CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 411 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-5

EXHAUST SYSTEMS

INDEX

Page

General Description

. . 8-5

Component Part Replacement

8-5

Muffler Assembly.

8-5

Exhaust Pipes.

8-5

Tail Pipes.

8-5

GENERAL DESCRIPTION

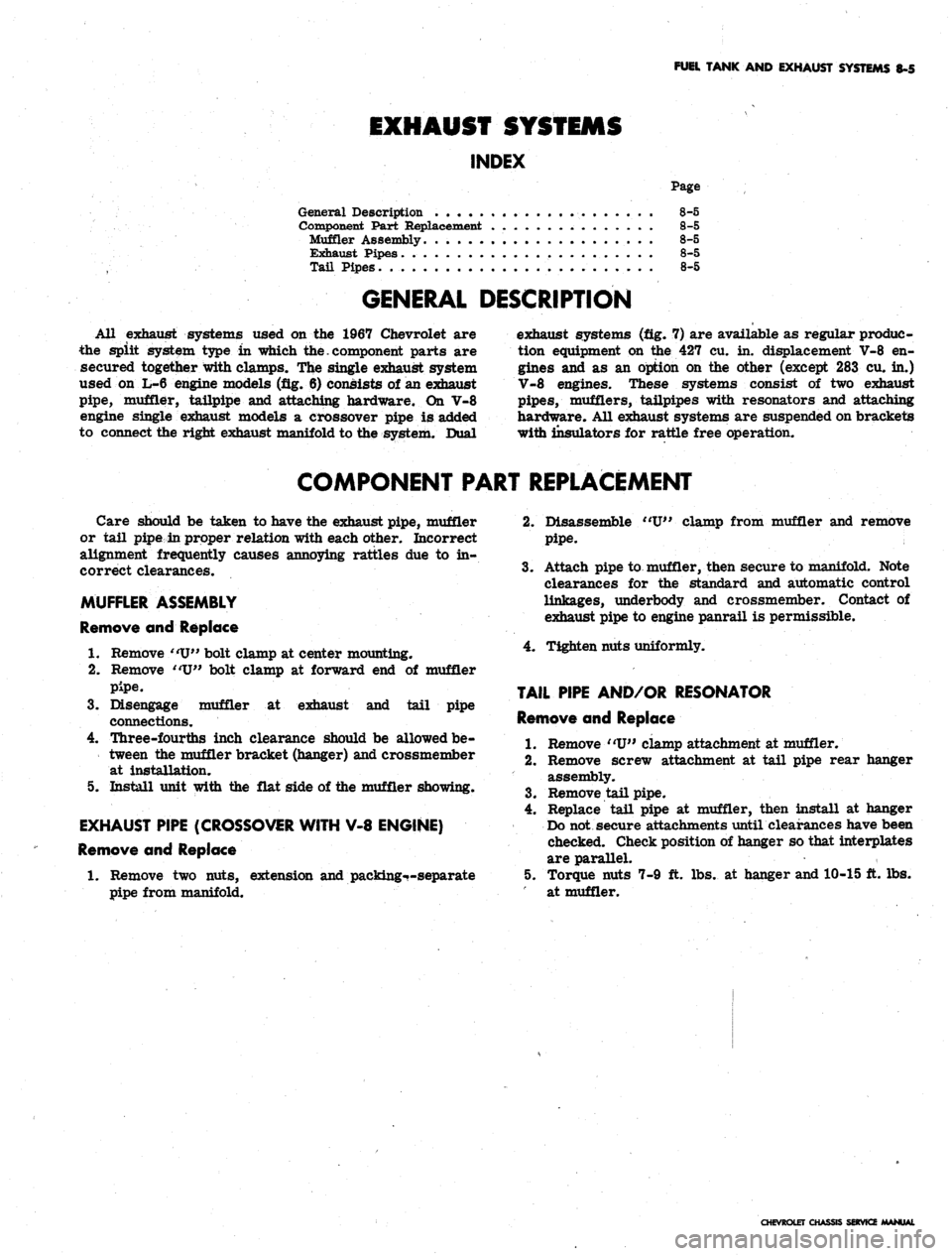

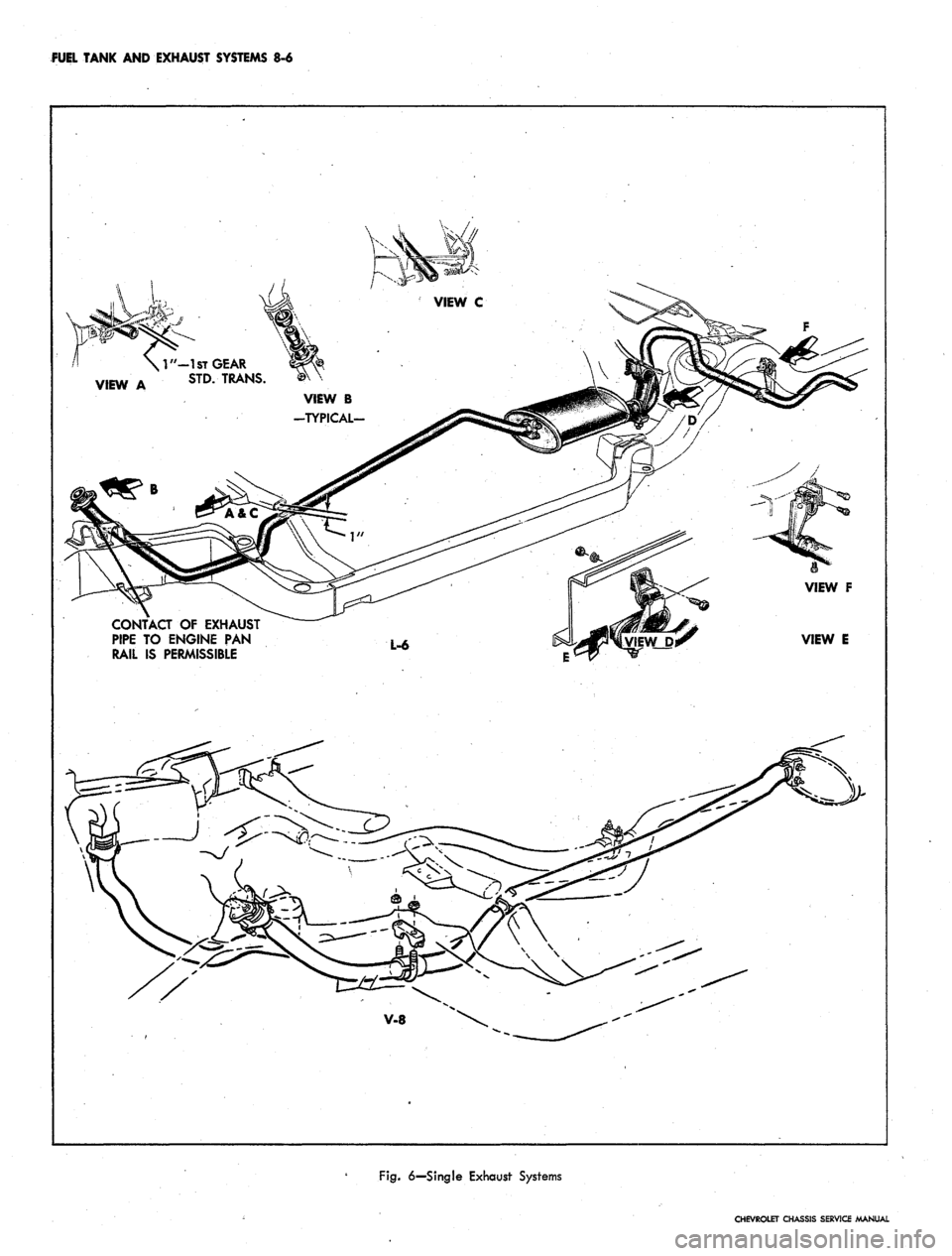

All exhaust systems used

on the 1967

Chevrolet

are

exhaust systems

(fig. 7) are

available

as

regular produc-

the split system type

in

which the. component parts

are

tion equipment

on the 427 cu. in.

displacement

V-8 en-

secured together with clamps.

The

single exhaust system gines

and as an

option

on the

other (except

283 cu. in.)

used

on L-6

engine models

(fig. 6)

consists

of an

exhaust

V-8

engines. These systems consist

of two

exhaust

pipe, muffler, tailpipe

and

attaching hardware.

On V-8

pipes, mufflers, tailpipes with resonators

and

attaching

engine single exhaust models

a

crossover pipe

is

added hardware.

All

exhaust systems

are

suspended on brackets

to connect

the

right exhaust manifold

to the

system. Dual with insulators

for

rattle free operation.

COMPONENT PART REPLACEMENT

Care should

be

taken

to

have

the

exhaust pipe, muffler

or tail pipe

in

proper relation with each other. Incorrect

alignment frequently causes annoying rattles

due to in-

correct clearances.

MUFFLER ASSEMBLY

Remove

and

Replace

1.

Remove "U" bolt clamp

at

center mounting.

2.

Remove

"U"

bolt clamp

at

forward

end of

muffler

pipe.

3.

Disengage muffler

at

exhaust

and

tail pipe

connections.

4.

Three-fourths inch clearance should

be

allowed

be-

tween

the

muffler bracket (hanger)

and

crossmember

at installation.

5. Install unit with

the

flat side

of the

muffler showing.

EXHAUST PIPE (CROSSOVER WITH

V-8

ENGINE)

Remove

and

Replace

1.

Remove

two

nuts, extension

and

packings-separate

pipe from manifold.

2.

3.

Disassemble

pipe.

"U"

damp from muffler

and

remove

Attach pipe

to

muffler, then secure

to

manifold. Note

clearances

for the

standard

and

automatic control

linkages, underbody

and

crossmember. Contact

of

exhaust pipe

to

engine panrail

is

permissible.

4.

Tighten nuts uniformly.

TAIL PIPE AND/OR RESONATOR

Remove

and

Replace

1.

Remove

"U"

clamp attachment

at

muffler.

2.

Remove screw attachment

at

tail pipe rear hanger

assembly.

3.

Remove tail pipe.

4.

Replace tail pipe

at

muffler, then install

at

hanger

Do

not

secure attachments until clearances have been

checked. Check position

of

hanger

so

that interplates

are parallel.

5. Torque nuts

7-9 ft. lbs. at

hanger

and 10-15 ft. lbs.

at muffler.

CHEVROLET CHASSIS

SEI

Page 412 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-6

1"-1STGEAR

STD.

TRANS.

CONTACT OF EXHAUST

PIPE TO ENGINE PAN

RAIL IS PERMISSIBLE

VIEW E

Fig.

6—Single Exhaust Systems

CHEVROLET

CHASSIS SERVICE MANUAL

Page 413 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-7

1

I

kSSIS SERVICE

Page 414 of 659

FUEL TANK AND EXHAUST SYSTEMS

8-8

CHEVELLE

FUEL TANKS

INDEX

Page

General Description.

g.g

Component Part Replacement

8-8

Fuel Tanks

. 8-8

Fuel Lines

8-8

Metering Units (Gauge, Sending Unit)

Fuel Tank Filler Neck Caps.

. .

Fuel Tank Vent Lines

Page

8-8

8-8

8-9

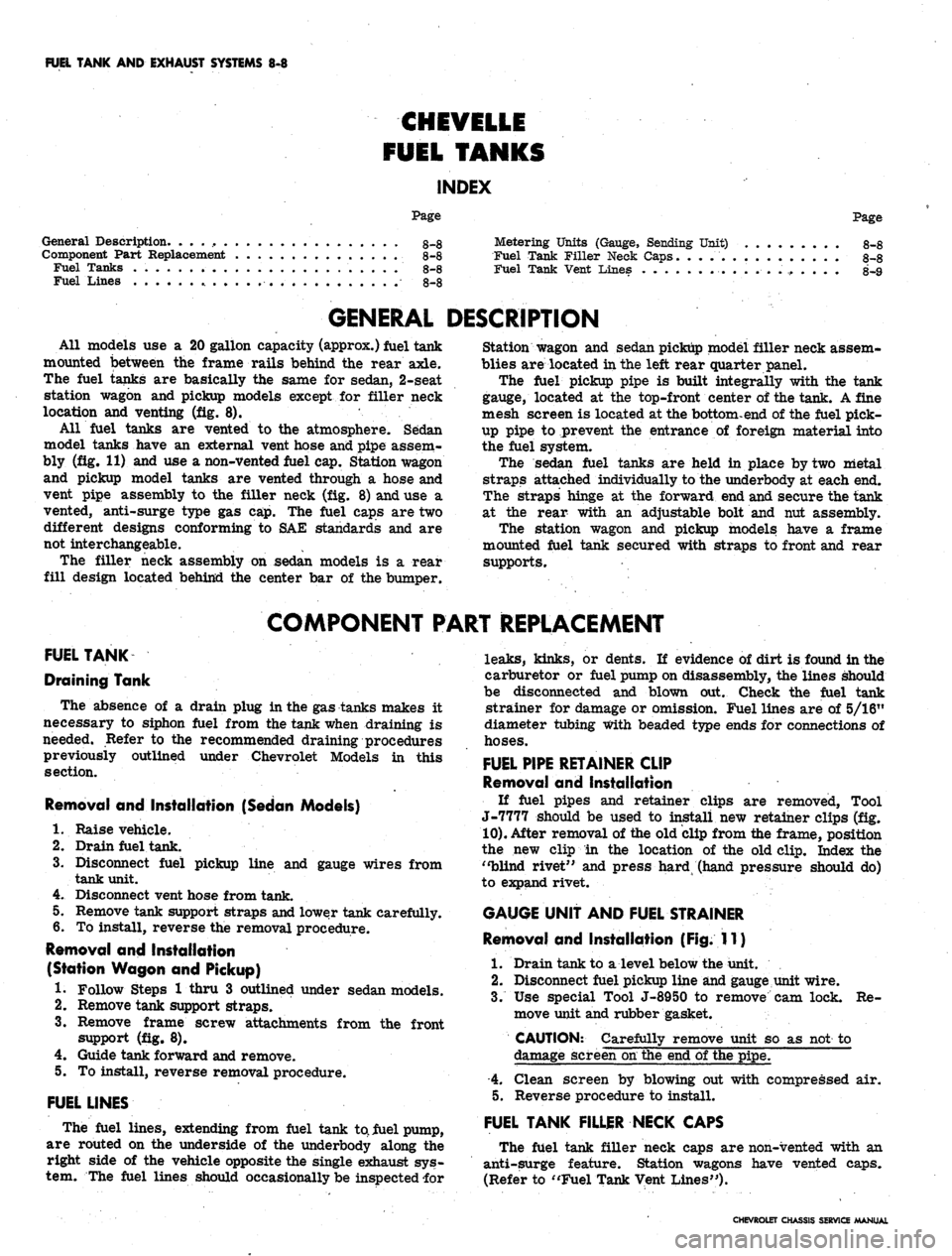

GENERAL DESCRIPTION

All models

use a 20

gallon capacity (approx.) fuel tank

mounted between

the

frame rails behind

the

rear axle.

The fuel tanks

are

basically

the

same

for

sedan, 2-seat

station wagon

and

pickup models except

for

filler neck

location

and

venting

(fig. 8).

All fuel tanks

are

vented

to the

atmosphere. Sedan

model tanks have

an

external vent hose and pipe assem-

bly

(fig. 11) and use a

non-vented fuel cap. Station wagon

and pickup model tanks

are

vented through

a

hose

and

vent pipe assembly

to the

filler neck

(fig. 8)

and

use a

vented, anti-surge type

gas cap. The

fuel caps

are two

different designs conforming

to SAE

standards

and are

not interchangeable.

The filler neck assembly

on

sedan models

is a

rear

fill design located behind

the

center

bar of the

bumper.

Station wagon

and

sedan pickup model filler neck assem-

blies

are

located

in

the left rear quarter panel.

The fuel pickup pipe

is

built integrally with

the

tank

gauge, located

at the

top-front center

of

the tank.

A

fine

mesh screen

is

located

at

the bottom-end

of the

fuel pick-

up pipe

to

prevent

the

entrance

of

foreign material into

the fuel system.

The sedan fuel tanks

are

held

in

place

by

two metal

straps attached individually

to the

underbody

at

each

end.

The straps hinge

at the

forward end and secure

the

tank

at

the

rear with

an

adjustable bolt

and nut

assembly.

The station wagon

and

pickup models have

a

frame

mounted fuel tank secured with straps

to

front and rear

supports.

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

The absence

of a

drain plug

in the gas

tanks makes

it

necessary

to

siphon fuel from

the

tank when draining

is

needed. Refer

to the

recommended draining procedures

previously outlined under Chevrolet Models

in

this

section.

Removal

and

Installation (Sedan Models)

1.

Raise vehicle.

2.

Drain fuel tank.

3.

Disconnect fuel pickup line

and

gauge wires from

tank unit.

4.

Disconnect vent hose from tank.

5. Remove tank support straps and lower tank carefully.

6.

To

install, reverse

the

removal procedure.

Removal

and

Installation

(Station Wagon

and

Pickup)

1.

Follow Steps

1

thru

3

outlined under sedan models.

2.

Remove tank support straps.

3.

Remove frame screw attachments from

the

front

support

(fig. 8).

4.

Guide tank forward

and

remove.

5.

To

install, reverse removal procedure.

FUEL LINES

The fuel lines, extending from fuel tank toiiuelpump,

are routed

on the

underside

of the

underbody along

the

right side

of the

vehicle opposite

the

single exhaust

sys-

tem.

The

fuel lines should occasionally

be

inspected

for

leaks,

kinks,

or

dents.

If

evidence

of

dirt

is

found

in the

carburetor

or

fuel pump

on

disassembly,

the

lines should

be disconnected

and

blown

out.

Check

the

fuel tank

strainer

for

damage

or

omission. Fuel lines

are of 5/16"

diameter tubing with beaded type ends

for

connections

of

hoses.

FUEL PIPE RETAINER

CUP

Removal

and

Installation

If fuel pipes

and

retainer clips

are

removed, Tool

J-7777 should

be

used

to

install

new

retainer clips

(fig.

10).

After removal

of the old

clip from

the

frame, position

the

new

clip

in the

location

of the old

clip. Index

the

"blind rivet"

and

press hard (hand pressure should

do)

to expand rivet.

GAUGE UNIT

AND

FUEL STRAINER

Removal

and

Installation

(Fig. 11)

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit

and

rubber gasket.

CAUTION: Carefully remove unit

so as not to

damage screen

on the end of

the pipe.

4.

Clean screen

by

blowing

out

with compressed

air.

5. Reverse procedure

to

install.

FUEL TANK FILLER NECK CAPS

The fuel tank filler neck caps

are

non-vented with

an

anti-surge feature. Station wagons have vented caps.

(Refer

to

"Fuel Tank Vent Lines").

CHEVROLET CHASSIS SERVICE MANUAL

Page 415 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-9

SEDAN

STATION WAGON AND PICKUP

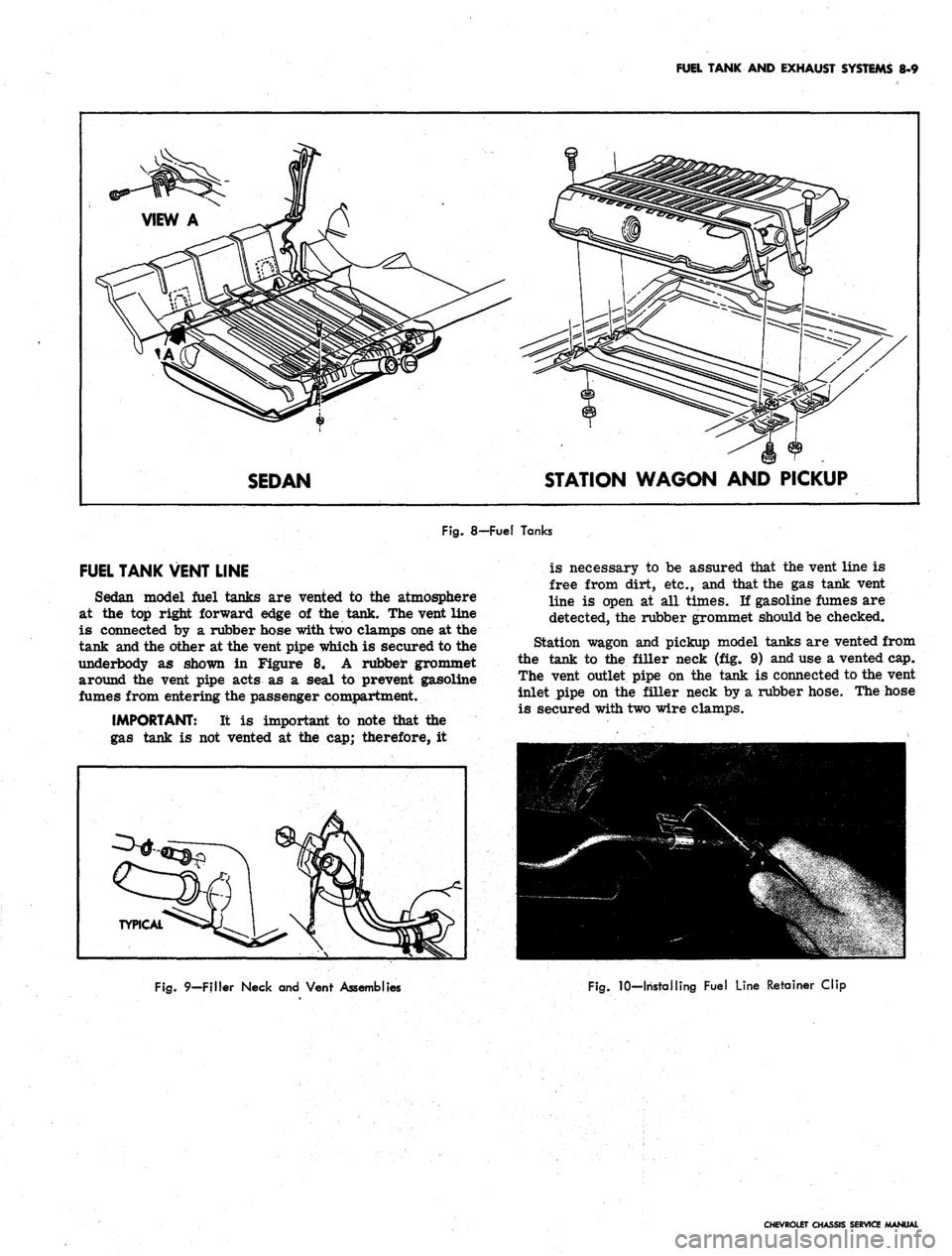

Fig.

8—Fuel Tanks

FUEL TANK VENT LINE

Sedan model fuel tanks are vented to the atmosphere

at the top right forward edge of the tank. The vent line

is connected by a rubber hose with two clamps one at the

tank and the other at the vent pipe which is secured to the

underbody as shown in Figure 8. A rubber grommet

around the vent pipe acts as a seal to prevent gasoline

fumes from entering the passenger compartment.

IMPORTANT: It is important to note that the

gas tank is not vented at the cap; therefore, it

is necessary to be assured that the vent line is

free from dirt, etc., and that the gas tank vent

line is open at all times. If gasoline fumes are

detected, the rubber grommet should be checked.

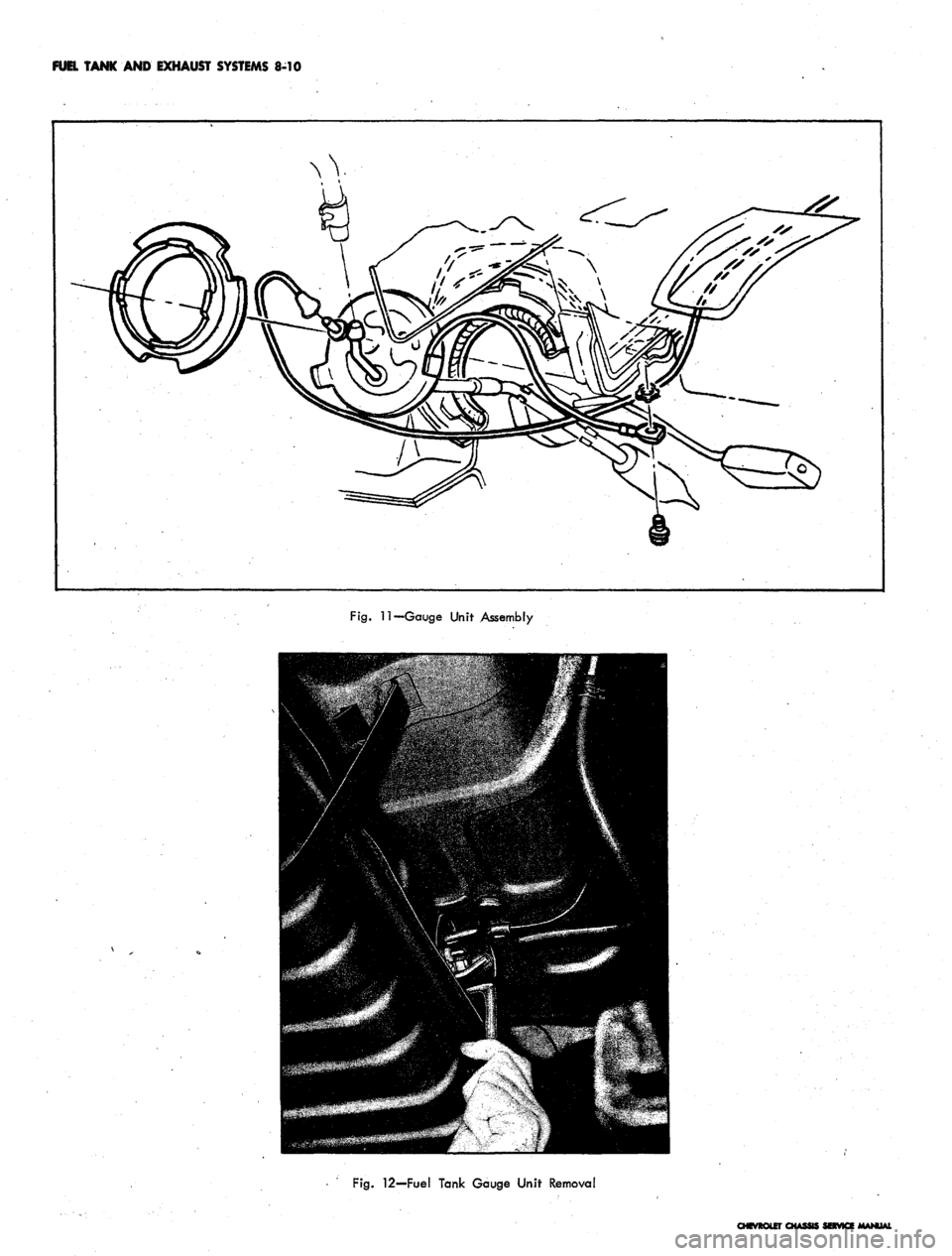

Station wagon and pickup model tanks are vented from

the tank to the filler neck (fig. 9) and use a vented cap.

The vent outlet pipe on the tank is connected to the vent

inlet pipe on the filler neck by a rubber hose. The hose

is secured with two wire clamps.

Fig.

9—Filler Neck and Vent Assemblies

Fig.

10—Installing Fuel Line Retainer Clip

CHEVROLET CHASSIS SERVICE MANUAL

Page 416 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-10

Fig.

11—Gauge Unit Assembly

Fig.

12—Fuel Tank Gauge Unit Removal

CHEVROLET CHASSIS SERVICE

Page 417 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-11

EXHAUST SYSTEMS

INDEX

Page

General Description 8-11

Component Part Replacement 8-12

Muffler Assembly 8-12

Exhaust Pipes. 8-12

Tail Pipes 8-12

GENERAL DESCRIPTION

V-8

VIEW C

VIEW D

(EXCEPT WAGON)

L-6

VIEW A

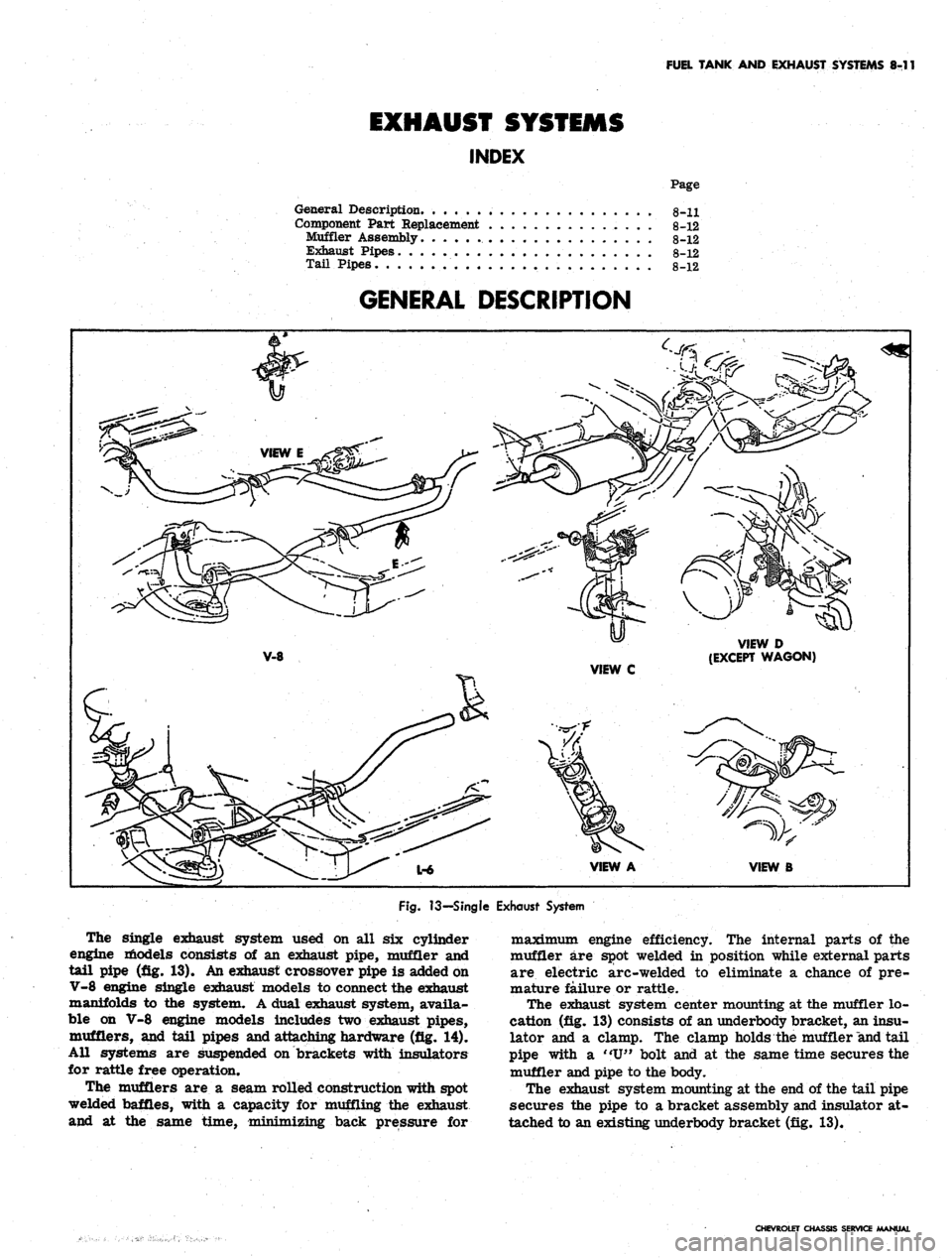

Fig.

13—Single Exhaust System

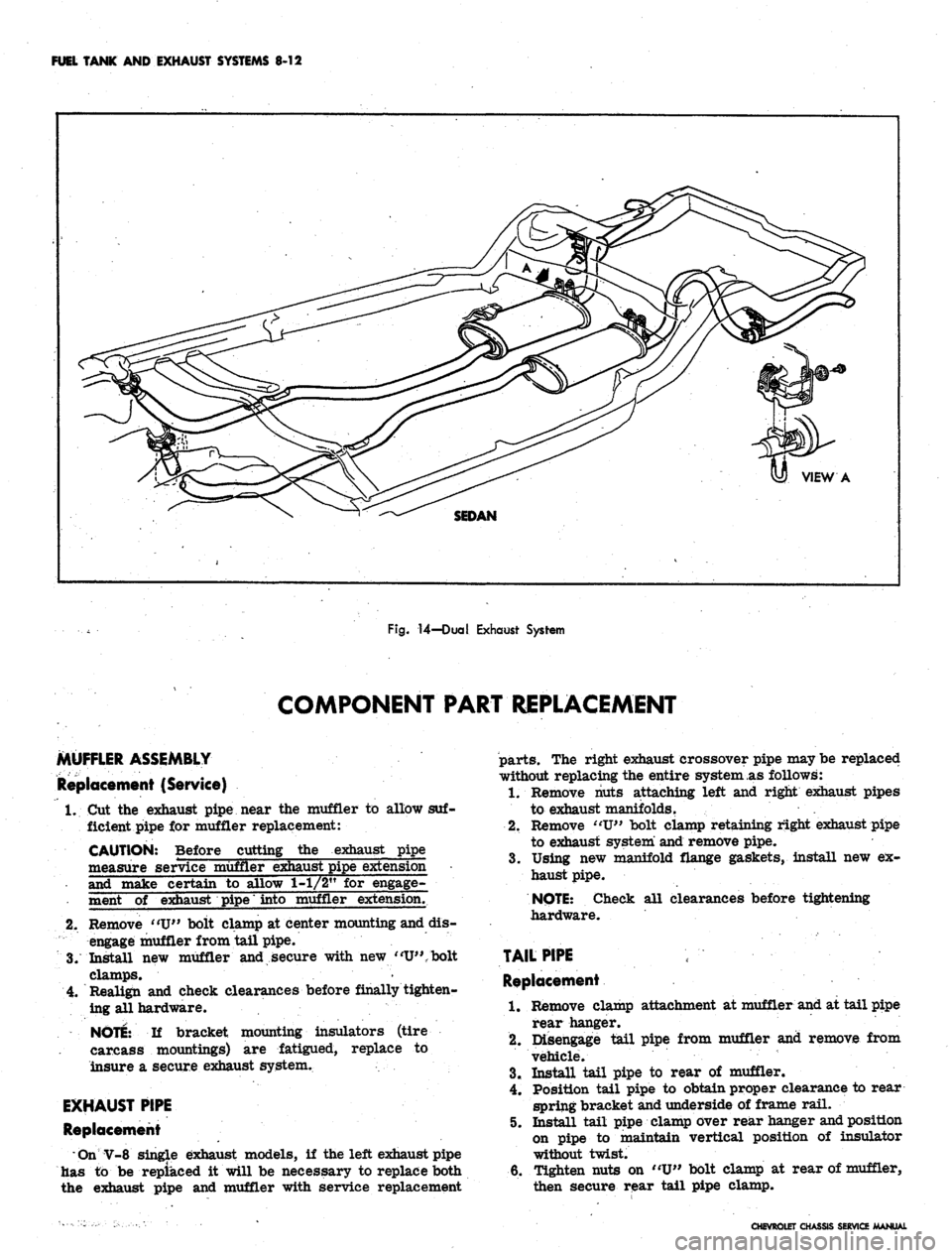

The single exhaust system used on all six cylinder

engine models consists of an exhaust pipe, muffler and

tail pipe (fig. 13), An exhaust crossover pipe is added on

V-8 engine single exhaust models to connect the exhaust

manifolds to the system. A dual exhaust system, availa-

ble on V-8 engine models includes two exhaust pipes,

mufflers, and tail pipes and attaching hardware (fig. 14).

All systems are suspended on brackets with insulators

for rattle free operation.

The mufflers are a seam rolled construction with spot

welded baffles, with a capacity for muffling the exhaust

and at the same time, minimizing back pressure for

maximum engine efficiency. The internal parts of the

muffler are spot welded in position while external parts

are electric arc-welded to eliminate a chance of pre-

mature failure or rattle.

The exhaust system center mounting at the muffler lo-

cation (fig. 13) consists of an underbody bracket, an insu-

lator and a clamp. The clamp holds the muffler and tail

pipe with a "U" bolt and at the same time secures the

muffler and pipe to the body.

The exhaust system mounting at the end of the tail pipe

secures the pipe to a bracket assembly and insulator at-

tached to an existing underbody bracket (fig. 13).

CHEVROLET CHASSIS SERVICE MANUAL

Page 418 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-12

Fig.

14—Dual Exhaust System

COMPONENT PART REPLACEMENT

MUFFLER ASSEMBLY

Replacement (Service)

1.

Cut the exhaust pipe near the muffler to allow suf-

ficient pipe for muffler replacement:

CAUTION: Before cutting the exhaust pipe

measure service muffler exhaust pipe extension

and make certain to allow 1-1/2" for engage-

ment of exhaust pipe' into muffler extension.

2.

Remove "U" bolt clamp at center mounting and dis-

engage muffler from tail pipe.

3.

Install new muffler and secure with new

"U"

/bolt

clamps. •

4.

Realign and check clearances before finally tighten-

ing all hardware.

NOTE:

If bracket mounting insulators (tire

carcass mountings) are fatigued, replace to

insure a secure exhaust system.

EXHAUST PIPE

Replacement

On V-8 single exhaust models, if the left exhaust pipe

has to be replaced it will be necessary to replace both

the exhaust pipe and muffler with service replacement

parts.

The right exhaust crossover pipe may be replaced

without replacing the entire system as follows:

1.

Remove nuts attaching left and right exhaust pipes

to exhaust manifolds. ' • .

2.

Remove "TJ" bolt clamp retaining right exhaust pipe

to exhaust system and remove pipe.

3.

Using new manifold flange gaskets, install new ex-

haust pipe.

NOTE:

Check all clearances before tightening

hardware.

TAILPIPE

Replacement

1.

Remove clamp attachment at muffler and at tail pipe

rear hanger.

2.

Disengage tail pipe from muffler and remove from

vehicle.

3.

Install tail pipe to rear of muffler.

4.

Position tail pipe to obtain proper clearance to rear

spring bracket and underside of frame rail.

5. Install tail pipe clamp over rear hanger and position

on pipe to maintain vertical position of insulator

without twist.

6. Tighten nuts on "TJ" bolt clamp at rear of muffler,

then secure rear tail pipe clamp.

CHEVROLET CHASSIS SERVICE MANUAL

Page 419 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-13

CHEVY II

FUEL TANKS

INDEX

Page

Page

General Description.

8-13

Component Part Replacement

8-13

Fuel Tanks

8-13

Fuel Lines

8-14

Metering Units (Gauge Sending Unit)

8-13

Fuel Tank Filler- Neck Caps.

. . 8-14

Fuel Tank Vent Lines .......

8-14

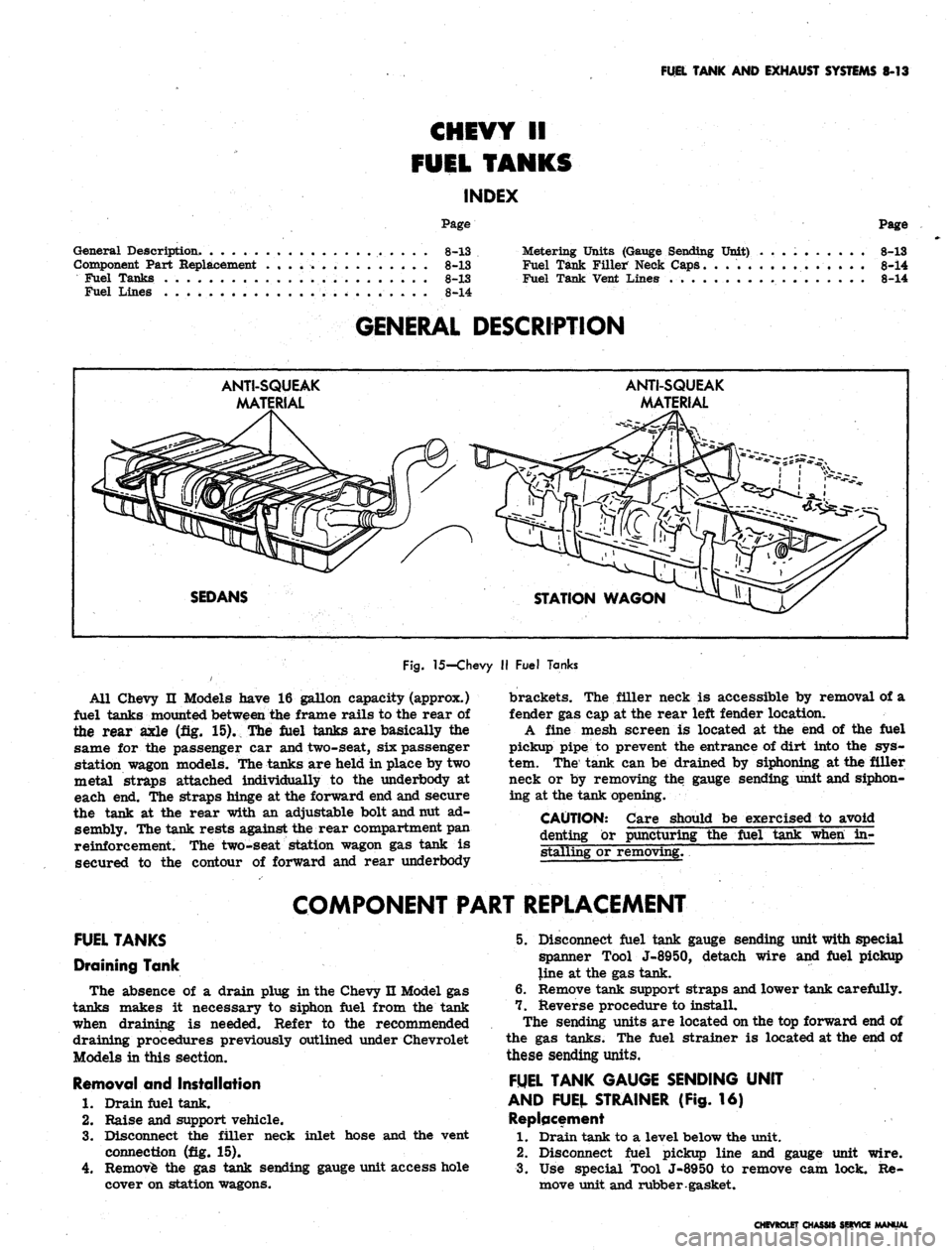

GENERAL DESCRIPTION

ANTI-SQUEAK

MA'

ANTI-SQUEAK

MATERIAL

SEDANS

STATION WAGON

Fig.

15-Chevy

II

Fuel Tanks

All Chevy

II

Models have

16

gallon capacity (approx.)

fuel tanks mounted between

the

frame rails

to the

rear

of

the rear axle

(fig. 15). The

fuel tanks

are

basically

the

same

for the

passenger

car

and two-seat,

six

passenger

station wagon models. The tanks

are

held

in

place

by two

metal straps attached individually

to the

underbody

at

each

end. The

straps hinge

at the

forward

end

and secure

the tank

at the

rear with

an

adjustable bolt and nut

ad-

sembly. The tank rests against the rear compartment

pan

reinforcement.

The

two-seat station wagon

gas

tank

is

secured

to the

contour

of

forward

and

rear underbody

brackets.

The

filler neck

is

accessible

by

removal

of a

fender

gas cap at the

rear left fender location.

A fine mesh screen

is

located

at the end of the

fuel

pickup pipe

to

prevent

the

entrance

of

dirt into

the sys-

tem.

The

tank

can be

drained

by

siphoning

at the

filler

neck

or by

removing

the

gauge sending unit and siphon-

ing

at the

tank opening.

CAUTION: Care should

be

exercised

to

avoid

denting

or

puncturing

the

fuel tank when

in-

stalling

or

removing.

~

COMPONENT PART REPLACEMENT

FUEL TANKS

Draining Tank

The absence

of a

drain plug

in

the Chevy

n

Model

gas

tanks makes

it

necessary

to

siphon fuel from

the

tank

when draining

is

needed. Refer

to the

recommended

draining procedures previously outlined under Chevrolet

Models

in

this section.

Removal

and

Installation

1.

Drain fuel tank.

2.

Raise

and

support vehicle.

3.

Disconnect

the

filler neck inlet hose

and the

vent

connection

(fig. 15).

4.

Remove

the gas

tank sending gauge unit access hole

cover

on

station wagons.

5. Disconnect fuel tank gauge sending unit with special

spanner Tool J-8950, detach wire

and

fuel pickup

line

at the gas

tank.

6. Remove tank support straps and lower tank carefully.

7. Reverse procedure

to

install.

The sending units

are

located on

the top

forward

end of

the

gas

tanks.

The

fuel strainer

is

located

at the end of

these sending units.

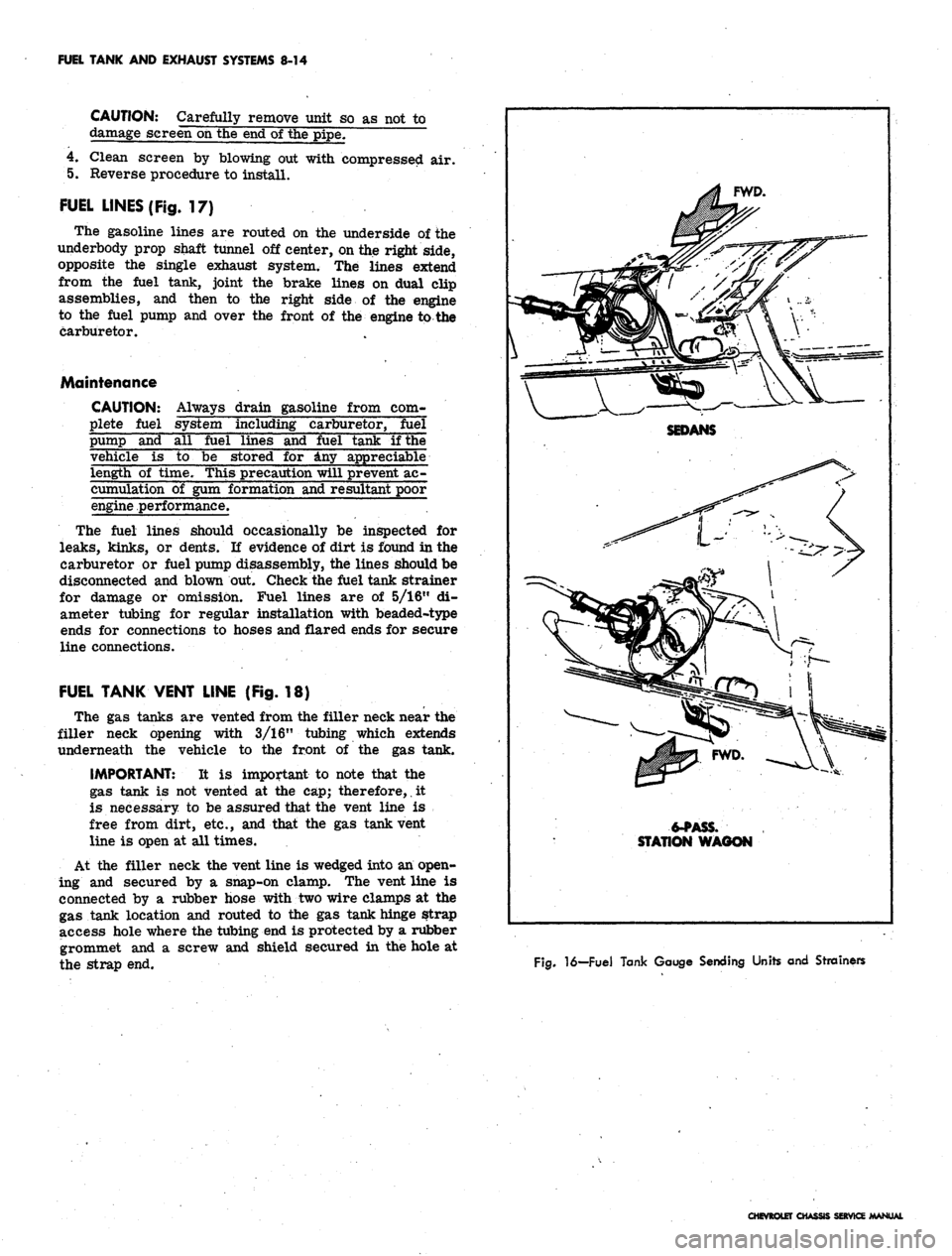

FUEL TANK GAUGE SENDING UNIT

AND FUEL STRAINER

(Fig. 16)

Replacement

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit and rubber gasket.

CHEVROLET CHASSIS SERVICE MANUAL

Page 420 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-14

CAUTION: Carefully remove unit so as not to

damage screen oh the end of the pipe,

4.

Clean screen by blowing out with compressed air.

5. Reverse procedure to install.

FUEL LINES (Fig. 17)

The gasoline lines are routed on the underside of the

underbody prop shaft tunnel off center, on the right side,

opposite the single exhaust system. The lines extend

from the fuel tank, joint the brake lines on dual clip

assemblies, and then to the right side of the engine

to the fuel pump and over the front of the engine to the

carburetor.

Maintenance

CAUTION:

plete fuel

Always drain gasoline from com-

system including carburetor, fuel

pump and all fuel lines and fuel tank if the

vehicle is to be stored for any appreciable

length of time. This precaution will prevent ac-

cumulation of gum formation and resultant poor

engine performance.

The fuel lines should occasionally be inspected for

leaks,

kinks, or dents. If evidence of dirt is found in the

carburetor or fuel pump disassembly, the lines should be

disconnected and blown out. Check the fuel tank strainer

for damage or omission. Fuel lines are of 5/16" di-

ameter tubing for regular installation with beaded-type

ends for connections to hoses and flared ends for secure

line connections.

FUEL TANK VENT LINE (Fig. 18)

The

gas

tanks

are

vented from

the

filler neck near

the

filler neck opening with

3/16"

tubing which extends

underneath

the

vehicle

to the

front

of the gas

tank.

IMPORTANT:

It is

important

to

note that

the

gas tank

is not

vented

at the cap;

therefore,

it

is necessary

to be

assured that

the

vent line

is

free from dirt,

etc., and

that

the gas

tank vent

line

is

open

at all

times.

At

the

filler neck

the

vent line

is

wedged into

an

open-

ing

and

secured

by a

snap-on clamp.

The

vent line

is

connected

by a

rubber hose with

two

wire clamps

at the

gas tank location

and

routed

to the gas

tank hinge strap

access hole where

the

tubing

end is

protected

by a

rubber

grommet

and a

screw

and

shield secured

in the

hole

at

the strap

end.

FWD.

SEDANS

6-PASS.

STATION WAGON

Fig. 16—Fuel Tank Gauge Sending Units and Strainers

CHEVROLET CHASSIS SERVICE MANUAL