CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 431 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-25

4.

Cut the exhaust pipe near the muffler (see cau-

tion above) to allow sufficient pipe for muffler

replacement.

5.

^

Replace muffler and secure with new clamps.

NOTE:

Clamps must be assembled with nuts

attached toward the rear of the vehicle -

reference 90° to sawcuts in service muffler

pipe.

6. Reverse procedure for installation.

NOTE:

If bracket mounting insulators (tire

carcass mountings) are fatigued, replace to in-

sure a secure exhaust system.

7. In the event the tail pipe bezel has been damaged and

replacement is required, remove three screws and

replace the bezel. i

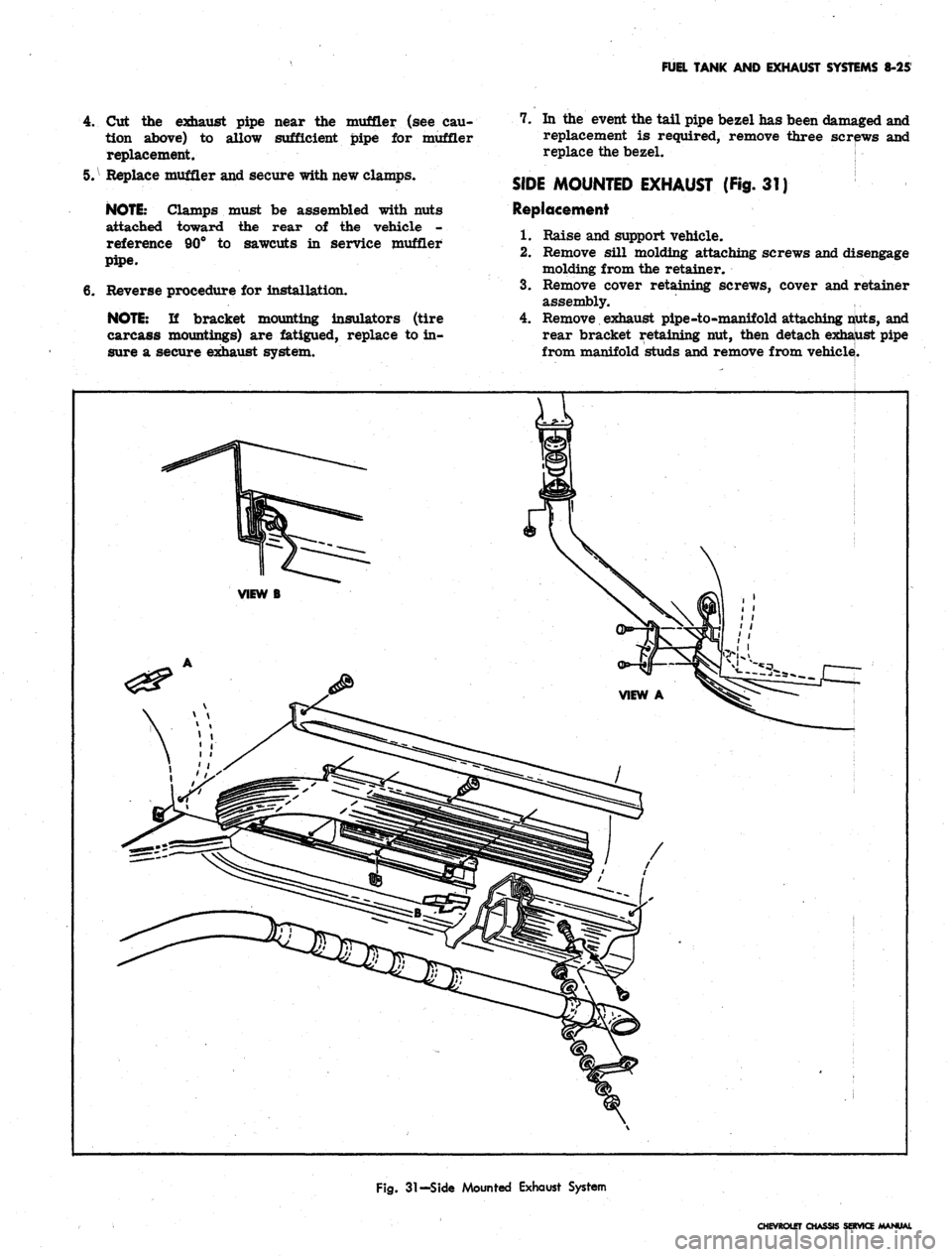

SIDE MOUNTED EXHAUST (Fig. 31)

Replacement

1.

Raise and support vehicle.

2.

Remove sill molding attaching screws and disengage

molding from the retainer.

3.

Remove cover retaining screws, cover and retainer

assembly.

4.

Remove exhaust pipe-to-manifold attaching nuts, and

rear bracket retaining nut, then detach exhaust pipe

from manifold studs and remove from vehicle.

Fig.

31—Side Mounted Exhaust System

CHEVROLET

CHASSIS SEKVK

Page 432 of 659

FUEL TANK AND EXHAUST SYSTEMS

8-26

5. To install, assemble the bolt, washers, insulator, install pipe-to-manifold retaining nuts. Tighten all

cover bracket and retaining nut to the exhaust pipe retaining nuts.

rear bracket. . 7. Position molding retainer and cover to sill and in-

6. Insert rear bracket bolt in frame opening, position stall retaining screws.

exhaust pipe to the manifold attaching studs and 8. Position sill molding and install retaining screws.

CHEVROLET CHASSIS SERVICE MANUAL

Page 433 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-27

CAMARO

INDEX

Page

General Description 8-27

Service Operations

Fuel Tank 8-28

Fuel Lines 8-28

Metering Units (Gauge Sending Unit) 8-28

GENERAL DESCRIPTION

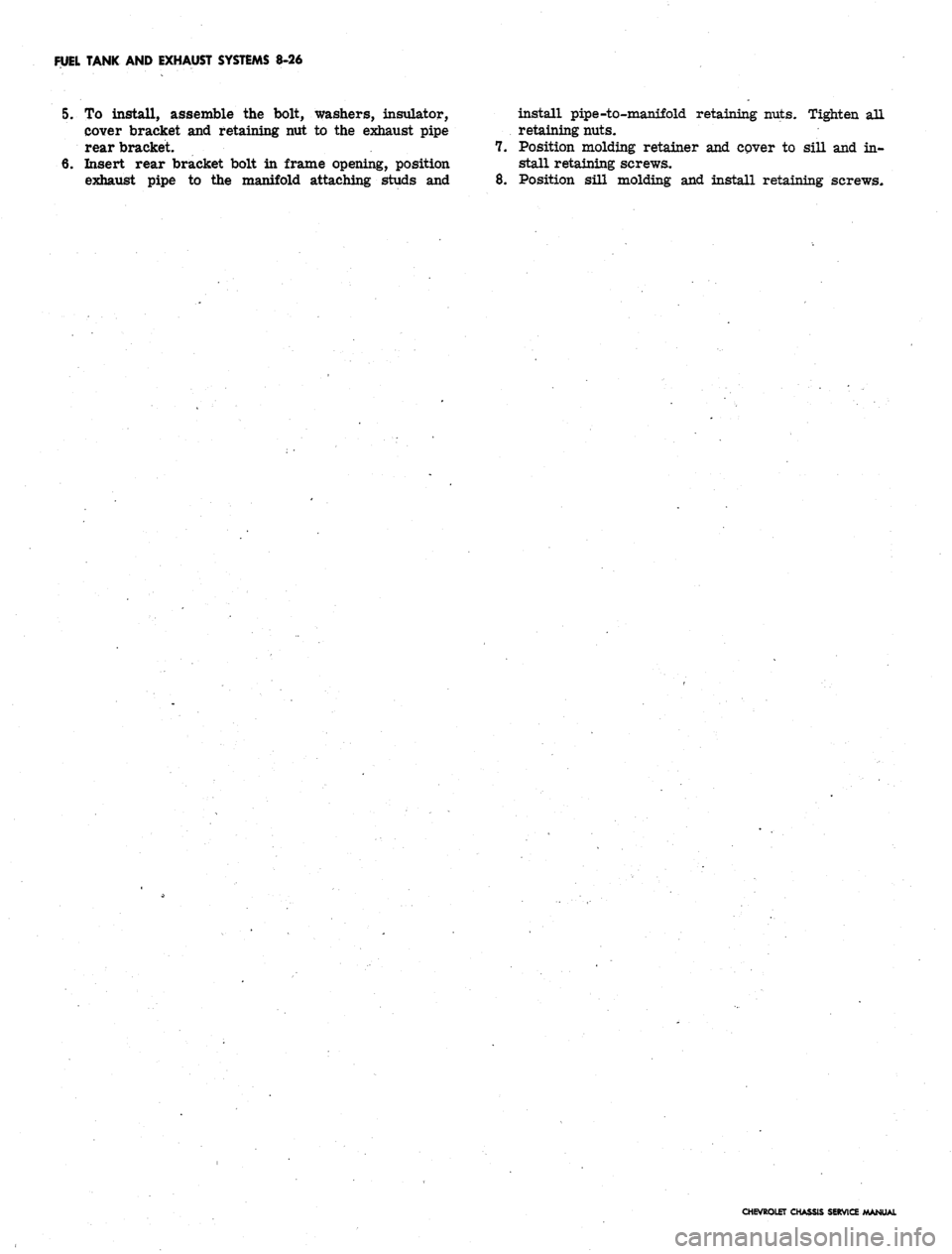

All models use an 18.5 gallon capacity (approx.) fuel

tank mounted between the frame rails behind the rear

axle (fig. 32). All fuel tanks are vented through an anti-

surge type filler cap assembly consisting of cap and

handle. The carrying straps hook through a double slot

in the front of the rear compartment reinforcements and

attach to strap bolts positioned in slots provided at the

rear panel reinforcements. A conventional fuel meter

VIEW B

Fig.

32—Fuel Tank Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 434 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-28

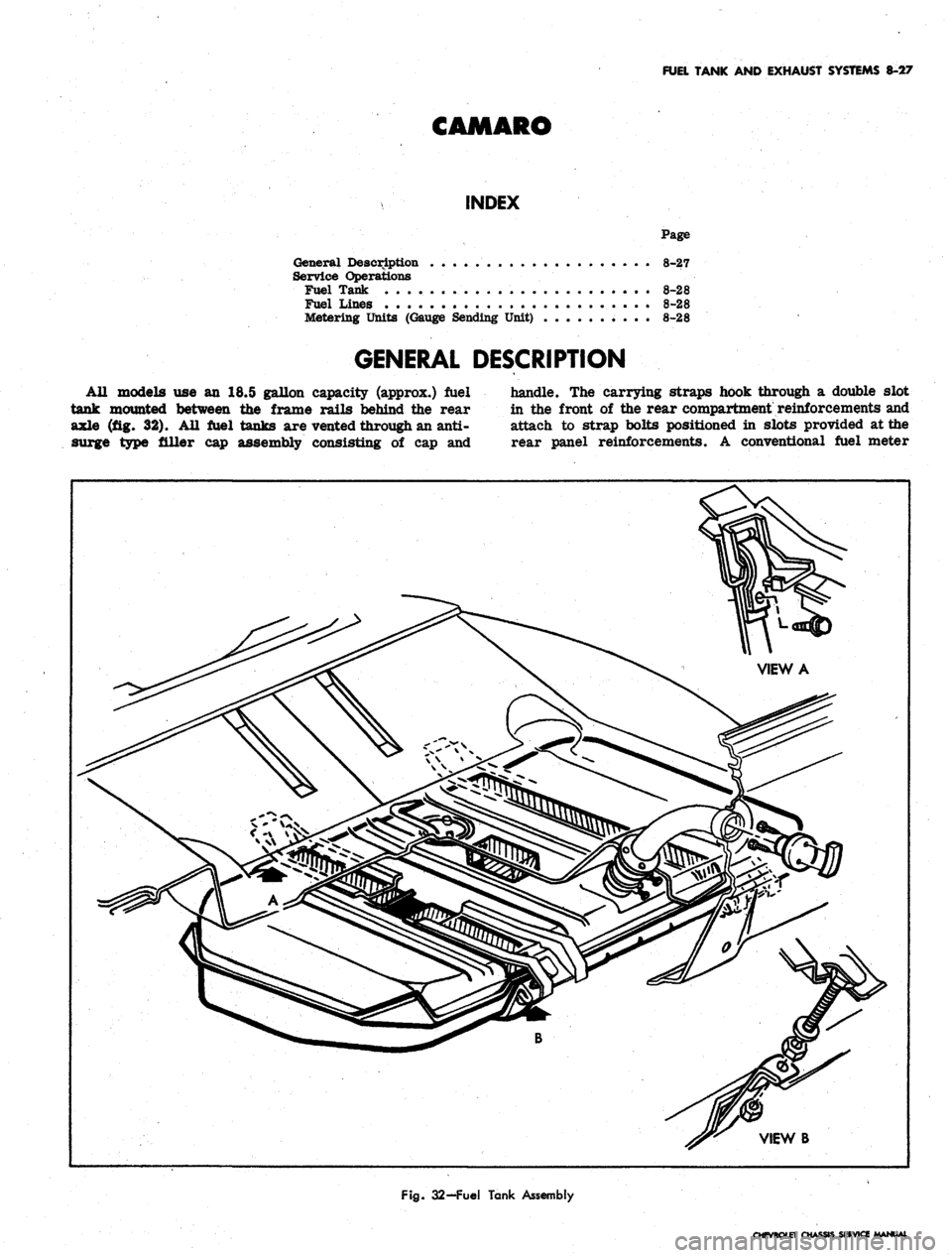

assembly is mounted on top of the tank and cannot be

removed for service without lowering the tank. The

upper filler neck assembly is routed through an opening

in the rear panel above the bumper and through the trunk

floor pan (fig. 33). The filler neck is not centered in the

rear panel but offset to the right to obtain the proper fill

rate.

The fuel pickup pipe is an integral part of the tank

meter unit^ located at the top front center of the tank. A

fine mesh screen is located at the bottom end of the fuel

pickup pipe to prevent the entrance of foreign material

into the fuel system.

Fig.

33—Filler Neck Assembly

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

Refer to Chevrolet page 8-2.

Removal and Installation

1.

Drain fuel tank. .'...' .

2.

Raise vehicle.

3.

Disconnect fuel pickup line, gauge wire and ground

lead from tank unit.

4.

Loosen filler neck inlet hose clamp.

5. Remove tank support strap bolts and straps, then

lower tank carefully.

6. Reverse procedure to install.

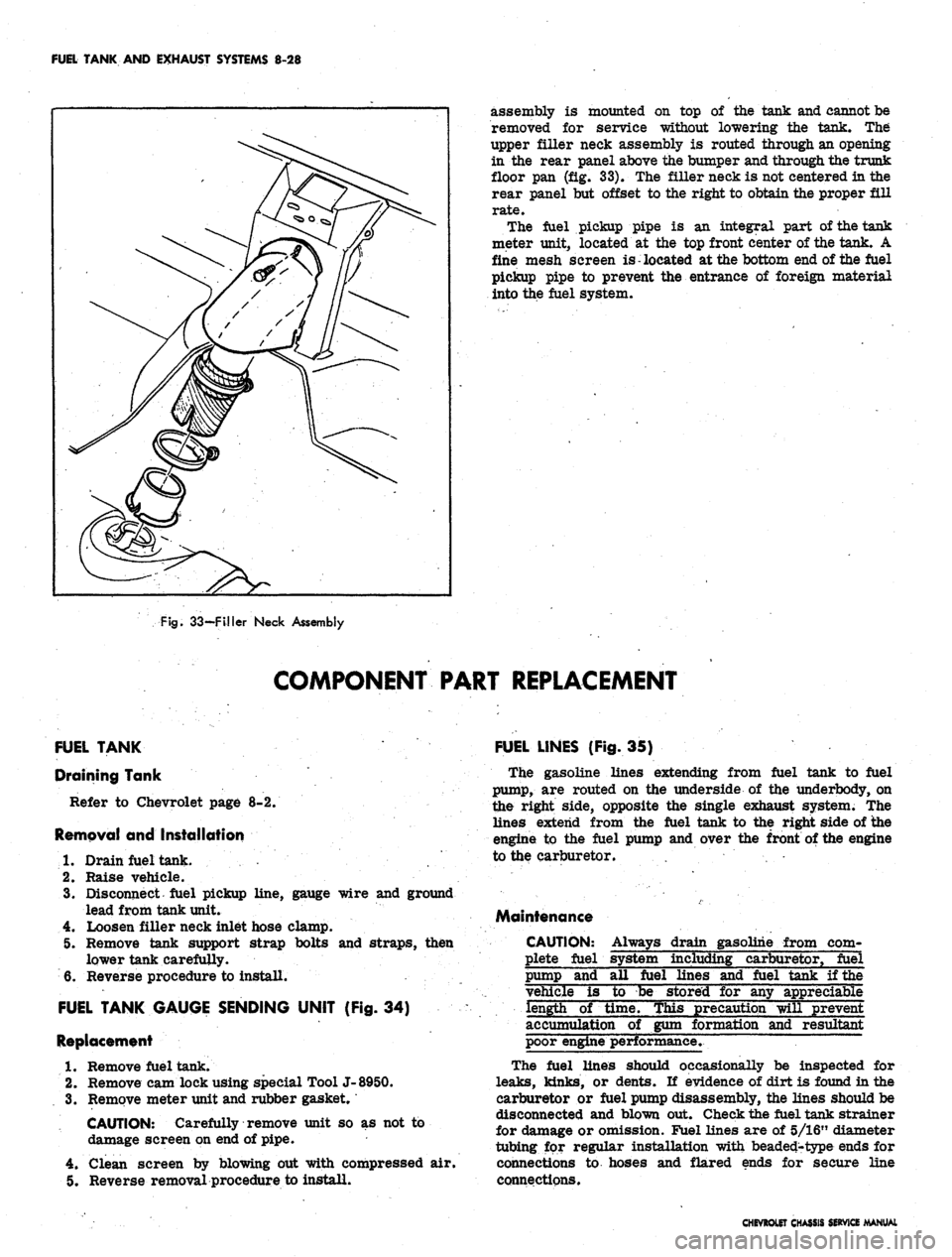

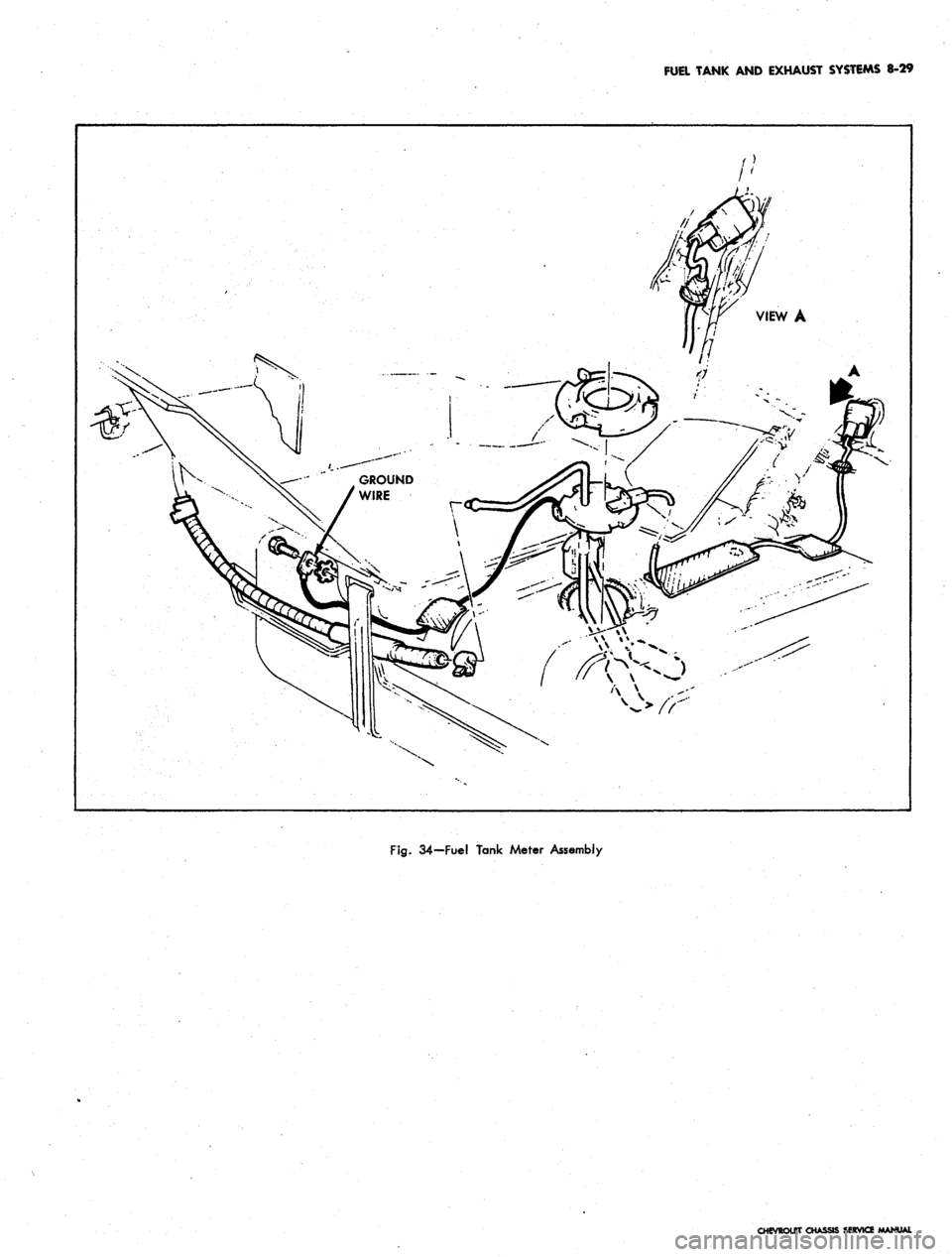

FUEL TANK GAUGE SENDING UNIT (Fig. 34)

Replacement

1.

Remove fuel tank.

2.

Remove cam lock using special Tool J-8950.

3.

Remove meter unit and rubber gasket.

CAUTION: Carefully remove unit so as not to

damage screen on end of pipe.

4.

Clean screen by blowing out with compressed air.

5. Reverse removal procedure to install.

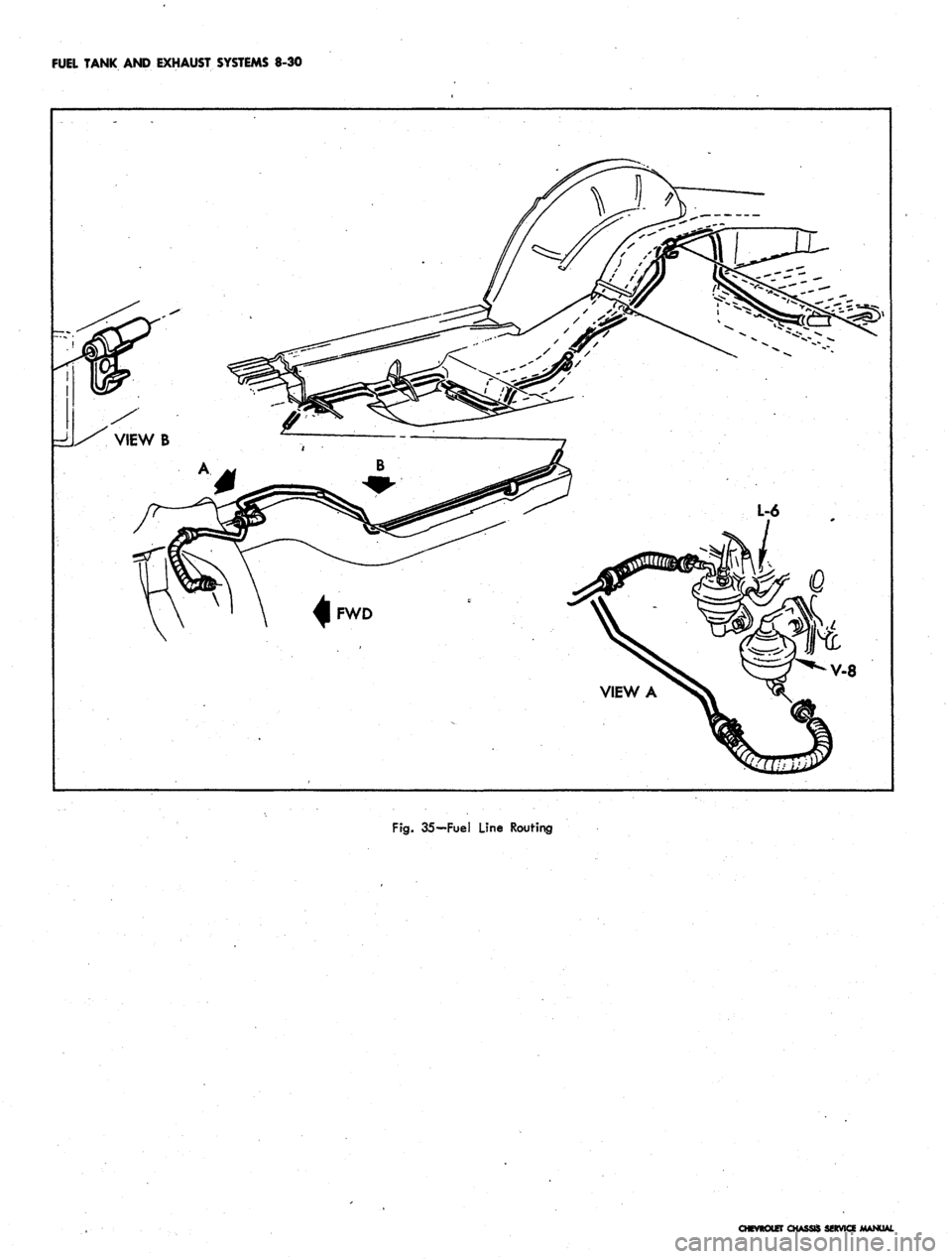

FUEL LINES (Fig. 35)

The gasoline lines extending from fuel tank to fuel

pump,

are routed on the underside of the underbody, on

the right side, opposite the single exhaust system. The

lines extend from the fuel tank to the right side of the

engine to the fuel pump and over the front of the engine

to the carburetor.

Maintenance

CAUTION:

plete fuel

Always drain gasoline from corn-

including carburetor, fuel

pump and

fuel lines and fuel tank if the

vehicle is to be stored for any

eciable

length of time. This precaution will prevent

accumulation of gum formation and resultant

poor engine performance.

The fuel lines should occasionally be inspected for

leaks,

kinks, or dents. If evidence of dirt is found in the

carburetor or fuel pump disassembly, the lines should be

disconnected and blown out. Check the fuel tank strainer

for damage or omission. Fuel lines are of 5/16" diameter

tubing for regular installation with beaded-type ends for

connections to hoses and flared ends for secure line

connections.

CHEVROLET CHASSIS SERVICE MANUAL

Page 435 of 659

FUEL TANK AND EXHAUST SYSTEMS 8*29

Fig.

34—Fuel Tank Meter Assembly

CHEVROUET CHASSIS SERVICE MANUAL

Page 436 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-30

Fig.

35—Fuel Line Routing

CHEVROLET CHASSIS SERVICE MANUAL

Page 437 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-31

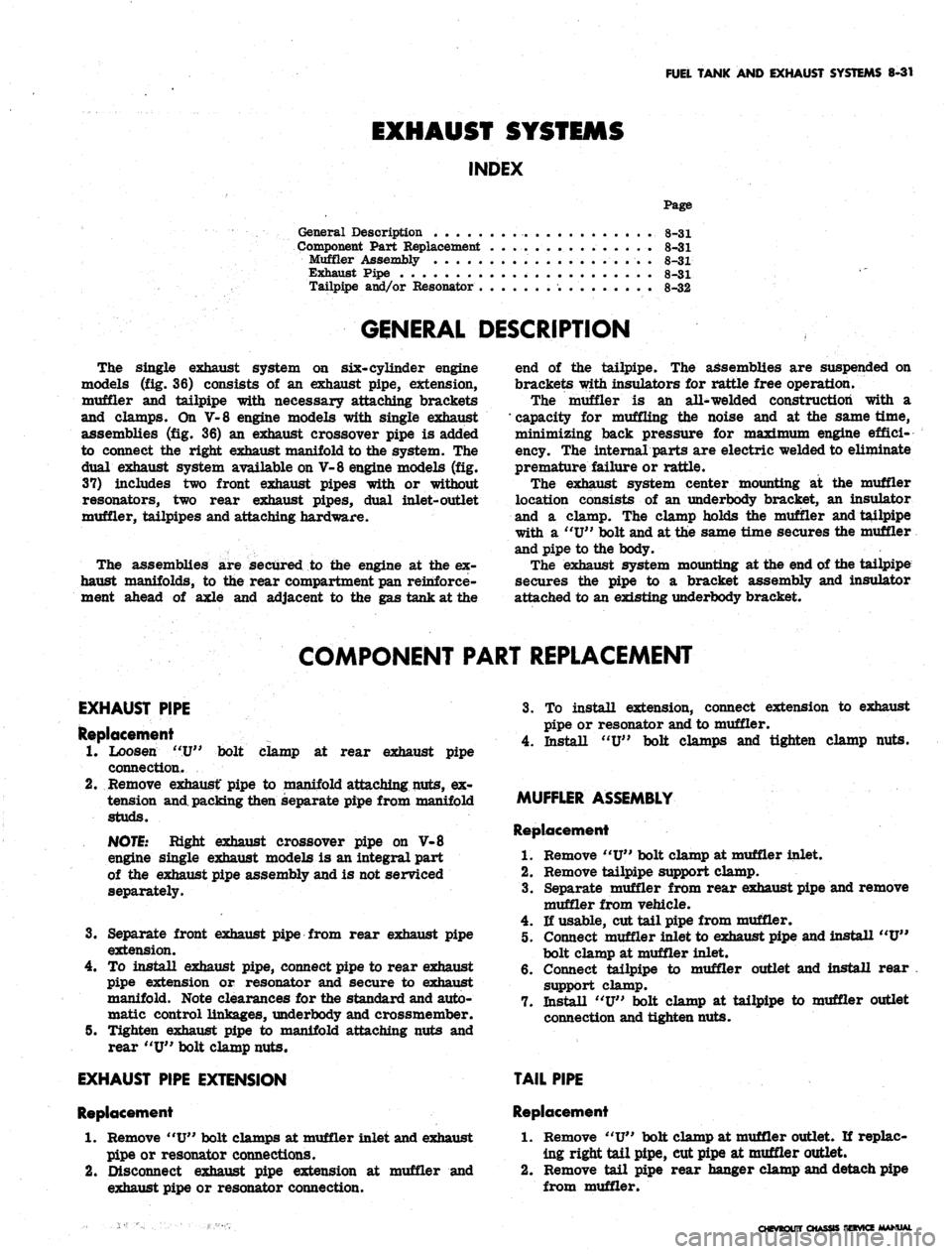

EXHAUST SYSTEMS

INDEX

Page

General Description

8-31

Component Part Replacement

8-31

Muffler Assembly

8-31

Exhaust Pipe

. 8-31

Tailpipe and/or Resonator

8-32

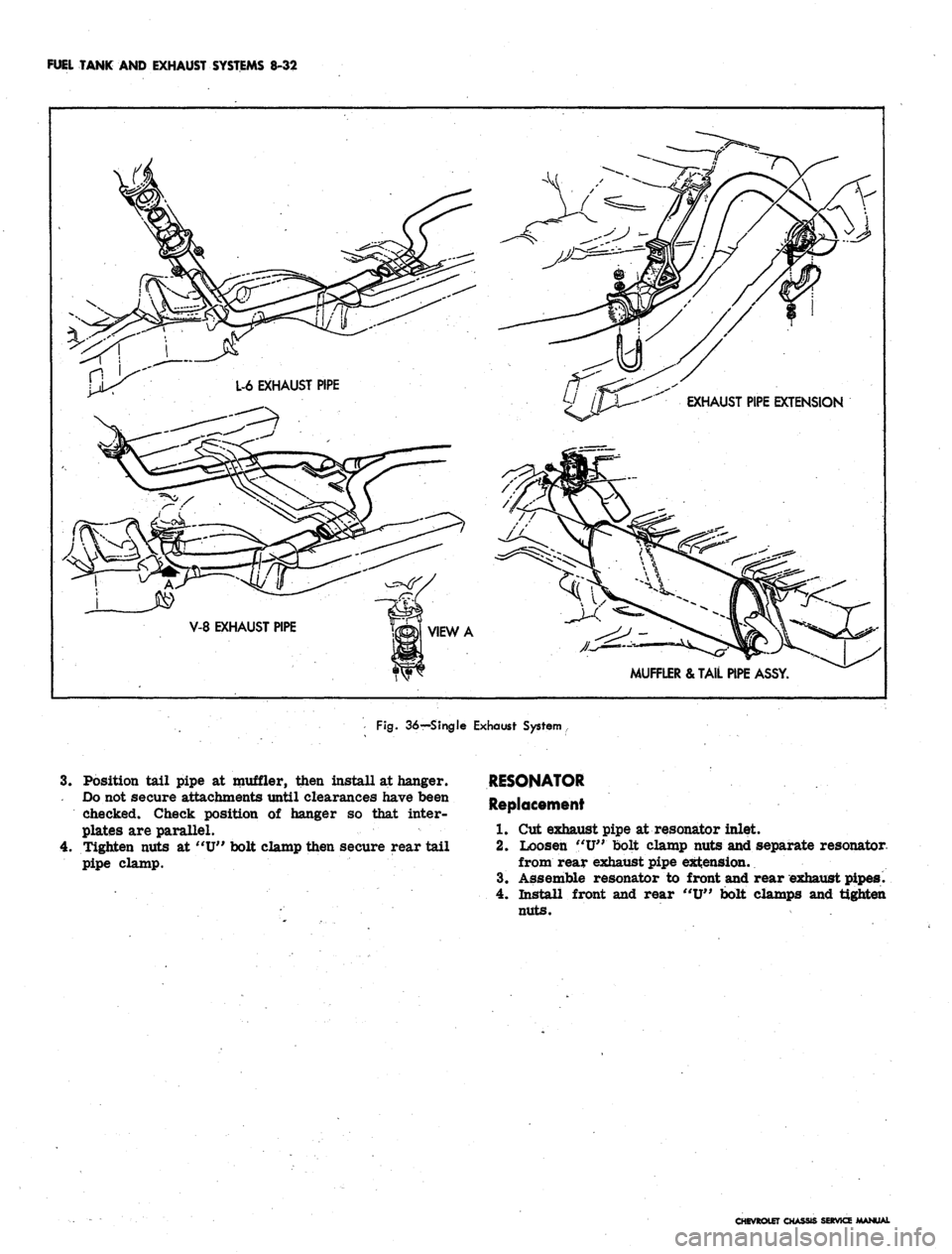

GENERAL DESCRIPTION

The single exhaust system

cm

six* cylinder engine

models

(fig. 36)

consists

of an

exhaust pipe, extension,

muffler

and

tailpipe with necessary attaching brackets

and clamps.

On V-8

engine models with single exhaust

assemblies

(fig. 36) an

exhaust crossover pipe

is

added

to connect

the

right exhaust manifold

to the

system.

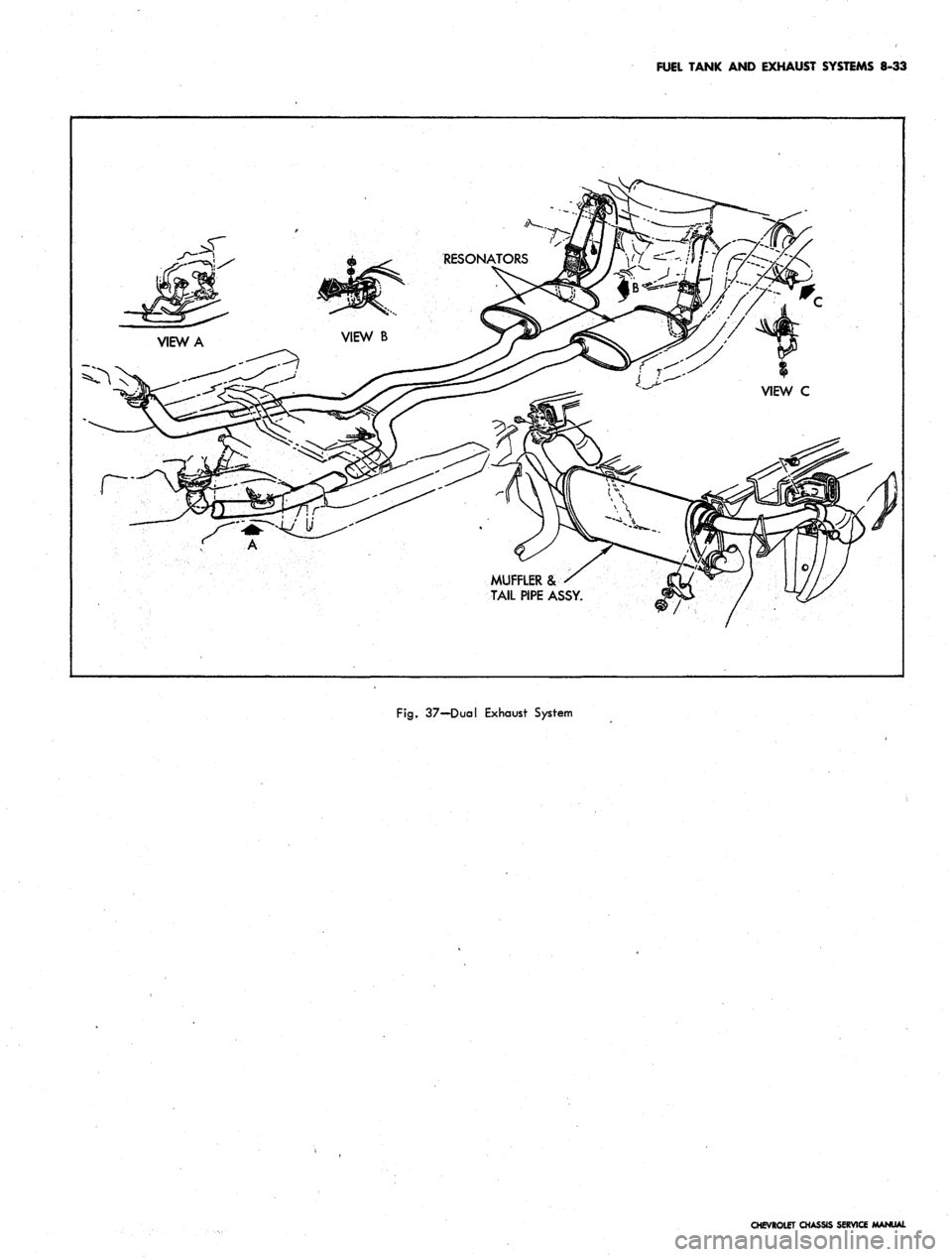

The

dual exhaust system available

on V-8

engine models

(fig.

37) includes

two

front exhaust pipes -with

or

without

resonators,

two

rear exhaust pipes, dual inlet-outlet

muffler, tailpipes and attaching hardware.

The assemblies

are

secured

to the

engine

at the ex-

haust manifolds,

to the

rear compartment pan reinforce-

ment ahead

of

axle

and

adjacent

to the gas

tank

at the

end

of the

tailpipe.

The

assemblies

are

suspended

on

brackets with insulators

for

rattle free operation.

The muffler

is an

all-welded construction with

a

•

capacity

for

muffling

the

noise

and at the

same time,

minimizing back pressure

for

maximum engine effici-

ency.

The

internal parts

are

electric welded

to

eliminate

premature failure

or

rattle.

The exhaust system center mounting

at the

muffler

location consists

of an

underbody bracket,

an

insulator

and

a

clamp.

The

clamp holds

the

muffler and tailpipe

with

a

"U" bolt and

at

the same time secures

the

muffler

and pipe

to the

body.

The exhaust system mounting

at the

end

of

the tailpipe

secures

the

pipe

to a

bracket assembly

and

insulator

attached

to an

existing underbody bracket.

COMPONENT PART REPLACEMENT

EXHAUST PIPE

Replacement

1.

Loosen

"U"

bolt clamp

at

rear exhaust pipe

connection.

2.

Remove exhaust pipe

to

manifold attaching nuts,

ex-

tension

and.

packing then separate pipe from manifold

studs.

NOTE:

Right exhaust crossover pipe

on V-8

engine single exhaust models

is an

integral part

of

the

exhaust pipe assembly and

is not

serviced

separately.

3.

Separate front exhaust pipe from rear exhaust pipe

extension.

4.

To

install exhaust pipe, connect pipe

to

rear exhaust

pipe extension

or

resonator

and

secure

to

exhaust

manifold. Note clearances

for

the standard and auto-

matic control linkages, underbody

and

crossmember.

5. Tighten exhaust pipe

to

manifold attaching nuts

and

rear "U" bolt clamp nuts.

EXHAUST PIPE EXTENSION

Replacement

1.

Remove "U" bolt clamps

at

muffler inlet and exhaust

pipe

or

resonator connections.

2.

Disconnect exhaust pipe extension

at

muffler

and

exhaust pipe

or

resonator connection.

3.

To

install extension, connect extension

to

exhaust

pipe

or

resonator and

to

muffler.

4.

Install

"V"

bolt clamps

and

tighten clamp nuts.

MUFFLER ASSEMBLY

Replacement

1.

Remove "U" bolt clamp

at

muffler inlet.

2.

Remove tailpipe support clamp.

3.

Separate muffler from rear exhaust pipe

and

remove

muffler from vehicle.

4.

If

usable,

cut

tail pipe from muffler.

5. Connect muffler inlet

to

exhaust pipe and install

"U"

bolt clamp

at

muffler inlet.

6. Connect tailpipe

to

muffler outlet

and

install rear

support clamp.

7. Install

"U"

bolt clamp

at

tailpipe

to

muffler outlet

connection and tighten nuts.

TAILPIPE

Replacement

1.

Remove

"U"

bolt clamp

at

muffler outlet.

If

replac-

ing right tail pipe, eut pipe

at

muffler outlet.

2.

Remove tail pipe rear hanger clamp and detach pipe

from muffler.

&IS SBtVKE MANUAL

Page 438 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-32

EXHAUST PIPE EXTENSION

MUFFLER & TAIL PIPE ASSY.

Fig.

36—Single Exhaust System

3.

Position tail pipe at muffler, then install at hanger.

Do not secure attachments until clearances have been

checked. Check position of hanger so that inter-

plates are parallel.

4.

Tighten nuts at "U" bolt clamp then secure rear tail

pipe clamp.

RESONATOR

Replacement

1.

Cut exhaust pipe at resonator inlet.

2.

Loosen "U" bolt clamp nuts and separate resonator

from rear exhaust pipe extension.

3.

Assemble resonator to front and rear exhaust pipes!

4.

Install front and rear "U" bolt clamps and tighten

nuts.

CHEVROLET CHASSIS SERVICE MANUAL

Page 439 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-33

MUFFLER &

TAIL PIPE ASSY.

Fig.

37—Dual Exhaust System

CHEVROLET CHASSIS SERVICE MANUAL

Page 440 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-34

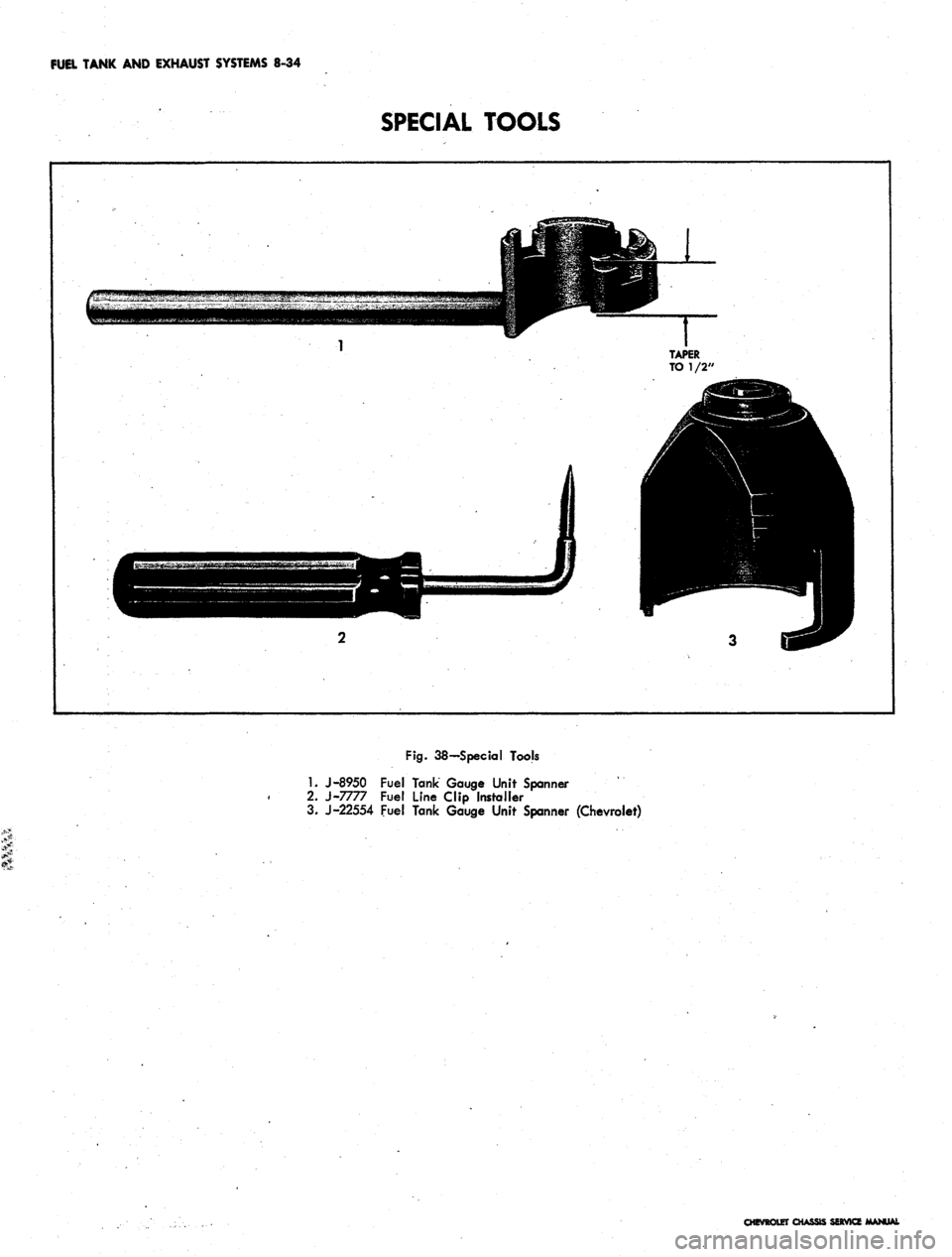

SPECIAL

TOOLS

Fig.

38-Special Tools

1.

J-8950 Fuel Tank Gauge Unit Spanner '

2.

J-7777 Fuel Line Clip Installer

3. J-22554 Fuel Tank Gauge Unit Spanner (Chevrolet)

CHEVROLET CHASSIS SERVICE MANUAL