coil CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 197 of 659

REAR SUSPENSION AND DRIVE LINE 4-7

tioned vertically in the torque arm before ap-

plying pressure to the puller screw.

5.

Remove shim and bearing spacer from spindle

support.

6. Note size of shim used. If dial indicator reading

was more than

.008",

select a shim thinner by the

amount needed to bring end play within limits. If

dial indicator reading was less than

.001",

select a

shim thicker by the amount needed to bring end play

within limits.

NOTE: Shims are available in thicknesses from

.097"

to .148" in increments of

.003".

EXAMPLE: Bearing end play reading obtained

on dial indicator was

.011",

.003" over limit.

Bearing shim removed from spindle measures

.145".

New shim installed measures .139", .006"

smaller. End play is now decreased by .006" and

is

.005",

which is within the .001" to .008" limit.

7.

After determining shim thickness, install bearing

spacer and shim on spindle. Position spindle in

spindle support.

8. Press inner bearing race and roller assembly on

spindle as follows.

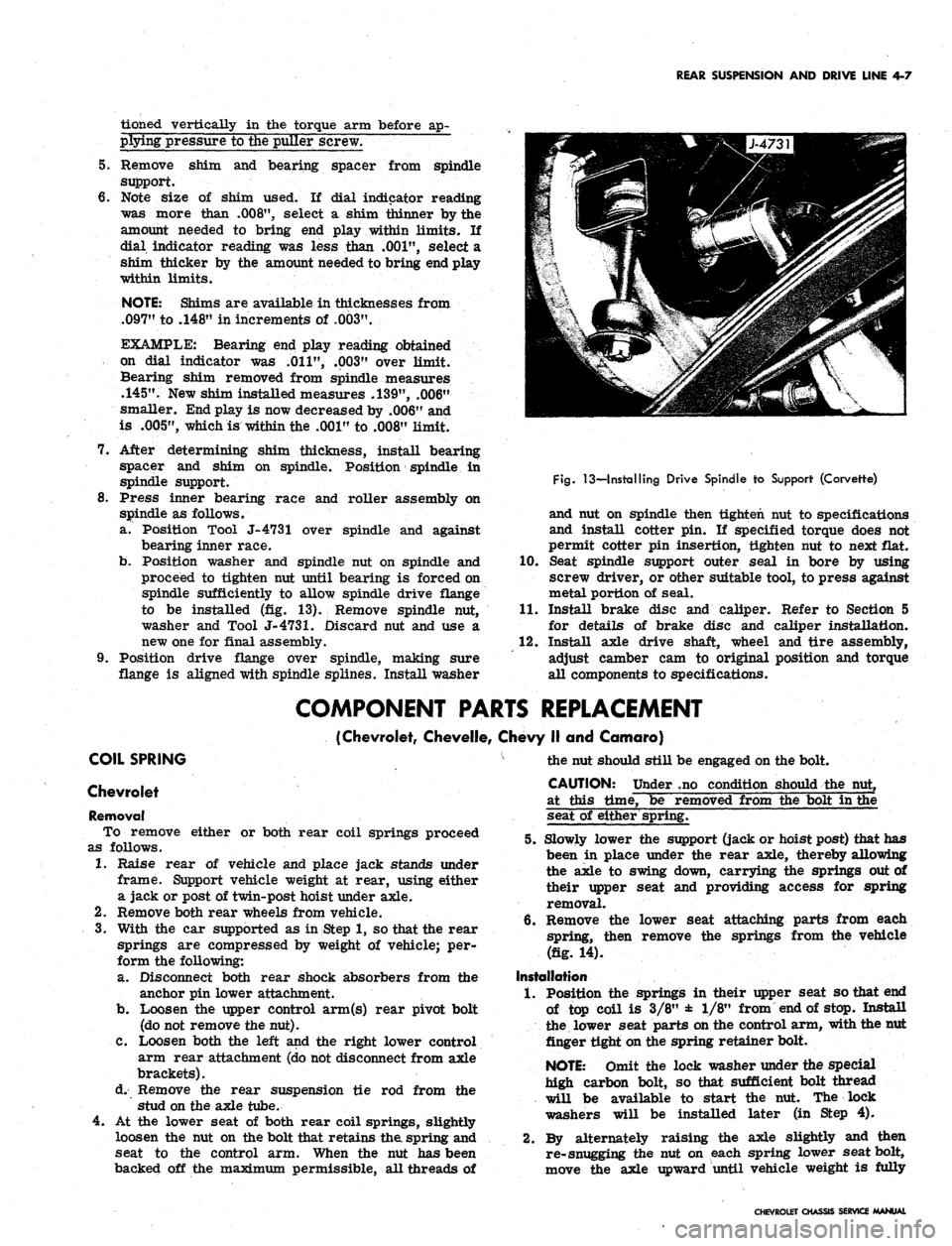

a. Position Tool J-4731 over spindle and against

bearing inner race.

b.

Position washer and spindle nut on spindle and

proceed to tighten nut until bearing is forced on

spindle sufficiently to allow spindle drive flange

to be installed (fig. 13). Remove spindle nut,

washer and Tool

J-4731.

Discard nut and use a

new one for final assembly.

9. Position drive flange over spindle, making sure

flange is aligned with spindle splines. Install washer

Fig.

13—Installing Drive Spindle to Support (Corvette)

and nut on spindle then tighten nut to specifications

and install cotter pin. If specified torque does not

permit cotter pin insertion, tighten nut to next flat.

10.

Seat spindle support outer seal in bore by using

screw driver, or other suitable tool, to press against

metal portion of seal.

11.

Install brake disc and caliper. Refer to Section 5

for details of brake disc and caliper installation.

12.

Install axle drive shaft, wheel and tire assembly,

adjust camber cam to original position and torque

all components to specifications.

COMPONENT PARTS REPLACEMENT

(Chevrolet, Chevelle, Chevy II and Camaro)

COIL SPRING

Chevrolet

Removal

To remove either or both rear coil springs proceed

as follows.

1.

Raise rear of vehicle and place jack stands under

frame. Support vehicle weight at rear, using either

a jack or post of twin-post hoist under axle.

2.

Remove both rear wheels from vehicle.

3.

With the car supported as in Step 1, so that the rear

springs are compressed by weight of vehicle; per-

form the following:

a. Disconnect both rear shock absorbers from the

anchor pin lower attachment.

b.

Loosen the upper control arm(s) rear pivot bolt

(do not remove the nut).

C. Loosen both the left and the right lower control

arm rear attachment (do not disconnect from axle

brackets).

d. Remove the rear suspension tie rod from the

stud on the axle tube.

4.

At the lower seat of both rear coil springs, slightly

loosen the nut on the bolt that retains the spring and

seat to the control arm. When the nut has been

backed off the maximum permissible, all threads of

the nut should still be engaged on the bolt.

CAUTION: Under ,no condition should the nut,

at this time, be removed from the bolt in the

seat of either spring.

5.

Slowly lower the support (jack or hoist post) that has

been in place under the rear axle, thereby allowing

the axle to swing down, carrying the springs out of

their upper seat and providing access for spring

removal.

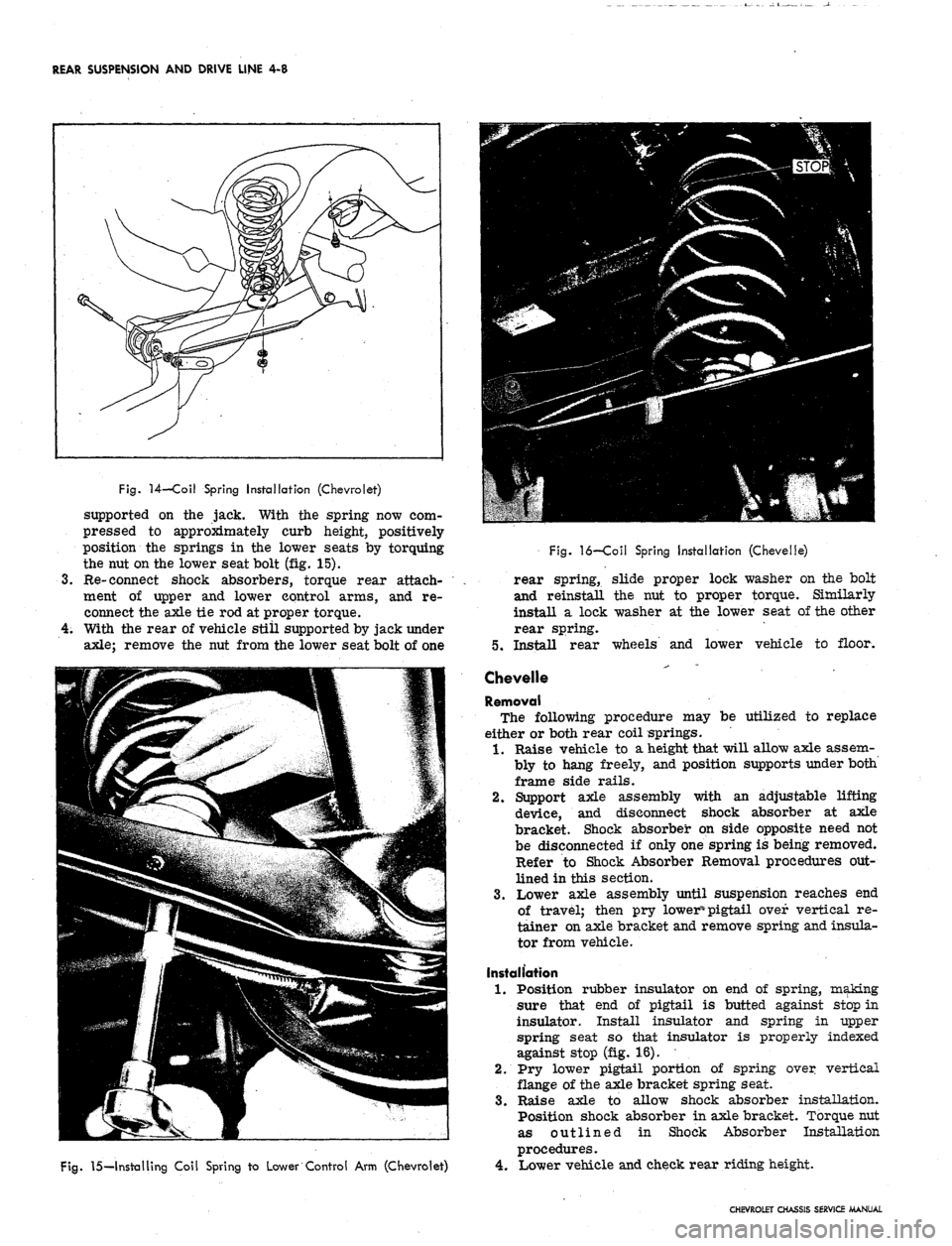

6. Remove the lower seat attaching parts from each

spring, then remove the springs from the vehicle

(fig. 14).

Installation

1.

Position the springs in their upper seat so that end

of top coil is 3/8" ± 1/8" from end of stop. Install

the lower seat parts on the control arm, with the nut

finger tight on the spring retainer bolt.

NOTE: Omit the lock washer under the special

high carbon bolt, so that sufficient bolt thread

will be available to start the nut. The lock

washers will be installed later (in Step 4).

2.

By alternately raising the axle slightly and then

re-snugging the nut on each spring lower seat bolt,

move the axle upward until vehicle weight is fully

CHEVROLET CHASSIS SERVICE MANUAL

Page 198 of 659

REAR SUSPENSION AND DRIVE LINE 4-8

Fig.

14—Coil Spring Installation (Chevrolet)

supported on the jack. With the spring now com-

pressed to approximately curb height, positively

position the springs in the lower seats by torquing

the nut on the lower seat bolt (fig. 15).

Re-connect shock absorbers, torque rear attach-

ment of upper and lower control arms, and re-

connect the axle tie rod at proper torque.

With the rear of vehicle still supported by jack under

axle;

remove the nut from the lower seat bolt of one

Fig.

15—Installing Coil Spring to Lower Control Arm (Chevrolet)

Fig.

16—Coil Spring Installation (Chevelle)

rear spring, slide proper lock washer on the bolt

and reinstall the nut to proper torque. Similarly

install a lock washer at the lower seat of the other

rear spring.

5.

Install rear wheels and lower vehicle to floor.

Chevelle

Removal

The following procedure may be utilized to replace

either or both rear coil springs.

1.

Raise vehicle to a height that will allow axle assem-

bly to hang freely, and position supports under both

frame side rails.

2.

Support axle assembly with an adjustable lifting

device, and disconnect shock absorber at axle

bracket. Shock absorber on side opposite need not

be disconnected if only one spring is being removed.

Refer to Shock Absorber Removal procedures out-

lined in this section.

3.

Lower axle assembly until suspension reaches end

of travel; then pry lower% pigtail over vertical re-

tainer on axle bracket and remove spring and insula-

tor from vehicle.

Installation

1.

Position rubber insulator on end of spring, making

sure that end of pigtail is butted against stop in

insulator. Install insulator and spring in upper

spring seat so that insulator is properly indexed

against stop (fig. 16).

2.

Pry lower pigtail portion of spring over vertical

flange of the axle bracket spring seat.

3.

Raise axle to allow shock absorber installation.

Position shock absorber in axle bracket. Torque nut

as outlined in Shock Absorber Installation

procedures.

4.

Lower vehicle and check rear riding height.

CHEVROLET CHASSIS SERVICE MANUAL

Page 205 of 659

REAR SUSPENSION AND DRIVE LINE 4-15

ship of parts, then install Spacer J-

7574-

3 over

the partially installed bushing and between the

sides of the control arm.

f. Continue to tighten J-

21058-

8

until bushing is

pulled flush against control arm. Do not exert

undue force against control arm after bushing is

installed. Overtightening of J-21058-

8

will cause

damage to walls of control arm.

g. Disassemble tools and inspect bushing for proper

installation.

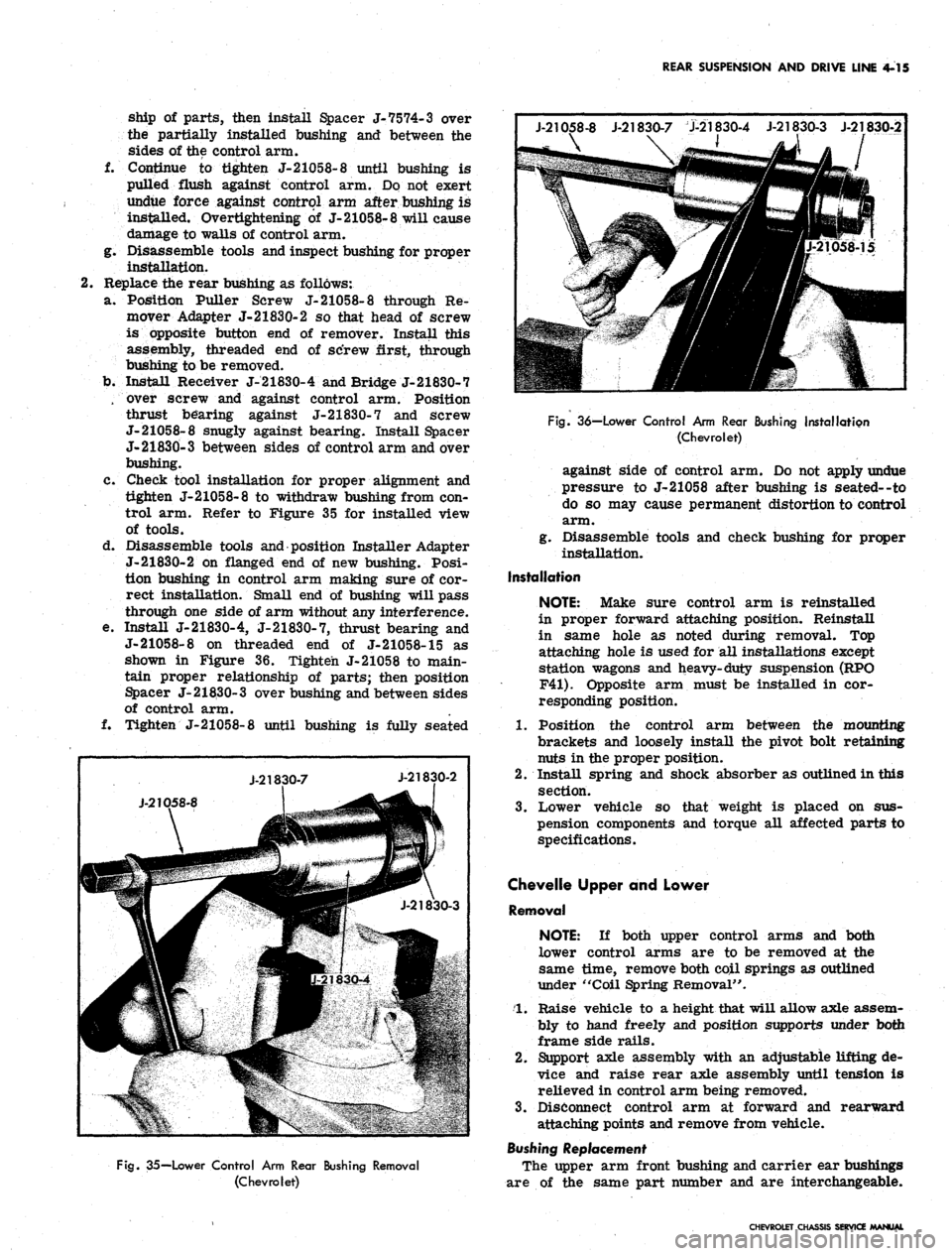

Replace the rear bushing as follows:

a. Position Puller Screw J-21058-8 through Re-

mover Adapter J-21830-2 so that head of screw

is opposite button end of remover. Install this

assembly, threaded end of sc'rew first, through

bushing to be removed.

b.

Install Receiver J-21830-4 and Bridge J-21830-7

. over screw and against control arm. Position

thrust bearing against J-21830-7 and screw

J-21058-8 snugly against bearing. Install Spacer

J-

2183d-

3

between sides of control arm and over

bushing.

c. Check tool installation for proper alignment and

tighten J-21058-8 to withdraw bushing from con-

trol arm. Refer to Figure 35 for installed view

of tools.

d. Disassemble tools and position Installer Adapter

J-21830-2 on flanged end of new bushing. Posi-

tion bushing in control arm making sure of cor-

rect installation. Small end of bushing will pass

through one side of arm without any interference.

e. Install J-21830-4, J-21830-7, thrust bearing and

J-21058-8 on threaded end of J-21058-15 as

shown in Figure 36. Tighten J-21058 to main-

tain proper relationship of parts; then position

Spacer J- 21830- 3 over bushing and between sides

of control arm.

f. Tighten J-21058-8 until bushing is fully seated

J-21058-8 J-21830-7 J-21830-4 J-21830-3 J-21830-2

\

J-2K

X

D58-8

J-218

30-7

IP

•he?

21830-4

J-21830-2

JfSir

J-21830-3

Fig.

35—Lower Control Arm Rear Bushing Removal

(Chevrolet)

Fig.

36—Lower Control Arm Rear Bushing Installation

(Chevrolet)

against side of control arm. Do not apply undue

pressure to J-21058 after bushing is seated--to

do so may cause permanent distortion to control

arm.

g. Disassemble tools and check bushing for proper

installation.

Installation

NOTE:

Make sure control arm is reinstalled

in proper forward attaching position. Reinstall

in same hole as noted during removal. Top

attaching hole is used for all installations except

station wagons and heavy-duty suspension (RPO

F41).

Opposite arm must be installed in cor-

responding position.

1.

Position the control arm between the mounting

brackets and loosely install the pivot bolt retaining

nuts in the proper position.

2.

Install spring and shock absorber as outlined in this

section.

3.

Lower vehicle so that weight is placed on sus-

pension components and torque all affected parts to

specifications.

Chevelle Upper and Lower

Removal

NOTE:

If both upper control arms and both

lower control arms are to be removed at the

same time, remove both coil springs as outlined

under "Coil Spring Removal".

1.

Raise vehicle to a height that will allow axle assem-

bly to hand freely and position supports under both

frame side rails.

2.

Support axle assembly with an adjustable lifting de-

vice and raise rear axle assembly until tension is

relieved in control arm being removed.

3.

Disconnect control arm at forward and rearward

attaching points and remove from vehicle.

Bushing Replacement

The upper arm front bushing and carrier ear bushings

are of the same part number and are interchangeable.

CHEVROLET CHASSIS SERVICE MANUAL

Page 220 of 659

REAR SUSPENSION AND DRIVE LINE 4-30

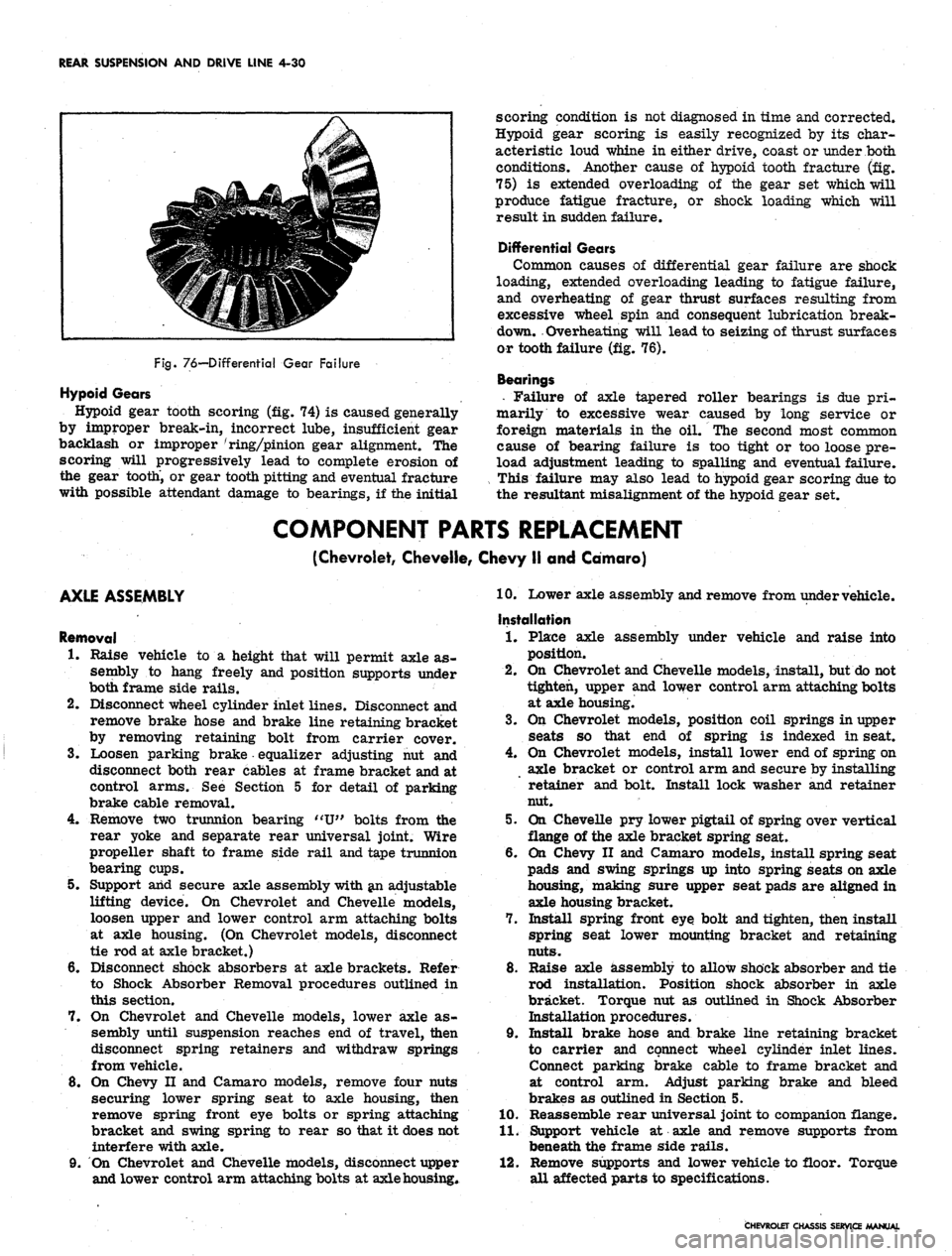

Fig.

76—Differential Gear Failure

Hypoid Gears

Hypoid gear tooth scoring (fig. 74) is caused generally

by improper break-in, incorrect lube, insufficient gear

backlash or improper 'ring/pinion gear alignment. The

scoring will progressively lead to complete erosion of

the gear tooth, or gear tooth pitting and eventual fracture

with possible attendant damage to bearings, if the initial

scoring condition is not diagnosed in time and corrected.

Hypoid gear scoring is easily recognized by its char-

acteristic loud whine in either drive, coast or under both

conditions. Another cause of hypoid tooth fracture (fig.

75) is extended overloading of the gear set which will

produce fatigue fracture, or shock loading which will

result in sudden failure.

Differential Gears

Common causes of differential gear failure are shock

loading, extended overloading leading to fatigue failure,

and overheating of gear thrust surfaces resulting from

excessive wheel spin and consequent lubrication break-

down. Overheating will lead to seizing of thrust surfaces

or tooth failure (fig. 76).

Bearings

• Failure of axle tapered roller bearings is due pri-

marily to excessive wear caused by long service or

foreign materials in the oil. The second most common

cause of bearing failure is too tight or too loose pre-

load adjustment leading to spalling and eventual failure.

This failure may also lead to hypoid gear scoring due to

the resultant misalignment of the hypoid gear set.

COMPONENT PARTS REPLACEMENT

(Chevrolet, Cheveile, Chevy II and Camaro)

AXLE ASSEMBLY

Removal

1.

Raise vehicle to a height that will permit axle as-

sembly to hang freely and position supports under

both frame side rails.

2.

Disconnect wheel cylinder inlet lines. Disconnect and

remove brake hose and brake line retaining bracket

by removing retaining bolt from carrier cover.

3.

Loosen parking brake equalizer adjusting nut and

disconnect both rear cables at frame bracket and at

control arms. See Section 5 for detail of parking

brake cable removal.

4.

Remove two trunnion bearing "U" bolts from the

rear yoke and separate rear universal joint. Wire

propeller shaft to frame side rail and tape trunnion

bearing cups.

5. Support arid secure axle assembly with an adjustable

lifting device. On Chevrolet and Cheveile models,

loosen upper and lower control arm attaching bolts

at axle housing. (On Chevrolet models, disconnect

tie rod at axle bracket.)

6. Disconnect shock absorbers at axle brackets. Refer

to Shock Absorber Removal procedures outlined in

this section.

7. On Chevrolet and Cheveile models, lower axle as-

sembly until suspension reaches end of travel, then

disconnect spring retainers and withdraw springs

from vehicle.

8. On Chevy II and Camaro models, remove four nuts

securing lower spring seat to axle housing, then

remove spring front eye bolts or spring attaching

bracket and swing spring to rear so that it does not

interfere with axle.

9. On Chevrolet and Cheveile models, disconnect upper

and lower control arm attaching bolts at axle housing*

10.

Lower axle assembly and remove from under vehicle.

Installation

1.

Place axle assembly under vehicle and raise into

position.

2.

On Chevrolet and Cheveile models, install, but do not

tighten, upper and lower control arm attaching bolts

at axle housing.

3.

On Chevrolet models, position coil springs in upper

seats so that end of spring is indexed in seat.

4.

On Chevrolet models, install lower end of spring on

axle bracket or control arm and secure by installing

retainer and bolt. Install lock washer and retainer

nut.

5. On Cheveile pry lower pigtail of spring over vertical

flange of the axle bracket spring seat.

6. On Chevy II and Camaro models, install spring seat

pads and swing springs up into spring seats on axle

housing, making sure upper seat pads are aligned in

axle housing bracket.

7. Install spring front eye bolt and tighten, then install

spring seat lower mounting bracket and retaining

nuts.

8. Raise axle assembly to allow shock absorber and tie

rod installation. Position shock absorber in axle

bracket. Torque nut as outlined in Shock Absorber

Installation procedures.

9. Install brake hose and brake line retaining bracket

to carrier and connect wheel cylinder inlet lines.

Connect parking brake cable to frame bracket and

at control arm. Adjust parking brake and bleed

brakes as outlined in Section 5.

10.

Reassemble rear universal joint to companion flange.

11.

Support vehicle at axle and remove supports from

beneath the frame side rails.

12.

Remove supports and lower vehicle to floor. Torque

all affected parts to specifications.

CHEVROLET CHASSIS SERVICE MANUAL

Page 267 of 659

ENGINE 6-2

remotely at the starter, with a special jumper

cable or other means, the primary distributor

lead must be disconnected from the negative

post on the coil and the ignition switch must be

in the "ON" position. Failure to do this will

result in a damaged grounding circuit in the

ignition switch.

3.

Crank engine through at least four compression

strokes to obtain highest possible reading.

4.

Check and record compression of each cylinder.

5.

If one or more cylinders read low tor uneven, inject

about a tablespoon of engine oil on top of pistons

in low reading cylinders (through spark plug

port).

Crank engine several times and recheck

compression.

• If compression comes up but does not necessarily

reach normal, rings are worn.

• If compression does not improve, valves are

burnt, sticking or not seating properly.

• If two adjacent cylinders indicate low compres-

sion and injecting oil does not increase compres-

sion, the cause may be a head gasket leak between

the cylinders. Engine coolant and/or oil in cylin-

ders could result from this defect.

NOTE: If a weak cylinder cannot be located

with the compression check, see "Cylinder Bal-

ance Test" under "Additional Checks and Adjust-

ments" in this section.

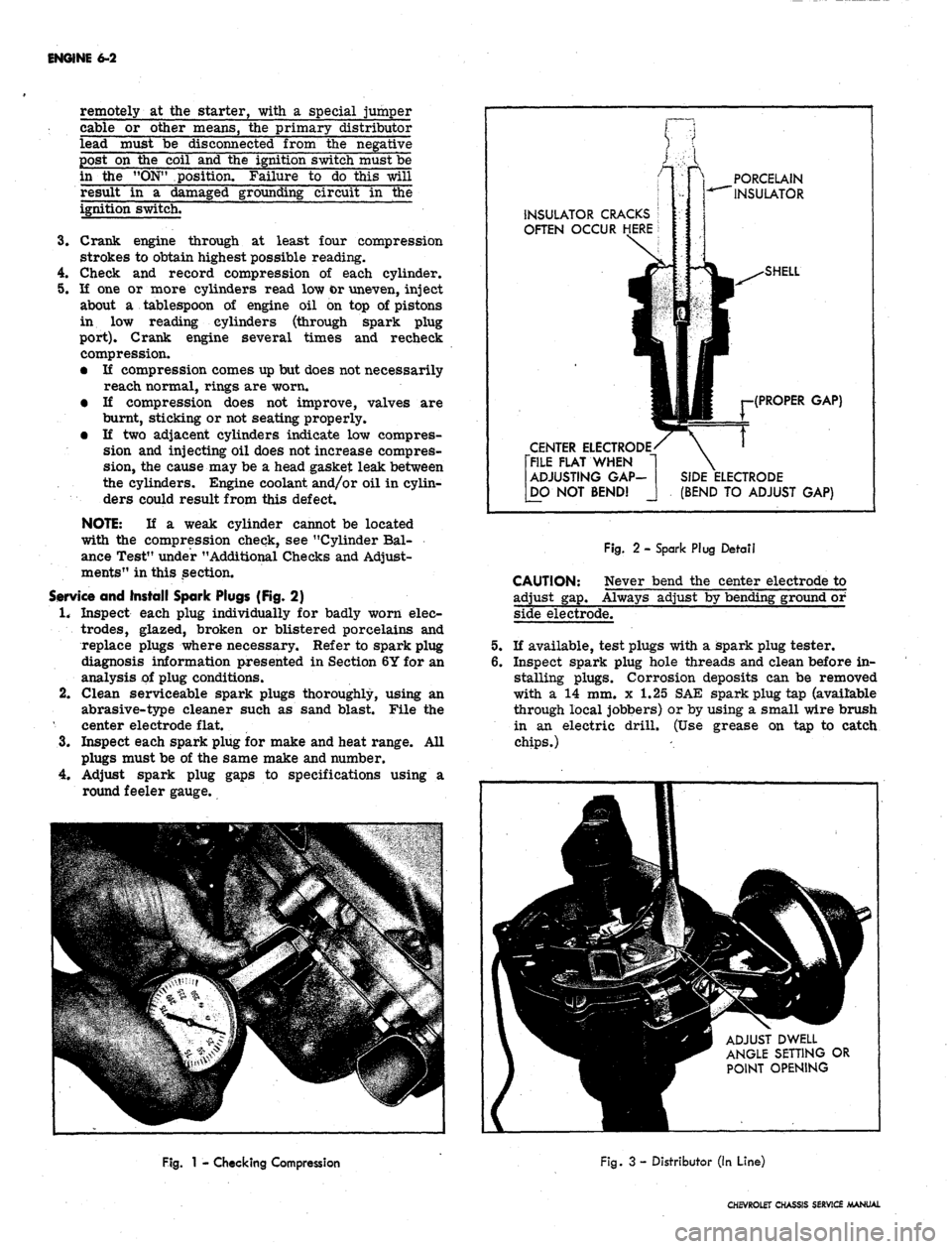

Service and Install Spark Plugs (Fig. 2)

1.

Inspect each plug individually for badly worn elec-

trodes,

glazed, broken or blistered porcelains and

replace plugs where necessary. Refer to spark plug

diagnosis information presented in Section 6Y for an

analysis of plug conditions.

2.

Clean serviceable spark plugs thoroughly, using an

abrasive-type cleaner such as sand blast. File the

center electrode flat.

3.

Inspect each spark plug for make and heat range. All

plugs must be of the same make and number.

4.

Adjust spark plug gaps to specifications using a

round feeler gauge.

PORCELAIN

INSULATOR

INSULATOR CRACKS

OFTEN OCCUR HERE

CENTER ELECTRODE

[FILE FLAT WHEN

ADJUSTING GAP-

[DO NOT BEND!

(PROPER GAP)

(BEND TO ADJUST GAP)

CAUTION:

adjust gap.

Fig.

2 - Spark Plug Detail

Never bend the center electrode to

Always adjust by bending ground or

side electrode.

If available, test plugs with a spark plug tester.

Inspect spark plug hole threads and clean before in-

stalling plugs. Corrosion deposits can be removed

with a 14 mm. x 1.25 SAE spark plug tap (available

through local jobbers) or by using a small wire brush

in an electric drill. (Use grease on tap to catch

chips.)

ADJUST DWELL

ANGLE SETTING OR

POINT OPENING

Fig.

1 - Checking Compression

Fig.

3 - Distributor (In Line)

CHEVROLET CHASSIS SERVICE MANUAL

Page 270 of 659

ENGINE

6-5

Service Battery and Battery Cables

1.

Measure the specific gravity of the electrolyte in

each cell (fig. 6). If it is below 1.230 (corrected to

80°F.) recharge with a slow rate charger, or if de-

sired, further check battery.

2.

Connect a voltmeter across the battery terminals and

measure the terminal voltage of the battery during

cranking (disconnect the coil primary lead at the

negative terminal during this check to prevent engine

from firing). If the terminal voltage is less than 9.0

volts at room temperature, approximately 80°

±

20°

F.,

the battery should be further checked. See

Section 6Y for further tests.

3.

Inspect for signs of corrosion on battery, cables and

surrounding area, loose or broken carriers, cracked

or bulged cases,- dirt and acid, electrolyte leakage

and low electrolyte level. !Fill cells to proper level

with distilled water or water passed through a

"demineralizer".

The top of the battery should be clean and the bat-

tery hold-down bolts properly tightened. Particular

care should be taken to see that the top of the battery

is kept clean of acid film and dirt. When cleaning

batteries, wash first with a dilute ammonia or soda

solution to neutralize any acid present and then flush

off with clean water. Keep vent plugs tight so that

the neutralizing solution does not enter the cell. The

hold-down bolts should be kept tight enough to prevent

the battery from shaking around in its holder, but

they should not be tightened to the point where the

battery case will be placed under a severe strain.

To insure good contact, the battery cables should

be tight on the battery posts. Oil battery terminal

felt washer. If the battery posts or cable terminals

are corroded, the cables should be cleaned separately

with a soda solution and wire brush. After cleaning

and before installing clamps, apply a thin coating of

petrolatum to the posts and cable clamps to help

retard corrosion.

If the battery has remained undercharged, check

for loose or defective fan belt, defective Delcotron,

high resistance in the charging circuit, oxidized

regulator contact points, or a low voltage setting.

If the battery has been using too much water, the

voltage output

is-

too high.

Service Deicotron and Regulator

The Delcotron and regulator tests during tune up con-

sist of the above battery tests; the condition of the battery

indicating further tests and adjustments as outlined in

Section 6Y.

Service Belts (Fig. 7)

Inspect belt condition.

Check and adjust if necessary for correct tension of

belt, as follows:

• Using a strand tension gauge, check the belt tension.

• Adjust belt until the specified tension is reached.

(See Tune Up Chart.)

Service Manifold Heat Valve (Figs. 8 or 9)

Check manifold heat control valve for freedom of oper-

ation. If shaft is sticking, free it up with GM Manifold

Heat Control Solvent or its equivalent.

NOTE: Tap shaft end to end to help free it up.

Tighten Manifold

Tighten intake manifold bolts to specifications in the

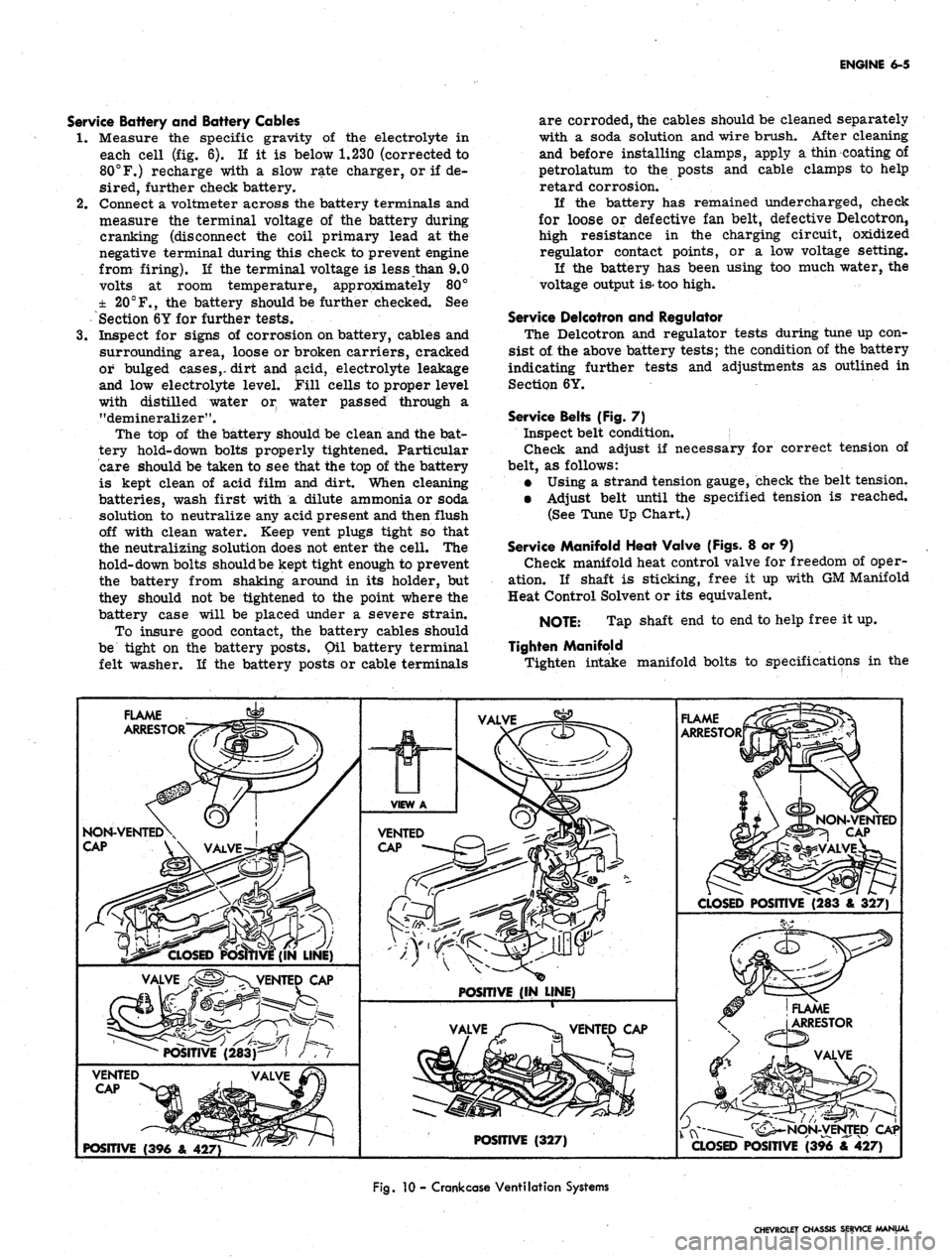

FLAME

ARRESTOR

FLAME

ARRESTOR

NON-VENTED\

CAP

V\ VALVE

CLOSED

POSITIVE (283 & 327)

POSITIVE

(IN LINE)

POSITIVE

(327)

POSITIVE

(396 & 427)

Fig.

10 -

Crank case

Ventilation Systems

CHEVROLET CHASSIS SERVICE MANUAL

Page 273 of 659

ENGINE

6-8

Check

and

Adjust Ignition Timing

(Fig. 13)

1.

Disconnect

the

distributor spark advance hose

and

plug

the

vacuum source opening.

2.

Start engine

and run at

idle speed

(see

tune

up

chart).

3.

Aim

timing light

at

timing

tab.

NOTE:

- The

markings

on the

tabs

are in 2°

increments

(the

greatest number

of

markings

on

the

"A"

side

of the "O"). the "O"

markings

is

TDC

of

#1 cylinder

and all

BTDC settings fall

on

the

"A"

(advance) side

of "O".

4.

Adjust

the

timing

by

loosening

the

distributor clamp

and

,

rotating

the

distributor body

as

required, then

tighten

the

clamp.

5.

Stop engine

and

remove timing light

and

reconnect

the spark advance hose.

Adjust Idle Speed

and

Mixture

(Fig. 14)

(Except when

equipped with

Air

Injection Reactor System)

1.

As a

preliminary adjustment, turn idle mixture

screws lightly

to

seat

and

back

out 2

turns.

CAUTION:

Do not

turn idle mixture screw

tightly against seat

or

damage

may

result.

2.

With engine running

at

operating temperature (choke

wide open) adjust idle speed screw

to

bring idle

speed

to

specified

rpm

(automatic transmission

in

drive, manual transmission

in

neutral).

3.

Adjust idle mixture screw

to

obtain highest steady

idle speed

(1/4

turn

out

from lean roll).

4.

Repeat Steps

2 and 3 as

needed

for

final adjustment.

5.

Shut down

the

engine, remove gauges

and

install

air

cleaner.

Adjust Idle Speed

and

Mixture

(Fig. 14)

(With

Air

Injection Reactor System)

The recommended adjustment procedure

for Air

Injec-

tion Reactor System equipped engines

is as

follows:

1.

As a

preliminary adjustment, turn idle mixture

screws lightly

to

seat

and

than back

out 3

turns.

CAUTION:

Do not

turn idle mixture screw

tightly against seat

or

damage

may

result.

2.

With engine running

at

operating temperature, choke

wide open,

and

parking brake applied, adjust idle

specified idle speed (automatic

"drive"-manual transmission

in

to

in

screw

transmission

"neutral").

;3.

Adjust idle mixture screw (turn

in) to

"lean roll"

position; then turn screw

out 1/4

turn

(1/4

turn rich

from "lean roll").

The

definition

of

"lean roll" point

is

a 20 to 30 rpm

drop

in

engine speed, obtained

by

leaning

the

idle mixture.

4.

Repeat Steps

2 and 3 as

needed

for

final adjustments.

ADDITIONAL CHECKS

AND

ADJUSTMENTS

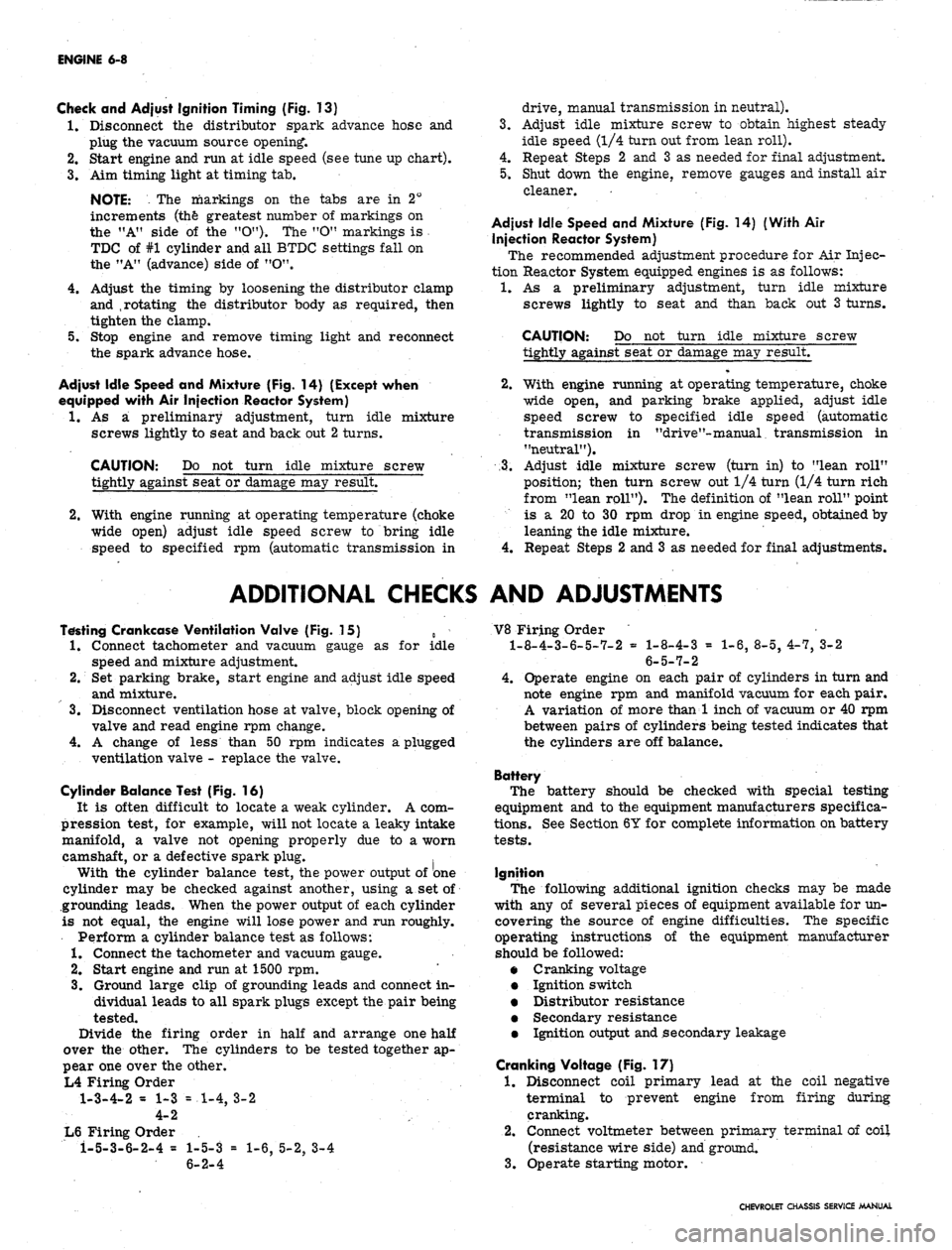

Testing Crankcase Ventilation Valve

(Fig. 15) 0

1.

Connect tachometer

and

vacuum gauge

as for

idle

speed

and

mixture adjustment.

2.

Set

parking brake, start engine

and

adjust idle speed

and mixture.

3.

Disconnect ventilation hose

at

valve, block opening

of

valve

and

read engine

rpm

change.

4.

A

change

of

less than

50 rpm

indicates

a

plugged

ventilation valve

-

replace

the

valve.

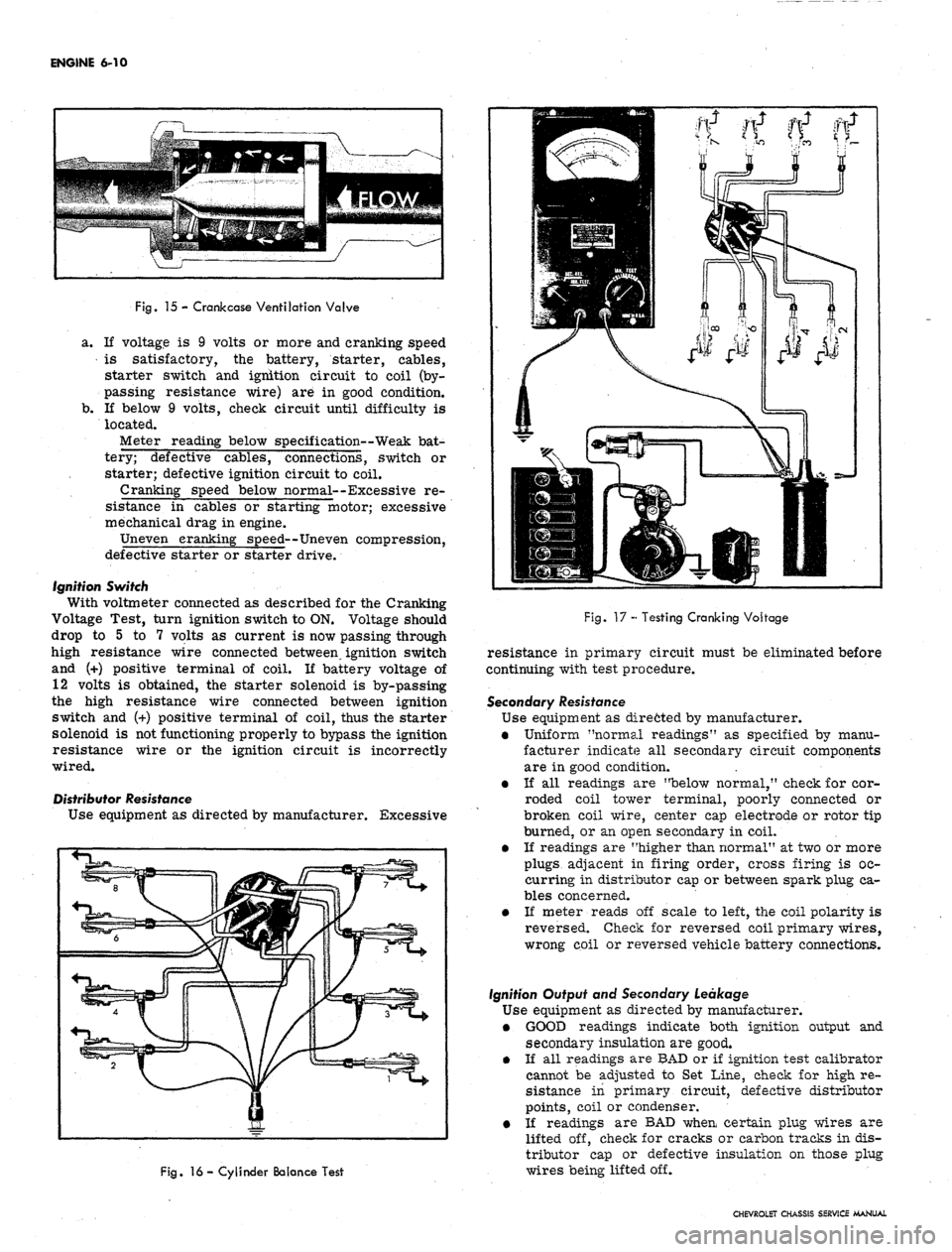

Cylinder Balance Test

(Fig. 16)

It

is

often difficult

to

locate

a

weak cylinder.

A com-

pression test,

for

example, will

not

locate

a

leaky intake

manifold,

a

valve

not

opening properly

due to a

worn

camshaft,

or a

defective spark plug.

With

the

cylinder balance test,

the

power output

of one

cylinder

may be

checked against another, using

a set of

grounding leads. When

the

power output

of

each cylinder

is

not

equal,

the

engine will lose power

and run

roughly.

Perform

a

cylinder balance test

as

follows:

1.

Connect

the

tachometer

and

vacuum gauge.

2.

Start engine

and run at 1500 rpm.

3.

Ground large clip

of

grounding leads

and

connect

in-

dividual leads

to all

spark plugs except

the

pair being

tested.

Divide

the

firing order

in

half

and

arrange

one

half

over

the

other.

The

cylinders

to be

tested together

ap-

pear

one

over

the

other.

L4 Firing Order

V8 Firing Order

1-8-4-3-6-5-7-2

1-6, 8-5, 4-7, 3-2

1-3-4-2

= 1-3

4-2

L6 Firing Order

1-5-3-6-2-4

=

=

1-4. 3-2

1-5-3

6-2-4

1-6, 5-2, 3-4

1-8-4-3

6-5-7-2

4.

Operate engine

on

each pair

of

cylinders

in

turn

and

note engine

rpm and

manifold vacuum

for

each pair.

A variation

of

more than

1

inch

of

vacuum

or 40 rpm

between pairs

of

cylinders being tested indicates that

the cylinders

are off

balance.

Battery

The battery should

be

checked with special testing

equipment

and to the

equipment manufacturers specifica-

tions.

See

Section 6Y

for

complete information

on

battery

tests.

Ignition

The following additional ignition checks

may be

made

with

any of

several pieces

of

equipment available

for un-

covering

the

source

of

engine difficulties.

The

specific

operating instructions

of the

equipment manufacturer

should

be

followed:

Cranking voltage

Ignition switch

Distributor resistance

Secondary resistance

Ignition output

and

secondary leakage

Cranking Voltage

(Fig. 17)

1.

Disconnect coil primary lead

at the

coil negative

terminal

to

prevent engine from firing during

cranking.

2.

Connect voltmeter between primary terminal

of coi|

(resistance wire side)

and

ground.

3.

Operate starting motor.

CHEVROLET CHASSIS SERVICE MANUAL

Page 275 of 659

ENGINE 6-10

Fig.

15 - Crank case Ventilation Valve

a. If voltage is 9 volts or more and cranking speed

is satisfactory, the battery, starter, cables,

starter switch and ignition circuit to coil (by-

passing resistance wire) are in good condition.

b.

If below 9 volts, check circuit until difficulty is

located.

Meter reading below specification—Weak bat-

tery; defective cables, connections, switch or

starter; defective ignition circuit to coil.

Cranking speed below normal--Excessive re-

sistance in cables or starting motor; excessive

mechanical drag in engine.

Uneven cranking speed—Uneven compression,

defective starter or starter drive.

Ignition Switch

With voltmeter connected as described for the Cranking

Voltage Test, turn ignition switch to ON. Voltage should

drop to 5 to 7 volts as current is now passing through

high resistance wire connected between ignition switch

and (+) positive terminal of coil. If battery voltage of

12 volts is obtained, the starter solenoid is by-passing

the high resistance wire connected between ignition

switch and (+) positive terminal of coil, thus the starter

solenoid is not functioning properly to bypass the ignition

resistance wire or the ignition circuit is incorrectly

wired.

Distributor Resistance

Use equipment as directed by manufacturer.

Excessive

(t n ti ft

Fig.

16 - Cylinder Balance Test

Fig.

17 - Testing Cranking Voltage

resistance in primary circuit must be eliminated before

continuing with test procedure.

Secondary Resistance

Use equipment as dire6ted by manufacturer.

• Uniform "normal readings" as specified by manu-

facturer indicate all secondary circuit components

are in good condition.

• If all readings are "below normal," check for cor-

roded coil tower terminal, poorly connected or

broken coil wire, center cap electrode or rotor tip

burned, or an open secondary in coil.

• If readings are "higher than normal" at two or more

plugs adjacent in firing order, cross firing is oc-

curring in distributor cap or between spark plug ca-

bles concerned.

• If meter reads off scale to left, the coil polarity is

reversed. Check for reversed coil primary wires,

wrong coil or reversed vehicle battery connections.

Ignition Output and Secondary Leakage

Use equipment as directed by manufacturer.

• GOOD readings indicate both ignition output and

secondary insulation are good.

• If all readings are BAD or if ignition test calibrator

cannot be adjusted to Set Line, check for high re-

sistance in primary circuit, defective distributor

points, coil or condenser.

e If readings are BAD when certain plug wires are

lifted off, check for cracks or carbon tracks in dis-

tributor cap or defective insulation on those plug

wires being lifted off.

CHEVROLET CHASSIS SERVICE MANUAL

Page 277 of 659

ENGINE

6-12

ENGINE

MECHANICAL

IN LINE

INDEX

Page

General Description . „ 6-12

Component Replacement and Adjustment 6-12

.Engine Assembly 6-12

Removal 6-12

Installation 6-13

Manifold Assembly 6-14

Removal . 6-14

Installation 6-14

Rocker Arm Cover . 6-14

Removal 6-14

mstallation . . . 6-14

Valve Mechanism

......

1 6-14

Removal 6-14

Installation and Adjustment . 6-14

Valve Lifters

..............

6-15

Locating Noisy Lifters

„.;....

6-15

Removal

.'.*...•

6-15

Installation . 6-15

Valve Stem Oil Seal and/or Valve Spring . 6-16

Replacement . 6-16

Cylinder Head Assembly . 6-16

Removal 6-16

Installation . 6-16

Oil Pan . » 6-17

Removal . . . ; . . 6-17

Installation

.........

. 6-17

Oil Pump . 6-18

Page

Removal . 6-18

Installation . 6-18

Oil Seal (Rear Main) . 6-19

Replacement 6-19

Crankshaft Pulley and Hub 6-19

Removal 6-19

Installation 6-19

Torsional Damper 6-19

Removal 6-19

Installation 6-19

Crankcase Front Cover . 6-20

Removal . 6-20

Installation 6-20

•

Oil Seal (Front Cover) 6-20

Replacement 6-20

Camshaft 6-21

Measuring Lobe Lift . ... .

.-.••.-.

6-21

Removal 6-21

Installation 6-22

Timing Gears

..••••.............••• 6—22

Replacement

6-22

Flywheel

6-22

Removal

* 6-22

Installation

6-22

Engine

Mounts

6-23

Replacement

(Front)

6-23

Replacement

(Rear)

. 6-23

GENERAL DESCRIPTION

The

In

Line engines

(fig. 1L)

covered

in

this section

are

the 1H3 cu. in. L4, the 194,

230

and

250

cu. in. L6,

regardless

of

which passenger vehicle they

are

used

in.

This section covers

the

removal

and

installation

of en-

gine assemblies;

the

removal, installation

and

adjustment

of some sub-assemblies

and

replacement

of

some

com-

ponents.

For

service

to all

components

and

sub-assem-

blies (after removal)

and

removal

of

some sub-assem-

blies,

refer

to

Section

6 of the

Chassis Overhaul Manual.

Because

of the

interchangeability

and

similarity

of

many engine sub-assemblies

and

engine parts, regardless

of which passenger vehicle they

are

used

in,

typical illus-

trations

and

procedures

are

used except where specific

illustrations

or

procedures

are

necessary

to

clarify

the

operation. Although illustrations showing bench opera-

tions

are

used, most single operations, when

not

part

of a

general overhaul, should

be

performed

(if

practical) with

the engine

in the

vehicle.

COMPONENT REPLACEMENT

AND

ADJUSTMENT

ENGINE ASSEMBLY

Removal

1.

Drain cooling system

and

engine

oil.

2.

Remove

air

cleaner

and

disconnect battery cables

at 7.

battery.

3.

Remove hood

as

outlined

in

Section 11.

4.

Remove radiator

and

radiator shroud

as

outlined

in

Section 13.

5.

Remove

fan

blade

and

pulley

as

outlined

in

Section

6K.

6. Disconnect wires

at:

• Starter Solenoid

8.

• Delcotron

9.

Temperature Switch

Oil Pressure Switch

Coil

Disconnect:

Accelerator linkage

at

manifold bellerank.

Exhaust pipe

at

manifold flange.

.

Fuel line (from tank)

at

fuel pump.

Vacuum line

to

power brake unit

at

manifold

(if

so equipped).

• Power steering pump lines

at

pump

end (if so

equipped).

Raise vehicle

and

place

on

jack stands.

Remove propeller shaft.

CHEVROLET CHASSIS SERVICE MANUAL

Page 279 of 659

ENGINE 6-14

b.

Bolt transmission to engine, then raise engine and

transmission assembly and install flywheel to

converter attaching bolts.

c. Install converter

housing*

underpan and starter.

3.

Tilt and lower engine and transmission assembly into

the chassis as a unit, guiding engine to align front

mounts with frame supports.

4.

Install front mount through bolts and torque to

specifications.

5.

Raise engine enough to install rear crossmember,

then install crossmember, install rear mount, lower

engine and torque bolts to specifications.

6. Remove lifting device and lifting adapter then install

rocker arm cover as outlined.

7.

On synchromesh equipped vehicles, install clutch

cross shaft engine bracket, then adjust and connect

clutch as outlined in Section 7.

8. Connect:

• Speedometer cable.

• Shift linkage at transmission.

9; Install propeller shaft.

10.

Remove jack stands and lower vehicle.

11.

Connect:

Power steering pump lines (if disconnected).

Vacuum line to power brake unit (if disconnected).

Fuel line at fuel pump.

Exhaust pipe at manifold flange.

Accelerator linkage at manifold bellcrank.

12.

Connect wires at:

Coil

Oil pressure switch

Temperature switch

Delcotron

Starter solenoid

13.

Install pulley, fan blade and fan belt as outlined in

Section 6K.

14.

Install radiator and shroud as outlined in Section 13.

15.

Install and adjust hood as outlined in Section 11.

16.

Connect battery cables.

17.

Fill with coolant, engine oil and transmission oil,

then start engine and check for leaks.

18.

Perform necessary adjustments and install air

cleaner.

MANIFOLD ASSEMBLY

Removal

1.

Remove air cleaner.

2.

Disconnect both throttle rods at bellcrank and re-

move throttle return spring.

3.

Disconnect fuel and vacuum lines at carburetor.

Disconnect choke cable on \A engines.

4.

Disconnect crankcase ventilation hose at rocker arm

cover.

5.

Disconnect exhaust pipe at manifold flange and dis-

card packing.

6. Remove manifold attaching bolts and clamps then

remove manifold assembly and discard gaskets.

7.

Check for cracks in manifold castings.

8. If necessary to replace either intake or exhaust

manifolds, separate them by removing one bolt and

two nuts at center of assembly. Reassemble mani-

folds using a new gasket. Tighten finger tight and

torque to specifications after assembly to cylinder

head. Transfer all necessary parts.

Installation

1.

Clean gasket surfaces on cylinder head and

manifolds*

2.

Position new gasket over manifold end studs on head

and carefully install the manifold in position making

sure the gaskets are in place.

3.

Install bolts and clamps while holding manifold in

place with hand.

4.

Torque bolts to specifications.

NOTE: On L6 engines center bolt and end bolt

torque differ.

5.

Connect exhaust pipe to manifold using a new

packing.

6. Connect crankcase ventilation hose at rocker arm

cover.

7.

Connect fuel and vacuum lines at carburetor.

8. On L4 engines connect choke cable and adjust as out-

lines in Section 6M.

9. Connect throttle rods at bellcrank and install throttle

return spring.

10.

Install air cleaner, start engine, check for leaks and

adjust carburetor idle speed and mixture.

ROCKER ARM COVER

Removal

1.

Disconnect crankcase ventilation hose(s) at rocker

arm cover.

2.

Remove air cleaner.

3.

Disconnect temperature wire from rocker arm cover

clips.

4.

Remove rocker arm cover. '

CAUTION: Do Not pry rocker arm cover loose

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand or

a rubber mallet.

Installation

1.

Clean gasket surfaces on cylinder head and rocker

arm cover with degreaser then, using anew gasket,

install rocker arm cover and torque bolts to

specifications.

2.

Connect temperature wire at rocker arm cover clips.

3.

Install air cleaner.

4.

Connect crankcase ventilation hoses.

VALVE MECHANISM

Removal

1.

Remove rocker arm cover as outlined.

2.

Remove rocker arm nuts, rocker arm

balls,

rocker

arms and push rods.

NOTE:

Place rocker arms, rocker arm balls

and push rods in a rack so they may be rein-

stalled in the same location.

Installation and Adjustment

NOTE:

Whenever new rocker arms and/or

rocker arm balls are being installed, coat bear-

ing surfaces of rocker arms and rocker arm

balls with Molykote or its equivalent.

1.

Install push rods,

socket.

Be sure push rods seat in lifter

CHEVROLET CHASSIS SERVICE MANUAL