coil CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 173 of 659

FRONT SUSPENSION 3-9

Inspection

1.

Check bearings for cracked separators or worn or

pitted rollers and races.

2.

Check brake drum for

out-of-

round or scoring.

3.

Check fit of bearing outer cups in hub.

Repairs

Replacement of Bearing Cups

1.

Using steel bar stock, make press-out tools shown in

Figure 11.

2.

Insert removers through hub, indexing ends into slots

in hub shoulder behind bearing cup.

3.

Using a suitable extension pipe or rod, press bearing

cups from hub.

4.

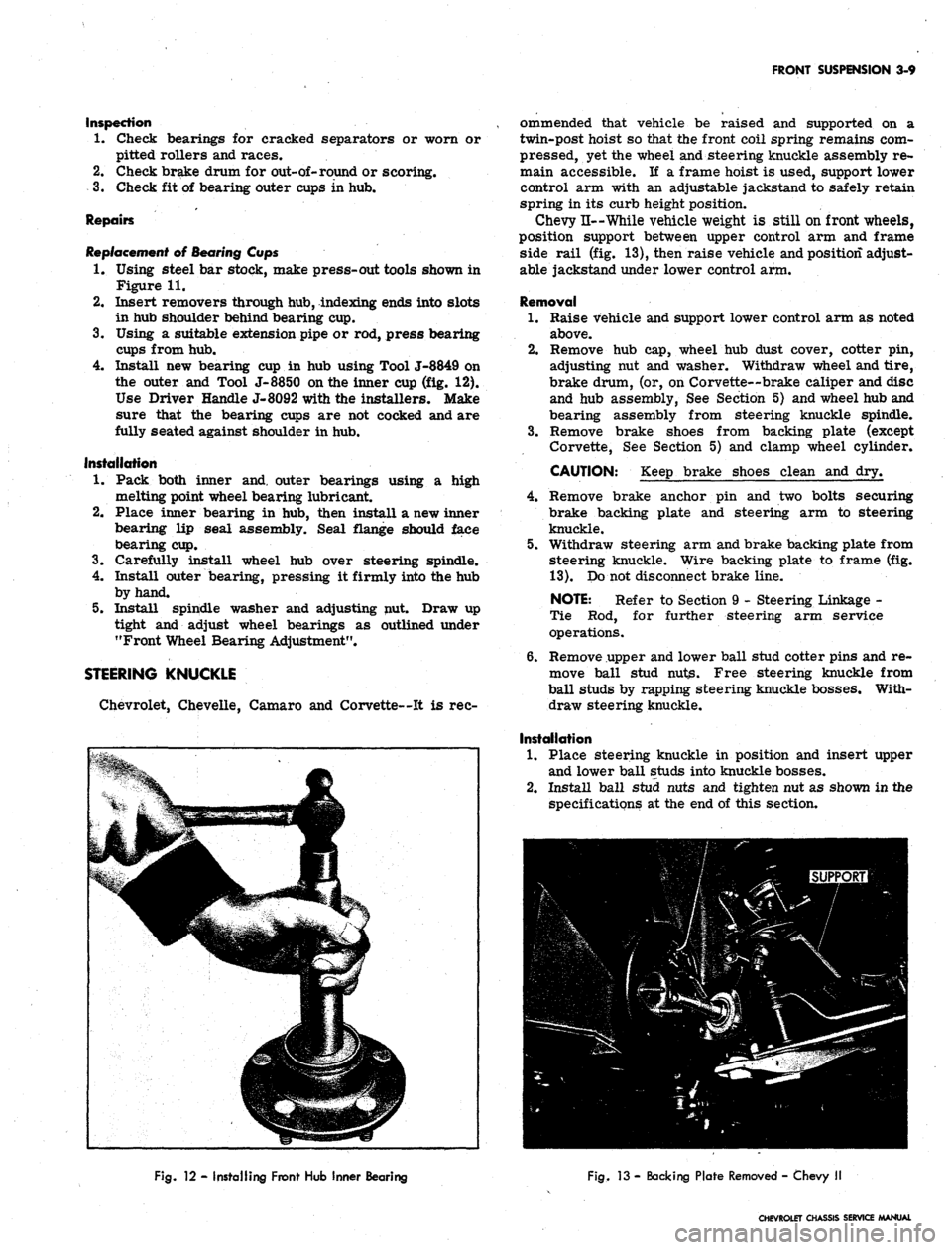

Install new bearing cup in hub using Tool J-8849 on

the outer and Tool J-8850 on the inner cup (fig. 12).

Use Driver Handle J-8092 with the installers. Make

sure that the bearing cups are not cocked and are

fully seated against shoulder in hub.

Installation

1.

Pack both inner and. outer bearings using a high

melting point wheel bearing lubricant.

2.

Place inner bearing in hub, then install a new inner

bearing lip seal assembly. Seal flange should face

bearing cup.

3.

Carefully install wheel hub over steering spindle.

4.

Install outer bearing, pressing it firmly into the hub

by hand.

5.

Install spindle washer and adjusting nut. Draw up

tight and adjust wheel bearings as outlined under

"Front Wheel Bearing Adjustment".

STEERING KNUCKLE

Chevrolet, Chevelle, Camaro and Corvette—It is rec-

ommended that vehicle be raised and supported on a

twin-post hoist so that the front coil spring remains com-

pressed, yet the wheel and steering knuckle assembly re-

main accessible. If a frame hoist is used, support lower

control arm with an adjustable jackstand to safely retain

spring in its curb height position.

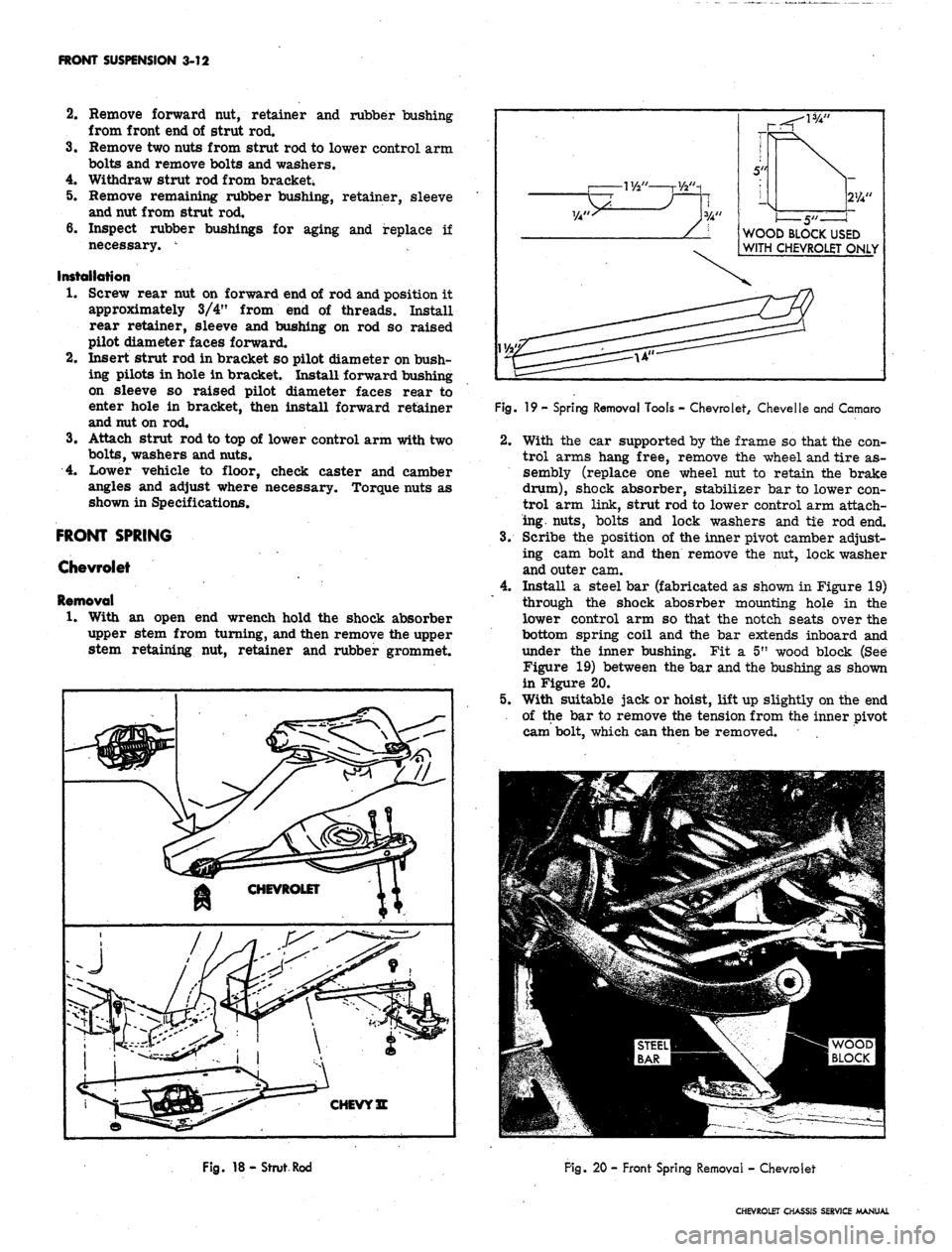

Chevy n— While vehicle weight is still on front wheels,

position support between upper control arm and frame

side rail (fig. 13), then raise vehicle and position adjust-

able jackstand under lower control arm.

Removal

1.

Raise vehicle and support lower control arm as noted

above.

2.

Remove hub cap, wheel hub dust cover, cotter pin,

adjusting nut and washer. Withdraw wheel and tire,

brake drum, (or, on Corvette--brake caliper and disc

and hub assembly, See Section 5) and wheel hub and

bearing assembly from steering knuckle spindle.

3.

Remove brake shoes from backing plate (except

Corvette, See Section 5) and clamp wheel cylinder.

CAUTION: Keep brake shoes clean and dry.

4.

Remove brake anchor pin and two bolts securing

brake backing plate and steering arm to steering

knuckle.

5.

Withdraw steering arm and brake backing plate from

steering knuckle. Wire backing plate to frame (fig.

13).

Do not disconnect brake line.

NOTE: Refer to Section 9 - Steering Linkage -

Tie Rod, for further steering arm service

operations.

6. Remove upper and lower ball stud cotter pins and re-

move ball stud nuts. Free steering knuckle from

ball studs by rapping steering knuckle bosses. With-

draw steering knuckle.

Installation

1.

Place steering knuckle in position and insert upper

and lower ball studs into knuckle bosses.

2.

Install ball stud nuts and tighten nut as shown in the

specifications at the end of this section.

Fig.

12 - Installing Front Hub Inner Bearing

Fig.

13 - Backing Plate Removed - Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 176 of 659

FRONT SUSPENSION 3-12

2.

Remove forward nut, retainer and rubber bushing

from front end of strut rod.

3.

Remove two nuts from strut rod to lower control arm

bolts and remove bolts and washers.

4.

Withdraw strut rod from bracket.

5. Remove remaining rubber bushing, retainer, sleeve

and nut from strut rod.

6. Inspect rubber bushings for aging and replace if

necessary. *•

Installation

1.

Screw rear nu$ on forward end of rod and position it

approximately 3/4" from end of threads. Install

rear retainer, sleeve and bushing on rod so raised

pilot diameter faces forward.

2.

Insert strut rod in bracket so pilot diameter on bush-

ing pilots in hole in bracket. Install forward bushing

on sleeve so raised pilot diameter faces rear to

enter hole in bracket, then install forward retainer

and nut on rod.

3.

Attach strut rod to top of lower control arm with two

bolts,

washers and nuts.

4.

Lower vehicle to floor, check caster and camber

angles and adjust where necessary. Torque nuts as

shown in Specifications.

FRONT SPRING

Chevrolet

Removal

1.

With an open end wrench hold the shock absorber

upper stem from turning, and then remove the upper

stem retaining nut, retainer and rubber grommet.

I IVi" rVi"i

\>. j ii

>

I

5'4

s

WOOD

BLOCK

USED

WITH

CHEVROLET

ONLY

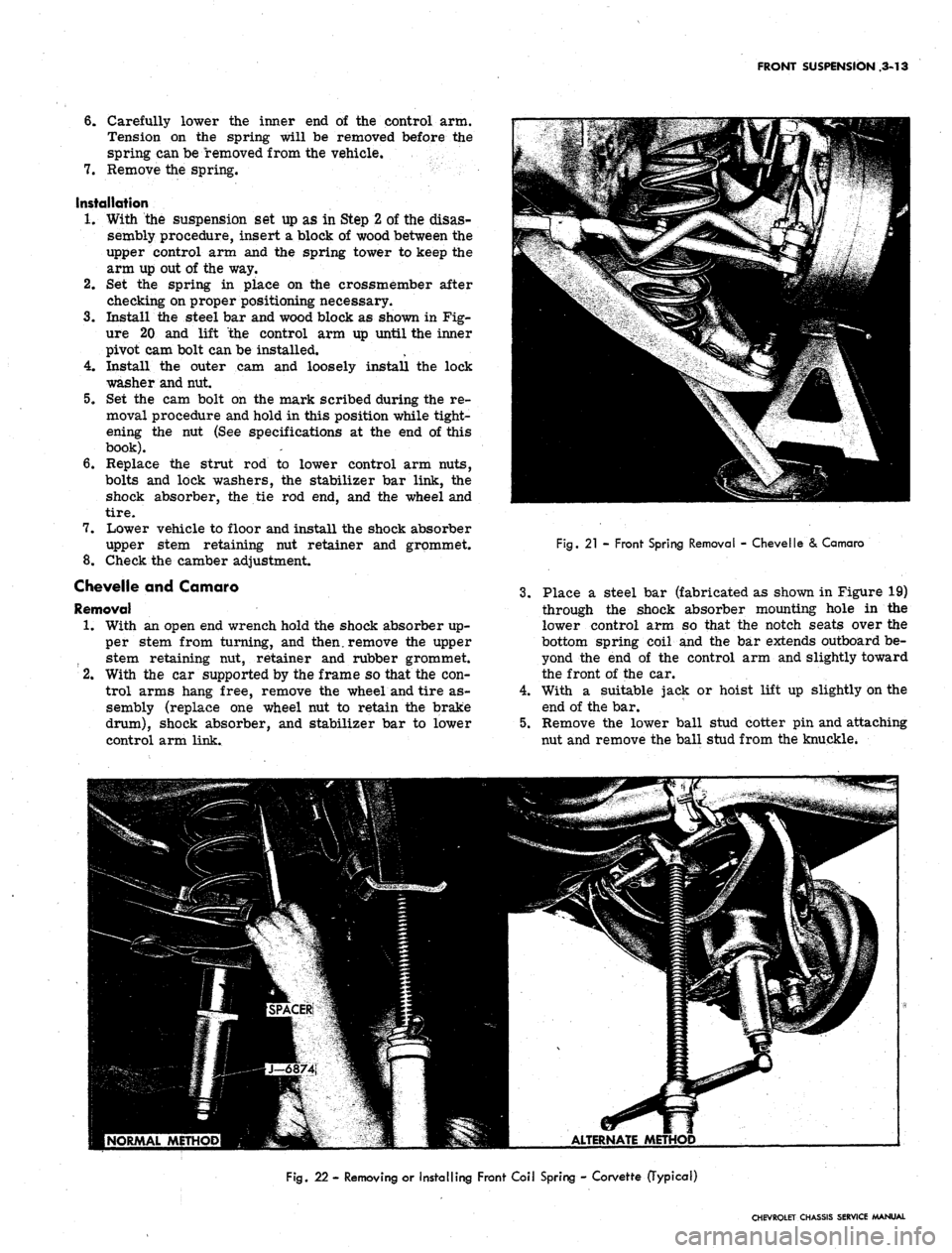

Fig.

19

- Spring Removal Tools - Chevrolet, Chevelle and Comoro

2.

With the car supported by the frame so that the con-

trol arms hang free, remove the wheel and tire as-

sembly (replace one wheel nut to retain the brake

drum),

shock absorber, stabilizer bar to lower con-

trol arm link, strut rod to lower control arm attach-

ing, nuts, bolts and lock washers and tie rod end.

3.

Scribe the position of the inner pivot camber adjust-

ing cam bolt and then remove the nut, lock washer

and outer cam.

4.

Install a steel bar (fabricated as shown in Figure 19)

through the shock abosrber mounting hole in the

lower control arm so that the notch seats over the

bottom spring coil and the bar extends inboard and

under the inner bushing. Fit a 5" wood block (See

Figure 19) between the bar and the bushing as shown

in Figure 20.

5.

With suitable jack or hoist, lift up slightly on the end

of the bar to remove the tension from the inner pivot

cam bolt, which can then be removed.

Fig.

18-Strut Rod

Pig. 20 - Front Spring Removal - Chevrolet

CHEVROLET CHASSIS SERVICE MANUAL

Page 177 of 659

FRONT SUSPENSION ,3-13

6. Carefully lower the inner end of the control arm.

Tension on the spring will be removed before the

spring can be removed from the vehicle.

7.

Remove the spring.

Installation

1.

With the suspension set up as in Step 2 of the disas-

sembly procedure, insert a block of wood between the

upper control arm and the spring tower to keep the

arm up out of the way.

2.

Set the spring in place on the crossmember after

checking on proper positioning necessary.

3.

Install the steel bar and wood block as shown in Fig-

ure 20 and lift the control arm up until the inner

pivot cam bolt can be installed. ,

4.

Install the outer cam and loosely install the lock

washer and nut

5.

Set the cam bolt on the mark scribed during the re-

moval procedure and hold in this position while tight-

ening the nut (See specifications at the end of this

book).

6. Replace the strut rod to lower control arm nuts,

bolts and lock washers, the stabilizer bar link, the

shock absorber, the tie rod end, and the wheel and

tire.

7.

Lower vehicle to floor and install the shock absorber

upper stem retaining nut retainer and grommet.

8. Check the camber adjustment.

Chevelle and Camaro

Removal

1.

With an open end wrench hold the shock absorber up-

per stem from turning, and then, remove the upper

stem retaining nut, retainer and rubber grommet.

2.

With the car supported by the frame so that the con-

trol arms hang free, remove the wheel and tire as-

sembly (replace one wheel nut to retain the brake

drum),

shock absorber, and stabilizer bar to lower

control arm link.

4.

5.

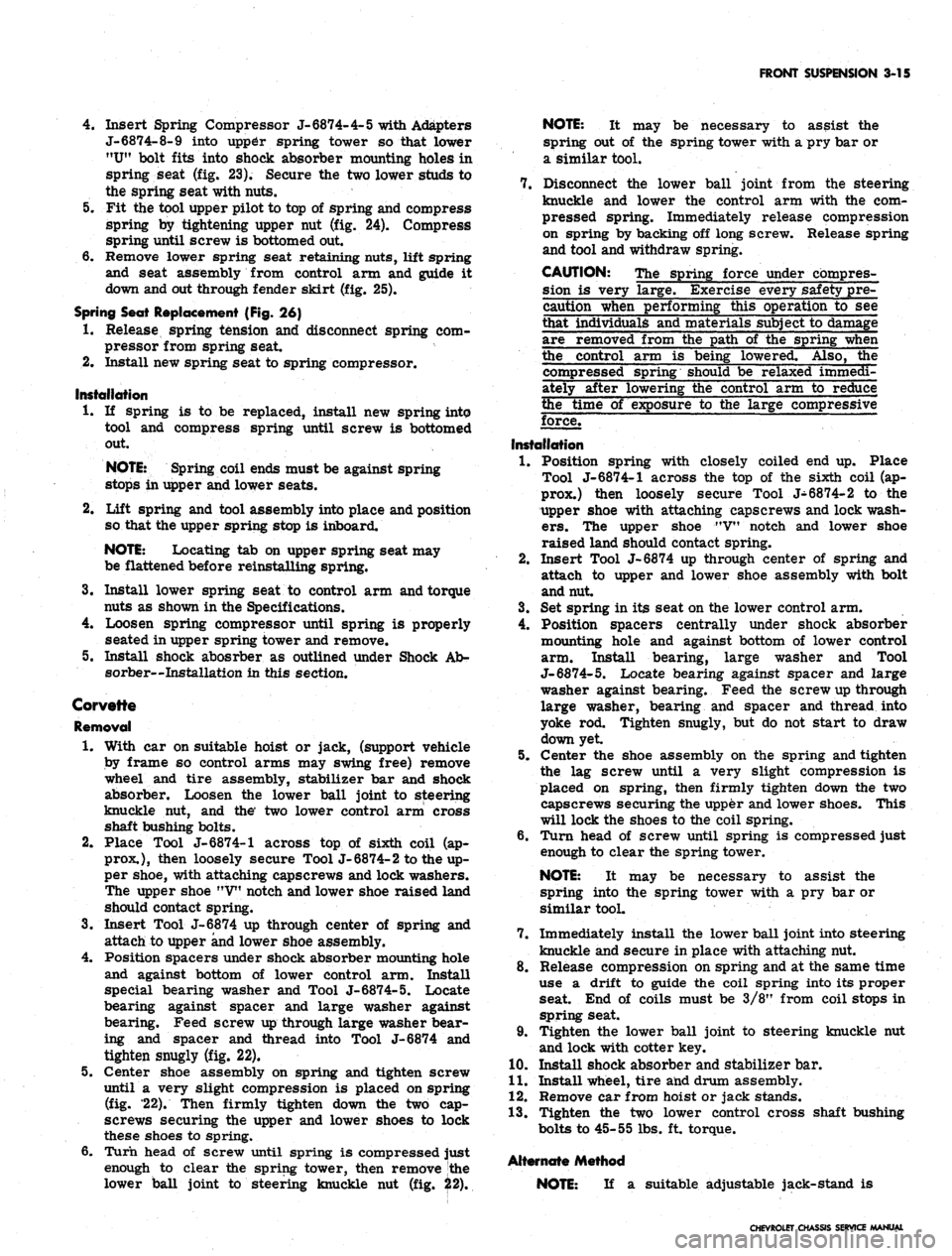

Fig.

21 - Front Spring Removal - Chevelle & Camaro

Place a steel bar (fabricated as shown in Figure 19)

through the shock absorber mounting hole in the

lower control arm so that the notch seats over the

bottom spring coil and the bar extends outboard be-

yond the end of the control arm and slightly toward

the front of the car.

With a suitable jack or hoist lift up slightly on the

end of the bar.

Remove the lower ball stud cotter pin and attaching

nut and remove the ball stud from the knuckle.

ALTERNATE METHOD

Fig.

22 - Removing or Installing Front Coil Spring - Corvette (Typical)

CHEVROLET CHASSIS SERVICE MANUAL

Page 179 of 659

FRONT SUSPENSION 3-15

4.

Insert Spring Compressor J-

6874-

4-

5 with Adapters

J-6874-8-9 into upp^r spring tower so that lower

MU"

bolt fits into shock absorber mounting holes in

spring seat (fig. 23). Secure the two lower studs to

the spring seat with nuts.

5.

Fit the tool upper pilot to top of spring and compress

spring by tightening upper nut (fig. 24). Compress

spring until screw is bottomed out.

6. Remove lower spring seat retaining nuts, lift spring

and seat assembly from control arm and guide it

down and out through fender skirt (fig. 25).

Spring Seat Replacement (Fig. 26)

1.

Release spring tension and disconnect spring com-

pressor from spring seat.

2.

Install new spring seat to spring compressor.

Installation

1.

If spring is to be replaced, install new spring into

tool and compress spring until screw is bottomed

out.

NOTE: Spring coil ends must be against spring

stops in upper and lower seats.

2.

Lift spring and tool assembly into place and position

so that the upper spring stop is inboard.

NOTE: Locating tab on upper spring seat may

be flattened before reinstalling spring.

3.

Install lower spring seat to control arm and torque

nuts as shown in the Specifications.

4.

Loosen spring compressor until spring is properly

seated in upper spring tower and remove.

5.

Install shock abosrber as outlined under Shock Ab-

sorber—Installation in this section.

Corvette

Removal

1.

With car on suitable hoist or jack, (support vehicle

by frame so control arms may swing free) remove

wheel and tire assembly, stabilizer bar and shock

absorber. Loosen the lower ball joint to steering

knuckle nut, and the' two lower control arm cross

shaft bushing bolts.

2.

Place Tool J-6874-1 across top of sixth coil (ap-

prox.),

then loosely secure Tool J-6874-2 to the up-

per shoe, with attaching capscrews and lock washers.

The upper shoe "V" notch and lower shoe raised land

should contact spring.

3.

Insert Tool J-6874 up through center of spring and

attach to upper and lower shoe assembly.

4.

Position spacers under shock absorber mounting hole

and against bottom of lower control arm. Install

special bearing washer and Tool J-6874-5. Locate

bearing against spacer and large washer against

bearing. Feed screw up through large washer bear-

ing and spacer and thread into Tool J-6874 and

tighten snugly (fig. 22).

5.

Center shoe assembly on spring and tighten screw

until a very slight compression is placed on spring

(fig. '22). Then firmly tighten down the two cap-

screws securing the upper and lower shoes to lock

these shoes to spring.

6. Turn head of screw until spring is compressed just

enough to clear the spring tower, then remove the

lower ball joint to steering knuckle nut (fig. 22).

NOTE: It may be necessary to assist the

spring out of the spring tower with a pry bar or

a similar tool.

7.

Disconnect the lower ball joint from the steering

knuckle and lower the control arm with the com-

pressed spring. Immediately release compression

on spring by backing off long screw. Release spring

and tool and withdraw spring.

CAUTION: The spring force under compres-

sion is very large. Exercise every safety pre-

caution when performing this operation to see

that individuals and materials subject to damage

are removed from the path of the spring when

the control arm is being lowered. Also, the

compressed spring

be relaxed immedi-

ately after lowering the control arm to reduce

the time of exposure to the large compressive

force.

Installation

1.

Position spring with closely coiled end up. Place

Tool J-6874-1 across the top of the sixth coil (ap-

prox.) then loosely secure Tool J-6874-2 to the

upper shoe with attaching capscrews and lock wash-

ers.

The upper shoe MV" notch and lower shoe

raised land should contact spring.

2.

Insert Tool J-6874 up through center of spring and

attach to upper and lower shoe assembly with bolt

and nut.

3.

Set spring in its seat on the lower control arm.

4.

Position spacers centrally under shock absorber

mounting hole and against bottom of lower control

arm. Install bearing, large washer and Tool

J-6874-5.

Locate bearing against spacer and large

washer against bearing. Feed the screw up through

large washer, bearing and spacer and thread into

yoke rod. Tighten snugly, but do not start to draw

down yet

5.

Center the shoe assembly on the spring and tighten

the lag screw until a very slight compression is

placed on spring, then firmly tighten down the two

capscrews securing the upper and lower shoes. This

will lock the shoes to the coil spring.

6. Turn head of screw until spring is compressed just

enough to clear the spring tower.

NOTE: It may be necessary to assist the

spring into the spring tower with a pry bar or

similar tool.

7.

Immediately install the lower ball joint into steering

knuckle and secure in place with attaching nut.

8. Release compression on spring and at the same time

use a drift to guide the coil spring into its proper

seat. End of coils must be 3/8" from coil stops in

spring seat.

9. Tighten the lower ball joint to steering knuckle nut

and lock with cotter key.

10.

Install shock absorber and stabilizer bar.

11.

Install wheel, tire and drum assembly.

12.

Remove car from hoist or jack stands.

13.

Tighten the two lower control cross shaft bushing

bolts to 45-55 lbs. ft. torque.

NOTE: If a suitable adjustable jack-stand is

CHEVROLET CHASSIS SERVICE MANUAL

Page 180 of 659

FRONT SUSPENSION 3-16

available the following procedure may also be

used (fig. 22-Alternate Method).

1.

Support car on suitable hoist or jack (so control

arms may swing free) and remove the wheel and

tire assembly, shock absorber, and stabilizer link

at control arm.

2.

Place suitable jack stand under the lower control

arm cross shaft.

3.

Follow Steps 2-5 as outlined on previous page.

4.

Turn head of tool screw to partially compress

spring.

5. Remove the three control arm cross shaft attaching

bolts,

washers and nuts.

6. Carefully lower jack stand and if necessary increase

compression on spring and when coil spring is out of

its upper seat, relax tension on spring (fig. 22).

7. By using a pry bar to assist, if necessary, remove

the coil spring from the lower control arm.

8. Installation is the reverse of the above procedure.

Carefully follow instructions for installing spring

tool.

LOWER CONTROL ARM SPHERICAL JOINT

Chevrolet, Chevelle, Comoro and Corvette

Inspection

The lower control arm spherical joint should be re-

placed whenever wear is indicated in the upper joint

inspection.

NOTE: The lower control arm spherical joint

is a loose fit in the assembly when not connected

to the steering knuckle.

Only if inspection of each upper joint indicates them

both to be within limits, inspect each lower joint for ex-

cessive wear as follows:

1.

After reconnecting upper joints to steering knuckles,

support vehicle weight on wheels or wheel hubs.

2.

With outside micrometer or caliper, measure dis-

tance from top of lubrication fitting to bottom of ball

stud, and record the dimensions for each side.

3.

Then support vehicle weight at outer end of each

lower control arm, so that wheels or wheel hubs are

free,

then repeat Step 2.

4.

If the difference in dimensions on either side is

greater than 1/16" (.0625"), the joint is excessively

worn and both lower joints should be replaced.

If inspection of lower spherical joints does not indicate

excessive wear, inspect further as follows:

5.

On Chevrolet Only--Examine lubrication hole in each

joint assembly after cleaning out hole. Look for evi-

dence of the liner partially or fully blocking lubrica-

tion opening. Such evidence indicates that liner is

disintegrating and that both lower spherical joints

should be replaced.

Another indication of lower spherical joint excessive

wear is indicated when difficulty is experienced when

lubricating the joint. If the liner has worn to the point

where the lubrication grooves in the liner have worn

away, then abnormal pressure is required to force lubri-

cant through the joint. This is another reason to recom-

mend replacement of both lower joints.

If the above inspections do not indicate any reason for

spherical joint replacements, test the torque tightness of

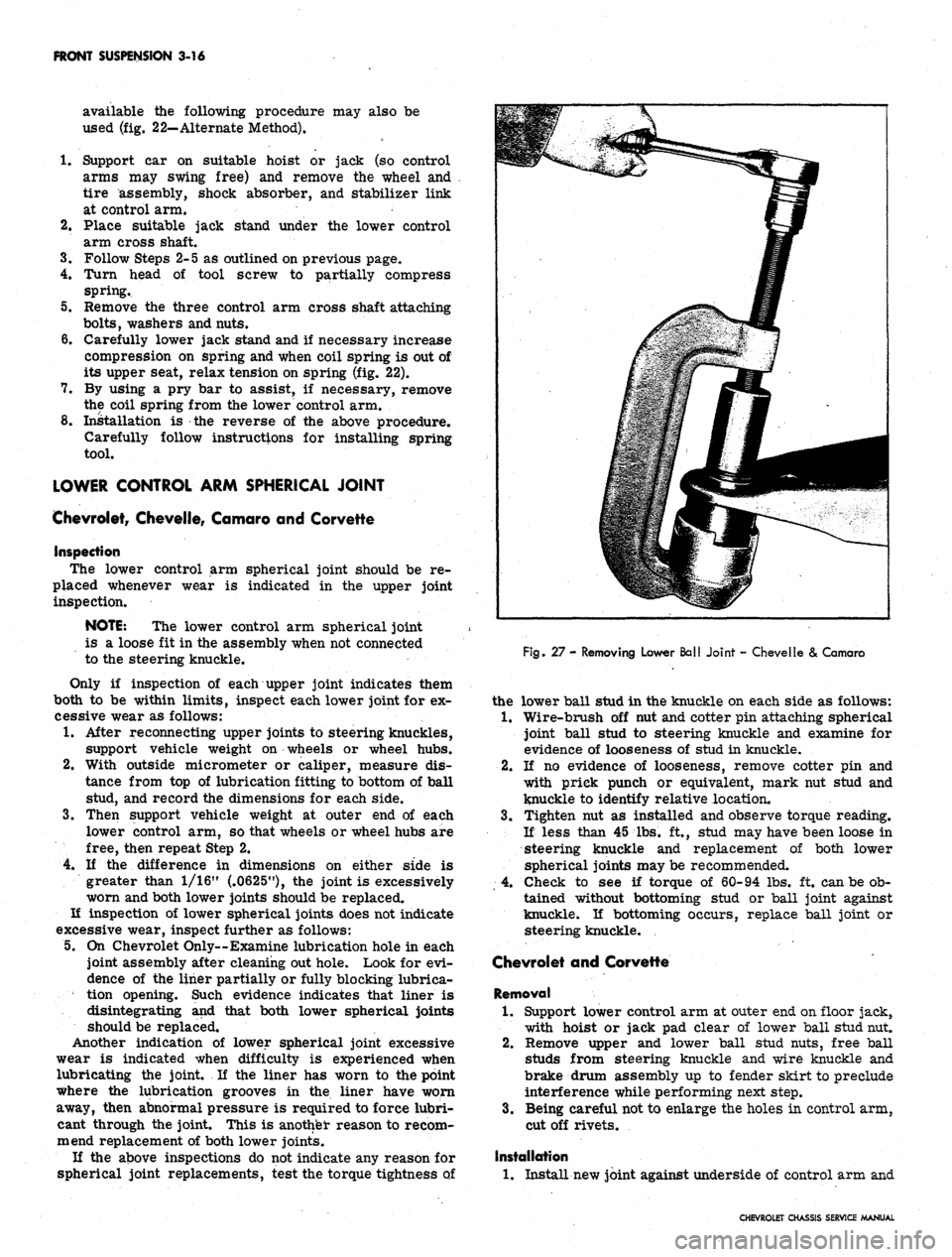

Fig. 27 - Removing Lower Ball Joint - Chevelle

&

Camaro

the lower ball stud in the knuckle on each side as follows:

1.

Wire-brush off nut and cotter pin attaching spherical

joint ball stud to steering knuckle and examine for

evidence of looseness of stud in knuckle.

2.

If no evidence of looseness, remove cotter pin and

with prick punch or equivalent, mark nut stud and

knuckle to identify relative location.

3.

Tighten nut as installed and observe torque reading.

If less than 45 lbs. ft., stud may have been loose in

steering knuckle and replacement of both lower

spherical joints may be recommended.

4.

Check to see if torque of 60-94 lbs. ft. can be ob-

tained without bottoming stud or ball joint against

knuckle. If bottoming occurs, replace ball joint or

steering knuckle.

Chevrolet and Corvette

Removal

1.

Support lower control arm at outer end on floor jack,

with hoist or jack pad clear of lower ball stud nut.

2.

Remove upper and lower ball stud nuts, free ball

studs from steering knuckle and wire knuckle and

brake drum assembly up to fender skirt to preclude

interference while performing next step.

3.

Being careful not to enlarge the holes in control arm,

cut off rivets.

Installation

1.

Install new joint against underside of control arm and

CHEVROLET CHASSIS SERVICE MANUAL

Page 182 of 659

FRONT SUSPENSION 3-18

CHEVROLET

CHEVELLE

CAMARO (TYPICAL)

CHEVY U

LOWER CONTROL ARM

CORVETTE

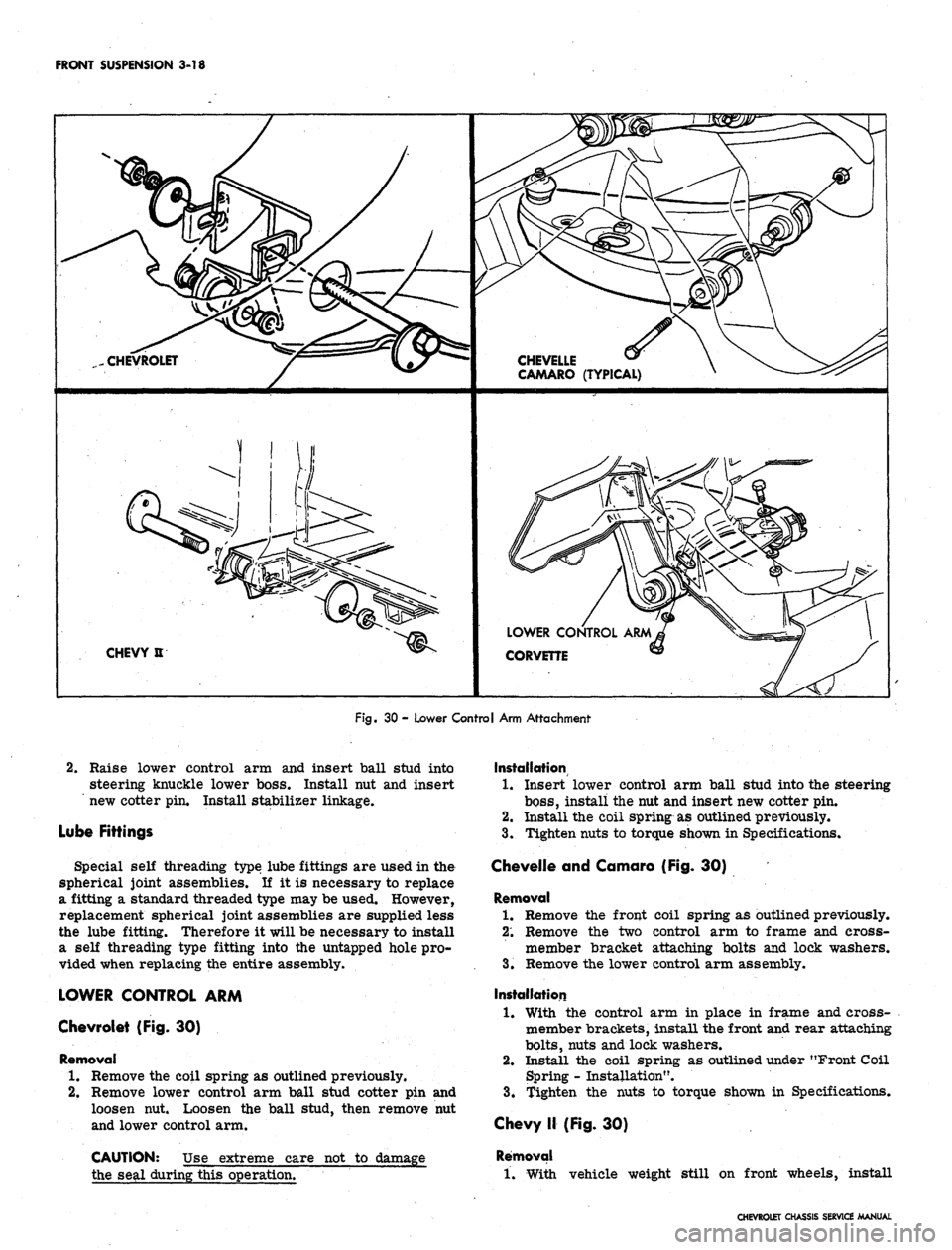

Fig.

30 - Lower Control Arm Attachment

2.

Raise lower control arm and insert ball stud into

steering knuckle lower boss. Install nut and insert

new cotter pin. Install stabilizer linkage.

Lube Fittings

Special self threading type lube fittings are used in the

spherical joint assemblies. If it is necessary to replace

a fitting a standard threaded type may be used. However,

replacement spherical joint assemblies are supplied less

the lube fitting. Therefore it will be necessary to install

a self threading type fitting into the untapped hole pro-

vided when replacing the entire assembly.

LOWER CONTROL ARM

Chevrolet (Fig. 30)

Removal

1.

Remove the coil spring as outlined previously.

2.

Remove lower control arm ball stud cotter pin and

loosen nut. Loosen the ball stud, then remove nut

and lower control arm.

CAUTION: Use extreme care not to damage

the seal during this operation.

Installation

1.

Insert lower control arm ball stud into the steering

boss,

install the nut and insert new cotter pin.

2.

Install the coil spring as outlined previously.

3.

Tighten nuts to torque shown in Specifications.

Chevelle and Camaro (Fig. 30)

Removal

1.

Remove the front coil spring as outlined previously.

2;

Remove the two control arm to frame and cross-

member bracket attaching bolts and lock washers.

3.

Remove the lower control arm assembly.

Installation

1.

With the control arm in place in frame and cross-

member brackets, install the front and rear attaching

bolts,

nuts and lock washers.

2.

Install the coil spring as outlined under "Front Coil

Spring - Installation".

3.

Tighten the nuts to torque shown in Specifications.

Chevy II (Fig. 30)

Removal

1.

With vehicle weight still on front wheels, install

CHEVROLET CHASSIS SERVICE MANUAL

Page 183 of 659

FRONT

SUSPENSION 3-19

spacer between upper control arm and frame side

rail (fig. 15). Raise vehicle.

2.

Remove lower control arm ball stud cotter pin and

loosen hut.

3.

Loosen ball stud and remove nut. Drop lower control

arm.

CAUTION: Use extreme care not to damage

the seal during this operation? "~~~~

4.

Mark lower control arm pivot bolt and adjusting cam

for realignment. Remove nut securing pivot bolt and

cam assembly. Remove pivot bolt and cam. Remove

lower control arm.

Installation

1.

Insert lower control arm into its support bracket,

index pivot bolt and cams, pivot nut and tighten to

torque shown in Specifications.

2.

Raise lower control arm ball stud into steering

knuckle boss and install nut. Tighten nut to torque

shown in Specifications and insert new cotter pin.

3.

Lower vehicle and remove upper control arm to

frame support.

Corvette (Fig. 30)

Removal

1.

Remove the front coil spring as outlined under

"Front Spring, Removal".

2.

Remove the two front cross shaft to frame attaching

bolts and lock washers and the rear frame attaching

nut and lock washer.

3.

Remove the lower control arm assembly from the

vehicle.

THRUST

BEARING

FLAT

WASHER

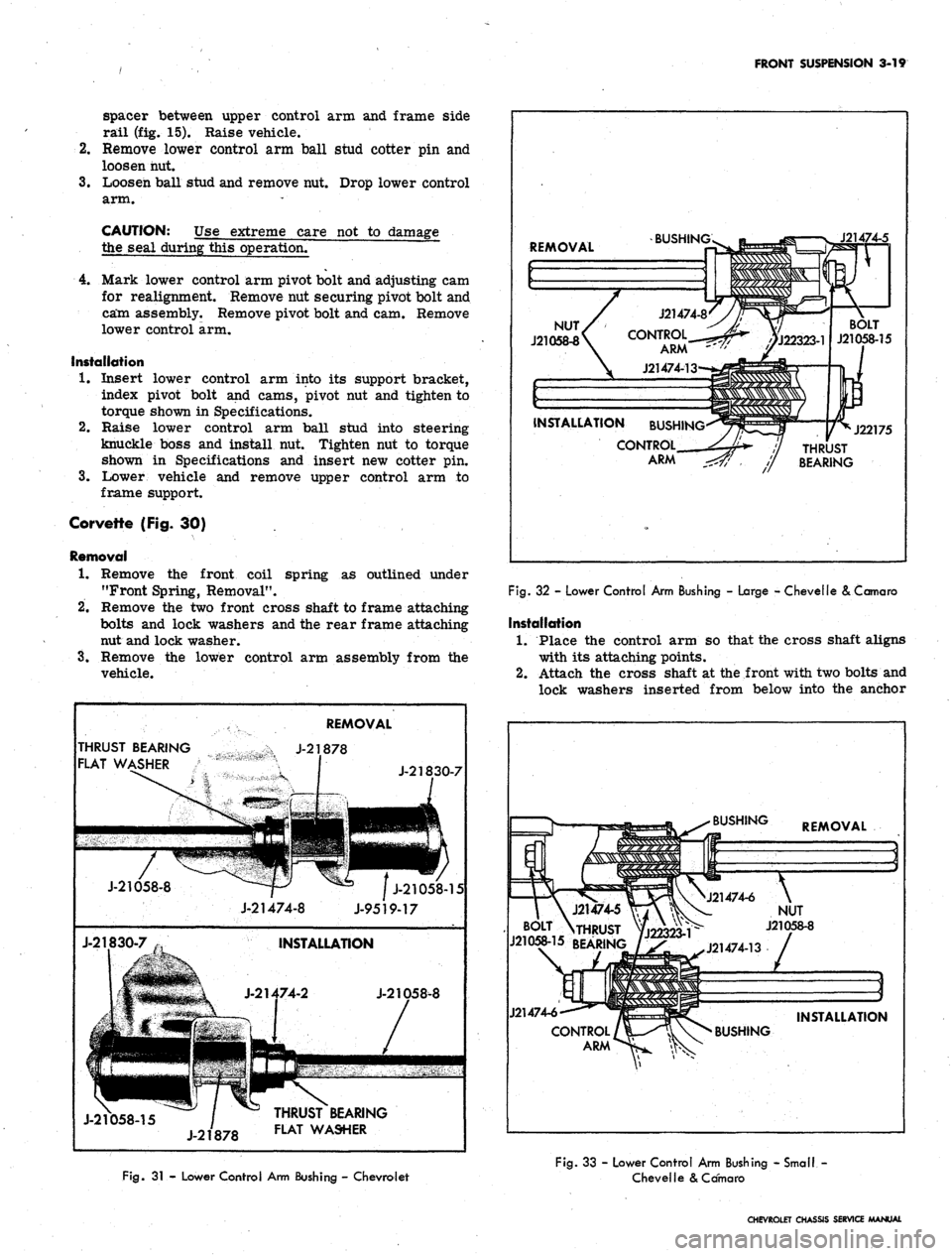

REMOVAL

J-21878

J-21830-7

J-21058-8

J-21474-8

/J-21058-15

J-9519-17

J-21830-7

INSTALLATION

J-21058-15

J-2/878 FLAT

REMOVAL

BUSHING

INSTALLATION

BUSHING

CONTROL

J22175

THRUST

ARM

^ ,. / BEARING

Fig.

32 - Lower Control Arm Bushing - Large - Chevelle & Comoro

Installation

1.

Place the control arm so that the cross shaft aligns

with its attaching points.

2.

Attach the cross shaft at the front with two bolts and

lock washers inserted from below into the anchor

BUSHING

REMOVAL

J21474-6

J21474-5

TTf\ ft^\- NUT

BOLT

VHRUST

^22323-^ J21058"8

J21058-15

REARING, / ^_ ^

J21474-13

INSTALLATION

Fig.

31 - Lower Control Arm Bushing - Chevrolet

Fig.

33 - Lower Control Arm Bushing - Small -

Chevelle

& Comoro

CHEVROLET CHASSIS SERVICE MANUAL

Page 184 of 659

FRONT SUSPENSION 3-20

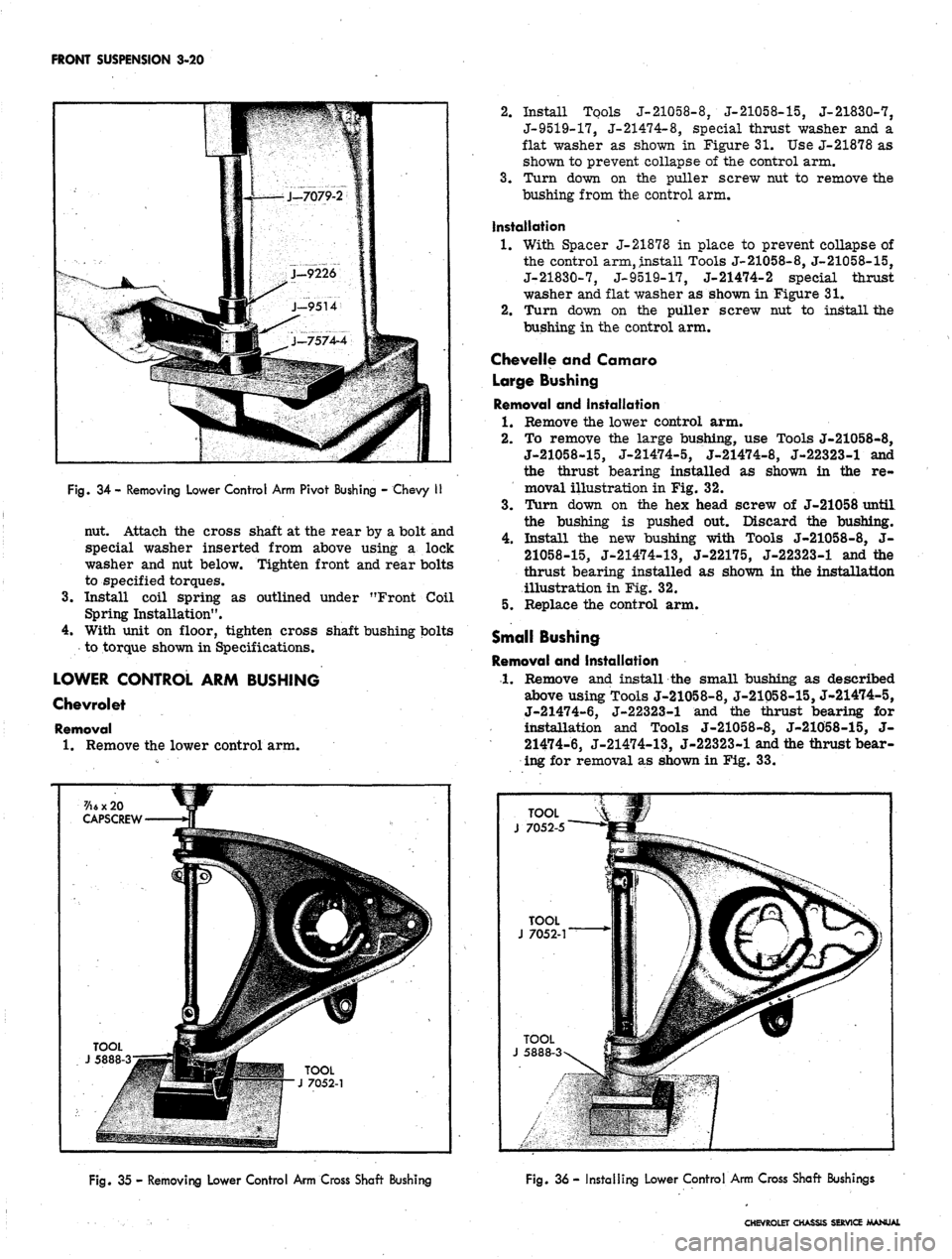

Fig.

34 - Removing Lower Control Arm Pivot Bushing - Chevy II

nut. Attach the cross shaft at the rear by a bolt and

special washer inserted from above using a lock

washer and nut below. Tighten front and rear bolts

to specified torques.

3.

Install coil spring as outlined under "Front Coil

Spring Installation".

4.

With unit on floor, tighten cross shaft bushing bolts

to torque shown in Specifications.

LOWER CONTROL ARM BUSHING

Chevrolet

Removal

1.

Remove the lower control arm.

2.

Install Tools J-21058-8, J-21058-15, J-21830-7,

J-9519-17, J-21474-8, special thrust washer and a

flat washer as shown in Figure

31.

Use J-21878 as

shown to prevent collapse of the control arm.

3.

Turn down on the puller screw nut to remove the

bushing from the control arm.

Installation

1.

With Spacer J-21878 in place to prevent collapse of

the control arm, install Tools J-21058-8, J-21058-15,

J-21830-7, J-9519-17, J-21474-2 special thrust

washer and flat washer as shown in Figure 31,

2.

Turn down on the puller screw nut to install the

bushing in the control arm.

Chevelle and Camaro

Large Bushing

Removal and Installation

1.

Remove the lower control arm.

2.

To remove the large bushing, use Tools J-21058-8,

J-21058-15, J-21474-5, J-21474-8, J-22323-1 and

the thrust bearing installed as shown in the re-

moval illustration in Fig. 32.

3.

Turn down on the hex head screw of J-21058 until

the bushing is pushed out. Discard the bushing.

4.

Install the new bushing with Tools J-21058-8, J-

21058-15,

J-21474-13, J-22175, J-22323-1 and the

thrust bearing installed as shown in the installation

illustration in Fig. 32.

5.

Replace the control arm.

Small Bushing

Removal and Installation

1.

Remove and install the small bushing as described

above using Tools J-21058-8, J-21058-15, J-21474-5,

J-21474-6, J-22323-1 and the thrust bearing for

installation and Tools J-21058-8, J-21058-15, J-

21474-6, J-21474-13, J-22323-1 and tiie thrust bear-

ing for removal as shown in Fig. 33.

7/\6 x 20

CAPSCREW

TOOL

J 5888-3

TOOL

J 7052-5

TOOL

J 7052-1

TOOL

J 5888-3-

Fig.

35 - Removing Lower Control Arm Cross Shaft Bushing

Fig.

36 - Installing Lower Control Arm Cross Shaft Bushings

CHEVROLET CHASSIS SERVICE MANUAL

Page 191 of 659

SECTION

4

REAR SUSPENSION

AND

DRIVE LINE

CONTENTS

OF

THIS SECTION

Page

Rear Suspension

4-1

Drive Line.

. 4-26

Rear Axle ......

4-26

Propeller Shaft

and

Universal Joints

Special Tools

4-37

4-43

REAR SUSPENSION

INDEX

General Description

4-1

Chevrolet

4-1

Chevelle

4-1

Chevy

n and

Camaro

. . . . . 4-2

Corvette

. . . . . . 4-3

Maintenance

and

Adjustments ...............

4-4

Riding Height Check (Chevrolet, Camaro,

Chevelle

and

Chevy

II) 4-5

Wheel Alignment (Corvette)

4-5

Wheel Bearing Adjustment (Corvette)

4-6

Component Parts Replacement (Chevrolet, Camaro,

Chevelle

and

Chevy

JJ) 4-7

Coil Spring

4-7

Chevrolet

4-7

Removal

4-7

Installation

4-7

Chevelle

4-8

Removal

4-8

4-8

Installation

.

Leaf Spring, Spring Seat Pads, Spring

Eye

Bushings

4-9

Chevy

H 4-9

Removal

4-9

Installation

4-9

Camaro

4-10

Removal

4-10

Installation

4-11

Shock Absorber

4-11

Chevrolet

and

Chevelle

. 4-11

Removal

4-11

Installation

. . 4-12

Chevy

II 4-12

Removal

4-12

Installation

4-rl2

Camaro

4-12

Removal

. 4-12

Installation

4-12

Control

Arm . . 4-12

Chevrolet Upper

4-12

Removal

. 4-12

Page

Bushing Replacement

. 4-13

Installation

4-14

Chevrolet Lower

4-14

Removal

4-14

Bushing Replacement

4-14

Installation

. 4-15

Chevelle Upper

and

Lower.

. 4-15

Removal

4-15

Bushing Replacement

4-15

Installation

4-17

Rear Suspension

Tie Rod

(Chevrolet)

. . .

......

. . . 4-17

Removal

4-17

Bushing Replacement

4-17

Installation

4-17

Component Parts Replacement (Corvette)

. . 4-17

Wheel Spindle

and

Support

4-17

Removal

4-17

Repairs

', . 4-17

Installation

4-18

Differential Carrier Support Bracket Replacement.

. 4-20

Shock Absorber

4-20

Removal

4-20

Installation

* .... 4-20

Strut

Rod and

Bracket

4-20

Removal

4-20

Repairs

4-21

Installation

4-21

Spring

4-21

Removal

4-21

Repairs

4-22

Installation

4-22

Torque Control

Arm 4-23

Removal

4-23

Repairs

. 4-23

Installation

4-24

Suspension Crossmember

4-24

Removal

4-24

Repairs—Isolation Mount

4-25

Installation

4-25

Stabilizer Shaft Replacement

4-25

GENERAL DESCRIPTION

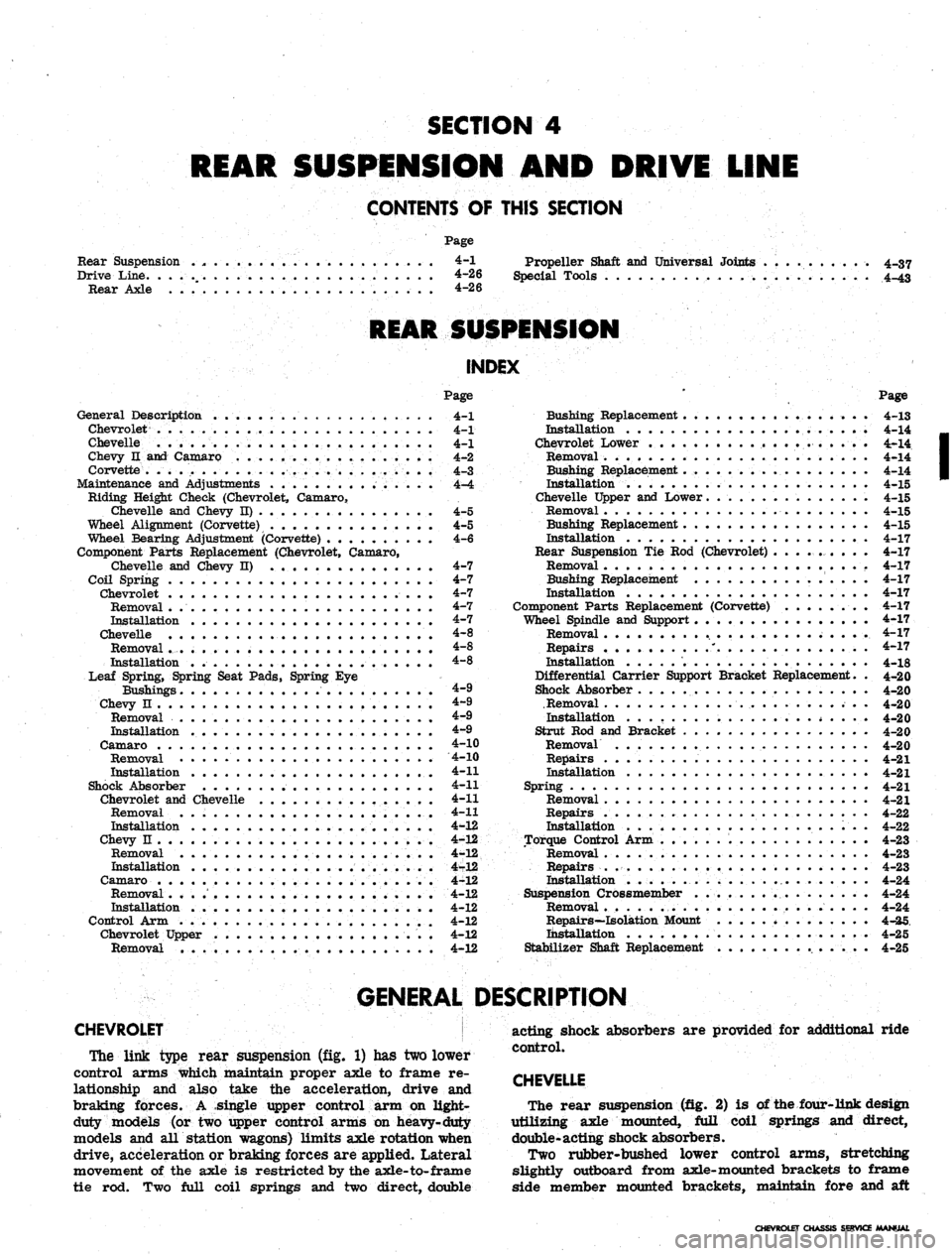

CHEVROLET

The link type rear suspension (fig. 1) has two lower

control arms which maintain proper axle to frame re-

lationship and also take the acceleration, drive and

braking forces. A single upper control arm on light-

duty models (or two upper control arms on heavy-duty

models and all station wagons) limits axle rotation when

drive, acceleration or braking forces are applied. Lateral

movement of the axle is restricted by the axle-to-frame

tie rod. Two full coil springs and two direct, double

acting shock absorbers are provided for additional ride

control.

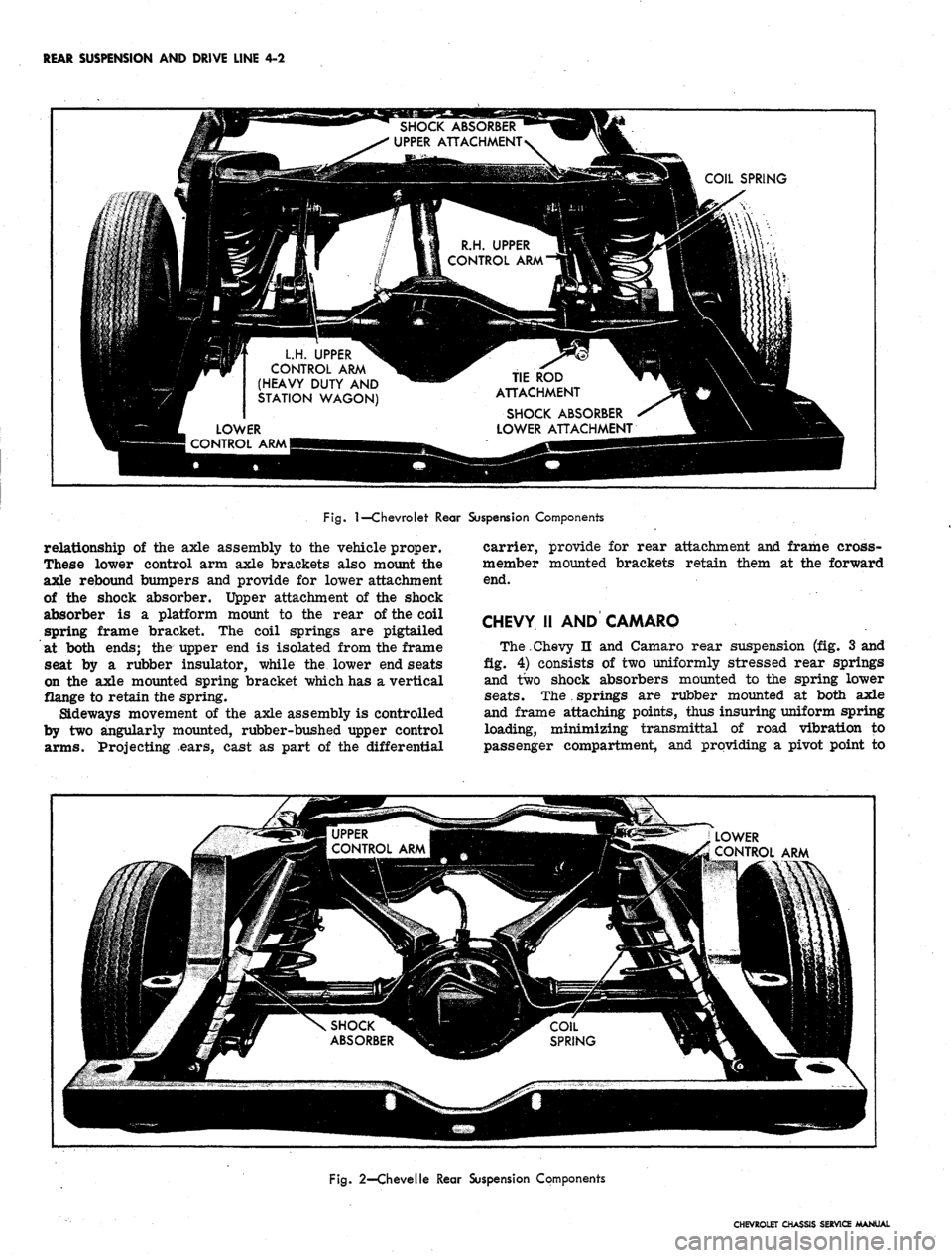

CHEVELLE

The rear suspension (fig. 2) is of the four-link design

utilizing axle mounted, full coil springs and direct,

double-acting shock absorbers.

Two rubber-bushed lower control arms, stretching

slightly outboard from axle-mounted brackets to frame

side member mounted brackets, maintain fore and aft

CHEVROLET CHASSIS SERVICE MANUAL

Page 192 of 659

REAR SUSPENSION AND DRIVE LINE 4-2

SHOCK ABSORBER

UPPER ATTACHMENT

COIL SPRING

\

R.H. UPPER

CONTROL ARM

LH.

UPPER

CONTROL ARM

(HEAVY DUTY AND

STATION WAGON)

TIE ROD

ATTACHMENT

SHOCK ABSORBER

LOWER ATTACHMENT

LOWER

CONTROL ARM

Fig.

1—Chevrolet Rear Suspension Components

relationship of the axle assembly to the vehicle proper.

These lower control arm axle brackets also mount the

axle rebound bumpers and provide for lower attachment

of the shock absorber. Upper attachment of the shock

absorber is a platform mount to the rear of the coil

spring frame bracket. The coil springs are pigtailed

at both ends; the upper end is isolated from the frame

seat by a rubber insulator, while the lower end seats

on the axle mounted spring bracket which has a vertical

flange to retain the spring.

Sideways movement of the axle assembly is controlled

by two angularly mounted, rubber-bushed upper control

arms.

Projecting ears, cast as part of the differential

carrier, provide for rear attachment and frame cross-

member mounted brackets retain them at the forward

end.

CHEVY 11 AND CAMARO

The.Chevy n and Camaro rear suspension (fig. 3 and

fig.

4) consists of two uniformly stressed rear springs

and two shock absorbers mounted to the spring lower

seats.

The

.

springs are rubber mounted at both axle

and frame attaching points, thus insuring uniform spring

loading, minimizing transmittal of road vibration to

passenger compartment, and providing a pivot point to

•MMMi

MMM—Hi—1—1——1——1MMMMiM_

[•?{aw-i

'

"'

i

\ SHOCK^^BBB^^B(^^CO1L

ABSORBER ^HH^ SPRING

g^8^"

_ LOWER

feSfcto^

CONTROL

ARM

Fig.

2—Chevelle Rear Suspension Components

CHEVROLET CHASSIS SERVICE MANUAL