ABS CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 502 of 659

CHASSIS SHEET METAL 11-15

FRONT FENDER TRIM

If fender spear molding is to be replaced without re-

moving fender from vehicle, proceed as follows:

1.

Perform Operations 2 and 5 only of Front Fender

Assembly—Removal.

2.

Pull rear* end of fender away from body far enough

to insert a short piece of 2 x 4 between lower rear

corner of fender and rocker panel extension.

3.

It should now be possible to gain access to first and

second retaining nuts forward of rear end of fender.

All other nuts can be reached from front wheel

opening.

SKIRT ASSEMBLY

Removal

1.

Remove hood and hinge assemblies as outlined in

this section.

2.

Remove grille and radiator support as outlined in

Section ia.

3.

Remove fender assembly as outlined in this section.

4.

Raise car from floor and place jack stands under

rocker panel extension.

5.

Remove suspension bumper support, shock absorber,

front spring and stabilizer link as outlined in Section

3.

6. If removing left skirt assembly, remove steering

gear mounting bolts, power steering hose clamp (if

so equipped) and outer (left) clutch cordon shaft

bracket (if so equipped).

7.

Remove tie rod ball stud from steering arm as out-

lined in Section 9.

8. Support engine and remove engine mount cushion as

outlined in Section 6.

9. Remove spring clip from brake line junction which

passes through skirt and remove junction from skirt

(see Section 5).

10.

Remove four bolts retaining front crossmember to

skirt.

11.

Remove four bolts retaining skirt assembly to dash

front brace. Remove 3 bolts retaining upper end of

skirt to dash (fig. 26); record shims removed.

12.

Remove skirt assembly with remaining suspension

parts attached as shown in Figure 27.

13.

Suspension parts may be detached as outlined in

Section 3.

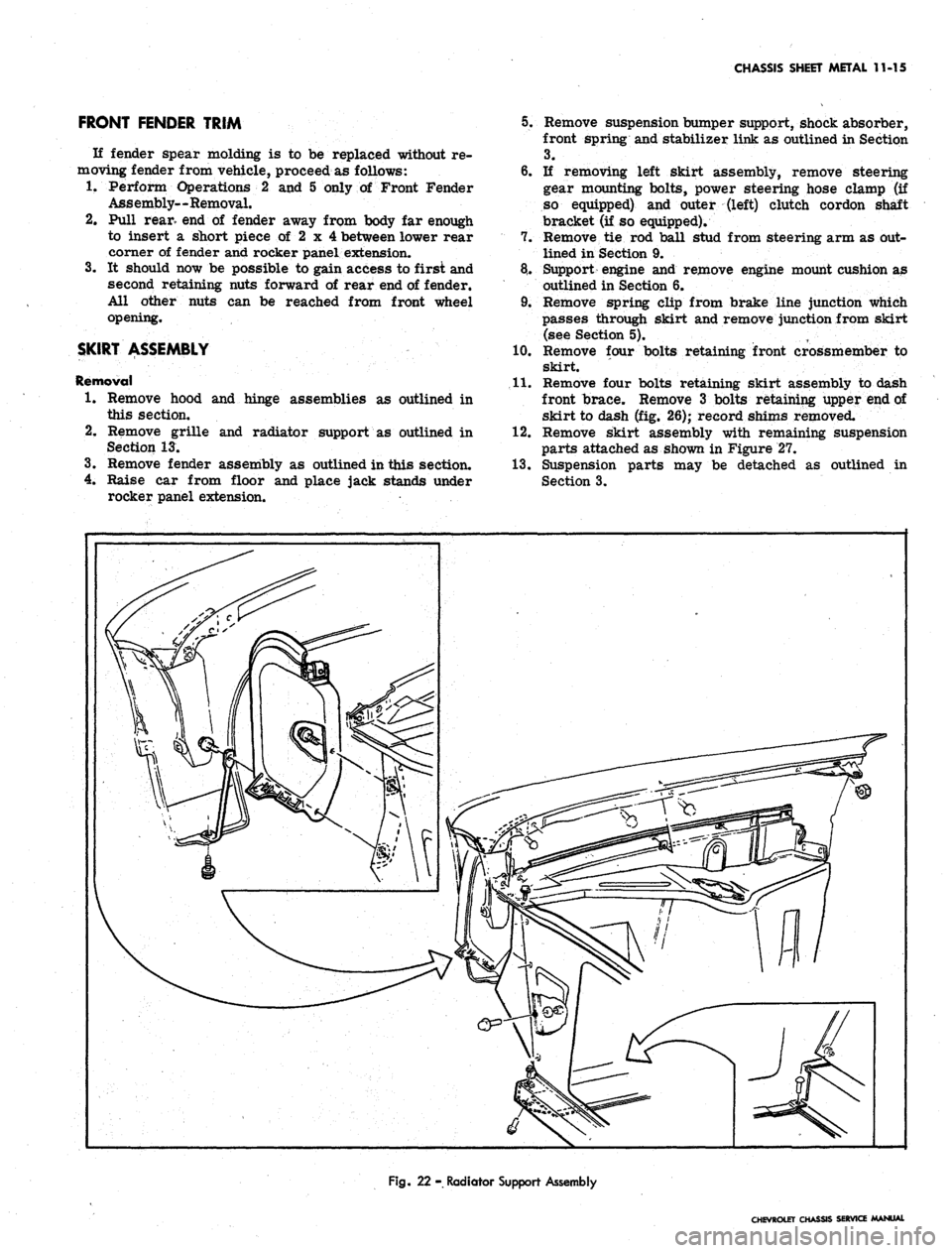

Fig.

22 - Radiator Support Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 516 of 659

ELECTRICAL-BODY AND CHASSIS 12-4

b.

hand lamp until the string is positioned over the

crossarm centerline. Turn the screw clockwise

in making the final adjustment to take up play in

the headlamp mechanism.

Repeat the above procedure on the right-hand

lamp to complete the horizontal adjustment of the

headlamps.

VERTICAL ADJUSTMENT

8. a. Numeral "2" (fig. 5) should appear in the "down"

window of each aimer. If not, loosen knob at

underside of aimer arm and slide back and forth

until the numeral does appear.

NOTE:

This setting will give a 2" drop of the

headlamp high beam spot centerline on a screen

placed 25 feet forward of the vehicle. Check

state laws for proper vertical setting.

b.

Turn headlamp vertical aim screw (fig. 5) on left-

hand unit counter-clockwise until the bubble is at

the inner end of the glass tube. Then turn screw

clockwise until bubble is centered in tube.

c. Repeat this procedure on right-hand headlamp

unit to complete vertical adjustment of lamps.

9. Recheck the string at the ends of each crossarm for

correct setting and the bubble on each aimer for

centered position.

10.

Remove the aimers by pulling on the suction cup tabs

through the openings in the aimers (fig. 6).

11.

With headlamps properly aimed, replace headlamp

bezels.

HOW TO SELECT A LEVEL AIMING AREA

1.

Select area you believe to be level.

2.

Remove headlamp bezels and install Aimers on each

headlamp (fig. 3) making sure aiming lugs engage

smoooth inner ring of the Aimer.

"

To install Aimer,

press firmly on the knob extending out from the cen-

ter of the Aimer base. This forces the suction cup

into place on the Sealed Beam unit.:

3.

Loosen the slider knob beneath the aimer arm and

set the numeral "2" in the DOWN view window (fig.

7).

Back vertical lamp adjustment out on each lamp

until bubble is outside of black line of vial, then cen-

ter bubble in between black line of vial by turning

clockwise.

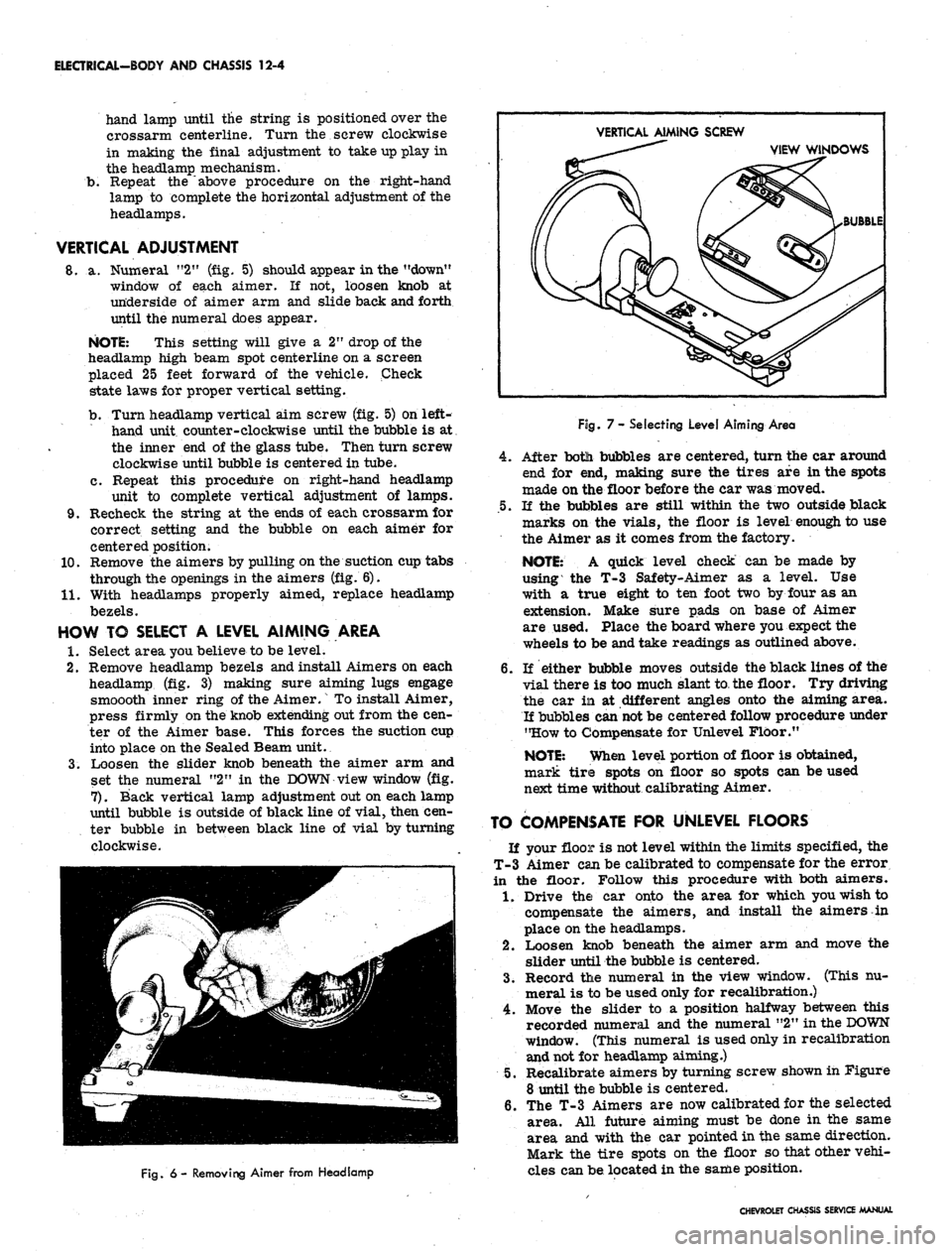

VERTICAL AIMING SCREW

VIEW WINDOWS

BUBBLE

Fig.

6 - Removing Aimer from Headlamp

Fog.

7- Selecting Level Aiming Area

4.

After botli bubbles are centered, turn the car around

end for end, making sure the tires are in the spots

made on the floor before the car was moved.

.5.

If the bubbles are still within the two outside black

marks on the vials, the floor is level enough to use

the Aimer as it comes from the factory.

NOTE:

A quick level check can be made by

using the T-3 Safety-Aimer as a level. Use

with a true eight to ten foot two by four as an

extension. Make sure pads on base of Aimer

are used. Place the board where you expect the

wheels to be and take readings as outlined above.

6. If either bubble moves outside the black lines of the

vial there is too much slant to the floor. Try driving

the car in at different angles onto the aiming area.

If bubbles can

not

be centered follow procedure under

"How to Compensate for Unlevel Floor."

NOTE:

When level portion of floor is obtained,

mark tire spots on floor so spots can be used

next time without calibrating Aimer.

TO COMPENSATE FOR UNLEVEL FLOORS

If your floor is not level within the limits specified, the

T-3 Aimer can be calibrated to compensate for the error

in the floor. Follow this procedure with both aimers.

1.

Drive the car onto the area for which you wish to

compensate the aimers, and install the aimers in

place on the headlamps.

2.

Loosen knob beneath the aimer arm and move the

slider until the bubble is centered.

3.

Record the numeral in the view window. (This nu-

meral is to be used only for recalibration.)

4.

Move the slider to a position halfway between this

recorded numeral and the numeral "2" in the

DOWN

window. (This numeral is used only in recalibration

and not for headlamp aiming.)

5.

Recalibrate aimers by turning screw shown in Figure

8 until the bubble is centered.

6. The T-3 Aimers are now calibrated for the selected

area. All future aiming must be done in the same

area and with the car pointed in the same direction.

Mark the tire spots on the floor so that other vehi-

cles can be located in the same position.

CHEVROLET CHASSIS SERVICE MANUAL

Page 517 of 659

ELECTRICAL-BODY AND CHASSIS 12-5

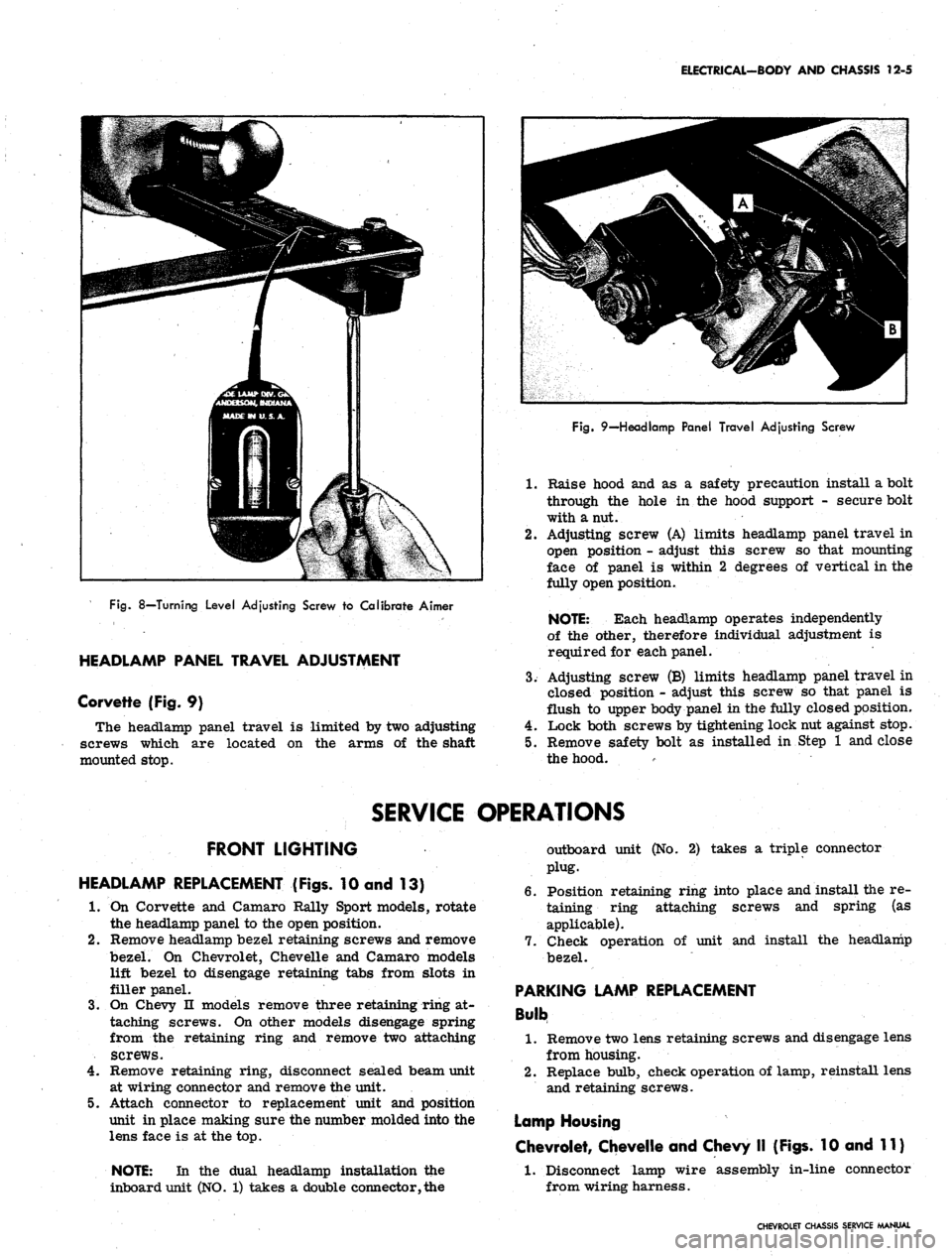

Fig.

8—Turning Level Adjusting Screw to Calibrate Aimer

HEADLAMP PANEL TRAVEL ADJUSTMENT

Corvette (Fig. 9)

The headlamp panel travel is limited by two adjusting

screws which are located on the arms of the shaft

mounted stop.

Fig.

9—Headlamp Panel Travel Adjusting Screw

1.

Raise hood and as a safety precaution install a bolt

through the hole in the hood support - secure bolt

with a nut.

2.

Adjusting screw (A) limits headlamp panel travel in

open position - adjust this screw so that mounting

face of panel is within 2 degrees of vertical in the

fully open position.

NOTE: Each headlamp operates independently

of the other, therefore individual adjustment is

required for each panel.

3.

Adjusting screw (B) limits headlamp panel travel in

closed position - adjust this screw so that panel is

flush to upper body panel in the fully closed position.

4.

Lock both screws by tightening lock nut against stop.

5.

Remove safety bolt as installed in Step 1 and close

the hood.

SERVICE OPERATIONS

FRONT LIGHTING

HEADLAMP REPLACEMENT (Figs. 10 and 13)

1.

On Corvette and Camaro Rally Sport models, rotate

the headlamp panel to the open position.

2.

Remove headlamp bezel retaining screws and remove

bezel. On Chevrolet, Chevelle and Camaro models

lift bezel to disengage retaining tabs from slots in

filler panel.

3.

On Chevy n models remove three retaining ring at-

taching screws. On other models disengage spring

from the retaining ring and remove two attaching

screws.

4.

Remove retaining ring, disconnect sealed beam unit

at wiring connector and remove the unit.

5.

Attach connector to replacement unit and position

unit in place making sure the number molded into the

lens face is at the top.

NOTE: In the dual headlamp installation the

inboard unit (NO. 1) takes a double connector, the

outboard unit (No. 2) takes a triple connector

plug.

6. Position retaining ring into place and install the re-

taining ring attaching screws and spring (as

applicable).

7.

Check operation of unit and install the headlamp

bezel.

PARKING LAMP REPLACEMENT

Bulb

1.

Remove two lens retaining screws and disengage lens

from housing.

2.

Replace bulb, check operation of lamp, reinstall lens

and retaining screws.

Lamp Housing

Chevrolet, Chevelle and Chevy II (Figs. 10 and 11)

1.

Disconnect lamp wire assembly in-line connector

from wiring harness.

CHEVROLET CHASSIS SERVICE MANUAL

Page 534 of 659

ELECTRICAL-BODY AND CHASSIS 12-22

SERVICE OPERATIONS

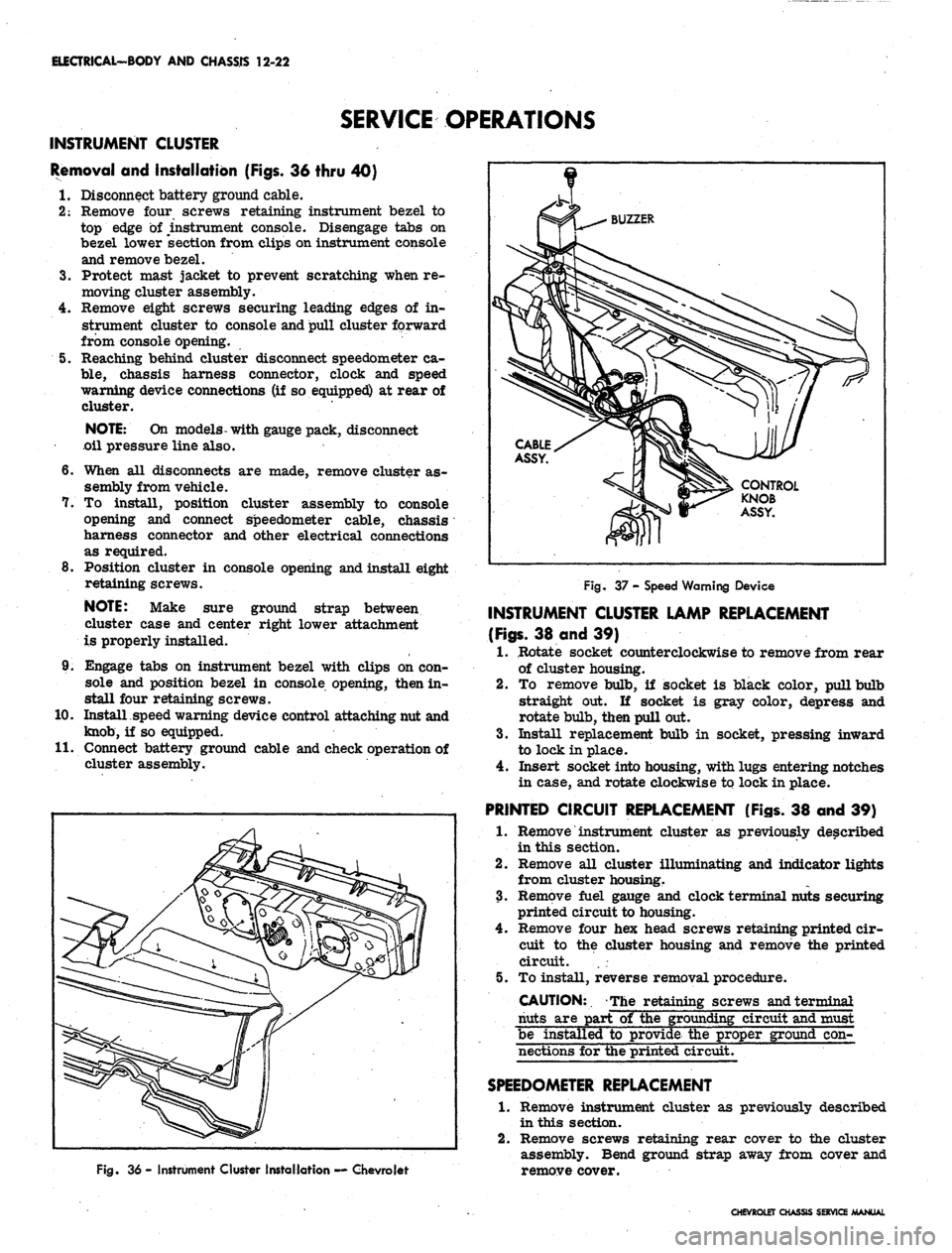

INSTRUMENT CLUSTER

Removal and Installation (Figs. 36 thru 40)

I. Disconnect battery ground cable.

2:

Remove four screws retaining instrument bezel to

top edge of instrument console. Disengage tabs on

bezel lower section from clips on instrument console

and remove bezel.

3.

Protect mast jacket to prevent scratching when re-

moving cluster assembly.

4.

Remove eight screws securing leading edges of in-

strument cluster to console and pull cluster forward

from console opening.

5. Reaching behind cluster disconnect speedometer ca-

ble,

chassis harness connector, clock and speed

warning device connections (if so equipped) at rear of

cluster.

NOTE:

On models- with gauge pack, disconnect

oil pressure line also.

6. When all disconnects are made, remove cluster as-

sembly from vehicle.

7. To install, position cluster assembly to console

opening and connect speedometer cable, chassis

harness connector and other electrical connections

as required.

8. Position cluster in console opening and install eight

retaining screws.

NOTE:

Make sure ground strap between

cluster case and center right lower attachment

is properly installed.

9. Engage tabs on instrument bezel with clips on con-

sole and position bezel in console opening, then in-

stall four retaining screws.

10.

Install speed warning device control attaching nut and

knob,

if so equipped.

II.

Connect battery ground cable and check operation of

cluster assembly.

Fig. 36 - Instrument Cluster Installation — Chevrolet

Fig. 37 - Speed Warning Device

INSTRUMENT CLUSTER LAMP REPLACEMENT

(Figs.

38 and 39)

1.

Rotate socket counterclockwise to remove from rear

of cluster housing.

2.

To remove bulb, if socket is black color, pull bulb

straight out. If socket is gray color, depress and

rotate bulb, then pull out.

3.

Install replacement bulb in socket, pressing inward

to lock in place.

4.

Insert socket into housing, with lugs entering notches

in case, and rotate clockwise to lock in place.

PRINTED CIRCUIT REPLACEMENT (Figs. 38 and 39)

1.

Remove instrument cluster as previously described

in this section.

2.

Remove all cluster illuminating and indicator lights

from cluster housing.

3.

Remove fuel gauge and clock terminal nuts securing

printed circuit to housing.

4.

Remove four hex head screws retaining printed cir-

cuit to the cluster housing and remove the printed

circuit. . .

5. To install, reverse removal procedure.

CAUTION:. The retaining screws and terminal

nuts are part of the grounding circuit and must

be installed to provide the proper ground con-

nections for the printed circuit.

SPEEDOMETER

REPLACEMENT

1.

Remove instrument cluster as previously described

in this section.

2.

Remove screws retaining rear cover to the cluster

assembly. Bend ground strap away from cover and

remove cover.

CHEVROLET CHASSIS SERVICE MANUAL

Page 552 of 659

ELECTRICAL-BODY AND CHASSIS 12-40

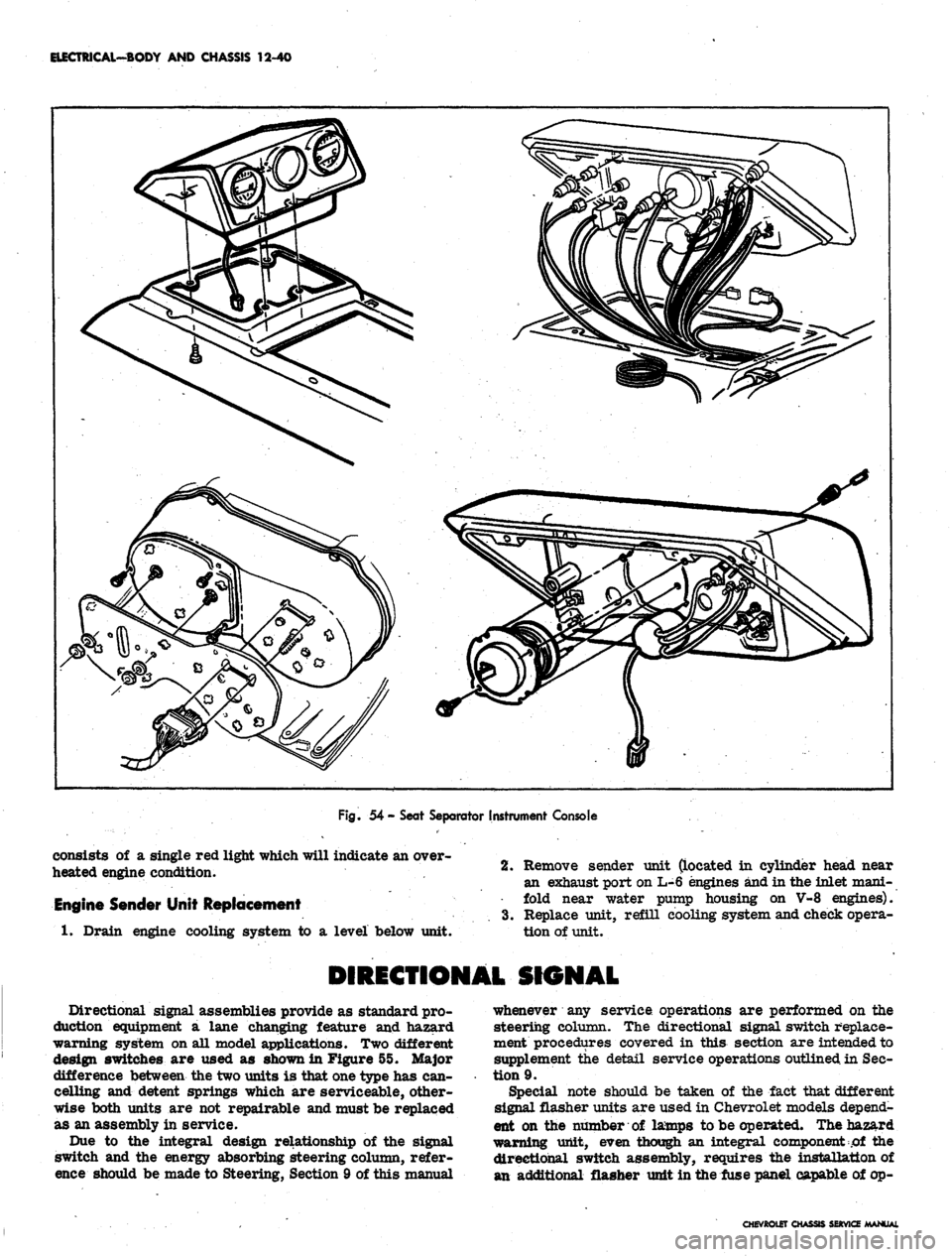

Fig.

54 - Seat Separator Instrument Console

consists of a single red light which will indicate an over-

heated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system to a level below unit.

2.

Remove sender unit (located in cylinder head near

an exhaust port on L-6 engines and in the inlet mani-

fold near water pump housing on V-8 engines).

3.

Replace unit, refill cooling system and check opera-

tion of unit.

DIRECTIONAL SIGNAL

Directional signal assemblies provide as standard pro-

duction equipment a lane changing feature and hazard

warning system on all model applications. Two different

design switches are used as shown in Figure 55. Major

difference between the two units is that one type has can-

celling and detent springs which are serviceable, other-

wise both units are not repairable and must be replaced

as an assembly in service.

Due to the integral design relationship of the signal

switch and the energy absorbing steering column, refer-

ence should be made to Steering, Section 9 of this manual

whenever any service operations are performed on the

steering column. The directional signal switch replace-

ment procedures covered in this section are intended to

supplement the detail service operations outlined in Sec-

tion 9.

Special note should be taken of the fact that different

signal flasher units are used in Chevrolet models depend-

ent on the number of lamps to be operated. The hazard

warning unit, even though an integral component of the

directional switch assembly, requires the installation of

an additional flasher unit in the fuse panel capable of op-

CHEVROtET CHASSIS SERVICE MANUAL

Page 562 of 659

ELECTRICAL-BODY AND CHASSIS 12-50

SERVICE OPERATIONS

MOTOR SECTION

DISASSEMBLY

NOTE:

Motor section

may be

disassembled

independently

of

the gear box.

Brush Plate and Circuit Breaker Removal

1.

Scribe

a

reference line along the side of the casting

and end cap to insure proper re-assembly.

2.

Remove the two motor thru bolts.

3.

Feed exposed excess length

of

motor leads thru the

casting grommet

and

carefully back

the

case

and

field assembly plus

the

armature away from

the

casting (fig. 76).

NOTE:

It may be

necessary

to

remove

the

armature end play adjusting screw and insert

a

rod thru

the

opening

in

order to apply pressure

against the end of the armature.

4.

Unsolder

the

black lead from circuit breaker

(fig.

77).

5.

Straighten

out the 4

tabs that secure the brush plate

to the field coil retainers (fig. 77).

CAUTION:

Be

careful

not to

break

any of

the

retainer tabs.

6. Install

"U"

shaped brush retainer clip over brush

holder that has brush lead attached to circuit breaker

(fig. 78).

7.

Holding

the

opposite brush from that retained in Step

6, carefully lift

the

brush holder

off the

mounting

tabs

far

enough

to

clear

the

armature commutator

(fig. 78).

8. Allow

the

brush, held

in

Step

7, to

move out

of its

holder. Remove

the

brush spring

and

lift the brush

holder

off

the armature shaft.

Armature Removal

1.

Follow Steps

1

thru

8

under brush plate removal.

2.

Lift armature out

of

case and field assembly.

3.

Remove thrust ball from

end of

armature shaft

as

PUMP

ASSEMBLY

CAM SLOT

DRIVE PLATE

AND

ASSEMBLY

RELAY SWITCH

ASSEMBLY

WASHER PUMP

DRIVE

PIN

Fig.

75

-

Wiper and Washer

Pump

Mechanism

required and save

for

reassembly.

NOTE: Thrust ball

may be

easily removed

with

a

magnet.

MOUNTING

GROMMET

WASHER PUMP COVER

RETAINING RING

STAKE MARKS -

CASE

TO

FIELD

LAMINA

(4

PLACES)

Fig. 74 - Depressed Park 2-Speed Wiper

Fig. 76 - Wiper Motor Separation

CHEVROLET CHASSIS SERVICE MANUAL

Page 564 of 659

ELECTRICAL-BODY AND CHASSIS 12-52

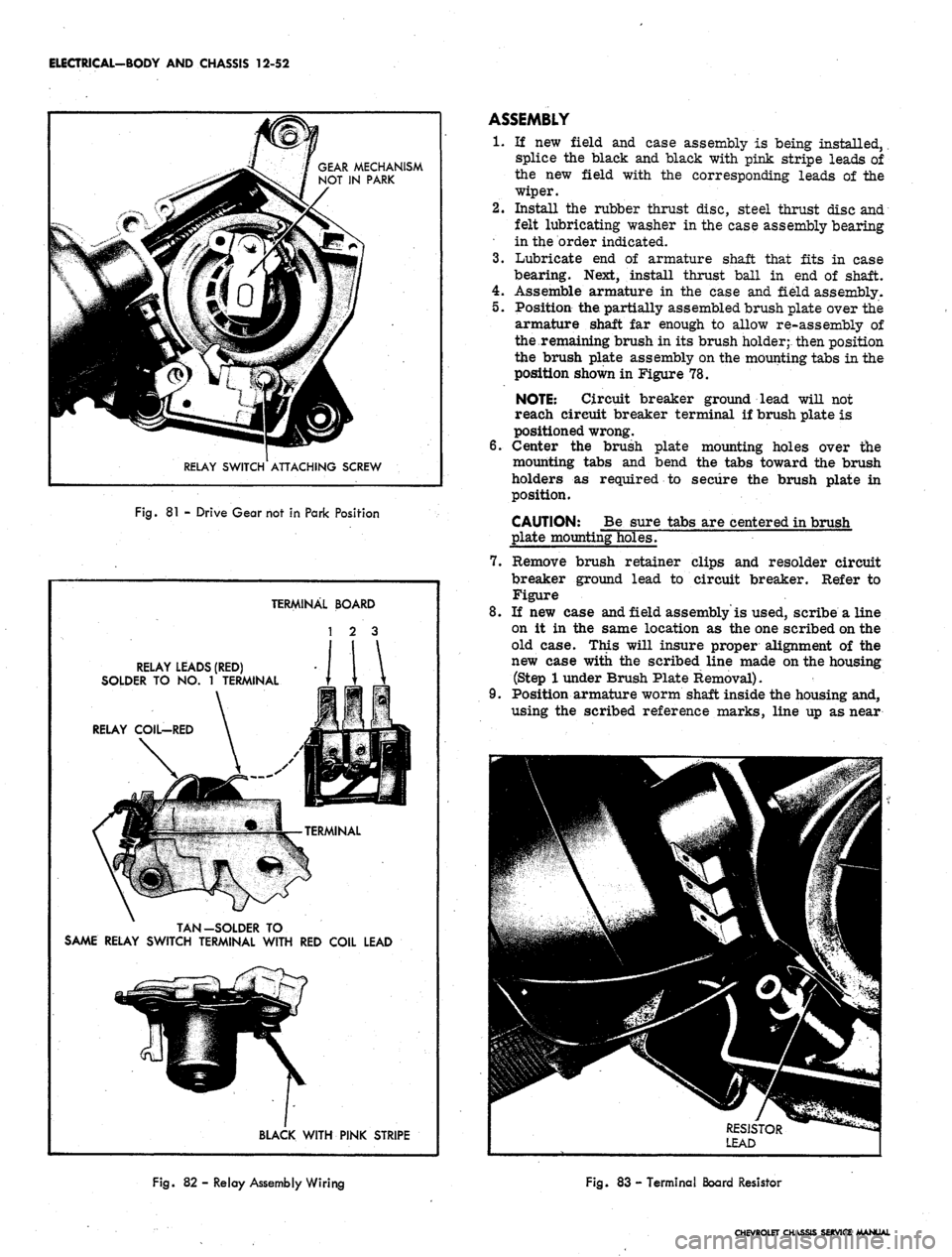

GEAR MECHANISM

NOT IN PARK

RELAY SWITCH ATTACHING SCREW

Fig.

81 -

Drive Gear not

in

Park Position

TERMINAL BOARD

1 2 3

RELAY LEADS (RED)

SOLDER TO NO. 1 TERMINAL

RELAY

COIL-RED

TAN-SOLDER TO

SAME RELAY SWITCH TERMINAL WITH RED COIL LEAD

BLACK WITH PINK STRIPE

ASSEMBLY

1.

If new field and case assembly is being installed,

splice the black and black with pink stripe leads of

the new field with the corresponding leads of the

wiper.

2.

Install the rubber thrust disc, steel thrust disc and

felt lubricating washer in the case assembly bearing

in the order indicated.

3.

Lubricate end of armature shaft that fits in case

bearing. Next, install thrust ball in end of shaft.

4.

Assemble armature in the case and field assembly.

5.

Position the partially assembled brush plate over the

armature shaft far enough to allow re-assembly of

the remaining brush in its brush holder;- then position

the brush plate assembly on the mounting tabs in the

position shown in Figure 78.

NOTE: Circuit breaker ground lead will not

reach circuit breaker terminal if brush plate is

positioned wrong.

6. Center the brush plate mounting holes over the

mounting tabs and bend the tabs toward the brush

holders as required to secure the brush plate in

position.

CAUTION: Be sure tabs are centered in brush

plate mounting holes.

7.

Remove brush retainer clips and resolder circuit

breaker ground lead to circuit breaker. Refer to

Figure

8. If new case and field assembly'is used, scribe a line

on it in the same location as the one scribed on the

old case. This will insure proper alignment of the

new case with the scribed line made on the housing

(Step

1

under Brush Plate Removal).

9. Position armature worm shaft inside the housing and,

using the scribed reference marks, line up as near

Fig.

82 - Relay Assembly Wiring

Fig.

83 -

Terminal Board Resistor

CHEVROLET CHASSIS SERVICE MANUAL

Page 603 of 659

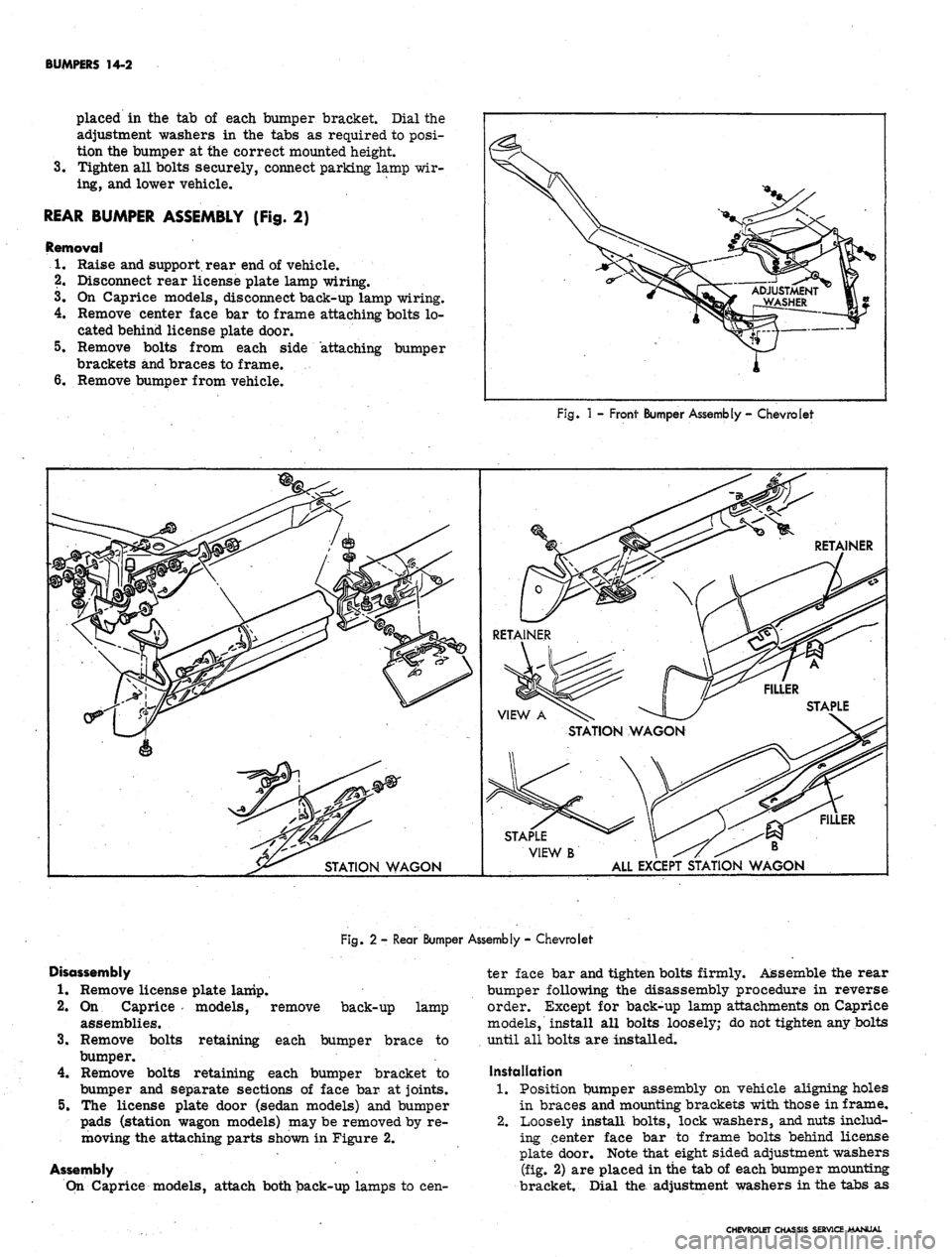

BUMPERS 14-2

placed in the tab of each bumper bracket. Dial the

adjustment washers in the tabs as required to posi-

tion the bumper at the correct mounted height

3.

Tighten all bolts securely, connect parking lamp wir-

ing, and lower vehicle.

REAR BUMPER ASSEMBLY (Fig. 2)

Removal

1.

Raise and support rear end of vehicle.

2.

Disconnect rear license plate lamp wiring.

3.

On Caprice models, disconnect back-up lamp wiring.

4.

Remove center face bar to frame attaching bolts lo-

cated behind license plate door.

5. Remove bolts from each side "attaching bumper

brackets and braces to frame.

6. Remove bumper from vehicle.

Fig.

1 -

Front Bumper Assembly

-

Chevrolet

FILLER

STAPLE

VIEW

B \ ^7 ^^ B

ALL EXCEPT STATION WAGON

Fig. 2 - Rear Bumper Assembly - Chevrolet

Disassembly

1.

Remove license plate lamp.

2.

On Caprice models, remove

assemblies.

Remove bolts

3.

back-up lamp

each bumper brace to

retaining

bumper.

4.

Remove bolts retaining each bumper bracket to

bumper and separate sections of face bar at joints.

5.

The license plate door (sedan models) and bumper

pads (station wagon models) may be removed by re-

moving the attaching parts shown in Figure 2.

Assembly

On Caprice models, attach both back-up lamps to cen-

ter face bar and tighten bolts firmly. Assemble the rear

bumper following the disassembly procedure in reverse

order. Except for back-up lamp attachments on Caprice

models, install all bolts loosely; do not tighten any bolts

until all bolts are installed.

Installation

1.

Position bumper assembly on vehicle aligning holes

in braces and mounting brackets with those in frame,

2.

Loosely install bolts, lock washers, and nuts includ-

ing center face bar to frame bolts behind license

plate door. Note that eight sided adjustment washers

(fig. 2) are placed in the tab of each bumper mounting

bracket. Dial the adjustment washers in the tabs as

CHEVROLET CHASSIS SERVICE MANUAL

Page 604 of 659

BUMPERS 14-3

required to position the bumper at the correct

mounted height. ,

3.

Tighten all mounting bolts securely and connect li-

cense plate lamp wiring. On Caprice models, con-

nect back-up lamp wiring. Lower vehicle.

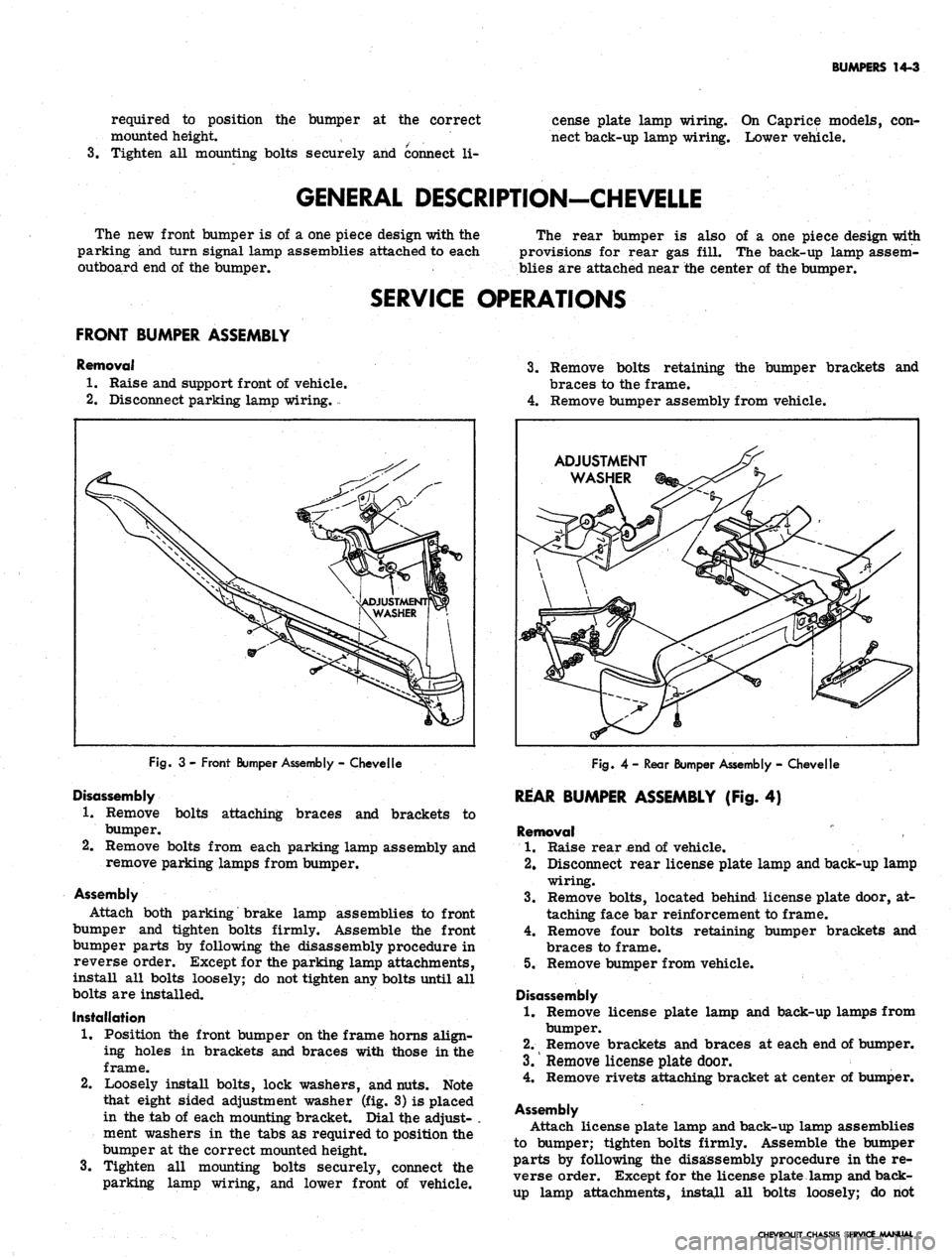

GENERAL DESCRIPTION-CHEVELLE

The new front bumper is of a one piece design with the

parking and turn signal lamp assemblies attached to each

outboard end of the bumper.

The rear bumper is also of a one piece design with

provisions for rear gas fill. The back-up lamp assem-

blies are attached near the center of the bumper.

SERVICE OPERATIONS

FRONT BUMPER ASSEMBLY

Removal

1.

Raise and support front of vehicle.

2.

Disconnect parking lamp wiring. -

Fig.

3 - Front Bumper Assembly - Chevelle

Disassembly

1.

Remove bolts attaching braces and brackets to

bumper.

2.

Remove bolts from each parking lamp assembly and

remove parking lamps from bumper.

Assembly

Attach both parking brake lamp assemblies to front

bumper and tighten bolts firmly. Assemble the front

bumper parts by following the disassembly procedure in

reverse order. Except for the parking lamp attachments,

install all bolts loosely; do not tighten any bolts until all

bolts are installed.

Installation

1.

Position the front bumper on the frame horns align-

ing holes in brackets and braces with those in the

frame.

2.

Loosely install bolts, lock washers, and nuts. Note

that eight sided adjustment washer (fig. 3) is placed

in the tab of each mounting bracket. Dial tjie adjust- .

ment washers in the tabs as required to position the

bumper at the correct mounted height.

3.

Tighten all mounting bolts securely, connect the

parking lamp wiring, and lower front of vehicle.

3.

Remove bolts retaining the bumper brackets and

braces to the frame.

4.

Remove bumper assembly from vehicle.

ADJUSTMENT

WASHER

Fig.

4-Rear Bumper Assembly - Chevelle

REAR BUMPER ASSEMBLY (Fig. 4)

Removal

1.

Raise rear end of vehicle.

2.

Disconnect rear license plate lamp and back-up lamp

wiring.

3.

Remove bolts, located behind license plate door, at-

taching face bar reinforcement to frame.

4.

Remove four bolts retaining bumper brackets and

braces to frame.

5. Remove bumper from vehicle.

Disassembly

1.

Remove license plate lamp and back-up lamps from

bumper.

2.

Remove brackets and braces at each end of bumper.

3.

Remove license plate door.

4.

Remove rivets attaching bracket at center of bumper.

Assembly

Attach license plate lamp and back-up lamp assemblies

to bumper; tighten bolts firmly. Assemble the bumper

parts by following the disassembly procedure in the re-

verse order. Except for the license plate lamp and back-

up lamp attachments, install all bolts loosely; do riot

CHEVROLET CHASSIS SERVICE MANUAL

Page 608 of 659

BUMPERS 14-7

only and the distance between inner upper brace and

frame filled in with shims. Bolts may then be installed

to secure brace to frame.

REAR LICENSE PLATE HOUSING

The rear license plate housing may be removed from

the vehicle by removing the license plate and removing

the retaining screws as shown in Figure 9.

Fig.

9- Rear License Plate Housing

GENERAL DESCRIPTION-CAMARO

The Camaro front and rear bumpers are of a single

piece wrap around design. The front license plate bracket

functions as a bumper support between the valance panel

and bumper. Holes in the underside of bumpers, slightly

inboard of lower bumper bracket bolt, provide for new

jack load rest stud for jacking purposes.

SERVICE OPERATIONS

FRONT BUMPER ASSEMBLY (Fig. 10)

Removal

1.

Raise and support front end of vehicle.

2.

Remove bolts securing bumper support brackets to

frame.

3.

Remove bolts, one on each side at fender extension

panels, securing bumper to outer bumper bracket.

4.

Remove screws and nuts securing license plate

bracket to valance panel and remove bumper from

vehicle.

Disassembly

1.

Remove bolts attaching two support brackets to

bumper.

2.

Remove screw and nut securing license plate bracket

to bumper.

Assembly

Assemble the front bumper following the disassembly

procedure in reverse order. Install all bolts loosely; do

not tighten any bolts until all bolts are installed.

Installation

1.

Position assembled bumper on frame horns aligning

holes in bumper brackets with those in frame.

2.

Loosely install bolts, lock washers, and nuts. .Note

3.

the eight sided adjustment washers (fig. 10) are

placed in the tab of each bumper bracket. Dial the

adjustment washers in the tabs as required to posi-

tion the bumper at the correct mounted height.

Tighten all bolts securely and lower vehicle.

REAR BUMPER ASSEMBLY (Fig. 11)

Removal

1.

Raise and support rear end of vehicle.

2.

Remove bolts securing bumper brackets to frame

and rear fenders.

3.

Remove screws securing license plate bracket to

body and remove bumper from vehicle.

Disassembly

1.

Remove bolts securing four support brackets to

bumper.

2.

Remove rivets securing license plate bracket to

bumper.

Assembly

Assemble the rear bumper following the disassembly

procedure in reverse order. Install all bolts loosely; do

not tighten any bolts until all bolts are installed.

CHEVROLET CHASSIS SERVICE MANUAL