

Fig.

lOi—Settihg Point Opening

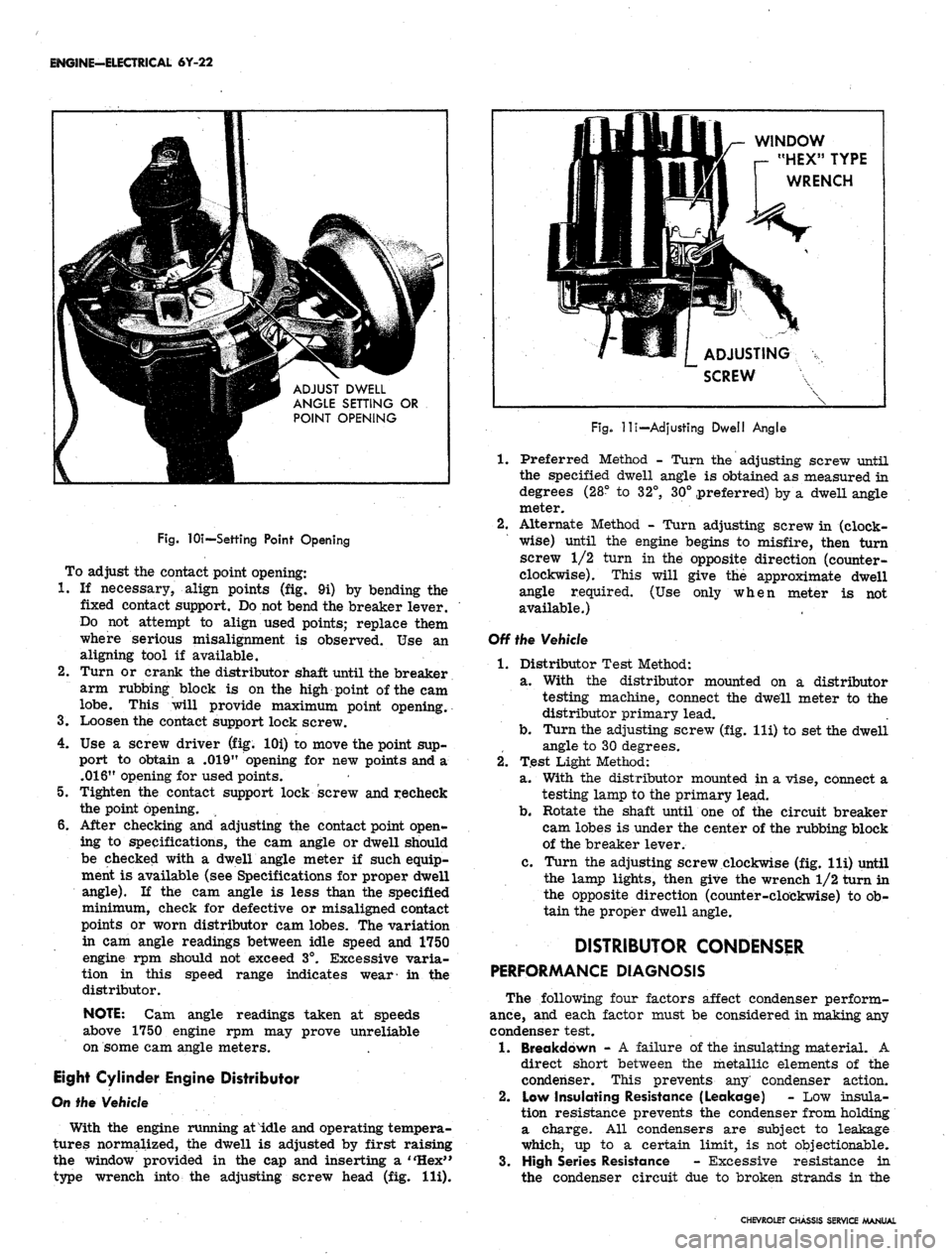

To adjust the contact point opening:

1.

If necessary, align points (fig. 9i) by bending the

fixed contact support. Do not bend the breaker lever.

Do not attempt to align used points; replace them

where serious misalignment is observed. Use an

aligning tool if available.

2.

Turn or crank the distributor shaft until the breaker

arm rubbing block is on the high point of the cam

lobe.

This will provide maximum point opening.

3.

Loosen the contact support lock screw.

4.

Use a screw driver (fig. lOi) to move the point sup-

port to obtain a .019" opening for new points and a

.016"

opening for used points.

5.

Tighten the contact support lock screw and recheck

the point opening.

6. After checking and adjusting the contact point open-

ing to specifications, the cam angle or dwell should

be checked with a dwell angle meter if such equip-

ment is available (see Specifications for proper dwell

angle).

If the cam angle is less than the specified

minimum, check for defective or misaligned contact

points or worn distributor cam lobes. The variation

in cam angle readings between idle speed and 1750

engine rpm should not exceed 3°. Excessive varia-

tion in this speed range indicates wear- in the

distributor.

NOTE:

Cam angle readings taken at speeds

above 1750 engine rpm may prove unreliable

on some cam angle meters.

Eight Cylinder Engine Distributor

On the Vehicle

With the engine running at idle and operating tempera-

tures normalized, the dwell is adjusted by first raising

the window provided in the cap and inserting a "Hex"

type wrench into the adjusting screw head (fig. Hi).

WINDOW

r- "HEX" TYPE

WRENCH

ADJUSTING

SCREW

Fig.

-lli—Adjusting Dwell Angle

1.

Preferred Method - Turn the adjusting screw until

the specified dwell angle is obtained as measured in

degrees (28° to 32°, 30° preferred) by a dwell angle

meter.

2.

Alternate Method - Turn adjusting screw in (clock-

wise) until the engine begins to misfire, then turn

screw 1/2 turn in the opposite direction (counter-

clockwise). This will give the approximate dwell

angle required. (Use only when meter is not

available.)

Off the Vehicle

1.

Distributor Test Method:

a. With the distributor mounted on a distributor

testing machine, connect the dwell meter to the

distributor primary lead.

b.

Turn the adjusting screw (fig. lli) to set the dwell

angle to 30 degrees.

2.

Test Light Method:

a. With the distributor mounted in a vise, connect a

testing lamp to the primary lead.

b.

Rotate the shaft until one of the circuit breaker

cam lobes is under the center of the rubbing block

of the breaker lever.

c. Turn the adjusting screw clockwise (fig. lli) until

the lamp lights, then give the wrench 1/2 turn in

the opposite direction (counter-clockwise) to ob-

tain the proper dwell angle.

DISTRIBUTOR CONDENSER

PERFORMANCE DIAGNOSIS

The following four factors affect condenser perform-

ance,

and each factor must be considered in making any

condenser test.

1.

Breakdown - A failure of the insulating material. A

direct short between the metallic elements of the

condenser. This prevents any' condenser action.

2.

Low Insulating Resistance (Leakage) - Low insula-

tion resistance prevents the condenser from holding

a charge. All condensers are subject to leakage

which, up to a certain limit, is not objectionable.

3.

High Series Resistance - Excessive resistance in

the condenser circuit due to broken strands in the

CHEVROLET CHASSIS SERVICE MANUAL

Page 349 of 659

ENGINE-ELECTRICAL 6Y-24

Fig.

13I-V-8 Distributor (Typical)-Exploded View

1.

2.

2a.

3.

4.

Condenser

Contact Point Assembly

Cam Lubricator

Retaining Ring

Breaker Plate

5.

5a.

6.

7.

Felt Washer

Plastic Seal

Vacuum Advance

Unit

Housing

8.^

Shim

Washer

9. Drive Gear Pin

10.

Drive Gear

11.

Cap

12.

Rotor

13.

Weight Springs

14.

Mainshaft

15.

Advance Weights

16.

Cam Weight

Base Assembly

When mounting distributors for tests, first secure the

gear in the test drive mechanism, then push the distribu-

tor housing downward toward the gear to take up any end

play between the gear and the housing.

NOTE:

When testing distributors that have

their lower shaft support bushing located in the

engine block (6 cylinder engines), a special

adapter should be used to insure the shaft will

run true in its housing.

Test the distributor for variation of spark, correct

centrifugal and vacuum advance and condition of contacts.

This test will give valuable information on distributor

condition and indicate parts replacement which may be

necessary. Check the area on the breaker plate just

beneath the contact points. A smudgy line indicates that

oil or crankcase vapors have been present between the

points.

Four and Six Cylinder Engines

Refer to Figure 12i.

1.

Remove the rotor.

2.

3.

Remove the vacuum control assembly retaining

screws, detach the unit from the distributor housing.

Disconnect the primary and condenser leads from the

contact point quick disconnect terminal, remove the

contact point set attaching screw, condenser attach-

ing screw. Remove the point set and condenser from

the breaker plate.

Remove the breaker plate attaching screws, remove

the breaker plate from the distributor housing (fig.

NOTE:

Do not disassemble breaker plate any

further.

5. Remove the roll pin retaining the driven gear to the

mainshaft, slide the gear from the shaft.

6. Slide the cam and mainshaft from the distributor

housing.

7. Remove the weight cover, and stop plate screws, re-

move the cover, weight springs, weights and slide

cam assembly from the mainshaft.

V-8 Engines

Refer to Figure 13i.

CHEVROLET CHASStS SERVICE MANUAL

Page 350 of 659

ENGINE-ELECTRICAL 6Y-25

1.

Remove the rotor.

2.

Remove both weight springs and advance weights.

3.

Remove roll pin retaining driven gear to distributor

shaft, slide the gear and spacers from the shaft.

Remove tachometer drive gear on Corvette models.

4.

Before sliding the distributor shaft from the hous-

ing, check for and remove any burrs on the shaft.

This will prevent damage to the seals and bushing

still positioned in the housing.

5. Slide the distributor mainshaft and cam-weight base

assembly from the housing.

6. Remove vacuum advance mechanism retaining

screws, remove the vacuum advance assembly.

7. Remove the spring retainer, remove the breaker

plate assembly from the distributor housing. Re-

move the contact point and condenser from the

breaker plate. Remove the felt washer and plastic

seal located beneath the breaker plate.

CLEANING AND INSPECTION

1.

Wash all parts in cleaning solvent except cap, rotor,

condenser, breaker plate assembly and vacuum con-

trol unit. Degreasing compounds may damage insula-

tion of these parts or saturate the lubricating felt in

the case of the breaker plate assembly.

2.

Inspect the breaker plate assembly for damage or

wear and replace if necessary.

3.

Inspect the shaft for wear and check its fit in the

bushings in the distributor body. If the shaft or bush-

ings are worn, the parts should be replaced.

4.

Mount the shaft in "V" blocks and check the shaft

alignment with a dial guage. The run-out should not

exceed .002".

5. Inspect the advance weights for wear or burrs and

free fit on their pivot pins.

6. Inspect the cam for wear or roughness. Then check

its fit on the end of the shaft. It should be absolutely

free without any roughness.

7. Inspect

the •

condition of the distributor points. Dirty

points should be cleaned and badly pitted points

should be replaced. (See Distributor Contact Points.)

8. Test the condenser for series resistance, micro-

farad capacity (.18 to .23) and leakage or breakdown,

following the instructions given by the manufacturer

of the test equipment used.

9. Inspect the distributor cap and sparkplug wires for

damage and replace if necessary.

ASSEMBLY

Four and Six Cylinder Engine

Refer to Figure 12i for Exploded View of Distributor.

1.

Replace cam assembly to mainshaft.

NOTE:

Lubricate top end of shaft with Delco

cam and ball bearing grease or equivalent prior

to replacing.

2.

Install governor weights on their pivot pins, replace

weight springs. Install weight cover and stop plate.

3.

Lubricate mainshaft and install it in distributor

housing.

4.

Install distributor driven gear to mainshaft and in-

sert attaching roll pin. Check to see that shaft turns

freely.

5. Install breaker plate assembly in the distributor body

and attach retaining screws.

6. Attach condenser and contact point set in proper lo-

cation with appropriate attaching screws.

NOTE:

Contact point set pilot must engage

matching hole in breaker plate. Connect primary

and condenser leads to contact set quick-

disconnect terminal.

7. Attach vacuum control assembly to distributor

housing.

8. Check and adjust contact point opening and align-

ment (See setting and alignment of points.)

9. Check breaker lever spring tension which should

be.

19-23 ounces. (See contact point replacement.)

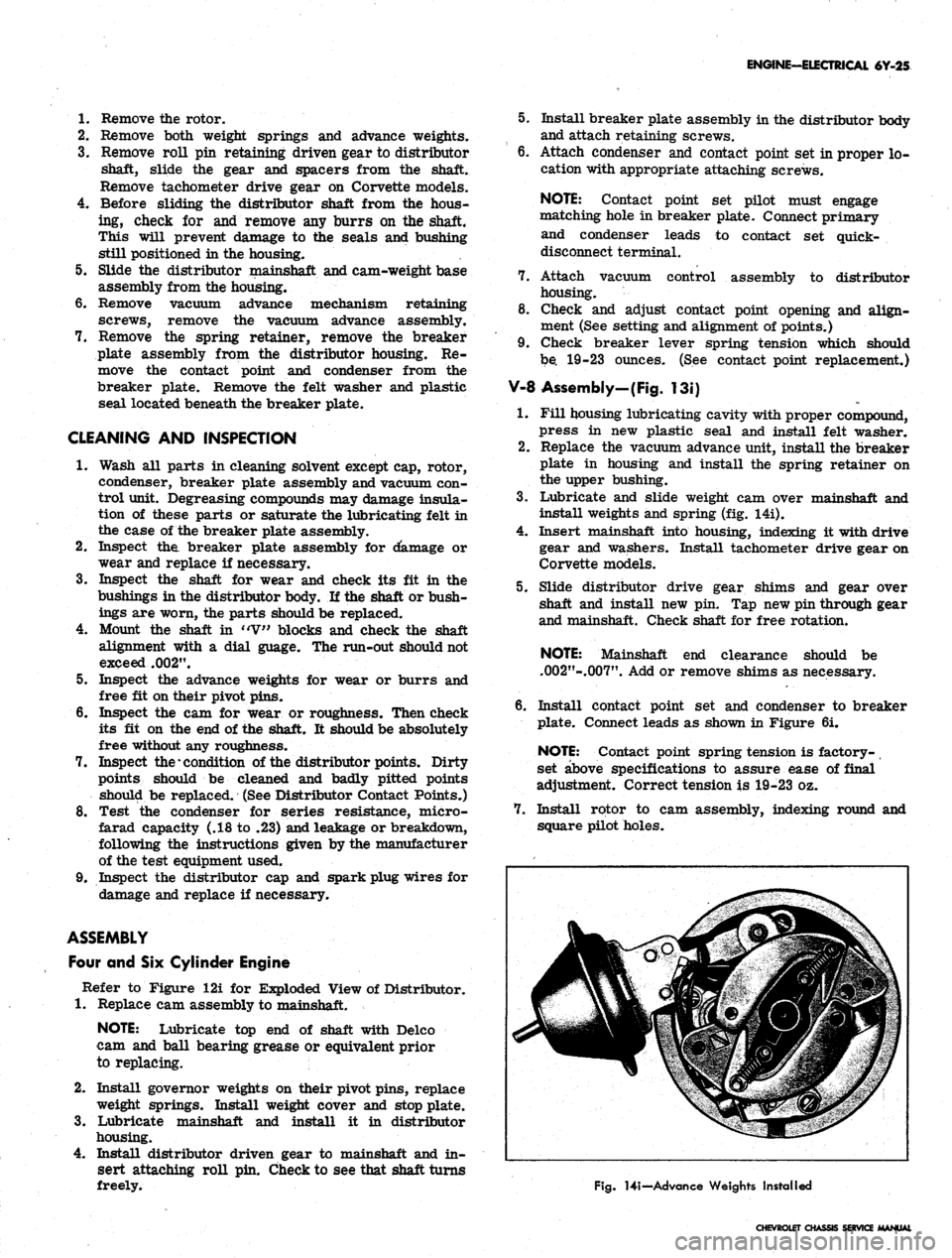

V-8 Assembly-(Fig. 13i)

1.

Fill housing lubricating cavity with proper compound,

press in new plastic seal and install felt washer.

2.

Replace the vacuum advance unit, install the breaker

plate in housing and install the spring retainer on

the upper bushing.

3.

Lubricate and slide weight cam over mainshaft and

install weights and spring (fig. 14i).

4.

Insert mainshaft into housing, indexing it with drive

gear and washers. Install tachometer drive gear on

Corvette models.

5. Slide distributor drive gear shims and gear over

shaft and install new pin. Tap new pin through gear

and mainshaft. Check shaft for free rotation.

NOTE:

Mainshaft end clearance should be

.002"-.007". Add or remove shims as necessary.

6. Install contact point set and condenser to breaker

plate. Connect leads as shown in Figure 6i.

NOTE:

Contact point spring tension is factory-

set above specifications to assure ease of final

adjustment. Correct tension is 19-23 oz.

7. Install rotor to cam assembly, indexing round and

square pilot holes.

Flg.

Hi-Advance Weights Installed

CHEVROLET CHASSIS SERVICE

Page 351 of 659

ENGINE-ELECTRICAL 6Y-26

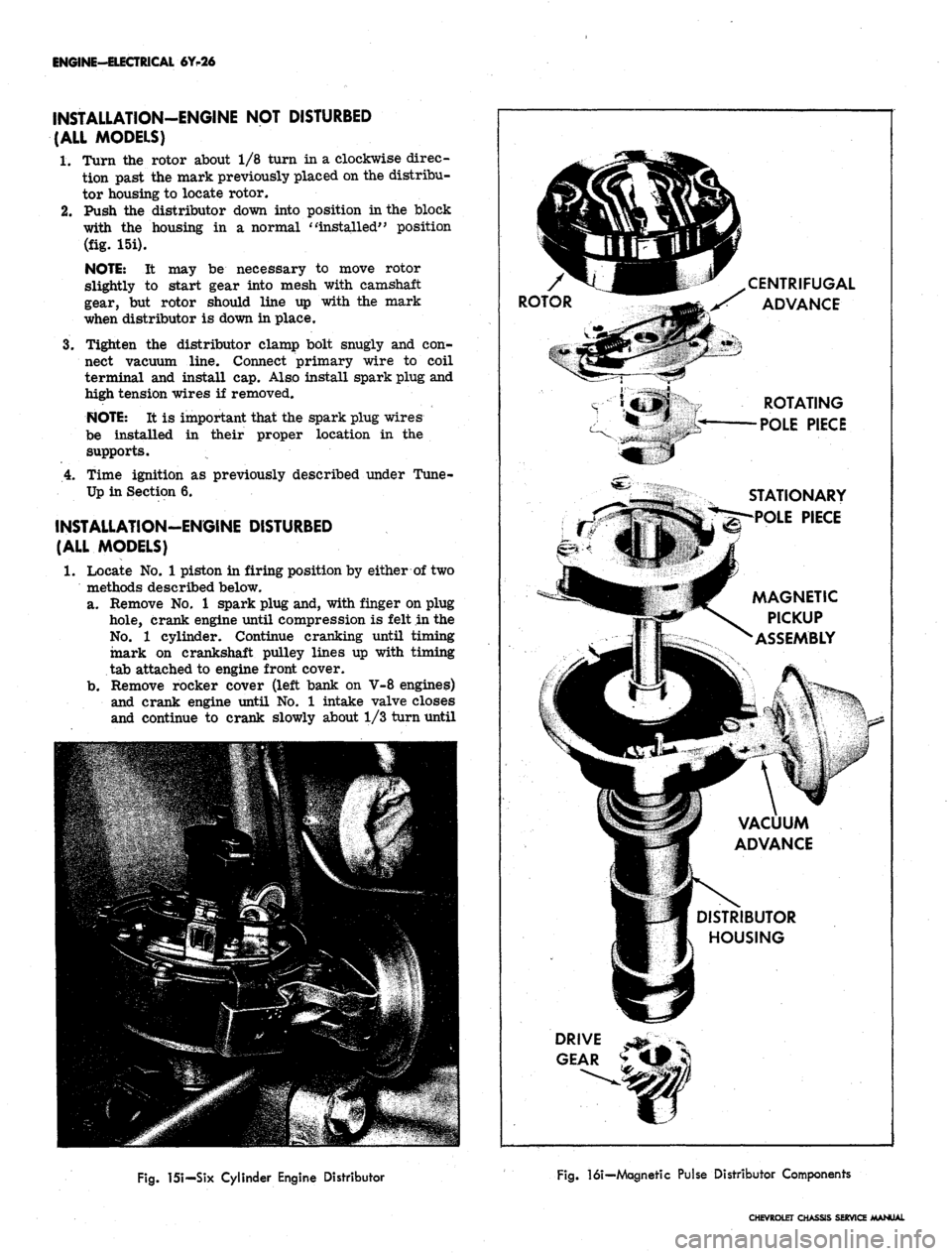

INSTALLATION-ENGINE NOT DISTURBED

(ALL MODELS)

1.

Turn the rotor about 1/8 turn in a clockwise direc-

tion past the mark previously placed on the distribu-

tor housing to locate rotor.

2.

Push the distributor down into position in the block

with the housing in a normal "installed" position

(fig. 15i).

NOTE: It may be necessary to move rotor

slightly to start gear into mesh with camshaft

gear, but rotor should line up with the mark

when distributor is down in place.

3.

Tighten the distributor clamp bolt snugly and con-

nect vacuum line. Connect primary wire to coil

terminal and install cap. Also install spark plug and

high tension wires if removed.

NOTE: It is important that the spark plug wires

be installed in their proper location in the

supports.

4.

Time ignition as previously described under Tune-

Up in Section 6.

INSTALLATION-ENGINE DISTURBED

(ALL MODELS)

1.

Locate No. 1 piston in firing position by either of two

methods described below,

a. Remove No. 1 spark plug and, with finger on plug

hole,

crank engine until compression is felt in the

No.

1 cylinder. Continue cranking until timing

mark on crankshaft pulley lines up with timing

tab attached to engine front cover.

b.

Remove rocker cover (left bank on V-8 engines)

and crank engine until No. 1 intake valve closes

and continue to crank slowly about 1/3 turn until

CENTRIFUGAL

jS ADVANCE

ROTATING

POLE PIECE

STATIONARY

POLE PIECE

MAGNETIC

PICKUP

ASSEMBLY

VACUUM

ADVANCE

DISTRIBUTOR

HOUSING

Fig.

151—Six Cylinder Engine Distributor

Fig.

16i—Magnetic Pulse Distributor Components

CHEVROLET CHASSIS SERVICE MANUAL

Page 352 of 659

ENGINE-ELECTRICAL 6Y-27

timing mark on pulley lines up with timing tab.

2.

Position distributor to opening in block in normal

installed attitude (fig. 15i), noting position of vacuum

control unit.

3.

Position rotor to point toward front of engine (with

distributor housing held in installed attitude), then

turn rotor counter-clockwise approximately 1/8 turn

more toward left cylinder bank and push distributor

down to engine camshaft. It may be necessary to ro-

tate rotor slightly until camshaft engagement is felt.

4.

While pressing firmly down on distributor housing,

kick starter over a few times to make sure oil pump

shaft is engaged. Install hold-down clamp and bolt

and snug up bolt.

5. Turn distributor body slightly until points just open

and tighten distributor clamp bolt.

6. Place distributor cap in position and check to see

that rotor lines up with terminal for No. 1 spark

plug.

7. Install cap, check all high tension wire connections

and connect spark plug wires if they have been re-

moved. It is important that the wires be installed in

their location in the supports.

NOTE:

The brackets are numbered to show the

correct installation. Wires must be installed as

indicated to prevent cross firing.

8. Connect vacuum line to distributor and distributor

primary wire to coil terminal.

9. Start engine and set timing as described under Turn-

Up in Section 6.

BREAKERLESS (MAGNETIC PULSE)

DISTRIBUTOR

REMOVAL (CORVETTE)

1.

If vehicle is equipped with radio, remove three bolts

securing ignition shield over distributor and coil.

One bolt is accessible from the top of shield, the

other two are at rear of shield, facing firewall.

2.

Disconnect tachometer drive cables from distributor

housing.

3.

Disconnect pickup coil leads at connector.

4.

Remove distributor cap.

5. Crank engine so rotor is in position to fire No. 1

cylinder and timing mark on harmonic balancer is

indexed with pointer.

6. Remove vacuum line from distributor.

7. Remove distributor clamping screw and hold-down

clamp.

8. Remove distributor and distributor-to-block gasket.

It will be noted that the rotor will rotate as the

distributor is pulled out of the block. Mark the re-

lationship of the rotor and the distributor housing

after removal so that the rotor can be set in the

same position when the distributor is being installed.

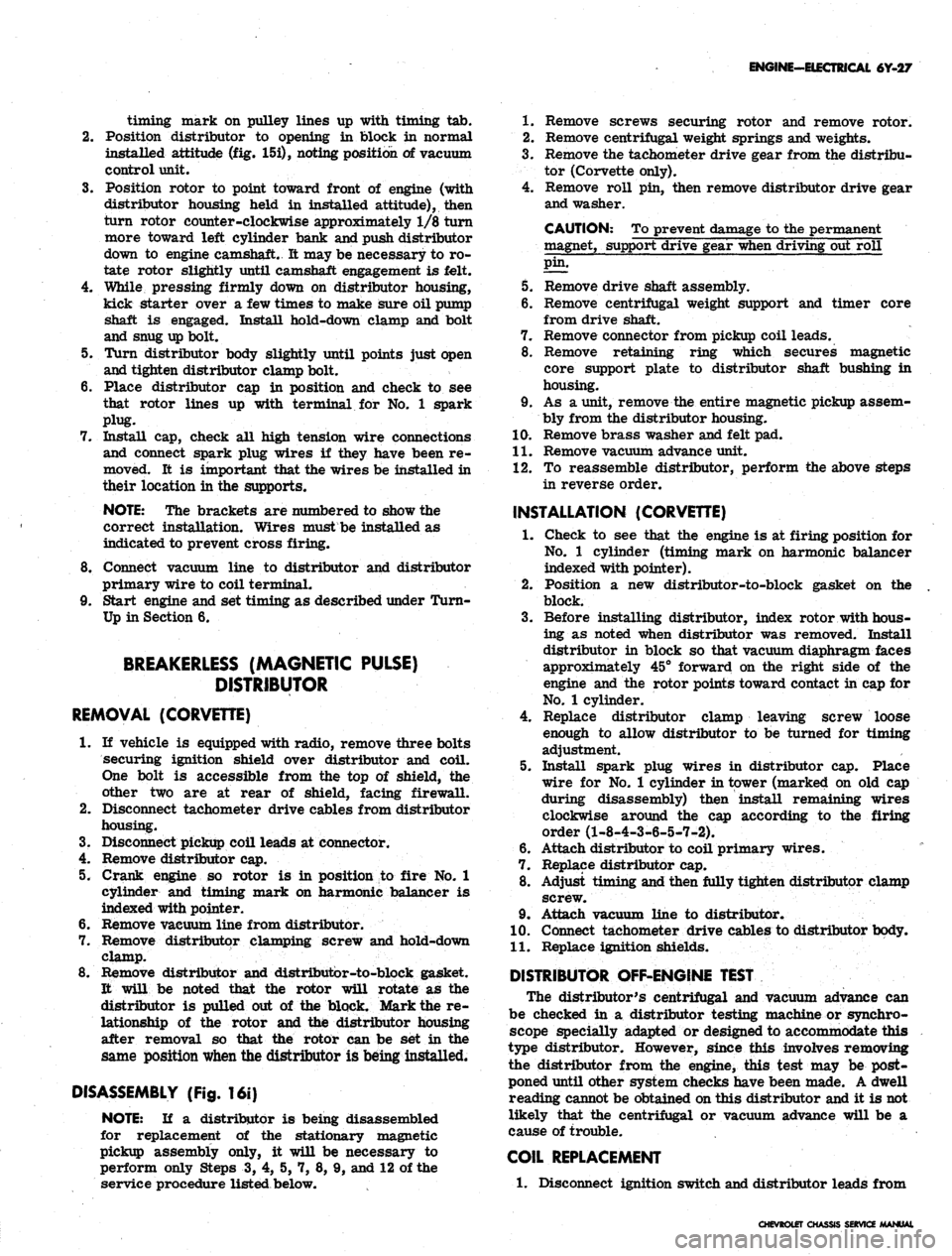

DISASSEMBLY (Fig. 16i)

NOTE:

If a distributor is being disassembled

for replacement of the stationary magnetic

pickup assembly only, it will be necessary to

perform only Steps 3, 4, 5, 7, 8, 9, and 12 of the

service procedure listed below.

1.

Remove screws securing rotor and remove rotor.

2.

Remove centrifugal weight springs and weights.

3.

Remove the tachometer drive gear from the distribu-

tor (Corvette only).

4.

Remove roll pin, then remove distributor drive gear

and washer.

CAUTION: To prevent

magnet, support drive gear

;e to the permanent

?n

driving out roll

pin.

5. Remove drive shaft assembly.

6. Remove centrifugal weight support and timer core

from drive shaft.

7. Remove connector from pickup coil leads.

8. Remove retaining ring which secures magnetic

core support plate to distributor shaft bushing in

housing.

9. As a unit, remove the entire magnetic pickup assem-

bly from the distributor housing.

10.

Remove brass washer and felt pad.

11.

Remove vacuum advance unit.

12.

To reassemble distributor, perform the above steps

in reverse order.

INSTALLATION (CORVETTE)

1.

Check to see that the engine is at firing position for

No.

1 cylinder (timing mark on harmonic balancer

indexed with pointer).

2.

Position a new distributor-to-block gasket on the

block.

3.

Before installing distributor, index rotor with hous-

ing as noted when distributor was removed. Install

distributor in block so that vacuum diaphragm faces

approximately 45° forward on the right side of the

engine and the rotor points toward contact in cap for

No.

1 cylinder.

4.

Replace distributor clamp leaving screw loose

enough to allow distributor to be turned for timing

adjustment.

5. Install spark plug wires in distributor cap. Place

wire for No. 1 cylinder in tower (marked on old cap

during disassembly) then install remaining wires

clockwise around the cap according to the firing

order (1-8-4-3-6-5-7-2).

6. Attach distributor to coil primary wires.

7. Replace distributor cap.

8. Adjust timing and then fully tighten distributor clamp

screw.

9. Attach vacuum line to distributor.

10.

Connect tachometer drive cables to distributor body.

11.

Replace ignition shields.

DISTRIBUTOR OFF-ENGINE TEST

The distributor's centrifugal and vacuum advance can

be checked in a distributor testing machine or synchro-

scope specially adapted or designed to accommodate this

type distributor. However, since this involves removing

the distributor from the engine, this test may be post-

poned until other system checks have been made. A dwell

reading cannot be obtained on this distributor and it is not

likely that the centrifugal or vacuum advance will be a

cause of trouble.

COIL REPLACEMENT

1.

Disconnect ignition switch and distributor leads from

CHEVROLET CHASSIS SERVICE MANUAL

Page 354 of 659

ENGINE-ELECTRICAL 6Y-29

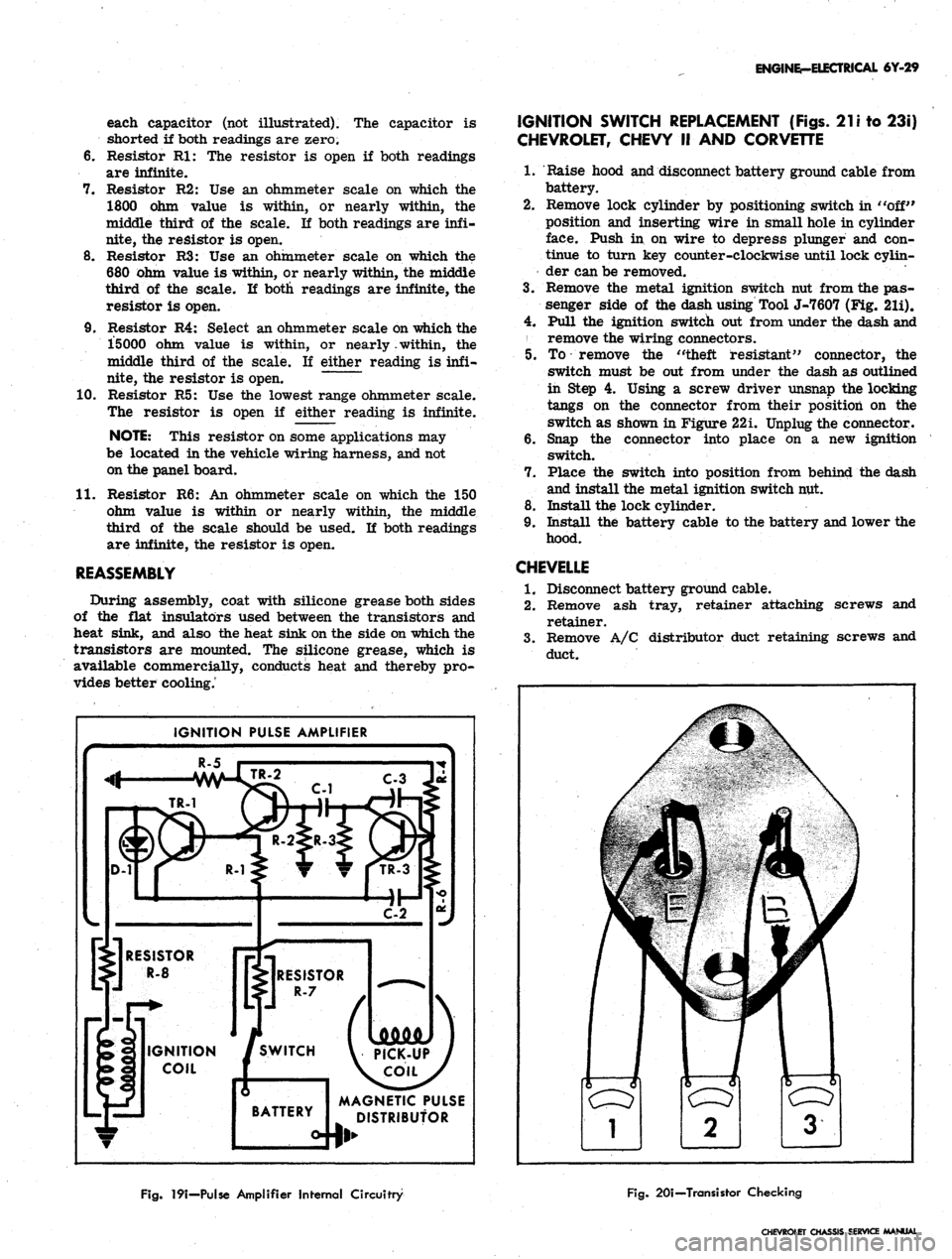

each capacitor (not illustrated). The capacitor is

shorted if both readings are zero.

6. Resistor Rl: The resistor is open if both readings

are infinite.

7. Resistor R2: Use an ohmmeter scale on which the

1800 ohm value is within, or nearly within, the

middle third of the scale. If both readings are infi-

nite, the resistor is open.

8. Resistor R3: Use an ohmmeter scale on which the

680 Ohm value is within, or nearly within, the middle

third of the scale. If both readings are infinite, the

resistor is open.

9. Resistor R4: Select an ohmmeter scale on which the

15000 ohm value is within, or nearly .within, the

middle third of the scale. If either reading is infi-

nite, the resistor is open. ~

10.

Resistor R5: Use the lowest range ohmmeter scale.

The resistor is open if either reading is infinite.

NOTE:

This resistor on some applications may

be located in the vehicle wiring harness, and not

on the panel board.

11.

Resistor R6: An ohmmeter scale on which the 150

ohm value is within or nearly within, the middle

third of the scale should be used. If both readings

are infinite, the resistor is open.

REASSEMBLY

During assembly, coat with silicone grease both sides

of the flat insulators used between the transistors and

heat sink, and also the heat sink on the side on which the

transistors are mounted. The silicone grease, which is

available commercially, conducts heat and thereby pro-

vides better cooling.'

IGNITION PULSE AMPLIFIER

R-5

C-3 Ju

MAGNETIC PULSE

DISTRIBUTOR

IGNITION SWITCH REPLACEMENT (Figs.

21

i to 23i)

CHEVROLET, CHEVY II AND CORVETTE

1.

Raise hood and disconnect battery ground cable from

battery.

2.

Remove lock cylinder by positioning switch in "off"

position and inserting wire in small hole in cylinder

face. Push in on wire to depress plunger and con-

tinue to turn key counter-clockwise until lock cylin-

der can be removed.

3.

Remove the metal ignition switch nut from the pas-

senger side of the dash using Tool J-7607 (Fig. 21i).

4.

Pull the ignition switch out from under the dash and

remove the wiring connectors.

5. To remove the "theft resistant" connector, the

switch must be out from under the dash as outlined

in Step 4. Using a screw driver unsnap the locking

tangs on the connector from their position on the

switch as shown in Figure 22i. Unplug the connector.

6. Snap the connector into place on a new ignition

switch.

7. Place the switch into position from behind the dash

and install the metal ignition switch nut.

8. Install the lock cylinder.

9. Install the battery cable to the battery and lower the

hood.

CHEVELLE

1.

Disconnect battery ground cable.

2.

Remove ash tray, retainer attaching screws and

retainer.

3.

Remove A/C distributor duct retaining screws and

duct.

Fig.

19i—Pulse Amplifier Internal Circuitry

Fig.

20i—Transistor Checking

CHEVROLET Oi

Page 355 of 659

ENGINE-ELECTRICAL-6Y-30

Fig.

2 li—Removing Ignition Switch Nut

4.

Remove heater and/or A/C control panel assembly

retaining screws and push panel assembly from

console.

NOTE: If interference between control panel

and radio is encountered, loosen radio retaining

nuts.

5.

Remove radio control knobs, bezels and retaining

nuts.

6. Disconnect radio wiring harness and antenna lead-in.

7.

Remove radio rear brace attaching screw and re-

move radio from vehicle.

Fig.

231—Switch and Connector Unplugged

8. Remove ignition switch bezel nut using Tool J-7607

and push switch rearward from panel opening.

9. Disconnect wiring connector from rear of switch.

10.

To install, reverse removal procedure.

SPARK PLUGS

CLEANING AND REGAPPING

Clean the spark plugs thoroughly, using an abrasive-

type cleaner. If the porcelains are badly glazed or

blistered, the spark plugs should be replaced. All spark

plugs must be of the same make and number or heat

range. Use a round feeler gauge to adjust the spark plug

gap to specifications (fig. 24i).

Fig.

22i—Unlocking Ignition Switch Connector

Fig.

241—Setting Sfxirk Plug Gap

CHEVROLET CHASSIS SERVICE MANUAL

Page 361 of 659

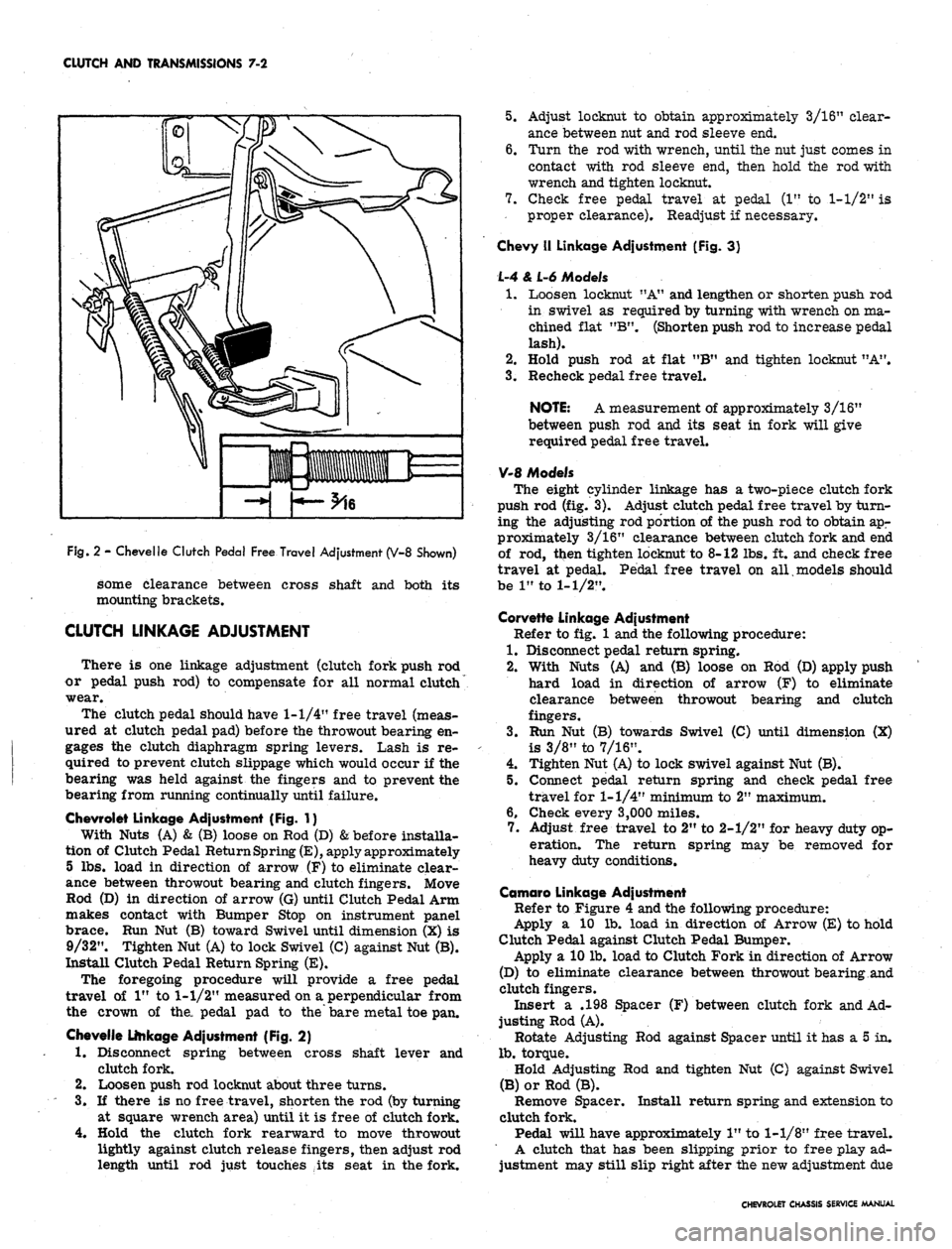

CLUTCH AND TRANSMISSIONS 7-2

Fig.

2 - Chevelle Clutch Pedal Free Travel Adjustment (V-8 Shown)

some clearance between cross shaft and both its

mounting brackets.

CLUTCH LINKAGE ADJUSTMENT

There is one linkage adjustment (clutch fork push rod

or pedal push rod) to compensate for all normal clutch

wear.

The clutch pedal should have

1-1/4"

free travel (meas-

ured at clutch pedal pad) before the throwout bearing en-

gages the clutch diaphragm spring levers. Lash is re-

quired to prevent clutch slippage which would occur if the

bearing was held against the fingers and to prevent the

bearing from running continually until failure.

Chevrolet Linkage Adjustment (Fig. 1}

With Nuts (A) & (B) loose on Rod (D)

&

before installa-

tion of Clutch Pedal Return Spring

(E),

apply approximately

5 lbs. load in direction of arrow (F) to eliminate clear-

ance between throwout bearing and clutch fingers. Move

Rod (D) in direction of arrow (G) until Clutch Pedal Arm

makes contact with Bumper Stop on instrument panel

brace. Run Nut (B) toward Swivel until dimension (X) is

9/32". Tighten Nut (A) to lock Swivel (C) against Nut (B).

Install Clutch Pedal Return Spring (E).

The foregoing procedure will provide a free pedal

travel of 1" to

1-1/2"

measured on a perpendicular from

the crown of the, pedal pad to the bare metal toe pan.

Chevelle Linkage Adjustment (Fig. 2)

1.

Disconnect spring between cross shaft lever and

clutch fork.

2.

Loosen push rod locknut about three turns.

3.

If there is no free travel, shorten the rod (by turning

at square wrench area) until it is free of clutch fork.

4.

Hold the clutch fork rearward to move throwout

lightly against clutch release fingers, then adjust rod

length until rod just touches ,its seat in the fork.

5.

Adjust locknut to obtain approximately 3/16" clear-

ance between nut and rod sleeve end.

6. Turn the rod with wrench, until the nut just comes in

contact with rod sleeve end, then hold the rod with

wrench and tighten locknut.

7.

Check free pedal travel at pedal (1" to

1-1/2"

is

proper clearance). Readjust if necessary.

Chevy II Linkage Adjustment (Fig. 3}

L-4 & L-6 Models

1.

Loosen locknut "A" and lengthen or shorten push rod

in swivel as required by turning with wrench on ma-

chined flat "B". (Shorten push rod to increase pedal

lash).

2.

Hold push rod at flat "B" and tighten locknut "A".

3.

Recheck pedal free travel.

NOTE: A measurement of approximately 3/16"

between push rod and its seat in fork will give

required pedal free travel.

V-8 Models

The eight cylinder linkage has a two-piece clutch fork

push rod (fig. 3). Adjust clutch pedal free travel by turn-

ing the adjusting rod portion of the push rod to obtain apr

proximately 3/16" clearance between clutch fork and end

of rod, ttien tighten locknut to 8-12 lbs. ft. and check free

travel at pedal. Pedal free travel on all models should

be 1" to

1-1/2".

Corvette Linkage Adjustment

Refer to fig. 1 and the following procedure:

1.

Disconnect pedal return spring.

2.

With Nuts (A) and (B) loose on Rod (D) apply push

hard load in direction of arrow (F) to eliminate

clearance between throwout bearing and clutch

fingers.

3.

Run Nut (B) towards Swivel (C) until dimension (X)

is 3/8" to 7/16".

4.

Tighten Nut (A) to lock swivel against Nut (B).

5.

Connect pedal return spring and check pedal free

travel for

1-1/4"

minimum to 2" maximum.

6. Check every 3,000 miles.

7.

Adjust free travel to 2" to 2-1/2" for heavy duty op-

eration. The return spring may be removed for

heavy duty conditions.

Camaro Linkage Adjustment

Refer to Figure 4 and the following procedure:

Apply a 10 lb. load in direction of Arrow (E) to hold

Clutch Pedal against Clutch Pedal Bumper.

Apply a 10 lb. load to Clutch Fork in direction of Arrow

(D) to eliminate clearance between throwout bearing and

clutch fingers.

Insert a .198 Spacer (F) between clutch fork and Ad-

justing Rod (A).

Rotate Adjusting Rod against Spacer until it has a 5 in.

lb.

torque.

Hold Adjusting Rod and tighten Nut (C) against Swivel

(B) or Rod (B).

Remove Spacer. Install return spring and extension to

clutch fork.

Pedal will have approximately 1" to

1-1/8"

free travel.

A clutch that has been slipping prior to free play ad-

justment may still slip right after the new adjustment due

CHEVROLET CHASSIS SERVICE MANUAL

Page 366 of 659

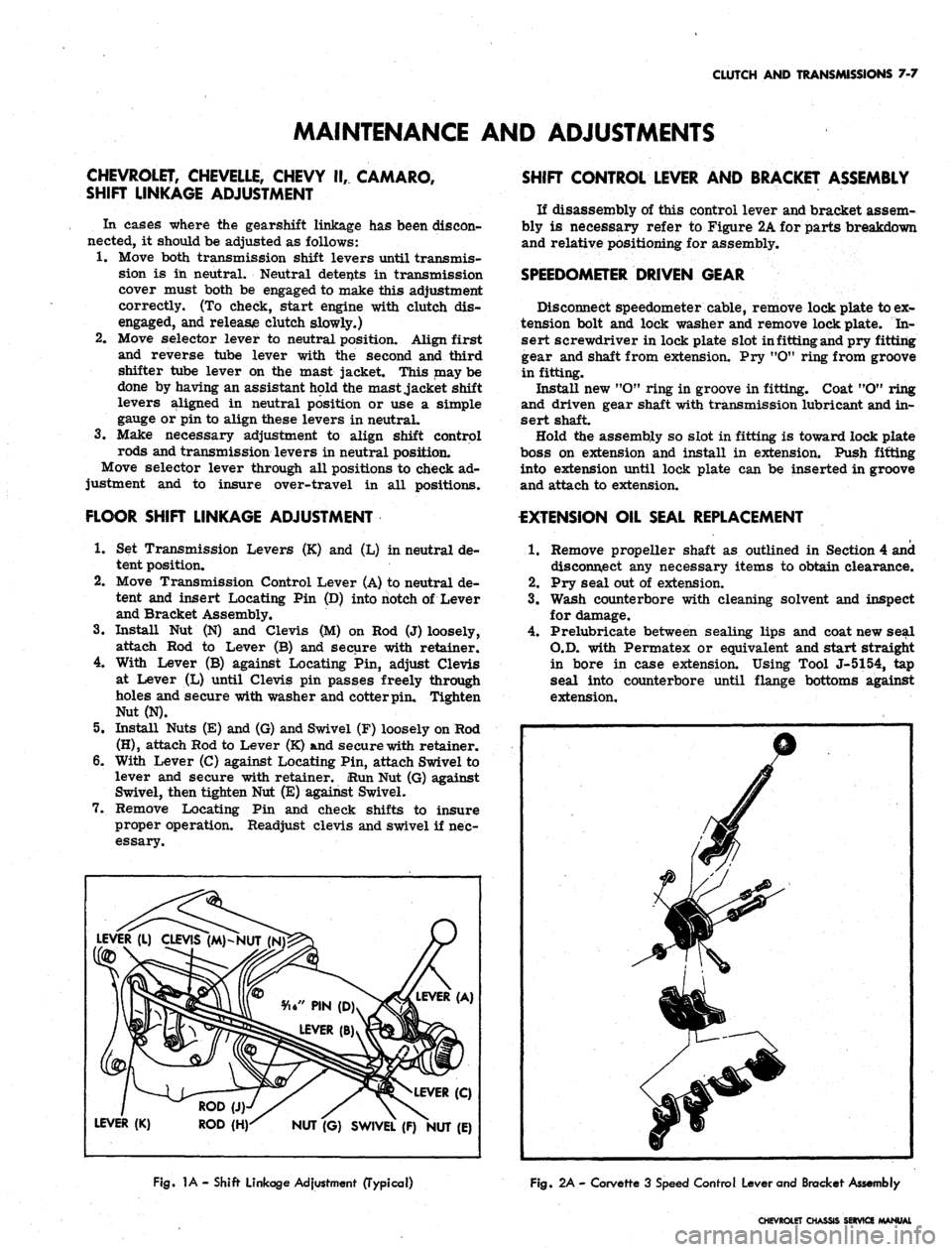

CLUTCH AND TRANSMISSIONS 7-7

MAINTENANCE AND ADJUSTMENTS

CHEVROLET, CHEVELLE, CHEVY II, CAMARO,

SHIFT LINKAGE ADJUSTMENT

In cases where the gearshift linkage has been discon-

nected, it should be adjusted as follows:

1.

Move both transmission shift levers until transmis-

sion is in neutral. Neutral detents in transmission

cover must both be engaged to make this adjustment

correctly. (To check, start engine with clutch dis-

engaged, and release clutch slowly.)

2.

Move selector lever to neutral position. Align first

and reverse tube lever with the second and third

shifter tube lever on the mast jacket. This may be

done by having an assistant hold the mast .jacket shift

levers aligned in neutral position or use a simple

gauge or pin to align these levers in neutral.

3.

Make necessary adjustment to align shift control

rods and transmission levers in neutral position.

Move selector lever through all positions to check ad-

justment and to insure over-travel in all positions.

FLOOR SHIFT LINKAGE ADJUSTMENT

1.

Set Transmission Levers (K) and (L) in neutral de-

tent position.

2.

Move Transmission Control Lever (A) to neutral de-

tent and insert Locating Pin (D) into notch of Lever

and Bracket Assembly.

3.

Install Nut (N) and Clevis (M) on Rod (J) loosely,

attach Rod to Lever (B) and secure with retainer.

4.

With Lever (B) against Locating Pin, adjust Clevis

at Lever (L) until Clevis pin passes freely through

holes and secure with washer and cotter pin. Tighten

Nut (N).

5.

Install Nuts (E) and (G) and Swivel (F) loosely on Rod

(H),

attach Rod to Lever (K) and secure with retainer.

6. With Lever (C) against Locating Pin, attach Swivel to

lever and secure with retainer. iRun Nut (G) against

Swivel, then tighten Nut (E) against Swivel.

7.

Remove Locating Pin and check shifts to insure

proper operation. Readjust clevis and swivel if nec-

essary.

LEVER (A)

LEVER (L) CLEVIS (M)-NUT (N

LEVER (C)

ROD(J).

" - -

LEVER (K) ROD (H)^ NUT '(G) SWIVEL (F) ^NUT (E)

SHIFT CONTROL LEVER AND BRACKET ASSEMBLY

If disassembly of this control lever and bracket assem-

bly is necessary refer to Figure 2A for parts breakdown

and relative positioning for assembly.

SPEEDOMETER DRIVEN GEAR

Disconnect speedometer cable, remove lock plate to ex-

tension bolt and lock washer and remove lock plate. In-

sert screwdriver in lock plate slot in fitting and pry fitting

gear and shaft from extension. Pry "O" ring from groove

in fitting.

Install new "OM ring in groove in fitting. Coat "O" ring

and driven gear shaft with transmission lubricant and in-

sert shaft.

Hold the assembly so slot in fitting is toward lock plate

boss on extension and install in extension. Push fitting

into extension until lock plate can be inserted in groove

and attach to extension.

EXTENSION OIL SEAL REPLACEMENT

.1.

Remove propeller shaft as outlined in Section 4 and

disconnect any necessary items to obtain clearance.

2.

Pry seal out of extension.

3.

Wash counterbore with cleaning solvent and inspect

for damage.

4.

Prelubricate between sealing lips and coat new seal

O.D. with Permatex or equivalent and start straight

in bore in case extension. Using Tool J-5154, tap

seal into counterbore until flange bottoms against

extension.

Fig.

1A- Shift Linkage Adjustment (Typical)

Fig.

2A - Corvette 3 Speed Control Lever and Bracket Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 367 of 659

CLUTCH AND TRANSMISSIONS 7-3

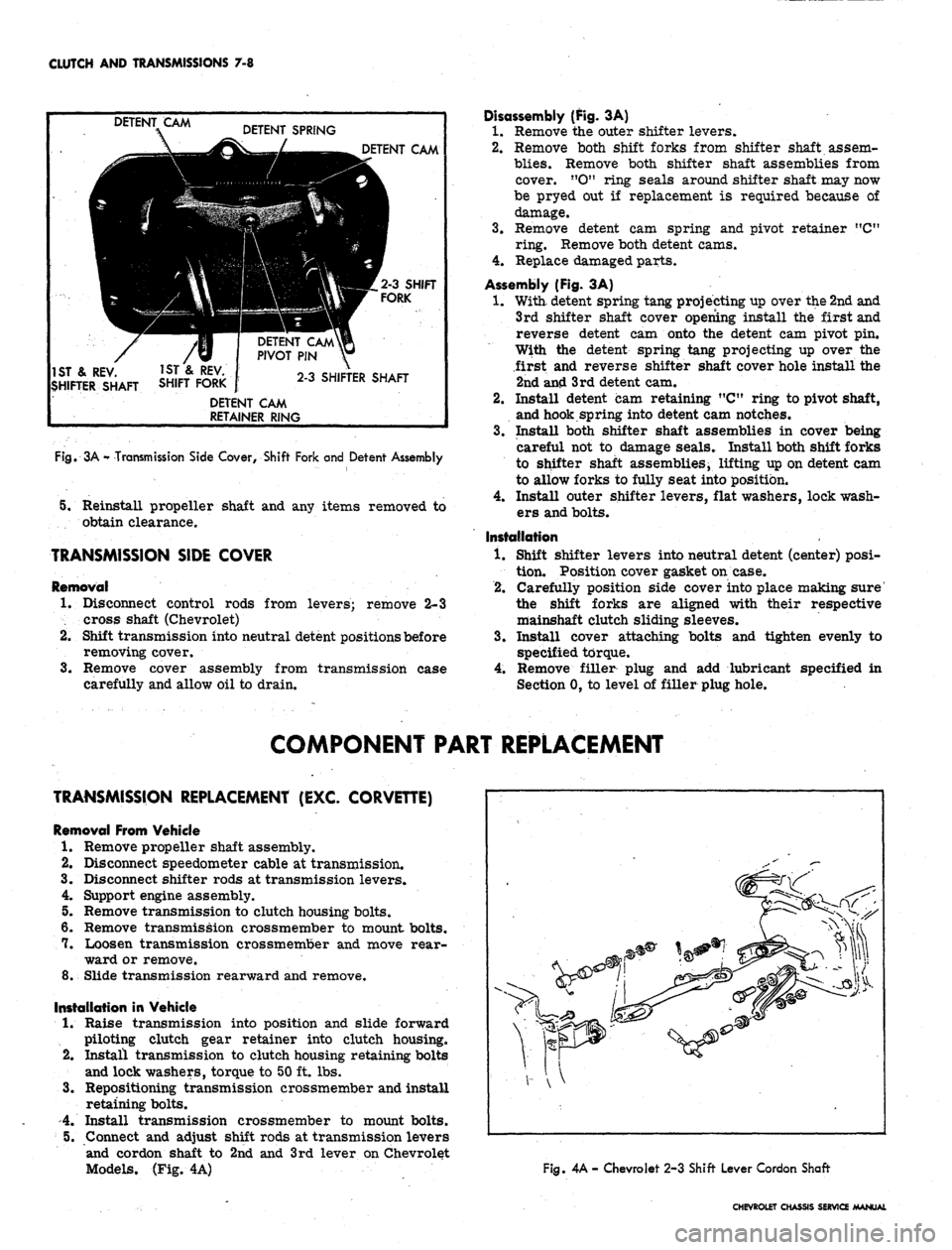

DETENT CAM

DETENT SPRING

DETENT CAM

2-3 SHIFT

FORK

DETENT CAM

PIVOT PIN

1ST & REV. 1ST& REV.

SHIFTER SHAFT SHIFT FORK

DETENT CAM

RETAINER RING

2-3 SHIFTER SHAFT

Fig. 3A

•*

Transmission Side Cover, Shift Fork and Detent Assembly

5. Reinstall propeller shaft and any items removed to

obtain clearance.

TRANSMISSION SIDE COVER

Removal •

1.

Disconnect control rods from levers; remove 2-3

cross shaft (Chevrolet)

2.

Shift transmission into neutral detent positions before

removing cover.

3.

Remove cover assembly from transmission case

carefully and allow oil to drain.

Disassembly (Fig. 3A)

1.

Remove the outer shifter levers.

2.

Remove both shift forks from shifter shaft assem-

blies.

Remove both shifter shaft assemblies from

cover. "OM ring seals around shifter shaft may now

be pryed out if replacement is required because of

damage.

3.

Remove detent cam spring and pivot retainer "C"

ring. Remove both detent cams.

4.

Replace damaged parts.

Assembly (Fig. 3A)

1.

With,

detent spring tang projecting up over the

2nd

and

3rd shifter shaft cover opening install the first and

reverse detent cam onto the detent cam pivot pin.

With the detent spring tang projecting up over the

first and reverse shifter shaft cover hole install the

2nd an£ 3rd detent cam.

2.

Install detent cam retaining "C" ring to pivot shaft,

and hook spring into detent cam notches.

3.

Install both shifter shaft assemblies in cover being

careful not to damage seals. Install both shift forks

to shifter shaft assemblies^ lifting up on detent cam

to allow forks to fully seat into position.

4.

Install outer shifter levers, flat washers, lock wash-

ers and bolts.

Installation

1.

Shift shifter levers into neutral detent (center) posi-

tion.

Position cover gasket on case.

2.

Carefully position side cover into place making sure'

the shift forks are aligned with their respective

mainshaft clutch sliding sleeves.

3.

Install cover attaching bolts and tighten evenly to

specified torque.

4.

Remove filler plug and add lubricant specified in

Section 0, to level of filler plug hole.

COMPONENT PART REPLACEMENT

TRANSMISSION REPLACEMENT (EXC. CORVETTE)

Removal From Vehicle

1.

Remove propeller shaft assembly.

2.

Disconnect speedometer cable at transmission.

3.

Disconnect shifter rods at transmission levers.

4.

Support engine assembly.

5. Remove transmission to clutch housing bolts.

6. Remove transmission crossmember to mount bolts.

7. Loosen transmission crossmember and move rear-

ward or remove.

8. Slide transmission rearward and remove.

Installation in Vehicle

1.

Raise transmission into position and slide forward

piloting clutch gear retainer into clutch housing.

2.

Install transmission to clutch housing retaining bolts

and lock washers, torque to 50 ft. lbs.

3.

Repositioning transmission crossmember and install

retaining bolts.

4.

Install transmission crossmember to mount bolts.

5. Connect and adjust shift rods at transmission levers

and cordon shaft to 2nd and 3rd lever on Chevrolet

Models. (Fig. 4A)

Fig. 4A - Chevrolet 2-3 Shift Lever Cordon Shaft

CHEVROLET CHASSIS SERVICE MANUAL