CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 401 of 659

CLUTCH AND TRANSMISSIONS 7-42

c. Converter

—•

leak in weld.

d. Pump tfO" ring seal — damaged. (Also check

pump groove and case bore.)

e. Porous casting (pump or case).

5. OIL COMES OUT VENT PIPE

a. Transmission over-filled.

b.

Water in oil.

c. Pump to case gasket mispositioned.

d. Foreign material between pump and case, or be-

tween pump cover and body.

e. Case — porous, pump face improperly machined.

f. Pump — shy of stock on mounting faces, porous

casting.

CASE POROSITY-REPAIR

Transmission leaks caused by aluminum case porosity

have been successfully repaired with the transmission in

the vehicle by using the following procedure.

1.

Road test and bring the transmission to operating

temperature.

2.

Raise the car and, with the engine running, locate the

source of the oil leak. Check for leaks in all operat-

ing positions.

NOTE:

The use of a mirror will be helpful in

finding leaks.

3.

Shut off engine and thoroughly clean area with a sol-

vent and air dry.

4.

Using the instruction of the manufacturer, mix a suf-

ficient amount of epoxy cement, part #1360016, to

make the repair.

5. While the transmission is still hot, apply the epoxy

to the area, making certain that the area is fully

covered.

6. Allow epoxy cement to dry for three hours and re-

test for leaks, as outlined in Steps 1 and 2.

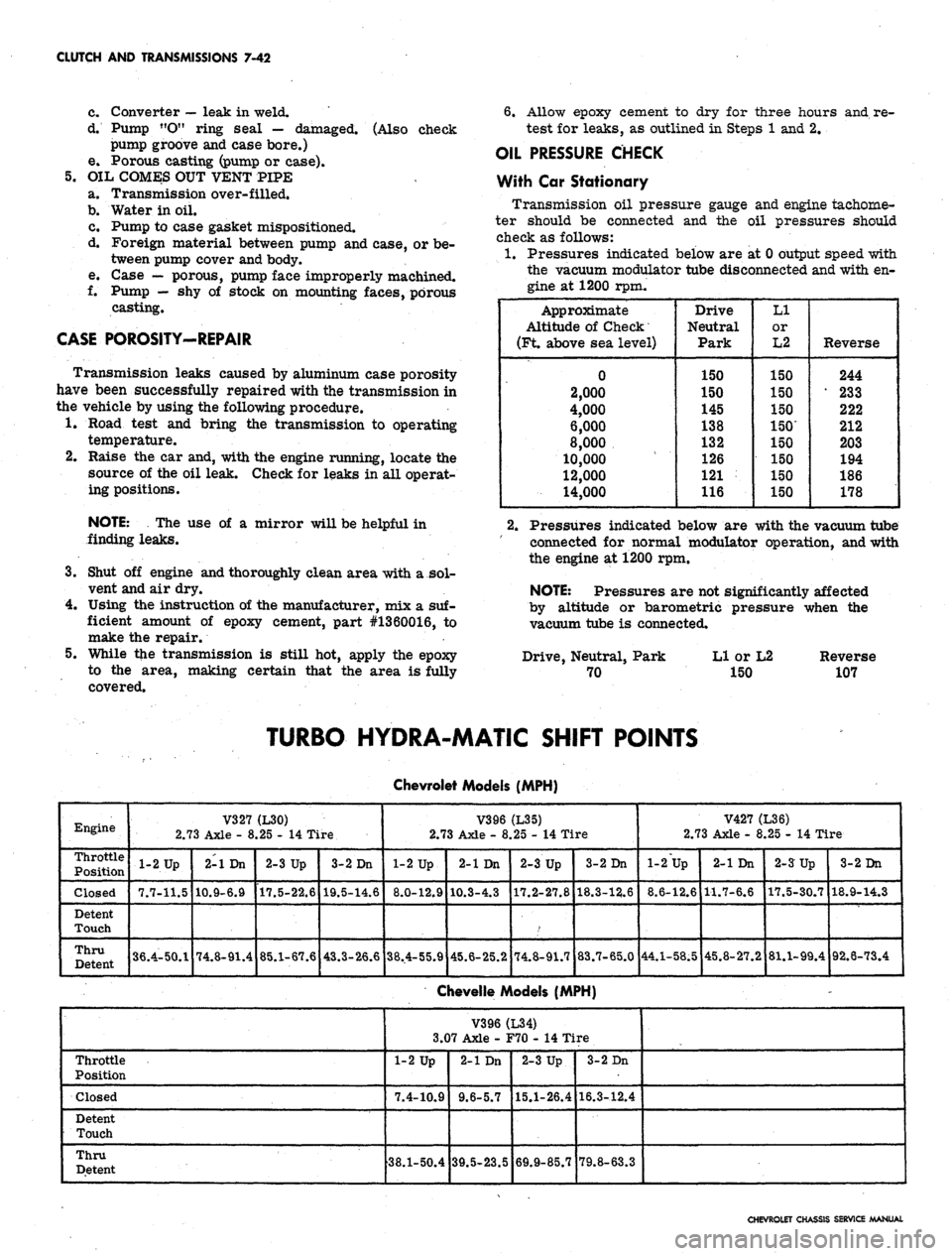

OIL PRESSURE CHECK

With Car Stationary

Transmission oil pressure gauge and engine tachome-

ter should be connected and the oil pressures should

check as follows:

1.

Pressures indicated below are at 0 output speed with

the vacuum modulator tube disconnected and with en-

gine at 1200 rpm.

Approximate

Altitude of Check

(Ft. above sea level)

0

2,000

4,000

6,000

8,000

10,000

12,000

14,000

Drive

Neutral

Park

150

150

145

138

132

126

121

116

LI

or

L2

150

150

150

150'

150

150

150

150

Reverse

244

233

222

212

203

194

186

178

2.

Pressures indicated below are with the vacuum tube

connected for normal modulator operation, and with

the engine at 1200 rpm.

NOTE:

Pressures are not significantly affected

by altitude or barometric pressure when the

vacuum tube is connected.

Drive, Neutral, Park Ll or L2 Reverse

70 150 107

TURBO HYDRA-MATIC SHIFT POINTS

Engine

Throttle

Position

Closed

Detent

Touch

Thru

Detent

V327 (L30)

2.73 Axle - 8.25 - 14 Tire

•1-2 Up

7.7-11.5

36.4-50.1

2-1 Dn

10.9-6.9

74.8-91.4

2-3 Up

17.5-22.6

85.1-67.6

3-2 Dn

19.5-14.6

43.3-26.6

Chevrolet Models

(MPH)

V396 (L35)

2.73 Axle - 8.25 - 14 Tire

1-2 Up

8.0-12.9

38.4-55.9

2-1 Dn

10.3-4.3

45.6-25.2

2-3 Up

17.2-27.8

/

74.8-91.7

3-2 Dn

18.3-12.6

83.7-65.0

V427 (L36)

2.73 Axle - 8.25 - 14 Tire

1-2 Up

8.6-12,6

44.1-58.5

2-1 Dn

1-1.7-6.6

45.8-27.2

2-3 Up

17.5-30.7

81.1-99.4

3-2 Dn

18.9-14.3

92.6-73.4

Chevelle Models (MPH)

Throttle

Position

Closed

Detent

Touch

Thru

Detent

V396(L34)

3.07 Axle - F70 - 14 Tire

1-2 Up

7.4-10.9

38.1-50.4

2-1 Dn

9.6-5.7

39.5-23.5

2-3 Up

15.1-26.4

69.9-85.7

3-2 Dn

16.3-12.4

79.8-63.3

CHEVROLET CHASSIS SERVICE MANUAL

Page 402 of 659

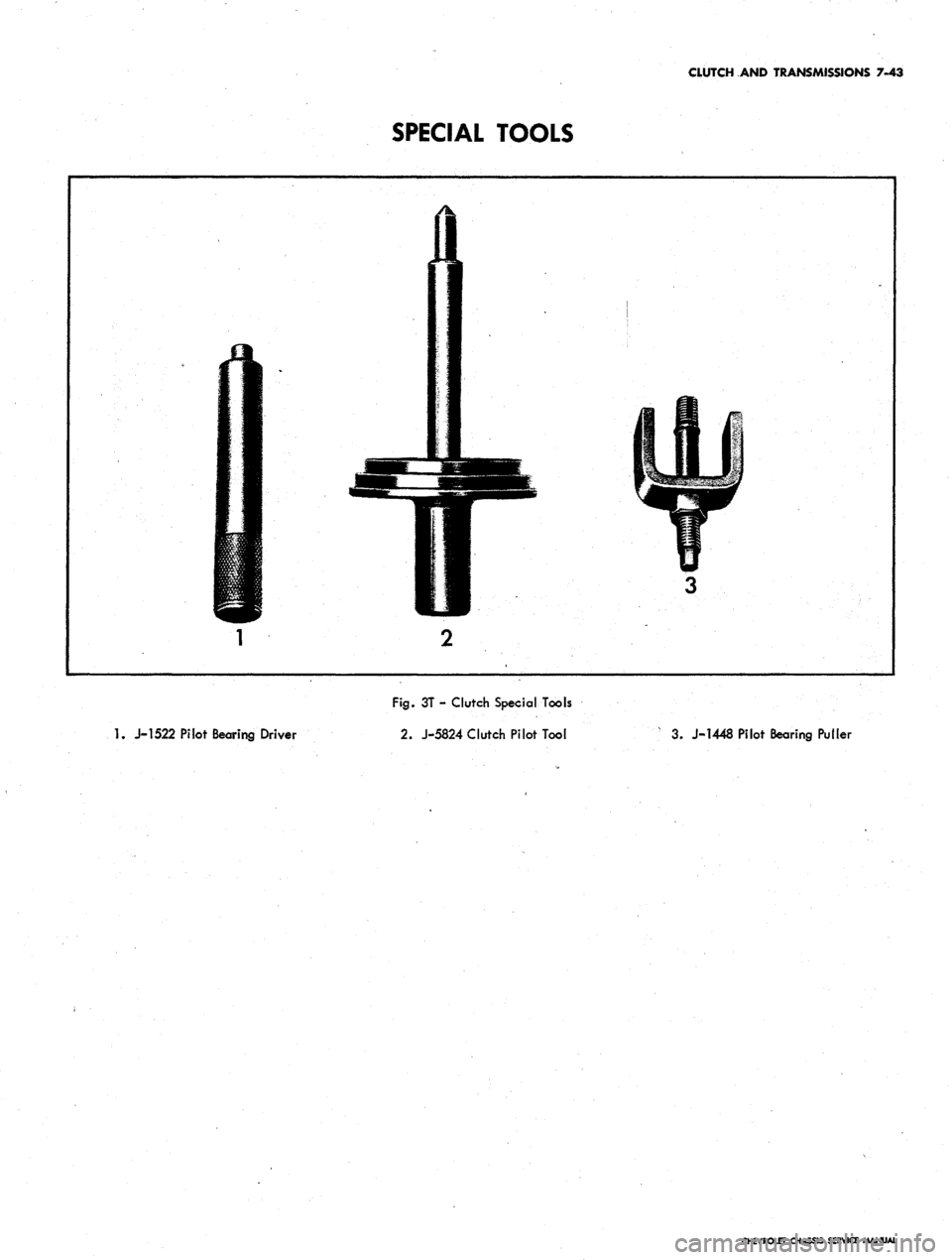

CLUTCH AND TRANSMISSIONS 7-43

SPECIAL TOOLS

1.

J-1522 Pilot Bearing Driver

Fig.

3T - Clutch Special Tools

2.

J-5824 Clutch Pilot Tool

3. J-1448 Pilot Bearing Puller

CHEVROLET CHASSIS SERVICE MANUAL

Page 403 of 659

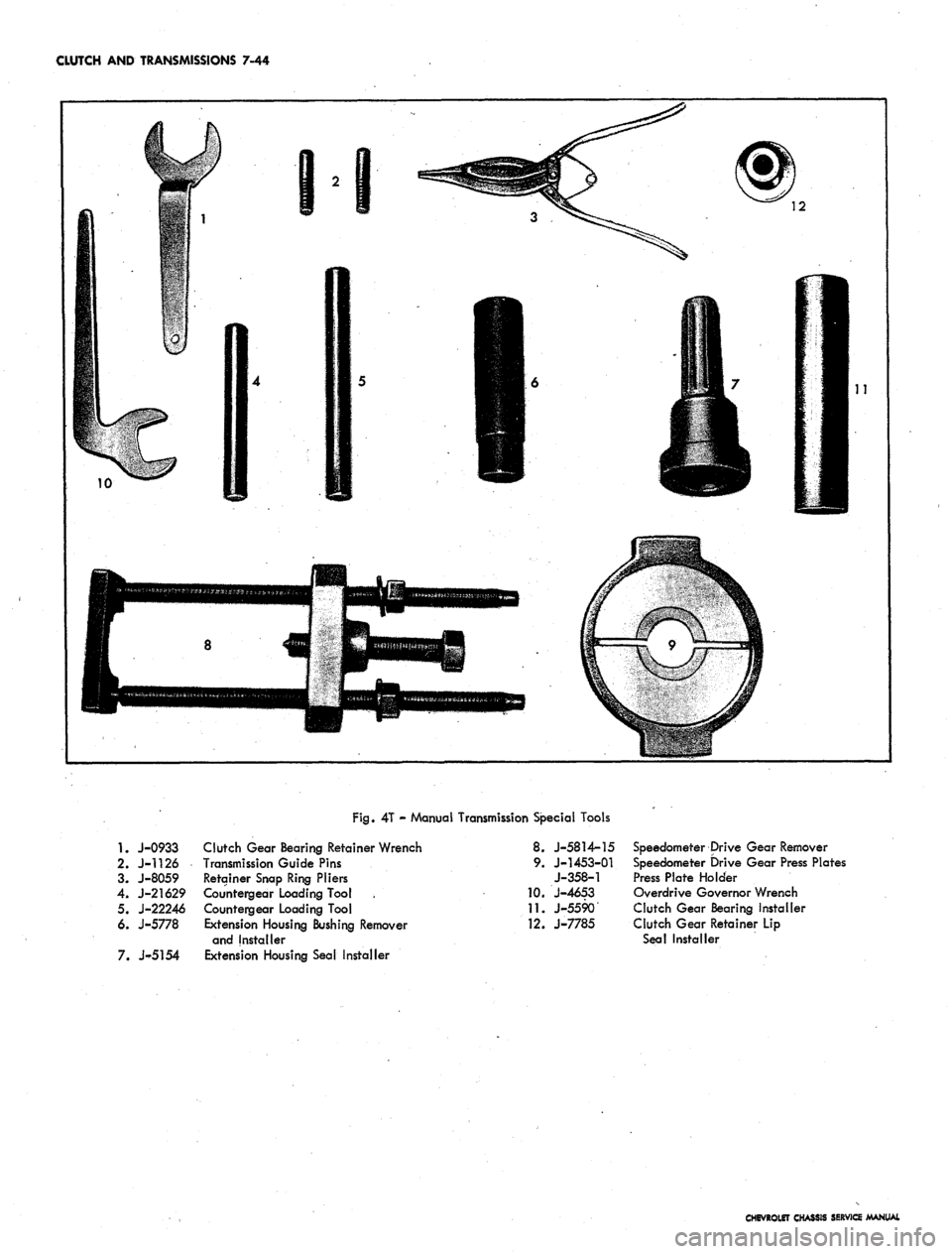

CLUTCH AND TRANSMISSIONS 7-44

Fig.

4T - Manual Transmission Special Tools

1.

J-0933 Clutch Gear Bearing Retainer Wrench

2.

J-1126 Transmission Guide Pins

3. J-8059 Retainer Snap Ring Pliers

4.

J-21629 Countergear Loading Tool

5. J-22246 Countergear Loading Tool

6. J-5778 Extension Housing Bushing Remover

and Installer

7. J-5154 Extension Housing Seal Installer

8. J-5814-15

9. J-1453-01

J-358-1

10.

J-4653

11.

J-5590

12.

J-7785

Speedometer Drive Gear Remover

Speedometer Drive Gear Press Plates

Press Plate Holder

Overdrive Governor Wrench

Clutch Gear Bearing Installer

Clutch Gear Retainer Lip

Seal Installer

CHEVROLET CHASSIS SERVICE MANUAL

Page 404 of 659

CLUTCH AND TRANSMISSIONS 7-45

23

Fig.

5T - Aluminum Powerglide Special Tools

1. J-9506

2.

J-3289-01

3.

J-9549

4.

J-21867

5.

J-4264

6. J-3387

7.

J-9539

8. J-6839

9. J-9546

10.

J-7782

11.

J-5133

12.

J-4599

13.

J-9542

14.

J-9557

Holding Fixture Adapters

Holding Fixture (Use with J-3289-20 Base)

Converter Safety Strap

Transmission Pressure Gauge and Hose

Oil Filler Tube and Funnel

Pilot Stud Set

Front Pump Puller Bolts (Use with weights

from Slide Hammers J-6585)

Front Pump Seal Driver

Clutch Drum Bushing Remover and Installer

Clutch Spring Compressor Adapter Plate

Clutch Spring Compressor

Planet Pinion Assembly Tool Set

Reverse Piston Spring Compressor

Transmission Case Rear Bushing Remover and

Installer and Rear Pump Bushing Remover

15.

J-7079

16.

J-6582

17.

J-9543

18.

J-5778

19.

J-5154

20.

J-5403

21.

J-5814

22.

J-5853

23.

J-8039

24.

J-21848

J-8001

J-5492

J-6585

J-6585-3

J-9534

Handle

Rear Pump Bushing Installer

Vacuum

Modu

lator Wrench

Extension Bushing Remover and Installer

Extension Oil Seal Installer

Snap Ring Pliers

Speedometer Drive Gear Remover and

Installer

Torque Wrench

Snap Ring Pliers

Low Band Adjusting Tool

Dial Indicator (Not Illustrated)

Dial Indicator Support Strap (Not Illustrated)

Slide Hammers (Not Illustrated)

Slide Hammer Adapters (Not Illustrated)

Bushing Remover (Not Illustrated)

CHEVROLET CHASSIS SERVICE MANUAL

Page 405 of 659

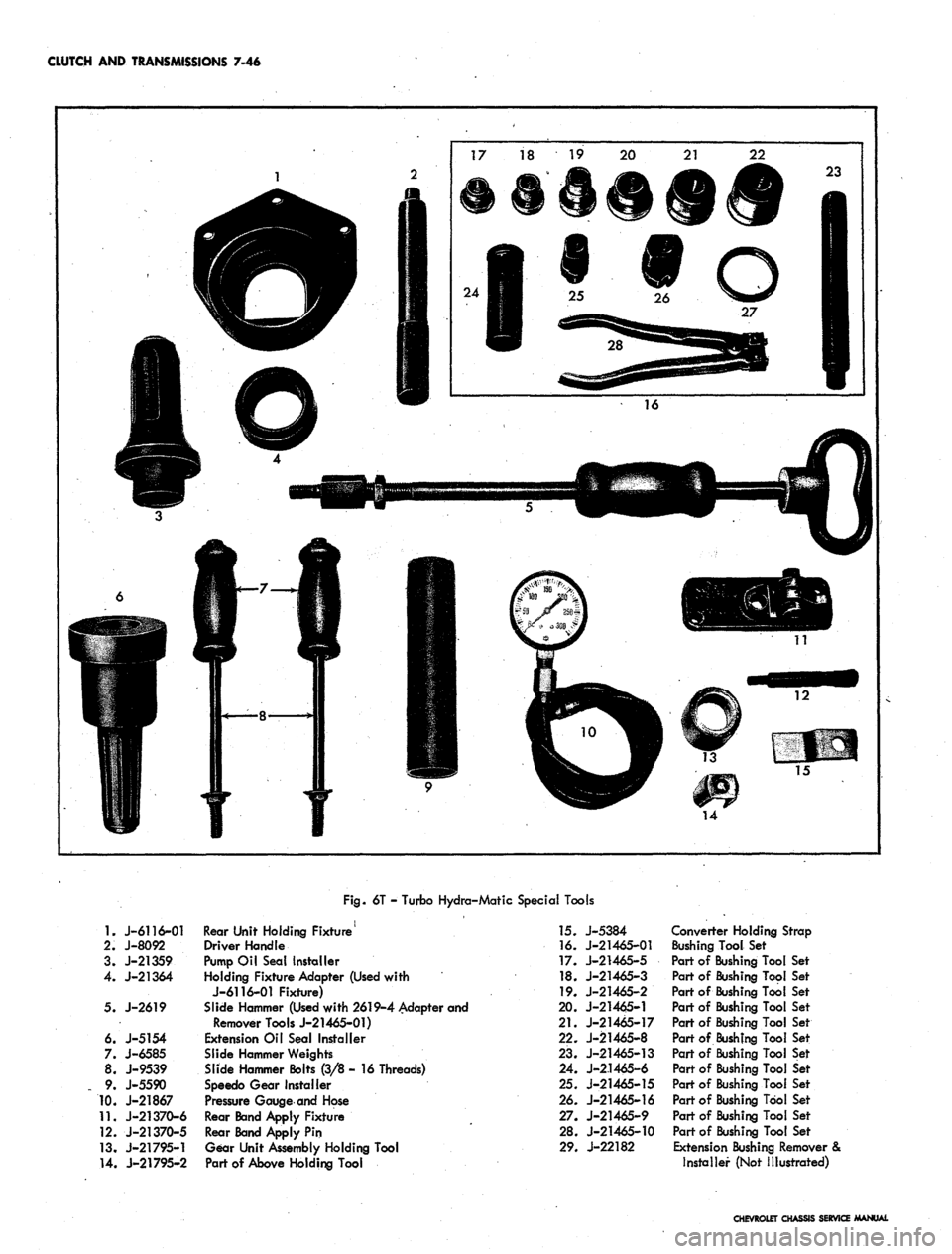

CLUTCH AND TRANSMISSIONS 7-46

17 18 19 20 21 22

Fig.

6T - Turbo Hydra-Matic Special Tools

1.

J-6116-01

2.

J-8092

3. J-21359

4.

J-21364

5. J-2619

6. J-5154

7. J-6585

8. J-9539

9.

J-5590

10.

J-21867

11.

J-21370-6

12.

J-21370-5

13.

J-21795-1

14.

J-21795-2

Rear Unit Holding Fixture

Driver Handle

Pump Oil Seal Installer

Holding Fixture Adapter (Used with

J-6116-01 Fixture)

Slide Hammer (Used with 2619-4 Adapter and

Remover Tools J-21465-01)

Extension Oil Seal Installer

Slide Hammer Weights

Slide Hammer Bolts (3/8 - 16 Threads)

Speedo Gear Installer

Pressure Gauge and Hose

Rear Band Apply Fixture

Rear Band Apply Pin

Gear Unit Assembly Holding Tool

Part of Above Holding Tool

]5. J-5384

16.

J-21465-01

17.

J-21465-5

18.

J-21465-3

19.

J-21465-2

20.

J-21465-1

21.

J-21465-17

22.

J-21465-8

23.

J-21465-13

24.

J-2.1465-6

25.

J-21465-15

26.

J-21465-16

27.

J-21465-9

28.

J-21465-10

29.

J-22182

Converter Holding Strap

Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Part of Bushing Tool Set

Extension Bushing Remover &

Installer (Not Illustrated)

CHEVROLET CHASSIS SERVICE MANUAL

Page 406 of 659

CLUTCH AND TRANSMISSIONS 7-47

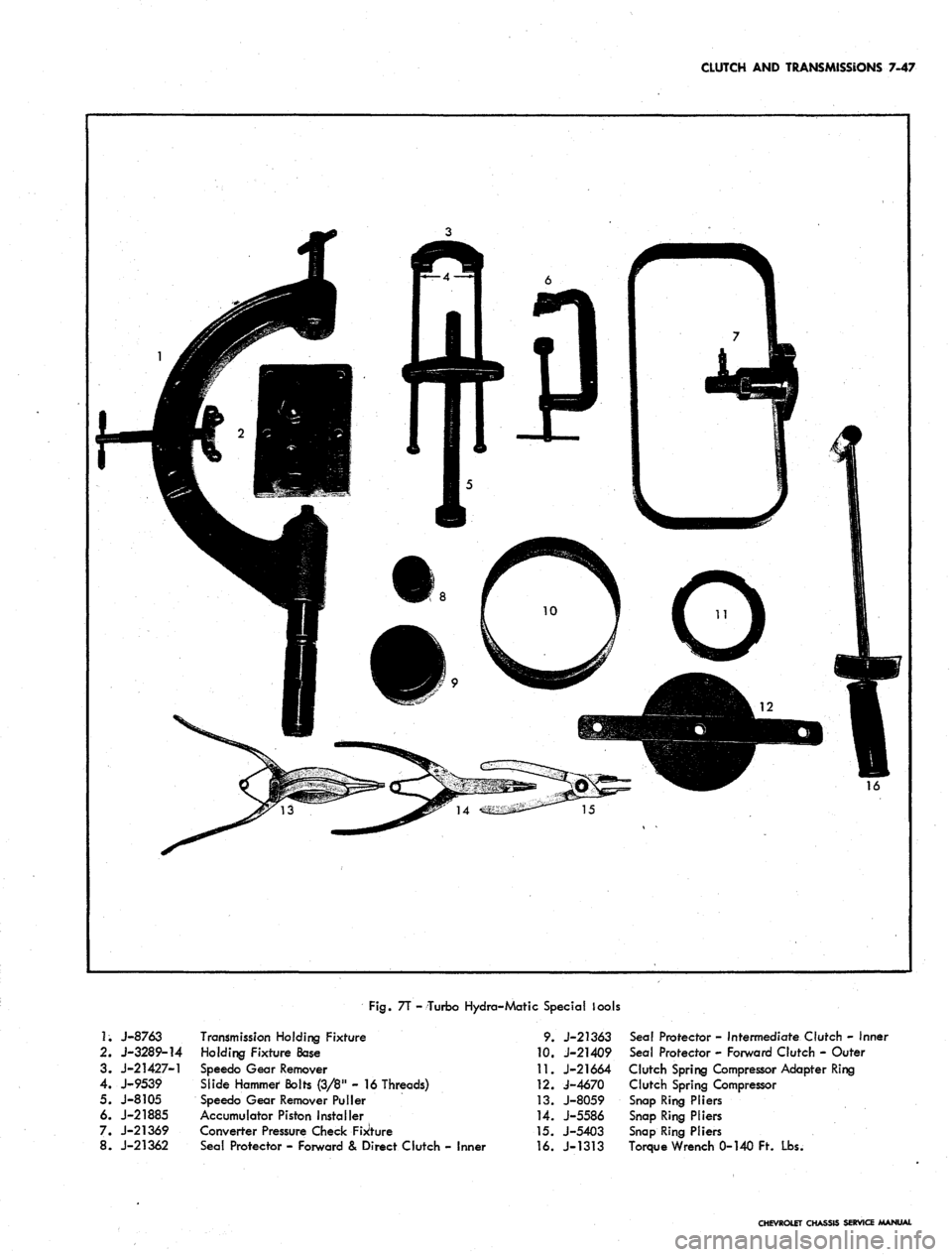

Fig.

7T - Turbo Hydro-Matic Special lools

1;

J-8763

2.

J-3289-14

3. J-21427-1

4.

J-9539

5. J-8105

6. J-21885

7. J-21369

8. J-21362

Transmission Holding Fixture

Holding Fixture Base

Speedo Gear Remover

Slide Hammer Bolts (3/8" - 16 Threads)

Speedo Gear Remover Puller

Accumulator Piston Installer

Converter Pressure Check Fixture

Seal Protector - Forward & Direct Clutch - Inner

9. J-21363

10.

J-21409

11.

J-21664

12.

J-4670

13.

J-8059

14.

J-5586

15.

J-5403

16.

J-1313

Seal Protector - Intermediate Clutch - Inner

Seal Protector - Forward Clutch - Outer

Clutch Spring Compressor Adapter Ring

Clutch Spring Compressor

Snap Ring Pliers

Snap Ring Pliers

Snap Ring Pliers

Torque Wrench 0-140 Ft. Lbs.

CHEVROLET CHASSIS SERVICE MANUAL

Page 407 of 659

SECTION 8

FUEL TANK AND EXHAUST SYSTEMS

CONTENTS OF THIS SECTION

Page

Chevrolet .. . . 8-1

Fuel Tanks 8-1

Exhaust Systems 8-5

Chevelle 8-8

Fuel Tanks 8-8

Exhaust Systems 8-11

Chevy n ...... 8-13

Fuel Tanks 8-13

Page

Exhaust Systems 8-16

Corvette 8-18

Fuel Tanks 8-18

Exhaust Systems 8-24

Camaro 8-26

Fuel Tank 8-26

Exhaust System 8-30

Special Tools 8-33

CHEVROLET

FUEL TANKS

INDEX

Page

Page

General Description

Component Part Replacement

Fuel Tank

8-1 Fuel Lines 8-3

8-2 Fuel Tank Vent Lines 8-4

8-2 Metering Units (Gauge Sending Unit ) 8-4

GENERAL DESCRIPTION

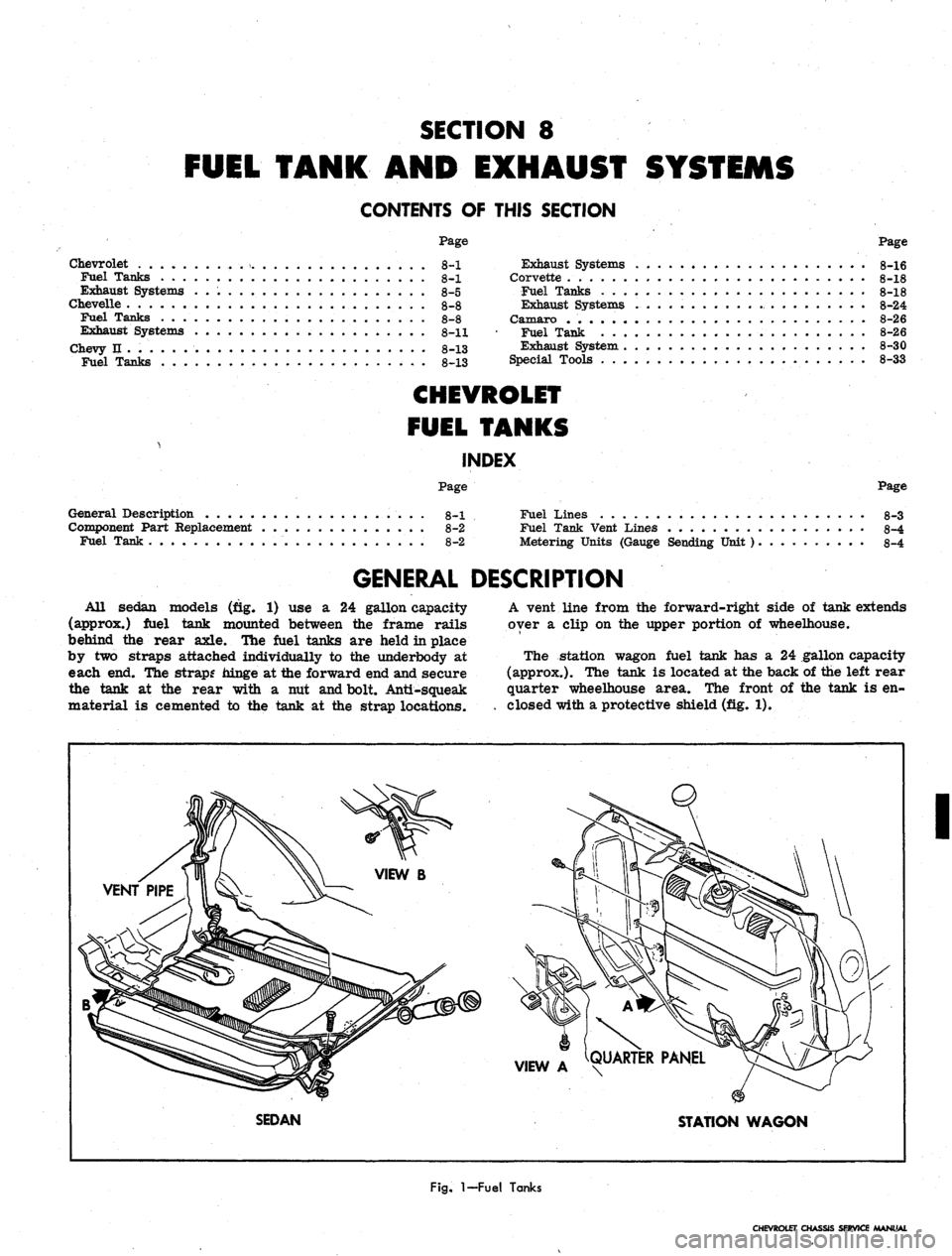

All Sedan models (fig. 1) use a 24 gallon capacity

(approx.) fuel tank mounted between the frame rails

behind the rear axle. The fuel tanks are held in place

by two straps attached individually to the underbody at

each end. The strap? hinge at the forward end and secure

the tank at the rear with a nut and bolt. Anti-squeak

material is cemented to the tank at the strap locations.

A vent line from the forward-right side of tank extends

over a clip on the upper portion of wheelhouse.

The station wagon fuel tank has a 24 gallon capacity

(approx.). The tank is located at the back of the left rear

quarter wheelhouse area. The front of the tank is en-

closed with a protective shield (fig. 1).

VIEW A ^QUARTER PANEL

SEDAN

STATION WAGON

I

Fig.

1-Fuel

Tanks

CHEVROLET CHASSIS SERVICE MANUAL

Page 408 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-2

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

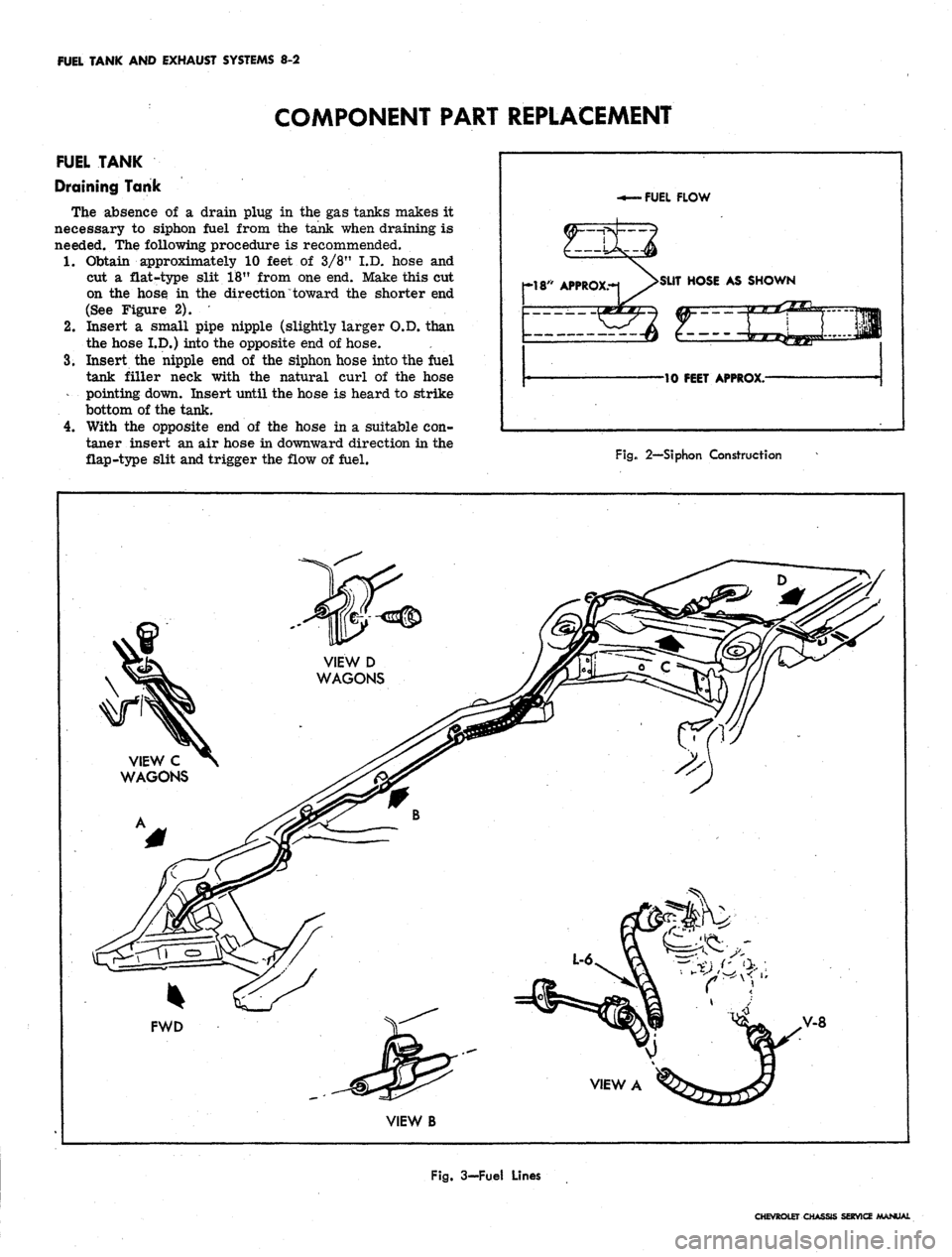

The absence of a drain plug in the gas tanks makes it

necessary to siphon fuel from the tank when draining is

needed. The following procedure is recommended.

1.

Obtain approximately 10 feet of 3/8" I.D. hose and

cut a flat-type slit 18" from one end. Make this cut

on the hose in the direction "toward the shorter end

(See Figure 2).

2.

Insert a small pipe nipple (slightly larger O.D. than

the hose I.D.) into the opposite end of hose.

3.

Insert the nipple end of the siphon hose into the fuel

tank filler neck with the natural curl of the hose

pointing down. Insert until the hose is heard to strike

bottom of the tank.

4.

With the opposite end of the hose in a suitable con-

taner insert an air hose in downward direction in the

flap-type slit and trigger the flow of fuel.

FUEL FLOW

-If*

APPROX.-1 >SUT «<>«

AS SHOWN

10 FEET APPROX.-

Fig. 2—Siphon Construction

FWD

V-8

VIEW B

Fig. 3-Fuel Lines

CHEVROLET CHASSIS SERVICE MANUAL

Page 409 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-3

CAUTION: Always drain gasoline from com-

plete fuel system including carburetor, fuel

pump and all fuel lines and fuel tank if the vehi-

cle is to be stored for any appreciable length of

time. This precaution will prevent accumulation

of gum formation and resultant poor engine

performance.

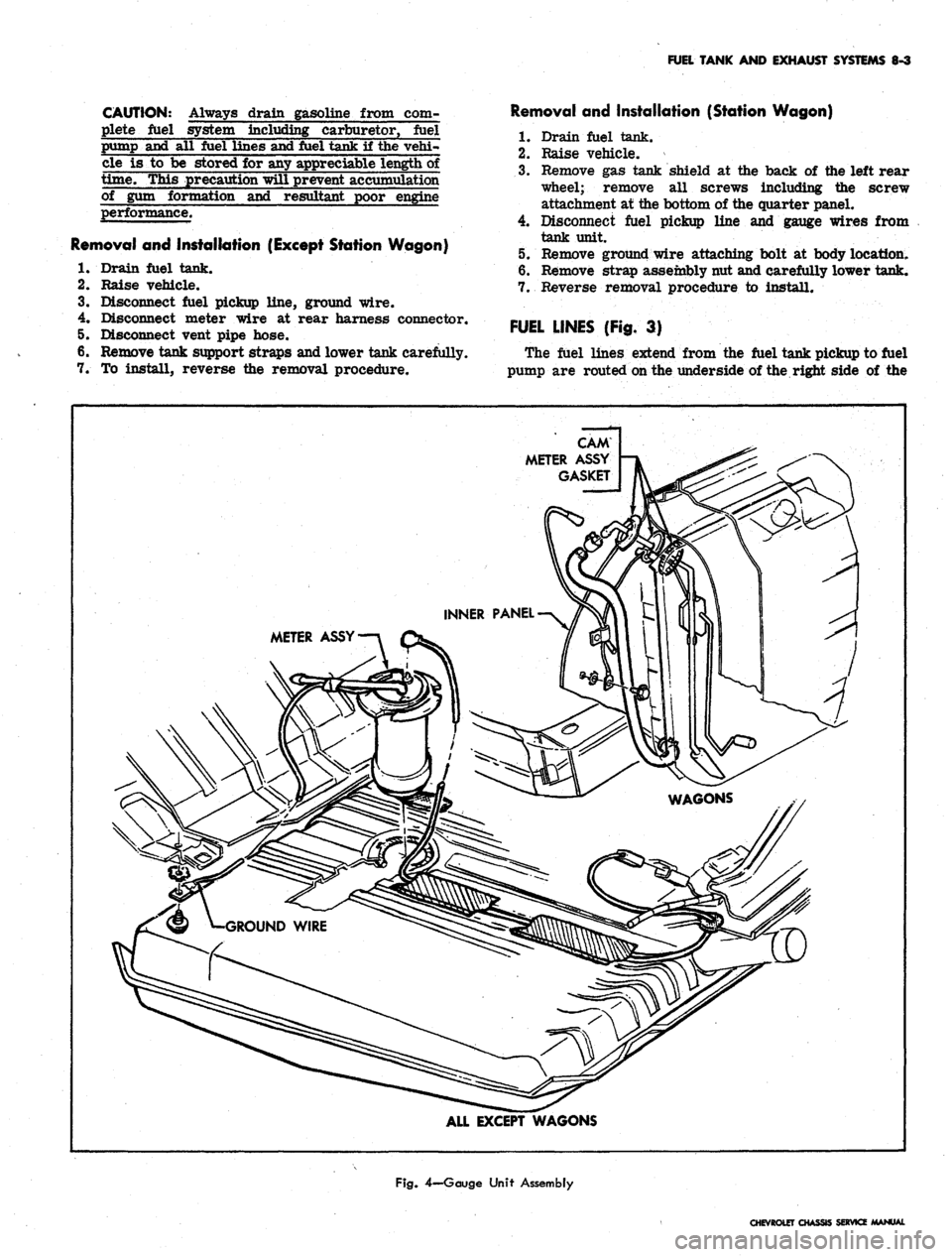

Removal and Installation (Except Station Wagon)

1.

Drain fuel tank.

2.

Raise vehicle.

3.

Disconnect fuel pickup line, ground wire.

4.

Disconnect meter wire at rear harness connector.

5. Disconnect vent pipe hose.

6. Remove tank support straps and lower tank carefully.

7. To install, reverse the removal procedure.

Removal and Installation (Station Wagon)

1.

Drain fuel tank.

2.

Raise vehicle.

3.

Remove gas tank shield at the back of the left rear

wheel; remove all screws including the screw

attachment at the bottom of the quarter panel.

4.

Disconnect fuel pickup line and gauge wires from

tank unit.

5. Remove ground wire attaching bolt at body location.

6. Remove strap assembly nut and carefully lower tank.

7. Reverse removal procedure to install.

FUEL LINES (Fig. 3)

The fuel lines extend from the fuel tank pickup to fuel

pump are routed on the underside of the right side of the

CAM

METER ASSY

GASKET

METER ASSY

ALL EXCEPT WAGONS

Fig.

4—Gauge Unit Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 410 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-4

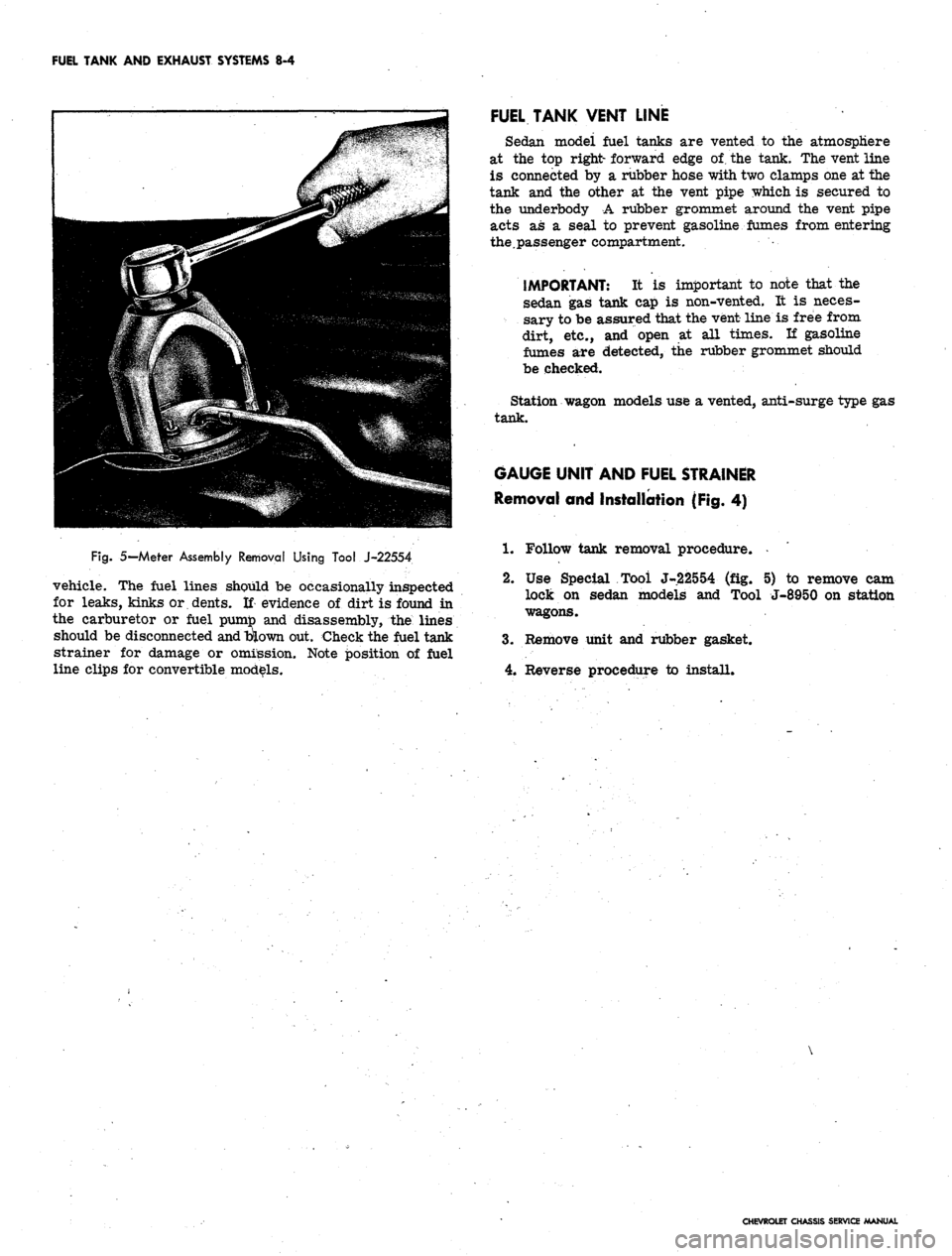

Fig.

5— Meter Assembly Removal Using Tool J-22554

vehicle. The fuel lines should be occasionally inspected

for leaks, kinks or dents. If evidence of dirt is found in

the carburetor or fuel pumto and disassembly, the lines

should be disconnected

and

blown out. Check the fuel tank

strainer for damage or omission. Note position of fuel

line clips for convertible models.

FUEL TANK VENT LINE

Sedan modei fuel tanks are vented to the atmosphere

at the top right- forward edge of. the tank. The vent line

is connected by a rubber hose with two clamps one at the

tank and the other at the vent pipe which is secured to

the underbody A rubber grommet around the vent pipe

acts as a seal to prevent gasoline fumes from entering

the.passenger compartment.

IMPORTANT: It is important to note that the

sedan gas tank cap is non-vented. It is neces-

sary to be assured that the vent line is free from

dirt, etc., and open at all times. If gasoline

fumes are detected, the rubber grommet should

be checked.

Station wagon models use a vented, anti-surge type gas

tank.

GAUGE UNIT AND FUEL STRAINER

Removal and Installation (Fig. 4)

1.

Follow tank removal procedure.

2.

Use Special Tool J-22554 (fig. 5) to remove cam

lock on sedan models and Tool J-8950 on station

wagons.

3.

Remove unit and rubber gasket.

4.

Reverse procedure to install.

CHEVROLET CHASSIS SERVICE MANUAL