ABS CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 335 of 659

ENGINE-ELECTRICAL 6Y-10

circuit. Make absolutely certain all connections in

the circuit are secure.

5.

Do not short across or ground any of the terminals

on the generator or regulator.

6. Do not attempt to polarize the generator.

7.

Do not disconnect lead at generator without first dis-

connecting battery ground cable.

Trouble in the A.C. charging system will usually be

indicated by one or more of the following conditions:

1.

Faulty indicator lamp or ammeter operation.

2.

An undercharged battery (usually evidenced by slow

cranking speeds).

3.

An overcharged battery (usually evidenced by exces-

sive battery water usage).

4.

Excessive generator noise or vibration.

Described below are a series of on-the-vehicle quick

checks which are designed to assist the service tech-

nician in locating troubles within the various components

of the engine electrical system. Additional checks, ad-

justments and overhaul procedures of these components

are also described in the "Charging Systems—Service

Operations Section" and should be referred to as

necessary.

STATIC CHECKS

Before making any electrical checks, perform the fol-

lowing static checks:

1.

Check for loose fan belt.

2.

Check for defective battery. (Refer to Battery).

3.

Inspect all connections, including the slip-on con-

nectors at the regulator and Delcotron.

NOTE: Do not short field to ground to check if

generator is charging since this will seriously

damage the charging system.

SYSTEM CONDITION TEST

This test is used .to indicate the overall condition of the

charging system (both good and defective) and to isolate

the malfunctioning unit if the system is defective.

NOTE: On Corvette models difficulty may be

encountered -when attempting to make the re-

quired test connections at the voltage regulator.

It is advisable to remove the regulator from its

mounting location to perform the necessary con-

nections at the regulator for the following tests

but make sure unit is grounded.

1.

With ignition off, perform the prescribed Static

Checks outlined in this section. Then set hand brake

and shift transmission

into

neutral.

2.

Connect a voltmeter from junction block relay to

ground at regulator base.

CAUTION: Be sure meter clip does not touch a

resistor or terminal extension under regulator,

3.

Connect a tachometer on engine.

4.

Models equipped with Indicator Lamp: Turn ignition

switch on "ON" position and check indicator lamp.

If lamp fails to glow, perform appropriate tests and

corrections (Indicator Lamp Circuit Tests) before

continuing.

Models equipped with Ammeter: Turn ignition

switch to "ACC" with an accessory on and check

ammeter. If ammeter fails to read discharge, check

ammeter circuit before continuing.

5.

Models equipped with Indicator Lamp: If lamp glows,

start the engine and run' it at 1500 rpm or above.

Check indicator lamp. If lamp fails to go out, per-

form appropriate test and corrections (Indicator

Lamp Circuit Test) before continuing.

Models equipped with Ammeter: If ammeter reads

discharge, start the engine and observe ammeter. If

meter fails to move toward charge (from original

position), perform appropriate test and corrections

(Field Circuit Tests) before continuing.

NOTE: At this point a field circuit has been

established and any other problem will lie in

generator or regulator.

6. Turn on high-beam headlights and heater blower

motor to high speed, run engine at or above 1500

rpm (for a few minutes, if necessary) and read the

voltage on meter.

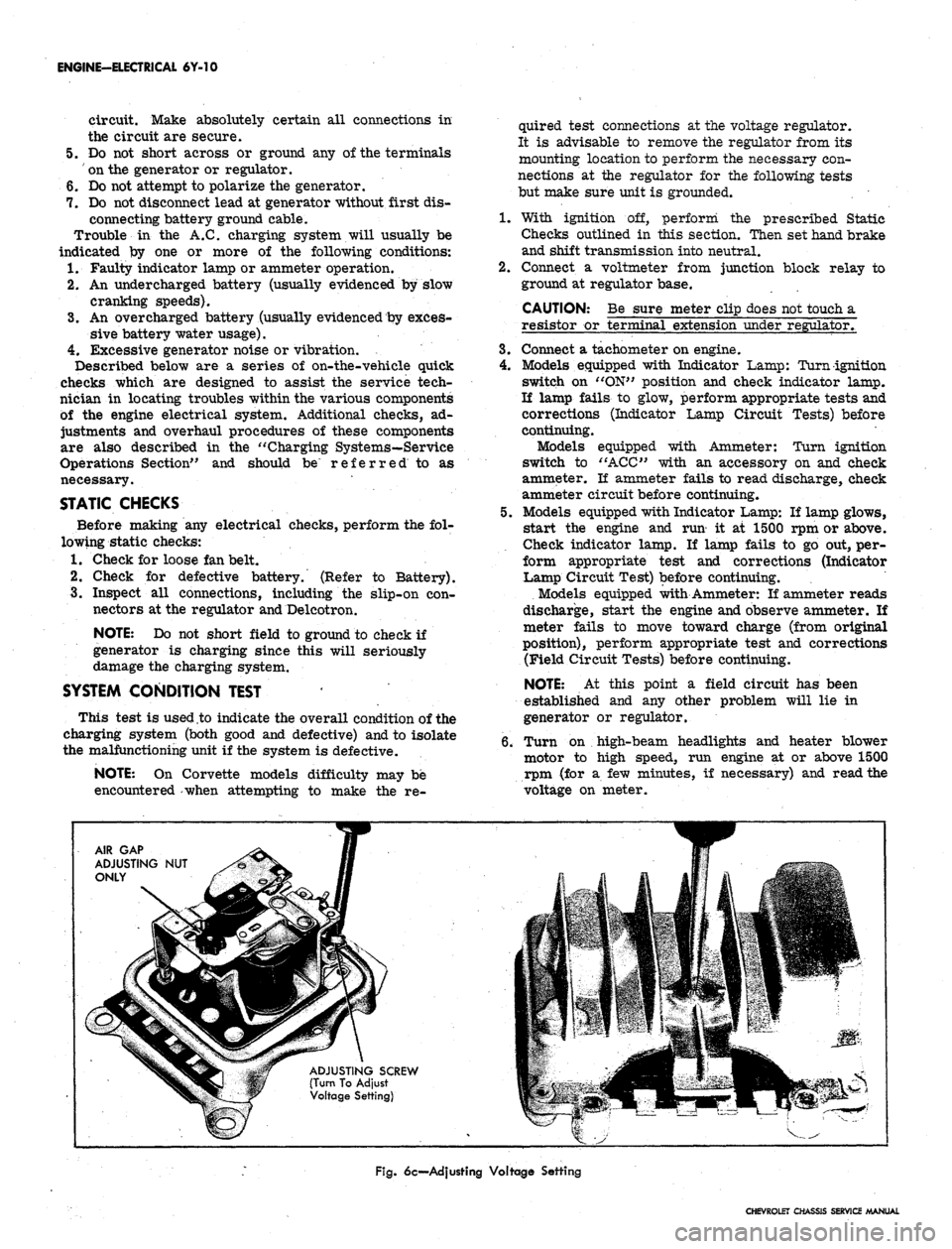

AIR GAP

ADJUSTING NUT

ONLY

ADJUSTING SCREW

(Turn To Adjust

Voltage Setting)

Fig.

6c—Adjusting Voltage Setting

CHEVROLET CHASSIS SERVICE MANUAL

Page 350 of 659

ENGINE-ELECTRICAL 6Y-25

1.

Remove the rotor.

2.

Remove both weight springs and advance weights.

3.

Remove roll pin retaining driven gear to distributor

shaft, slide the gear and spacers from the shaft.

Remove tachometer drive gear on Corvette models.

4.

Before sliding the distributor shaft from the hous-

ing, check for and remove any burrs on the shaft.

This will prevent damage to the seals and bushing

still positioned in the housing.

5. Slide the distributor mainshaft and cam-weight base

assembly from the housing.

6. Remove vacuum advance mechanism retaining

screws, remove the vacuum advance assembly.

7. Remove the spring retainer, remove the breaker

plate assembly from the distributor housing. Re-

move the contact point and condenser from the

breaker plate. Remove the felt washer and plastic

seal located beneath the breaker plate.

CLEANING AND INSPECTION

1.

Wash all parts in cleaning solvent except cap, rotor,

condenser, breaker plate assembly and vacuum con-

trol unit. Degreasing compounds may damage insula-

tion of these parts or saturate the lubricating felt in

the case of the breaker plate assembly.

2.

Inspect the breaker plate assembly for damage or

wear and replace if necessary.

3.

Inspect the shaft for wear and check its fit in the

bushings in the distributor body. If the shaft or bush-

ings are worn, the parts should be replaced.

4.

Mount the shaft in "V" blocks and check the shaft

alignment with a dial guage. The run-out should not

exceed .002".

5. Inspect the advance weights for wear or burrs and

free fit on their pivot pins.

6. Inspect the cam for wear or roughness. Then check

its fit on the end of the shaft. It should be absolutely

free without any roughness.

7. Inspect

the •

condition of the distributor points. Dirty

points should be cleaned and badly pitted points

should be replaced. (See Distributor Contact Points.)

8. Test the condenser for series resistance, micro-

farad capacity (.18 to .23) and leakage or breakdown,

following the instructions given by the manufacturer

of the test equipment used.

9. Inspect the distributor cap and sparkplug wires for

damage and replace if necessary.

ASSEMBLY

Four and Six Cylinder Engine

Refer to Figure 12i for Exploded View of Distributor.

1.

Replace cam assembly to mainshaft.

NOTE:

Lubricate top end of shaft with Delco

cam and ball bearing grease or equivalent prior

to replacing.

2.

Install governor weights on their pivot pins, replace

weight springs. Install weight cover and stop plate.

3.

Lubricate mainshaft and install it in distributor

housing.

4.

Install distributor driven gear to mainshaft and in-

sert attaching roll pin. Check to see that shaft turns

freely.

5. Install breaker plate assembly in the distributor body

and attach retaining screws.

6. Attach condenser and contact point set in proper lo-

cation with appropriate attaching screws.

NOTE:

Contact point set pilot must engage

matching hole in breaker plate. Connect primary

and condenser leads to contact set quick-

disconnect terminal.

7. Attach vacuum control assembly to distributor

housing.

8. Check and adjust contact point opening and align-

ment (See setting and alignment of points.)

9. Check breaker lever spring tension which should

be.

19-23 ounces. (See contact point replacement.)

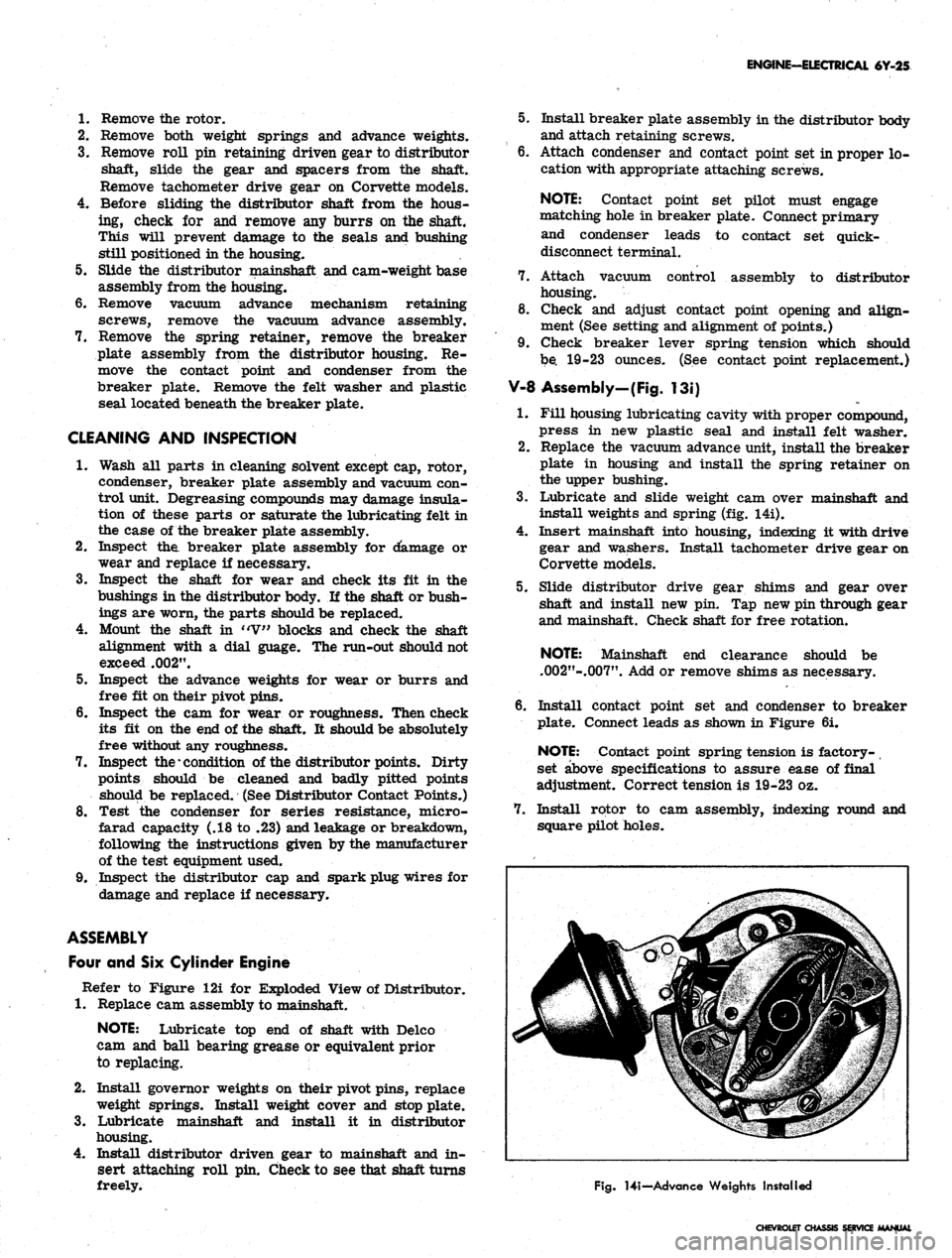

V-8 Assembly-(Fig. 13i)

1.

Fill housing lubricating cavity with proper compound,

press in new plastic seal and install felt washer.

2.

Replace the vacuum advance unit, install the breaker

plate in housing and install the spring retainer on

the upper bushing.

3.

Lubricate and slide weight cam over mainshaft and

install weights and spring (fig. 14i).

4.

Insert mainshaft into housing, indexing it with drive

gear and washers. Install tachometer drive gear on

Corvette models.

5. Slide distributor drive gear shims and gear over

shaft and install new pin. Tap new pin through gear

and mainshaft. Check shaft for free rotation.

NOTE:

Mainshaft end clearance should be

.002"-.007". Add or remove shims as necessary.

6. Install contact point set and condenser to breaker

plate. Connect leads as shown in Figure 6i.

NOTE:

Contact point spring tension is factory-

set above specifications to assure ease of final

adjustment. Correct tension is 19-23 oz.

7. Install rotor to cam assembly, indexing round and

square pilot holes.

Flg.

Hi-Advance Weights Installed

CHEVROLET CHASSIS SERVICE

Page 391 of 659

CLUTCH AND TRANSMISSIONS 7-32

21.

Remove transmission output shaft slip yoke and in-

sert a plastic shipping plug in end of extension to

prevent spillage of transmission fluid.

NOTE:

The yoke is removed to avoid tearing

the heat reflecting pad on the underbbdy, when

the transmission is being removed.

22.

Remove bright metal ignition shielding from dis-

tributor area.

23.

Remove the transmission dip stick and tube

assembly.

24.

Disconnect transmission vacuum modulator line at

distributor advance line tee.

25.

Position transmission hoist under transmission and

attach safety chain to transmission.

26.

Remove transmission converter housing-to-engine

attaching foolts and slide transmission rearward.

NOTE:

Observe converter when moving trans-

mission rearward. If converter does not move

with the transmission, pry it free of flywheel

before proceeding.

27.

Install converter retaining strap.

28.

Lower and remove transmission from vehicle by

tilting the front down and to the right while inter-

mittently lowering the transmission to facilitate its

• removal.

29.

Reinstall transmission assembly by performing the

above steps in reverse order.

Bolt Torques

Transmission Case to Flywheel

Housing Bolts 35 ft. lbs.

Converter to Flywheel Bolts. . , . . 35 ft. lbs.

OTHER SERVICE OPERATIONS

Although certain operations, such as oil pan or gasket

replacement, valve body, governor, filler pipe "O" ring,

speedometer drive gear, case extension "0" ring and

rear oil seal, vacuum modulator, and servo cover or

gasket service may be performed from underneath the

vehicle without removing the Powerglide; their service

procedure is covered in the Passenger Overhaul Manual

and is not repeated here. Refer to the- Powerglide Sec-

tion of the Passenger Overhaul Manual for all other

service operations not covered here.

DIAGNOSIS

Proper operation of the Powerglide transmission may

be affected by a number of factors, all of which must be

considered when trouble in the unit is diagnosed.

Proper trouble diagnosis can only be accomplished

when performed in a thorough step by step procedure.

The following procedure has been devised and tested and

is recommended for all trouble diagnosis complaints and

if the service man will follow this checking procedure,

accurate and dependable diagnosis may be accomplished.

This will result in a savings of time, not only to the

service man, but to the customer as well.

WARMING UP TRANSMISSION

Before attempting to check and/or correct any com-

plaints on the Powerglide transmission it is absolutely

essential that the oil level be checked and corrected if

necessary. An oil level which is either too high or too

low can be the cause of a number of abnormal conditions

from excessive noise to slippage in all ranges.

It must be remembered that cold oil will slow up the

action of the hydraulic controls in the transmission. For

this reason a trouble or oil leak diagnosis should not be

attempted until the transmission has been warmed up by

either of the following procedures:

Shop Warm Up

1.

Connect tachometer to engine.

2.

Set parking brake tight and start engine.

3.

Place selector light in

"D"

(drive) range.

4.

Adjust carburetor idle speed adjusting screw to run

engine at approximately 750 rpm and operate in this

manner for two minutes. At the end of two minutes

of operation, the transmission will be sufficiently

warmed up for diagnosis purposes.

NOTE:

At this point, readjust the engine idle

speed to 450-475 rpm in

"D"

range.

Road Warm Up

Drive the car approximately 5 miles with frequent

starts and stops.

NOTE:

At this point, make sure the engine idle

speed is set to 450-475 rpm in

"D"

range.

CHECKING FLUID LEVEL AND CONDITION

After transmission has been warmed up, check the

fluid level with the engine idling, parking brake set and

control lever in "N" (neutral). If the fluid level is low,

add fluid to bring level up to the full mark on gauge rod,

CAUTION: If fluid level is too high, fluid may

be aerated by the planet carrier. Aerated fluid

will cause turbulence in the converter which will

result in lost power, lower stall speed and lower

pressures in control circuits. Lower fluid level

to full mark, then shut off engine to allow air

bubbles to work out of fluid.

When checking oil level, aburned smell and discolora-

tion indicate burned clutches or bands and the transmis-

sion will have to be removed.

MANUAL LINKAGE

Manual linkage adjustment and the associated neutral

safety switch are important from a safety standpoint.

The neutral safety switch should be adjusted so that the

engine will start in the Park and Neutral positions only.

With the selector lever in the Park position, the park-

ing pawl should freely engage and prevent the vehicle

CHEVROLET CHASSIS SERVICE MANUAL

Page 408 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-2

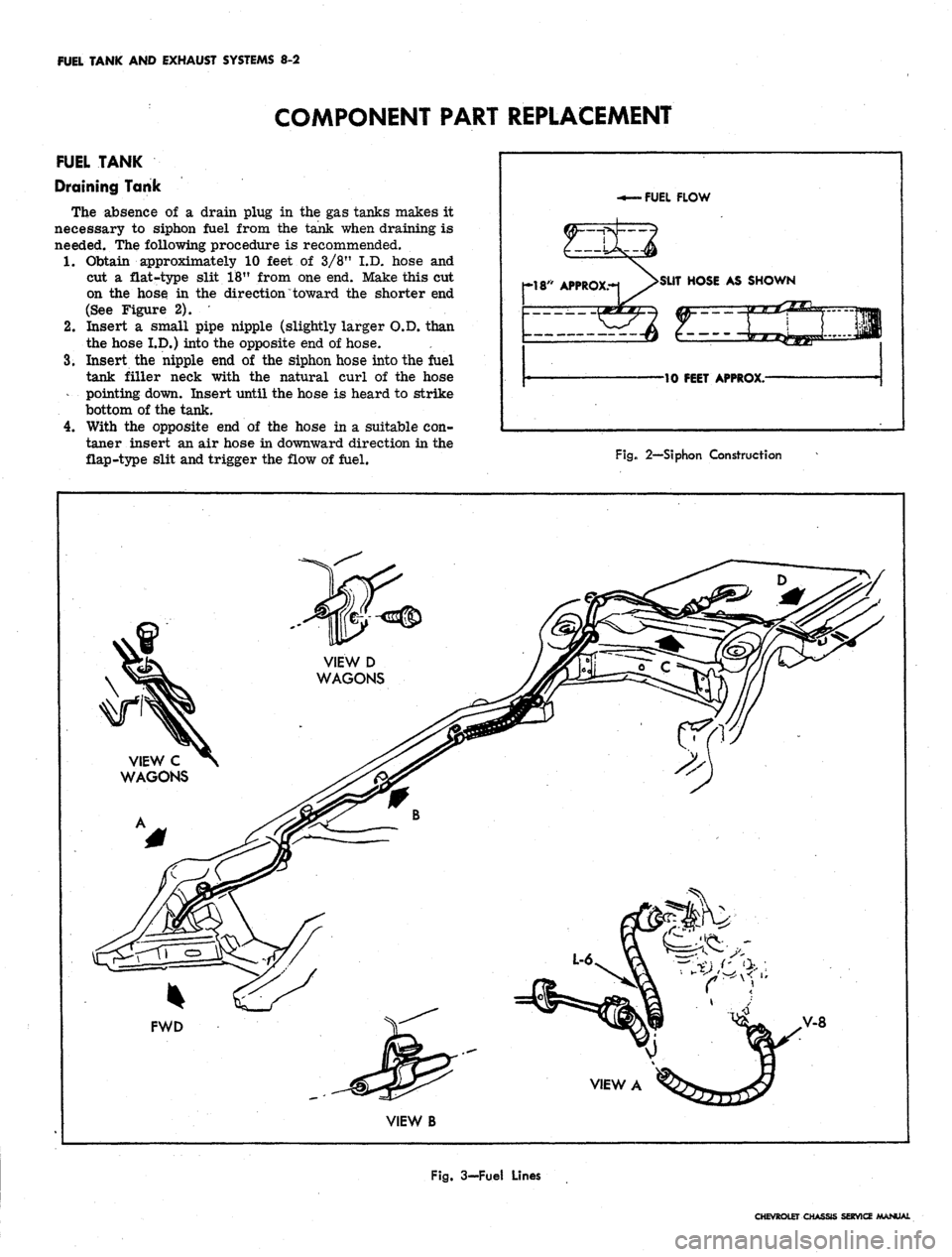

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

The absence of a drain plug in the gas tanks makes it

necessary to siphon fuel from the tank when draining is

needed. The following procedure is recommended.

1.

Obtain approximately 10 feet of 3/8" I.D. hose and

cut a flat-type slit 18" from one end. Make this cut

on the hose in the direction "toward the shorter end

(See Figure 2).

2.

Insert a small pipe nipple (slightly larger O.D. than

the hose I.D.) into the opposite end of hose.

3.

Insert the nipple end of the siphon hose into the fuel

tank filler neck with the natural curl of the hose

pointing down. Insert until the hose is heard to strike

bottom of the tank.

4.

With the opposite end of the hose in a suitable con-

taner insert an air hose in downward direction in the

flap-type slit and trigger the flow of fuel.

FUEL FLOW

-If*

APPROX.-1 >SUT «<>«

AS SHOWN

10 FEET APPROX.-

Fig. 2—Siphon Construction

FWD

V-8

VIEW B

Fig. 3-Fuel Lines

CHEVROLET CHASSIS SERVICE MANUAL

Page 414 of 659

FUEL TANK AND EXHAUST SYSTEMS

8-8

CHEVELLE

FUEL TANKS

INDEX

Page

General Description.

g.g

Component Part Replacement

8-8

Fuel Tanks

. 8-8

Fuel Lines

8-8

Metering Units (Gauge, Sending Unit)

Fuel Tank Filler Neck Caps.

. .

Fuel Tank Vent Lines

Page

8-8

8-8

8-9

GENERAL DESCRIPTION

All models

use a 20

gallon capacity (approx.) fuel tank

mounted between

the

frame rails behind

the

rear axle.

The fuel tanks

are

basically

the

same

for

sedan, 2-seat

station wagon

and

pickup models except

for

filler neck

location

and

venting

(fig. 8).

All fuel tanks

are

vented

to the

atmosphere. Sedan

model tanks have

an

external vent hose and pipe assem-

bly

(fig. 11) and use a

non-vented fuel cap. Station wagon

and pickup model tanks

are

vented through

a

hose

and

vent pipe assembly

to the

filler neck

(fig. 8)

and

use a

vented, anti-surge type

gas cap. The

fuel caps

are two

different designs conforming

to SAE

standards

and are

not interchangeable.

The filler neck assembly

on

sedan models

is a

rear

fill design located behind

the

center

bar of the

bumper.

Station wagon

and

sedan pickup model filler neck assem-

blies

are

located

in

the left rear quarter panel.

The fuel pickup pipe

is

built integrally with

the

tank

gauge, located

at the

top-front center

of

the tank.

A

fine

mesh screen

is

located

at

the bottom-end

of the

fuel pick-

up pipe

to

prevent

the

entrance

of

foreign material into

the fuel system.

The sedan fuel tanks

are

held

in

place

by

two metal

straps attached individually

to the

underbody

at

each

end.

The straps hinge

at the

forward end and secure

the

tank

at

the

rear with

an

adjustable bolt

and nut

assembly.

The station wagon

and

pickup models have

a

frame

mounted fuel tank secured with straps

to

front and rear

supports.

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

The absence

of a

drain plug

in the gas

tanks makes

it

necessary

to

siphon fuel from

the

tank when draining

is

needed. Refer

to the

recommended draining procedures

previously outlined under Chevrolet Models

in

this

section.

Removal

and

Installation (Sedan Models)

1.

Raise vehicle.

2.

Drain fuel tank.

3.

Disconnect fuel pickup line

and

gauge wires from

tank unit.

4.

Disconnect vent hose from tank.

5. Remove tank support straps and lower tank carefully.

6.

To

install, reverse

the

removal procedure.

Removal

and

Installation

(Station Wagon

and

Pickup)

1.

Follow Steps

1

thru

3

outlined under sedan models.

2.

Remove tank support straps.

3.

Remove frame screw attachments from

the

front

support

(fig. 8).

4.

Guide tank forward

and

remove.

5.

To

install, reverse removal procedure.

FUEL LINES

The fuel lines, extending from fuel tank toiiuelpump,

are routed

on the

underside

of the

underbody along

the

right side

of the

vehicle opposite

the

single exhaust

sys-

tem.

The

fuel lines should occasionally

be

inspected

for

leaks,

kinks,

or

dents.

If

evidence

of

dirt

is

found

in the

carburetor

or

fuel pump

on

disassembly,

the

lines should

be disconnected

and

blown

out.

Check

the

fuel tank

strainer

for

damage

or

omission. Fuel lines

are of 5/16"

diameter tubing with beaded type ends

for

connections

of

hoses.

FUEL PIPE RETAINER

CUP

Removal

and

Installation

If fuel pipes

and

retainer clips

are

removed, Tool

J-7777 should

be

used

to

install

new

retainer clips

(fig.

10).

After removal

of the old

clip from

the

frame, position

the

new

clip

in the

location

of the old

clip. Index

the

"blind rivet"

and

press hard (hand pressure should

do)

to expand rivet.

GAUGE UNIT

AND

FUEL STRAINER

Removal

and

Installation

(Fig. 11)

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit

and

rubber gasket.

CAUTION: Carefully remove unit

so as not to

damage screen

on the end of

the pipe.

4.

Clean screen

by

blowing

out

with compressed

air.

5. Reverse procedure

to

install.

FUEL TANK FILLER NECK CAPS

The fuel tank filler neck caps

are

non-vented with

an

anti-surge feature. Station wagons have vented caps.

(Refer

to

"Fuel Tank Vent Lines").

CHEVROLET CHASSIS SERVICE MANUAL

Page 419 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-13

CHEVY II

FUEL TANKS

INDEX

Page

Page

General Description.

8-13

Component Part Replacement

8-13

Fuel Tanks

8-13

Fuel Lines

8-14

Metering Units (Gauge Sending Unit)

8-13

Fuel Tank Filler- Neck Caps.

. . 8-14

Fuel Tank Vent Lines .......

8-14

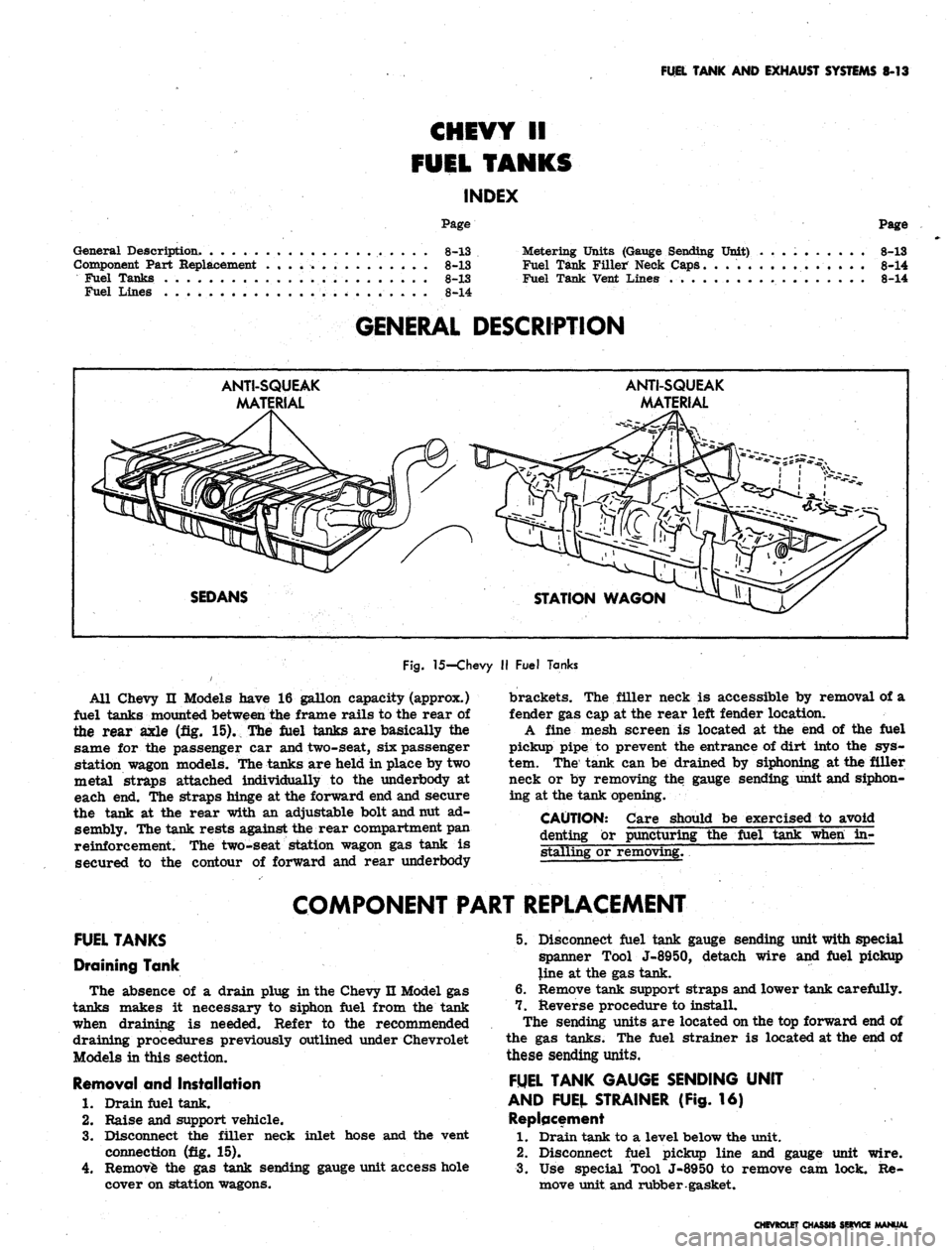

GENERAL DESCRIPTION

ANTI-SQUEAK

MA'

ANTI-SQUEAK

MATERIAL

SEDANS

STATION WAGON

Fig.

15-Chevy

II

Fuel Tanks

All Chevy

II

Models have

16

gallon capacity (approx.)

fuel tanks mounted between

the

frame rails

to the

rear

of

the rear axle

(fig. 15). The

fuel tanks

are

basically

the

same

for the

passenger

car

and two-seat,

six

passenger

station wagon models. The tanks

are

held

in

place

by two

metal straps attached individually

to the

underbody

at

each

end. The

straps hinge

at the

forward

end

and secure

the tank

at the

rear with

an

adjustable bolt and nut

ad-

sembly. The tank rests against the rear compartment

pan

reinforcement.

The

two-seat station wagon

gas

tank

is

secured

to the

contour

of

forward

and

rear underbody

brackets.

The

filler neck

is

accessible

by

removal

of a

fender

gas cap at the

rear left fender location.

A fine mesh screen

is

located

at the end of the

fuel

pickup pipe

to

prevent

the

entrance

of

dirt into

the sys-

tem.

The

tank

can be

drained

by

siphoning

at the

filler

neck

or by

removing

the

gauge sending unit and siphon-

ing

at the

tank opening.

CAUTION: Care should

be

exercised

to

avoid

denting

or

puncturing

the

fuel tank when

in-

stalling

or

removing.

~

COMPONENT PART REPLACEMENT

FUEL TANKS

Draining Tank

The absence

of a

drain plug

in

the Chevy

n

Model

gas

tanks makes

it

necessary

to

siphon fuel from

the

tank

when draining

is

needed. Refer

to the

recommended

draining procedures previously outlined under Chevrolet

Models

in

this section.

Removal

and

Installation

1.

Drain fuel tank.

2.

Raise

and

support vehicle.

3.

Disconnect

the

filler neck inlet hose

and the

vent

connection

(fig. 15).

4.

Remove

the gas

tank sending gauge unit access hole

cover

on

station wagons.

5. Disconnect fuel tank gauge sending unit with special

spanner Tool J-8950, detach wire

and

fuel pickup

line

at the gas

tank.

6. Remove tank support straps and lower tank carefully.

7. Reverse procedure

to

install.

The sending units

are

located on

the top

forward

end of

the

gas

tanks.

The

fuel strainer

is

located

at the end of

these sending units.

FUEL TANK GAUGE SENDING UNIT

AND FUEL STRAINER

(Fig. 16)

Replacement

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit and rubber gasket.

CHEVROLET CHASSIS SERVICE MANUAL

Page 441 of 659

SECTION

9

STEERING

CONTENTS

OF

THIS SECTION

Standard Steering

9-1

Power Steering

9-33

Special Tools

9-40

STANDARD STEERING

INDEX

Page

General Description 9.x

Maintenance and Adjustments 9.1

Adjustments

........................

9-2

Steering Gear 9-2

Steering Wheel Alignment and Higji

Point Centering. . . . 9-4

Toe-in Adjustment 9-4

Corvette Steering Ratio . . . . 9-4

Component Replacement and Repairs . . . . 9-4

Steering Wheel . . . 9-4

Regular Production 9-4

Simulated Wood . . . . 9-5

Corvette Telescoping 9-5

Steering Coupling . 9-6

Steering Gear . 9-9

Sector Shaft Seal Replacement 9-10

Steering Column 9-10

Removal 9-10

Disassembly—Syncromesh Column 9-12

Page

Assembly—Syncromesh Column . . 9-14

Disassembly—Column Mounted Powerglide

Lever or Floor Shift Column 9-16

Assembly-^Column Mounted Powerglide

Lever or Floor Shift Column g_x7

Disassembly—Tilt Column 9-19

Assembly—Tilt Column 9-21

Disassembly—Standard Corvette Column 9-23

Assembly—Standard Corvette Column 9-25

Disassembly—Corvette Telescoping Column .... 9.26

Assembly—Corvette Telescoping Column 9-27

Installation 9.27

Steering Linkage 9.29

Tie

Rods.

. 9-29

Relay Rod . . 9-31

Idler Arm . . . . 9-31

Pitman Arm. . 9-32

Steering Arms • • • • 9-32

Steering Damper 9-32

GENERAL DESCRIPTION

The regular production steering gear

is the

recirculat-

ing ball type. This gear provides

for

ease

of

handling

by

transmitting forces from worm

to

sector gear through

ball bearings.

The

steering linkage

is of

the relay type,

and extended interval lubrication design, with the pitman

arm connected

to one end of

the relay

rod. The

other

end

of

the

relay

rod is

connected

to an

idler

arm

which

is

connected

to the

frame side rail opposite

the

steering

gear.

Two

adjustable

tie

rods connect

the

relay

rod to

the steering arms.

All passenger

car

models

for 1967 are

equipped with

new energy absorbing steering columns.

The

mast jacket,

shift tube,

and

steering shaft

are

designed

to

collapse

under various front impact conditions.

All new

columns

are

of

this design, including

the

tilt option and telescope

option.

MAINTENANCE

AND

ADJUSTMENTS

The manual steering gear

is

filled

at the

factory with

a

water resistant grease. Seasonal change

of

this lubrica-

tion

is

unnecessary and

the

housing should

not be

drained.

The steering gear lubricant level should

be

checked every

36,000 miles. Whenever required, additions should

be

made using

a

water resistant

EP

chassis lubricant.

Check and fill steering gear

as

follows:

1.

Remove lower

and

outboard cover retaining screws

(fig.

1).

2.

Insert filling device

in

lower screw hole.

3.

Inject lubricant until

it

appears

in

outboard screw

hole; gear

is now

filled

to

correct level.

The steering linkage should

be

lubricated with water

resistant

EP

chassis lubricant every 6,000 miles

or six

months, whichever occurs first. Lubrication points

and

additional information

on the

chassis lubricant

to be

used

can

be

found

in

Section

0 --

General Information

and

Lubrication.

CHEVROLET CHASSIS SERVICE MANUAL

Page 442 of 659

STEERING 9-2

Fig.

1—Cover

Attaching Bolts—Chevy li Shown

ADJUSTMENTS

STEERING

GEAR

Before any adjustments are made to the steering gear

in an attempt to correct such conditions as shimmy,

loose or hard steering etc., a careful check should be

made of front end alignment, shock absorbers, wheel

balance and tire pressure for possible cause.

Correct adjustment of the steering gear is very im-

portant. Perform adjustments following the sequence

listed below,

1.

Remove pitman arm nut and mark relation of pitman

arm position to sector shaft. Remove pitman arm

with Tool J- 6632 as shown in Figure 2.

2.

Loosen the pitman shaft lash adjuster screw locknut

and turn the adjuster screw a few turns in a counter-

clockwise direction (fig. 3). This removes the load

Fig. 2—Removing Pitman Arm

imposed on the worm bearings by the close meshing

of rack and sector teeth. Turn steering wheel gently

in one direction until stopped by gear, then back away

about one turn.

CAUTION: Do not turn steering wheel hard

against stops when steering relay rod is discon-

nected as damage to ball guides may result.

3.

All except Corvette and telescopic columns:

a. Disconnect steering column harness at chassis

wiring connector plug.

b.

Remove horn cap or ornament and using an inch

pound torque wrench and socket on steering wheel

nut, measure torque required to keep the wheel

in motion.

LASH ADJUSTER

SCREW

LOCK NUT

WORM BEARING

ADJUSTER

\

WORM

ADJUSTER

Fig.

3—Steering Gear Adjustment Points

CHEVROLET CHASSIS SERVICE MANUAL

Page 450 of 659

STEERING 9-10

SECTOR SHAFT SEAL REPLACEMENT

A faulty seal may be replaced without removal of

steering gear from car by removing pitman arm as out-

lined under Maintenance and Adjustments--Steering Gear

Adjustments and proceed as follows:

1.

Loose lash adjuster lock nut and turn lash adjuster

screw several turns counterclockwise.

2.

Remove three cap screws holding side cover to gear

bushing.

3.

Pull side cover and sector shaft from gear housing

as a unit. Do not separate side cover from sector

shaft.

4.

Pull sector shaft seal from gear housing using

hooked tool or pliers.

5. Coat new seal with chassis grease and position in

sector shaft bore.

6. Place a socket or piece of pipe of suitable diameter

on top of seal and drive seal into bore by tapping

pipe or socket with soft hammer.

7. Install sector shaft side cover assembly, being care-

ful not to damage new seal with splines on end of

shaft; splines may be wrapped with a few turns of

tape to prevent this.

8. Install new side cover gasket and align side cover on

gear housing and install cap screw.

9. Perform steering gear adjustment and install pitman

arm as outlined under Maintenance and Adjustments.

STEERING COLUMN

All models are equipped with new energy absorbing

steering columns. The columns are of five basic designs

as follows:

1.

Syncromesh. The syncromesh column is used on

models with standard, column mounted, conventional

shift levers. The shift tube, within the outer mast

jacket, includes two lower shift levers for connection

to the transmission control linkage.

2.

Automatic and floor shift. This column is used on

models equipped with column mounted powerglide

shift levers, or models with floor shift. If the ve-

hicle has the column mounted powerglide shift con-

trol, the inner shift tube has a single lower shift

lever for connection to the transmission control

linkage. On floor shift models, no lower shift levers

are present on the shift tube.

3.

Tilt wheel option. The upper end and steering shaft

of this column is specially designed to accommodate

the optional tilt steering wheel.

4.

Standard Corvette Column. The standard Corvette

column is similar in design to the Automatic and

Floor Shift column used on other models, except

no shift tube is used. Other differences are pointed

out in the disassembly and assembly procedures for

Standard Corvette column.

5. Telescopic wheel option. The upper end and steering

shaft of this column is specially designed to ac-

commodate the optional telescoping steering wheel.

To perform service procedures on steering column

upper end components, it is not necessary to remove the

column from the vehicle. The steering wheel, horn com-

ponents, turn signal switch, upper housing with bearing,

shift control lever, hazard warning knob, and upper shift

bowl may all be removed with the column remaining in

the vehicle. When servicing the above components, omit

the removal procedure and proceed with the applicable

disassembly procedures. Because of the numerous dif-

ferences in steering column types, be sure to refer to the

set of instructions below which apply to the exact column

to be serviced:

CAUTION: The outer mast jacket, shift tube, _

steering shaft, and instrument panel column

mounting b

racket

are designed as energy ab-

sorbing units. Because of the design of these

components, it is absolutely necessary to handle

the column with care when performing any serv-

ice operation required. Avoid hammering, jar-

ring, dropping, or leaning on any portion of the

column.

Removal

1.

Disconnect steering column harness at connector.

Disconnect neutral safety switch and back-up lamp

switch connectors if so equipped.

Remove steering wheel as outlined in this section.

Remove nuts and washers securing flanged end of

column to steering gear. On Chevy H models, re-

move nut and clamp bolt securing lower end of steer-

ing column to steering gear.

Disconnect transmission control linkage, if so

equipped, from lower column shift tube, levers.

Chevrolet and Chevy II only: Remove screws at-

taching upper and lower mast jacket covers together.

On Chevrolet, remove screws attaching lower cover

to instrument panel (figs. 15 and 18). Remove lower

cover.

Chevelle only: Remove screws securing mast jacket

trim cover to instrument panel and remove cover

(fig. 15).

Corvette, only: Remove screws securing escutcheon

to instrument panel. Remove screws securing upper

and lower covers together and remove covers.

On Chevrolet and Chevelle columns with Powerglide

shift levers, loosen set screw at six o'clock position

at bottom of column and remove the transmission

shift indicator pointer (fig. 15).

9. Chevrolet only (fig. 19):

a. Remove screws securing cover trim to dash

panel and remove cover trim.

2.

3.

4.

5.

6.

7.

8.

Fig.

18—Mast Jacket Cover Attachments—Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 469 of 659

STEERING 9-29

column mounting bracket, and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws and bracket to instrument panel

washers and bolts.

NOTE: Steering shaft to gear clamp must be

tightened before column attaching bolts are

torqued. Refer to "Steering Gear-Chevy n",

installation procedure, for correct Chevy II

steering column alignment procedure.

5.

Camaro only (fig. 60):

Lay wedge shim in position on instrument panel

column mounting bracket and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws, nuts, and washer and bolt as shown

in Figure 60.

6. Corvette only (fig. 61):

Loosely secure column mounting bracket to sup-

port plate and instrument panel with washers and

bolts.

7.

Secure flanged end of column to steering coupling

with lockwashers and nuts. On Chevy n, connect col-

umn to steering gear with clamp, clamp bolt, and

nut. On Corvette, slide steering shaft flange into

lower coupling

half,

and install upper clamp bolt

loosely; also secure support, seal and clamp loosely

at dash on engine side.

8. Tighten instrument panel mounting bracket bolts and

nuts.

Refer to torque specifications at rear of manual

for correct torque values.

9. Chevrolet only (fig. 15):

Place upper and lower mast jacket covers in po-

sition and secure covers together and to instrument

panel using nuts and screws as shown in Figure 15.

10.

Chevy H only (fig. 18):

Place lower mast jacket cover in position under

mast jacket and secure to upper cover with screws.

11.

CheveUe only (fig. 15):

Place mast jacket trim cover in position over col-

Fig.

61—Instrument Panel Mounting Bracket and

Support Plqte—Corvette

umn on underside of instrument panel and secure

with screws.

12.

Corvette only (fig. 14):

Slide escutcheon into position at instrument panel

and secure with screws. Place upper end lower

covers in position and secure with screws.

13.

On Chevrolet and CheveUe models with column

mounted powerglide controls, secure transmission

shift indicator pointer into position with set screw

(fig. 15). ,

14.

Chevrolet only (fig. 19):

a. Secure seal and cover to dash panel with screws.

b.

Place clamp assembly in position and install

clamp screw.

c. Install dash panel trim cover with mounting

screws.

15.

Chevelle only (fig. 20):

a. Secure seal and inner and outer covers to dash

panel with screws.

b.

Secure inner and outer covers together with

screws.

c. Install trim cover to dash panel with two

retainers.

16.

Chevy H only (fig. 21):

a. Secure seal, retainer, and clamp to dash panel

with screws.

b.

Install clamp screw.

c. Slide collar into position. Pinch and staple upper

tabs together.

17.

Camaro only (fig. 22):

a. Secure seal, upper cover, and lower cover to

dash panel with screws.

b.

Secure upper and lower cover together with

screws.

c. Fold rubber boot over securely against dash panel

to conceal covers.

18.

Corvette only (fig. 23):

a. Secure seal and support assembly to dash panel

on engine compartment side.

b.

Tighten clamp, washer, and clamp bolt on engine

compartment side.

19.

Connect transmission linkage to lower shift tube

levers in engine compartment, if column is so

equipped. Adjust levers as outlined in Section 7.

20.

Install steering wheel as outlined in this section.

21.

Connect directional signal, horn, back-up lamp, and

neutral start switch at wiring harness plugs. Adjust

back-up lamp, neutral start switch as outlined in

Section 12.

22.

Adjust steering gear and align and center steering

wheel as outlined in this section.

STEERING LINKAGE (Fig. 62)

TIE RODS

There are two tie rod assemblies used on all models.

Each assembly is of three piece construction, consisting

of a sleeve and two tie rod ends. The ends are threaded

into the sleeve and locked with clamps. Right and left

hand threads are provided to facilitate toe-in adjustment

and steering gear centering.

The tie rod ends are self-adjusting for wear and re-

quire no attention in service other than periodic lubrica-

tion and occasional inspection to see that ball studs are

tight. Replacement of tie rod ends should be made when

CHEVROLET CHASSIS SERVICE MANUAL